wheel torque DODGE SPRINTER 2006 1.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: SPRINTER, Model: DODGE SPRINTER 2006 1.GPages: 330, PDF Size: 10.82 MB

Page 170 of 330

170 STARTING AND OPERATING

Acceleration Skid Control (ASR)

ASR makes it possible to pull away and accelerate on a

slippery surface. A spinning wheel is braked and its

tractive power is transferred to the wheel with full

grip.

The acceleration skid control (ASR) improves driving

stability at all speeds only on vehicles of the chassis

and cargo/passenger vans type 3500 C/HC/SHC

(without ESP

®).

The engine’s torque is limited to improve driving

stability. When this is happening, the warning

lampv in the speedometer flashes.

If the road surface is not capable of providing traction,

bearing in mind the tires, load and grade, it may not be

possible to pull away even with ASR.

If wheels with tires of a different size than those offered

by an authorized Sprinter Dealer are used, the correct

operation of the ASR cannot be guaranteed.

WARNING!

ASR cannot prevent the natural laws of physics

from acting on the vehicle, nor can it increase the

traction afforded.

The ASR cannot prevent accidents, including

those resulting from excessive speed in turns,

following another vehicle too closely, or

hydroplaning. Only a safe, attentive, and skillful

driver can prevent accidents.

The capabilities of an ASR equipped vehicle must

never be exploited in a reckless or dangerous

manner which could jeopardize the user’s safety

or the safety of others.

If the ASR function is used for a prolonged period

of time, the rear axle brakes may fail due to

overheating.

If the vehicle is to be towed away with the front

wheels clear of the ground, or if the brakes are to

be tested on a brake dynamometer, do not pull the

key in position 2 in the ignition lock, because the

drive wheels could lock.

Page 171 of 330

STARTING AND OPERATING 171

5

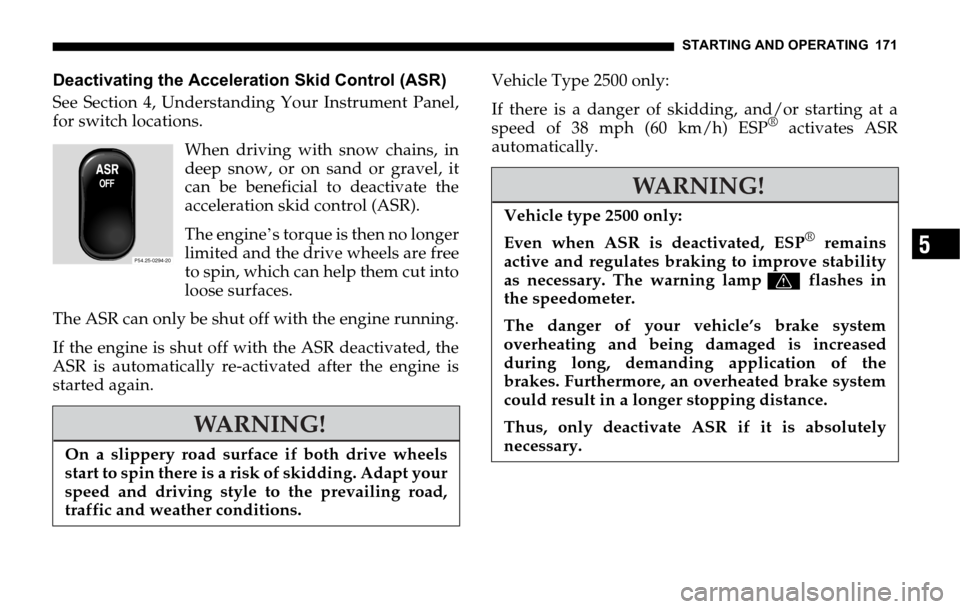

Deactivating the Acceleration Skid Control (ASR)

See Section 4, Understanding Your Instrument Panel,

for switch locations.

When driving with snow chains, in

deep snow, or on sand or gravel, it

can be beneficial to deactivate the

acceleration skid control (ASR).

The engine’s torque is then no longer

limited and the drive wheels are free

to spin, which can help them cut into

loose surfaces.

The ASR can only be shut off with the engine running.

If the engine is shut off with the ASR deactivated, the

ASR is automatically re-activated after the engine is

started again.Vehicle Type 2500 only:

If there is a danger of skidding, and/or starting at a

speed of 38 mph (60 km/h) ESP

® activates ASR

automatically.

WARNING!

On a slippery road surface if both drive wheels

start to spin there is a risk of skidding. Adapt your

speed and driving style to the prevailing road,

traffic and weather conditions.

P54.25-0294-20

WARNING!

