AUX DODGE TOWN AND COUNTRY 2001 Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: TOWN AND COUNTRY, Model: DODGE TOWN AND COUNTRY 2001Pages: 2321, PDF Size: 68.09 MB

Page 40 of 2321

LUBRICATION & MAINTENANCE - RG - 2.5 L TURBO

DIESEL

TABLE OF CONTENTS

page page

LUBRICATION & MAINTENANCE - RG - 2.5 L

TURBO DIESEL

SPECIFICATIONS.........................1

INTERNATIONAL SYMBOLS

DESCRIPTION............................2

FLUID TYPES

DESCRIPTION............................2

FLUID FILL/CHECK LOCATIONS

DESCRIPTION............................5

MAINTENANCE SCHEDULES

DESCRIPTION............................5HOISTING

STANDARD PROCEDURE...................7

HOISTING.............................7

JUMP STARTING

STANDARD PROCEDURE...................8

JUMP STARTING........................8

TOWING

STANDARD PROCEDURE...................8

TOWING RECOMMENDATIONS.............8

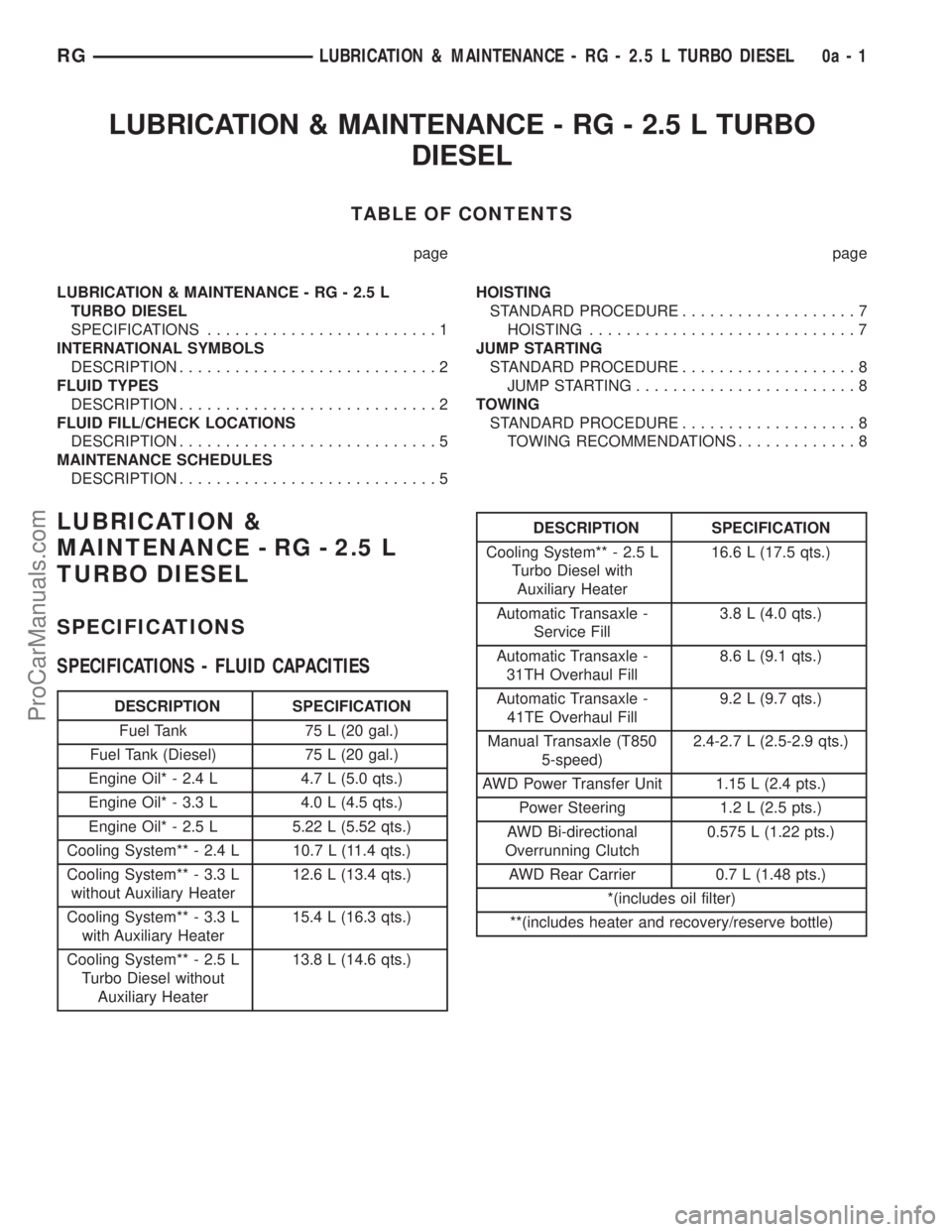

LUBRICATION &

MAINTENANCE - RG - 2.5 L

TURBO DIESEL

SPECIFICATIONS

SPECIFICATIONS - FLUID CAPACITIES

DESCRIPTION SPECIFICATION

Fuel Tank 75 L (20 gal.)

Fuel Tank (Diesel) 75 L (20 gal.)

Engine Oil* - 2.4 L 4.7 L (5.0 qts.)

Engine Oil* - 3.3 L 4.0 L (4.5 qts.)

Engine Oil* - 2.5 L 5.22 L (5.52 qts.)

Cooling System** - 2.4 L 10.7 L (11.4 qts.)

Cooling System** - 3.3 L

without Auxiliary Heater12.6 L (13.4 qts.)

Cooling System** - 3.3 L

with Auxiliary Heater15.4 L (16.3 qts.)

Cooling System** - 2.5 L

Turbo Diesel without

Auxiliary Heater13.8 L (14.6 qts.)

DESCRIPTION SPECIFICATION

Cooling System** - 2.5 L

Turbo Diesel with

Auxiliary Heater16.6 L (17.5 qts.)

Automatic Transaxle -

Service Fill3.8 L (4.0 qts.)

Automatic Transaxle -

31TH Overhaul Fill8.6 L (9.1 qts.)

Automatic Transaxle -

41TE Overhaul Fill9.2 L (9.7 qts.)

Manual Transaxle (T850

5-speed)2.4-2.7 L (2.5-2.9 qts.)

AWD Power Transfer Unit 1.15 L (2.4 pts.)

Power Steering 1.2 L (2.5 pts.)

AWD Bi-directional

Overrunning Clutch0.575 L (1.22 pts.)

AWD Rear Carrier 0.7 L (1.48 pts.)

