ignition DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2898 of 5267

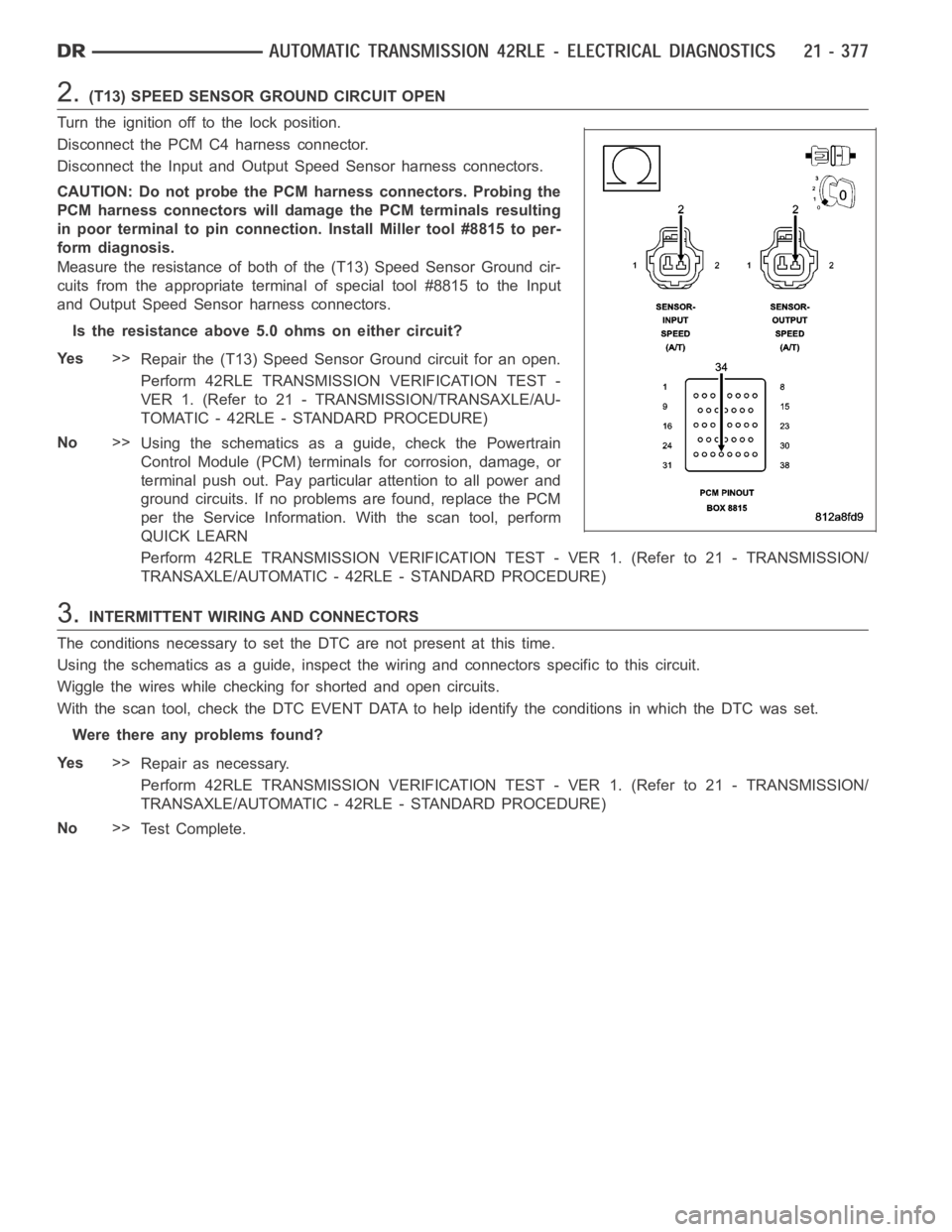

2.(T13) SPEED SENSOR GROUND CIRCUIT OPEN

Turn the ignition off to the lock position.

Disconnect the PCM C4 harness connector.

Disconnect the Input and Output Speed Sensor harness connectors.

CAUTION: Do not probe the PCM harness connectors. Probing the

PCM harness connectors will damage the PCM terminals resulting

in poor terminal to pin connection. Install Miller tool #8815 to per-

form diagnosis.

Measure the resistance of both of the (T13) Speed Sensor Ground cir-

cuits from the appropriate terminal of special tool #8815 to the Input

and Output Speed Sensor harness connectors.

Is the resistance above 5.0 ohms on either circuit?

Ye s>>

Repair the (T13) Speed Sensor Ground circuit for an open.

Perform 42RLE TRANSMISSION VERIFICATION TEST -

VER 1. (Refer to 21 - TRANSMISSION/TRANSAXLE/AU-

TOMATIC - 42RLE - STANDARD PROCEDURE)

No>>

Using the schematics as a guide, check the Powertrain

Control Module (PCM) terminals for corrosion, damage, or

terminal push out. Pay particular attention to all power and

ground circuits. If no problems are found, replace the PCM

per the Service Information.With the scan tool, perform

QUICK LEARN

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

3.INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set the DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specifictothiscircuit.

Wiggle the wires while checking for shorted and open circuits.

