jump start DODGE TOWN AND COUNTRY 2001 Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: TOWN AND COUNTRY, Model: DODGE TOWN AND COUNTRY 2001Pages: 2321, PDF Size: 68.09 MB

Page 22 of 2321

LUBRICATION & MAINTENANCE

TABLE OF CONTENTS

page page

LUBRICATION & MAINTENANCE

SPECIFICATIONS.........................1

INTERNATIONAL SYMBOLS

DESCRIPTION............................1

PARTS & LUBRICANT RECOMMENDATION

STANDARD PROCEDURE...................2

LUBRICANT CLASSIFICATIONS.............2

PARTS AND LUBRICANT

RECOMMENDATIONS....................2

FLUID TYPES

DESCRIPTION............................3

OPERATION.............................7

FLUID FILL/CHECK LOCATIONS

DESCRIPTION............................7MAINTENANCE SCHEDULES

DESCRIPTION............................7

HOISTING

STANDARD PROCEDURE..................16

HOISTING............................16

JUMP STARTING

STANDARD PROCEDURE..................16

JUMP STARTING.......................16

TOWING

STANDARD PROCEDURE..................17

TOWING RECOMMENDATIONS............17

LUBRICATION &

MAINTENANCE

SPECIFICATIONS

SPECIFICATIONS - FLUID CAPACITIES

DESCRIPTION SPECIFICATION

Fuel Tank 75 L (20 gal.)

Engine Oil* - 2.4L 4.7 L (5.0 qts.)

Engine Oil* - 3.3/3.8L 4.0 L (4.5 qts.)

Cooling System** - 2.4L 10.7 L (11.4 qts.)

Cooling System** -

3.3/3.8L without Rear

Heater12.6 L (13.4 qts.)

Cooling System** -

3.3/3.8L with Rear Heater15.4 L (16.3 qts.)

Automatic Transaxle -

Service Fill3.8 L (4.0 qts.)

Automatic Transaxle -

31TH Overhaul Fill8.6 L (9.1 qts.)

Automatic Transaxle -

41TE Overhaul Fill9.2 L (9.7 qts.)

AWD Power Transfer Unit 1.15 L (2.4 pts.)

Power Steering 1.2 L (2.5 pts.)

AWD Bi-directional

Overrunning Clutch0.575 L (1.22 pts.)

DESCRIPTION SPECIFICATION

AWD Rear Carrier 0.7 L (1.48 pts.)

*(includes oil filter)

**(includes heater and recovery/reserve bottle)

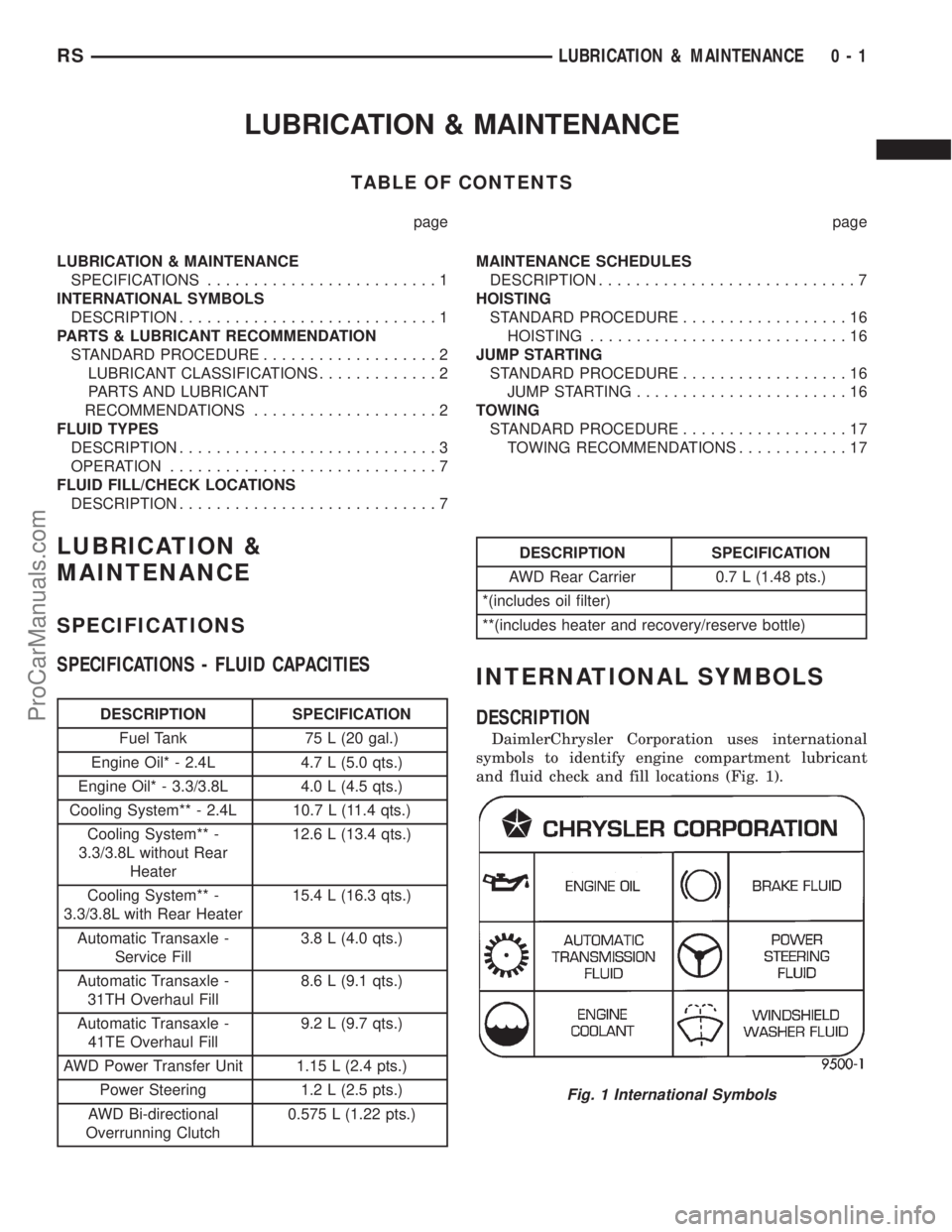

INTERNATIONAL SYMBOLS

DESCRIPTION

DaimlerChrysler Corporation uses international

symbols to identify engine compartment lubricant

and fluid check and fill locations (Fig. 1).

Fig. 1 International Symbols

RSLUBRICATION & MAINTENANCE0-1

ProCarManuals.com

Page 37 of 2321

Inspection and service should also be performed

anytime a malfunction is observed or suspected.

