eco mode DODGE RAM SRT-10 2006 Service Manual Online

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 4199 of 5267

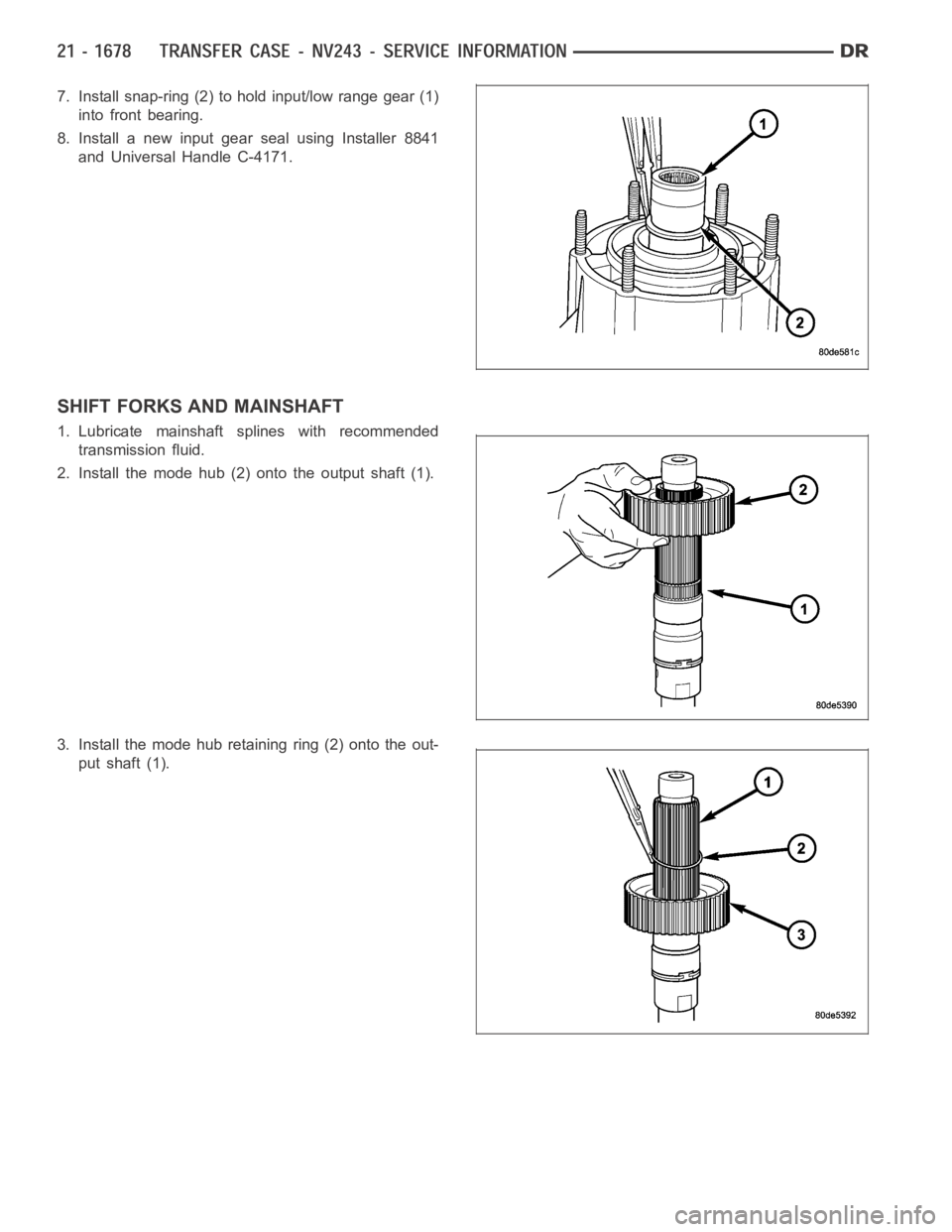

7. Install snap-ring (2) to hold input/low range gear (1)

into front bearing.

8. Install a new input gear seal using Installer 8841

and Universal Handle C-4171.

SHIFT FORKS AND MAINSHAFT

1. Lubricate mainshaft splines with recommended

transmission fluid.

2. Install the mode hub (2) onto the output shaft (1).

3. Install the mode hub retaining ring (2) onto the out-

put shaft (1).

