service schedule DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1598 of 5267

OIL

STANDARD PROCEDURE - ENGINE OIL SERVICE

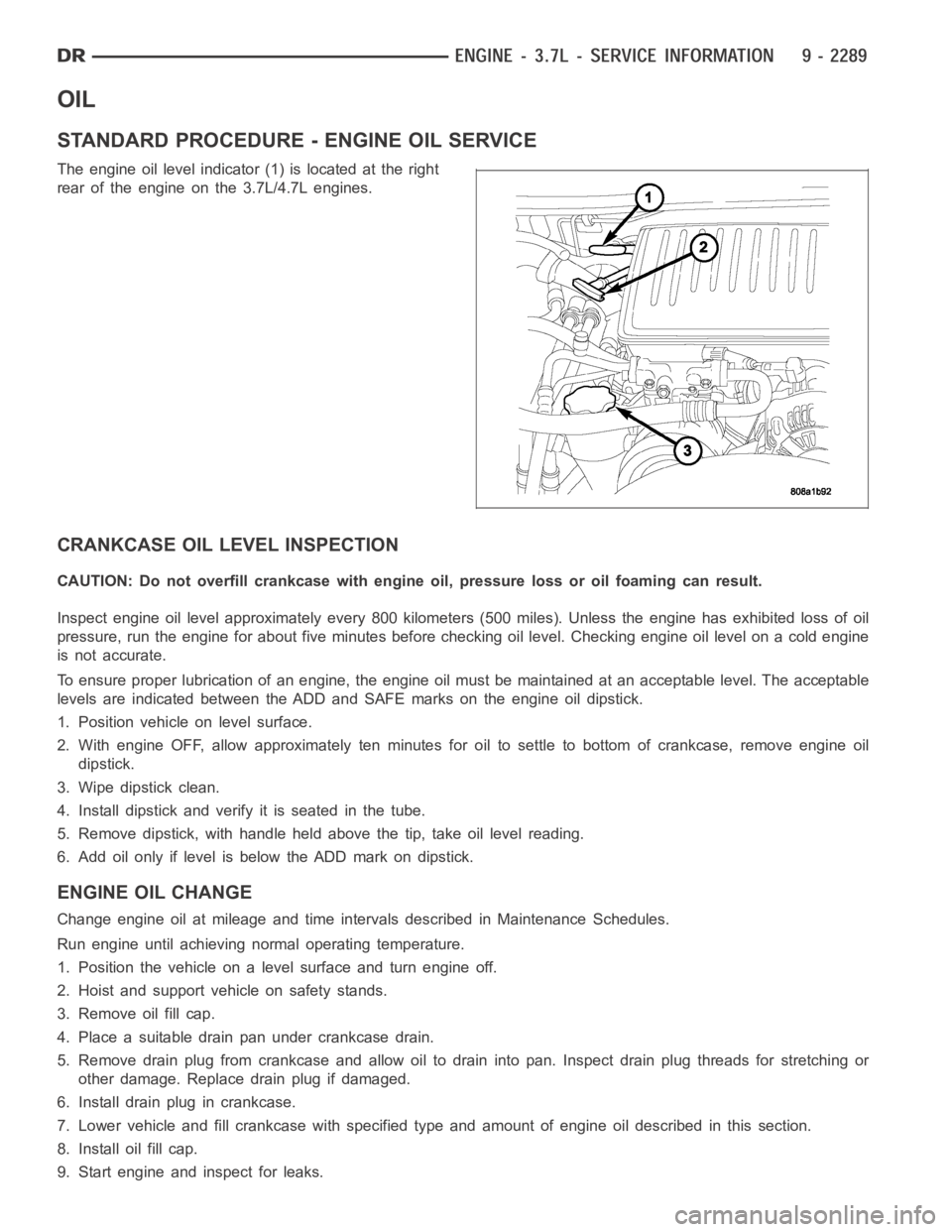

The engine oil level indicator (1) is located at the right

rear of the engine on the 3.7L/4.7L engines.

