ignition DODGE SPRINTER 2006 1.G Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: SPRINTER, Model: DODGE SPRINTER 2006 1.GPages: 330, PDF Size: 10.82 MB

Page 216 of 330

216 STARTING AND OPERATING

Bleeding the Diesel Fuel System

The diesel fuel system must be bled before starting the

engine.

Turn the key in the ignition lock position 2 for at

least 30 seconds.

Return the key to position 0.

Start the engine three to four times. The engine

control unit indicator lamp± must go out.

NOTE: Too many attempts to start the engine could

drain the battery. If the engine does not start after

several attempts, consult an authorized Sprinter

Dealer.PERMISSIBLE ROOF LOAD

The maximum permissible roof load is:

Vehicles with low roof 660 lbs (300 kg)

Vehicles with high roof 330 lbs (150 kg)

The weight of any load carried on the roof,

including the roof rack, must not exceed the

maximum permissible roof load.

LOADING THE VEHICLE

Two labels on the vehicle show how much weight it

may properly carry.

The Tire and Loading Information placard can be

found on the driver’s door B-pillar. This placard

tells you important information about the number

of people that can be in the vehicle and the total

weight that can be carried in the vehicle. It also

contains information on the proper size and

recommended tire inflation pressures for the

original equipment tires on the vehicle.

The Certification Label can be found below the

driver’s seat on an outward facing position of the

mounting pillar. It tells you about the gross weight

Page 249 of 330

WHAT TO DO IN EMERGENCIES 249

6

*Vehicle Type 2500 onlyIf the Engine is Damaged

For towing distances up to 30 miles (about 50 km)

Shift gear selector lever to "N" position.

Do not exceed a towing speed of 30 mph (50 km / h).

For towing distances greater than 30 miles (about

50 km)

Remove the propeller shafts leading to the drive

axles.

The vehicle can be towed without restriction.

If the Transmission is Damaged

Remove the propeller shafts leading to the drive

axles.

If the Front Axle is Damaged

Raise the front axle.

Observe the same towing restrictions as for engine

damage.

If the Rear Axle is Damaged

Raise the rear axle.

NOTE: Comply with local legal regulations regarding

towing vehicles.

WARNING!

Do not tow the vehicle if the key cannot be turned

in the ignition lock.

If the key cannot be turned, the ignition lock re-

mains locked and the vehicle cannot be steered.

With the engine not running there is no power

assistance for the braking and steering systems.

In this case, it is important to keep in mind that a

considerably higher degree of effort is necessary

to brake and steer the vehicle.

The vehicle must not be towed with the front axle

raised and the key in position 2 in the ignition

lock as the drive wheels could then lock due to the

acceleration skid control (ASR) or the optional

Electronic Stability Program (ESP

®)*.

Page 256 of 330

256 MAINTAINING YOUR VEHICLE

Disposal of Service Products

Dispose of service products and of parts which come

into contact with them (e.g. filters) in an

environmentally responsible manner. Comply with

applicable bars and regulations.

EMISSION RELATED COMPONENT WARRANTY

STATEMENT

The Manufacturer warrants to the original and each

subsequent owner of a Sprinter heavy-duty on

highway diesel engine that:

(1) the engine was designed, built and equipped so as

to conform at the time of sale with the applicable

regulations adopted by the Federal Environmental

Protection Agency, and

(2) the emission control system of such engine is free

from defects in materials and workmanship which

would cause it not to conform with those regulations

for a period of use of five years or 100 000 miles or

3 000 hours of engine operation, whichever occurs

first.REGULAR CHECKS

WARNING!

When the hood is open, there is a risk of injury

due to very hot engine components.

When the engine is running or the key is in posi-

tion 2 in the ignition lock, there is a risk of injury

due to moving engine components and the electri-

cal system.

If you see flames or smoke coming from the

engine compartment, or if the coolant temperature

gauge indicates that the engine is overheated, do

not open the hood. Move away from vehicle and

do not open the hood until the engine has cooled.

