air condition DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 5197 of 5267

COMPONENT MONITORS

There are several components that will affect vehicle emissions if they malfunction. If one of these components

malfunctions the Malfunction Indicator Lamp (MIL) will illuminate.

Some of the component monitors are checking for proper operation of the part. Electrically operated components

now have input (rationality) and output (functionality) checks. Previously, a component like the Throttle Position sen-

sor (TPS) was checked by the PCM for an open or shorted circuit. If one of these conditions occurred, a DTC was

set. Now there is a check to ensure that the component is working. This is donebywatchingforaTPSindication

of a greater or lesser throttle opening than MAP and engine rpm indicate. Inthe case of the TPS, if engine vacuum

is high and engine rpm is 1600 or greater, and the TPS indicates a large throttle opening, a DTC will be set. The

same applies to low vacuum if the TPS indicates a small throttle opening.

All open/short circuit checks, or any component that has an associated limp-in, will set a fault after 1 trip with the

malfunction present. Components without an associated limp-in will taketwo trips to illuminate the MIL.

OPERATION

OPERATION

The Powertrain Control Module (PCM) monitors many

different circuits in the fuel injection, ignition, emission

and engine systems. If the PCM senses a problem

withamonitoredcircuitoftenenoughtoindicatean

actual problem, it stores a Diagnostic Trouble Code

(DTC) in the PCM’s memory. If the problem is repaired

or ceases to exist, the PCM cancels the code after 40

warm-up cycles. Diagnostic trouble codes that affect

vehicle emissions illuminatethe Malfunction Indicator

Lamp (MIL). The MIL is displayed as an engine icon

(graphic) on the instrument panel. Refer to Malfunction

Indicator Lamp in this section.

Certain criteria must be met before the PCM stores a

DTC in memory. The criteria may be a specific range

of engine RPM, engine temperature, and/or input volt-

age to the PCM.

The PCM might not store a DTC for a monitored cir-

cuit even though a malfunction has occurred. This

may happen because one of the DTC criteria for the

circuit has not been met.For example,assume the diagnostic trouble code criteria requires the PCM to monitor the

circuit only when the engine operates between 750 and 2000 RPM. Suppose thesensor’s output circuit shorts to

ground when engine operates above 2400 RPM (resulting in 0 volt input to thePCM). Because the condition hap-

pens at an engine speed above the maximum threshold (2000 rpm), the PCM willnot store a DTC.

There are several operating conditions for which the PCM monitors and setsDTC’s. Refer to Monitored Systems,

Components, and Non-Monitored Circuits in this section.