Page 4214 of 5267

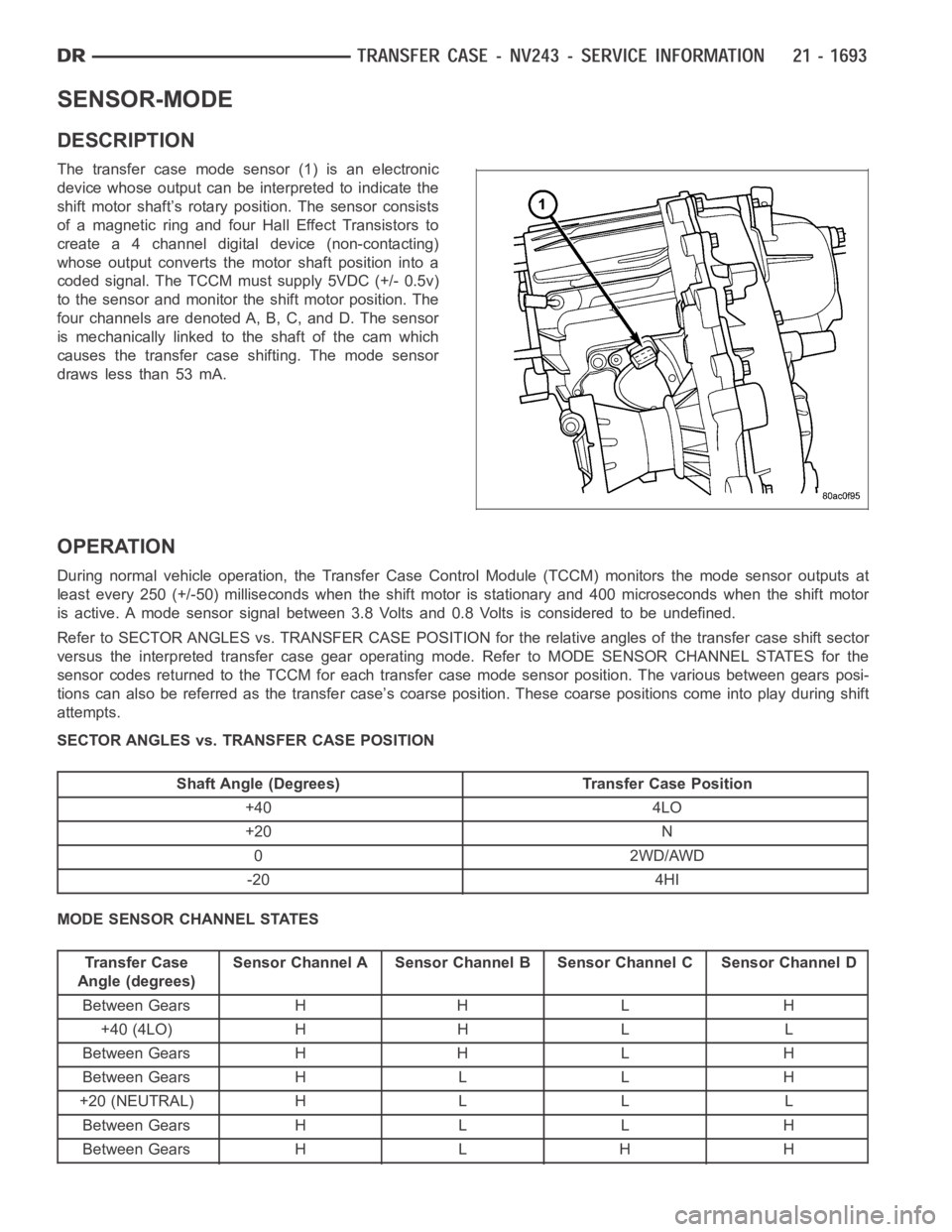

SENSOR-MODE

DESCRIPTION

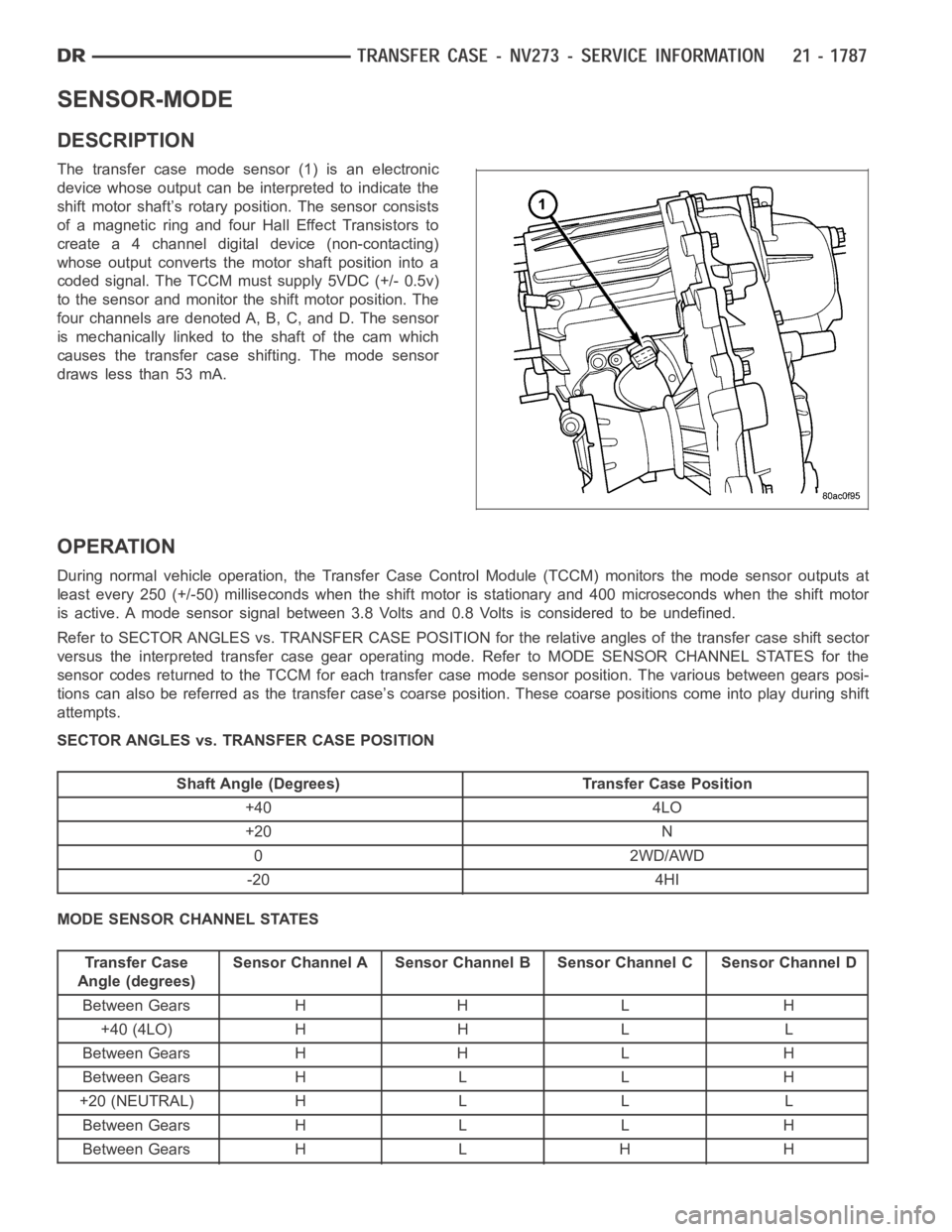

The transfer case mode sensor (1) is an electronic

device whose output can be interpreted to indicate the

shift motor shaft’s rotary position. The sensor consists

of a magnetic ring and four Hall Effect Transistors to

create a 4 channel digital device (non-contacting)

whose output converts the motor shaft position into a

coded signal. The TCCM must supply 5VDC (+/- 0.5v)

to the sensor and monitor the shift motor position. The

four channels are denoted A, B, C, and D. The sensor

is mechanically linked to the shaft of the cam which

causes the transfer case shifting. The mode sensor

draws less than 53 mA.

