engine DODGE SPRINTER 2006 1.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: SPRINTER, Model: DODGE SPRINTER 2006 1.GPages: 330, PDF Size: 10.82 MB

Page 261 of 330

MAINTAINING YOUR VEHICLE 261

7

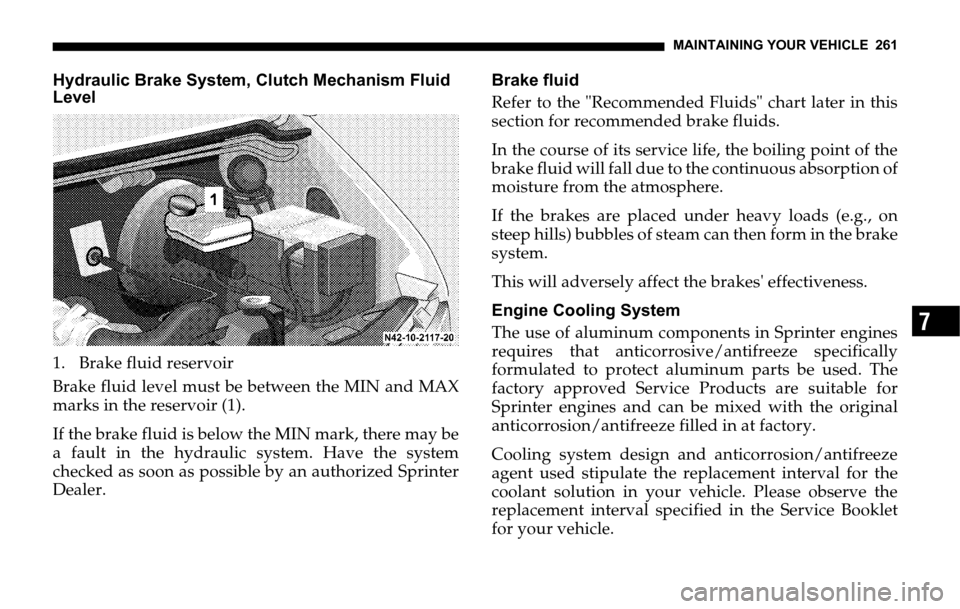

Hydraulic Brake System, Clutch Mechanism Fluid

Level

1. Brake fluid reservoir

Brake fluid level must be between the MIN and MAX

marks in the reservoir (1).

If the brake fluid is below the MIN mark, there may be

a fault in the hydraulic system. Have the system

checked as soon as possible by an authorized Sprinter

Dealer.Brake fluid

Refer to the "Recommended Fluids" chart later in this

section for recommended brake fluids.

In the course of its service life, the boiling point of the

brake fluid will fall due to the continuous absorption of

moisture from the atmosphere.

If the brakes are placed under heavy loads (e.g., on

steep hills) bubbles of steam can then form in the brake

system.

This will adversely affect the brakes' effectiveness.

Engine Cooling System

The use of aluminum components in Sprinter engines

requires that anticorrosive/antifreeze specifically

formulated to protect aluminum parts be used. The

factory approved Service Products are suitable for

Sprinter engines and can be mixed with the original

anticorrosion/antifreeze filled in at factory.

Cooling system design and anticorrosion/antifreeze

agent used stipulate the replacement interval for the

coolant solution in your vehicle. Please observe the

replacement interval specified in the Service Booklet

for your vehicle.

Page 262 of 330

262 MAINTAINING YOUR VEHICLE

Failure to use MB 325.0 anticorrosion/antifreeze and/or

equivalent to DaimlerChrysler material standard MS-

9769 and/or adhere to the specified replacement interval

may result in a significantly shortened service life.

For coolant composition and water quality, contact

your authorized Sprinter Dealer.

Engine Coolant

The coolant is a mixture of water and a corrosion

inhibitor/antifreeze additive. Within the cooling

system, the corrosion inhibitor/antifreeze ensures

anti-corrosion protection

antifreeze protection

a higher boiling point.

The coolant added in the factory ensures adequate

antifreeze and anti-corrosion protection.

Refer to the "Recommended Fluids" chart for coolant

recommendations.

For reasons of anti-corrosion protection and to increase

the boiling point, the coolant added to the cooling

system is designed for all year round operation – even

in countries with high prevailing temperatures.Have the coolant renewed at least every 15 years or

after 160,000 miles.

