change wheel DODGE SPRINTER 2004 1.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2004, Model line: SPRINTER, Model: DODGE SPRINTER 2004 1.GPages: 272, PDF Size: 22.71 MB

Page 56 of 272

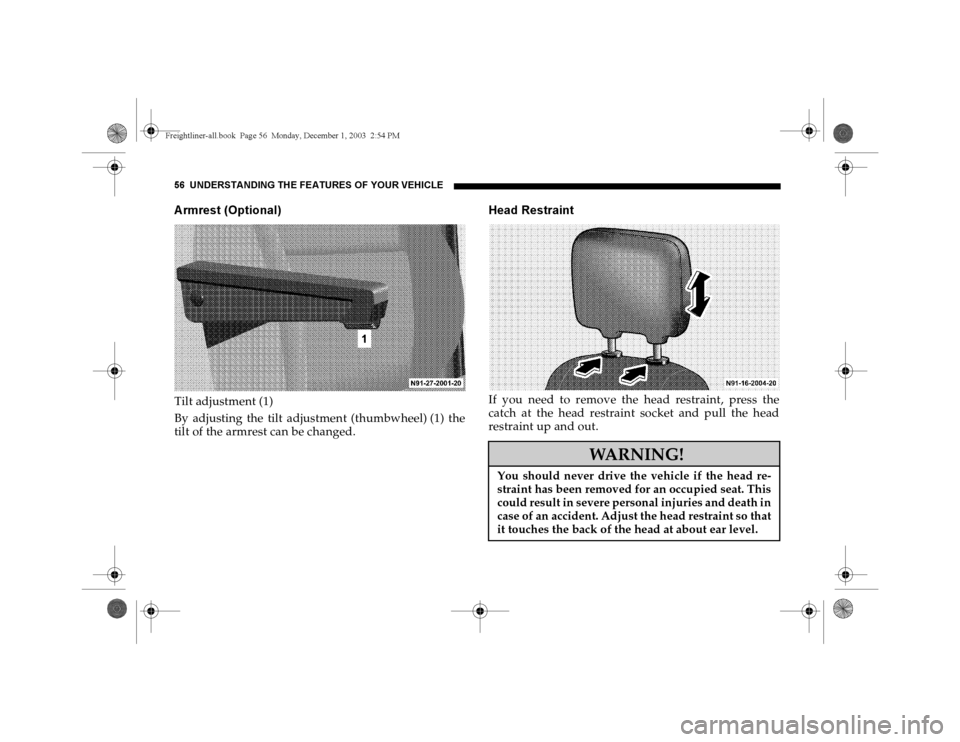

56 UNDERSTANDING THE FEATURES OF YOUR VEHICLEArmrest (Optional)Tilt adjustment (1)

By adjusting the tilt adjustment (thumbwheel) (1) the

tilt of the armrest can be changed.

Head RestraintIf you need to remove the head restraint, press the

catch at the head restraint socket and pull the head

restraint up and out.

WARNING!

You should never drive the vehicle if the head re-

straint has been removed for an occupied seat. This

could result in severe personal injuries and death in

case of an accident. Adjust the head restraint so that

it touches the back of the head at about ear level.

Freightliner-all.book Pag e 56 Monday , December 1, 2003 2:54 PM

Page 153 of 272

STARTING AND OPERATING 153

5

as the voltage reaches this level again

– the ABS is then

reactivated.

If ABS malfunctions, the other driving safety systems

are deactivated. The handling and braking

characteristics of your vehicle change. The other

braking and driving systems still function normally.

I

A nti-Lock Brake System (A BS)ABS prevents the wheels from locking at any speed

above about 5 mph (8 km/h), regardless of road

surface conditions. The vehicle remains steerable even

if the brakes are applied fully.

A light vibrating of the steering wheel and pulsating of

the brake pedal indicate that the ABS is working.

On slippery road surfaces, the ABS will respond even

with light brake pedal pressure because of the

increased likelihood of locking wheels. The pulsating

brake pedal can be an indication of hazardous road

conditions and works as a reminder to take extra care

while driving.

WARNING!

If the ABS indicator lamp- does not go out or

lights up again while driving, the ABS is malfunc-

tioning. If ABS malfunctions, the other driving

safety systems are deactivated. The vehicle’s brak-

ing characteristics may be affected. There is an in-

creased risk that your vehicle could skid in the

event of sharp braking. Have the malfunction

traced and repaired without delay by an autho-

rized Sprinter Dealer.