OPERATION

During normal vehicle operation, the Transfer Case Control Module (TCCM)monitors the mode sensor outputs at

least every 250 (+/-50) milliseconds when the shift motor is stationary and 400 microseconds when the shift motor

is active. A mode sensor signal between 3.8 Volts and 0.8 Volts is considered to be undefined.

Refer to SECTOR ANGLES vs. TRANSFER CASE POSITION for the relative angles of the transfer case shift sector

versus the interpreted transfer case gear operating mode. Refer to MODE SENSOR CHANNEL STATES for the

sensor codes returned to the TCCM for each transfer case mode sensor position. The various between gears posi-

tions can also be referred as the transfer case’s coarse position. These coarse positions come into play during shift

attempts.

SECTOR ANGLES vs. TRANSFER CASE POSITION

Shaft Angle (Degrees) Transfer Case Position

+40 4LO

+20 N

0 2WD/AWD

-20 4HI

MODE SENSOR CHANNEL STATES

Transfer Case

Angle (degrees)Sensor Channel A Sensor Channel B Sensor Channel C Sensor Channel D

Between Gears H H L H

+40 (4LO) H H L L

Between Gears H H L H

Between Gears H L L H

+20 (NEUTRAL) H L L L

Between Gears H L L H

Between Gears H L H H

Page 4242 of 5267

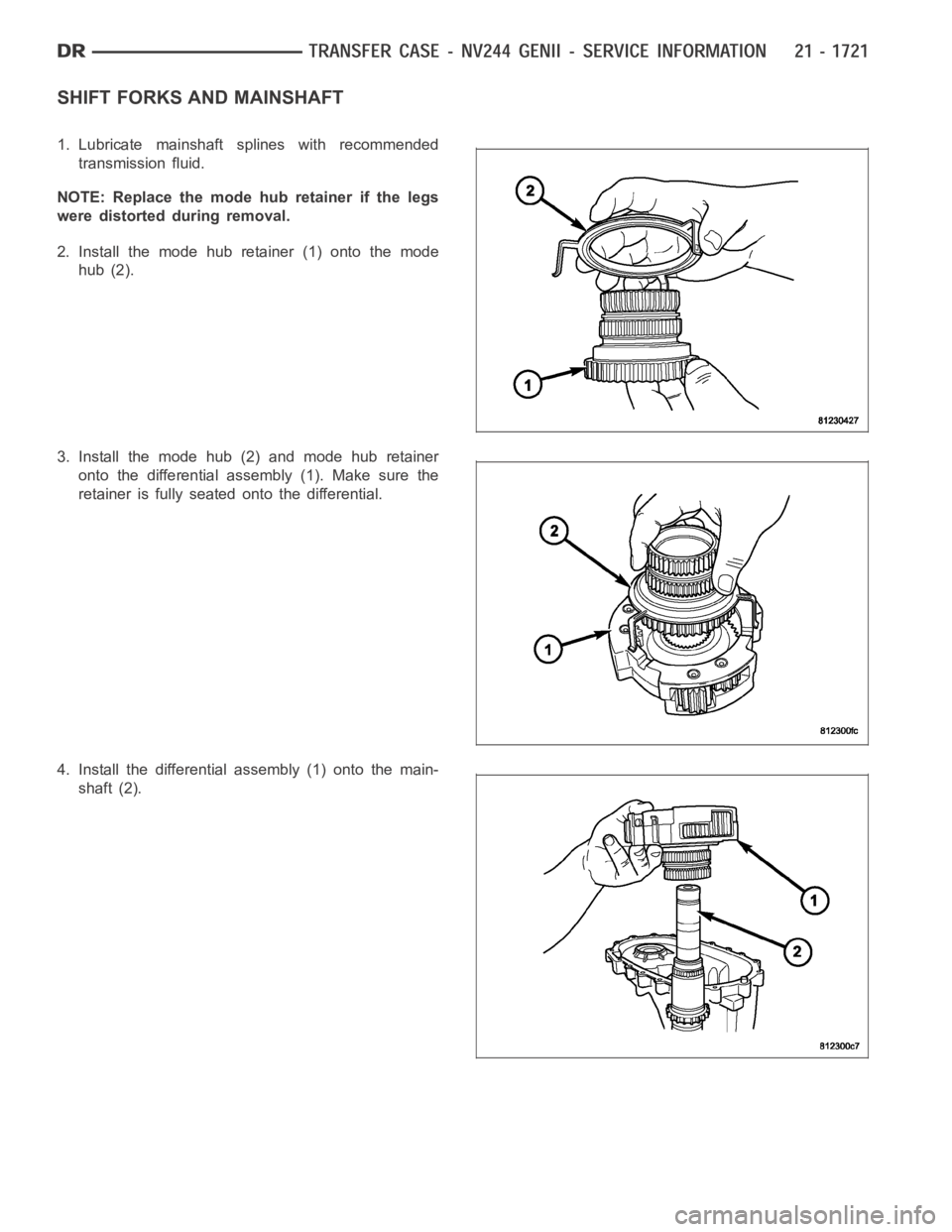

SHIFT FORKS AND MAINSHAFT

1. Lubricate mainshaft splines with recommended

transmission fluid.