*(includes oil filter)

**(includes heater and recovery/reserve bottle)

RGLUBRICATION & MAINTENANCE - RG - 2.5 L TURBO DIESEL0a-1

ProCarManuals.com

Page 315 of 2321

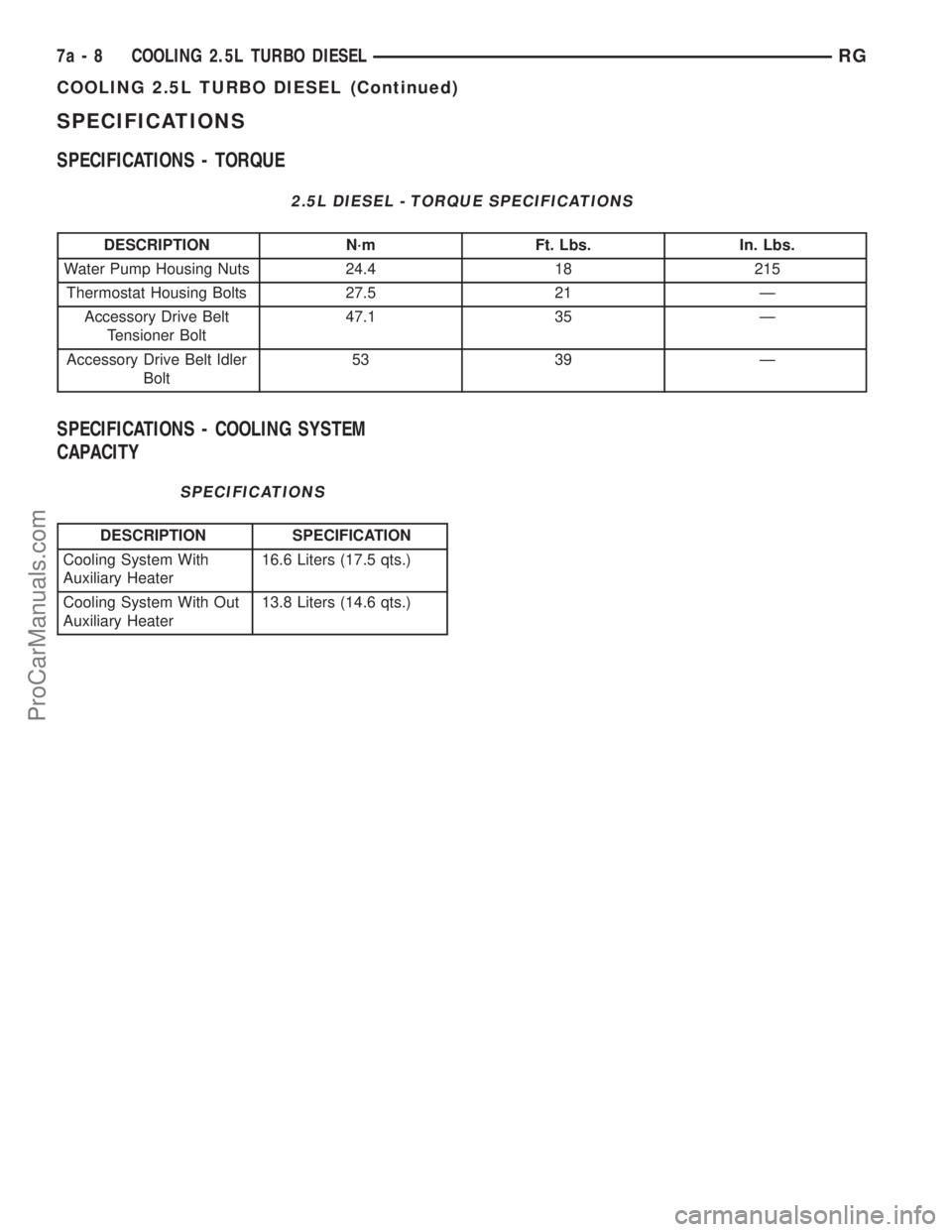

SPECIFICATIONS

SPECIFICATIONS - TORQUE

2.5L DIESEL - TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Water Pump Housing Nuts 24.4 18 215

Thermostat Housing Bolts 27.5 21 Ð

Accessory Drive Belt

Tensioner Bolt47.1 35 Ð

Accessory Drive Belt Idler

Bolt53 39 Ð

SPECIFICATIONS - COOLING SYSTEM

CAPACITY

SPECIFICATIONS

DESCRIPTION SPECIFICATION

Cooling System With

Auxiliary Heater16.6 Liters (17.5 qts.)

Cooling System With Out

Auxiliary Heater13.8 Liters (14.6 qts.)

7a - 8 COOLING 2.5L TURBO DIESELRG

COOLING 2.5L TURBO DIESEL (Continued)

ProCarManuals.com

Page 374 of 2321

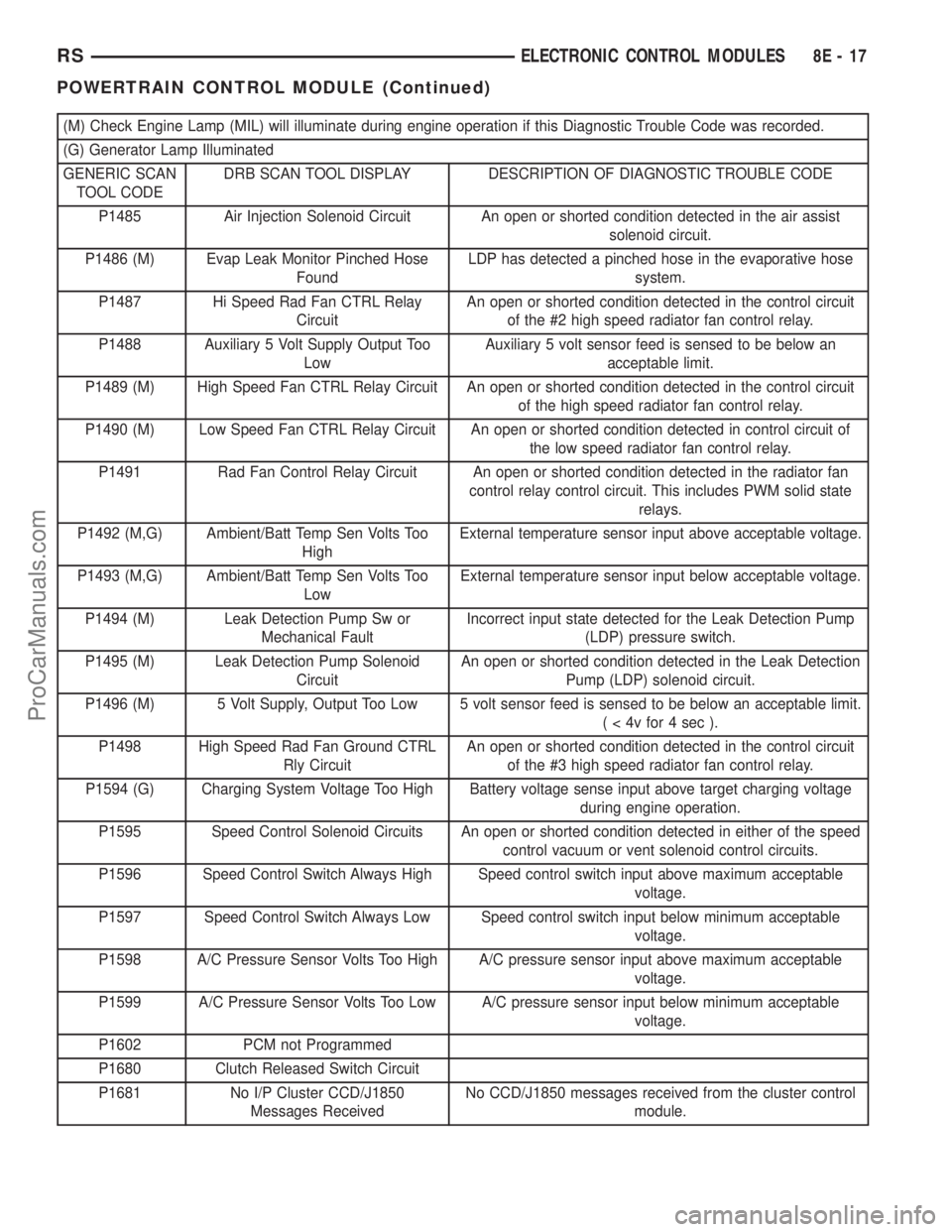

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

(G) Generator Lamp Illuminated

GENERIC SCAN

TOOL CODEDRB SCAN TOOL DISPLAY DESCRIPTION OF DIAGNOSTIC TROUBLE CODE

P1485 Air Injection Solenoid Circuit An open or shorted condition detected in the air assist

solenoid circuit.