If necessary, call the fire department.

Page 264 of 330

264 MAINTAINING YOUR VEHICLE

Open the hood.

At first, only turn the pressure cap on coolant

reservoir to the first detent to release the pressure

from the cooling system. Only then should the

pressure cap be removed completely.

To add coolant:

If the engine is cold:

Add coolant until the coolant level reaches the base

area which is visible through the filler opening (area

moistened).If the engine is already at its regular operating

temperature:

Add coolant until the coolant level is about 0.6 inch

(1.5 cm) above the base area which is visible

through the filler opening.

Replace and tighten the pressure cap on coolant

reservoir.

If a large quantity of coolant has been lost, or if smaller

amounts are lost at regular intervals, have the engine

cooling system examined by an authorized Sprinter

Dealer.

For coolant composition and water quality, contact

your Sprinter Dealer.

WARNING!

Do not spill antifreeze on hot engine parts. Anti-

freeze contains ethylene glycol which may burn

if it comes into contact with hot engine parts.

Check coolant level only with the engine

switched off and the key in position 0 in the

ignition lock.

Page 266 of 330

266 MAINTAINING YOUR VEHICLE

The auxiliary battery is located underneath the front

passenger seat (optional equipment).

The battery will not achieve its maximum service life

unless it is kept adequately charged at all times. If the

vehicle is used primarily for short distances, or left

parked for lengthy periods, have the battery charge

checked more frequently.

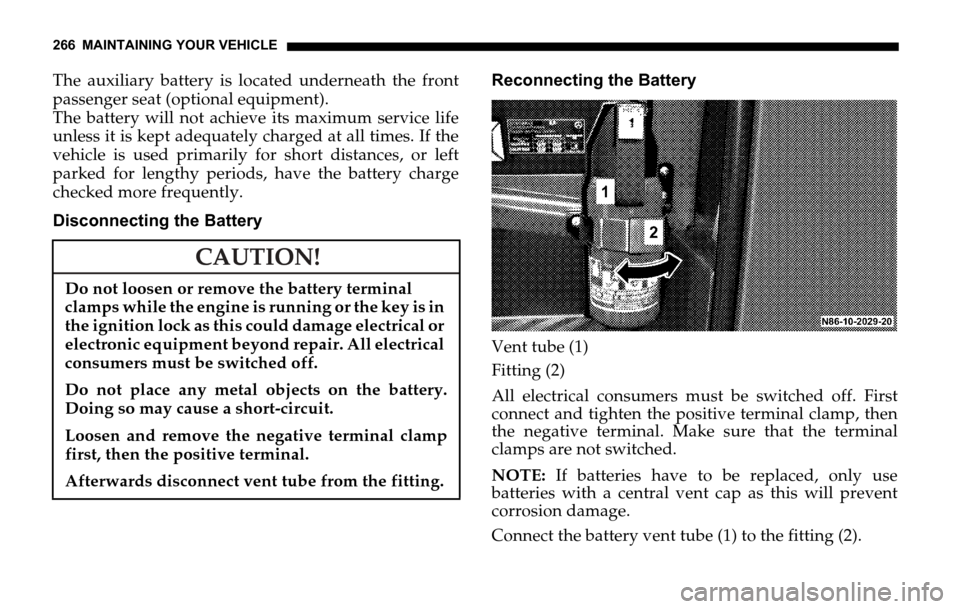

Disconnecting the BatteryReconnecting the Battery

Vent tube (1)

Fitting (2)

All electrical consumers must be switched off. First

connect and tighten the positive terminal clamp, then

the negative terminal. Make sure that the terminal

clamps are not switched.

NOTE: If batteries have to be replaced, only use

batteries with a central vent cap as this will prevent

corrosion damage.

Connect the battery vent tube (1) to the fitting (2).