When the coolant is renewed, the new coolant should

contain 50% antifreeze/corrosion inhibitor by volume.

This corresponds to antifreeze protection down to -

37 °C/-35°F.

Do not exceed a proportion of about 55 % by volume

(antifreeze protection down to about -45 °C/-49 °F) as

the heat dissipation properties then deteriorate.

In the event of coolant loss, do not add water only, but

sufficient antifreeze/corrosion inhibitor to maintain

the correct concentration.

The water in the coolant must satisfy certain

requirements. These are often met by tap supply

drinking water.

The water must be specially prepared if the water

quality does not come up to the required standards.

Have the corrosion inhibitor/antifreeze concentration

in the coolant checked at the outset of winter,

respectively once a year in countries with high

prevailing temperatures.

Page 263 of 330

MAINTAINING YOUR VEHICLE 263

7

A regular check is included in the maintenance service.

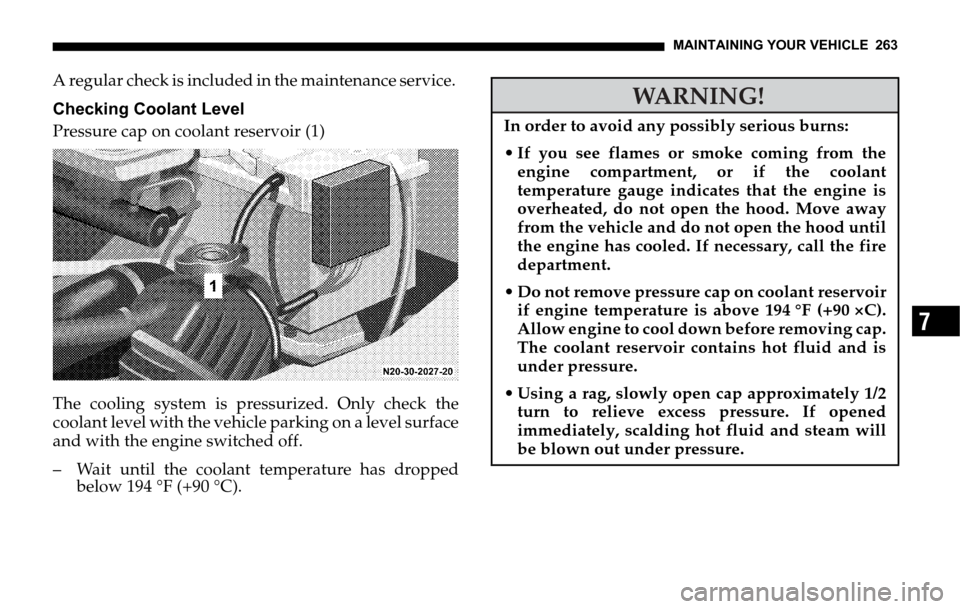

Checking Coolant Level

Pressure cap on coolant reservoir (1)

The cooling system is pressurized. Only check the

coolant level with the vehicle parking on a level surface

and with the engine switched off.

– Wait until the coolant temperature has dropped

below 194 °F (+90 °C).

WARNING!

In order to avoid any possibly serious burns:

If you see flames or smoke coming from the

engine compartment, or if the coolant

temperature gauge indicates that the engine is

overheated, do not open the hood. Move away

from the vehicle and do not open the hood until

the engine has cooled. If necessary, call the fire

department.

Do not remove pressure cap on coolant reservoir

if engine temperature is above 194 °F (+90 ×C).

Allow engine to cool down before removing cap.

The coolant reservoir contains hot fluid and is

under pressure.

Using a rag, slowly open cap approximately 1/2

turn to relieve excess pressure. If opened

immediately, scalding hot fluid and steam will

be blown out under pressure.

Page 264 of 330

264 MAINTAINING YOUR VEHICLE

Open the hood.

At first, only turn the pressure cap on coolant

reservoir to the first detent to release the pressure

from the cooling system. Only then should the

pressure cap be removed completely.

To add coolant:

If the engine is cold:

Add coolant until the coolant level reaches the base

area which is visible through the filler opening (area

moistened).If the engine is already at its regular operating

temperature:

Add coolant until the coolant level is about 0.6 inch

(1.5 cm) above the base area which is visible

through the filler opening.