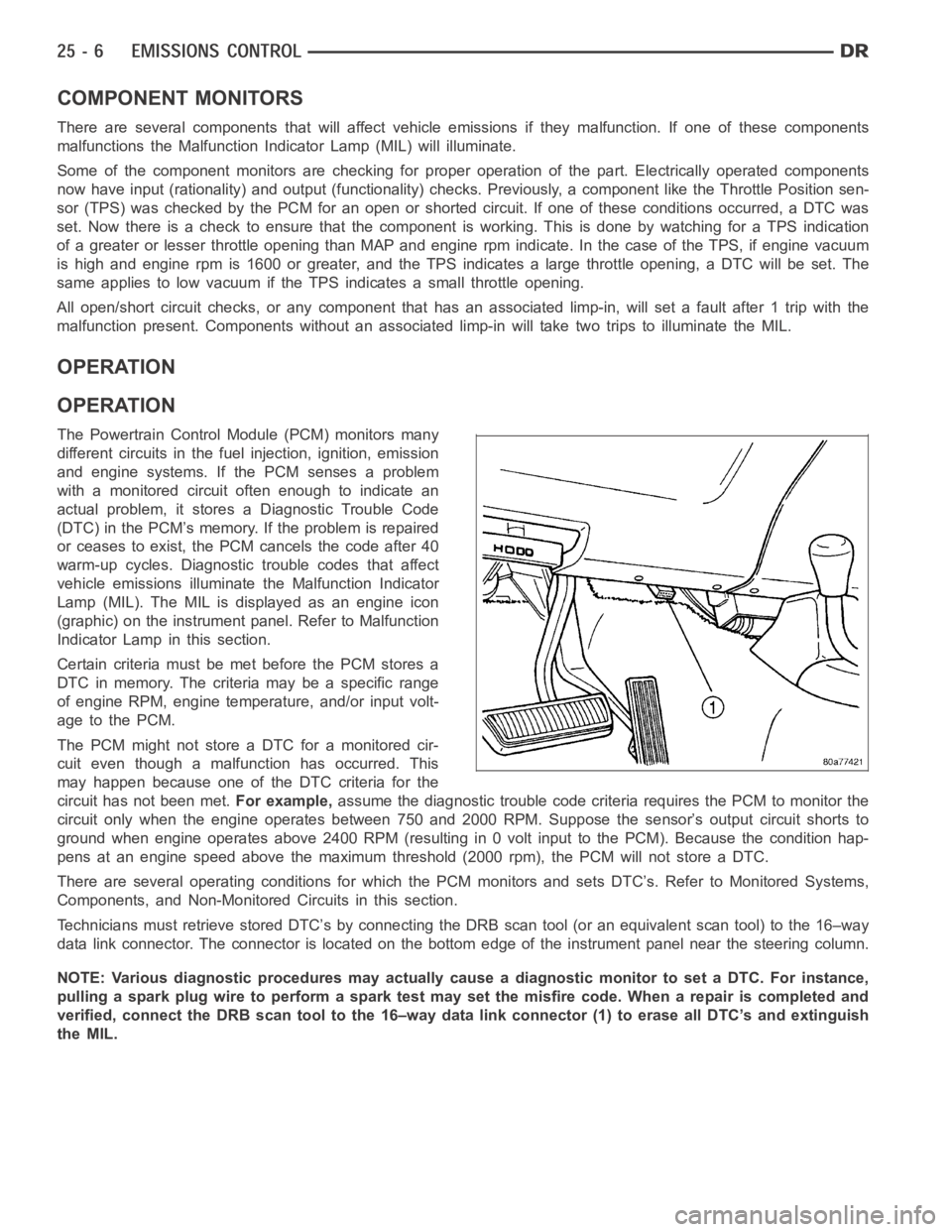

Technicians must retrieve stored DTC’s by connecting the DRB scan tool (oran equivalent scan tool) to the 16–way

data link connector. The connector is located on the bottom edge of the instrument panel near the steering column.

NOTE: Various diagnostic procedures may actually cause a diagnostic monitor to set a DTC. For instance,

pulling a spark plug wire to perform a spark test may set the misfire code. When a repair is completed and

verified, connect the DRB scan tool to the 16–way data link connector (1) toerase all DTC’s and extinguish

the MIL.

Page 5198 of 5267

TA S K M A N A G E R

The Task Manager determines which tests happen when and which functions occur when. Many of the diagnostic

steps required by OBD II must be performed under specific operating conditions. The Task Manager software orga-

nizes and prioritizes the diagnostic procedures. The job of the Task Manager is to determine if conditions are appro-

priate for tests to be run, monitor theparameters for a trip for each test, and record the results of the test. Following

are the responsibilities of the Task Manager software:

Test Sequence

MIL Illumination

Diagnostic Trouble Codes (DTCs)

Trip Indicator

Freeze Frame Data Storage

Similar Conditions Window

Te s t S e q u e n c e

In many instances, emissions systems must fail diagnostic tests more thanonce before the PCM illuminates the

MIL. These tests are know as ’two trip monitors.’ Other tests that turn the MIL lamp on after a single failure are

known as ’one trip monitors.’ A trip is defined as ’start the vehicle and operate it to meet the criteria necessary to

run the given monitor.’

Many of the diagnostic tests must be performed under certain operating conditions. However, there are times when

tests cannot be run because another test is in progress (conflict), another test has failed (pending) or the Task

Manager has set a fault that may cause a failure of the test (suspend).

Pending

Under some situations the Task Manager will not run a monitor if the MIL is illuminated and a fault is stored

from another monitor. In these situations, the Task Manager postpones monitorspendingresolution of the

original fault. The Task Manager does not run the test until the problem is remedied.

For example, when the MIL is illuminated for an Oxygen Sensor fault, the Task Manager does not run the

Catalyst Monitor until the Oxygen Sensor fault is remedied. Since the Catalyst Monitor is based on signals

from the Oxygen Sensor, running the test would produce inaccurate results.

Conflict

There are situations when the Task Manager does not run a test if another monitor is in progress. In these

situations, the effects of another monitor running could result in an erroneous failure. If thisconflictis present,

themonitorisnotrununtiltheconflicting condition passes. Most likelythe monitor will run later after the con-

flicting monitor has passed.