P1486 (M) Evap Leak Monitor Pinched Hose

FoundLDP has detected a pinched hose in the evaporative hose

system.

P1487 Hi Speed Rad Fan CTRL Relay

CircuitAn open or shorted condition detected in the control circuit

of the #2 high speed radiator fan control relay.

P1488 Auxiliary 5 Volt Supply Output Too

LowAuxiliary 5 volt sensor feed is sensed to be below an

acceptable limit.

P1489 (M) High Speed Fan CTRL Relay Circuit An open or shorted condition detected in the control circuit

of the high speed radiator fan control relay.

P1490 (M) Low Speed Fan CTRL Relay Circuit An open or shorted condition detected in control circuit of

the low speed radiator fan control relay.

P1491 Rad Fan Control Relay Circuit An open or shorted condition detected in the radiator fan

control relay control circuit. This includes PWM solid state

relays.

P1492 (M,G) Ambient/Batt Temp Sen Volts Too

HighExternal temperature sensor input above acceptable voltage.

P1493 (M,G) Ambient/Batt Temp Sen Volts Too

LowExternal temperature sensor input below acceptable voltage.

P1494 (M) Leak Detection Pump Sw or

Mechanical FaultIncorrect input state detected for the Leak Detection Pump

(LDP) pressure switch.

P1495 (M) Leak Detection Pump Solenoid

CircuitAn open or shorted condition detected in the Leak Detection

Pump (LDP) solenoid circuit.

P1496 (M) 5 Volt Supply, Output Too Low 5 volt sensor feed is sensed to be below an acceptable limit.

( < 4v for 4 sec ).

P1498 High Speed Rad Fan Ground CTRL

Rly CircuitAn open or shorted condition detected in the control circuit

of the #3 high speed radiator fan control relay.

P1594 (G) Charging System Voltage Too High Battery voltage sense input above target charging voltage

during engine operation.

P1595 Speed Control Solenoid Circuits An open or shorted condition detected in either of the speed

control vacuum or vent solenoid control circuits.

P1596 Speed Control Switch Always High Speed control switch input above maximum acceptable

voltage.

P1597 Speed Control Switch Always Low Speed control switch input below minimum acceptable

voltage.

P1598 A/C Pressure Sensor Volts Too High A/C pressure sensor input above maximum acceptable

voltage.

P1599 A/C Pressure Sensor Volts Too Low A/C pressure sensor input below minimum acceptable

voltage.

P1602 PCM not Programmed

P1680 Clutch Released Switch Circuit

P1681 No I/P Cluster CCD/J1850

Messages ReceivedNo CCD/J1850 messages received from the cluster control

module.

RSELECTRONIC CONTROL MODULES8E-17

POWERTRAIN CONTROL MODULE (Continued)

ProCarManuals.com

Page 1317 of 2321

OIL FILTER

DESCRIPTION...........................52

REMOVAL..............................53

INSTALLATION...........................53

OIL JET

DESCRIPTION...........................53

REMOVAL..............................53

INSTALLATION...........................53

INTAKE MANIFOLD

DESCRIPTION...........................54

REMOVAL..............................54

INSTALLATION...........................54

VALVE TIMING

STANDARD PROCEDURE..................54

LOCKING ENGINE 90É AFTER TDC.........54

BALANCE SHAFT

DESCRIPTION...........................55OPERATION.............................56

REMOVAL..............................56

INSTALLATION...........................57

TIMING BELT / CHAIN COVER(S)