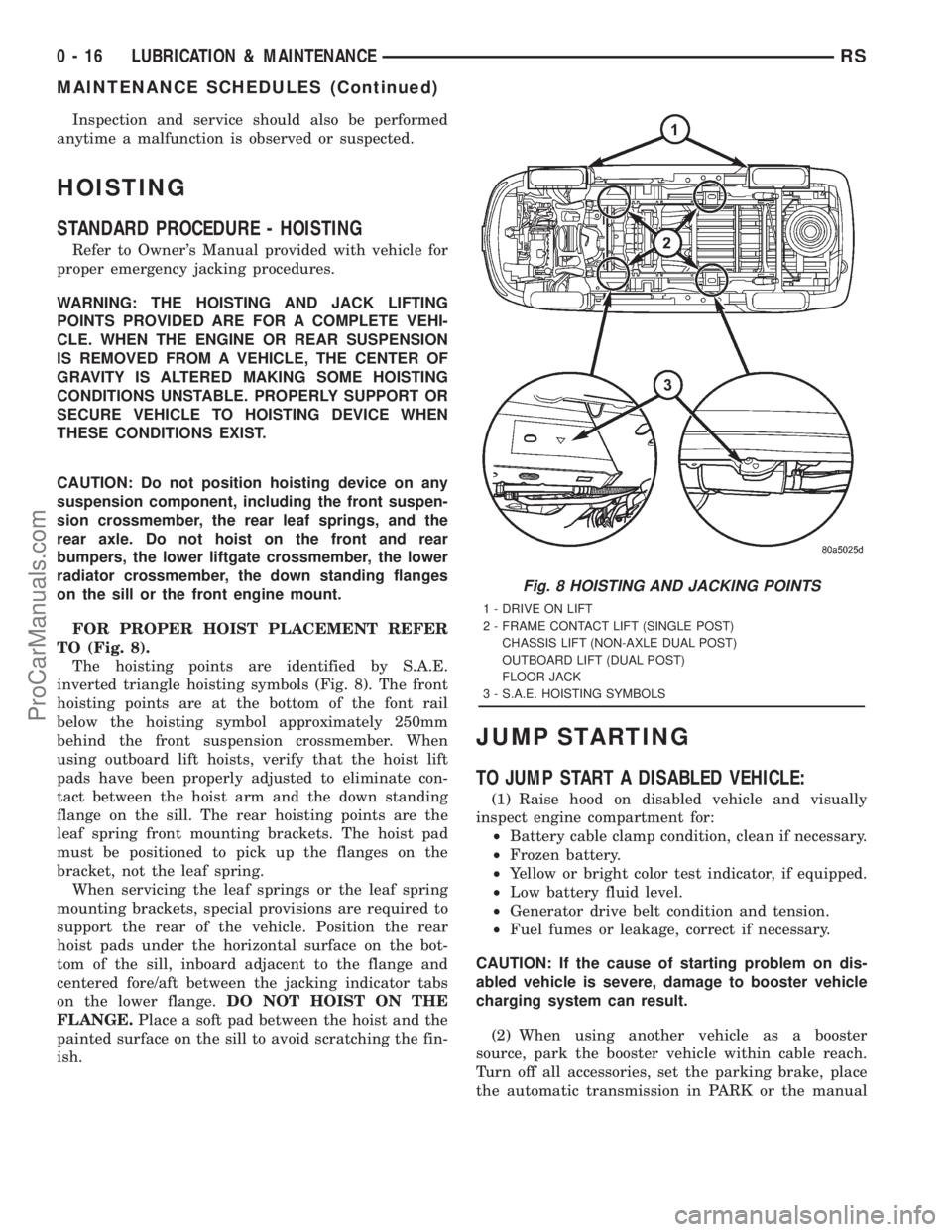

HOISTING

STANDARD PROCEDURE - HOISTING

Refer to Owner's Manual provided with vehicle for

proper emergency jacking procedures.

WARNING: THE HOISTING AND JACK LIFTING

POINTS PROVIDED ARE FOR A COMPLETE VEHI-

CLE. WHEN THE ENGINE OR REAR SUSPENSION

IS REMOVED FROM A VEHICLE, THE CENTER OF

GRAVITY IS ALTERED MAKING SOME HOISTING

CONDITIONS UNSTABLE. PROPERLY SUPPORT OR

SECURE VEHICLE TO HOISTING DEVICE WHEN

THESE CONDITIONS EXIST.

CAUTION: Do not position hoisting device on any

suspension component, including the front suspen-

sion crossmember, the rear leaf springs, and the

rear axle. Do not hoist on the front and rear

bumpers, the lower liftgate crossmember, the lower

radiator crossmember, the down standing flanges

on the sill or the front engine mount.

FOR PROPER HOIST PLACEMENT REFER

TO (Fig. 8).

The hoisting points are identified by S.A.E.

inverted triangle hoisting symbols (Fig. 8). The front

hoisting points are at the bottom of the font rail

below the hoisting symbol approximately 250mm

behind the front suspension crossmember. When

using outboard lift hoists, verify that the hoist lift

pads have been properly adjusted to eliminate con-

tact between the hoist arm and the down standing

flange on the sill. The rear hoisting points are the

leaf spring front mounting brackets. The hoist pad

must be positioned to pick up the flanges on the

bracket, not the leaf spring.

When servicing the leaf springs or the leaf spring

mounting brackets, special provisions are required to

support the rear of the vehicle. Position the rear

hoist pads under the horizontal surface on the bot-

tom of the sill, inboard adjacent to the flange and

centered fore/aft between the jacking indicator tabs

on the lower flange.DO NOT HOIST ON THE

FLANGE.Place a soft pad between the hoist and the

painted surface on the sill to avoid scratching the fin-

ish.

JUMP STARTING

TO JUMP START A DISABLED VEHICLE:

(1) Raise hood on disabled vehicle and visually

inspect engine compartment for:

²Battery cable clamp condition, clean if necessary.

²Frozen battery.

²Yellow or bright color test indicator, if equipped.

²Low battery fluid level.

²Generator drive belt condition and tension.

²Fuel fumes or leakage, correct if necessary.

CAUTION: If the cause of starting problem on dis-

abled vehicle is severe, damage to booster vehicle

charging system can result.

(2) When using another vehicle as a booster

source, park the booster vehicle within cable reach.

Turn off all accessories, set the parking brake, place

the automatic transmission in PARK or the manual

Fig. 8 HOISTING AND JACKING POINTS

1 - DRIVE ON LIFT

2 - FRAME CONTACT LIFT (SINGLE POST)

CHASSIS LIFT (NON-AXLE DUAL POST)

OUTBOARD LIFT (DUAL POST)

FLOOR JACK

3 - S.A.E. HOISTING SYMBOLS

0 - 16 LUBRICATION & MAINTENANCERS

MAINTENANCE SCHEDULES (Continued)

ProCarManuals.com

Page 38 of 2321

transmission in NEUTRAL and turn the ignition

OFF.

(3) On disabled vehicle, place gear selector in park

or neutral and set park brake. Turn off all accesso-

ries.

