hood release DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 4341 of 5267

POSSIBLE CAUSE OF WIND NOISE

Moldings standing away from body surface can catch wind and whistle.

Gaps in sealed areas behind overhanging body flanges can cause wind-rushing sounds.

Misaligned movable components.

Missing or improperly installed plugs in pillars.

Weld burn through holes.

Improperly installed roof rack cross bars.

STANDARD PROCEDURE

BODY LUBRICATION

All mechanisms and linkages should be lubricated when necessary. This will maintain ease of operation and provide

protection against rust and excessive wear. The weatherstrip seals should be lubricated to prolong their life as well

as to improve door sealing.

All applicable exterior and interior vehicle operating mechanisms should be inspected and cleaned. Pivot/sliding con-

tact areas on the mechanisms should then be lubricated.

1. When necessary, lubricate the operating mechanisms with the specifiedlubricants.

2. Apply silicone lubricant to a clothand wipe it on door seals to avoid over-spray that can soil passenger’s cloth-

ing.

3. Before applying lubricant, the component should be wiped clean. After lubrication, any excess lubricant should be

removed.

4. The hood latch, latch release mechanism, latch striker, and safety latch should be lubricated periodically.

5. The door lock cylinders should be lubricated twice each year (preferably autumn and spring).

Spray a small amount of lock cylinder lubricant directly into the lock cylinder.

Apply a small amount to the key and insert it into the lock cylinder.

Rotate it to the locked position and then back to the unlocked position several times.

Remove the key. Wipe the lubricant from it with a clean cloth to avoid soiling of clothing.

HEAT STAKING

1. Remove trim panel.

2. Bend or move the trim panel components at the heat staked joints. Observethe heat staked locations and/or

component seams for looseness.

3. Heat stake the components.

a. If the heat staked or component seam location is loose, hold the two components tightly together and using

a soldering gun with a flat tip, melt the material securing the components together. Do not over heat the

affected area, damage to the exterior of the trim panel may occur.

b. Iftheheatstakedmaterialisbrokenormissing,useahotglueguntoapplynewmaterialtotheareatobe

repaired. The panels that are being heat staked must be held together whiletheapplyingtheglue.Oncethe

new material is in place, it may be necessary to use a soldering gun to melt the newly applied material. Do

not over heat the affected area, damage to the exterior of the trim panel mayoccur.

4. Allow the repaired area to cool and verify the repair.

5. Install trim panel.

BUZZ, SQUEAK & RATTLE

Buzz, Squeak & Rattles (BSR) may be caused by any one or more of the followingand may be corrected as indi-

cated:

Loose fasteners should be tightened to specifications.

Damaged or missing clips should be replaced.

Damaged trim panels should be replaced.

Incorrectly installed trim panels should be reinstalled properly.