REMOVAL..............................57

INSTALLATION...........................58

TIMING BELT IDLER PULLEY

REMOVAL..............................59

INSTALLATION...........................60

TIMING BELT/CHAIN TENSIONER

REMOVAL..............................60

INSTALLATION...........................60

ADJUSTMENTS..........................61

TIMING BELT/CHAIN AND SPROCKETS

REMOVAL..............................62

INSTALLATION...........................63

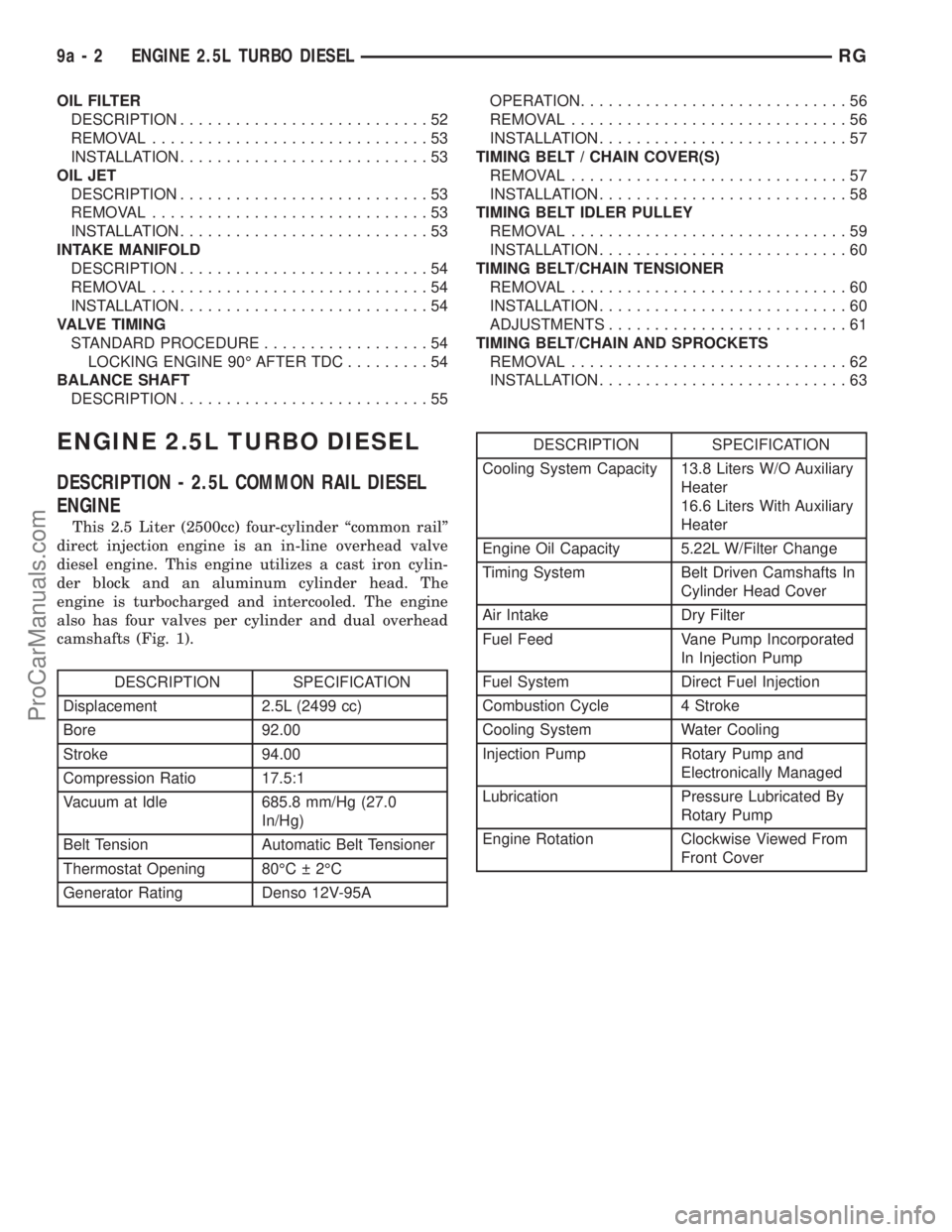

ENGINE 2.5L TURBO DIESEL

DESCRIPTION - 2.5L COMMON RAIL DIESEL

ENGINE

This 2.5 Liter (2500cc) four-cylinder ªcommon railº

direct injection engine is an in-line overhead valve

diesel engine. This engine utilizes a cast iron cylin-

der block and an aluminum cylinder head. The

engine is turbocharged and intercooled. The engine

also has four valves per cylinder and dual overhead

camshafts (Fig. 1).

DESCRIPTION SPECIFICATION

Displacement 2.5L (2499 cc)

Bore 92.00

Stroke 94.00

Compression Ratio 17.5:1

Vacuum at Idle 685.8 mm/Hg (27.0

In/Hg)

Belt Tension Automatic Belt Tensioner

Thermostat Opening 80ÉC 2ÉC

Generator Rating Denso 12V-95A

DESCRIPTION SPECIFICATION

Cooling System Capacity 13.8 Liters W/O Auxiliary

Heater

16.6 Liters With Auxiliary

Heater

Engine Oil Capacity 5.22L W/Filter Change

Timing System Belt Driven Camshafts In

Cylinder Head Cover

Air Intake Dry Filter

Fuel Feed Vane Pump Incorporated

In Injection Pump

Fuel System Direct Fuel Injection

Combustion Cycle 4 Stroke

Cooling System Water Cooling

Injection Pump Rotary Pump and

Electronically Managed

Lubrication Pressure Lubricated By

Rotary Pump

Engine Rotation Clockwise Viewed From

Front Cover

9a - 2 ENGINE 2.5L TURBO DIESELRG

ProCarManuals.com

Page 1413 of 2321

pump outlet, maintains pump pressure during engine

off conditions. The fuel pump relay provides voltage

to the fuel pump.

The fuel pump has a maximum deadheaded pres-

sure output of approximately 880 kPa (130 psi). The

regulator adjusts fuel system pressure to approxi-

mately 400634 kPa (5865 psi).

FUEL PUMP ELECTRICAL CONTROL

Voltage to operate the electric pump is supplied

through the fuel pump relay. For an electrical opera-

tional description of the fuel pump refer to fuel Pump

RelayÐPCM Output.

ELECTRICAL PUMP REPLACEMENT

The electric fuel pump is not serviceable. If the

fuel pump or electrical wiring harness needs replace-

ment, the complete fuel pump module must be

replaced. Perform the Fuel System Pressure Release

procedure before servicing the fuel pump.

REMOVAL

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

SERVICE VEHICLES IN WELL VENTILATED AREAS

AND AVOID IGNITION SOURCES. NEVER SMOKE

WHILE SERVICING THE VEHICLE.

(1) Remove fuel filler cap and perform Fuel Sys-

tem Pressure Release procedure.

(2) Disconnect negative cable from auxiliary

jumper terminal.

(3) Drain fuel tank, refer to the Fuel Tank proce-

dure in the Fuel Delivery section.

(4) Remove fuel tank, refer to the Fuel Tank

removal section.

(5) Clean top of tank to remove loose dirt and

debris.

