ignition DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2352 of 5267

HEATER-FUEL

DESCRIPTION

The fuel heater assembly is located on the side of the fuel filter housing and internal to the fuel filter housing .

The heater/element assembly is equipped with a temperature sensor (thermostat) that senses fuel temperature. This

sensor is attached to the fuel heater/element assembly.

OPERATION

The fuel heater is used to prevent diesel fuel from waxing during cold weather operation.

When the fuel temperature is below 45° ±8 F (7°C), the temperature sensor allows current to flow to the heater

element warming the fuel. When the fuel temperature is above 75° ±8 F (24°C), the sensor stops current flow to the

heater element.

Battery voltage to operate the fuel heater element is supplied from the ignition switch and through a solid stated

device in the IPM.The fuel heater element and

solid state device in IPMinstead offuel heater relayare not

computer controlled.

The heater element operates on 12 volts, 300 watts at 0° F (-18° C).

DIAGNOSIS AND TESTING

FUEL HEATER

The fuel heater is used to prevent diesel fuel from waxing during cold weather operation.

NOTE: The fuel heater element,

solid state device in IPMinstead offuel heater relayand fuel heater tem-

perature sensor are not controlled by the Engine Control Module (ECM).

A malfunctioning fuel heater can cause a wax build-up in the fuel filter/water separator. Wax build-up in the filter/

separator can cause engine starting problems and prevent the engine from revving up. It can also cause blue or

white fog-like exhaust. If the heater is not operating in cold temperatures, the engine may not operate due to fuel

waxing.

The fuel heater assembly is located on the side of fuel filter housing and internal to the fuel filter housing.

The heater assembly is equipped with a built-in fuel temperature sensor (thermostat) that senses fuel temperature.

When fuel temperature drops below 45° ± 8° F (7° C), the sensor allows current to flow to built-in heater element

to warm fuel. When fuel temperature rises above 75 °± 8° F (24° C), the sensorstops current flow to heater ele-

ment (circuit is open).

Voltage to operate fuel heater element is supplied from ignition switch, through

solid state device in IPM,tofuel

temperature sensor and on to fuel heater element.

The heater element operates on 12 volts, 300 watts at 0 °F (-18° C). As temperature increases, power requirements

decrease.

A minimum of 7 volts is required to operate the fuel heater. The resistance value of the heater element is less than

1 ohm (cold) and up to 1000 ohms warm.

TESTING

1. Disconnect electrical connector from thermostat.

Ambient temperature must be below the circuit close temperature. If necessary, induce this ambient temperature by

placing ice packs on thermostat to produce an effective ambient temperature below circuit close temperature.

Measure resistance across two pins. Operating range is 0.3 - 0.45 Ohms.

2. If resistance is out of range, remove thermostat and check resistance across terminal connections of heater. The

heater can be checked at room temperature. Operating range is 0.3 - 0.45 Ohms.