Replace and tighten the pressure cap on coolant

reservoir.

If a large quantity of coolant has been lost, or if smaller

amounts are lost at regular intervals, have the engine

cooling system examined by an authorized Sprinter

Dealer.

For coolant composition and water quality, contact

your Sprinter Dealer.

WARNING!

Do not spill antifreeze on hot engine parts. Anti-

freeze contains ethylene glycol which may burn

if it comes into contact with hot engine parts.

Check coolant level only with the engine

switched off and the key in position 0 in the

ignition lock.

Page 265 of 330

MAINTAINING YOUR VEHICLE 265

7

WINTER OPERATION

Have your vehicle winterized by an authorized

Sprinter Dealer before the onset of winter.

Have the engine oil changed, if the engine oil filled

is not approved for winter use.

Coolant: antifreeze/anti-corrosion concentration in

the coolant checked.

Windshield washer system and headlamp cleaning

system (optional): add windshield washer fluid

"winter wash" to the water, depending on ambient

temperatures.

Battery: the battery will lose capacity as

temperatures drop. Only a well-charged battery will

ensure reliable engine starting even at low outside

temperatures.

Tires: fit M+S radial tires with a minimum tread

depth of approximately 1/6 in (4 mm) on all wheels

for the winter season.BATTERIES

The standard battery is located in the engine

compartment.

WARNING!

Failure to follow these instructions can result in

severe personal injuries and death.

Never lean over batteries while connecting, you

might get injured, if the battery explodes.

Battery fluid contains sulfuric acid. Do not allow

this fluid to come in contact with eyes, skin or

clothing. In case it does, immediately flush

affected area with water and seek medical help if

necessary.

A battery will also produce hydrogen gas, which

is flammable and explosive. Keep flames or

sparks away from battery, avoid improper

connection of jumper cables, smoking etc.

Use only impact-resistant batteries with a central

gas release cover to prevent corrosion damage and

to prevent occupants from caustic burns in the

event of an accident.

Page 266 of 330

266 MAINTAINING YOUR VEHICLE

The auxiliary battery is located underneath the front

passenger seat (optional equipment).

The battery will not achieve its maximum service life

unless it is kept adequately charged at all times. If the

vehicle is used primarily for short distances, or left

parked for lengthy periods, have the battery charge

checked more frequently.

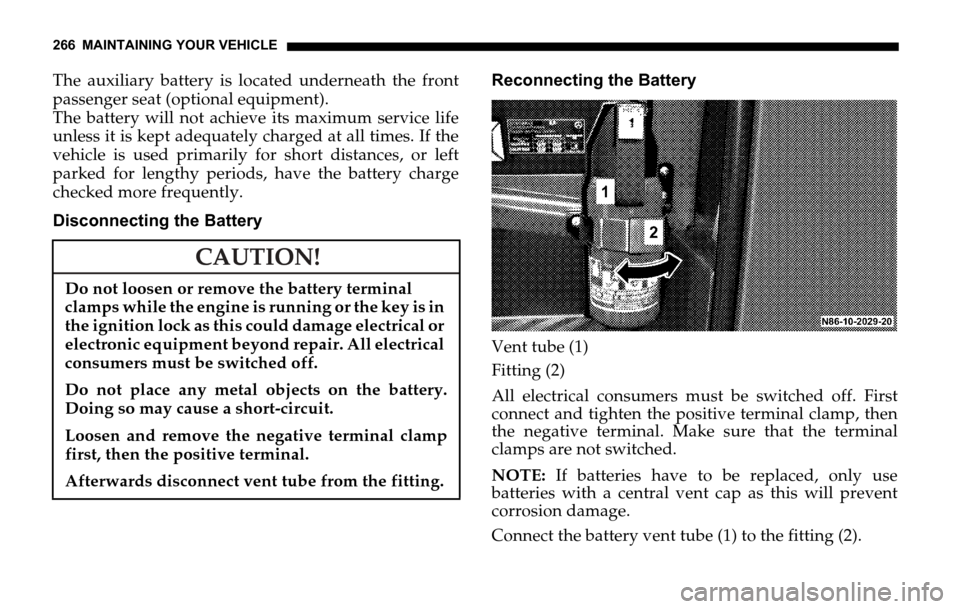

Disconnecting the BatteryReconnecting the Battery

Vent tube (1)

Fitting (2)

All electrical consumers must be switched off. First

connect and tighten the positive terminal clamp, then

the negative terminal. Make sure that the terminal

clamps are not switched.