CRANKCASE OIL LEVEL INSPECTION

CAUTION: Do not overfill crankcase with engine oil, pressure loss or oil foaming can result.

Inspect engine oil level approximately every 800 kilometers (500 miles).Unless the engine has exhibited loss of oil

pressure, run the engine for about five minutes before checking oil level.Checking engine oil level on a cold engine

is not accurate.

To ensure proper lubrication of an engine, the engine oil must be maintained at an acceptable level. The acceptable

levels are indicated between the ADD and SAFE marks on the engine oil dipstick.

1. Position vehicle on level surface.

2. With engine OFF, allow approximately ten minutes for oil to settle to bottom of crankcase, remove engine oil

dipstick.

3. Wipe dipstick clean.

4. Install dipstick and verify it is seated in the tube.

5. Remove dipstick, with handle held above the tip, take oil level reading.

6. Add oil only if level is below the ADD mark on dipstick.

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals described in Maintenance Schedules.

Run engine until achieving normal operating temperature.

1. Position the vehicle on a level surface and turn engine off.

2. Hoist and support vehicle on safety stands.

3. Remove oil fill cap.

4. Place a suitable drain pan under crankcase drain.

5. Remove drain plug from crankcase and allow oil to drain into pan. Inspectdrain plug threads for stretching or

other damage. Replace drain plug if damaged.