3. Replace heater if resistance is not within operating range.

4. If heater is within operating range, replace heater thermostat.

Page 2375 of 5267

SENSOR-WATER IN FUEL

DESCRIPTION

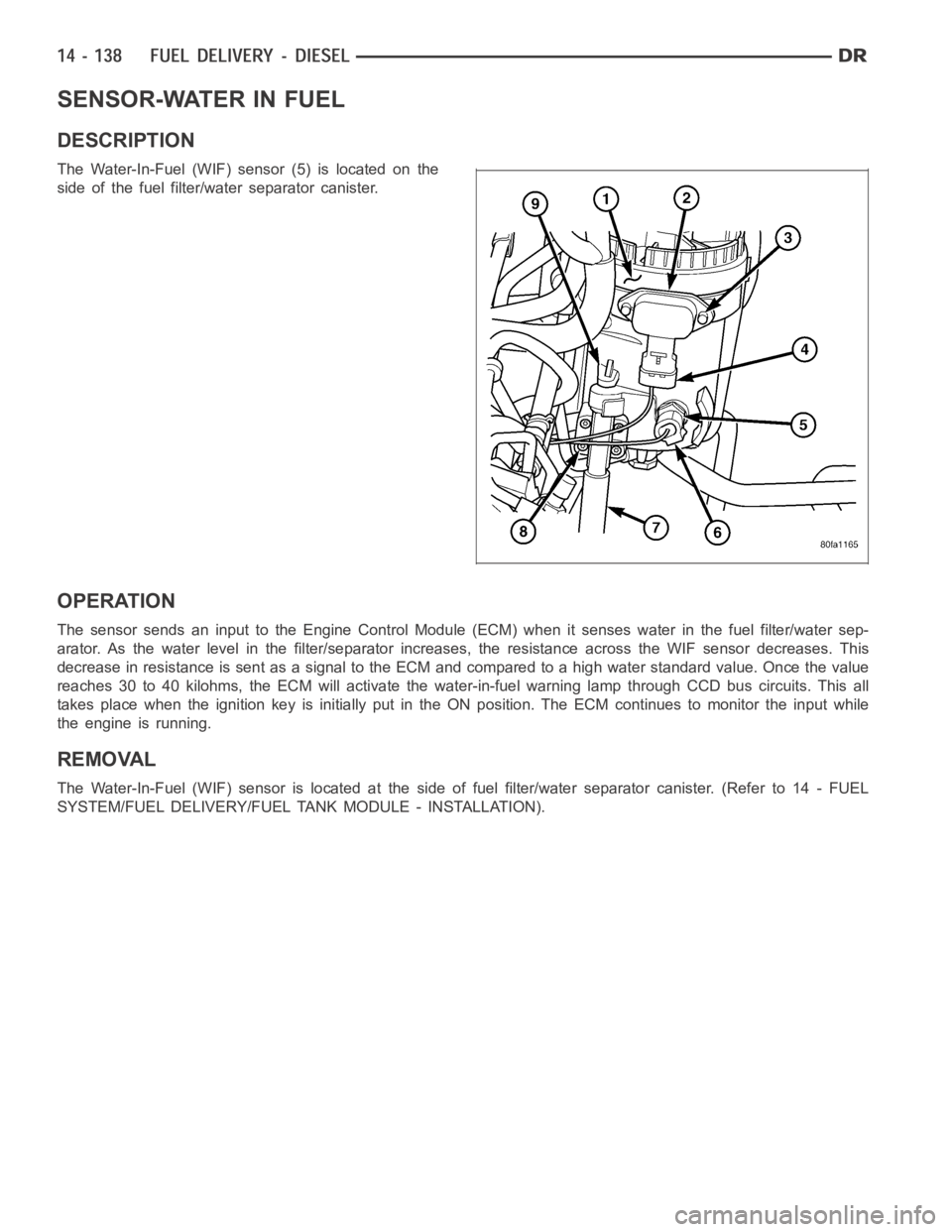

The Water-In-Fuel (WIF) sensor (5) is located on the

side of the fuel filter/water separator canister.

OPERATION

The sensor sends an input to the Engine Control Module (ECM) when it senses water in the fuel filter/water sep-

arator. As the water level in the filter/separator increases, the resistance across the WIF sensor decreases. This

decreaseinresistanceissentasasignaltotheECMandcomparedtoahighwater standard value. Once the value

reaches 30 to 40 kilohms, the ECM will activate the water-in-fuel warning lamp through CCD bus circuits. This all

takes place when the ignition key is initially put in the ON position. The ECM continues to monitor the input while

the engine is running.

REMOVAL

The Water-In-Fuel (WIF) sensor is located at the side of fuel filter/waterseparator canister. (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY/FUEL TANK MODULE - INSTALLATION).