With the scan tool, check the DTC EVENT DATA to help identify the conditionsin which the DTC was set.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

No>>

Te s t C o m p l e t e .

Page 2908 of 5267

STANDARD PROCEDURE

PRE-DIAGNOSTIC TROUBLESHOOTING PROCEDURE - 42RLE

For a complete wiring diagramRefer to Section 8W.

1.

Perform the following steps prior to any diagnostic procedure:

Many transmission symptoms can be caused by a low fluid level. If the fluid level is low, locate and repair any

leaks and fill the transmission to the proper fluid level. Refer to the Service Information for the proper repair

and fluid fill procedures.

Testing should only be performed with the battery fully charged to avoid false diagnosis.

With the scan tool, read Engine (PCM) DTCs. If Engine DTCs are present, refer to the Driveability Category

and perform to the appropriate diagnostic procedure(s) before proceeding.

With the scan tool, read Transmission (TCM) DTCs. Record all Stored, Active, and Pending DTC information.

Diagnose any Pending DTC as a matured DTC.

With the scan tool, read DTC EVENT DATA.Use this data to identify the conditions in which the DTC was set.

Note: Performing a Battery Disconnect will clear all DTC EVENT DATA and reset all learned Transmis-

sion values to the controllers default values, which may temporarily result in erratic shift schedules.

With the scan tool, perform the Shift Lever Position Test. If the test does not pass, refer to the diagnostic

procedure for P0706-Check Shifter Signal.

For Gear Ratio Error DTCs, use the scan tool to read and record the Clutch Volume Index (CVI) information.

Use the wiring diagram as a guide, inspect the wiring and connectors related to this circuit and repair as nec-

essary.

Refer to the When Monitored and Set Conditions for this DTC. DTCs can set at ignition on, at start up, driving

under specific conditions, and after controller diagnostic monitors haverun.

Refer to applicable Technical Service Bulletins (TSBs) for controller software update information. Some condi-

tions can be corrected by upgrading the Engine (PCM) or Transmission (TCM)controller software.

Check for any Service Information Tune-ups or Service Bulletins for any possible causes that may apply.

Were there any repairs made that fixed the vehicle?

Ye s>>

Testing complete.

Perform 42RLE VERIFICATION TEST - VER1(Referto21-TRANSMISSION/TRANSAXLE/AUTO-

MATIC - 42RLE - STANDARD PROCEDURE)

No>>

Refer to the Transmission category and perform the appropriate diagnostic procedure(s). (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC - 42RLE - DIAGNOSIS AND TESTING)