NOTE: If batteries have to be replaced, only use

batteries with a central vent cap as this will prevent

corrosion damage.

Connect the battery vent tube (1) to the fitting (2).

CAUTION!

Do not loosen or remove the battery terminal

clamps while the engine is running or the key is in

the ignition lock as this could damage electrical or

electronic equipment beyond repair. All electrical

consumers must be switched off.

Do not place any metal objects on the battery.

Doing so may cause a short-circuit.

Loosen and remove the negative terminal clamp

first, then the positive terminal.

Afterwards disconnect vent tube from the fitting.

Page 272 of 330

272 MAINTAINING YOUR VEHICLE

Tar Stains

Quickly remove tar stains before they dry and become

more difficult to remove. A tar remover is

recommended.

Paintwork, Painted Body Components

Paint care should be applied when water drops on the

paint surface do not "bead up", normally every 3 to

5 months, depending on climate and washing

detergent used.

Paint cleaner should be applied if paint surface shows

signs of dirt embedding (i.e. loss of gloss).

Do not apply any of these products or wax if your

vehicle is parked in the sun or if the hood is still hot.

Use the appropriate paint stick for quick and

provisional repairs of minor paint damage (i.e., chips

from stones, vehicle doors etc.).

Engine Cleaning

Prior to cleaning the engine compartment, make sure

to protect electrical components and connectors from

the intrusion of water and cleaning agents.Corrosion protection, such as anticorrosion wax

should be applied to the engine compartment after

every engine cleaning. Before applying, all control

linkage bushings and joints should be lubricated. The

poly-V-belt and all pulleys should be protected from

any wax.

Vehicle Washing

Do not use hot water or wash your vehicle in direct

sunlight. Use only a mild car wash detergent.

Thoroughly spray the vehicle with a diffused jet of

water. Direct only a very weak spray towards the

ventilation intake. Use plenty of water and rinse the

sponge and chamois frequently.

Rinse with clear water and thoroughly wipe dry with a

chamois. Do not allow cleaning agents to dry on the

finish.

Due to the width of the vehicle, prior to running the

vehicle through an automatic car wash, fold back the

outside mirrors to prevent them from getting

damaged.

In the winter, thoroughly remove all traces of road salt

as soon as possible.

Page 280 of 330

280 MAINTAINING YOUR VEHICLE

No. Rated Circuit

1. 10A Parking lamp right, taillamp right

2. 10A High beam head lamp,right

3. 10A High beam head lamp, left,

high beam indicator lamp

4. 10A Backup lamp

5. 10A Brake lamp

6. 20A Windshield wiper motor

7. 15A Horn, heated rear window,

air recirculation switch,

optional equipment relay (terminal 15)

8. 20A Interior lighting, cigarette lighter,

radio (terminal 30)

9. 15A Clock, hazard warning lamps,

parking lamps10. 10A Instrument lighting, license plate lamp

daytime driving lamps

11. 10A Side lamp, left; taillamp, left

12. 10A Low beam headlamp, right

13. 10A Low beam headlamp, left

14. 15A Fog lamp

15. 10A Radio (terminal 15)

16. 25A Engine control unit

17. 15A Engine control unit

18. 15A Ignition (terminal 15)

19. 15A Not in use

20. 15A Heater controls (terminal 30)

21. 30A Heater blower (terminal 30)