Page 2412 of 5267

page page

COLUMN

DESCRIPTION

DESCRIPTION ............................... 8

DESCRIPTION - SRT10 ....................... 9

DIAGNOSIS AND TESTING

STEERING COLUMN ......................... 9

REMOVAL ..................................... 9

INSTALLATION ............................... 12

SPECIFICATIONS

TORQUE ................................... 14

IGNITION SWITCH

DESCRIPTION ................................ 15

OPERATION .................................. 15

DIAGNOSIS AND TESTING

IGNITION SWITCH .......................... 15

REMOVAL .................................... 16

INSTALLATION ............................... 17

IGNITION SWITCH - SRT10

REMOVAL - SRT10 ............................ 19

INSTALLATION - SRT10 ....................... 21

KEY-IN IGNITION SWITCH

DESCRIPTION ................................ 22

DIAGNOSIS AND TESTING

IGNITION SWITCH AND KEY LOCK

CYLINDER................................. 22KEY CYLINDER

REMOVAL .................................... 23

INSTALLATION ............................... 23

STEERING WHEEL

REMOVAL .................................... 24

INSTALLATION ............................... 24

TILT LEVER KNOB RELEASE

REMOVAL .................................... 25

INSTALLATION ............................... 26

GEAR SHIFT LEVER

REMOVAL .................................... 28

INSTALLATION ............................... 29

UPPER STEERING COUPLING

REMOVAL .................................... 32

INSTALLATION ............................... 33

LOWER STEERING COUPLING

REMOVAL

ALL LD & HD EXCEPT 4X4 HD ............... 34

4X4 HD .................................... 34

INSTALLATION

ALL LD & HD EXCEPT 4X4 HD ............... 36

4X4 HD .................................... 36

Page 2413 of 5267

COLUMN

DESCRIPTION

DESCRIPTION

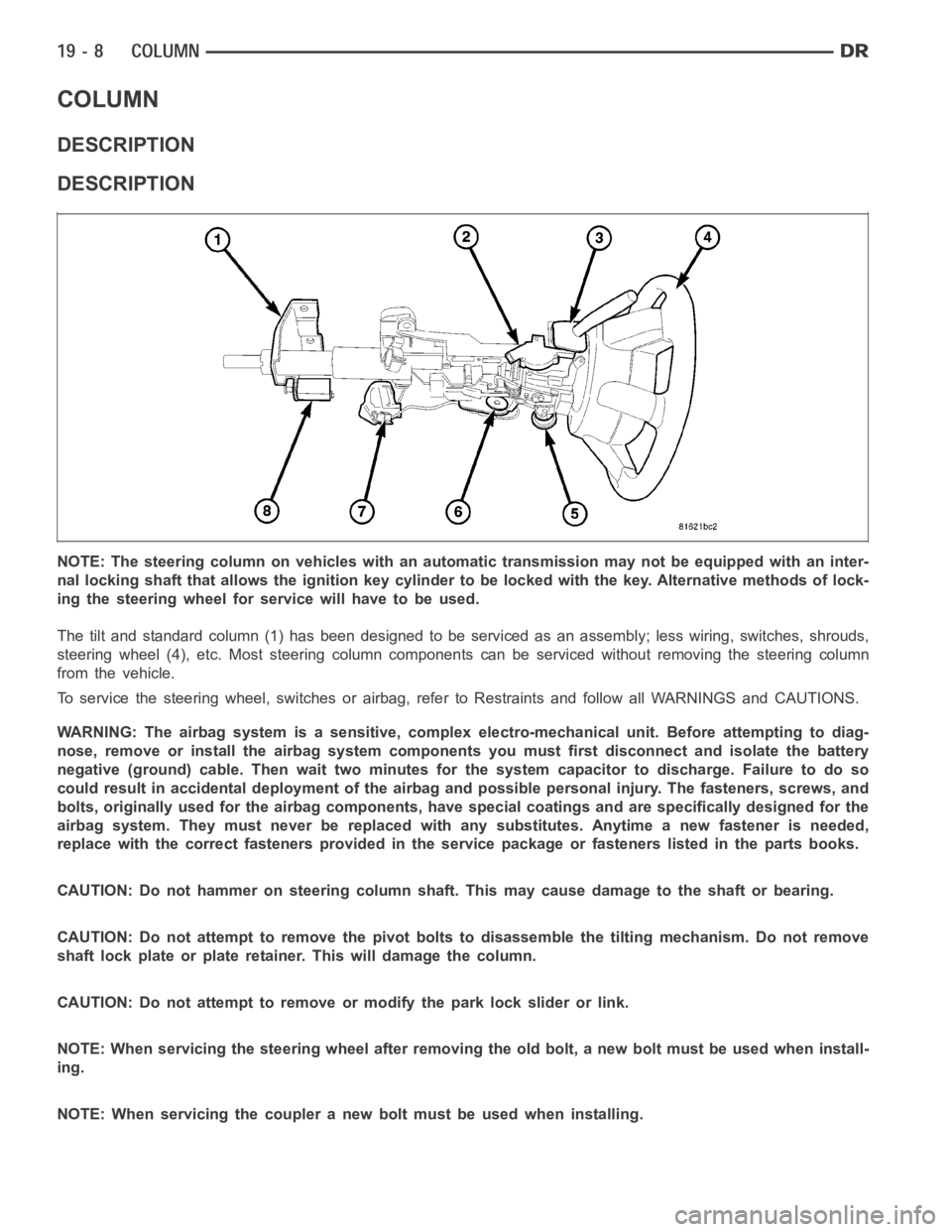

NOTE: The steering column on vehicles with an automatic transmission may not be equipped with an inter-

nal locking shaft that allows the ignition key cylinder to be locked with the key. Alternative methods of lock-

ing the steering wheel for service will have to be used.

The tilt and standard column (1) has been designed to be serviced as an assembly; less wiring, switches, shrouds,

steering wheel (4), etc. Most steering column components can be serviced without removing the steering column

from the vehicle.

To service the steering wheel, switches or airbag, refer to Restraints andfollow all WARNINGS and CAUTIONS.

WARNING: The airbag system is a sensitive, complex electro-mechanical unit. Before attempting to diag-

nose, remove or install the airbag system components you must first disconnect and isolate the battery

negative (ground) cable. Then wait two minutes for the system capacitor todischarge. Failure to do so

could result in accidental deployment of the airbag and possible personalinjury. The fasteners, screws, and

bolts, originally used for the airbag components, have special coatings and are specifically designed for the

airbag system. They must never be replaced with any substitutes. Anytime anew fastener is needed,

replace with the correct fasteners provided in the service package or fasteners listed in the parts books.

CAUTION: Do not hammer on steering column shaft. This may cause damage to the shaft or bearing.

CAUTION: Do not attempt to remove the pivot bolts to disassemble the tilting mechanism. Do not remove

shaft lock plate or plate retainer. This will damage the column.

CAUTION: Do not attempt to remove or modify the park lock slider or link.

NOTE: When servicing the steering wheel after removing the old bolt, a new bolt must be used when install-

ing.

NOTE: When servicing the coupler a new bolt must be used when installing.