Page 4463 of 5267

page page

BEZEL-HOOD SRT-10

REMOVAL ................................... 127

INSTALLATION .............................. 128

HINGE

REMOVAL ................................... 130

INSTALLATION .............................. 130

HOOD

REMOVAL ................................... 132

INSTALLATION .............................. 132

LATCH

REMOVAL ................................... 133INSTALLATION .............................. 133

LATCH RELEASE CABLE/HANDLE ASSEMBLY

REMOVAL

REMOVAL ................................ 134

INSTALLATION .............................. 134

LATCH STRIKER / SECONDARY CATCH

REMOVAL ................................... 135

INSTALLATION .............................. 135

SUPPORT CYLINDER

REMOVAL ................................... 136

INSTALLATION .............................. 137

Page 4471 of 5267

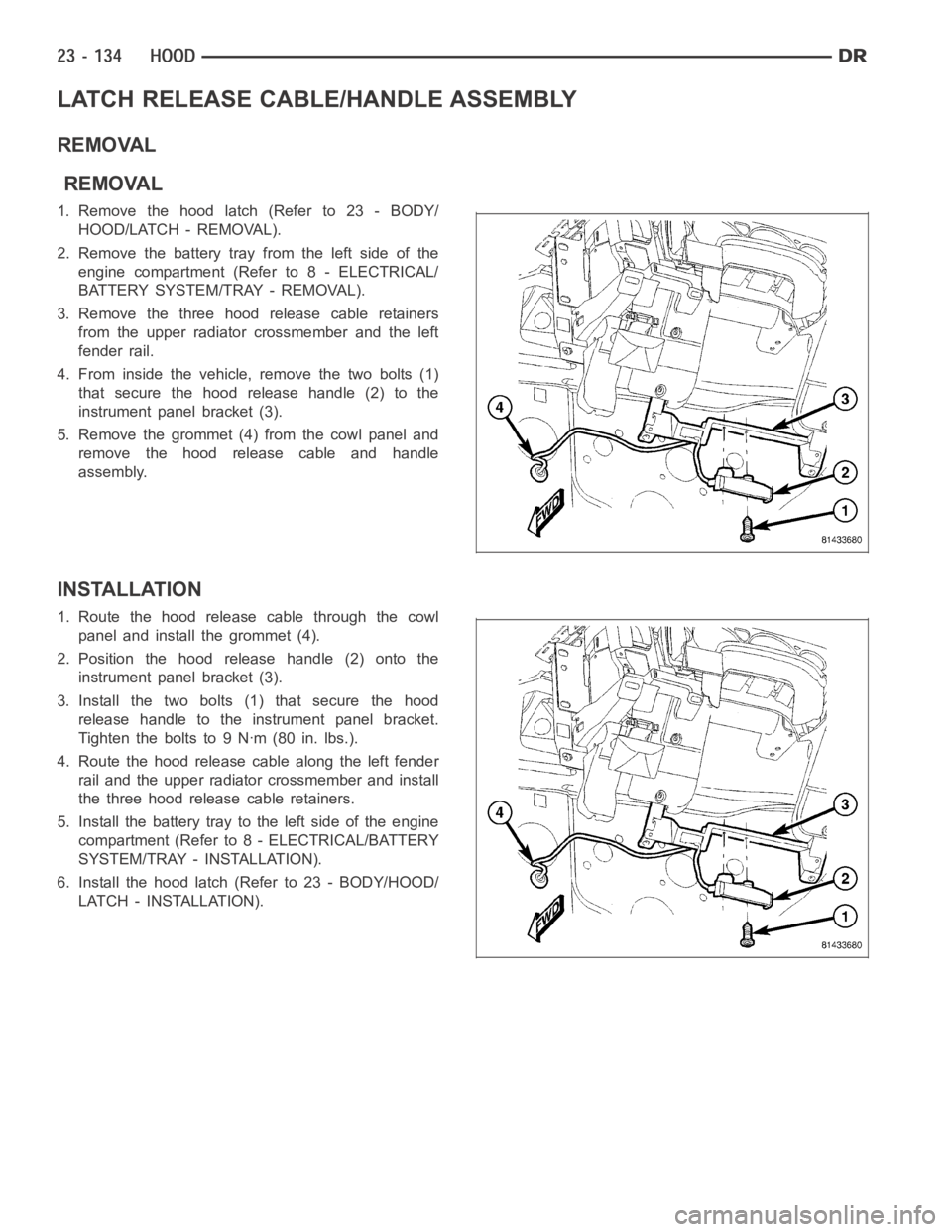

LATCH RELEASE CABLE/HANDLE ASSEMBLY

REMOVAL

REMOVAL

1.Removethehoodlatch(Referto23-BODY/

HOOD/LATCH - REMOVAL).

2. Remove the battery tray from the left side of the

engine compartment (Refer to 8 - ELECTRICAL/

BATTERY SYSTEM/TRAY - REMOVAL).

3. Remove the three hood release cable retainers

from the upper radiator crossmember and the left

fender rail.

4. From inside the vehicle, remove the two bolts (1)

that secure the hood release handle (2) to the

instrument panel bracket (3).

