ignition DODGE SPRINTER 2004 1.G Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2004, Model line: SPRINTER, Model: DODGE SPRINTER 2004 1.GPages: 272, PDF Size: 22.71 MB

Page 176 of 272

176 STARTING AND OPERATING Open immediately the water drain screw (3) about 1

turn (counterclockwise) until fluid emerges. Ensure

that the fluid is collected in the receptacle.

Close the water drain screw (3) as soon as about 0.25

US qt (0.2 liters) are emerged.

After draining, return the key in the ignition lock to

position 0.

Dispose of the collected fluid in an environmentally

responsible manner.

If the filter is still saturated, drain the filter once

more.

After draining, the engine may run briefly but stall for

lack of fuel. If this occurs, bleed the system.

NOTE: Should the water in the fuel indicator lamp

still not go out after the fuel filter has been drained

twice, the cause should be examined by an authorized

Sprinter Dealer.

Bleeding the Diesel Fuel SystemThe diesel fuel system is bled before starting the

engine.

Turn the key in the ignition lock position 2 for at

least 30 seconds.

Return the key to position 0.

Start the engine three to four times. The engine

control unit indicator lamp± must go out.

NOTE: Too many attempts to start the engine could

drain the battery. If the engine does not start after

several attempts, consult an authorized Sprinter

Dealer.

Freightliner-all.book Pag e 176 Monday, December 1, 2003 2:54 PM

Page 201 of 272

WHAT TO DO IN EMERGENCIES 201

6

If the Engine is DamagedFor towing distances up to 30 miles (about 50 km)

Shift selector lever to "N" position.

Do not exceed a towing speed of 30 mph (50 km / h).

For towing distances greater than 30 miles (about

50 km)

Remove the propeller shafts leading to the drive

axles.

The vehicle can be towed without restriction.If the Transmission is Damaged Remove the propeller shafts leading to the drive

axles.

WARNING!

Do not tow the vehicle if the key cannot be turned

in the ignition lock.

If the key cannot be turned, the ignition lock re-

mains locked and the vehicle cannot be steered.

With the engine not running there is no power

assistance for the braking and steering systems.

In this case, it is important to keep in mind that a

considerably higher degree of effort is necessary

to brake and steer the vehicle.

The vehicle must not be towed with the front axle

raised and the key in position 2 in the ignition

lock as the drive wheels could then lock due to the

acceleration skid control (ASR) or the optional

Electronic Stability Program (ESP).

Freightliner-all.book Pag e 201 Monday, December 1, 2003 2:54 PM

Page 214 of 272

214 MAINTAINING YOUR VEHICLE

Open the hood.

At first, only turn the radiator cap to the first detent

to release the pressure from the cooling system.

Only then should the radiator cap be removed

completely.

To add coolant:

If the engine is cold:

Add coolant until the coolant level reaches the base

area which is visible through the filler opening (area

moistened).

If the engine is already at its regular operating

temperature:

Add coolant until the coolant level is about 0.6 inch

WARNING!

In order to avoid any possibly serious burns:

If you see flames or smoke coming from the

engine compartment, or if the coolant

temperature gauge indicates that the engine is

overheated, do not open the hood. Move away

from the vehicle and do not open the hood until

the engine has cooled. If necessary, call the fire

department.

Do not remove pressure cap on coolant reservoir

if engine temperature is above 194 °F (+90 ×C).

Allow engine to cool down before removing cap.

The coolant reservoir contains hot fluid and is

under pressure.

Using a rag, slowly open cap approximately 1/2

turn to relieve excess pressure. If opened

immediately, scalding hot fluid and steam will

be blown out under pressure.

Do not spill antifreeze on hot engine parts.

Antifreeze contains ethylene glycol which may

burn if it comes into contact with hot engine

parts.

Check coolant level only with the engine

switched off and the key in position 0 in the

ignition lock.