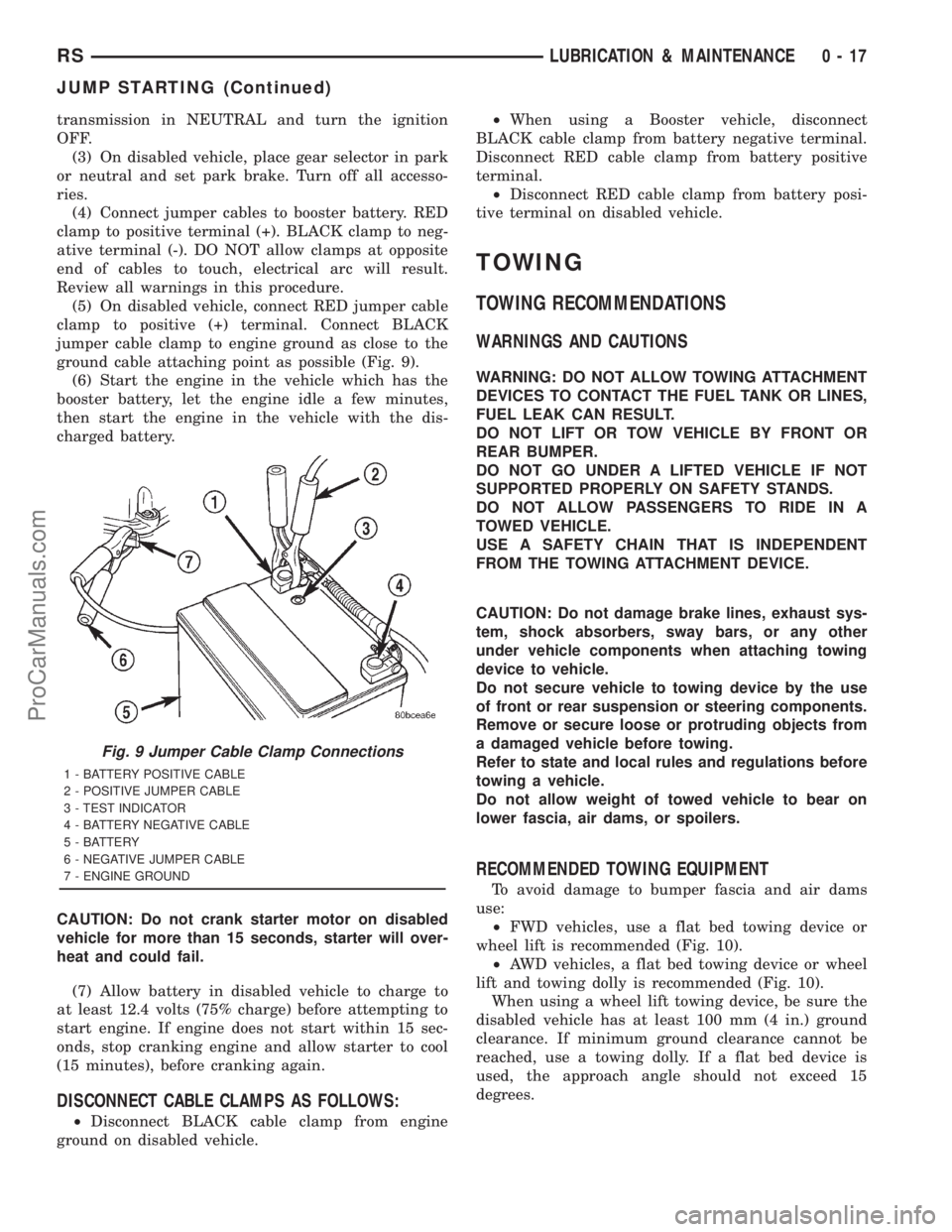

(4) Connect jumper cables to booster battery. RED

clamp to positive terminal (+). BLACK clamp to neg-

ative terminal (-). DO NOT allow clamps at opposite

end of cables to touch, electrical arc will result.

Review all warnings in this procedure.

(5) On disabled vehicle, connect RED jumper cable

clamp to positive (+) terminal. Connect BLACK

jumper cable clamp to engine ground as close to the

ground cable attaching point as possible (Fig. 9).

(6) Start the engine in the vehicle which has the

booster battery, let the engine idle a few minutes,

then start the engine in the vehicle with the dis-

charged battery.

CAUTION: Do not crank starter motor on disabled

vehicle for more than 15 seconds, starter will over-

heat and could fail.

(7) Allow battery in disabled vehicle to charge to

at least 12.4 volts (75% charge) before attempting to

start engine. If engine does not start within 15 sec-

onds, stop cranking engine and allow starter to cool

(15 minutes), before cranking again.

DISCONNECT CABLE CLAMPS AS FOLLOWS:

²Disconnect BLACK cable clamp from engine

ground on disabled vehicle.²When using a Booster vehicle, disconnect

BLACK cable clamp from battery negative terminal.

Disconnect RED cable clamp from battery positive

terminal.

²Disconnect RED cable clamp from battery posi-

tive terminal on disabled vehicle.

TOWING

TOWING RECOMMENDATIONS

WARNINGS AND CAUTIONS

WARNING: DO NOT ALLOW TOWING ATTACHMENT

DEVICES TO CONTACT THE FUEL TANK OR LINES,

FUEL LEAK CAN RESULT.

DO NOT LIFT OR TOW VEHICLE BY FRONT OR

REAR BUMPER.

DO NOT GO UNDER A LIFTED VEHICLE IF NOT

SUPPORTED PROPERLY ON SAFETY STANDS.

DO NOT ALLOW PASSENGERS TO RIDE IN A

TOWED VEHICLE.

USE A SAFETY CHAIN THAT IS INDEPENDENT

FROM THE TOWING ATTACHMENT DEVICE.

CAUTION: Do not damage brake lines, exhaust sys-

tem, shock absorbers, sway bars, or any other

under vehicle components when attaching towing

device to vehicle.

Do not secure vehicle to towing device by the use

of front or rear suspension or steering components.

Remove or secure loose or protruding objects from

a damaged vehicle before towing.

Refer to state and local rules and regulations before

towing a vehicle.

Do not allow weight of towed vehicle to bear on

lower fascia, air dams, or spoilers.

RECOMMENDED TOWING EQUIPMENT

To avoid damage to bumper fascia and air dams

use:

²FWD vehicles, use a flat bed towing device or

wheel lift is recommended (Fig. 10).

²AWD vehicles, a flat bed towing device or wheel

lift and towing dolly is recommended (Fig. 10).

When using a wheel lift towing device, be sure the

disabled vehicle has at least 100 mm (4 in.) ground

clearance. If minimum ground clearance cannot be

reached, use a towing dolly. If a flat bed device is

used, the approach angle should not exceed 15

degrees.

Fig. 9 Jumper Cable Clamp Connections

1 - BATTERY POSITIVE CABLE

2 - POSITIVE JUMPER CABLE

3 - TEST INDICATOR

4 - BATTERY NEGATIVE CABLE

5 - BATTERY

6 - NEGATIVE JUMPER CABLE

7 - ENGINE GROUND

RSLUBRICATION & MAINTENANCE0-17

JUMP STARTING (Continued)

ProCarManuals.com

Page 40 of 2321

LUBRICATION & MAINTENANCE - RG - 2.5 L TURBO

DIESEL

TABLE OF CONTENTS

page page

LUBRICATION & MAINTENANCE - RG - 2.5 L

TURBO DIESEL

SPECIFICATIONS.........................1

INTERNATIONAL SYMBOLS

DESCRIPTION............................2

FLUID TYPES

DESCRIPTION............................2

FLUID FILL/CHECK LOCATIONS

DESCRIPTION............................5

MAINTENANCE SCHEDULES

DESCRIPTION............................5HOISTING

STANDARD PROCEDURE...................7

HOISTING.............................7

JUMP STARTING

STANDARD PROCEDURE...................8

JUMP STARTING........................8

TOWING

STANDARD PROCEDURE...................8

TOWING RECOMMENDATIONS.............8

LUBRICATION &

MAINTENANCE - RG - 2.5 L

TURBO DIESEL

SPECIFICATIONS

SPECIFICATIONS - FLUID CAPACITIES

DESCRIPTION SPECIFICATION

Fuel Tank 75 L (20 gal.)

Fuel Tank (Diesel) 75 L (20 gal.)

Engine Oil* - 2.4 L 4.7 L (5.0 qts.)

Engine Oil* - 3.3 L 4.0 L (4.5 qts.)

Engine Oil* - 2.5 L 5.22 L (5.52 qts.)

Cooling System** - 2.4 L 10.7 L (11.4 qts.)

Cooling System** - 3.3 L

without Auxiliary Heater12.6 L (13.4 qts.)

Cooling System** - 3.3 L

with Auxiliary Heater15.4 L (16.3 qts.)

Cooling System** - 2.5 L

Turbo Diesel without

Auxiliary Heater13.8 L (14.6 qts.)

DESCRIPTION SPECIFICATION

Cooling System** - 2.5 L

Turbo Diesel with

Auxiliary Heater16.6 L (17.5 qts.)

Automatic Transaxle -

Service Fill3.8 L (4.0 qts.)

Automatic Transaxle -

31TH Overhaul Fill8.6 L (9.1 qts.)

Automatic Transaxle -

41TE Overhaul Fill9.2 L (9.7 qts.)

Manual Transaxle (T850

5-speed)2.4-2.7 L (2.5-2.9 qts.)

AWD Power Transfer Unit 1.15 L (2.4 pts.)

Power Steering 1.2 L (2.5 pts.)

AWD Bi-directional

Overrunning Clutch0.575 L (1.22 pts.)

AWD Rear Carrier 0.7 L (1.48 pts.)