Page 3010 of 5267

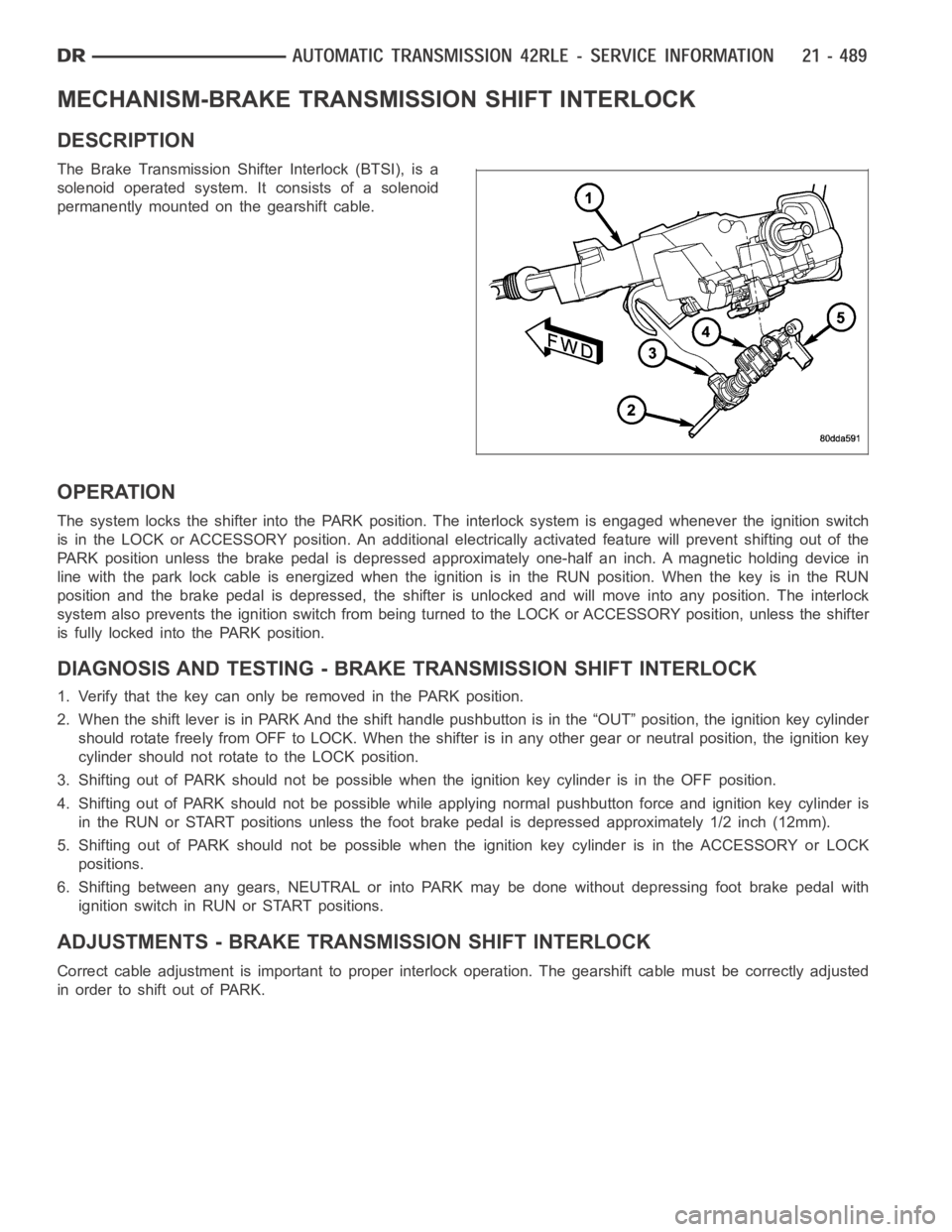

MECHANISM-BRAKE TRANSMISSION SHIFT INTERLOCK

DESCRIPTION

The Brake Transmission Shifter Interlock (BTSI), is a

solenoid operated system. It consists of a solenoid

permanently mounted on the gearshift cable.

OPERATION

The system locks the shifter into the PARK position. The interlock system is engaged whenever the ignition switch

is in the LOCK or ACCESSORY position. An additional electrically activated feature will prevent shifting out of the

PARK position unless the brake pedal is depressed approximately one-halfan inch. A magnetic holding device in

line with the park lock cable is energized when the ignition is in the RUN position. When the key is in the RUN

position and the brake pedal is depressed, the shifter is unlocked and willmove into any position. The interlock

system also prevents the ignition switch from being turned to the LOCK or ACCESSORY position, unless the shifter

is fully locked into the PARK position.

DIAGNOSIS AND TESTING - BRAKE TRANSMISSION SHIFT INTERLOCK

1. Verify that the key can only be removed in the PARK position.

2. When the shift lever is in PARK And the shift handle pushbutton is in the “OUT” position, the ignition key cylinder

should rotate freely from OFF to LOCK. When the shifter is in any other gear or neutral position, the ignition key

cylinder should not rotate to the LOCK position.

3. Shifting out of PARK should not be possible when the ignition key cylinder is in the OFF position.

4. Shifting out of PARK should not be possible while applying normal pushbutton force and ignition key cylinder is

in the RUN or START positions unless the foot brake pedal is depressed approximately 1/2 inch (12mm).

5. Shifting out of PARK should not be possible when the ignition key cylinderisintheACCESSORYorLOCK

positions.

6. Shifting between any gears, NEUTRAL or into PARK may be done without depressing foot brake pedal with

ignition switch in RUN or START positions.

ADJUSTMENTS - BRAKE TRANSMISSION SHIFT INTERLOCK

Correct cable adjustment is important to proper interlock operation. Thegearshift cable must be correctly adjusted

in order to shift out of PARK.