For example, if the Fuel System Monitor is in progress, the Task Manager does not run the EGR Monitor.

Since both tests monitor changes in air/fuel ratio and adaptive fuel compensation, the monitors will conflict with

each other.

Suspend

Occasionally the Task Manager may not allow a two trip fault to mature. The Task Manager willsuspendthe

maturing of a fault if a condition exists that may induce an erroneous failure. This prevents illuminating the MIL

for the wrong fault and allows more precis diagnosis.

For example, if the PCM is storing a one trip fault for the Oxygen Sensor and the EGR monitor, the Task

Manager may still run the EGR Monitor but will suspend the results until theOxygen Sensor Monitor either

passes or fails. At that point the Task Manager can determine if the EGR system is actually failing or if an

Oxygen Sensor is failing.

MIL Illumination

The PCM Task Manager carries out the illumination of the MIL. The Task Manager triggers MIL illumination upon

test failure, depending on monitor failure criteria.

The Task Manager Screen shows both a Requested MIL state and an Actual MIL state. When the MIL is illuminated

upon completion of a test for a third trip, the Requested MIL state changes to OFF. However, the MIL remains

illuminated until the next key cycle. (On some vehicles, the MIL will actually turn OFF during the third key cycle)

During the key cycle for the third good trip, the Requested MIL state is OFF,while the Actual MIL state is ON. After

the next key cycle, the MIL is not illuminated and both MIL states read OFF.

Page 5202 of 5267

EXHAUST SYSTEM

The PCM cannot detect a plugged, restricted or leaking exhaust system, although it may set a fuel system fault.

FUEL INJECTOR MECHANICAL MALFUNCTIONS

The PCM cannot determine if a fuel injector is clogged, the needle is sticking or if the wrong injector is installed.

However, these could result in a rich or lean condition causing the PCM to store a diagnostic trouble code for either

misfire, an oxygen sensor, or the fuel system.

EXCESSIVE OIL CONSUMPTION

Although the PCM monitors engine exhaust oxygen content when the system isin closed loop, it cannot determine

excessive oil consumption.

THROTTLE BODY AIR FLOW

The PCM cannot detect a clogged or restricted air cleaner inlet or filter element.

VACUUM ASSIST

The PCM cannot detect leaks or restrictions in the vacuum circuits of vacuum assisted engine control system

devices. However, these could cause the PCM to store a MAP sensor diagnostic trouble code and cause a high idle

condition.

PCM SYSTEM GROUND

The PCM cannot determine a poor system ground. However, one or more diagnostic trouble codes may be gener-

ated as a result of this condition. The module should be mounted to the body at all times, also during diagnostic.

PCM CONNECTOR ENGAGEMENT

The PCM may not be able to determine spread or damaged connector pins. However, it might store diagnostic

trouble codes as a result of spread connector pins.