6. Install drain plug in crankcase.

7. Lower vehicle and fill crankcase with specified type and amount of engine oil described in this section.

8. Install oil fill cap.

9. Start engine and inspect for leaks.

Page 1723 of 5267

OIL

STANDARD PROCEDURE - ENGINE OIL SERVICE

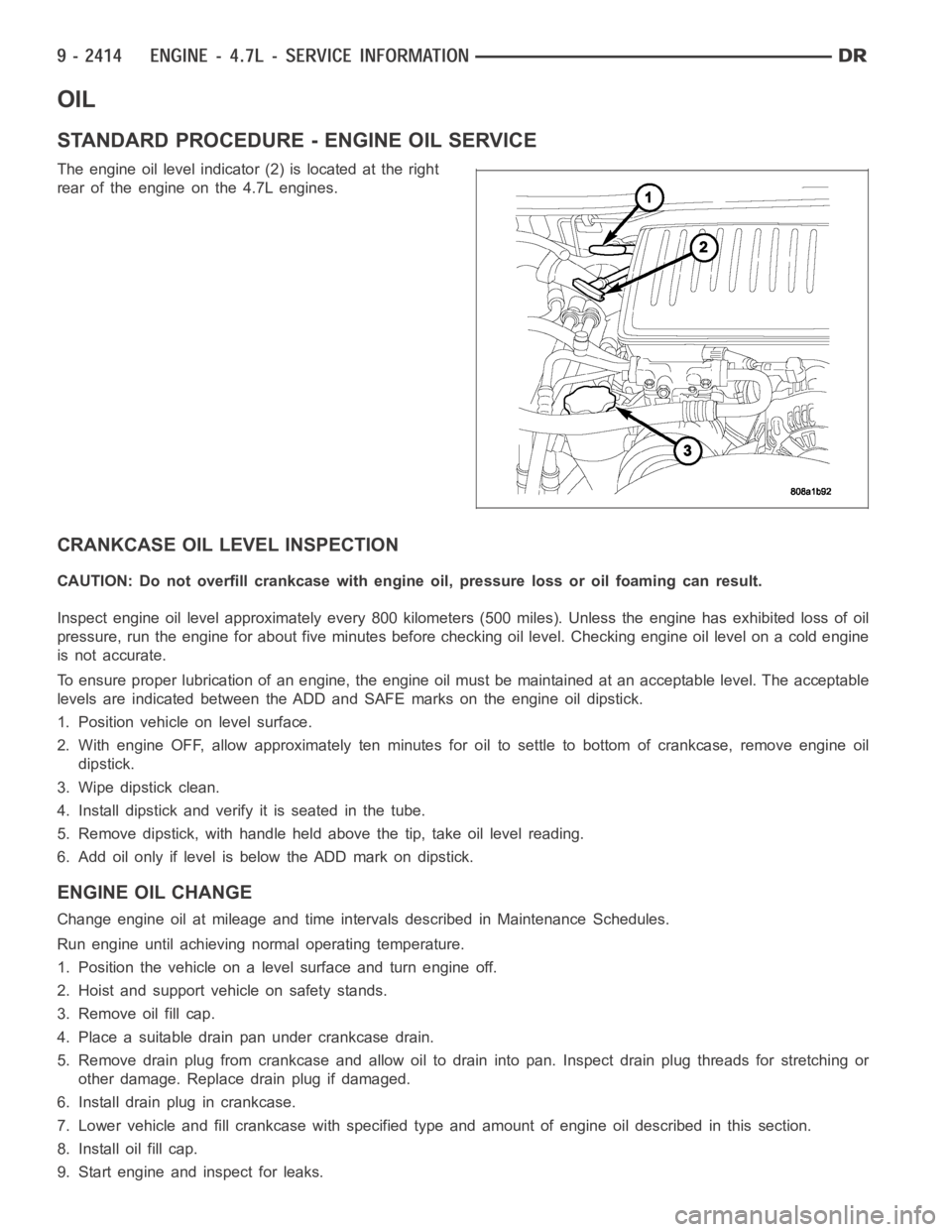

The engine oil level indicator (2) is located at the right

rear of the engine on the 4.7L engines.

CRANKCASE OIL LEVEL INSPECTION

CAUTION: Do not overfill crankcase with engine oil, pressure loss or oil foaming can result.

Inspect engine oil level approximately every 800 kilometers (500 miles).Unless the engine has exhibited loss of oil

pressure, run the engine for about five minutes before checking oil level.Checking engine oil level on a cold engine

is not accurate.

To ensure proper lubrication of an engine, the engine oil must be maintained at an acceptable level. The acceptable

levels are indicated between the ADD and SAFE marks on the engine oil dipstick.

1. Position vehicle on level surface.

2. With engine OFF, allow approximately ten minutes for oil to settle to bottom of crankcase, remove engine oil

dipstick.

3. Wipe dipstick clean.

4. Install dipstick and verify it is seated in the tube.

5. Remove dipstick, with handle held above the tip, take oil level reading.

6. Add oil only if level is below the ADD mark on dipstick.

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals described in Maintenance Schedules.

Run engine until achieving normal operating temperature.

1. Position the vehicle on a level surface and turn engine off.

2. Hoist and support vehicle on safety stands.

3. Remove oil fill cap.