Page 2420 of 5267

IGNITION SWITCH

DESCRIPTION

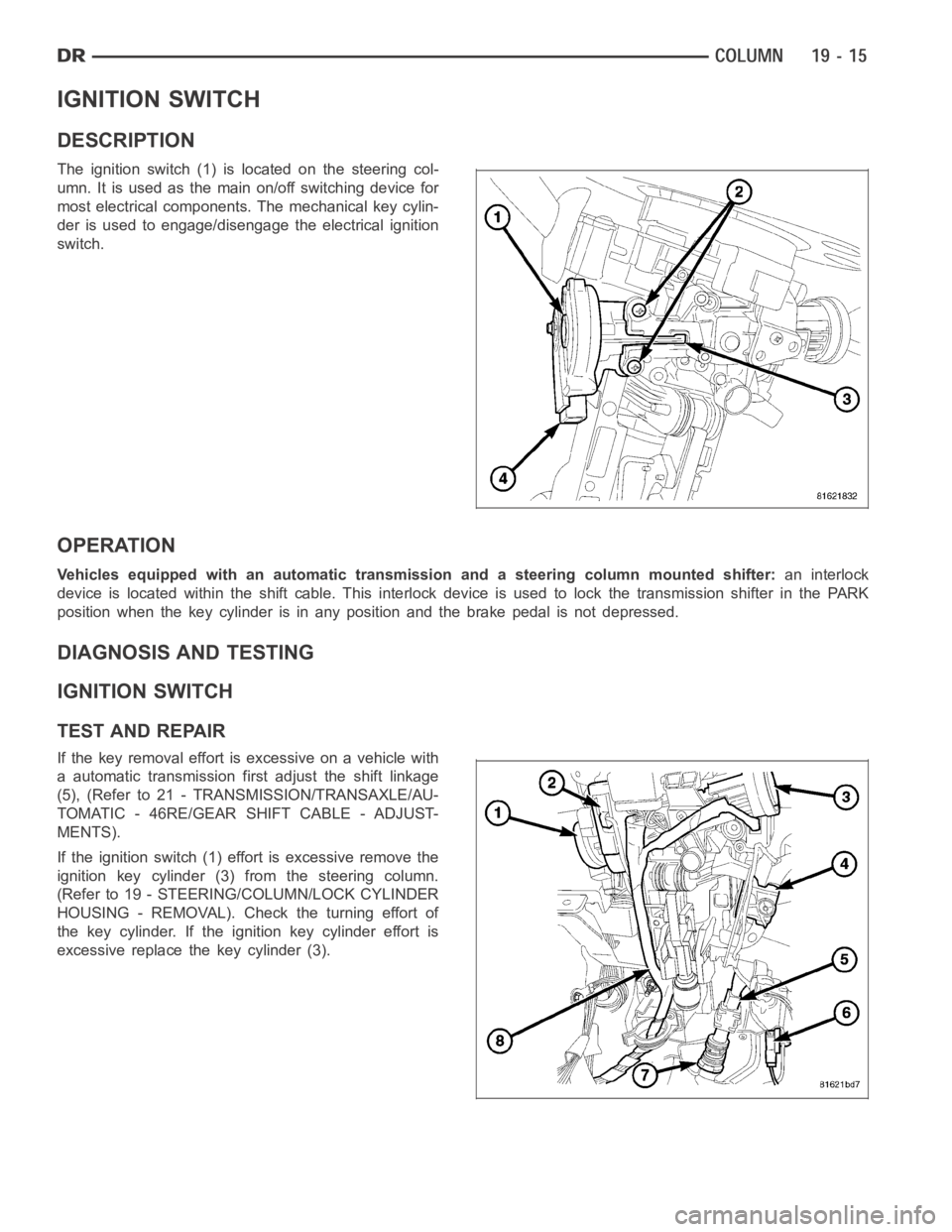

The ignition switch (1) is located on the steering col-

umn. It is used as the main on/off switching device for

most electrical components. The mechanical key cylin-

der is used to engage/disengage the electrical ignition

switch.

OPERATION

Vehicles equipped with an automatic transmission and a steering column mounted shifter:an interlock

device is located within the shift cable. This interlock device is used to lock the transmission shifter in the PARK

position when the key cylinder is in any position and the brake pedal is not depressed.

DIAGNOSIS AND TESTING

IGNITION SWITCH

TEST AND REPAIR

If the key removal effort is excessive on a vehicle with

a automatic transmission first adjust the shift linkage

(5), (Refer to 21 - TRANSMISSION/TRANSAXLE/AU-

TOMATIC - 46RE/GEAR SHIFT CABLE - ADJUST-

MENTS).

If the ignition switch (1) effort is excessive remove the

ignition key cylinder (3) from the steering column.

(Refer to 19 - STEERING/COLUMN/LOCK CYLINDER

HOUSING - REMOVAL). Check the turning effort of

the key cylinder. If the ignition key cylinder effort is

excessive replace the key cylinder (3).

Page 2421 of 5267

REMOVAL

SERVICE PRECAUTIONS

NOTE: The steering column on vehicles equipped with an automatic transmission is not equipped with an

internal locking shaft with the ignition cylinder. Alternative methods of locking the steering wheel for ser-

vice will have to be used.

To service the steering wheel, switches or airbag, Refer to Electrical Restraints and follow all WARNINGS and CAU-

TIONS.

WARNING: The airbag system is a sensitive, complex electro-mechanical unit. Before attempting to diag-

nose, remove or install the airbag system components you must first disconnect and isolate the battery

negative (ground) cable. Then wait two minutes for the system capacitor todischarge. Failure to do so

could result in accidental deployment of the airbag and possible personalinjury. The fasteners, screws, and

bolts, originally used for the airbag components, have special coatings and are specifically designed for the

airbag system. They must never be replaced with any substitutes. Anytime anew fastener is needed,

replace with the correct fasteners provided in the service package or fasteners listed in the parts books.

CAUTION: Do not hammer on steering column shaft. This may cause damage to the shaft or bearing.

CAUTION: Do not attempt to remove the pivot bolts to disassemble the tilting mechanism.