NOTE: Replace the mode hub retainer if the legs

were distorted during removal.

2. Install the mode hub retainer (1) onto the mode

hub (2).

3. Install the mode hub (2) and mode hub retainer

onto the differential assembly (1). Make sure the

retainer is fully seated onto the differential.

4. Install the differential assembly (1) onto the main-

shaft (2).

Page 4258 of 5267

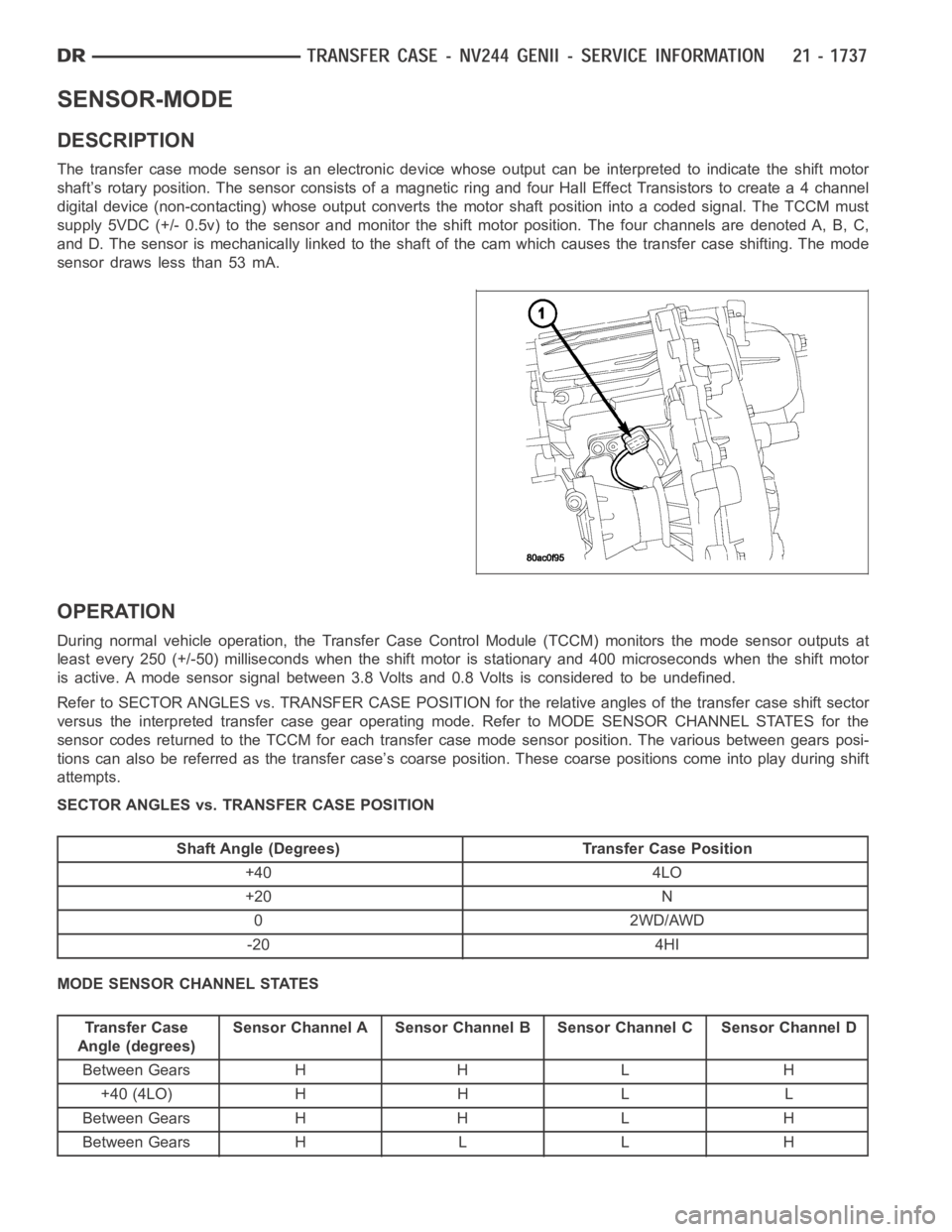

SENSOR-MODE

DESCRIPTION

The transfer case mode sensor is an electronic device whose output can be interpreted to indicate the shift motor

shaft’s rotary position. The sensor consists of a magnetic ring and four Hall Effect Transistors to create a 4 channel

digital device (non-contacting) whose output converts the motor shaft position into a coded signal. The TCCM must

supply 5VDC (+/- 0.5v) to the sensor and monitor the shift motor position. The four channels are denoted A, B, C,

and D. The sensor is mechanically linked to the shaft of the cam which causesthe transfer case shifting. The mode

sensor draws less than 53 mA.

OPERATION

During normal vehicle operation, the Transfer Case Control Module (TCCM)monitors the mode sensor outputs at

least every 250 (+/-50) milliseconds when the shift motor is stationary and 400 microseconds when the shift motor

is active. A mode sensor signal between 3.8 Volts and 0.8 Volts is considered to be undefined.

Refer to SECTOR ANGLES vs. TRANSFER CASE POSITION for the relative angles of the transfer case shift sector

versus the interpreted transfer case gear operating mode. Refer to MODE SENSOR CHANNEL STATES for the

sensor codes returned to the TCCM for each transfer case mode sensor position. The various between gears posi-

tions can also be referred as the transfer case’s coarse position. These coarse positions come into play during shift

attempts.