4. Place a suitable drain pan under crankcase drain.

5. Remove drain plug from crankcase and allow oil to drain into pan. Inspectdrain plug threads for stretching or

other damage. Replace drain plug if damaged.

6. Install drain plug in crankcase.

7. Lower vehicle and fill crankcase with specified type and amount of engine oil described in this section.

8. Install oil fill cap.

9. Start engine and inspect for leaks.

Page 1877 of 5267

OIL

STANDARD PROCEDURE - ENGINE OIL SERVICE

The engine oil level indicator is located at the left hand of the engine on the 5.7L engines.

CRANKCASE OIL LEVEL INSPECTION

CAUTION: Do not overfill crankcase with engine oil, pressure loss or oil foaming can result.

Inspect engine oil level approximately every 800 kilometers (500 miles).Unless the engine has exhibited loss of oil

pressure, run the engine for about ten minutes before checking oil level. Checking engine oil level on a cold engine

is not accurate.

To ensure proper lubrication of an engine, the engine oil must be maintained at an acceptable level. The acceptable

levels are indicated between the ADD and SAFE marks on the engine oil dipstick.

1. Position vehicle on level surface.

2. With engine OFF, allow approximately five minutes for oil to settle to bottom of crankcase, remove engine oil

dipstick.

3. Wipe dipstick clean.

4. Install dipstick and verify it is seated in the tube.

5. Remove dipstick, with handle held above the tip, take oil level reading.

6. Add oil only if level is below the ADD mark on dipstick.

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals described in Maintenance Schedules (Refer to LUBRICATION &

MAINTENANCE/MAINTENANCESCHEDULES - DESCRIPTION).

