service reset DODGE TOWN AND COUNTRY 2001 User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: TOWN AND COUNTRY, Model: DODGE TOWN AND COUNTRY 2001Pages: 2321, PDF Size: 68.09 MB

Page 564 of 2321

trically and independently using the separate power

seat switches found on the outboard seat cushion

side shield of each front seat. See the owner's manual

in the vehicle glove box for more information on the

features, use and operation of the power seat system.

OPERATION - MEMORY SYSTEM

The Memory Seat/Mirror Module (MSMM) will

drive a maximum of 2 motors at a time in a given

direction. If conflicting directions are requested, the

priority for response will be as follows:

²Seat Track Rearward

²Seat Front Down

²Seat Rear Down

²Recliner Rearward

²Seat Track Forward

²Seat Front Up

²Seat Rear Up

²Recliner Forward

The inputs from these switches to the MSMM is a

current limited battery source fed by the MSMM.

This protects the MSMM printed circuit board traces

from acting as fuses. All of these switch contact

inputs to the MSMM are normally closed to ground,

except when actuated.

Soft stops are incorporated to prevent the motor

from being driven into a stall. Should the seat have

restricted travel, refer to Resetting Soft Stops in this

section.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the memory system. For diagnosis of the MSM, the

PCI data bus, or the other electronic modules on the

PCI data bus that provide inputs and outputs for the

memory system, the use of a DRBtscan tool and the

proper Diagnostic Procedures manual are recom-

mended.

ELECTRONIC VEHICLE INFORMATION CENTER

The Electronic Vehicle Information Center (EVIC)

serves as the user interface for the memory system.

It displays memory system status messages and pro-

vides the user with the means for enabling and dis-

abling the many customer programmable features

available on the vehicle, including those for the mem-

ory system.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the EVIC. Refer toElectronic Vehicle Informa-

tion Centerin Overhead Console Systems for more

information on the EVIC.

DIAGNOSIS AND TESTING - POWER SEAT

SYSTEM

Following are tests that will help to diagnose the

hard wired components and circuits of the power seatsystem. However, if the vehicle is also equipped with

the optional memory system, these tests may not

prove conclusive in the diagnosis of the driver side

power seat. In order to obtain conclusive testing of

the driver side power seat with the memory system

option, the Programmable Communications Interface

(PCI) data bus network and all of the electronic mod-

ules that provide inputs to, or receive outputs from

the memory system components must be checked.

The most reliable, efficient, and accurate means to

diagnose the driver side power seat with the memory

system option requires the use of a DRBtscan tool

and the proper Diagnostic Procedures manual. The

DRBtscan tool can provide confirmation that the

PCI data bus is functional, that all of the electronic

modules are sending and receiving the proper mes-

sages on the PCI data bus, and that the memory sys-

tem is receiving the proper hard wired inputs and

relaying the proper hard wired outputs to perform its

driver side power seat functions.

WARNING: SOME VEHICLES ARE EQUIPPED WITH

SEATBACK MOUNTED AIRBAGS (Fig. 1). BEFORE

ATTEMPTING TO DIAGNOSE OR SERVICE ANY

SEAT OR POWER SEAT SYSTEM COMPONENT

YOU MUST FIRST DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE CABLE. THEN WAIT TWO MIN-

UTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE BEFORE FURTHER SYSTEM SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

AIRBAG SYSTEM. FAILURE TO DO SO COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Before any testing of the power seat system is

attempted, the battery should be fully-charged and

all of the power seat system wire harness connections

and pins cleaned and tightened to ensure proper cir-

cuit continuity and ground paths. For complete cir-

cuit diagrams, refer toPower Seatin Wiring

Diagrams.

With the dome lamp on, apply the power seat

switch in the direction of the failure. If the dome

lamp dims, the seat may be jamming. Check under

and behind the seat for binding or obstructions. If

the dome lamp does not dim, proceed with testing of

the individual components and circuits.