5. Remove the grommet (4) from the cowl panel and

remove the hood release cable and handle

assembly.

INSTALLATION

1. Route the hood release cable through the cowl

panel and install the grommet (4).

2. Position the hood release handle (2) onto the

instrument panel bracket (3).

3. Install the two bolts (1) that secure the hood

release handle to the instrument panel bracket.

Tightentheboltsto9Nꞏm(80in.lbs.).

4. Route the hood release cable along the left fender

rail and the upper radiator crossmember and install

the three hood release cable retainers.

5. Install the battery tray to the left side of the engine

compartment (Refer to 8 - ELECTRICAL/BATTERY

SYSTEM/TRAY - INSTALLATION).

6. Install the hood latch (Refer to 23 - BODY/HOOD/

LATCH - INSTALLATION).

Page 4472 of 5267

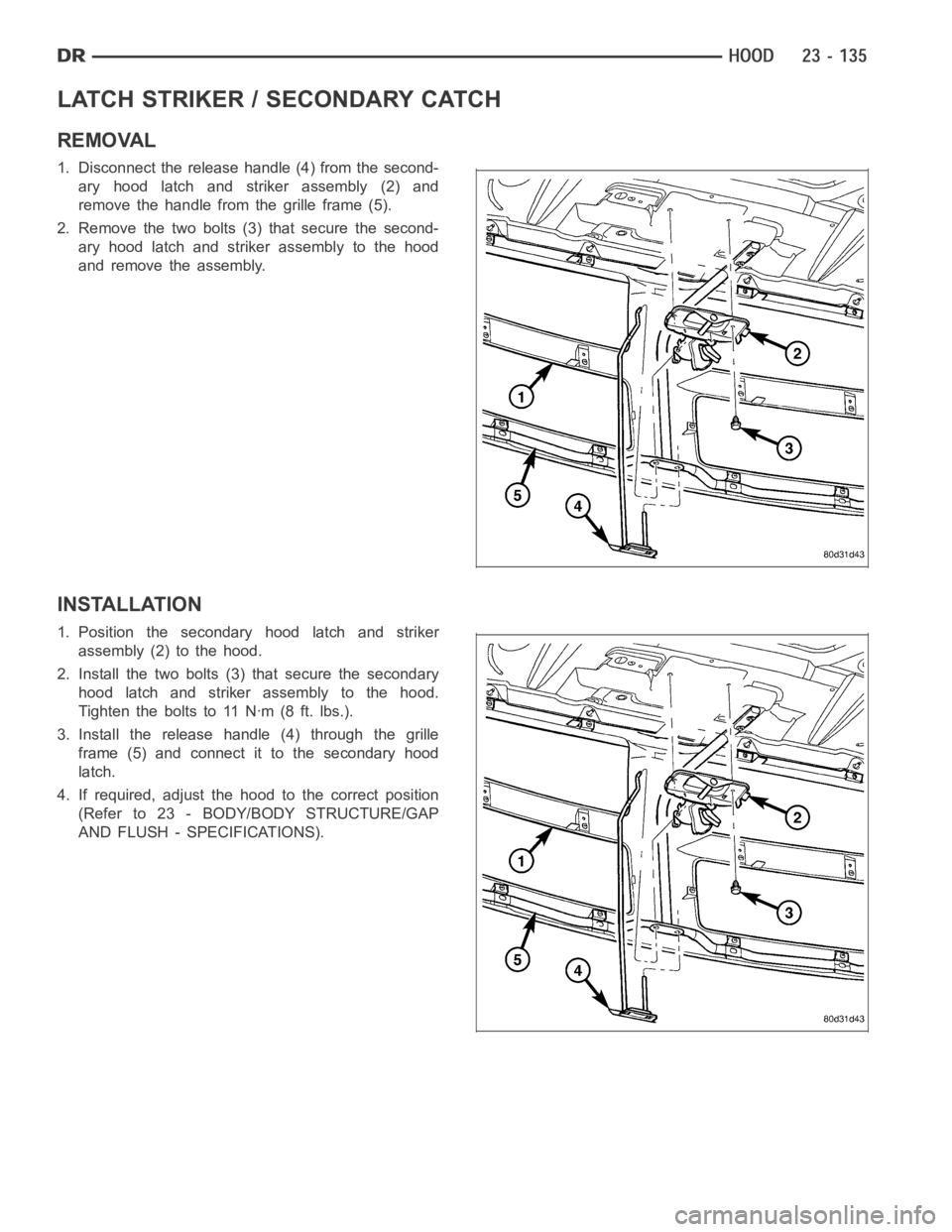

LATCH STRIKER / SECONDARY CATCH

REMOVAL

1. Disconnect the release handle (4) from the second-

ary hood latch and striker assembly (2) and

remove the handle from the grille frame (5).

2. Remove the two bolts (3) that secure the second-

ary hood latch and striker assembly to the hood

and remove the assembly.

INSTALLATION

1. Position the secondary hood latch and striker

assembly (2) to the hood.

2. Install the two bolts (3) that secure the secondary

hood latch and striker assembly to the hood.

Tighten the bolts to 11 Nꞏm (8 ft. lbs.).

3. Install the release handle (4) through the grille

frame (5) and connect it to the secondary hood

latch.

4. If required, adjust the hood to the correct position

(Refer to 23 - BODY/BODY STRUCTURE/GAP

AND FLUSH - SPECIFICATIONS).