*(includes oil filter)

**(includes heater and recovery/reserve bottle)

RGLUBRICATION & MAINTENANCE - RG - 2.5 L TURBO DIESEL0a-1

ProCarManuals.com

Page 47 of 2321

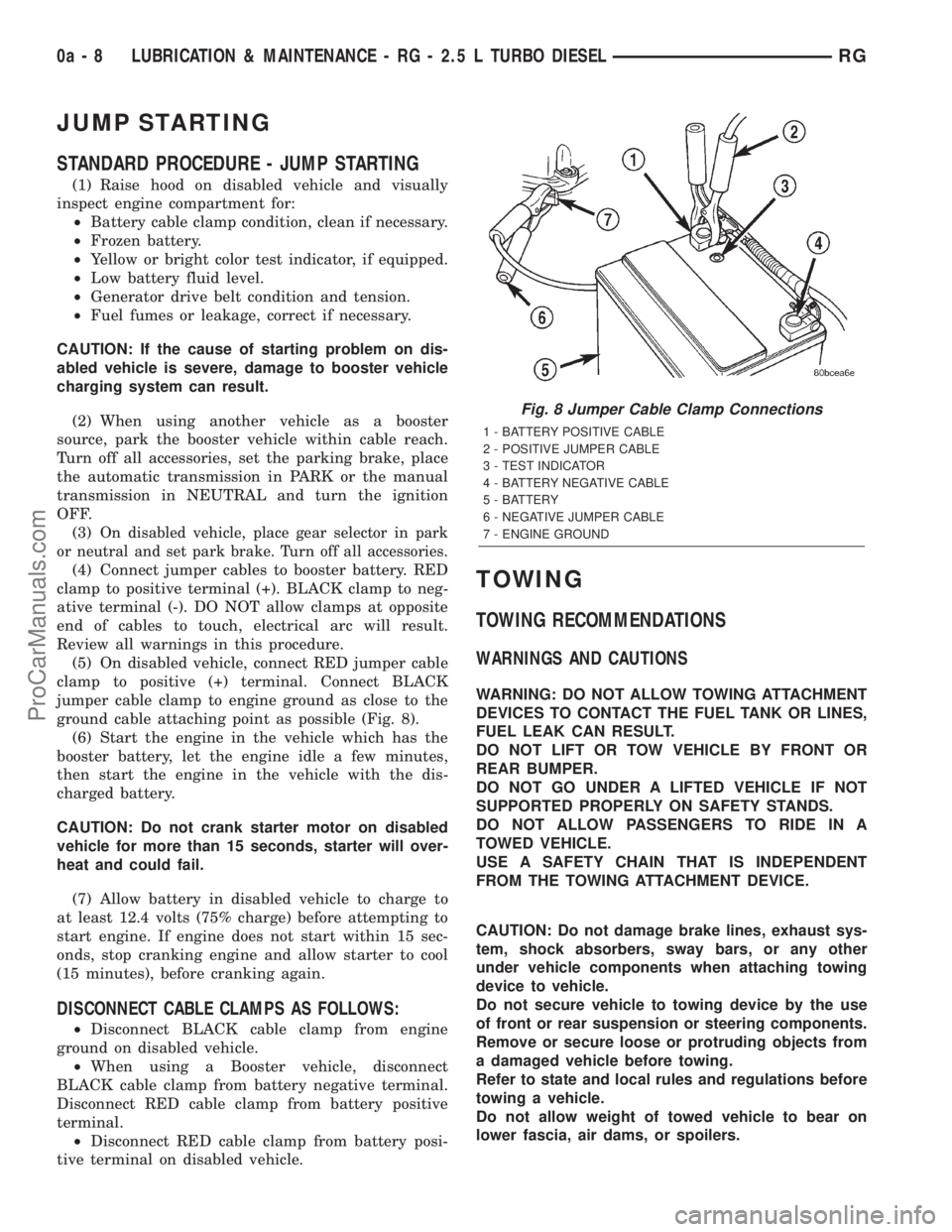

JUMP STARTING

STANDARD PROCEDURE - JUMP STARTING

(1) Raise hood on disabled vehicle and visually

inspect engine compartment for:

²Battery cable clamp condition, clean if necessary.

²Frozen battery.

²Yellow or bright color test indicator, if equipped.

²Low battery fluid level.

²Generator drive belt condition and tension.

²Fuel fumes or leakage, correct if necessary.

CAUTION: If the cause of starting problem on dis-

abled vehicle is severe, damage to booster vehicle

charging system can result.

(2) When using another vehicle as a booster

source, park the booster vehicle within cable reach.

Turn off all accessories, set the parking brake, place

the automatic transmission in PARK or the manual

transmission in NEUTRAL and turn the ignition

OFF.

(3)

On disabled vehicle, place gear selector in park

or neutral and set park brake. Turn off all accessories.

(4) Connect jumper cables to booster battery. RED

clamp to positive terminal (+). BLACK clamp to neg-

ative terminal (-). DO NOT allow clamps at opposite

end of cables to touch, electrical arc will result.

Review all warnings in this procedure.

(5) On disabled vehicle, connect RED jumper cable

clamp to positive (+) terminal. Connect BLACK

jumper cable clamp to engine ground as close to the

ground cable attaching point as possible (Fig. 8).

(6) Start the engine in the vehicle which has the

booster battery, let the engine idle a few minutes,

then start the engine in the vehicle with the dis-

charged battery.

CAUTION: Do not crank starter motor on disabled

vehicle for more than 15 seconds, starter will over-

heat and could fail.

(7) Allow battery in disabled vehicle to charge to

at least 12.4 volts (75% charge) before attempting to

start engine. If engine does not start within 15 sec-

onds, stop cranking engine and allow starter to cool

(15 minutes), before cranking again.

DISCONNECT CABLE CLAMPS AS FOLLOWS:

²Disconnect BLACK cable clamp from engine

ground on disabled vehicle.

²When using a Booster vehicle, disconnect

BLACK cable clamp from battery negative terminal.

Disconnect RED cable clamp from battery positive

terminal.

²Disconnect RED cable clamp from battery posi-

tive terminal on disabled vehicle.

TOWING

TOWING RECOMMENDATIONS

WARNINGS AND CAUTIONS

WARNING: DO NOT ALLOW TOWING ATTACHMENT

DEVICES TO CONTACT THE FUEL TANK OR LINES,

FUEL LEAK CAN RESULT.

DO NOT LIFT OR TOW VEHICLE BY FRONT OR

REAR BUMPER.

DO NOT GO UNDER A LIFTED VEHICLE IF NOT

SUPPORTED PROPERLY ON SAFETY STANDS.

DO NOT ALLOW PASSENGERS TO RIDE IN A

TOWED VEHICLE.

USE A SAFETY CHAIN THAT IS INDEPENDENT

FROM THE TOWING ATTACHMENT DEVICE.

CAUTION: Do not damage brake lines, exhaust sys-

tem, shock absorbers, sway bars, or any other

under vehicle components when attaching towing

device to vehicle.

Do not secure vehicle to towing device by the use

of front or rear suspension or steering components.

Remove or secure loose or protruding objects from

a damaged vehicle before towing.

Refer to state and local rules and regulations before

towing a vehicle.

Do not allow weight of towed vehicle to bear on

lower fascia, air dams, or spoilers.

Fig. 8 Jumper Cable Clamp Connections

1 - BATTERY POSITIVE CABLE

2 - POSITIVE JUMPER CABLE

3 - TEST INDICATOR

4 - BATTERY NEGATIVE CABLE

5 - BATTERY

6 - NEGATIVE JUMPER CABLE

7 - ENGINE GROUND

0a - 8 LUBRICATION & MAINTENANCE - RG - 2.5 L TURBO DIESELRG

ProCarManuals.com

Page 389 of 2321

BATTERY SYSTEM

DESCRIPTION

A single 12-volt battery system is standard factory-

installed equipment on this model. All of the compo-

nents of the battery system are located within the

engine compartment of the vehicle. The service infor-

mation for the battery system in this vehicle covers

the following related components, which are covered

in further detail elsewhere in this service manual:

²Battery- The storage battery provides a reli-

able means of storing a renewable source of electrical

energy within the vehicle.

²Battery Cable- The battery cables connect the

battery terminal posts to the vehicle electrical sys-

tem.

²Battery Holddown- The battery holddown

hardware secures the battery in the battery tray in

the engine compartment.