DIAGNOSIS AND TESTING - MEMORY SYSTEM

CHECK AND RESET SOFT STOPS

To check and reset the power memory seat soft

stops, use the power seat control switches to move

the seat in one direction to the end of travel, allow a

couple of seconds before re-energizing the seat in the

same direction until it stops and for three additional

seconds after it stops. (The amount the seat moved

RSPOWER SEATS8N-51

POWER SEATS (Continued)

ProCarManuals.com

Page 566 of 2321

limit of the adjuster is reached. When the switch is

moved in the opposite direction, the battery feed and

ground path to the motor are reversed through the

switch contacts. This causes the adjuster motor to

run in the opposite direction.

No power seat switch should be held applied in any

direction after the adjuster has reached its travel

limit. The power seat adjuster motors each contain a

self-resetting circuit breaker to protect them from

overload. However, consecutive or frequent resetting

of the circuit breaker must not be allowed to con-

tinue, or the motor may be damaged.

DIAGNOSIS AND TESTING - DRIVER SEAT

SWITCH

(1) Remove switch, refer to Switch Removal and

Installation in this section.

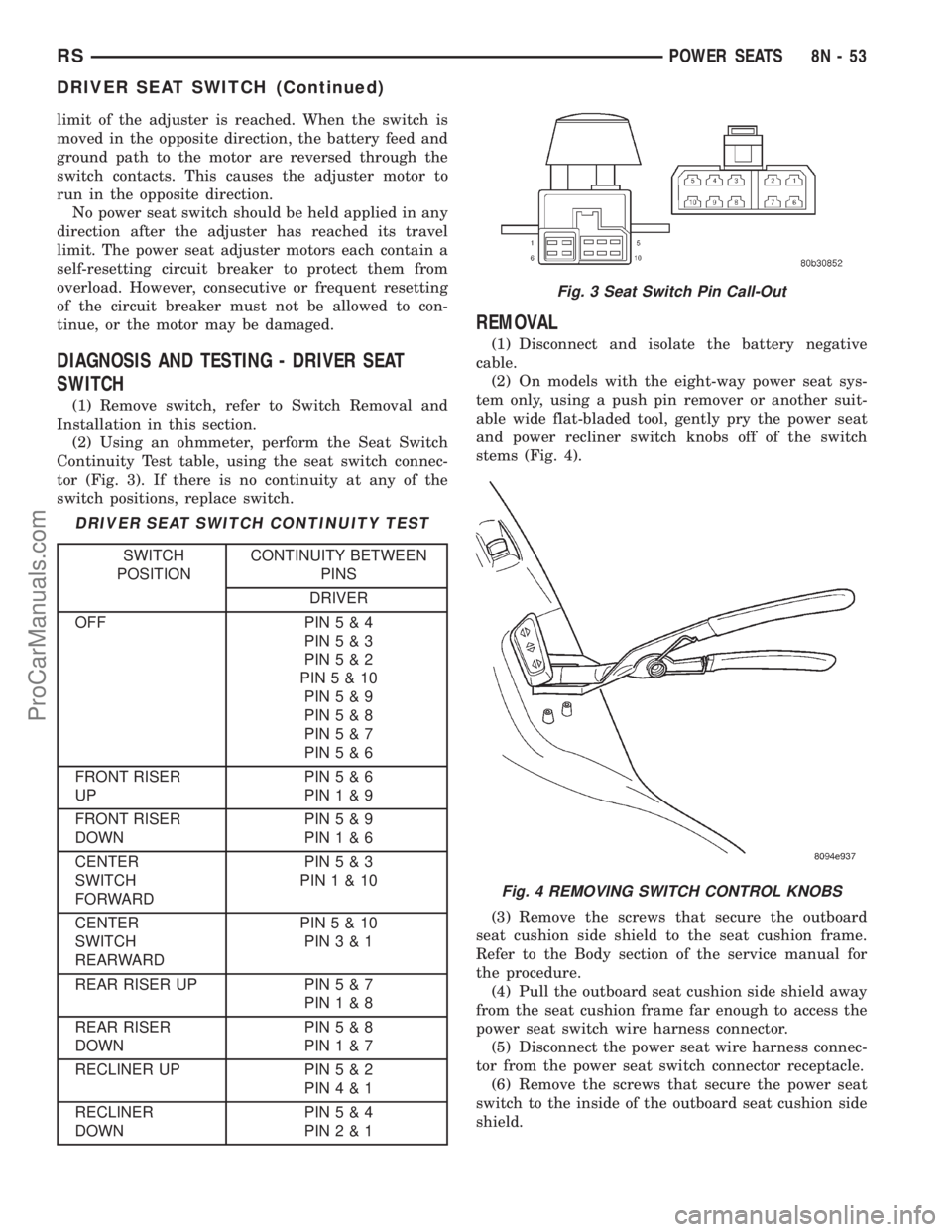

(2) Using an ohmmeter, perform the Seat Switch

Continuity Test table, using the seat switch connec-

tor (Fig. 3). If there is no continuity at any of the

switch positions, replace switch.

DRIVER SEAT SWITCH CONTINUITY TEST

SWITCH

POSITIONCONTINUITY BETWEEN

PINS

DRIVER

OFF PIN5&4

PIN5&3

PIN5&2

PIN5&10

PIN5&9

PIN5&8

PIN5&7

PIN5&6

FRONT RISER

UPPIN5&6

PIN1&9

FRONT RISER

DOWNPIN5&9

PIN1&6

CENTER

SWITCH