Page 3011 of 5267

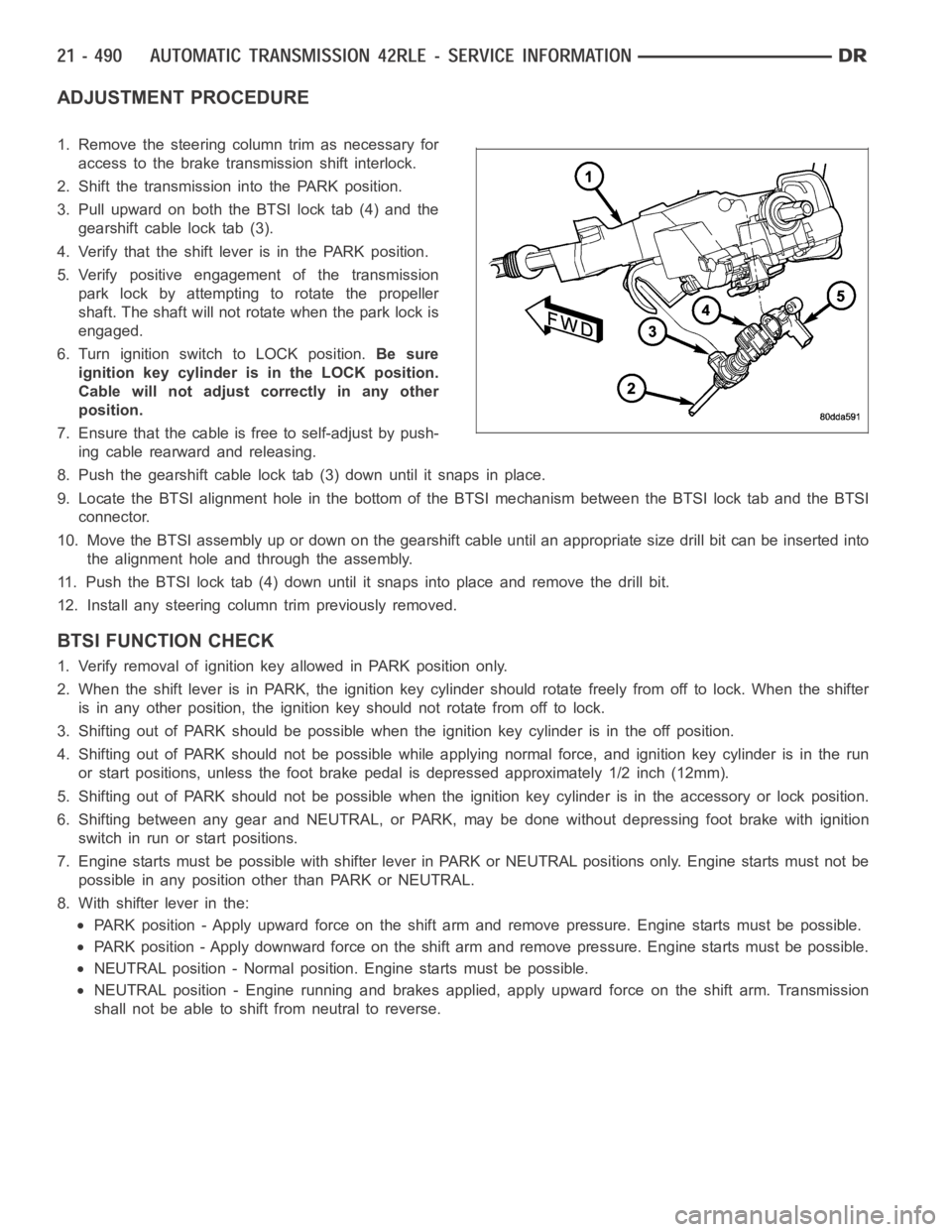

ADJUSTMENT PROCEDURE

1. Remove the steering column trim as necessary for

access to the brake transmission shift interlock.

2. Shift the transmission into the PARK position.

3. Pull upward on both the BTSI lock tab (4) and the

gearshift cable lock tab (3).

4. Verify that the shift lever is in the PARK position.

5. Verify positive engagement of the transmission

park lock by attempting to rotate the propeller

shaft. The shaft will not rotate when the park lock is

engaged.

6. Turn ignition switch to LOCK position.Be sure

ignition key cylinder is in the LOCK position.

Cable will not adjust correctly in any other

position.

7. Ensure that the cable is free to self-adjust by push-

ing cable rearward and releasing.

8. Push the gearshift cable lock tab (3) down until it snaps in place.

9. Locate the BTSI alignment hole in the bottom of the BTSI mechanism betweentheBTSIlocktabandtheBTSI

connector.

10. Move the BTSI assembly up or down on the gearshift cable until an appropriate size drill bit can be inserted into

the alignment hole and through the assembly.

11. Push the BTSI lock tab (4) down until it snaps into place and remove the drill bit.

12. Install any steering column trim previously removed.

BTSI FUNCTION CHECK

1. Verify removal of ignition key allowed in PARK position only.

2. When the shift lever is in PARK, the ignition key cylinder should rotate freely from off to lock. When the shifter

is in any other position, the ignition key should not rotate from off to lock.

3. Shifting out of PARK should be possible when the ignition key cylinder isin the off position.

4. Shifting out of PARK should not be possible while applying normal force,and ignition key cylinder is in the run

or start positions, unless the foot brake pedal is depressed approximately1/2inch(12mm).

5. Shifting out of PARK should not be possible when the ignition key cylinder is in the accessory or lock position.

6. Shifting between any gear and NEUTRAL, or PARK, may be done without depressing foot brake with ignition

switch in run or start positions.

7. Engine starts must be possible with shifter lever in PARK or NEUTRAL positions only. Engine starts must not be

possible in any position other than PARK or NEUTRAL.

8. With shifter lever in the:

PARK position - Apply upward force on the shift arm and remove pressure. Enginestartsmustbepossible.

PARK position - Apply downward force on the shift arm and remove pressure. Engine starts must be possible.

NEUTRAL position - Normal position. Engine starts must be possible.

NEUTRAL position - Engine running and brakes applied, apply upward force on the shift arm. Transmission

shall not be able to shift from neutral to reverse.