²Battery Thermoguard- The battery thermo-

guard insulates the battery to protect it from engine

compartment temperature extremes.

²Battery Tray- The battery tray provides a

secure mounting location in the vehicle for the bat-

tery and an anchor point for the battery holddown

hardware.

For battery system maintenance schedules and

jump starting procedures, see the owner's manual in

the vehicle glove box. Optionally, refer to Lubrication

and Maintanance for the recommended battery main-

tenance schedules and for the proper battery jump

starting procedures. While battery charging can be

considered a maintenance procedure, the battery

charging procedures and related information are

located in the standard procedures section of this ser-

vice manual. This was done because the battery must

be fully-charged before any battery system diagnosis

or testing procedures can be performed. Refer to

Standard procedures for the proper battery charging

procedures.

OPERATION

The battery system is designed to provide a safe,

efficient, reliable and mobile means of delivering and

storing electrical energy. This electrical energy is

required to operate the engine starting system, as

well as to operate many of the other vehicle acces-sory systems for limited durations while the engine

and/or the charging system are not operating. The

battery system is also designed to provide a reserve

of electrical energy to supplement the charging sys-

tem for short durations while the engine is running

and the electrical current demands of the vehicle

exceed the output of the charging system. In addition

to delivering, and storing electrical energy for the

vehicle, the battery system serves as a capacitor and

voltage stabilizer for the vehicle electrical system. It

absorbs most abnormal or transient voltages caused

by the switching of any of the electrical components

or circuits in the vehicle.

DIAGNOSIS AND TESTING - BATTERY SYSTEM

The battery, starting, and charging systems in the

vehicle operate with one another and must be tested

as a single complete system. In order for the engine

to start and the battery to charge properly, all of the

components that are used in these systems must per-

form within specifications. It is important that the

battery, starting, and charging systems be thoroughly

tested and inspected any time a battery needs to be

charged or replaced. The cause of abnormal battery

discharge, overcharging or early battery failure must

be diagnosed and corrected before a battery is

replaced and before a vehicle is returned to service.

The service information for these systems has been

separated within this service manual to make it eas-

ier to locate the specific information you are seeking.

However, when attempting to diagnose any of these

systems, it is important that you keep their interde-

pendency in mind.

The diagnostic procedures used for the battery,

starting, and charging systems include the most

basic conventional diagnostic methods, to the more

sophisticated On-Board Diagnostics (OBD) built into

the Powertrain Control Module (PCM). Use of an

induction-type milliampere ammeter, a volt/ohmme-

ter, a battery charger, a carbon pile rheostat (load

tester) and a 12-volt test lamp may be required. All

OBD-sensed systems are monitored by the PCM.

Each monitored circuit is assigned a Diagnostic Trou-

ble Code (DTC). The PCM will store a DTC in elec-

tronic memory for any failure it detects. Refer to

Charging System for the proper charging system on-

board diagnostic test procedures.

8F - 2 BATTERY SYSTEMRS

ProCarManuals.com

Page 415 of 2321

²Battery- Visually inspect the battery for indi-

cations of physical damage and loose or corroded

cable connections. Determine the state-of-charge and

cranking capacity of the battery. Charge or replace

the battery, if required. Refer to the Battery section

for more information.

²Ignition Switch- Visually inspect the ignition

switch for indications of physical damage and loose

or corroded wire harness connections.

²Transmission Range Sensor- Visually inspect

the transmission range sensor for indications of phys-

ical damage and loose or corroded wire harness con-

nections.

²Starter Relay- Visually inspect the starter

relay for indications of physical damage and loose or

corroded wire harness connections.²Starter- Visually inspect the starter for indica-

tions of physical damage and loose or corroded wire

harness connections.

²Starter Solenoid- Visually inspect the starter

solenoid for indications of physical damage and loose

or corroded wire harness connections.

²Wiring- Visually inspect the wire harness for

damage. Repair or replace any faulty wiring, as

required. Check for loose or corroded wire harness

connections at main engine ground and remote jump

post.

²Power Distribution Center (PDC)- Visually

inspect the B+ connections at the PDC for physical

damage and loose or corroded harness connections.

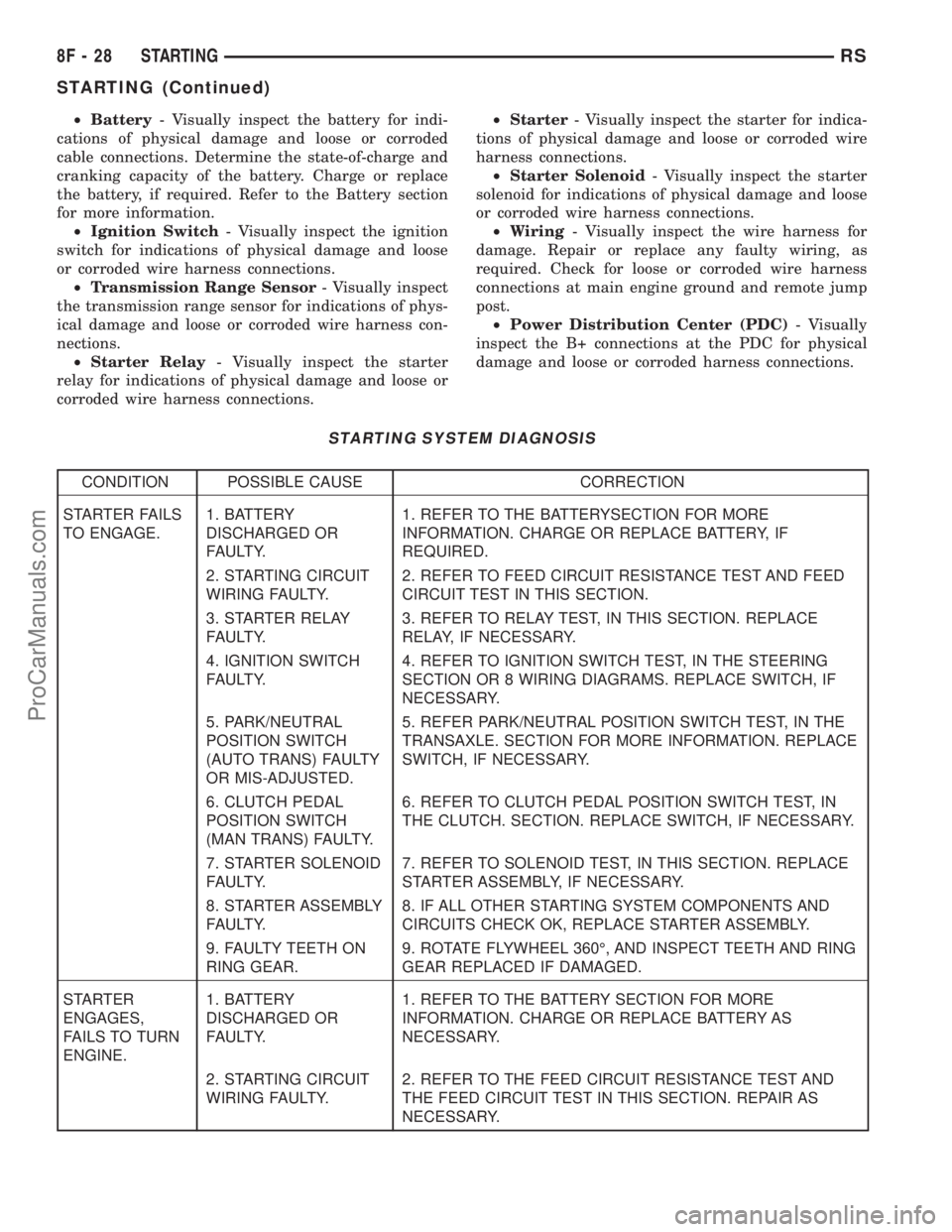

STARTING SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSE CORRECTION

STARTER FAILS

TO ENGAGE.1. BATTERY

DISCHARGED OR

FAULTY.1. REFER TO THE BATTERYSECTION FOR MORE

INFORMATION. CHARGE OR REPLACE BATTERY, IF

REQUIRED.