FORWARDPIN5&3

PIN1&10

CENTER

SWITCH

REARWARDPIN5&10

PIN3&1

REAR RISER UP PIN5&7

PIN1&8

REAR RISER

DOWNPIN5&8

PIN1&7

RECLINER UP PIN5&2

PIN4&1

RECLINER

DOWNPIN5&4

PIN2&1

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) On models with the eight-way power seat sys-

tem only, using a push pin remover or another suit-

able wide flat-bladed tool, gently pry the power seat

and power recliner switch knobs off of the switch

stems (Fig. 4).

(3) Remove the screws that secure the outboard

seat cushion side shield to the seat cushion frame.

Refer to the Body section of the service manual for

the procedure.

(4) Pull the outboard seat cushion side shield away

from the seat cushion frame far enough to access the

power seat switch wire harness connector.

(5) Disconnect the power seat wire harness connec-

tor from the power seat switch connector receptacle.

(6) Remove the screws that secure the power seat

switch to the inside of the outboard seat cushion side

shield.

Fig. 3 Seat Switch Pin Call-Out

Fig. 4 REMOVING SWITCH CONTROL KNOBS

RSPOWER SEATS8N-53

DRIVER SEAT SWITCH (Continued)

ProCarManuals.com

Page 1706 of 2321

INSTALLATION

NOTE: If transaxle assembly has been replaced or

overhauled (clutch and/or seal replacement), it is

necessary to perfrom the TCM Quick Learn proce-

dure. (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/TRANSMISSION CONTROL

MODULE - STANDARD PROCEDURE)

NOTE: If torque converter assembly has been

replaced, it is necessary to reset the TCC Break-In

Strategy. (Refer to 8 - ELECTRICAL/ELECTRONIC

CONTROL MODULES/TRANSMISSION CONTROL

MODULE - STANDARD PROCEDURE)