Adapt your speed and driving style to the

prevailing road, traffic and weather conditions.

Driving too fast increases the risk of an accident.

Freightliner-all.book Pag e 153 Monday, December 1, 2003 2:54 PM

Page 160 of 272

160 STARTING AND OPERATINGTo deactivate the ASR:– Press the upper section of the switch – the warning

lamp

v in the speedometer lights up.

Traction control continues to cut in if, for example, a

wheel on one side of the vehicle reaches its limit of

adhesion. The wheel is then braked to increase the

vehicle’s overall traction.

The warning lamp v will flash in the speedometer

at any speed when a tire reaches its limit of adhesion.

To activate the ASR:

– Press the upper section of the switch again

– the

warning lamp v in the speedometer goes out.

Brake A ssist System (BA S) (Cargo/passenger vans

type 2500 C/HC/SHC only)The Brake Assist System (BAS) operates in emergency

situations. If you apply the brakes very quickly, the

BAS automatically provides full brake boost, thereby

potentially reducing braking distance.

Apply continuous full braking pressure until the

emergency braking situation is over.

The ABS will prevent the wheels from locking.

When you release the brake pedal, the brakes function

again as normal. The BAS is then deactivated.

WARNING!

If the indicator lamp k remains on, a malfunc-

tion may not only have occurred in the ASR sys-

tem but also in the BAS.

The handling and braking characteristics of your

vehicle change. Drive with extra caution.

Have the malfunction traced and repaired as soon

as possible by an authorized Sprinter Dealer.

Freightliner-all.book Pag e 160 Monday, December 1, 2003 2:54 PM

Page 164 of 272

164 STARTING AND OPERATING

WARNING!

Fitting other wheel sizes to the vehicle will change

the vehicle’s handling characteristics and may

lead to an accident resulting in severe personal in-

juries, death and property damage.

Do not use retreaded/ remolded tires. This process

does not always permit previous damage to the

detected. Therefore vehicle safety cannot be

guaranteed if retreaded/remolded tires are fitted

.

WARNING!

A wheel could work loose. To avoid the risk of serious or

fatal injuries or vehicle damage, please bear the follow-

ing points in mind: Always replace wheel bolts that are damaged or

rusted.

Never apply oil or grease to wheel bolts. If a wheel hub thread is damaged, you must not drive the

vehicle. Consult a qualified specialist workshop. Be sure to use correct mounting bolts. Check

tightness of wheel bolts or nuts regularly and

retighten with a torque wrench, if necessary.

Tighten wheel bolts or nuts in a cross-pattern

sequence.Mounting bolts and tightening torque, see Chapter 12,

‘‘Installing a Wheel’’. After changing a wheel, the wheel bolts or nuts

must be tightened once the vehicle has been

driven for about 30 miles (50 km).If new or repainted wheels are fitted, the wheel bolts or

nuts must be retightened again after about 600 to 3,000

miles (about 1,000 to 5,000 km).

Freightliner-all.book Pag e 164 Monday, December 1, 2003 2:54 PM

Page 166 of 272

166 STARTING AND OPERATINGThe vehicle’s safety on the road depends to a great

extent on tire condition and correct tire pressure.

If tire pressures are too high or too low, handling

characteristics will be adversely affected and fuel

consumption and tire wear will increase. Check tire

pressures regularly (each time the vehicle is refueled).

Check tire pressures (including the spare wheel) with

the tires cold. The pressure difference between the tires

on a single axle should not exceed 1.5 psi (10 kPa). If

tire pressure in individual tires is too low: check the

valves, wheels and tires for signs of leaks.

After a period of fast driving, or in hot weather, tire

pressures can increase by as much as 14.5 psi (100 kPa).

Never release air from a warm tire or else the tire

pressure will be too low.NOTE: Tire pressure changes by about 1.5 psi (10 kPa)

for every 18

°F (+10

°C) change in air temperature. For

this reason, do not release pressure from tires when

they are warm.

Remember to allow for this when checking tire

pressures indoors, particularly in winter.

Example:

Room temperature: about 68

°F (+20

°C)

Outside temperature: about 32

°F (0

°C)

Required tire pressure, specified tire pressure 3 psi

(20 kPa).

Information on tires can be obtained from any

authorized Sprinter Dealer.

WARNING!

Correct the tire pressures before loading the

vehicle fully. If the tire pressure is too low driving

safety and tire mileage are decreased.