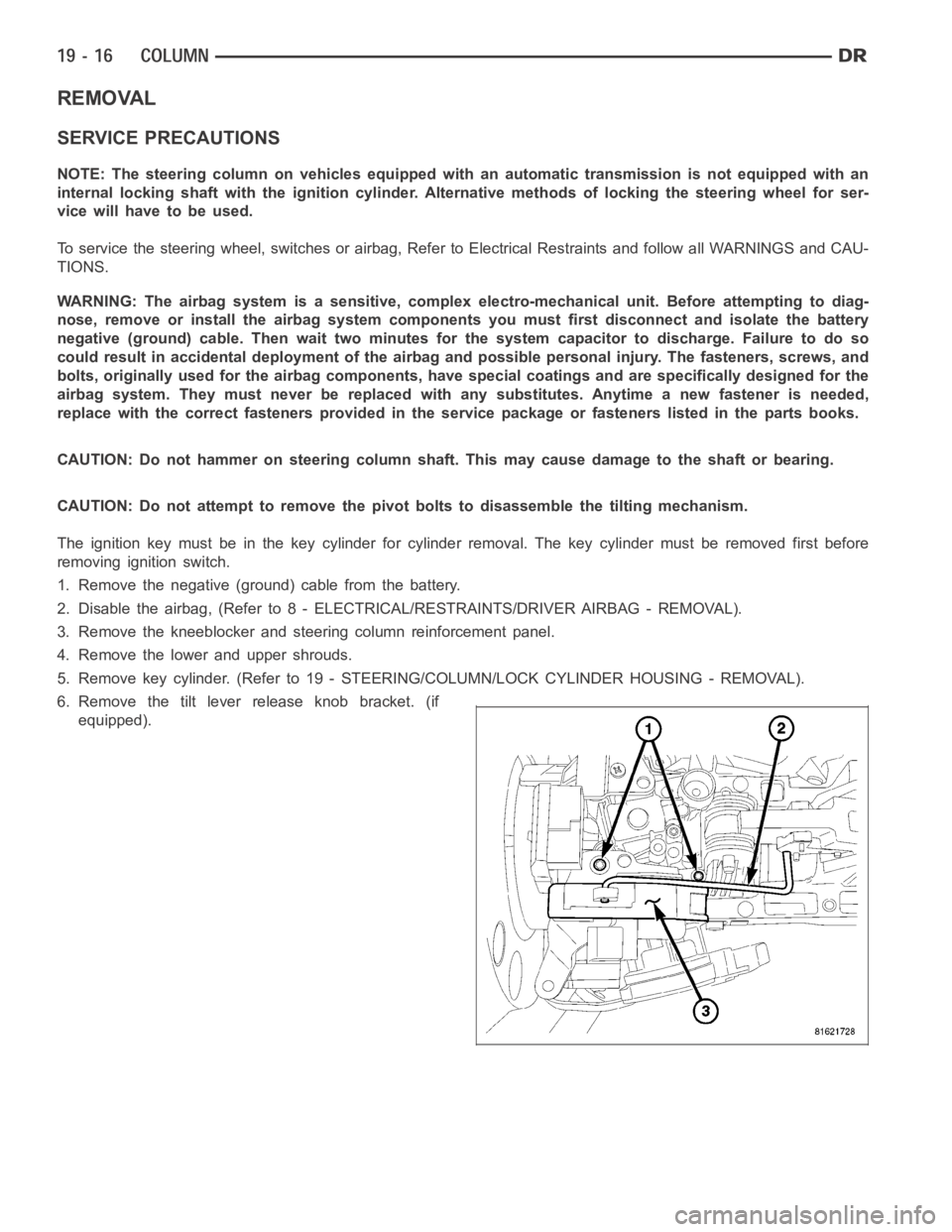

The ignition key must be in the key cylinder for cylinder removal. The key cylinder must be removed first before

removing ignition switch.

1. Remove the negative (ground) cable from the battery.

2. Disable the airbag, (Refer to 8 - ELECTRICAL/RESTRAINTS/DRIVER AIRBAG- REMOVAL).

3. Remove the kneeblocker and steering column reinforcement panel.

4. Remove the lower and upper shrouds.

5. Remove key cylinder. (Refer to 19 - STEERING/COLUMN/LOCK CYLINDER HOUSING - REMOVAL).

6. Remove the tilt lever release knob bracket. (if

equipped).