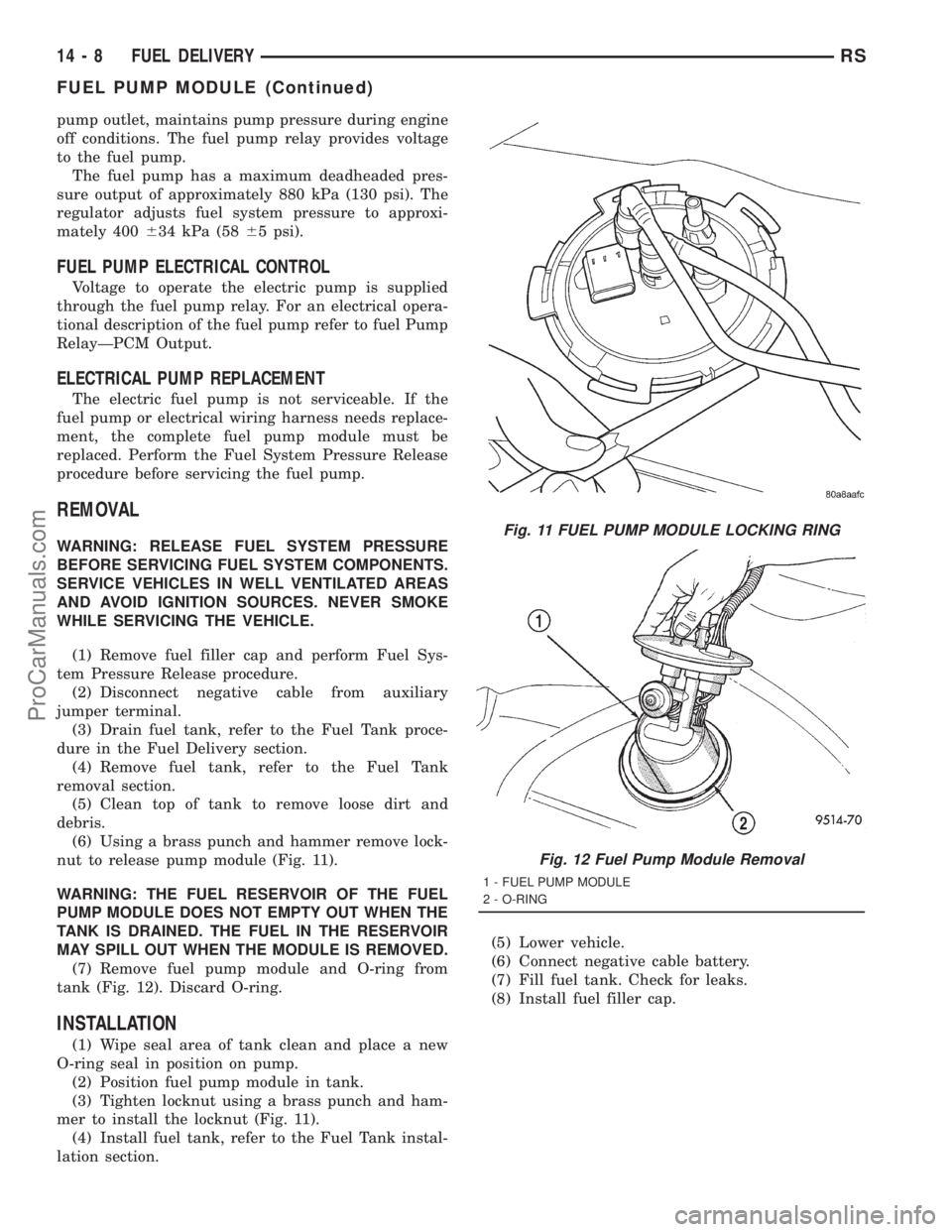

(6) Using a brass punch and hammer remove lock-

nut to release pump module (Fig. 11).

WARNING: THE FUEL RESERVOIR OF THE FUEL

PUMP MODULE DOES NOT EMPTY OUT WHEN THE

TANK IS DRAINED. THE FUEL IN THE RESERVOIR

MAY SPILL OUT WHEN THE MODULE IS REMOVED.

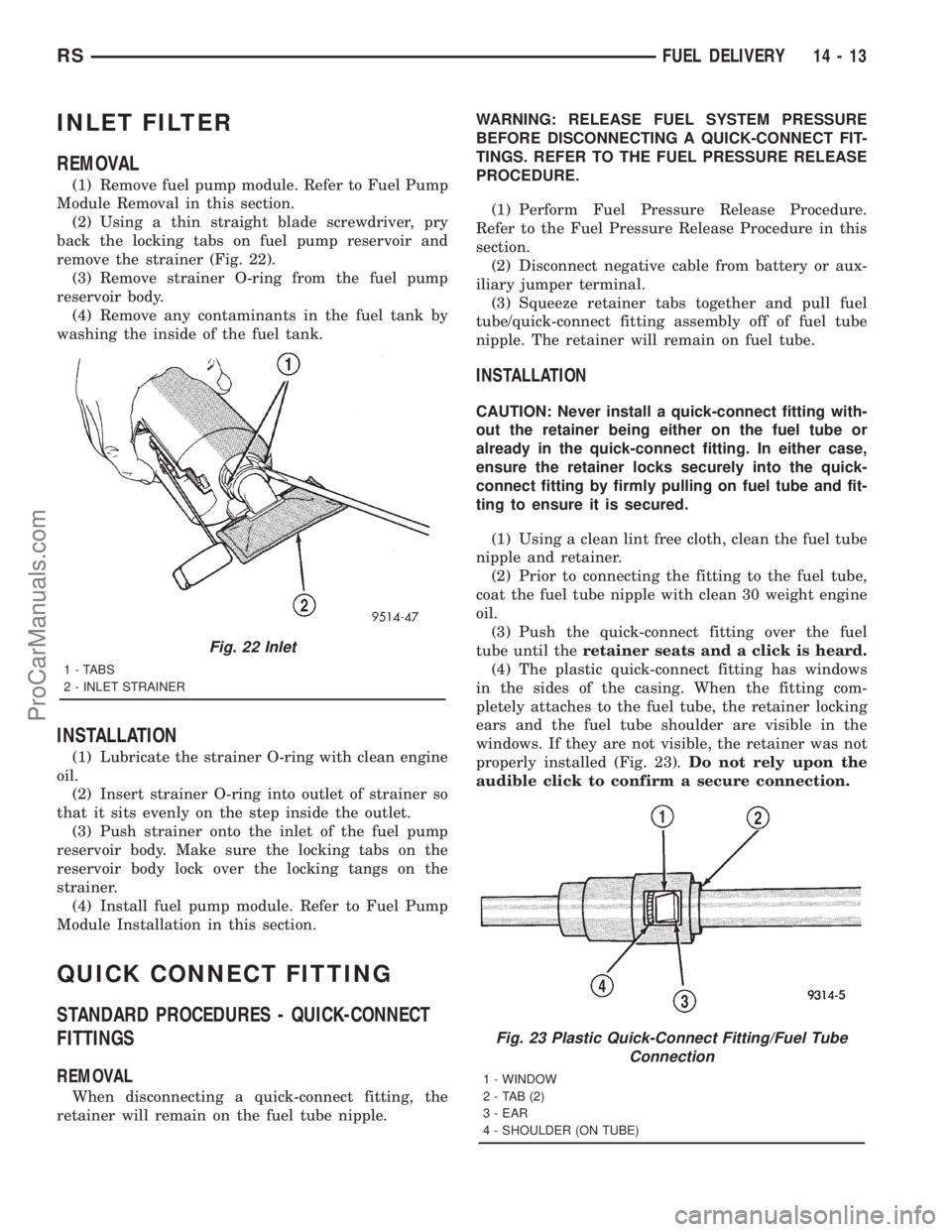

(7) Remove fuel pump module and O-ring from

tank (Fig. 12). Discard O-ring.

INSTALLATION

(1) Wipe seal area of tank clean and place a new

O-ring seal in position on pump.

(2) Position fuel pump module in tank.

(3) Tighten locknut using a brass punch and ham-

mer to install the locknut (Fig. 11).

(4) Install fuel tank, refer to the Fuel Tank instal-

lation section.(5) Lower vehicle.

(6) Connect negative cable battery.

(7) Fill fuel tank. Check for leaks.

(8) Install fuel filler cap.

Fig. 11 FUEL PUMP MODULE LOCKING RING

Fig. 12 Fuel Pump Module Removal

1 - FUEL PUMP MODULE

2 - O-RING

14 - 8 FUEL DELIVERYRS

FUEL PUMP MODULE (Continued)

ProCarManuals.com

Page 1418 of 2321

INLET FILTER

REMOVAL

(1) Remove fuel pump module. Refer to Fuel Pump

Module Removal in this section.