Vehicle type 2500 only:

Even when ASR is deactivated, ESP

® remains

active and regulates braking to improve stability

as necessary. The warning lampv flashes in

the speedometer.

The danger of your vehicle’s brake system

overheating and being damaged is increased

during long, demanding application of the

brakes. Furthermore, an overheated brake system

could result in a longer stopping distance.

Thus, only deactivate ASR if it is absolutely

necessary.

Page 205 of 330

STARTING AND OPERATING 205

5

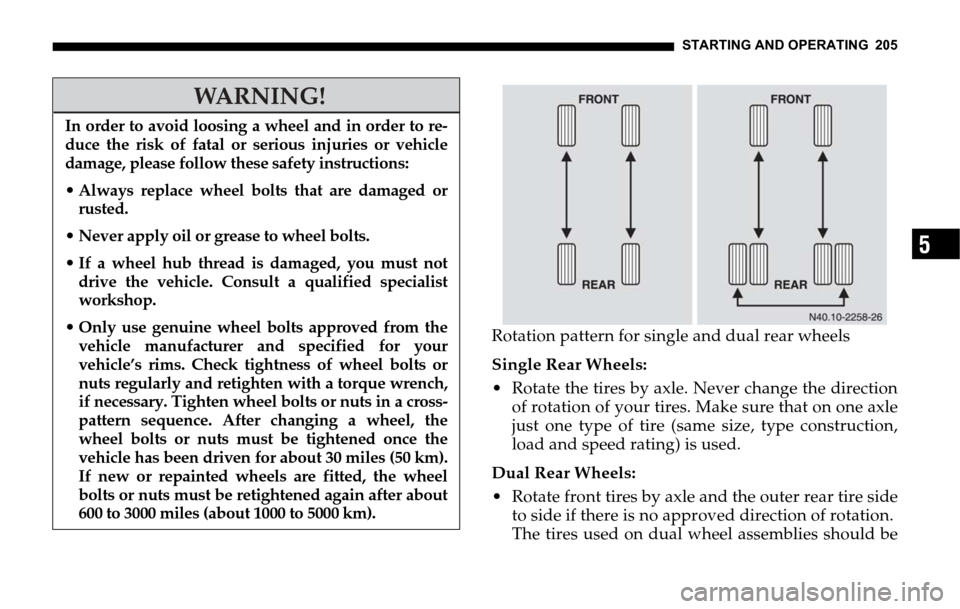

Rotation pattern for single and dual rear wheels

Single Rear Wheels:

Rotate the tires by axle. Never change the direction

of rotation of your tires. Make sure that on one axle

just one type of tire (same size, type construction,

load and speed rating) is used.

Dual Rear Wheels:

Rotate front tires by axle and the outer rear tire side

to side if there is no approved direction of rotation.

The tires used on dual wheel assemblies should be

WARNING!

In order to avoid loosing a wheel and in order to re-

duce the risk of fatal or serious injuries or vehicle

damage, please follow these safety instructions:

Always replace wheel bolts that are damaged or

rusted.

Never apply oil or grease to wheel bolts.

If a wheel hub thread is damaged, you must not

drive the vehicle. Consult a qualified specialist

workshop.

Only use genuine wheel bolts approved from the

vehicle manufacturer and specified for your

vehicle’s rims. Check tightness of wheel bolts or

nuts regularly and retighten with a torque wrench,

if necessary. Tighten wheel bolts or nuts in a cross-

pattern sequence. After changing a wheel, the

wheel bolts or nuts must be tightened once the

vehicle has been driven for about 30 miles (50 km).

If new or repainted wheels are fitted, the wheel

bolts or nuts must be retightened again after about

600 to 3000 miles (about 1000 to 5000 km).

Page 235 of 330

WHAT TO DO IN EMERGENCIES 235

6

Procedure:

1. Park the vehicle on a firm, level, non-slippery

surface.

2. Switch on the hazard warning flasher switch, apply

the parking brake, and place the transmission

selector in "P".3. Everyone must leave the vehicle before you jack it

up.

4. Everyone must leave the danger zone, before

jacking the vehicle.

5. The vehicle must be safeguarded in accordance

with legal regulations (such as using a warning

triangle).

6. Prevent vehicle from rolling away by blocking

wheels with wheel chocks (not supplied with

vehicle) or sizable wood block or stone.

On a level road, place one chock in front of and one

behind the wheel that is diagonally opposite to the

wheel being changed.

When changing a wheel on mild uphill or downhill

grades, place chocks on the downhill side blocking

both wheels of the other axle.

WARNING!

Do not jack the vehicle up more than 1.2 in (30

mm) between the tire and the surface. Otherwise,

the vehicle may tip over and may cause serious in-

jury or death to you or others.