2. STARTING CIRCUIT

WIRING FAULTY.2. REFER TO FEED CIRCUIT RESISTANCE TEST AND FEED

CIRCUIT TEST IN THIS SECTION.

3. STARTER RELAY

FAULTY.3. REFER TO RELAY TEST, IN THIS SECTION. REPLACE

RELAY, IF NECESSARY.

4. IGNITION SWITCH

FAULTY.4. REFER TO IGNITION SWITCH TEST, IN THE STEERING

SECTION OR 8 WIRING DIAGRAMS. REPLACE SWITCH, IF

NECESSARY.

5. PARK/NEUTRAL

POSITION SWITCH

(AUTO TRANS) FAULTY

OR MIS-ADJUSTED.5. REFER PARK/NEUTRAL POSITION SWITCH TEST, IN THE

TRANSAXLE. SECTION FOR MORE INFORMATION. REPLACE

SWITCH, IF NECESSARY.

6. CLUTCH PEDAL

POSITION SWITCH

(MAN TRANS) FAULTY.6. REFER TO CLUTCH PEDAL POSITION SWITCH TEST, IN

THE CLUTCH. SECTION. REPLACE SWITCH, IF NECESSARY.

7. STARTER SOLENOID

FAULTY.7. REFER TO SOLENOID TEST, IN THIS SECTION. REPLACE

STARTER ASSEMBLY, IF NECESSARY.

8. STARTER ASSEMBLY

FAULTY.8. IF ALL OTHER STARTING SYSTEM COMPONENTS AND

CIRCUITS CHECK OK, REPLACE STARTER ASSEMBLY.

9. FAULTY TEETH ON

RING GEAR.9. ROTATE FLYWHEEL 360É, AND INSPECT TEETH AND RING

GEAR REPLACED IF DAMAGED.

STARTER

ENGAGES,

FAILS TO TURN

ENGINE.1. BATTERY

DISCHARGED OR

FAULTY.1. REFER TO THE BATTERY SECTION FOR MORE

INFORMATION. CHARGE OR REPLACE BATTERY AS

NECESSARY.

2. STARTING CIRCUIT

WIRING FAULTY.2. REFER TO THE FEED CIRCUIT RESISTANCE TEST AND

THE FEED CIRCUIT TEST IN THIS SECTION. REPAIR AS

NECESSARY.

8F - 28 STARTINGRS

STARTING (Continued)

ProCarManuals.com

Page 417 of 2321

(5) Connect a remote starter switch or a jumper

wire between the remote battery positive post and

terminal 87 of the starter relay connector.

(a) If engine cranks, starter/starter solenoid is

good. Go to the Starter Relay Test.

(b) If engine does not crank or solenoid chatters,

check wiring and connectors from starter relay to

starter solenoid for loose or corroded connections.

Particularly at starter terminals.

(c) Repeat test. If engine still fails to crank prop-

erly, trouble is within starter or starter mounted

solenoid, and replace starter.

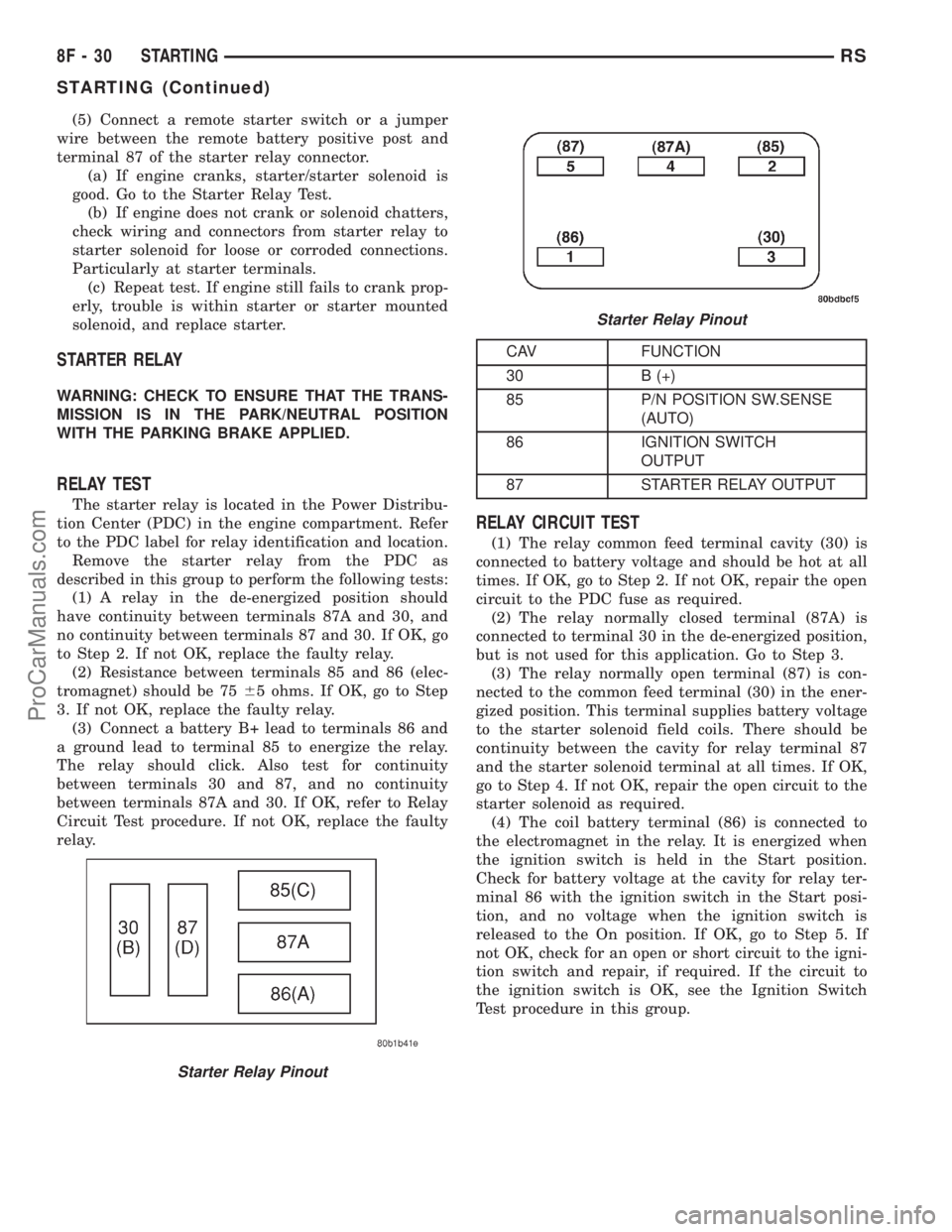

STARTER RELAY

WARNING: CHECK TO ENSURE THAT THE TRANS-

MISSION IS IN THE PARK/NEUTRAL POSITION

WITH THE PARKING BRAKE APPLIED.

RELAY TEST

The starter relay is located in the Power Distribu-

tion Center (PDC) in the engine compartment. Refer

to the PDC label for relay identification and location.

Remove the starter relay from the PDC as

described in this group to perform the following tests:

(1) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 2. If not OK, replace the faulty relay.

(2) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 7565 ohms. If OK, go to Step

3. If not OK, replace the faulty relay.

(3) Connect a battery B+ lead to terminals 86 and

a ground lead to terminal 85 to energize the relay.

The relay should click. Also test for continuity

between terminals 30 and 87, and no continuity

between terminals 87A and 30. If OK, refer to Relay

Circuit Test procedure. If not OK, replace the faulty

relay.

CAV FUNCTION

30 B (+)

85 P/N POSITION SW.SENSE

(AUTO)

86 IGNITION SWITCH

OUTPUT

87 STARTER RELAY OUTPUT

RELAY CIRCUIT TEST

(1) The relay common feed terminal cavity (30) is

connected to battery voltage and should be hot at all

times. If OK, go to Step 2. If not OK, repair the open

circuit to the PDC fuse as required.