Page 3071 of 5267

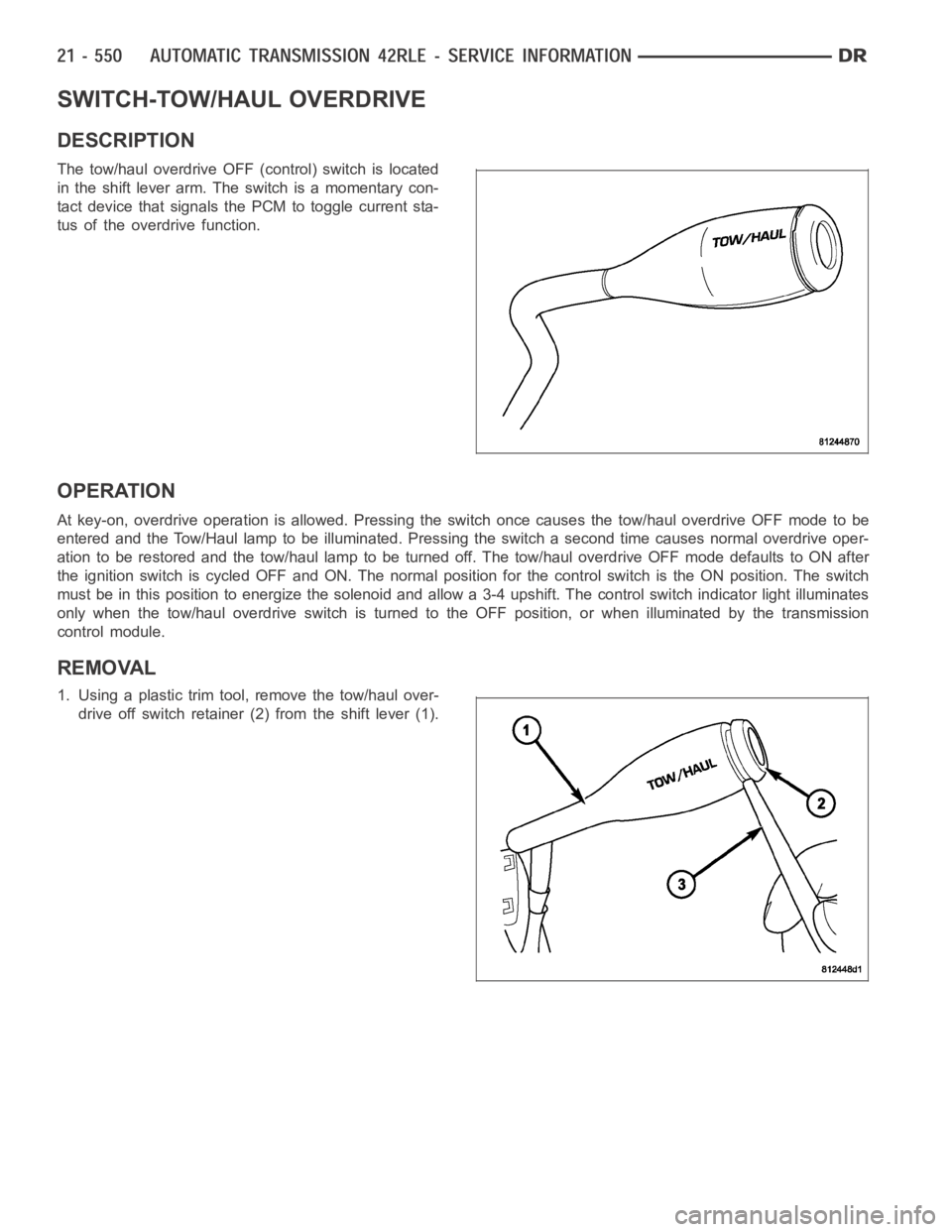

SWITCH-TOW/HAUL OVERDRIVE

DESCRIPTION

The tow/haul overdrive OFF (control) switch is located

in the shift lever arm. The switch is a momentary con-

tact device that signals the PCM to toggle current sta-

tus of the overdrive function.

OPERATION

At key-on, overdrive operation is allowed. Pressing the switch once causes the tow/haul overdrive OFF mode to be

entered and the Tow/Haul lamp to be illuminated. Pressing the switch a second time causes normal overdrive oper-

ationtoberestoredandthetow/haullamptobeturnedoff.Thetow/hauloverdrive OFF mode defaults to ON after

the ignition switch is cycled OFF and ON. The normal position for the control switch is the ON position. The switch

must be in this position to energize the solenoid and allow a 3-4 upshift. The control switch indicator light illuminates

only when the tow/haul overdrive switch is turned to the OFF position, or when illuminated by the transmission

control module.