Run engine until achieving normal operating temperature.

1. Position the vehicle on a level surface and turn engine off.

2. Hoist and support vehicle on safety stands.

3. Remove oil fill cap.

4. Place a suitable drain pan under crankcase drain.

5. Remove drain plug from crankcase and allow oil to drain into pan. Inspectdrain plug threads for stretching or

other damage. Replace drain plug if damaged.

6. Install drain plug in crankcase. Torque to 34 Nꞏm ( 25 ft. lbs.).

7. Lower vehicle and fill crankcase with specified type and amount of engine oil described in this section.

8. Install oil fill cap.

9. Start engine and inspect for leaks.

10. Stop engine and inspect oil level.

USED ENGINE OIL DISPOSAL

Care should be exercised when disposing used engine oil after it has been drained from a vehicle engine. Refer to

the WARNING at beginning of this section.

Page 2246 of 5267

FUEL FILTER/PRESSURE REGULATOR

DESCRIPTION

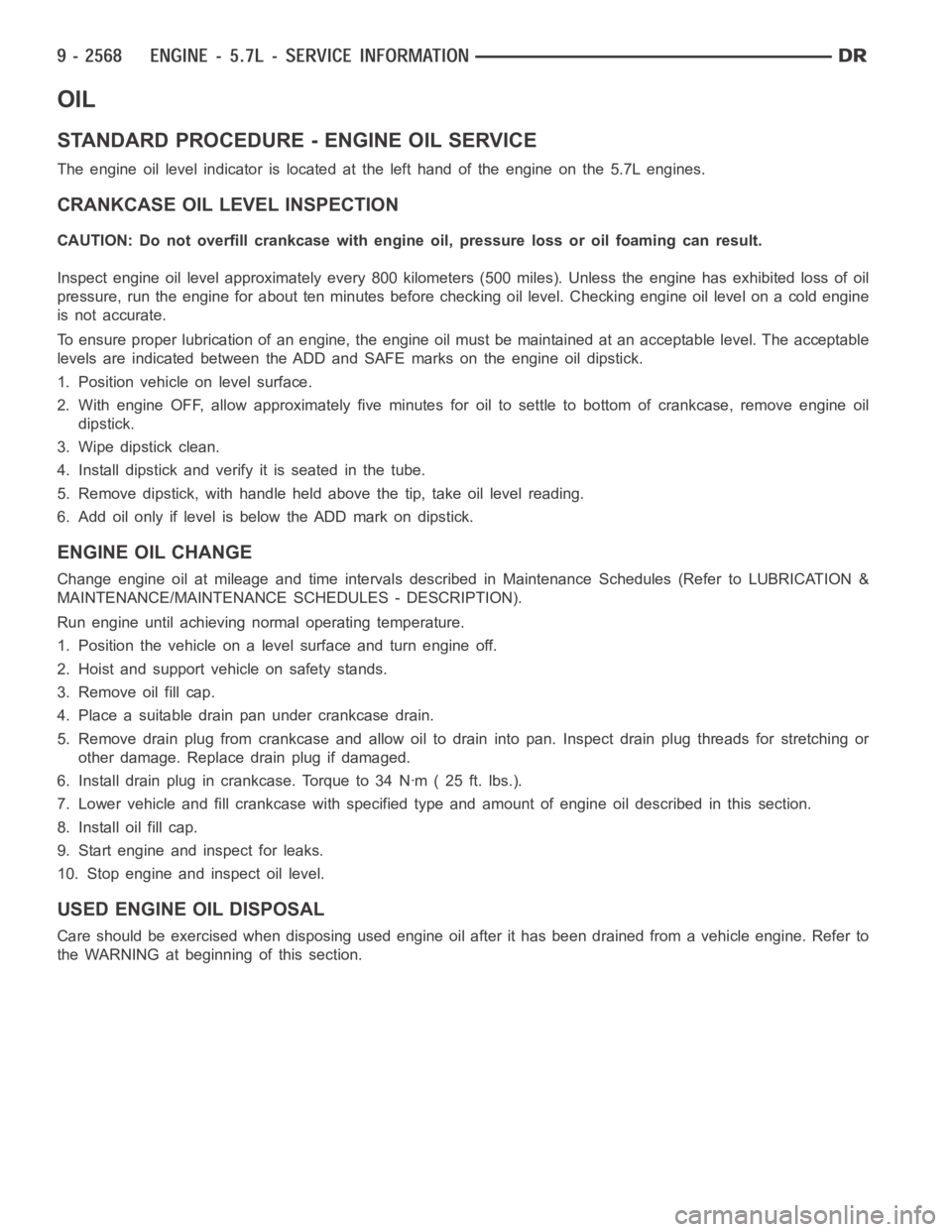

A combination fuel filter and fuel pressure regulator (3)

is used on all engines. It is located on the top of the

fuel pump module. A separate frame mounted fuel fil-

ter is not used with any engine.

Both fuel filters (at bottom of fuel pump module and

within fuel pressure regulator) are designed for

extended service. They do not require normal sched-

uled maintenance. Filters should only be replaced if a

diagnostic procedure indicates to do so.

OPERATION

Fuel Pressure Regulator Operation:The pressure regulator is a mechanical device that is not controlled by

engine vacuum or the Powertrain Control Module (PCM).

The regulator is calibrated to maintain fuel system operating pressure ofapproximately 58 ± 2 psi at the fuel injec-

tors. It contains a diaphragm, calibrated springs and a fuel return valve.The internal fuel filter is also part of the

assembly.

Fuel is supplied to the filter/regulator by the electric fuel pump throughan opening tube at the bottom of filter/reg-

ulator.

The regulator acts as a check valve to maintain some fuel pressure when the engine is not operating. This will help

to start the engine. A second check valve is located at the outlet end of the electric fuel pump.Refer to Fuel Pump

- Description and Operation for more information.

If fuel pressure at the pressure regulator exceeds approximately 60 psi, an internal diaphragm opens and excess

fuel pressure is routed back into the tank through the bottom of pressure regulator.

Both fuel filters (at bottom of fuel pump module and within fuel pressure regulator) are designed for extended ser-

vice. They do not require normal scheduled maintenance. Filters should only be replaced if a diagnostic procedure

indicates to do so.