Freightliner-all.book Pag e 214 Monday, December 1, 2003 2:54 PM

Page 216 of 272

216 MAINTAINING YOUR VEHICLEBA TTERIESThe standard battery is located in the engine

compartment.The auxiliary battery is located underneath the front

passenger seat (optional equipment).

The battery will not achieve its maximum service life

unless it is kept adequately charged at all times. If the

vehicle is used primarily for short distances, or left

parked for lengthy periods, have the battery charge

checked more frequently.

Disconnecting the Battery

WARNING!

Failure to follow these instructions can result in

severe personal injuries and death.

Never lean over batteries while connecting, you

might get injured, if the battery explodes.

Battery fluid contains sulfuric acid. Do not allow

this fluid to come in contact with eyes, skin or

clothing. In case it does, immediately flush

affected area with water and seek medical help if

necessary.

A battery will also produce hydrogen gas, which

is flammable and explosive. Keep flames or

sparks away from battery, avoid improper

connection of jumper cables, smoking etc.

Use only impact-resistant batteries with a central

gas release cover to prevent corrosion damage and

to prevent occupants from caustic burns in the

event of an accident.

CAUTION!

Do not loosen or remove the battery terminal

clamps while the engine is running or the key is in

the ignition lock as this could damage electrical or

electronic equipment beyond repair. All electrical

consumers must be switched off.

Do not place any metal objects on the battery.

Doing so may cause a short-circuit.

Loosen and remove the negative terminal clamp

first, then the positive terminal.

Afterwards disconnect vent tube from the fitting.

Freightliner-all.book Pag e 216 Monday, December 1, 2003 2:54 PM

Page 223 of 272

MAINTAININ G YOUR VEHICLE 223

7

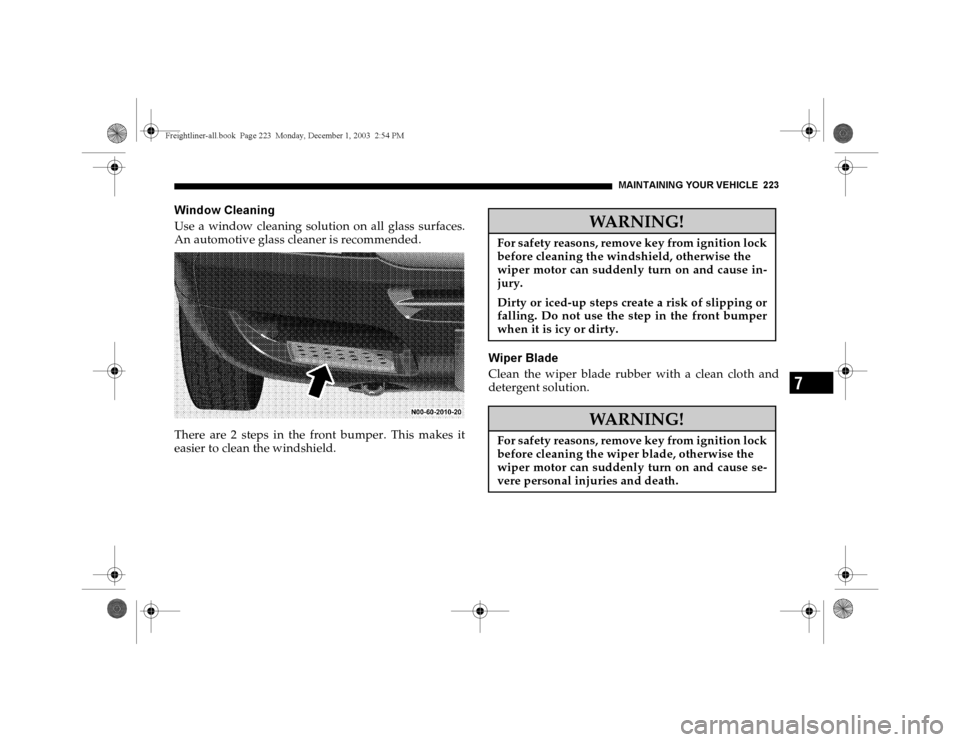

Window CleaningUse a window cleaning solution on all glass surfaces.