Page 4473 of 5267

SUPPORT CYLINDER

REMOVAL

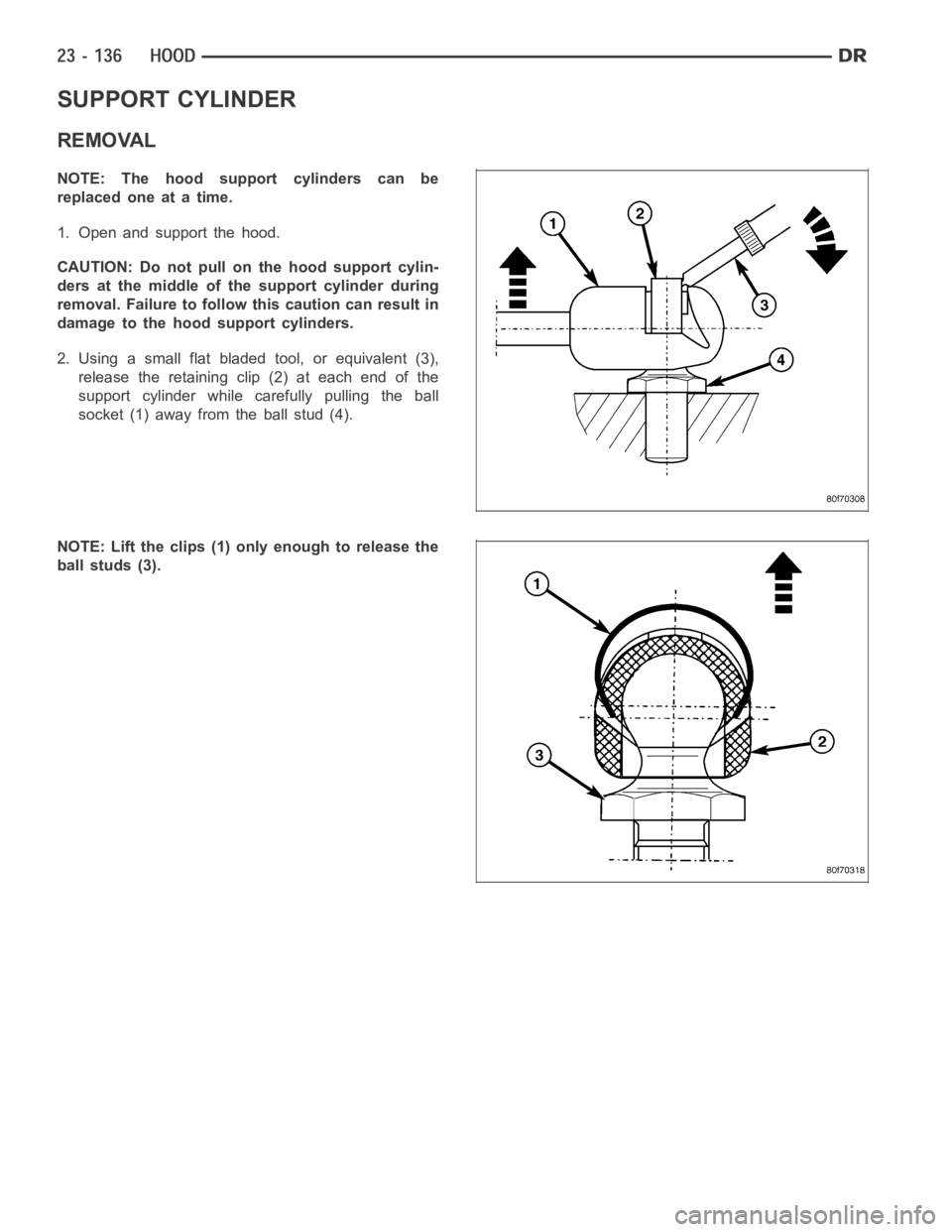

NOTE: The hood support cylinders can be

replaced one at a time.

1. Open and support the hood.

CAUTION: Do not pull on the hood support cylin-

ders at the middle of the support cylinder during

removal. Failure to followthis caution can result in

damage to the hood support cylinders.

2. Using a small flat bladed tool, or equivalent (3),

release the retaining clip (2) at each end of the

support cylinder while carefully pulling the ball

socket (1) away from the ball stud (4).

NOTE: Lift the clips (1) only enough to release the

ball studs (3).