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position,

but is not used for this application. Go to Step 3.

(3) The relay normally open terminal (87) is con-

nected to the common feed terminal (30) in the ener-

gized position. This terminal supplies battery voltage

to the starter solenoid field coils. There should be

continuity between the cavity for relay terminal 87

and the starter solenoid terminal at all times. If OK,

go to Step 4. If not OK, repair the open circuit to the

starter solenoid as required.

(4) The coil battery terminal (86) is connected to

the electromagnet in the relay. It is energized when

the ignition switch is held in the Start position.

Check for battery voltage at the cavity for relay ter-

minal 86 with the ignition switch in the Start posi-

tion, and no voltage when the ignition switch is

released to the On position. If OK, go to Step 5. If

not OK, check for an open or short circuit to the igni-

tion switch and repair, if required. If the circuit to

the ignition switch is OK, see the Ignition Switch

Test procedure in this group.

Starter Relay Pinout

Starter Relay Pinout

8F - 30 STARTINGRS

STARTING (Continued)

ProCarManuals.com

Page 636 of 2321

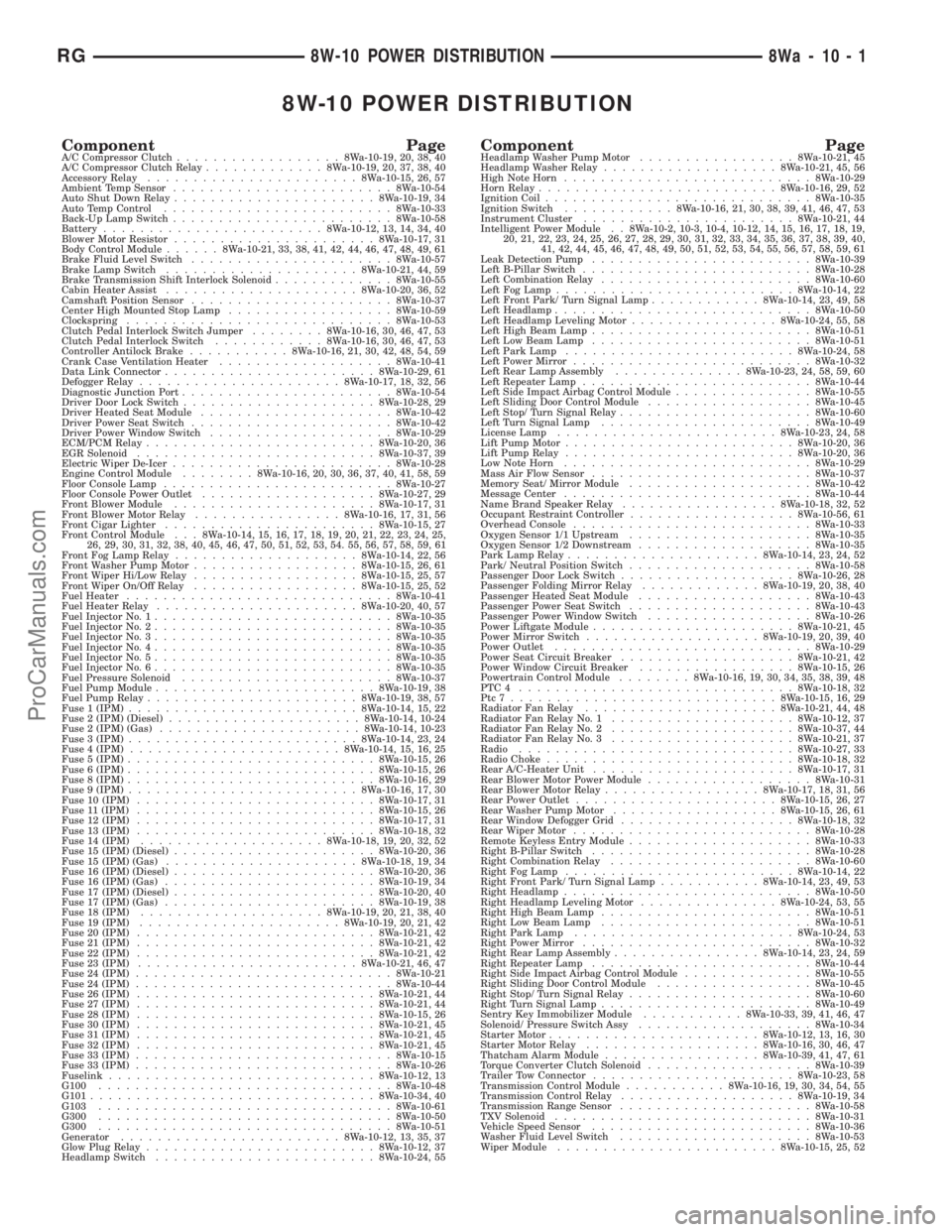

8W-10 POWER DISTRIBUTION

Component PageA/C Compressor Clutch..................8Wa-10-19, 20, 38, 40

A/C Compressor Clutch Relay.............8Wa-10-19, 20, 37, 38, 40

Accessory Relay.......................8Wa-10-15, 26, 57

Ambient Temp Sensor........................8Wa-10-54

Auto Shut Down Relay......................8Wa-10-19, 34

Auto Temp Control.........................8Wa-10-33

Back-Up Lamp Switch........................8Wa-10-58

Battery........................8Wa-10-12, 13, 14, 34, 40

Blower Motor Resistor......................8Wa-10-17, 31

Body Control Module......8Wa-10-21, 33, 38, 41, 42, 44, 46, 47, 48, 49, 61

Brake Fluid Level Switch......................8Wa-10-57

Brake Lamp Switch.....................8Wa-10-21, 44, 59

Brake Transmission Shift Interlock Solenoid.............8Wa-10-55

Cabin Heater Assist.....................8Wa-10-20, 36, 52

Camshaft Position Sensor......................8Wa-10-37

Center High Mounted Stop Lamp..................8Wa-10-59

Clockspring.............................8Wa-10-53

Clutch Pedal Interlock Switch Jumper........8Wa-10-16, 30, 46, 47, 53

Clutch Pedal Interlock Switch............8Wa-10-16, 30, 46, 47, 53

Controller Antilock Brake...........8Wa-10-16, 21, 30, 42, 48, 54, 59

Crank Case Ventilation Heater...................8Wa-10-41

Data Link Connector.......................8Wa-10-29, 61

Defogger Relay......................8Wa-10-17, 18, 32, 56

Diagnostic Junction Port.......................8Wa-10-54

Driver Door Lock Switch.....................8Wa-10-28, 29

Driver Heated Seat Module.....................8Wa-10-42

Driver Power Seat Switch......................8Wa-10-42

Driver Power Window Switch....................8Wa-10-29

ECM/PCM Relay.........................8Wa-10-20, 36

EGR Solenoid..........................8Wa-10-37, 39

Electric Wiper De-Icer........................8Wa-10-28

Engine Control Module........8Wa-10-16, 20, 30, 36, 37, 40, 41, 58, 59

Floor Console Lamp.........................8Wa-10-27

Floor Console Power Outlet...................8Wa-10-27, 29

Front Blower Module......................8Wa-10-17, 31

Front Blower Motor Relay................8Wa-10-16, 17, 31, 56

Front Cigar Lighter.......................8Wa-10-15, 27

Front Control Module . . . 8Wa-10-14, 15, 16, 17, 18, 19, 20, 21, 22, 23, 24, 25,

26, 29, 30, 31, 32, 38, 40, 45, 46, 47, 50, 51, 52, 53, 54. 55, 56, 57, 58, 59, 61