CAUTION!

Do not loosen or remove the battery terminal

clamps while the engine is running or the key is in

the ignition lock as this could damage electrical or

electronic equipment beyond repair. All electrical

consumers must be switched off.

Do not place any metal objects on the battery.

Doing so may cause a short-circuit.

Loosen and remove the negative terminal clamp

first, then the positive terminal.

Afterwards disconnect vent tube from the fitting.

Page 274 of 330

274 MAINTAINING YOUR VEHICLE

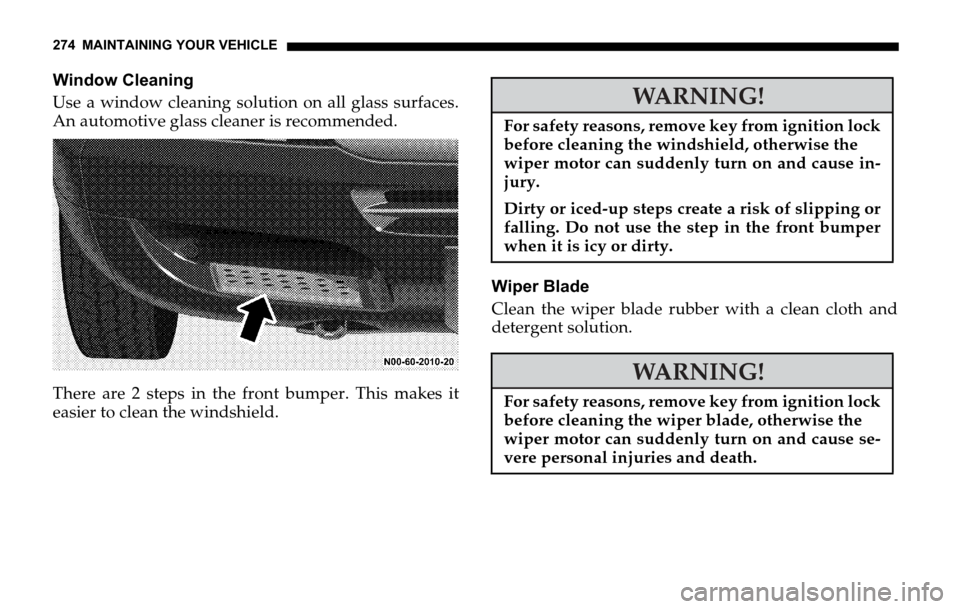

Window Cleaning

Use a window cleaning solution on all glass surfaces.

An automotive glass cleaner is recommended.

There are 2 steps in the front bumper. This makes it

easier to clean the windshield.Wiper Blade

Clean the wiper blade rubber with a clean cloth and

detergent solution.

WARNING!

For safety reasons, remove key from ignition lock

before cleaning the windshield, otherwise the

wiper motor can suddenly turn on and cause in-

jury.

Dirty or iced-up steps create a risk of slipping or

falling. Do not use the step in the front bumper

when it is icy or dirty.

WARNING!

For safety reasons, remove key from ignition lock

before cleaning the wiper blade, otherwise the

wiper motor can suddenly turn on and cause se-

vere personal injuries and death.

Page 276 of 330

276 MAINTAINING YOUR VEHICLE

Upholstery

Using aftermarket seat covers or wearing clothing that

have the tendency to give off coloring (e.g. when wet

etc.) may cause the upholstery to become permanently

discolored. By lining the seats with a proper

intermediate cover, contact discoloration will be

prevented.

Leather Upholstery

Wipe leather upholstery with a damp cloth and dry

thoroughly or clean with a leather care product.

Exercise particular care when cleaning perforated

leather as its underside should not become wet.

Cloth Upholstery

Clean with soft bristle brush, or use a dry-shampoo

cleaner in case of excessive dirt.

Tex Upholstery

Pour an interior care product onto soft lint-free cloth

and apply with light pressure.