SECTOR ANGLES vs. TRANSFER CASE POSITION

Shaft Angle (Degrees) Transfer Case Position

+40 4LO

+20 N

0 2WD/AWD

-20 4HI

MODE SENSOR CHANNEL STATES

Transfer Case

Angle (degrees)Sensor Channel A Sensor Channel B Sensor Channel C Sensor Channel D

Between Gears H H L H

+40 (4LO) H H L L

Between Gears H H L H

Between Gears H L L H

Page 4292 of 5267

SHIFT FORKS AND MAINSHAFT

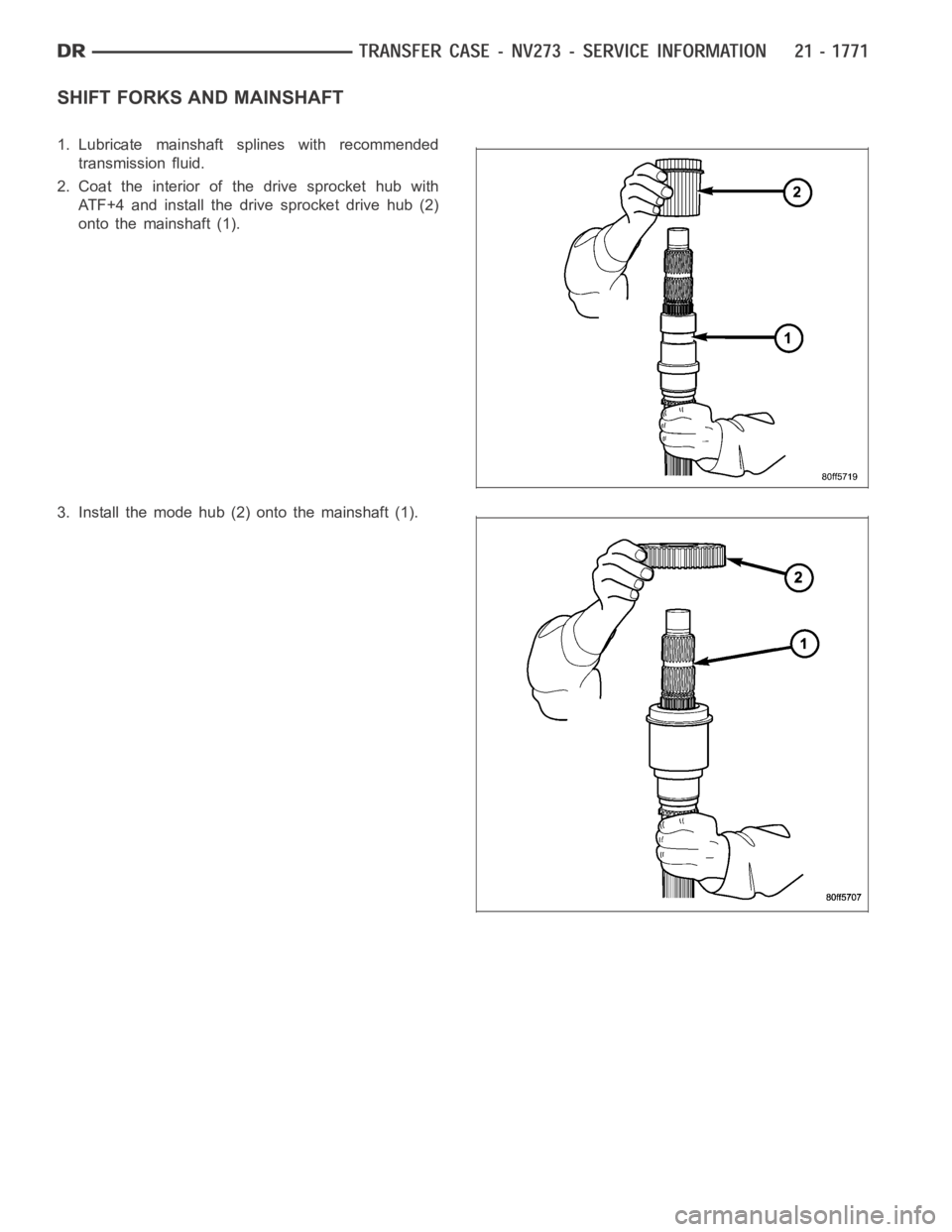

1. Lubricate mainshaft splines with recommended

transmission fluid.

2. Coat the interior of the drive sprocket hub with

ATF+4 and install the drive sprocket drive hub (2)

onto the mainshaft (1).

3. Install the mode hub (2) onto the mainshaft (1).

Page 4308 of 5267

SENSOR-MODE

DESCRIPTION

The transfer case mode sensor (1) is an electronic

device whose output can be interpreted to indicate the

shift motor shaft’s rotary position. The sensor consists

of a magnetic ring and four Hall Effect Transistors to

create a 4 channel digital device (non-contacting)

whose output converts the motor shaft position into a

coded signal. The TCCM must supply 5VDC (+/- 0.5v)

to the sensor and monitor the shift motor position. The

four channels are denoted A, B, C, and D. The sensor

is mechanically linked to the shaft of the cam which

causes the transfer case shifting. The mode sensor

draws less than 53 mA.

OPERATION

During normal vehicle operation, the Transfer Case Control Module (TCCM)monitors the mode sensor outputs at

least every 250 (+/-50) milliseconds when the shift motor is stationary and 400 microseconds when the shift motor

is active. A mode sensor signal between 3.8 Volts and 0.8 Volts is considered to be undefined.

Refer to SECTOR ANGLES vs. TRANSFER CASE POSITION for the relative angles of the transfer case shift sector

versus the interpreted transfer case gear operating mode. Refer to MODE SENSOR CHANNEL STATES for the

sensor codes returned to the TCCM for each transfer case mode sensor position. The various between gears posi-

tions can also be referred as the transfer case’s coarse position. These coarse positions come into play during shift

attempts.