Always lower the vehicle onto sufficient capacity

jack stands before working under the vehicle.

Precautions when changing a wheel:

For tire inflation pressures, see “Tire Pressures”

For the torque, refer to "Installing a wheel";

Do not damage, grease or oil wheel bolts or their

threads.

WARNING!

Do not change wheels on either steep uphill or

downhill grades. The vehicle may begin to move

and fall from the jack which could cause personal

injury and property damage.

Page 245 of 330

WHAT TO DO IN EMERGENCIES 245

6

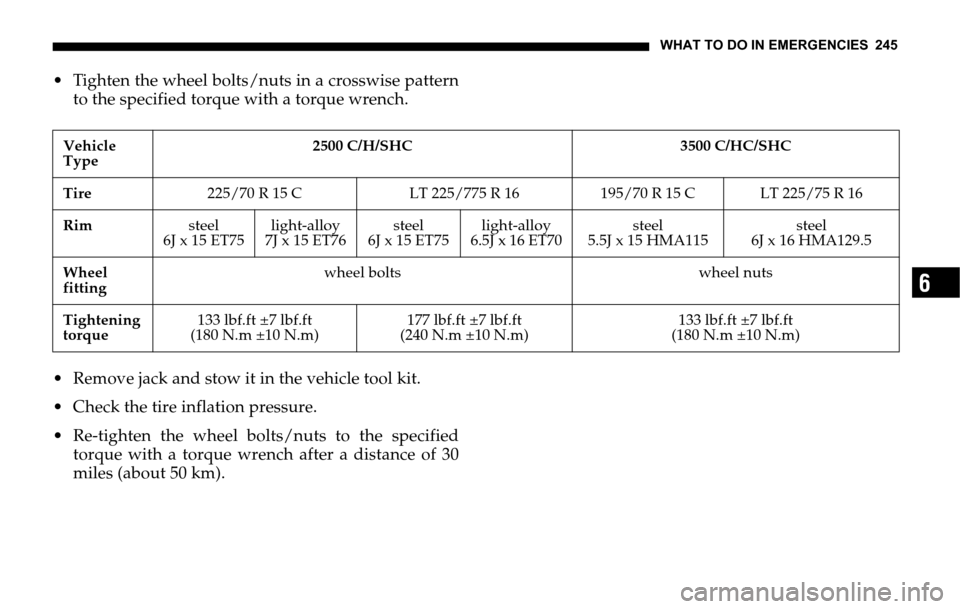

Tighten the wheel bolts/nuts in a crosswise pattern

to the specified torque with a torque wrench.

Remove jack and stow it in the vehicle tool kit.

Check the tire inflation pressure.

Re-tighten the wheel bolts/nuts to the specified

torque with a torque wrench after a distance of 30

miles (about 50 km).

Vehicle

Type2500 C/H/SHC 3500 C/HC/SHC

Tire225/70 R 15 C LT 225/775 R 16 195/70 R 15 C LT 225/75 R 16

Rimsteel

6J x 15 ET75light-alloy

7J x 15 ET76steel

6J x 15 ET75light-alloy

6.5J x 16 ET70steel

5.5J x 15 HMA115steel

6J x 16 HMA129.5

Wheel

fittingwheel bolts wheel nuts

Tightening

torque133 lbf.ft ±7 lbf.ft

(180 N.m ±10 N.m)177 lbf.ft ±7 lbf.ft

(240 N.m ±10 N.m)133 lbf.ft ±7 lbf.ft

(180 N.m ±10 N.m)

Page 246 of 330

246 WHAT TO DO IN EMERGENCIES

JUMP STARTING

If the battery is dead, the engine can be started with

jumper cables from another vehicle’s battery.

WARNING!

After changing a wheel, you must, for safety reasons,

have the specified tightening torque checked. The

wheels could otherwise work loose.

check the tire inflation pressure and correct it if

necessary.

retighten the wheel bolts and wheel nuts to the

specified tightening torque once the vehicle has

been driven for 30 miles (50 km). If new or

repainted wheels are fitted, the wheel bolts or nuts

must be retightened again after about 600 to 3,000

miles (about 1,000 to 5,000 km).

have a reversed direction of tire rotation corrected

as soon as possible at a qualified specialist

workshop. The vehicle handling characteristics

could otherwise be affected.WARNING!

A battery will produce hydrogen gas, which is

flammable and very explosive. Avoid open flames

and the formation of sparks in the vicinity of the

batteries. Refrain from smoking or cell phone use.

Avoid improper connection of jumper cables.

Observe safety precautions when handling

batteries.

Exercise care near moving engine components and

electrical cables.

Failure to follow these directions will cause

damage to the electronic components and can lead

to a battery explosion and severe injury or death.