Page 2422 of 5267

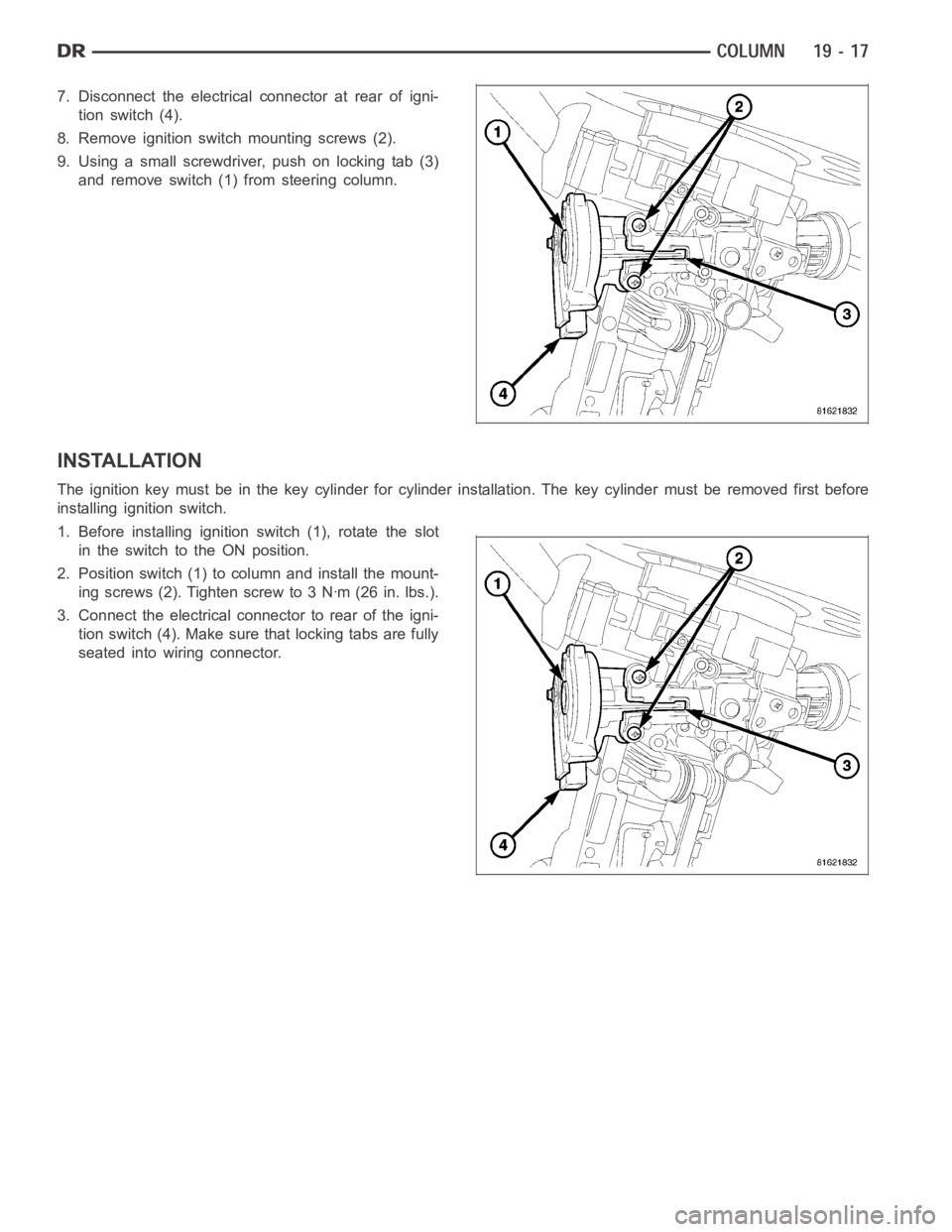

7. Disconnect the electrical connector at rear of igni-

tion switch (4).

8. Remove ignition switch mounting screws (2).

9. Using a small screwdriver, push on locking tab (3)

and remove switch (1) from steering column.

INSTALLATION

The ignition key must be in the key cylinder for cylinder installation. Thekey cylinder must be removed first before

installing ignition switch.

1. Before installing ignitionswitch (1), rotate the slot

in the switch to the ON position.

2. Position switch (1) to column and install the mount-

ing screws (2). Tighten screw to 3 Nꞏm (26 in. lbs.).

3. Connect the electrical connector to rear of the igni-

tion switch (4). Make sure that locking tabs are fully

seated into wiring connector.