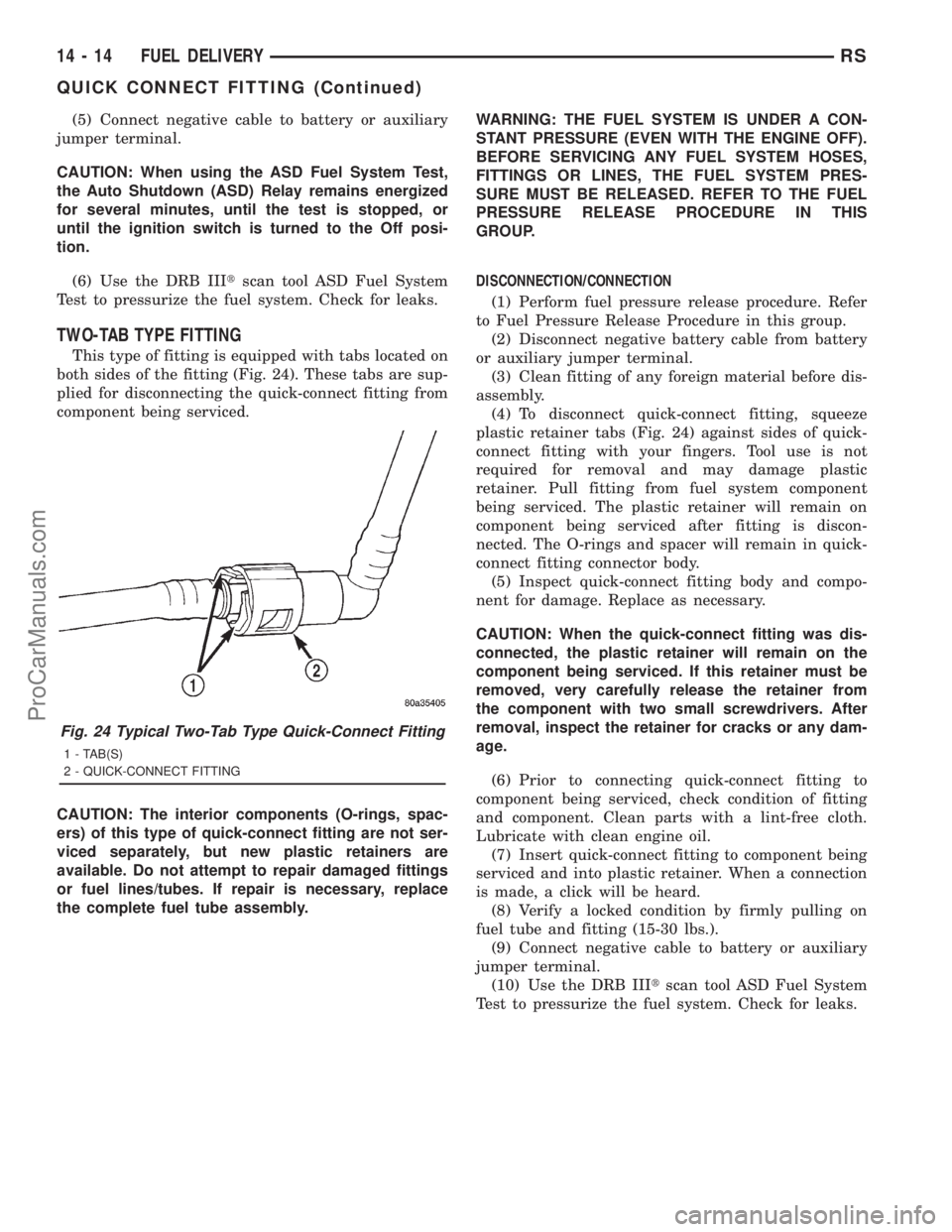

(2) Using a thin straight blade screwdriver, pry

back the locking tabs on fuel pump reservoir and

remove the strainer (Fig. 22).

(3) Remove strainer O-ring from the fuel pump

reservoir body.

(4) Remove any contaminants in the fuel tank by

washing the inside of the fuel tank.

INSTALLATION

(1) Lubricate the strainer O-ring with clean engine

oil.

(2) Insert strainer O-ring into outlet of strainer so

that it sits evenly on the step inside the outlet.

(3) Push strainer onto the inlet of the fuel pump

reservoir body. Make sure the locking tabs on the

reservoir body lock over the locking tangs on the

strainer.

(4) Install fuel pump module. Refer to Fuel Pump

Module Installation in this section.

QUICK CONNECT FITTING

STANDARD PROCEDURES - QUICK-CONNECT

FITTINGS

REMOVAL

When disconnecting a quick-connect fitting, the

retainer will remain on the fuel tube nipple.WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE DISCONNECTING A QUICK-CONNECT FIT-

TINGS. REFER TO THE FUEL PRESSURE RELEASE

PROCEDURE.

(1) Perform Fuel Pressure Release Procedure.

Refer to the Fuel Pressure Release Procedure in this

section.

(2) Disconnect negative cable from battery or aux-

iliary jumper terminal.

(3) Squeeze retainer tabs together and pull fuel

tube/quick-connect fitting assembly off of fuel tube

nipple. The retainer will remain on fuel tube.

INSTALLATION

CAUTION: Never install a quick-connect fitting with-

out the retainer being either on the fuel tube or

already in the quick-connect fitting. In either case,

ensure the retainer locks securely into the quick-

connect fitting by firmly pulling on fuel tube and fit-

ting to ensure it is secured.

(1) Using a clean lint free cloth, clean the fuel tube

nipple and retainer.

(2) Prior to connecting the fitting to the fuel tube,

coat the fuel tube nipple with clean 30 weight engine

oil.

(3) Push the quick-connect fitting over the fuel

tube until theretainer seats and a click is heard.