Page 2472 of 5267

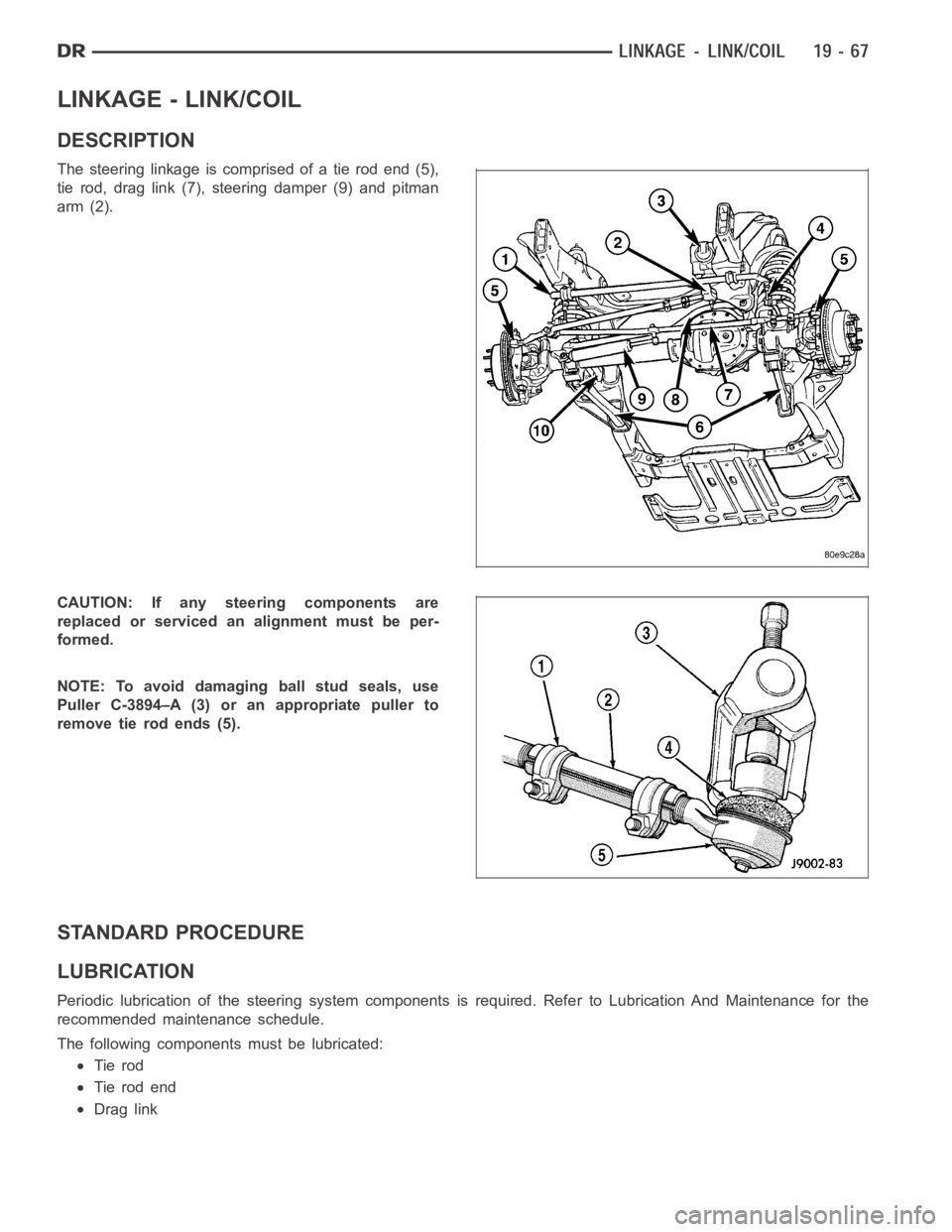

LINKAGE - LINK/COIL

DESCRIPTION

Thesteeringlinkageiscomprisedofatierodend(5),

tie rod, drag link (7), steering damper (9) and pitman

arm (2).

CAUTION: If any steering components are

replaced or serviced an alignment must be per-

formed.

NOTE: To avoid damaging ball stud seals, use

Puller C-3894–A (3) or an appropriate puller to

remove tie rod ends (5).

STANDARD PROCEDURE

LUBRICATION

Periodic lubrication of the steering system components is required. Refer to Lubrication And Maintenance for the

recommended maintenance schedule.

The following components must be lubricated:

Tie rod

Tie rod end

Drag link

Page 2726 of 5267

P0122-TPS/APP CIRCUIT LOW

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Continuously with the ignition on and engine running.

Set Condition:

This DTC will set if the monitored TPS voltage drops below .078 volts for theperiod of 0.48 seconds.

Possible Causes

RELATED TPS ENGINE DTCS PRESENT

POWERTRAIN CONTROL MODULE

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Theory of Operation

The powertrain controller receives the throttle position signal from theThrottle Position Sensor (TPS). The controller

provides the TPS with a 5 volt pull up and a sensor ground. The signal is checked for being out of range as well

as for intermittent operation (excessive signal changes). The engine controller transmits the throttle value onto the

Bus. Most engine controllers will calculate the throttle value if the throttle signal is lost. If an error is detected by the

transmission controller and the throttle value is available on the Bus, the Bus value will be used, normal operation

will continue, and a TPS code will be set. If an error is detected and the throttle value is not available on the Bus,

normal operation will be discontinued, a TPS DTC will be set, and the MIL will be turned on after 5 minutes of

calculated operation.

Diagnostic Test

1.DETERMINING IF RELATED ENGINE TPS DTCS ARE PRESENT

With the scan tool, check Engine DTCs, including pending DTCs and one trip failures.