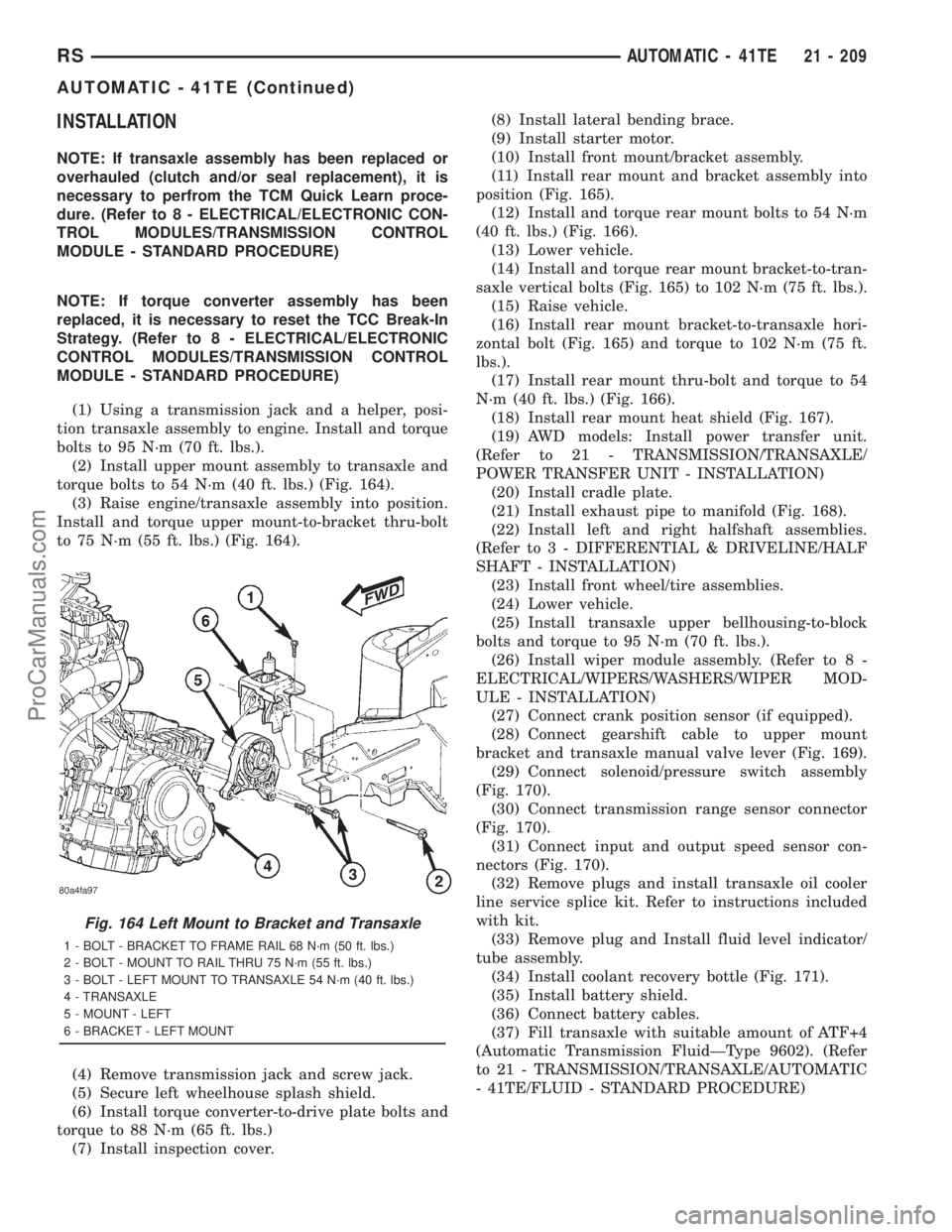

(1) Using a transmission jack and a helper, posi-

tion transaxle assembly to engine. Install and torque

bolts to 95 N´m (70 ft. lbs.).

(2) Install upper mount assembly to transaxle and

torque bolts to 54 N´m (40 ft. lbs.) (Fig. 164).

(3) Raise engine/transaxle assembly into position.

Install and torque upper mount-to-bracket thru-bolt

to 75 N´m (55 ft. lbs.) (Fig. 164).

(4) Remove transmission jack and screw jack.

(5) Secure left wheelhouse splash shield.

(6) Install torque converter-to-drive plate bolts and

torque to 88 N´m (65 ft. lbs.)

(7) Install inspection cover.(8) Install lateral bending brace.

(9) Install starter motor.

(10) Install front mount/bracket assembly.

(11) Install rear mount and bracket assembly into

position (Fig. 165).

(12) Install and torque rear mount bolts to 54 N´m

(40 ft. lbs.) (Fig. 166).

(13) Lower vehicle.

(14) Install and torque rear mount bracket-to-tran-

saxle vertical bolts (Fig. 165) to 102 N´m (75 ft. lbs.).

(15) Raise vehicle.

(16) Install rear mount bracket-to-transaxle hori-

zontal bolt (Fig. 165) and torque to 102 N´m (75 ft.

lbs.).

(17) Install rear mount thru-bolt and torque to 54

N´m (40 ft. lbs.) (Fig. 166).