Hard Plastic Trim Items

Pour an interior care product onto soft lint-free cloth

and apply with light pressure.Plastic and Rubber Parts

Do not use oil or wax on these parts.

Do not use any caustic or alcohol-based or solvent-

based substances to clean plastic surfaces.

Avoid the use of stain removers, iodine tincture, nail

varnish and nail varnish remover, acetone, methylated

spirits, chlorine or ammonium-based cleaning agents,

cleaning agents containing abrasive substances.

ELECTRICAL FUSES

Damaged fuses are recognizable from their burnt-out

filament.

Prior to exchanging a fuse, turn the key in the ignition-

column lock to the 0 position and switch off the

consumer involved.

NOTE: Fuses must not be bridged. Replace fuses with

specified rated current. Only replace fuses when the

cause of the malfunction has been rectified.

NOTE: Fuses and relays (standard equipment) are on

the underside of the ignition column, refer to "Fuses

and Relays Standard Equipment".

Page 280 of 330

280 MAINTAINING YOUR VEHICLE

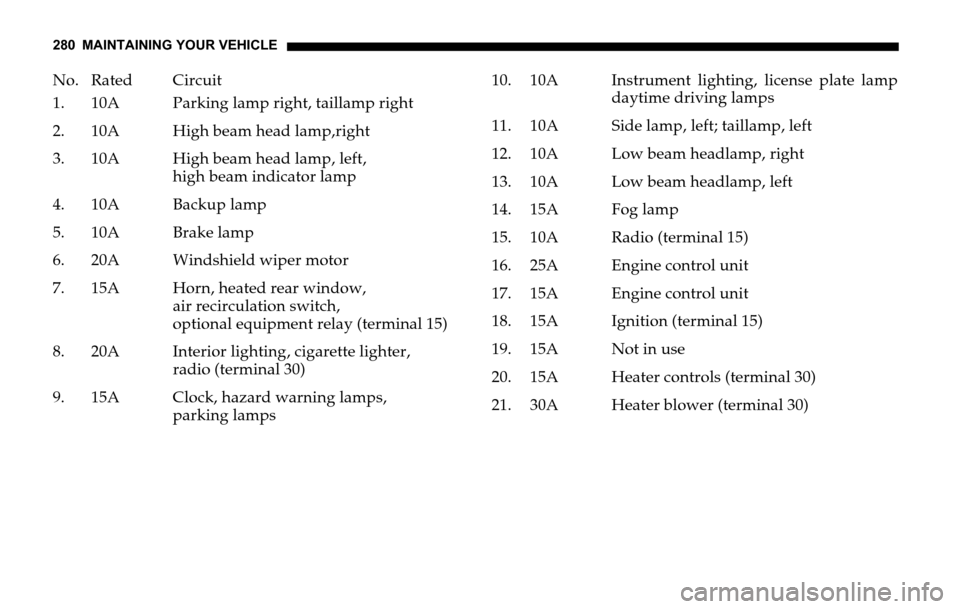

No. Rated Circuit

1. 10A Parking lamp right, taillamp right

2. 10A High beam head lamp,right

3. 10A High beam head lamp, left,

high beam indicator lamp

4. 10A Backup lamp

5. 10A Brake lamp

6. 20A Windshield wiper motor

7. 15A Horn, heated rear window,

air recirculation switch,

optional equipment relay (terminal 15)

8. 20A Interior lighting, cigarette lighter,

radio (terminal 30)

9. 15A Clock, hazard warning lamps,

parking lamps10. 10A Instrument lighting, license plate lamp

daytime driving lamps

11. 10A Side lamp, left; taillamp, left

12. 10A Low beam headlamp, right

13. 10A Low beam headlamp, left

14. 15A Fog lamp

15. 10A Radio (terminal 15)

16. 25A Engine control unit

17. 15A Engine control unit

18. 15A Ignition (terminal 15)