An automotive glass cleaner is recommended.

There are 2 steps in the front bumper. This makes it

easier to clean the windshield.

Wiper BladeClean the wiper blade rubber with a clean cloth and

detergent solution.

WARNING!

For safety reasons, remove key from ignition lock

before cleaning the windshield, otherwise the

wiper motor can suddenly turn on and cause in-

jury.

Dirty or iced-up steps create a risk of slipping or

falling. Do not use the step in the front bumper

when it is icy or dirty.

WARNING!

For safety reasons, remove key from ignition lock

before cleaning the wiper blade, otherwise the

wiper motor can suddenly turn on and cause se-

vere personal injuries and death.

Freightliner-all.book Pag e 223 Monday, December 1, 2003 2:54 PM

Page 225 of 272

MAINTAININ G YOUR VEHICLE 225

7

etc.) may cause the upholstery to become permanently

discolored. By lining the seats with a proper

intermediate cover, contact discoloration will be

prevented.

Leather Upholstery

Wipe leather upholstery with a damp cloth and dry

thoroughly or clean with a leather care product.

Exercise particular care when cleaning perforated

leather as its underside should not become wet.

Cloth Upholstery

Clean with soft bristle brush, or use a dry-shampoo

cleaner in case of excessive dirt.

Tex Upholstery

Pour an interior care product onto soft lint-free cloth

and apply with light pressure.Hard Plastic Trim ItemsPour an interior care product onto soft lint-free cloth

and apply with light pressure.Plastic and Rubber PartsDo not use oil or wax on these parts.

ELECTRICAL FUSESDamaged fuses are recognizable from their burnt-out

filament.

Prior to exchanging a fuse, turn the key in the ignition-

column lock to the 0 position and switch off the

consumer involved.

NOTE: Fuses must not be bridged. Replace fuses with

specified rated current. Only replace fuses when the

cause of the malfunction has been rectified.

NOTE: Fuses and relays (standard equipment) are on

the underside of the ignition column, refer to "Fuses

and Relays Standard Equipment".

Fuses, relays and diodes (optional equipment) are

below the driver’s seat, refer to "Optional Fuse and

Relay Equipment".