Page 2424 of 5267

IGNITION SWITCH - SRT10

REMOVAL - SRT10

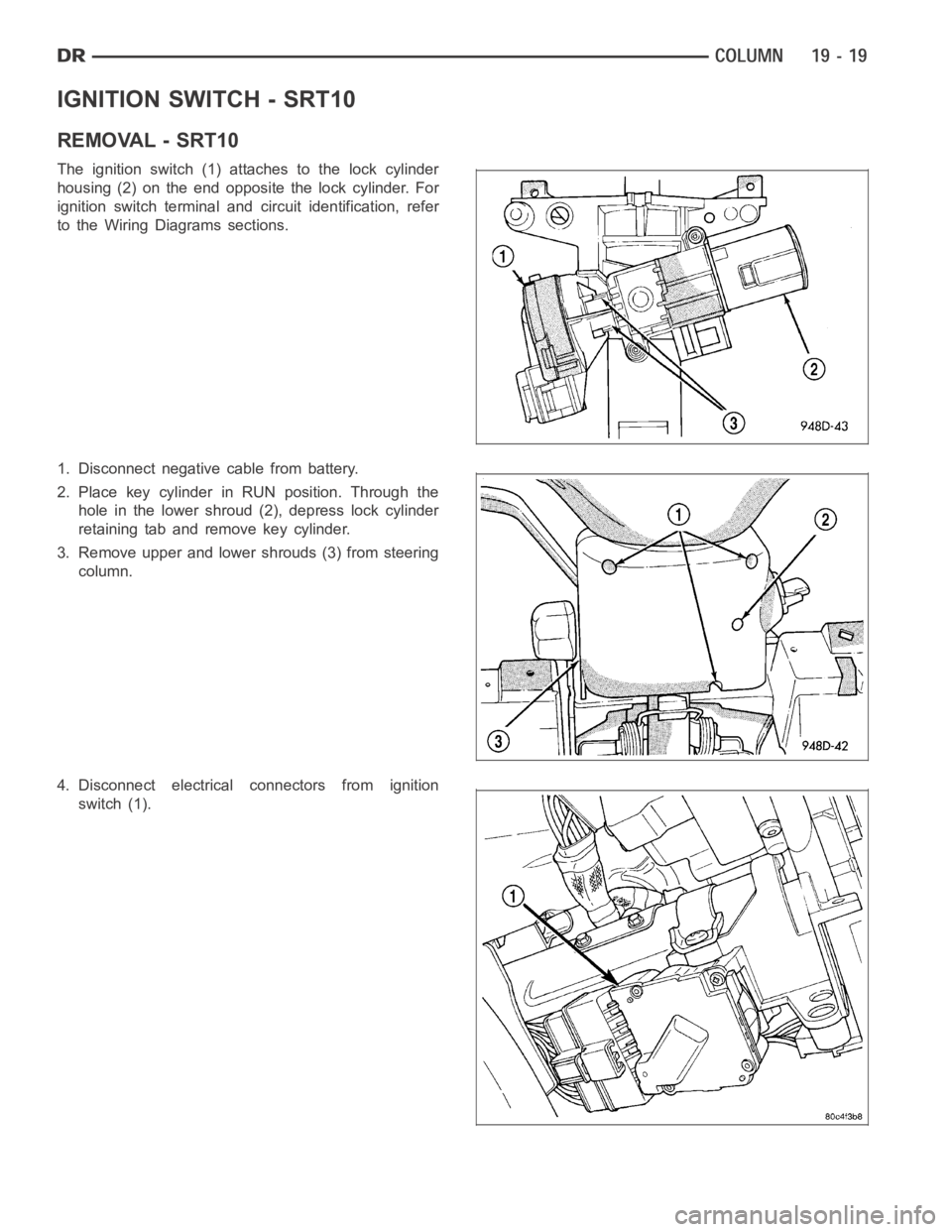

The ignition switch (1) attaches to the lock cylinder

housing (2) on the end opposite the lock cylinder. For

ignition switch terminal and circuit identification, refer

to the Wiring Diagrams sections.

1. Disconnect negative cable from battery.

2. Place key cylinder in RUN position. Through the

hole in the lower shroud (2), depress lock cylinder

retaining tab and remove key cylinder.

3. Remove upper and lower shrouds (3) from steering

column.

4. Disconnect electrical connectors from ignition

switch (1).