(18) Install rear mount heat shield (Fig. 167).

(19) AWD models: Install power transfer unit.

(Refer to 21 - TRANSMISSION/TRANSAXLE/

POWER TRANSFER UNIT - INSTALLATION)

(20) Install cradle plate.

(21) Install exhaust pipe to manifold (Fig. 168).

(22) Install left and right halfshaft assemblies.

(Refer to 3 - DIFFERENTIAL & DRIVELINE/HALF

SHAFT - INSTALLATION)

(23) Install front wheel/tire assemblies.

(24) Lower vehicle.

(25) Install transaxle upper bellhousing-to-block

bolts and torque to 95 N´m (70 ft. lbs.).

(26) Install wiper module assembly. (Refer to 8 -

ELECTRICAL/WIPERS/WASHERS/WIPER MOD-

ULE - INSTALLATION)

(27) Connect crank position sensor (if equipped).

(28) Connect gearshift cable to upper mount

bracket and transaxle manual valve lever (Fig. 169).

(29) Connect solenoid/pressure switch assembly

(Fig. 170).

(30) Connect transmission range sensor connector

(Fig. 170).

(31) Connect input and output speed sensor con-

nectors (Fig. 170).

(32) Remove plugs and install transaxle oil cooler

line service splice kit. Refer to instructions included

with kit.

(33) Remove plug and Install fluid level indicator/

tube assembly.

(34) Install coolant recovery bottle (Fig. 171).

(35) Install battery shield.

(36) Connect battery cables.

(37) Fill transaxle with suitable amount of ATF+4

(Automatic Transmission FluidÐType 9602). (Refer

to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC

- 41TE/FLUID - STANDARD PROCEDURE)

Fig. 164 Left Mount to Bracket and Transaxle

1 - BOLT - BRACKET TO FRAME RAIL 68 N´m (50 ft. lbs.)

2 - BOLT - MOUNT TO RAIL THRU 75 N´m (55 ft. lbs.)

3 - BOLT - LEFT MOUNT TO TRANSAXLE 54 N´m (40 ft. lbs.)

4 - TRANSAXLE

5 - MOUNT - LEFT

6 - BRACKET - LEFT MOUNT

RSAUTOMATIC - 41TE21 - 209

AUTOMATIC - 41TE (Continued)