Freightliner-all.book Pag e 225 Monday, December 1, 2003 2:54 PM

Page 229 of 272

MAINTAININ G YOUR VEHICLE 229

7

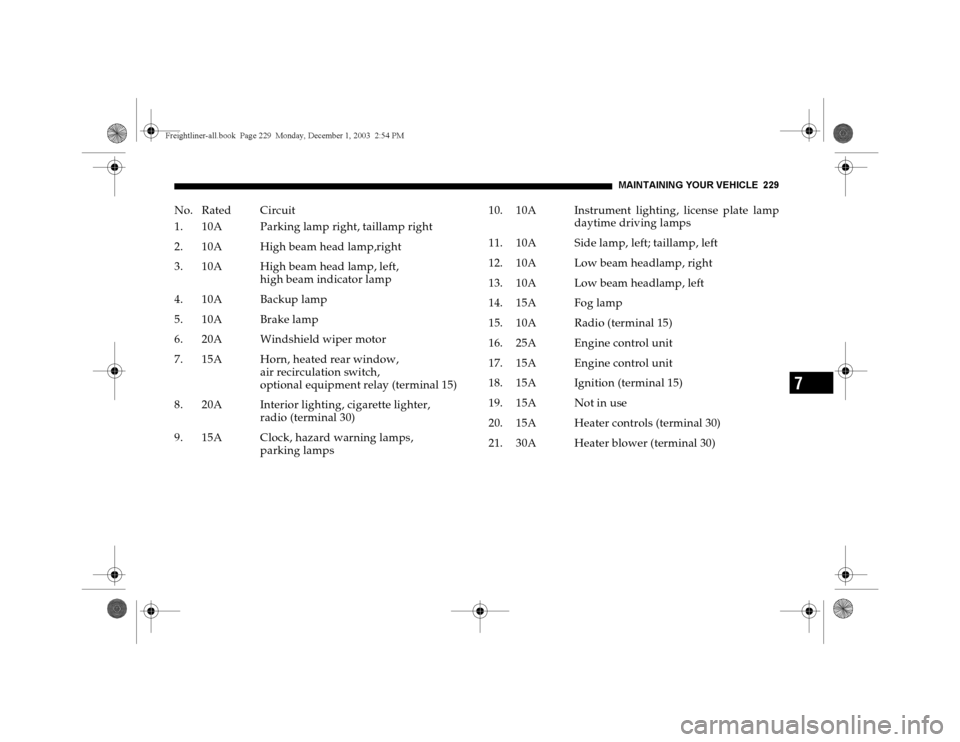

No. Rated Circuit

1. 10A Parking lamp right, taillamp right

2. 10A High beam head lamp,right

3. 10A High beam head lamp, left,

high beam indicator lamp

4. 10A Backup lamp

5. 10A Brake lamp

6. 20A Windshield wiper motor

7. 15A Horn, heated rear window,

air recirculation switch,

optional equipment relay (terminal 15)

8. 20A Interior lighting, cigarette lighter,

radio (terminal 30)

9. 15A Clock, hazard warning lamps,

parking lamps10. 10A Instrument lighting, license plate lamp

daytime driving lamps

11. 10A Side lamp, left; taillamp, left

12. 10A Low beam headlamp, right

13. 10A Low beam headlamp, left

14. 15A Fog lamp

15. 10A Radio (terminal 15)

16. 25A Engine control unit

17. 15A Engine control unit

18. 15A Ignition (terminal 15)

19. 15A Not in use

20. 15A Heater controls (terminal 30)

21. 30A Heater blower (terminal 30)Freightliner-all.book Pag e 229 Monday, December 1, 2003 2:54 PM

Page 266 of 272

266 INDEX

Fuel Tank Capacity . . . . . . . . . . . . . . . . . . . . . . . . . 173

Refueling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Fuse and Relay Optional Equipment . . . . . . . . . . . . 230

Fuse, Relay, and Diode Assignments - Optional

Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Fuses, Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

GGlove Compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Lockable Glove Compartment . . . . . . . . . . . . . . . . 79HHazard Warning Flasher Switch . . . . . . . . . . . . . . . . 186

Head Restraint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Headlamp Range Control. . . . . . . . . . . . . . . . . . . . . . . 62

Headlamps, taillamps, turn signal lenses . . . . . . . . 222

Heated Rear Window . . . . . . . . . . . . . . . . . . . . . . . . . 114

Heater, Seat. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109, 111

Hood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

How to Use this Manual . . . . . . . . . . . . . . . . . . . . . . . . . 4

Hydroplaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165Ignition

Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Starter Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Immobilizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Indicator Lamp Symbols . . . . . . . . . . . . . . . . . . . . . . . . 99

Inhalation of Exhaust Gas. . . . . . . . . . . . . . . . . . . . . . . 48

Installing a Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Instrument and Display Lighting . . . . . . . . . . . . . . . . 90

Instrument Cluster

Battery Charge Indicator Lamp . . . . . . . . . . . . . . . 95

Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Coolant Level Indicator Lamp . . . . . . . . . . . . . . . . 98

Coolant Temperature Gauge . . . . . . . . . . . . . . . . . . 93

Engine Control Unit Indicator Lamp . . . . . . . . . . . 99

Engine Oil Level Indicator Lamp . . . . . . . . . . . . . . 97

Tachometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Trip Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Water in Fuel Indicator Lamp . . . . . . . . . . . . . . . . . 96

Instrument Cluster and Indicator Lamps. . . . . . . . . . 85

Instruments and Controls . . . . . . . . . . . . . . . . . . . . . . . 83Freightliner-all.book Pag e 266 Monday, December 1, 2003 2:54 PM