Page 2425 of 5267

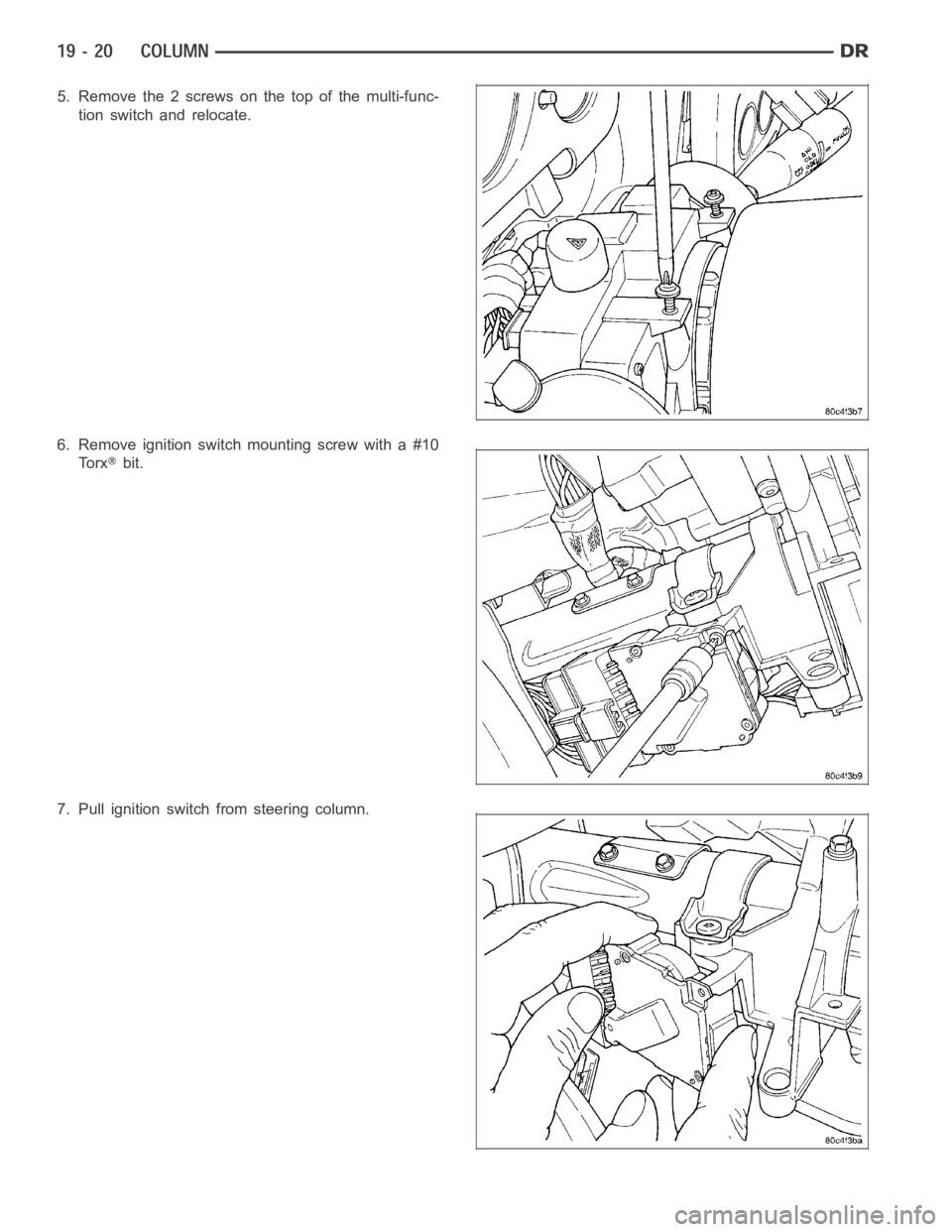

5. Remove the 2 screws on the top of the multi-func-

tion switch and relocate.

6. Remove ignition switch mounting screw with a #10

To r x

bit.

7. Pull ignition switch from steering column.

Page 2426 of 5267

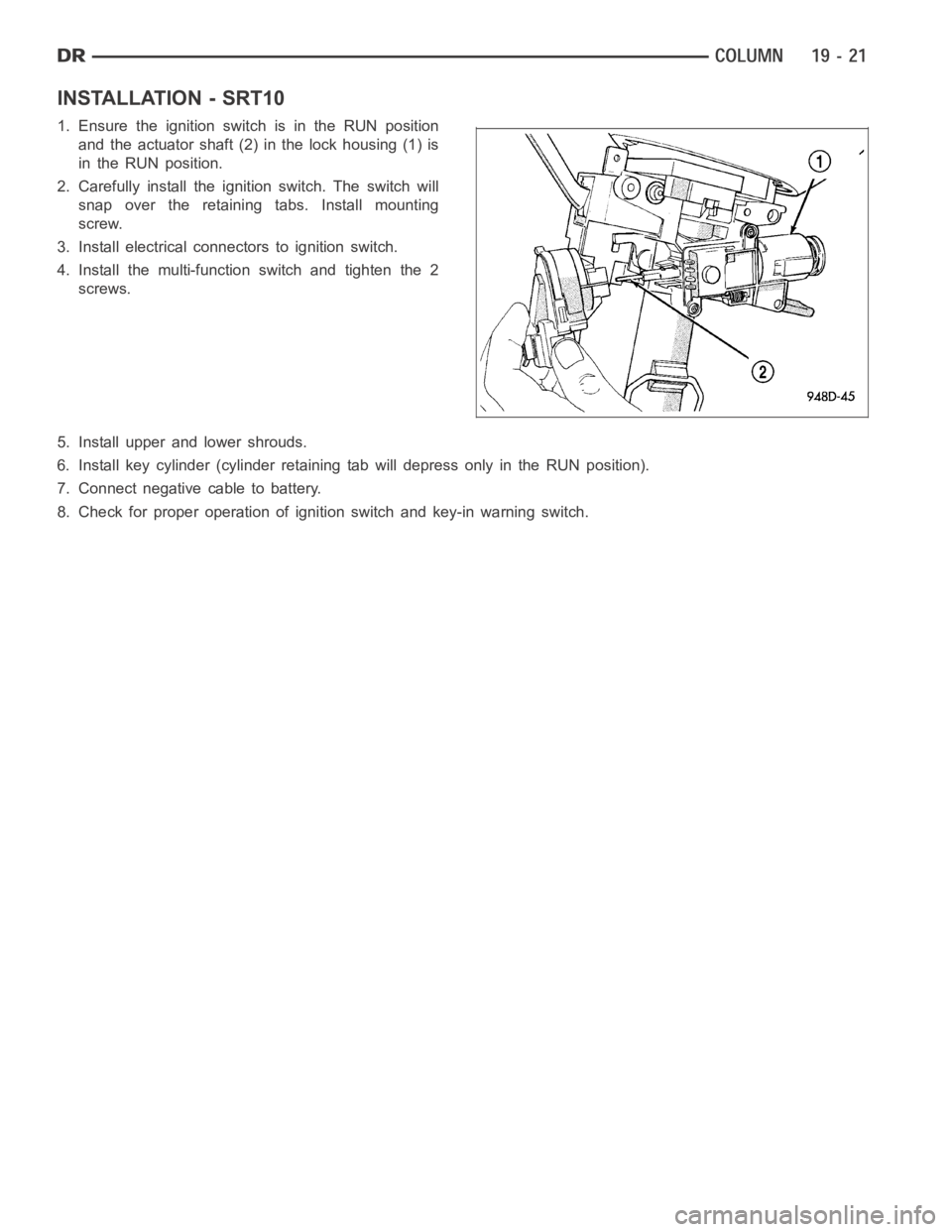

INSTALLATION - SRT10

1. Ensure the ignition switch is in the RUN position

and the actuator shaft (2) in the lock housing (1) is

in the RUN position.

2. Carefully install the ignition switch. The switch will

snap over the retaining tabs. Install mounting

screw.

3. Install electrical connectors to ignition switch.

4. Install the multi-function switch and tighten the 2

screws.

5. Install upper and lower shrouds.

6. Install key cylinder (cylinder retaining tab will depress only in the RUN position).

7. Connect negative cable to battery.

8. Check for proper operation of ignition switch and key-in warning switch.