Are there any Engine TPS DTCs present?

Ye s>>

Refer to the Driveability category and perform the appropriate diagnostic procedure.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

No>>

Go To 2

2.CHECK IF THE DTC IS CURRENT

With the scan tool, record the DTC EVENT DATA to help identify the conditionsinwhichtheDTCwasset.

With the scan tool, erase Transmission DTCs.

NOTE: To erase EVENT DATA information, a BATTERY DISCONNECT must be performed. Performing a BAT-

TERY DISCONNECT will reset all learned Transmission values to controllerdefaults which may lead to

erratic shift schedules.

Drive the vehicle and try to duplicate the conditions in which the DTC was reported by the DTC EVENT DATA.

With the scan tool, read Transmission DTCs.

Does this DTC reset?

Ye s>>

Using the schematics as a guide, check the Powertrain Control Module (PCM)terminals for corrosion,

damage, or terminal push out. Pay particular attention to all power and ground circuits. Check for Ser-

vice Information Tune-ups or Service Bulletins for any possible causes that may apply. If no problems

are found, replace the PCM per the Service Information. With the scan tool,perform QUICK LEARN.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

No>>

Go To 3

Page 2728 of 5267

P0123-TPS/APP CIRCUIT HIGH

For a complete wiring diagramRefer to Section 8W

When Monitored:

Continuously with the ignition on and engine running.

Set Condition:

This DTC will set if the monitored TPS voltage rises above 4.94 volts for theperiod of 0.48 seconds.

Possible Causes

RELATED TPS ENGINE DTCS PRESENT

POWERTRAIN CONTROL MODULE

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Theory of Operation

The powertrain controller receives the throttle position signal from theThrottle Position Sensor (TPS). The controller

provides the TPS with a 5 volt pull up and a sensor ground. The signal is checked for being out of range as well

as for intermittent operation (excessive signal changes). The engine controller transmits the throttle value onto the

Bus. Most engine controllers will calculate the throttle value if the throttle signal is lost. If an error is detected by the

transmission controller and the throttle value is available on the Bus, the Bus value will be used, normal operation

will continue, and a TPS code will be set. If an error is detected and the throttle value is not available on the Bus,

normal operation will be discontinued, a TPS DTC will be set, and the MIL will be turned on after 5 minutes of

calculated operation.

Diagnostic Test

1.DETERMINING IF RELATED ENGINE TPS DTCS ARE PRESENT

With the scan tool, check Engine DTCs, including pending DTCs and one trip failures.

Are there any Engine TPS DTCs present?

Ye s>>

Refer to the Driveability category and perform the appropriate diagnostic procedure.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

No>>

Go To 2

2.CHECK TO SEE IF DTC IS CURRENT

With the scan tool, record the DTC EVENT DATA to help identify the conditionsinwhichtheDTCwasset.

With the scan tool, erase Transmission DTCs.

NOTE: To erase DTC EVENT DATA information, a BATTERY DISCONNECT must be performed. Performing a

BATTERY DISCONNECT will reset all learned Transmission values to controller defaults which may lead to

erratic shift schedules.

Drive the vehicle and try to duplicate the conditions in which the DTC was reported by the DTC EVENT DATA.

With the scan tool, read Transmission DTCs.

Does this DTC reset?

Ye s>>

Using the schematics as a guide, check the Powertrain Control Module (PCM)terminals for corrosion,

damage, or terminal push out. Pay particular attention to all power and ground circuits. Check for Ser-

vice Information Tune-ups or Service Bulletins for any possible causes that may apply. If no problems

are found, replace the PCM per the Service Information. With the scan tool,perform QUICK LEARN.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

No>>

Go To 3

Page 2732 of 5267

P0218-HIGH TEMPERATURE OPERATION ACTIVATED

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Whenever the engine is running.

Set Condition:

Immediately when a Overheat shift schedule is activated when the Transmission Oil Temperature reaches 155°

C or 240° F.