SECTOR ANGLES vs. TRANSFER CASE POSITION

Shaft Angle (Degrees) Transfer Case Position

+40 4LO

+20 N

0 2WD/AWD

-20 4HI

MODE SENSOR CHANNEL STATES

Transfer Case

Angle (degrees)Sensor Channel A Sensor Channel B Sensor Channel C Sensor Channel D

Between Gears H H L H

+40 (4LO) H H L L

Between Gears H H L H

Between Gears H L L H

+20 (NEUTRAL) H L L L

Between Gears H L L H

Between Gears H L H H

Page 4329 of 5267

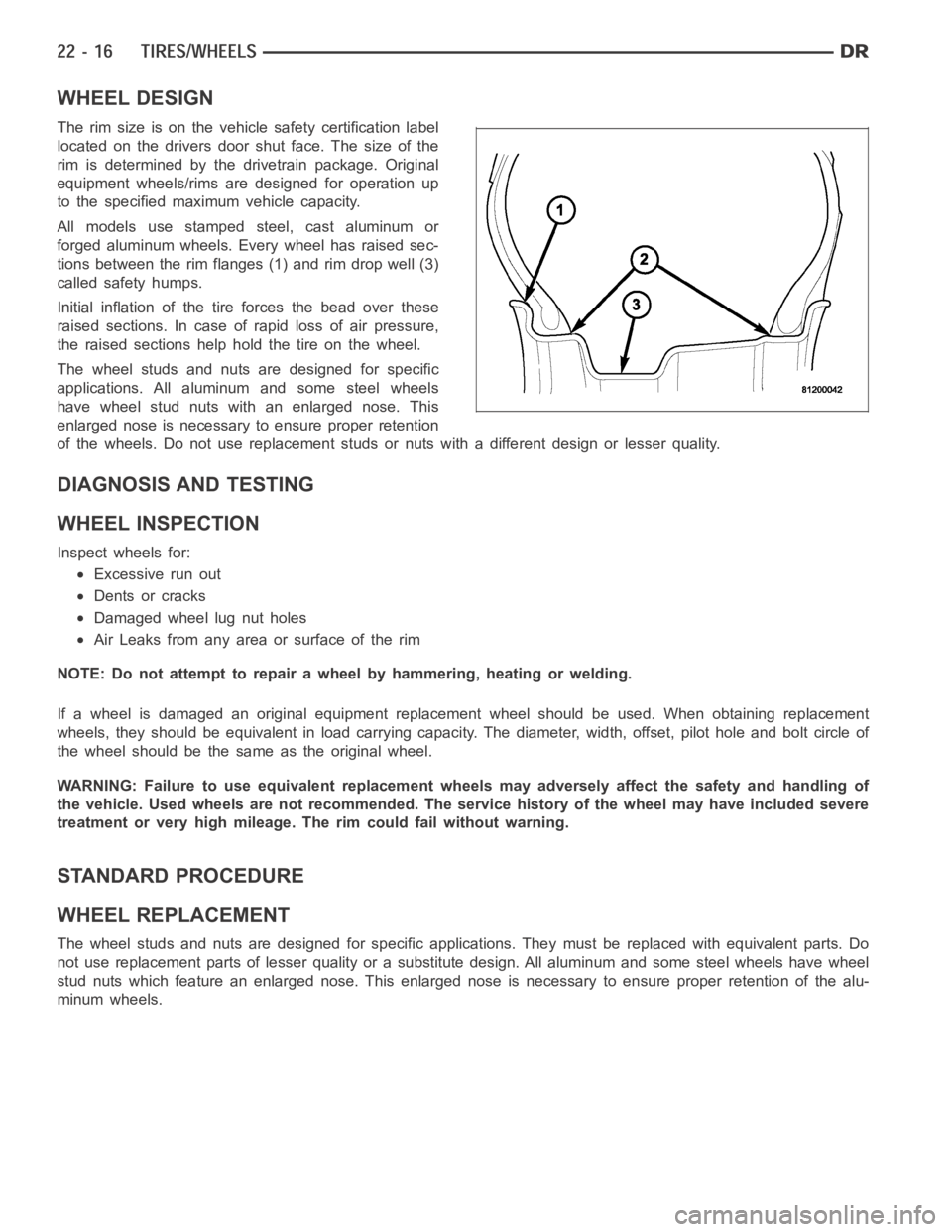

WHEEL DESIGN

The rim size is on the vehicle safety certification label

located on the drivers door shut face. The size of the

rim is determined by the drivetrain package. Original

equipment wheels/rims are designed for operation up

to the specified maximum vehicle capacity.

All models use stamped steel, cast aluminum or

forged aluminum wheels. Every wheel has raised sec-

tions between the rim flanges (1) and rim drop well (3)

called safety humps.

Initial inflation of the tire forces the bead over these

raised sections. In case of rapid loss of air pressure,

the raised sections help hold the tire on the wheel.

The wheel studs and nuts are designed for specific

applications. All aluminum and some steel wheels

have wheel stud nuts with an enlarged nose. This

enlarged nose is necessary to ensure proper retention

of the wheels. Do not use replacement studs or nuts with a different design orlesserquality.

DIAGNOSIS AND TESTING

WHEEL INSPECTION

Inspect wheels for:

Excessive run out

Dents or cracks

Damaged wheel lug nut holes

Air Leaks from any area or surface of the rim

NOTE: Do not attempt to repair a wheel by hammering, heating or welding.

If a wheel is damaged an original equipment replacement wheel should be used. When obtaining replacement

wheels, they should be equivalent in load carrying capacity. The diameter, width, offset, pilot hole and bolt circle of

the wheel should be the same as the original wheel.

WARNING: Failure to use equivalent replacement wheels may adversely affect the safety and handling of

the vehicle. Used wheels are not recommended. The service history of the wheel may have included severe

treatment or very high mileage. The rim could fail without warning.

STANDARD PROCEDURE

WHEEL REPLACEMENT

The wheel studs and nuts are designed for specific applications. They mustbe replaced with equivalent parts. Do

not use replacement parts of lesser quality or a substitute design. All aluminum and some steel wheels have wheel

stud nuts which feature an enlarged nose. This enlarged nose is necessary to ensure proper retention of the alu-

minum wheels.