Page 4474 of 5267

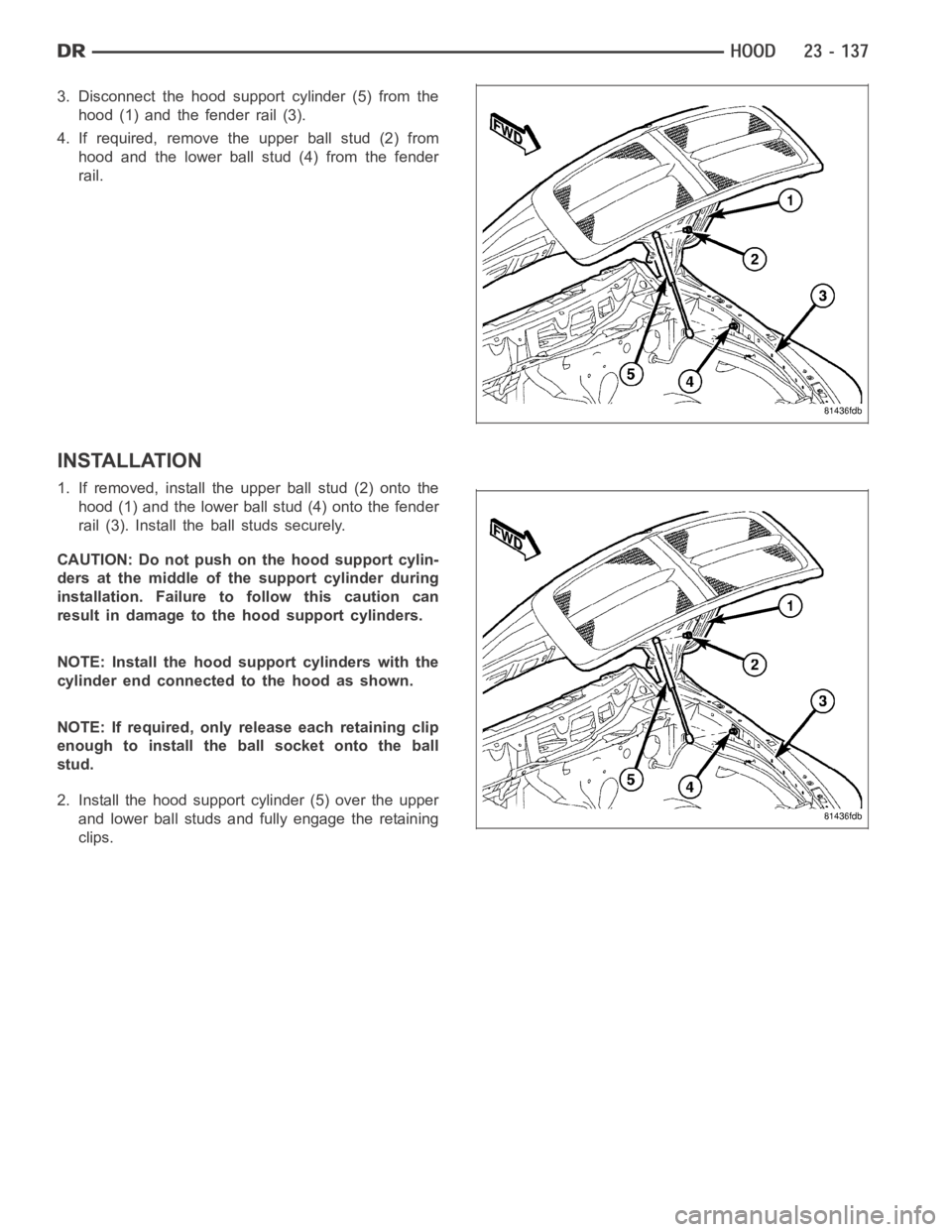

3. Disconnect the hood support cylinder (5) from the

hood (1) and the fender rail (3).

4. If required, remove the upper ball stud (2) from

hood and the lower ball stud (4) from the fender

rail.

INSTALLATION

1. If removed, install the upper ball stud (2) onto the

hood (1) and the lower ball stud (4) onto the fender

rail (3). Install the ball studs securely.

CAUTION: Do not push on the hood support cylin-

ders at the middle of the support cylinder during

installation. Failure to follow this caution can

result in damage to the hood support cylinders.

NOTE: Install the hood support cylinders with the

cylinder end connected to the hood as shown.

NOTE: If required, only release each retaining clip

enough to install the ball socket onto the ball

stud.

2. Install the hood support cylinder (5) over the upper

and lower ball studs and fully engage the retaining

clips.