Freightliner-all.book Pag e 166 Monday, December 1, 2003 2:54 PM

Page 170 of 272

170 STARTING AND OPERATINGSNOW CHA INSInstall snow chains on rear wheels only. Install snow

chains on exterior wheel in vehicles with double tires.

Comply with the manufacturer’s installation

instructions.

NOTE: Vehicles with snow chains installed are only to

be driven on a snow-covered surface. The snow chains

must be removed on road surfaces free of snow.FUELSUse only commercially available vehicular diesel fuels

No. 2 or No. 1 (ASTM D 975 No. 2-D or No. 1-D).

If diesel fuels are used with a sulphur content

exceeding 0.05 % by weight, engine oil change

intervals must be shortened. Please contact your

Sprinter Dealer to obtain the necessary information.

Marine diesel fuel, heating oil or the like must not be

used.

Refueling from drums or canisters may lead to the fuel

becoming contaminated. This in turn can cause faults

in the fuel system. Always filter the fuel before adding

it to the vehicle’s tank.

Fuel Filter with Water SeparatorCheck the water separator when the fuel indicator

lamp does not go out or comes on while the engine

is running. For more information on the indicator

lamp .

The interval for changing the fuel filter is reduced to

10,000 miles (about 15,000 km).

Freightliner-all.book Pag e 170 Monday, December 1, 2003 2:54 PM

Page 188 of 272

188 WHAT TO DO IN EMERGENCIES

Procedure:

1. Park the vehicle on a firm, level, non-slippery

surface.

2. Switch on the hazard warning flasher switch, apply

the parking brake, and place the transmission

selector in "P".

WARNING!

The jack is designed exclusively for jacking up the

vehicle at the jack take-up brackets built into ei-

ther side of the vehicle. To help avoid personal in-

jury, use the jack only to lift the vehicle during a

wheel change. Never get beneath the vehicle

while it is supported by the jack only.

Keep hands and feet away from the area under the

lifted vehicle. Always firmly set parking brake

and block wheels before raising vehicle with jack.

Do not disengage parking brake while the vehicle

is raised.

Always use the jack on a level surface.

Do not change wheels on either steep uphill or

downhill grades. Be sure that the jack arm end is

fully seated in the jack take-up bracket. The

vehicle may begin to move and fall from the jack

which could cause serious or fatal personal injury

and property damage.

Always lower the vehicle onto sufficient capacity

jack stands before working under the vehicle.

Precautions when changing a wheel:

For the torque, refer to "Installing a wheel";

Do not damage, grease or oil wheel bolts or their

threads.

Do not jack the vehicle up more than 1.2 in (30

mm) between the tire and the surface. Otherwise,

the vehicle may tip over and may cause serious

injury or death to you or others.

Precautions when changing a wheel:

For the torque, refer to "Installing a wheel";

Do not damage, grease or oil wheel bolts or their

threads.

Freightliner-all.book Pag e 188 Monday, December 1, 2003 2:54 PM

Page 189 of 272

WHAT TO DO IN EMERGENCIES 189

6

3. Everyone must leave the vehicle before you jack it

up.

4. Everyone must leave the danger zone, before

jacking the vehicle.

5. The vehicle must be safeguarded in accordance

with legal regulations (such as using a warning

triangle).

6. Prevent vehicle from rolling away by blocking

wheels with wheel chocks (not supplied with

vehicle) or sizable wood block or stone.

On a level road, place one chock in front of and one

behind the wheel that is diagonally opposite to the

wheel being changed.

When changing a wheel on mild uphill or downhill

grades, place chocks on the downhill side blocking

both wheels of the other axle.

Spare Wheel Location

WARNING!

Do not change wheels on either steep uphill or

downhill grades. The vehicle may begin to move

and fall from the jack which could cause personal

injury and property damage.

WARNING!

If the rear cargo doors are opened to 90° (detent

position), the rear lights will be concealed. The ve-

hicle is then not sufficiently safeguarded at the

rear and may only be seen by other road users

when they are close to the vehicle. This could lead

to an accident.

The vehicle must then be clearly marked in

accordance with state and local laws, e.g., with a

warning triangle.