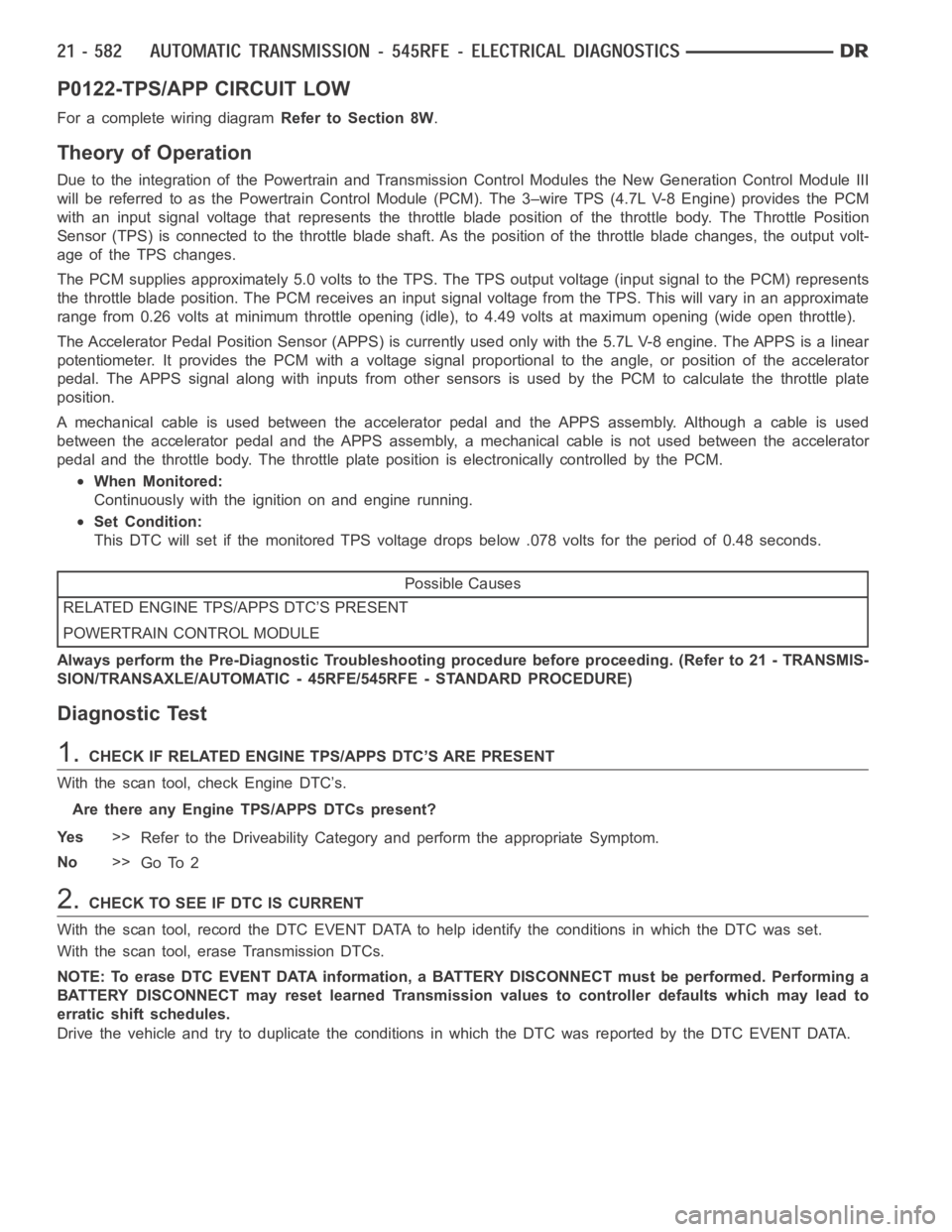

REMOVAL

1. Using a plastic trim tool, remove the tow/haul over-

drive off switch retainer (2) from the shift lever (1).

Page 3103 of 5267

P0122-TPS/APP CIRCUIT LOW

For a complete wiring diagramRefer to Section 8W.

Theory of Operation

Due to the integration of the Powertrain and Transmission Control Modulesthe New Generation Control Module III

will be referred to as the Powertrain Control Module (PCM). The 3–wire TPS (4.7L V-8 Engine) provides the PCM

with an input signal voltage that represents the throttle blade position of the throttle body. The Throttle Position

Sensor (TPS) is connected to the throttle blade shaft. As the position of the throttle blade changes, the output volt-

age of the TPS changes.

The PCM supplies approximately 5.0 volts to the TPS. The TPS output voltage(input signal to the PCM) represents

the throttle blade position. The PCM receives an input signal voltage fromthe TPS. This will vary in an approximate

range from 0.26 volts at minimum throttle opening (idle), to 4.49 volts at maximum opening (wide open throttle).

The Accelerator Pedal Position Sensor (APPS) is currently used only with the 5.7L V-8 engine. The APPS is a linear

potentiometer. It provides the PCM with a voltage signal proportional to the angle, or position of the accelerator

pedal. The APPS signal along with inputs from other sensors is used by the PCM to calculate the throttle plate

position.

A mechanical cable is used between the accelerator pedal and the APPS assembly. Although a cable is used

between the accelerator pedal and the APPS assembly, a mechanical cable isnot used between the accelerator

pedal and the throttle body. The throttle plate position is electronically controlled by the PCM.

When Monitored:

Continuously with the ignition on and engine running.

Set Condition:

This DTC will set if the monitored TPS voltage drops below .078 volts for theperiod of 0.48 seconds.

Possible Causes

RELATED ENGINE TPS/APPS DTC’S PRESENT

POWERTRAIN CONTROL MODULE

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Diagnostic Test

1.CHECK IF RELATED ENGINE TPS/APPS DTC’S ARE PRESENT

With the scan tool, check Engine DTC’s.

Are there any Engine TPS/APPS DTCs present?

Ye s>>

Refer to the Driveability Category and perform the appropriate Symptom.

No>>

Go To 2

2.CHECK TO SEE IF DTC IS CURRENT

With the scan tool, record the DTC EVENT DATA to help identify the conditionsinwhichtheDTCwasset.

With the scan tool, erase Transmission DTCs.

NOTE: To erase DTC EVENT DATA information, a BATTERY DISCONNECT must be performed. Performing a

BATTERY DISCONNECT may reset learned Transmission values to controller defaults which may lead to

erratic shift schedules.

Drive the vehicle and try to duplicate the conditions in which the DTC was reported by the DTC EVENT DATA.

Page 3105 of 5267

P0123-TPS/APP CIRCUIT HIGH

For a complete wiring diagramRefer to Section 8W.