Page 4510 of 5267

STEERING COLUMN OPENING SUPPORT BRACKET

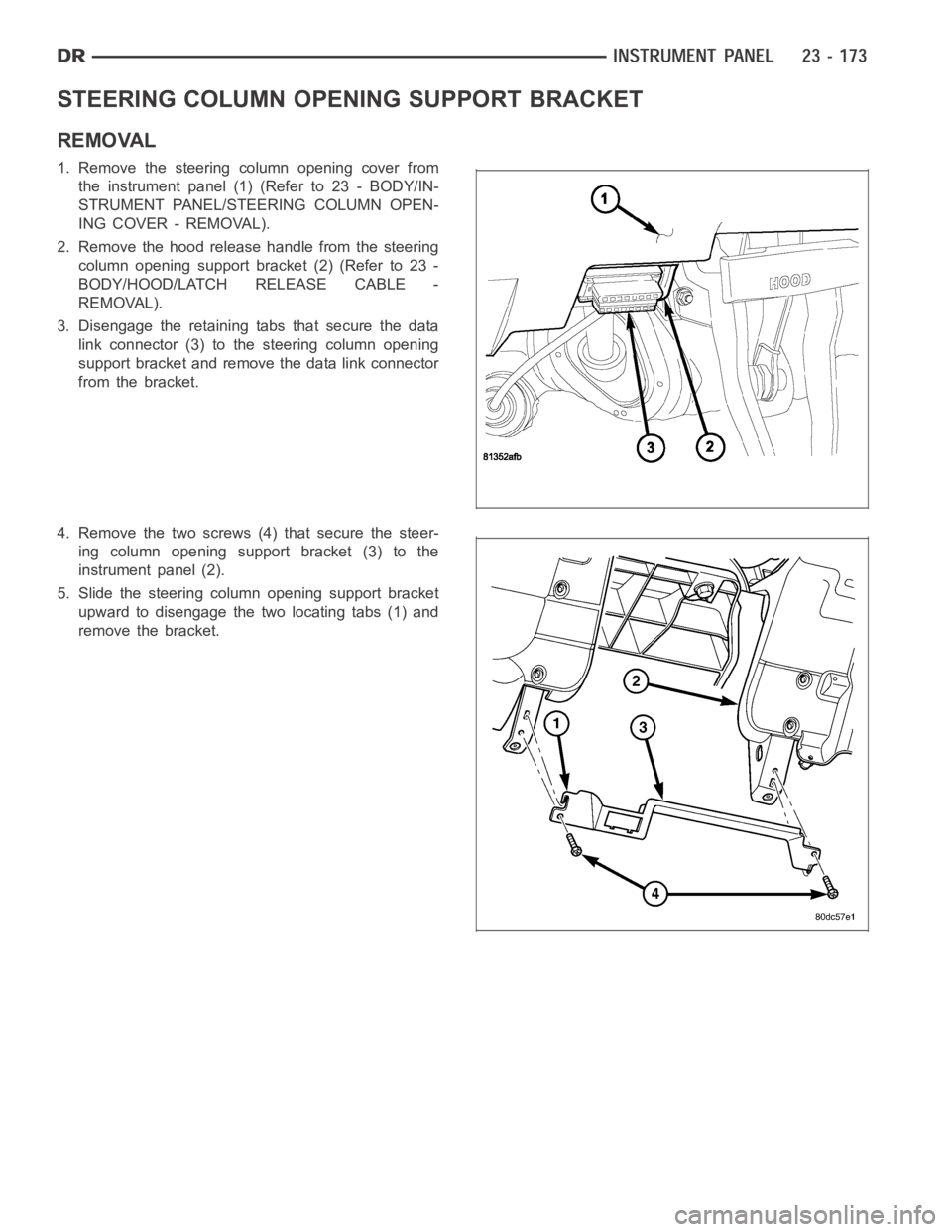

REMOVAL

1. Remove the steering column opening cover from

the instrument panel (1) (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN OPEN-

ING COVER - REMOVAL).

2. Remove the hood release handle from the steering

column opening support bracket (2) (Refer to 23 -

BODY/HOOD/LATCH RELEASE CABLE -

REMOVAL).

3. Disengage the retaining tabs that secure the data

link connector (3) to the steering column opening

support bracket and remove the data link connector

from the bracket.

4. Remove the two screws (4) that secure the steer-

ing column opening support bracket (3) to the

instrument panel (2).

5. Slide the steering column opening support bracket

upward to disengage the two locating tabs (1) and

remove the bracket.