Page 281 of 330

MAINTAINING YOUR VEHICLE 281

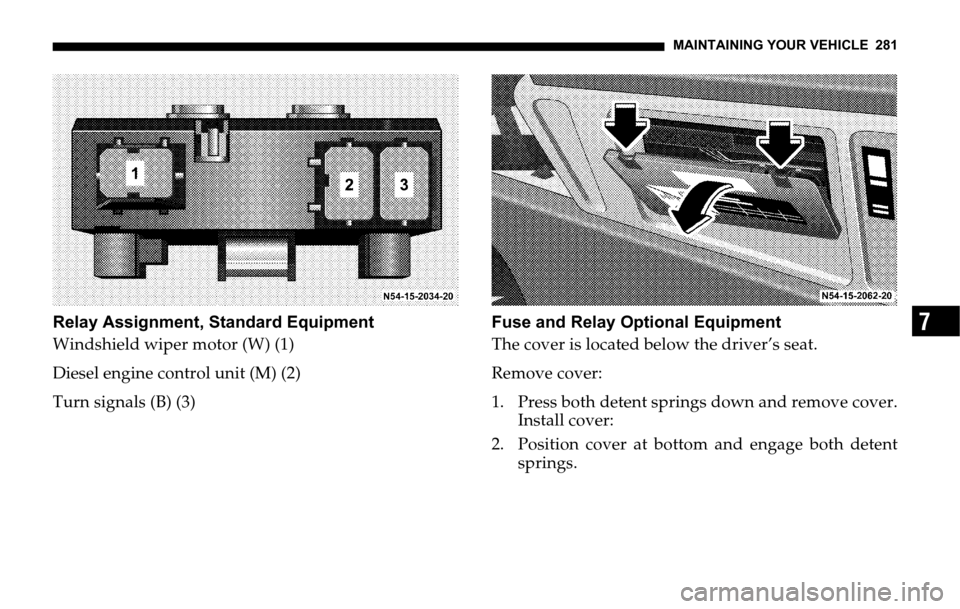

7Relay Assignment, Standard Equipment

Windshield wiper motor (W) (1)

Diesel engine control unit (M) (2)

Turn signals (B) (3)Fuse and Relay Optional Equipment

The cover is located below the driver’s seat.

Remove cover:

1. Press both detent springs down and remove cover.

Install cover:

2. Position cover at bottom and engage both detent

springs.

Page 284 of 330

284 MAINTAINING YOUR VEHICLE

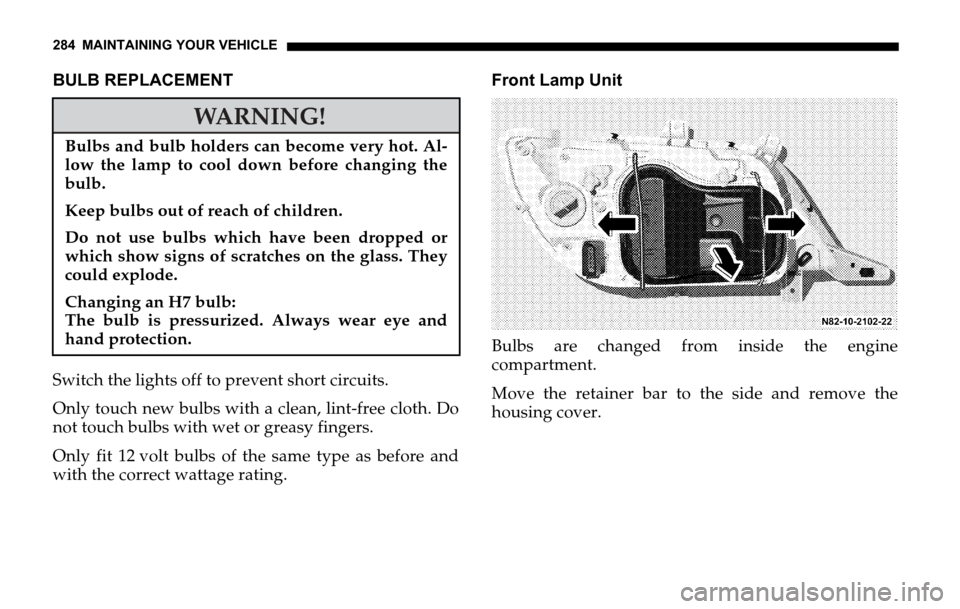

BULB REPLACEMENT

Switch the lights off to prevent short circuits.

Only touch new bulbs with a clean, lint-free cloth. Do

not touch bulbs with wet or greasy fingers.

Only fit 12 volt bulbs of the same type as before and

with the correct wattage rating.Front Lamp Unit

Bulbs are changed from inside the engine

compartment.

Move the retainer bar to the side and remove the

housing cover.

WARNING!

Bulbs and bulb holders can become very hot. Al-

low the lamp to cool down before changing the

bulb.

Keep bulbs out of reach of children.

Do not use bulbs which have been dropped or

which show signs of scratches on the glass. They

could explode.

Changing an H7 bulb:

The bulb is pressurized. Always wear eye and

hand protection.