Page 268 of 272

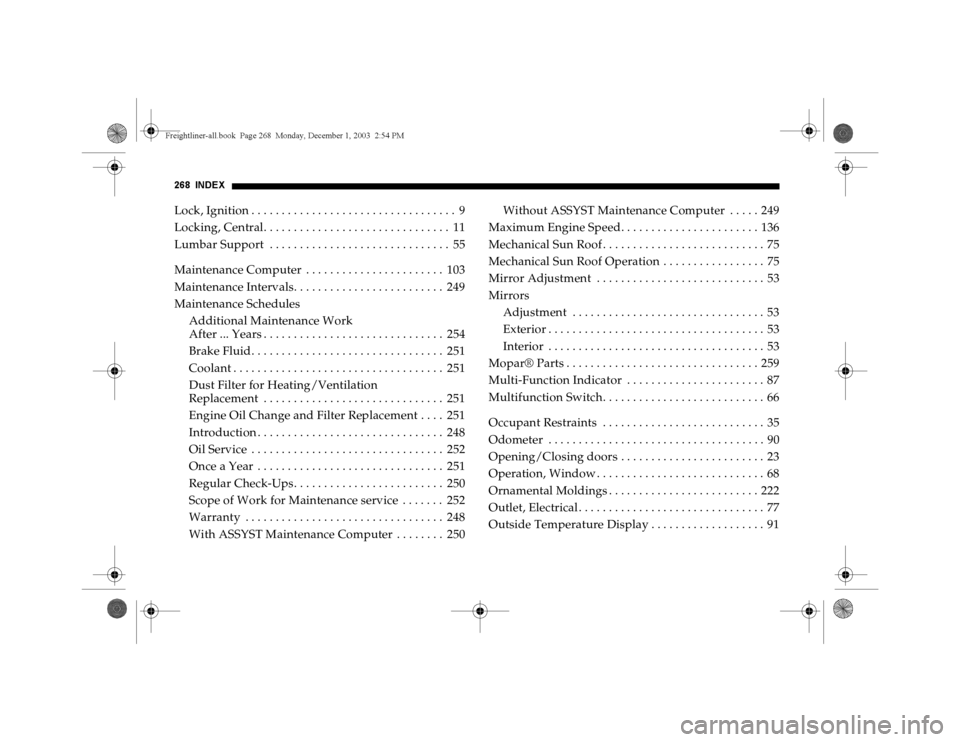

268 INDEXLock, Ignition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Locking, Central. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Lumbar Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55MMaintenance Computer . . . . . . . . . . . . . . . . . . . . . . . 103

Maintenance Intervals. . . . . . . . . . . . . . . . . . . . . . . . . 249

Maintenance Schedules

Additional Maintenance Work

After ... Years . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Brake Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

Dust Filter for Heating/Ventilation

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

Engine Oil Change and Filter Replacement . . . . 251

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Oil Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Once a Year . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

Regular Check-Ups. . . . . . . . . . . . . . . . . . . . . . . . . 250

Scope of Work for Maintenance service . . . . . . . 252

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

With ASSYST Maintenance Computer . . . . . . . . 250Without ASSYST Maintenance Computer . . . . . 249

Maximum Engine Speed. . . . . . . . . . . . . . . . . . . . . . . 136

Mechanical Sun Roof . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Mechanical Sun Roof Operation . . . . . . . . . . . . . . . . . 75

Mirror Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Mirrors

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Exterior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Interior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Mopar® Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Multi-Function Indicator . . . . . . . . . . . . . . . . . . . . . . . 87

Multifunction Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . 66

OOccupant Restraints . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Odometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Opening/Closing doors . . . . . . . . . . . . . . . . . . . . . . . . 23

Operation, Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Ornamental Moldings . . . . . . . . . . . . . . . . . . . . . . . . . 222

Outlet, Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Outside Temperature Display . . . . . . . . . . . . . . . . . . . 91

Freightliner-all.book Pag e 268 Monday, December 1, 2003 2:54 PM