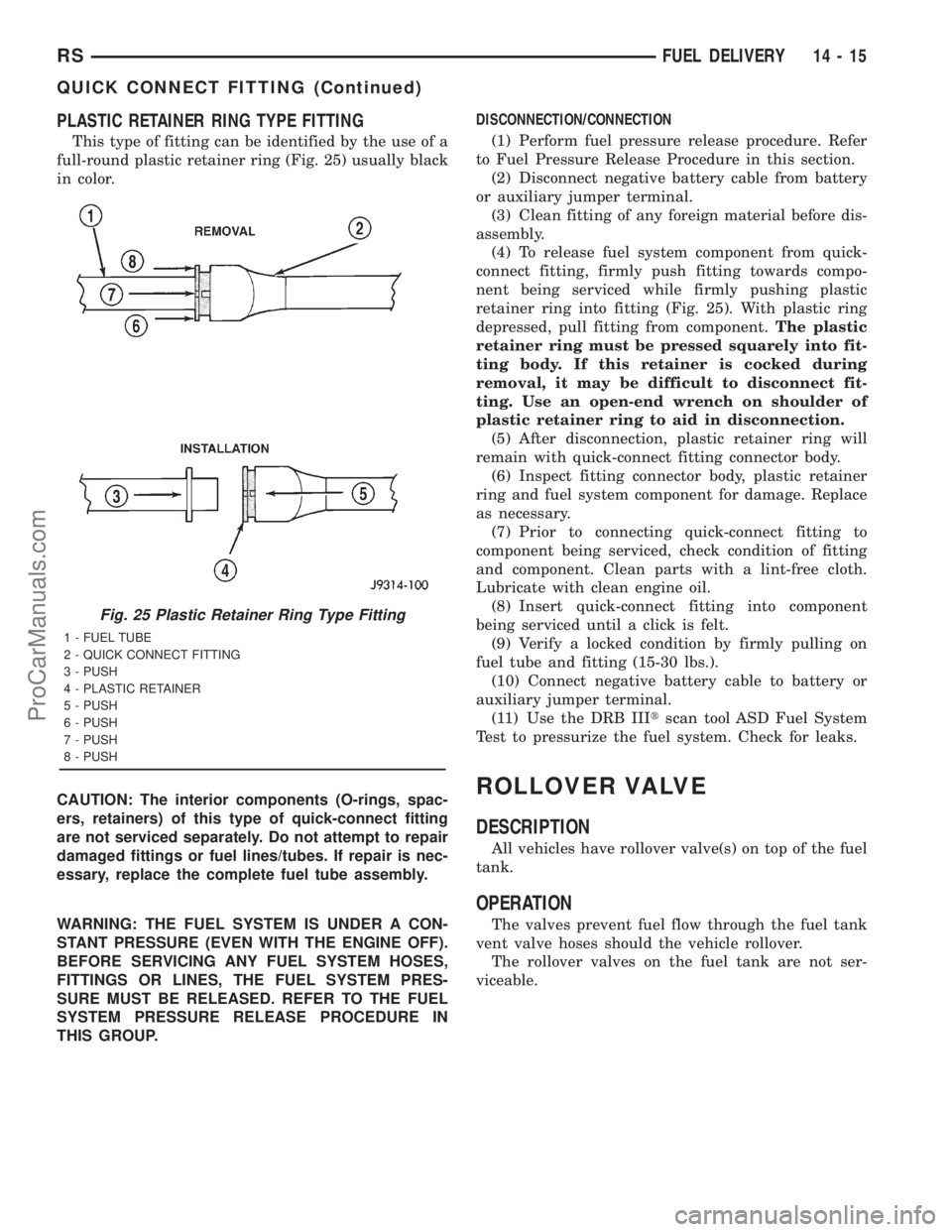

(4) The plastic quick-connect fitting has windows

in the sides of the casing. When the fitting com-

pletely attaches to the fuel tube, the retainer locking

ears and the fuel tube shoulder are visible in the

windows. If they are not visible, the retainer was not

properly installed (Fig. 23).Do not rely upon the

audible click to confirm a secure connection.

Fig. 22 Inlet

1 - TABS

2 - INLET STRAINER

Fig. 23 Plastic Quick-Connect Fitting/Fuel Tube

Connection

1 - WINDOW

2-TAB(2)

3 - EAR

4 - SHOULDER (ON TUBE)

RSFUEL DELIVERY14-13

ProCarManuals.com

Page 1419 of 2321

(5) Connect negative cable to battery or auxiliary

jumper terminal.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for several minutes, until the test is stopped, or

until the ignition switch is turned to the Off posi-

tion.

(6) Use the DRB IIItscan tool ASD Fuel System

Test to pressurize the fuel system. Check for leaks.

TWO-TAB TYPE FITTING

This type of fitting is equipped with tabs located on

both sides of the fitting (Fig. 24). These tabs are sup-

plied for disconnecting the quick-connect fitting from

component being serviced.

CAUTION: The interior components (O-rings, spac-

ers) of this type of quick-connect fitting are not ser-

viced separately, but new plastic retainers are

available. Do not attempt to repair damaged fittings

or fuel lines/tubes. If repair is necessary, replace

the complete fuel tube assembly.WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING ANY FUEL SYSTEM HOSES,

FITTINGS OR LINES, THE FUEL SYSTEM PRES-

SURE MUST BE RELEASED. REFER TO THE FUEL

PRESSURE RELEASE PROCEDURE IN THIS

GROUP.

DISCONNECTION/CONNECTION

(1) Perform fuel pressure release procedure. Refer

to Fuel Pressure Release Procedure in this group.

(2) Disconnect negative battery cable from battery

or auxiliary jumper terminal.

(3) Clean fitting of any foreign material before dis-

assembly.

(4) To disconnect quick-connect fitting, squeeze

plastic retainer tabs (Fig. 24) against sides of quick-

connect fitting with your fingers. Tool use is not

required for removal and may damage plastic

retainer. Pull fitting from fuel system component

being serviced. The plastic retainer will remain on

component being serviced after fitting is discon-

nected. The O-rings and spacer will remain in quick-

connect fitting connector body.

(5) Inspect quick-connect fitting body and compo-

nent for damage. Replace as necessary.

CAUTION: When the quick-connect fitting was dis-

connected, the plastic retainer will remain on the

component being serviced. If this retainer must be

removed, very carefully release the retainer from

the component with two small screwdrivers. After

removal, inspect the retainer for cracks or any dam-

age.

(6) Prior to connecting quick-connect fitting to

component being serviced, check condition of fitting

and component. Clean parts with a lint-free cloth.

Lubricate with clean engine oil.

(7) Insert quick-connect fitting to component being

serviced and into plastic retainer. When a connection

is made, a click will be heard.

(8) Verify a locked condition by firmly pulling on

fuel tube and fitting (15-30 lbs.).

(9) Connect negative cable to battery or auxiliary

jumper terminal.

(10) Use the DRB IIItscan tool ASD Fuel System

Test to pressurize the fuel system. Check for leaks.

Fig. 24 Typical Two-Tab Type Quick-Connect Fitting

1 - TAB(S)

2 - QUICK-CONNECT FITTING

14 - 14 FUEL DELIVERYRS

QUICK CONNECT FITTING (Continued)

ProCarManuals.com

Page 1420 of 2321

PLASTIC RETAINER RING TYPE FITTING

This type of fitting can be identified by the use of a

full-round plastic retainer ring (Fig. 25) usually black

in color.

CAUTION: The interior components (O-rings, spac-

ers, retainers) of this type of quick-connect fitting

are not serviced separately. Do not attempt to repair

damaged fittings or fuel lines/tubes. If repair is nec-

essary, replace the complete fuel tube assembly.

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING ANY FUEL SYSTEM HOSES,

FITTINGS OR LINES, THE FUEL SYSTEM PRES-

SURE MUST BE RELEASED. REFER TO THE FUEL

SYSTEM PRESSURE RELEASE PROCEDURE IN

THIS GROUP.DISCONNECTION/CONNECTION

(1) Perform fuel pressure release procedure. Refer

to Fuel Pressure Release Procedure in this section.

(2) Disconnect negative battery cable from battery

or auxiliary jumper terminal.

(3) Clean fitting of any foreign material before dis-

assembly.

(4) To release fuel system component from quick-

connect fitting, firmly push fitting towards compo-

nent being serviced while firmly pushing plastic

retainer ring into fitting (Fig. 25). With plastic ring

depressed, pull fitting from component.The plastic

retainer ring must be pressed squarely into fit-

ting body. If this retainer is cocked during

removal, it may be difficult to disconnect fit-

ting. Use an open-end wrench on shoulder of

plastic retainer ring to aid in disconnection.

(5) After disconnection, plastic retainer ring will

remain with quick-connect fitting connector body.

(6) Inspect fitting connector body, plastic retainer

ring and fuel system component for damage. Replace

as necessary.

(7) Prior to connecting quick-connect fitting to

component being serviced, check condition of fitting

and component. Clean parts with a lint-free cloth.

Lubricate with clean engine oil.

(8) Insert quick-connect fitting into component

being serviced until a click is felt.

(9) Verify a locked condition by firmly pulling on

fuel tube and fitting (15-30 lbs.).

(10) Connect negative battery cable to battery or

auxiliary jumper terminal.

(11) Use the DRB IIItscan tool ASD Fuel System

Test to pressurize the fuel system. Check for leaks.

ROLLOVER VALVE

DESCRIPTION

All vehicles have rollover valve(s) on top of the fuel

tank.