Freightliner-all.book Pag e 189 Monday, December 1, 2003 2:54 PM

Page 190 of 272

190 WHAT TO DO IN EMERGENCIESNOTE: Lug wrench and jack, refer to "Vehicle Tool

Kit". For reasons of safety, check at regular intervals

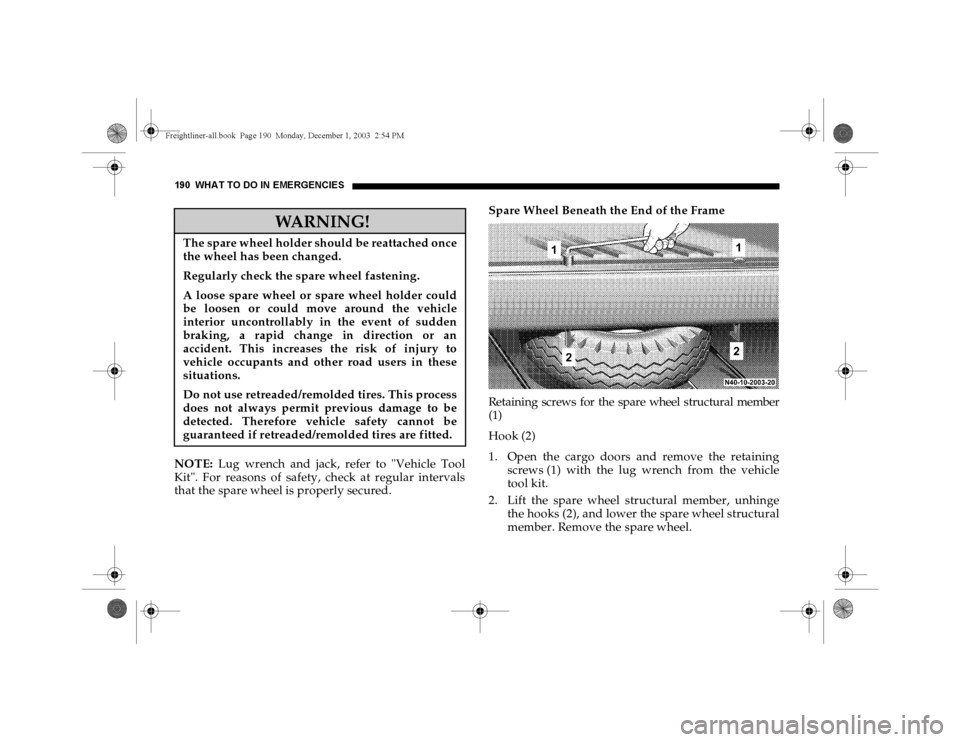

that the spare wheel is properly secured.Spare Wheel Beneath the End of the Frame

Retaining screws for the spare wheel structural member

(1)Hook (2)

1. Open the cargo doors and remove the retaining

screws (1) with the lug wrench from the vehicle

tool kit.

2. Lift the spare wheel structural member, unhinge

the hooks (2), and lower the spare wheel structural

member. Remove the spare wheel.

WARNING!

The spare wheel holder should be reattached once

the wheel has been changed.

Regularly check the spare wheel fastening.

A loose spare wheel or spare wheel holder could

be loosen or could move around the vehicle

interior uncontrollably in the event of sudden

braking, a rapid change in direction or an

accident. This increases the risk of injury to

vehicle occupants and other road users in these

situations.

Do not use retreaded/remolded tires. This process

does not always permit previous damage to be

detected. Therefore vehicle safety cannot be

guaranteed if retreaded/remolded tires are fitted.

Freightliner-all.book Pag e 190 Monday, December 1, 2003 2:54 PM

Page 192 of 272

192 WHAT TO DO IN EMERGENCIESSpare Wheel Location for Chassis

1. Loosen thumb nuts by hand and remove.

2. Use wrench to loosen fixing nut to the thread end.

3. Lift spare wheel holder.

4. Turn hooks to the side and lower spare wheel

holder. Remove the spare wheel.

JA CK

WARNING!

To avoid the risk of serious or fatal injuries or vehicle

damage, please bear the following points in mind:

The jack is intended only for raising the vehicle

briefly, for instance, when changing a wheel. If it is

not designed to enable work to be carried out

underneath the vehicle.

Do not crawl under the jacked-up vehicle. For work

under the vehicle, stands must be used.

The jack must be placed on a firm, flat surface only.

Do not change wheels on uphill or downhill

gradients under any circumstances.

Make sure that no persons are present in the vehicle

when jacking up the vehicle.

Do not start the engine while the vehicle is raised.

Make sure that the distance between the underside

of the tires and the ground does not exceed 1.2 in (30

mm). Otherwise the vehicle may tip over.

Freightliner-all.book Pag e 192 Monday, December 1, 2003 2:54 PM