Page 4400 of 5267

DOOR GLASS

REMOVAL

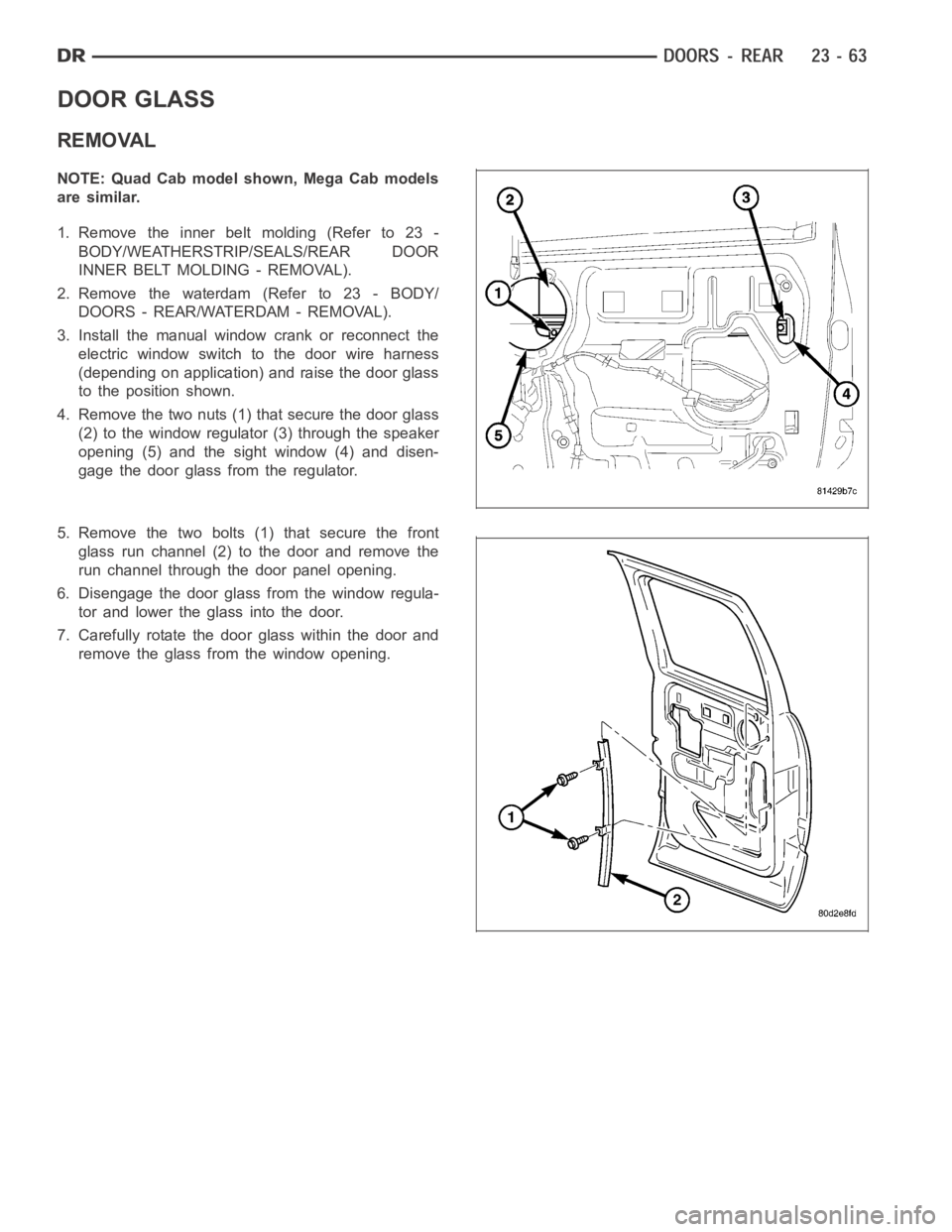

NOTE: Quad Cab model shown, Mega Cab models

are similar.

1. Remove the inner belt molding (Refer to 23 -

BODY/WEATHERSTRIP/SEALS/REAR DOOR

INNER BELT MOLDING - REMOVAL).

2. Remove the waterdam (Refer to 23 - BODY/

DOORS - REAR/WATERDAM - REMOVAL).

3. Install the manual window crank or reconnect the

electric window switch to the door wire harness

(depending on application) and raise the door glass

to the position shown.

4. Remove the two nuts (1) that secure the door glass

(2) to the window regulator (3) through the speaker

opening (5) and the sight window (4) and disen-

gage the door glass from the regulator.

5. Remove the two bolts (1) that secure the front

glass run channel (2) to the door and remove the

run channel through the door panel opening.

6. Disengage the door glass from the window regula-

tor and lower the glass into the door.

7. Carefully rotate the door glass within the door and

remove the glass from the window opening.