OPERATION

The valves prevent fuel flow through the fuel tank

vent valve hoses should the vehicle rollover.

The rollover valves on the fuel tank are not ser-

viceable.

Fig. 25 Plastic Retainer Ring Type Fitting

1 - FUEL TUBE

2 - QUICK CONNECT FITTING

3 - PUSH

4 - PLASTIC RETAINER

5 - PUSH

6 - PUSH

7 - PUSH

8 - PUSH

RSFUEL DELIVERY14-15

QUICK CONNECT FITTING (Continued)

ProCarManuals.com

Page 2116 of 2321

(5) Install the cup holder. Align the cup holder

assembly with the track and firmly slide shut to

engage retaining tang.

GLOVE BOX

REMOVAL

(1) Open glove box.

(2) Push in on sides of glove box bin and lower

door.

(3) Pivot glove box downward and disengage hinge

hooks from instrument panel.

(4) Remove glove box.

INSTALLATION

(1) Place glove box in position.

(2) Engage hinge hooks into instrument panel and

pivot glove box upward.

(3) Push in sides of glove box bin and snap glove

box assembly into instrument panel.

(4) Close glove box door.

GLOVE BOX LATCH

REMOVAL

(1) Open glove box.

(2) Push in on sides of glove box bin and lower

door.

(3) Pivot glove box downward and disengage hinge

hooks from instrument panel.

(4) Remove glove box.

(5) Remove the assembly screws.

(6) Disassemble the glove box.

(7) Separate the latch from the glove box assembly.

INSTALLATION

(1) Install the latch onto the glove box assembly.

(2) Assemble the glove box.

(3) Install the assembly screws.

(4) Engage hinge hooks into instrument panel and

pivot glove box upward.

(5) Push in sides of glove box bin and snap glove

box assembly into instrument panel.

(6) Close glove box door.

GLOVE BOX LATCH STRIKER

REMOVAL

(1) Open glove box door.

(2) Remove screws holding lock striker to instru-

ment panel.

(3) Remove glove box latch striker.

INSTALLATION

(1) Install the glove box latch striker.

(2) Install the screws holding latch striker to

instrument panel.

(3) Close glove box door.

INSTRUMENT PANEL

ASSEMBLY

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the lower console:

(a) Remove six retaining screws.

(b) Pull rearward and disconnect the auxiliary

power outlet.

(c) Remove lower console from vehicle.

(3) Remove the bolts holding the lower supports to

the instrument panel frame.

(4) Remove the bolts holding the lower supports to

the floor pan.

(5) Disconnect the wire connectors from the Pas-

senger Airbag.

(6) Remove the two screws to each right and left

cowl trim covers.

(7) Remove the both left and right side A-pillar

trim covers using a trim stick (special tool #C-4755)

or equivalent gently pry out on the trim covers and

remove.

(8) Remove the glove box:

(a) Push in on sides of glove box bin and lower

door.

(b) Pivot glove box downward and disengage

hinge hooks from instrument panel.

(c) Remove glove box from vehicle.

(9) Disconnect the antenna lead connector from

behind the glove box.

(10) Remove the four screws to the lower steering

column cover.

(11) Remove the eight screws to the plastic knee

blocker reinforcement.

(12) Unclip the Data Link Connector (DLC) from

the instrument panel reinforcement.

(13) Remove one screw to the left side instrument

panel silencer and remove.

(14) Disconnect the left side wiring:

(a) Brake switch.

(b) Main bulkhead connector.

(c) Five harness connectors.

(d) Driver airbag connector.

(15) Remove the two screws to the hood release

handle.

(16) Remove five screws to the left under column

instrument panel reinforcement brace and remove.

RSINSTRUMENT PANEL23 - 203

CUP HOLDER (Continued)

ProCarManuals.com

Page 2118 of 2321

(20) Install the two screws to the hood release

handle.

(21) Connect the left side wiring:

(a) Brake switch.

(b) Main bulkhead connector.

(c) Five harness connectors.

(d) Driver airbag connector.

(22) Install one screw to the left side instrument

panel silencer.

(23) Clip the Data Link Connector (DLC) to the

instrument panel reinforcement.

(24) Install the eight screws to the plastic knee

blocker reinforcement.

(25) Install the four screws to the lower steering

column cover.

(26) Install the glove box:

(a) Install glove box into the vehicle. Line up the

hinges and firmly snap together.

(b) Push in on sides of glove box bin and raise

door.

(27) Install the both left and right side A-pillar

trim covers. Position trim cover over slots and firmly

snap into place.

(28) Install the two screws to each right and left

cowl trim covers.

(29) Connect the wire connectors to the Passenger

Airbag.

(30) Install the bolts holding the lower supports to

the floor pan.

(31) Install the bolts holding the lower supports to

the instrument panel frame.

(32) Install the lower console:

(a) Install lower console to vehicle.

(b) Connect the auxiliary power outlet.

(c) Install the six retaining screws.

(33) Connect the battery negative cable.

INSTRUMENT PANEL CENTER

BEZEL

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove cup holder. Refer to Body, Instrument

Panel, Cup Holder, Removal.

(3) Insert the trim stick (special tool #C-4755) or

equivalent between access cover and center bezel.

(4) Carefully pry the access cover from the instru-

ment panel.

(5) Remove the cup holder track. Refer to Body,

Instrument Panel, Cup Holder, Removal.

(6) Using a trim stick or equivalent, gently pry out

on the edge of the instrument panel center bezel and

pull outward.(7) Disconnect the wire connectors to the accessory

switches and HVAC control.

(8) Remove the instrument panel center bezel from

the vehicle.

INSTALLATION

(1) Install the instrument panel center bezel from

the vehicle.

(2) Connect the wire connectors to the accessory

switches and HVAC control.

(3) Position the center bezel over the retaining

slots and firmly snap the instrument panel center

bezel into place.

(4) Install the cup holder track. Refer to Body,

Instrument Panel, Cup Holder, Installation.

(5) Position the center bezel over the retaining

slots and firmly snap into place.

(6) Install cup holder. Refer to Body, Instrument

Panel, Cup Holder, Installation.

(7) Connect the battery negative cable.

INSTRUMENT PANEL END

COVER

REMOVAL

(1) Open passenger side front door.

(2) Place fingers in end cover grille, and with a

firm outboard pulling motion, disengage clips holding

end cover to instrument panel.

INSTALLATION

(1) Position end cover over retaining slots and

firmly snap into place.

(2) Close passenger side front door.

INSTRUMENT PANEL TOP

COVER

REMOVAL

(1) Remove A-pillar trim. Using a trim stick (spe-

cial tool #C-4755) or equivalent, gently pry out and

remove.

(2) Using a trim stick, disengage clips holding rear

edge of top cover to instrument panel.

NOTE: The Instrument Panel Top Cover may be

hard to unsnap from the instrument panel. Be sure

not to mar, scuff, or damage the instrument panel

pad.

(3) Pull top cover rearward to disengage hooks

holding front of top cover to instrument panel.

(4) Remove top cover from vehicle.

RSINSTRUMENT PANEL23 - 205

INSTRUMENT PANEL ASSEMBLY (Continued)

ProCarManuals.com