Theory of Operation

Due to the integration of the Powertrain and Transmission Control Modulesthe New Generation Control Module III

will be referred as the Powertrain Control Module (PCM). The 4.7L V-8 Throttle Positioning Sensor (TPS) provides

the PCM with an input signal voltage that represents the throttle blade position of the throttle body. The TPS is

connected to the throttle blade shaft. As the position of the throttle blade changes, the output voltage of the TPS

changes.

The 5.7L V-8 Accelerator Pedal Position Sensor (APPS) is a linear potentiometer that provides the PCM with a

voltage signal proportional to the angle, or position of the accelerator pedal. The APPS signal along with inputs from

other sensors is used by the PCM to calculate the throttle plate position which is electronically controlled.

When Monitored:

Continuously with the ignition on and engine running.

Set Condition:

This DTC will set if the monitored TPS voltage rises above 4.94 volts for theperiod of 0.48 seconds.

Possible Causes

RELATED ENGINE TPS/APPS DTC’S PRESENT

POWERTRAIN CONTROL MODULE

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Diagnostic Test

1.DETERMINING IF RELATED ENGINE TPS/APPS DTCS ARE PRESENT

With the scan tool, check Engine DTCs, this includes all one trip failures.

Are there any Engine TPS/APPS DTCs present?

Ye s>>

Refer to the Driveability category and perform the appropriate symptom.

No>>

Go To 2

2.CHECK IF THE DTC IS CURRENT

With the scan tool, record the DTC EVENT DATA to help identify the conditionsinwhichtheDTCwasset.

With the scan tool, erase Transmission DTCs.

NOTE: To erase DTC EVENT DATA information, a BATTERY DISCONNECT must be performed. Performing a

BATTERY DISCONNECT may reset all learned Transmission values to controller defaults that could lead to

an inconsistent shift schedule.

Drive the vehicle and try to duplicate the conditions in which the DTC was reported by the DTC EVENT DATA.

With the scan tool, read Transmission DTCs.

Did the DTC P0123 TPS/APPS HIGH, reset?

Ye s>>

Using the schematics as a guide, check the Powertrain Control Module (PCM)terminals for corrosion,

damage, or terminal push out. Pay particular attention to all power and ground circuits. If no problems

are found, replace the PCM per the Service Information. With the scan tool,perform QUICK LEARN.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Go To 3

Page 3107 of 5267

P0124-TPS/APP INTERMITTENT

For a complete Transmission wiring diagramRefer to Section 8W

Theory of Operation

Due to the integration of the Powertrain and Transmission Control Modulesthe New Generation Control Module III

will be referred as the Powertrain Control Module (PCM). The 4.7L V-8 Throttle Positioning Sensor (TPS) provides

the PCM with an input signal voltage that represents the throttle blade position of the throttle body. The TPS is

connected to the throttle blade shaft. As the position of the throttle blade changes, the output voltage of the TPS

changes.

The 5.7L V-8 Accelerator Pedal Position Sensor (APPS) is a linear potentiometer that provides the PCM with a

voltage signal proportional to the angle, or position of the accelerator pedal. The APPS signal along with inputs from

other sensors is used by the PCM to calculate the throttle plate position which is electronically controlled.

When Monitored:

Continuously with the ignition on and engine running.

Set Condition:

This DTC will set if the monitored TPS throttle angle between the angles of 6° and 120° and the degree

change is greater than 5° within a period of less than 7.0 msec.

Possible Causes

RELATED TPS ENGINE DTC’S PRESENT

THROTTLE POSITION SENSOR

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Diagnostic Test

1.DETERMINING IF RELATED ENGINE TPS DTC’S ARE PRESENT

With the scan tool, check Engine DTC’s including all one trip failures.

Are there any Engine TPS/APPS DTCs present?

Ye s>>

Refer to the Powertrain category and perform the appropriate symptom.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Go To 2

2.CHECK TO SEE IF DTC IS CURRENT

With the scan tool, record the DTC EVENT DATA to help identify the conditionsinwhichtheDTCwasset.

With the scan tool, erase Transmission DTCs.

NOTE: To erase EVENT DATA information, a BATTERY DISCONNECT must be performed. Performing a BAT-

TERY DISCONNECT may reset all learned transmission values to controller default. This may lead to erratic

shift schedules.

Drive the vehicle and try to duplicate the conditions in which the DTC was reported by the DTC EVENT DATA.

With the scan tool, read Transmission DTCs.

Did the DTC P0124 TPS/APPS INTERMITTENT, reset?

Ye s>>

Go To 3

No>>

Go To 4

Page 3108 of 5267

3.CHECK THROTTLE POSITION SENSOR OPERATION

Ignition On, Engine Not Running.

With the scan tool, under Transmission Sensors, monitor the TPS voltage inthe following step.

Slowly open and close the throttle while checking for erratic voltage changes.

IfequippedwithETC,usetheETCThrottleFollowertestinthescantooltocheck for erratic voltage changes.

Was the TPS voltage change smooth and consistent?

Ye s>>

Using the schematics as a guide, check the Powertrain Control Module (PCM)terminals for corrosion,

damage, or terminal push out. Pay particular attention to all power and ground circuits. If no problems

are found, replace the PCM per the Service Information. With the scan tool,perform QUICK LEARN.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Replace the Throttle Position Sensor per the Service Information.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

4.INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set the DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specifictothiscircuit.