Page 4511 of 5267

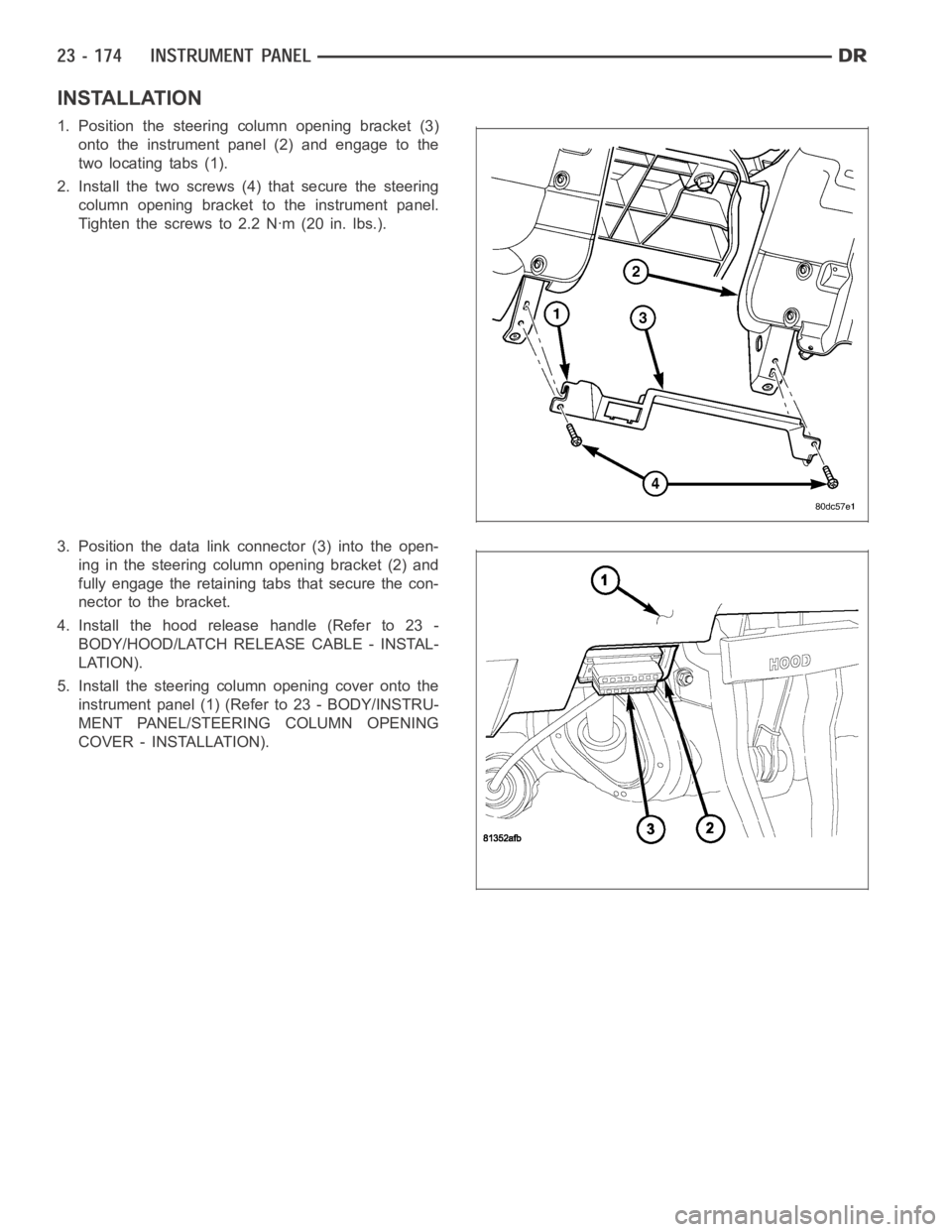

INSTALLATION

1. Position the steering column opening bracket (3)

onto the instrument panel (2) and engage to the

two locating tabs (1).

2. Install the two screws (4) that secure the steering

column opening bracket to the instrument panel.

Tighten the screws to 2.2 Nꞏm (20 in. lbs.).

3. Position the data link connector (3) into the open-

ing in the steering column opening bracket (2) and

fully engage the retaining tabs that secure the con-

nector to the bracket.

4. Install the hood release handle (Refer to 23 -

BODY/HOOD/LATCH RELEASE CABLE - INSTAL-

LATION).

5. Install the steering column opening cover onto the

instrument panel (1) (Refer to 23 - BODY/INSTRU-

MENT PANEL/STEERING COLUMN OPENING

COVER - INSTALLATION).