Page 4687 of 5267

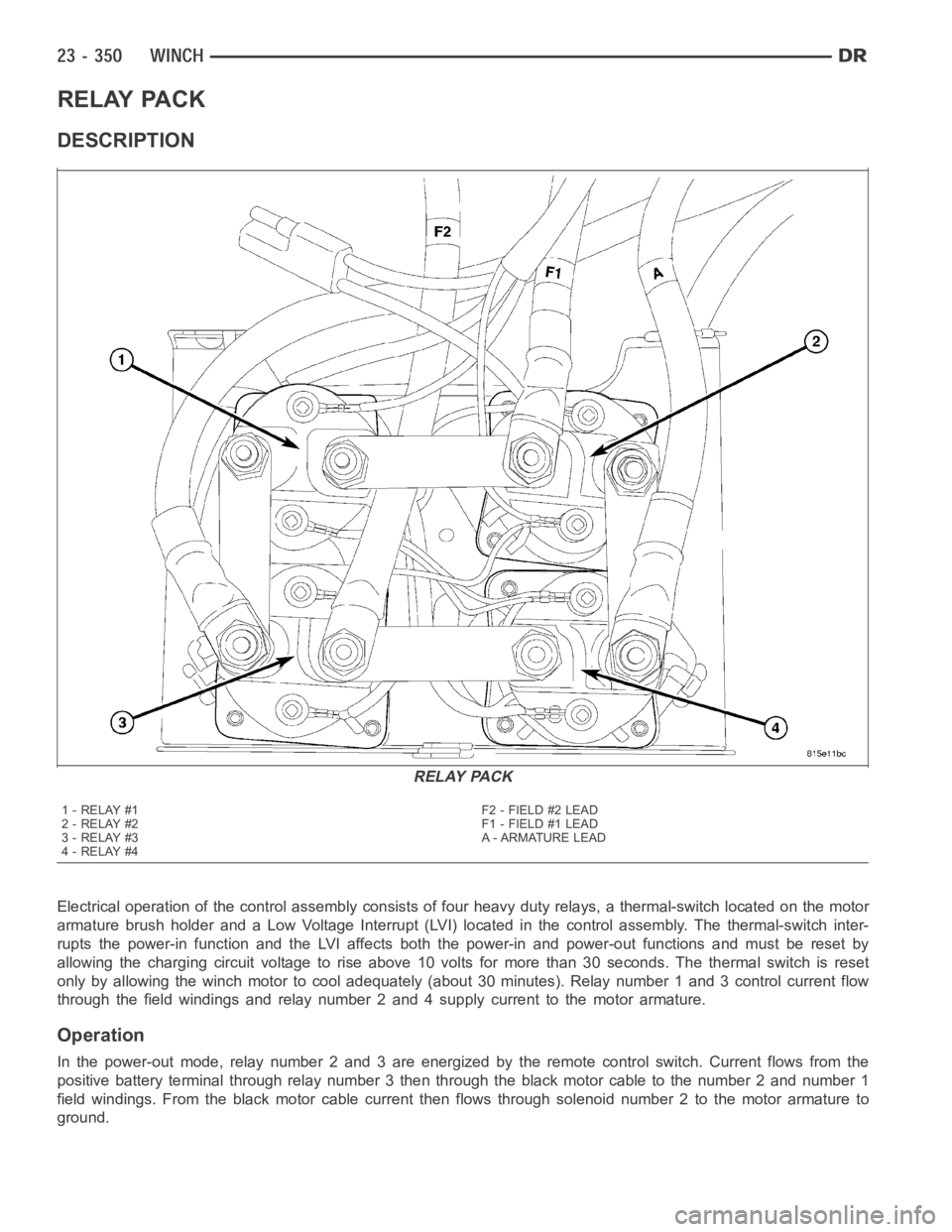

RELAY PACK

DESCRIPTION

Electrical operation of the control assembly consists of four heavy duty relays, a thermal-switch located on the motor

armature brush holder and a Low Voltage Interrupt (LVI) located in the control assembly. The thermal-switch inter-

rupts the power-in function and the LVI affects both the power-in and power-out functions and must be reset by

allowing the charging circuit voltage to rise above 10 volts for more than 30 seconds. The thermal switch is reset

only by allowing the winch motor to cool adequately (about 30 minutes). Relay number 1 and 3 control current flow

through the field windings and relay number 2 and 4 supply current to the motor armature.

Operation

In the power-out mode, relay number 2 and 3 are energized by the remote control switch. Current flows from the

positive battery terminal through relay number 3 then through the black motor cable to the number 2 and number 1

field windings. From the black motor cable current then flows through solenoid number 2 to the motor armature to

ground.

RELAY PACK

1-RELAY#1

2-RELAY#2

3-RELAY#3

4-RELAY#4F2 - FIELD #2 LEAD

F1 - FIELD #1 LEAD

A - ARMATURE LEAD

Page 4944 of 5267

B1001–A/C SWITCH REQUEST INPUT CIRCUIT LOW (SINGLE-ZONE)

For a complete wiring diagramRefer to Section 8W.

Theory of Operation

The A/C mode switch input changes when the switch is pushed down. A stored DTC B1001 indicates that the A/C

mode switch was stuck in a pushed position for more than two minutes, but hassince returned to its normal state.

An active DTC B1001 indicates that the A/C mode switch is stuck in a pushed position.AnactiveDTCB1001will

also prevent proper A/C mode switch and status indicator function as evidenced by not being able to turn the A/C

status indicator either on if off or off if on.

When Monitored:

With the ignition on.

Set Condition:

If the A/C mode switch stays in a pushed position for more than two minutes. This DTC has a maturing time

of two minutes and a de-maturing time of two seconds. If the DTC’s status changes from active to stored it will

stay in memory for 100 ignition cycles.

Possible Causes

A/C HEATER CONTROL DAMAGED

OBJECT HOLDING A/C MODE SWITCH IN A PUSHED POSITION

SUBSTANCE CAUSING A/C MODE SWITCH TO GET STUCK IN A PUSHED POSITION

A/C HEATER CONTROL

Diagnostic Test

1.INSPECT THE A/C HEATER CONTROL FOR DAMAGE

Inspect the A/C Heater Control for damage.

Is the A/C Heater Control damaged?

Ye s>>

Replace the A/C Heater Control in accordance with the Service Information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

No>>

Go To 2

2.INSPECT FOR OBJECT OR SUBSTANCE CAUSING THE A/C MODE SWITCH TO STAY OR STICKIN A

PUSHED POSITION

Inspect the A/C Heater Control for anything that would cause the A/C mode switch to stay or stick in a pushed

position.

Is anything present that would cause the A/C mode switch to stay or stick in apushed position?

Ye s>>

Repair as necessary.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

No>>

Go To 3