Wiggle the wiring and connectors while checking for shorted and open circuits.

With the scan tool, check the DTC EVENT DATA to help identify the conditionsin which the DTC was set.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Te s t C o m p l e t e .

Page 3112 of 5267

3.CONDITION P0562 PRESENT

With the scan tool, read Transmission DTCs.

With the scan tool, Check the STARTS SINCE SET counter for P0562.

NOTE: This counter only applies to the last DTC set.

Is the STARTS SINCE SET counter set at 0?

Ye s>>

Go To 4

No>>

Go To 7

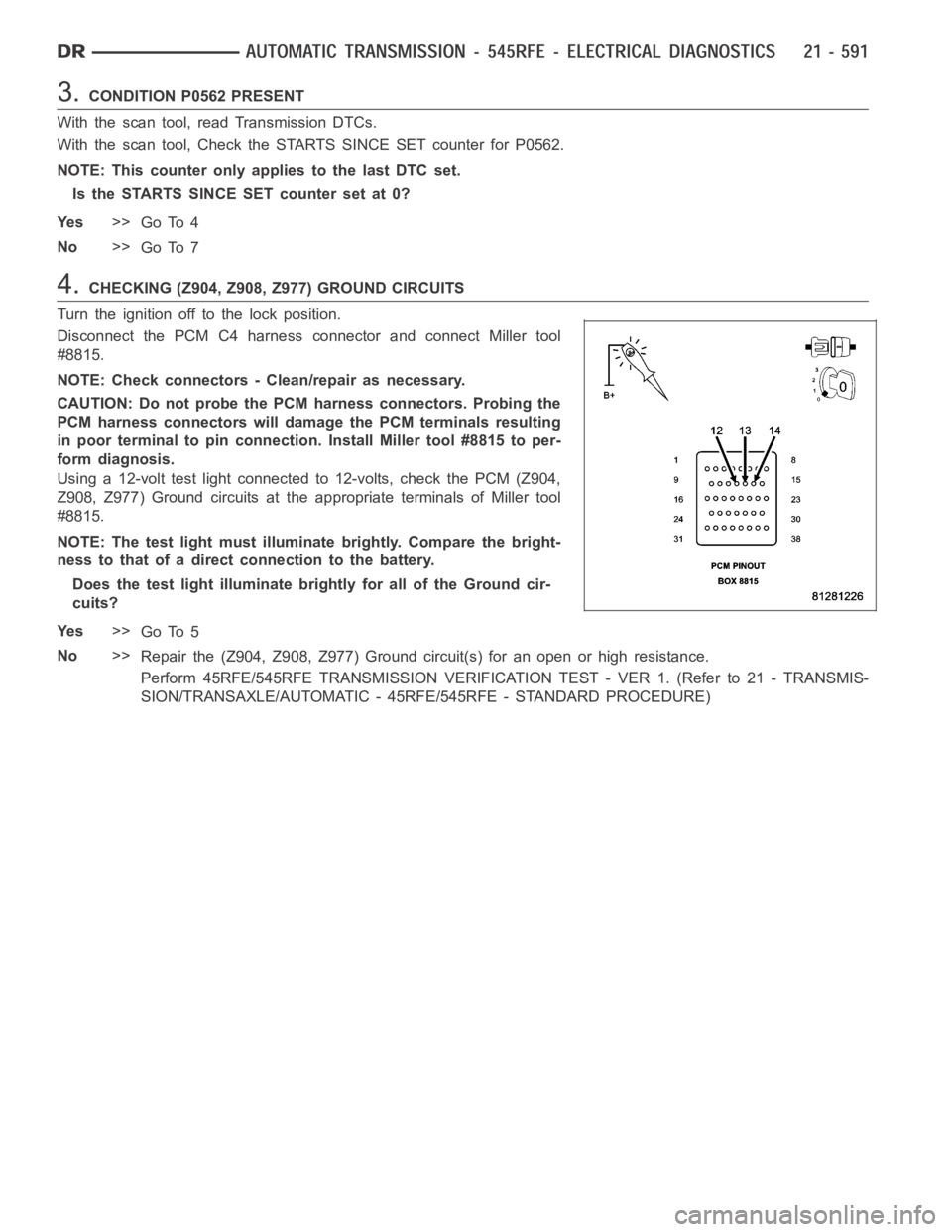

4.CHECKING (Z904, Z908, Z977) GROUND CIRCUITS

Turn the ignition off to the lock position.

Disconnect the PCM C4 harness connector and connect Miller tool

#8815.

NOTE: Check connectors - Clean/repair as necessary.

CAUTION: Do not probe the PCM harness connectors. Probing the

PCM harness connectors will damage the PCM terminals resulting

in poor terminal to pin connection. Install Miller tool #8815 to per-

form diagnosis.

Using a 12-volt test light connected to 12-volts, check the PCM (Z904,

Z908, Z977) Ground circuits at the appropriate terminals of Miller tool

#8815.

NOTE: The test light must illuminate brightly. Compare the bright-

ness to that of a direct connection to the battery.

Does the test light illuminate brightly for all of the Ground cir-

cuits?

Ye s>>

Go To 5

No>>

Repair the (Z904, Z908, Z977) Ground circuit(s) for an open or high resistance.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)