ProCarManuals.com

Page 1784 of 2321

TRANSMISSION CONTROL

RELAY

DESCRIPTION

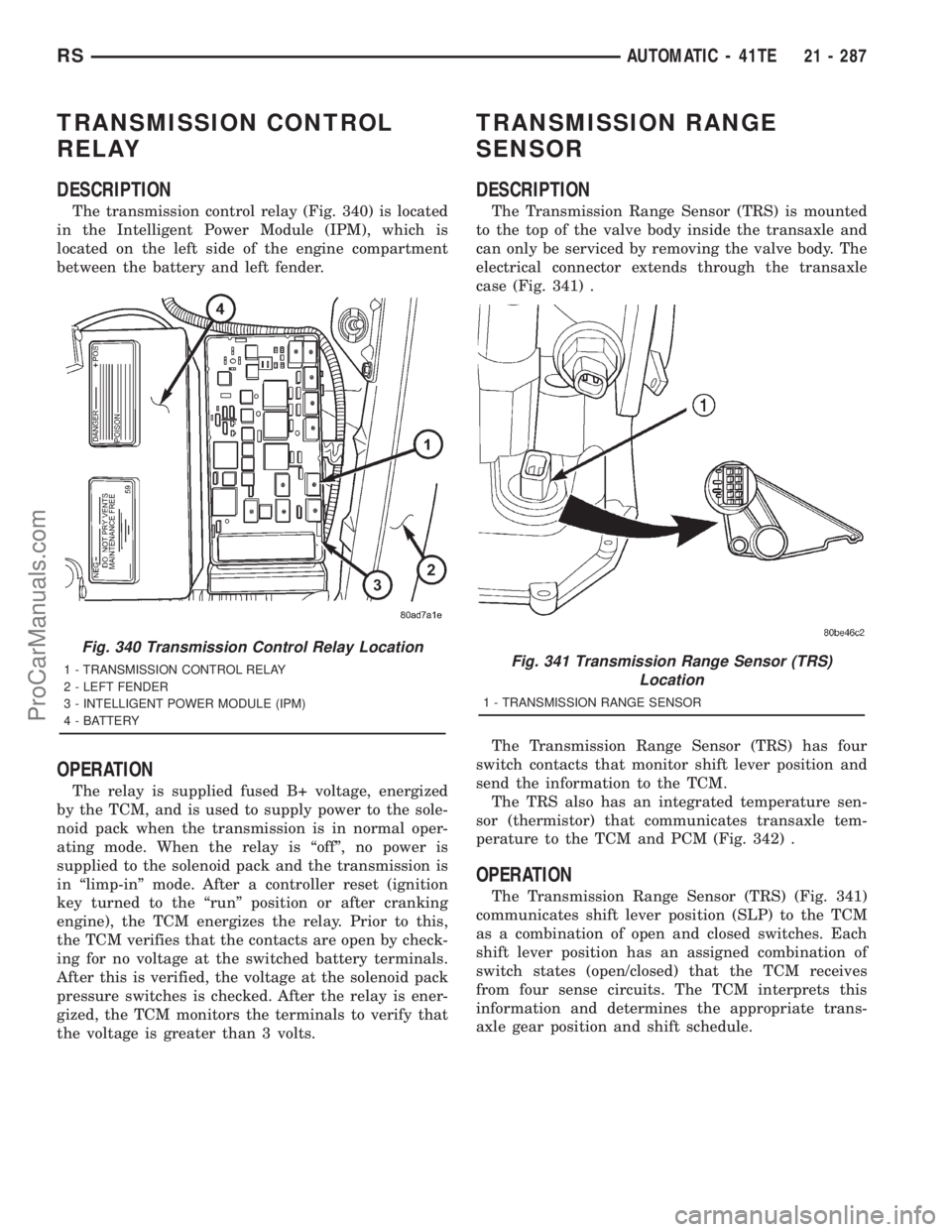

The transmission control relay (Fig. 340) is located

in the Intelligent Power Module (IPM), which is

located on the left side of the engine compartment

between the battery and left fender.

OPERATION

The relay is supplied fused B+ voltage, energized

by the TCM, and is used to supply power to the sole-

noid pack when the transmission is in normal oper-

ating mode. When the relay is ªoffº, no power is

supplied to the solenoid pack and the transmission is

in ªlimp-inº mode. After a controller reset (ignition

key turned to the ªrunº position or after cranking

engine), the TCM energizes the relay. Prior to this,

the TCM verifies that the contacts are open by check-

ing for no voltage at the switched battery terminals.

After this is verified, the voltage at the solenoid pack

pressure switches is checked. After the relay is ener-

gized, the TCM monitors the terminals to verify that

the voltage is greater than 3 volts.

TRANSMISSION RANGE

SENSOR

DESCRIPTION

The Transmission Range Sensor (TRS) is mounted

to the top of the valve body inside the transaxle and

can only be serviced by removing the valve body. The

electrical connector extends through the transaxle

case (Fig. 341) .

The Transmission Range Sensor (TRS) has four

switch contacts that monitor shift lever position and

send the information to the TCM.

The TRS also has an integrated temperature sen-

sor (thermistor) that communicates transaxle tem-

perature to the TCM and PCM (Fig. 342) .

OPERATION

The Transmission Range Sensor (TRS) (Fig. 341)

communicates shift lever position (SLP) to the TCM

as a combination of open and closed switches. Each

shift lever position has an assigned combination of

switch states (open/closed) that the TCM receives

from four sense circuits. The TCM interprets this

information and determines the appropriate trans-

axle gear position and shift schedule.

Fig. 340 Transmission Control Relay Location

1 - TRANSMISSION CONTROL RELAY

2 - LEFT FENDER

3 - INTELLIGENT POWER MODULE (IPM)

4 - BATTERYFig. 341 Transmission Range Sensor (TRS)

Location

1 - TRANSMISSION RANGE SENSOR

RSAUTOMATIC - 41TE21 - 287

ProCarManuals.com