Possible Causes

ENGINE COOLING SYSTEM OPERATION

TRANSMISSION OIL COOLER PLUGGED

H I G H T E M P E R AT U R E O P E R AT I O N S A C T I VAT E D

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Theory of Operation

If the transmission oil temperature rises above 115° C (240° F), the overheat shift schedule is activated refer to

Transmission Operation as a function of Transmission Oil Temperature andthe code is set. The DTC is an infor-

mational code only and is being set to aid the technician in determining root cause of a customer driveability issue.

The code is also intended to alert the technician to determine if a cooling system malfunction has occurred or if an

additional transmission air to oil cooler should be added to the vehicle ifthe customer regularly drives in a manner

that overheats the transmission. Extended operation above 115° C (240° F)will reduce the durability of the trans-

mission and should be avoided. Correcting the cooling system malfunctionor installing an additional transmission oil

cooler will improve transmission durability especially for customers who operate in city/construction stop and go traf-

fic, tow trailers regularly, drive aggressively in low gear or drive regularly in mountainous areas.

Diagnostic Test

1.CHECK ENGINE COOLING SYSTEM

Perform Engine Cooling System diagnostics per the Service Information.

Is the Engine Cooling System functioning properly?

Ye s>>

Go To 2

No>>

Repair the cause of the engine overheating. Refer to the Service Information for the related diagnostic

or repair procedures.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

2.TRANSMISSION OIL COOLER RESTRICTED

Check the Transmission Oil Cooler Flow in accordance with the Service Information.

Is the transmission oil cooler restricted or plugged?

Ye s>>

Go To 3

No>>

Repair the cause of the plugged Transmission Oil Cooler as necessary and repair or replace the Trans-

mission Oil Cooler per the Service Information.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Page 2733 of 5267

3.HIGH TEMPERATURE OPERATION

This DTC is an informational DTC designed to aid the Technician in diagnosing shift quality complaints.

This DTC indicates that the transmission has been operating in the

Overheatshift schedule which may generate

a customer complaint.

The customer driving patterns may indicate the need for an additional transmission oil cooler.

With the scan tool, check the DTC EVENT DATA to help identify the conditionsin which the DTC was set.

Check for any Service Information Tune-ups or Service Bulletins for any possible causes that may apply.

If there are no possible causes remaining, view repair.

Repair

Repair the cause of transmission overheating per the Service Information.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Page 2899 of 5267

P1797-MANUAL SHIFT OVERHEAT

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Continuously with engine running.

Set Condition:

If the Engine Temperature exceeds 123° C (255° F) or the Transmission Temperature exceeds 135° C (275° F)

while in AutoStick

mode. Note: Aggressive driving or driving in low for extended periods of time will set this

DTC.

Possible Causes

MANUAL SHIFT OVERHEAT

Always perform the 42RLE Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Theory of Operation

The major cause of heat build up in the transmission is torque converter slip.WiththetransmissionintheAuto-

Stick

mode, the torque converter can slip during aggressive driving or heavy loading conditions such as trailer

towing or driving up steep grades. In the non AutoStick

mode, internal controller logic prevents the transmission

from overheating by managing the shift and EMCC schedule. In the AutoStick

mode, when the transmission or

engine temperature approaches an overheat condition, the manual shift overheat DTC sets and the AutoStick

mode is temporarily suspended until the temperature returns to normal.

Diagnostic Test

1.MANUAL SHIFT OVERHEAT

This is an informational DTC only.

With the scan tool, check the DTC EVENT DATA to help identify the conditionsin which the DTC was set.

Check the engine and transmission cooling system for proper operation.

Check the Radiator Cooling Fan operation.

Check the Transmission Cooling operation.

Check the Transmission Fluid Level per the Service Information to verify that it is not overfilled.

NOTE: Aggressive driving or driving in low for extended periods of time will set this DTC.

If there are no possible causes remaining, view repair.

Repair

If the Transmission Fluid is low, repair any Transmission Fluid leak as necessary and adjust the Trans-

mission Fluid Level per the Service Information. Refer to Service Information for the related symptoms

and repair as necessary.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)