19. 15A Not in use

20. 15A Heater controls (terminal 30)

21. 30A Heater blower (terminal 30)

Page 322 of 330

322 INDEX

HHazard Warning Flasher Switch . . . . . . . . . . . . . . . . 232

Head Restraint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Headlamp Cleaning System . . . . . . . . . . . . . . . . . . . . 77

Headlamp Range Control. . . . . . . . . . . . . . . . . . . . . . . 68

Headlamps, taillamps, turn signal lenses . . . . . . . . 273

Heated Rear Window . . . . . . . . . . . . . . . . . . . . . . . . . 123

Heater, Seat. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118, 120

Hood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Hydroplaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

IIgnition

Lock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Starter Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Immobilizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Important Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . 179

Indicator Lamp Symbols . . . . . . . . . . . . . . . . . . . . . . 110

Inhalation of Exhaust Gas . . . . . . . . . . . . . . . . . . . . . . 54

Installing a Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Instrument and Display Lighting . . . . . . . . . . . . . . . . 99

Instrument ClusterBattery Charge Indicator Lamp . . . . . . . . . . . . . . 106

Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Coolant Level Indicator Lamp . . . . . . . . . . . . . . . 108

Coolant Temperature Gauge . . . . . . . . . . . . . . . . . 103

Engine Control Unit Indicator Lamp . . . . . . . . . . 109

Engine Oil Level Indicator Lamp . . . . . . . . . . . . . 107

Tachometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Trip Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Water in Fuel Indicator Lamp . . . . . . . . . . . . . . . . 106

Instrument Cluster and Indicator Lamps. . . . . . . . . . 93

Instruments and Controls . . . . . . . . . . . . . . . . . . . . . . . 91

Interior Lighting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Cargo Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Driver and Rear-Seat Passenger/Cargo Area. . . . 69

Interior Sensor Protection . . . . . . . . . . . . . . . . . . . . 69

Reading Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Intervals, Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 305

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Intrument Cluster

Fuel Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

JJack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Page 323 of 330

INDEX 323

10

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Jump Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

LLamps

Acceleration Skid Control . . . . . . . . . . . . . . . . . . . 167

Acceleration Skid Control Warning Lamp . 146, 169

Additional Brake Lamp . . . . . . . . . . . . . . . . . . . . . 291

Anti-Lock Brake System (ABS) Indicator Lamp. 164

Battery Charge Indicator Lamp . . . . . . . . . . . . . . 106

Brake Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Brake System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Coolant Level Indicator Lamp . . . . . . . . . . . . . . . 108

Electronic Brake Force Distribution . . . . . . . . . . . 160

Engine Control Unit Indicator Lamp . . . . . . . . . . 109

Engine Oil Level . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Engine Oil Level Indicator Lamp . . . . . . . . . . . . . 107

Exit Lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

Indicator Lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

License Plate Lamp . . . . . . . . . . . . . . . . . . . . . . . . . 291

Reading Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294

Reserve Fuel Indicator Lamp . . . . . . . . . . . . . . . . 105

Seat Belt Warning Lamp . . . . . . . . . . . . . . . . . . . . . 44Side-Marker Lamp . . . . . . . . . . . . . . . . . . . . . . . . . 292

SRS Malfunction Indicator Lamp . . . . . . . . . . . . . . 49

Taillamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

Water in Fuel Indicator Lamp . . . . . . . . . . . . . . . . 106

Lifting Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Lighter, Cigar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Lighting, Interior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Loading the Vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Lock, Ignition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Locking, Central . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Lumbar Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

MMaintenance Computer . . . . . . . . . . . . . . . . . . . . . . . 112

Maintenance Intervals . . . . . . . . . . . . . . . . . . . . . . . . . 305

Maintenance Schedules

Additional Maintenance Work After ... Years . . 310

Brake Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

Dust Filter for Heating/Ventilation

Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

Engine Oil Change and Filter Replacement . . . . 307