Page 5224 of 5267

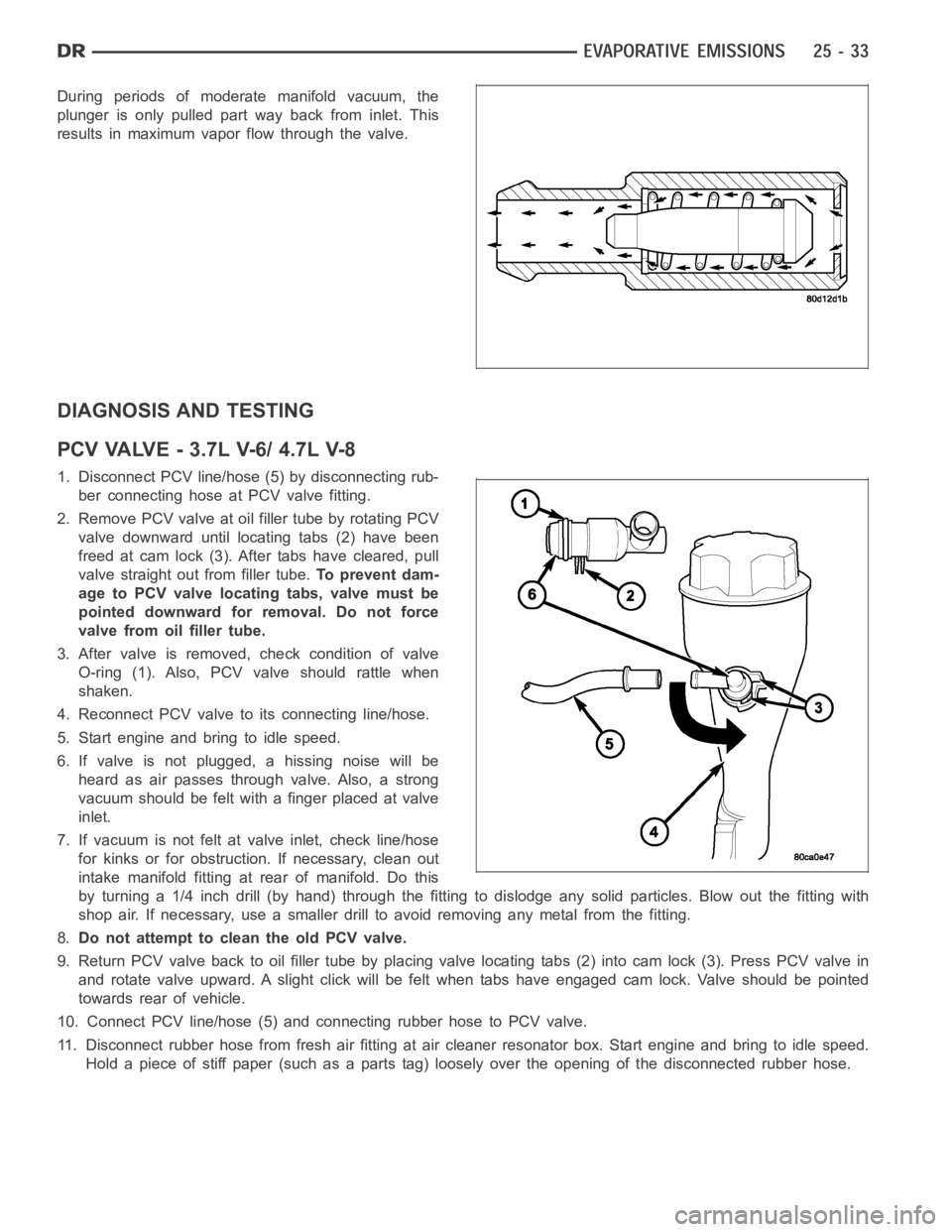

During periods of moderate manifold vacuum, the

plunger is only pulled part way back from inlet. This

results in maximum vapor flow through the valve.

DIAGNOSIS AND TESTING

PCVVALVE-3.7LV-6/4.7LV-8

1. Disconnect PCV line/hose (5) by disconnecting rub-

ber connecting hose at PCV valve fitting.

2. Remove PCV valve at oil filler tube by rotating PCV

valve downward until locating tabs (2) have been

freed at cam lock (3). After tabs have cleared, pull

valve straight out from filler tube.To prevent dam-

age to PCV valve locating tabs, valve must be

pointed downward for removal. Do not force

valve from oil filler tube.

3. After valve is removed, check condition of valve

O-ring (1). Also, PCV valve should rattle when

shaken.

4. Reconnect PCV valve to its connecting line/hose.

5. Start engine and bring to idle speed.

6. If valve is not plugged, a hissing noise will be

heard as air passes through valve. Also, a strong

vacuum should be felt with a finger placed at valve

inlet.

7. If vacuum is not felt at valve inlet, check line/hose

for kinks or for obstruction. If necessary, clean out

intake manifold fitting at rear of manifold. Do this

byturninga1/4inchdrill(byhand)throughthefittingtodislodgeanysolid particles. Blow out the fitting with

shop air. If necessary, use a smaller drill to avoid removing any metal fromthe fitting.

8.Do not attempt to clean the old PCV valve.

9. Return PCV valve back to oil filler tube by placing valve locating tabs (2) into cam lock (3). Press PCV valve in

and rotate valve upward. A slight click will be felt when tabs have engaged cam lock. Valve should be pointed

towards rear of vehicle.

10. Connect PCV line/hose (5) and connecting rubber hose to PCV valve.

11. Disconnect rubber hose from fresh air fitting at air cleaner resonatorbox. Start engine and bring to idle speed.

Hold a piece of stiff paper (such as a parts tag) loosely over the opening of the disconnected rubber hose.