Front Fog Lamp Relay....................8Wa-10-14, 22, 56

Front Washer Pump Motor..................8Wa-10-15, 26, 61

Front Wiper Hi/Low Relay..................8Wa-10-15, 25, 57

Front Wiper On/Off Relay..................8Wa-10-15, 25, 52

Fuel Heater.............................8Wa-10-41

Fuel Heater Relay......................8Wa-10-20, 40, 57

Fuel Injector No. 1..........................8Wa-10-35

Fuel Injector No. 2..........................8Wa-10-35

Fuel Injector No. 3..........................8Wa-10-35

Fuel Injector No. 4..........................8Wa-10-35

Fuel Injector No. 5..........................8Wa-10-35

Fuel Injector No. 6..........................8Wa-10-35

Fuel Pressure Solenoid.......................8Wa-10-37

Fuel Pump Module........................8Wa-10-19, 38

Fuel Pump Relay.......................8Wa-10-19, 38, 57

Fuse 1 (IPM).........................8Wa-10-14, 15, 22

Fuse 2 (IPM) (Diesel).....................8Wa-10-14, 10-24

Fuse 2 (IPM) (Gas)......................8Wa-10-14, 10-23

Fuse 3 (IPM).........................8Wa-10-14, 23, 24

Fuse 4 (IPM).......................8Wa-10-14, 15, 16, 25

Fuse 5 (IPM)...........................8Wa-10-15, 26

Fuse 6 (IPM)...........................8Wa-10-15, 26

Fuse 8 (IPM)...........................8Wa-10-16, 29

Fuse 9 (IPM).........................8Wa-10-16, 17, 30

Fuse 10 (IPM)..........................8Wa-10-17, 31

Fuse 11 (IPM)..........................8Wa-10-15, 26

Fuse 12 (IPM)..........................8Wa-10-17, 31

Fuse 13 (IPM)..........................8Wa-10-18, 32

Fuse 14 (IPM)....................8Wa-10-18, 19, 20, 32, 52

Fuse 15 (IPM) (Diesel)......................8Wa-10-20, 36

Fuse 15 (IPM) (Gas).....................8Wa-10-18, 19, 34

Fuse 16 (IPM) (Diesel)......................8Wa-10-20, 36

Fuse 16 (IPM) (Gas).......................8Wa-10-19, 34

Fuse 17 (IPM) (Diesel)......................8Wa-10-20, 40

Fuse 17 (IPM) (Gas).......................8Wa-10-19, 38

Fuse 18 (IPM)....................8Wa-10-19, 20, 21, 38, 40

Fuse 19 (IPM)......................8Wa-10-19, 20, 21, 42

Fuse 20 (IPM)..........................8Wa-10-21, 42

Fuse 21 (IPM)..........................8Wa-10-21, 42

Fuse 22 (IPM)..........................8Wa-10-21, 42

Fuse 23 (IPM)........................8Wa-10-21, 46, 47

Fuse 24 (IPM)............................8Wa-10-21

Fuse 24 (IPM)............................8Wa-10-44

Fuse 26 (IPM)..........................8Wa-10-21, 44

Fuse 27 (IPM)..........................8Wa-10-21, 44

Fuse 28 (IPM)..........................8Wa-10-15, 26

Fuse 30 (IPM)..........................8Wa-10-21, 45

Fuse 31 (IPM)..........................8Wa-10-21, 45

Fuse 32 (IPM)..........................8Wa-10-21, 45

Fuse 33 (IPM)............................8Wa-10-15

Fuse 33 (IPM)............................8Wa-10-26

Fuselink.............................8Wa-10-12, 13

G100................................8Wa-10-48

G101...............................8Wa-10-34, 40

G103................................8Wa-10-61

G300................................8Wa-10-50

G300................................8Wa-10-51

Generator........................8Wa-10-12, 13, 35, 37

Glow Plug Relay.........................8Wa-10-12, 37

Headlamp Switch........................8Wa-10-24, 55Component PageHeadlamp Washer Pump Motor.................8Wa-10-21, 45

Headlamp Washer Relay...................8Wa-10-21, 45, 56

High Note Horn...........................8Wa-10-29

Horn Relay..........................8Wa-10-16, 29, 52

Ignition Coil.............................8Wa-10-35

Ignition Switch............8Wa-10-16, 21, 30, 38, 39, 41, 46, 47, 53

Instrument Cluster.......................8Wa-10-21, 44

Intelligent Power Module . . 8Wa-10-2, 10-3, 10-4, 10-12, 14, 15, 16, 17, 18, 19,

20, 21, 22, 23, 24, 25, 26, 27, 28, 29, 30, 31, 32, 33, 34, 35, 36, 37, 38, 39, 40,

41, 42, 44, 45, 46, 47, 48, 49, 50, 51, 52, 53, 54, 55, 56, 57, 58, 59, 61

Leak Detection Pump........................8Wa-10-39

Left B-Pillar Switch.........................8Wa-10-28

Left Combination Relay.......................8Wa-10-60

Left Fog Lamp..........................8Wa-10-14, 22

Left Front Park/ Turn Signal Lamp............8Wa-10-14, 23, 49, 58

Left Headlamp............................8Wa-10-50

Left Headlamp Leveling Motor................8Wa-10-24, 55, 58

Left High Beam Lamp........................8Wa-10-51

Left Low Beam Lamp........................8Wa-10-51

Left Park Lamp.........................8Wa-10-24, 58

Left Power Mirror..........................8Wa-10-32

Left Rear Lamp Assembly..............8Wa-10-23, 24, 58, 59, 60

Left Repeater Lamp.........................8Wa-10-44

Left Side Impact Airbag Control Module...............8Wa-10-55

Left Sliding Door Control Module..................8Wa-10-45

Left Stop/ Turn Signal Relay.....................8Wa-10-60

Left Turn Signal Lamp.......................8Wa-10-49

License Lamp........................8Wa-10-23, 24, 58

Lift Pump Motor.........................8Wa-10-20, 36

Lift Pump Relay.........................8Wa-10-20, 36

Low Note Horn...........................8Wa-10-29

Mass Air Flow Sensor........................8Wa-10-37

Memory Seat/ Mirror Module....................8Wa-10-42

Message Center...........................8Wa-10-44

Name Brand Speaker Relay.................8Wa-10-18, 32, 52

Occupant Restraint Controller..................8Wa-10-56, 61

Overhead Console..........................8Wa-10-33

Oxygen Sensor 1/1 Upstream....................8Wa-10-35

Oxygen Sensor 1/2 Downstream...................8Wa-10-35

Park Lamp Relay.....................8Wa-10-14, 23, 24, 52

Park/ Neutral Position Switch....................8Wa-10-58

Passenger Door Lock Switch...................8Wa-10-26, 28

Passenger Folding Mirror Relay.............8Wa-10-19, 20, 38, 40

Passenger Heated Seat Module...................8Wa-10-43

Passenger Power Seat Switch....................8Wa-10-43

Passenger Power Window Switch..................8Wa-10-26

Power Liftgate Module......................8Wa-10-21, 45

Power Mirror Switch...................8Wa-10-19, 20, 39, 40

Power Outlet............................8Wa-10-29

Power Seat Circuit Breaker...................8Wa-10-21, 42

Power Window Circuit Breaker.................8Wa-10-15, 26

Powertrain Control Module........8Wa-10-16, 19, 30, 34, 35, 38, 39, 48

PTC4 ..............................8Wa-10-18, 32

Ptc7.............................8Wa-10-15, 16, 29

Radiator Fan Relay.....................8Wa-10-21, 44, 48

Radiator Fan Relay No. 1....................8Wa-10-12, 37

Radiator Fan Relay No. 2....................8Wa-10-37, 44

Radiator Fan Relay No. 3....................8Wa-10-21, 37

Radio..............................8Wa-10-27, 33

Radio Choke...........................8Wa-10-18, 32

Rear A/C-Heater Unit......................8Wa-10-17, 31

Rear Blower Motor Power Module..................8Wa-10-31

Rear Blower Motor Relay.................8Wa-10-17, 18, 31, 56

Rear Power Outlet......................8Wa-10-15, 26, 27

Rear Washer Pump Motor..................8Wa-10-15, 26, 61

Rear Window Defogger Grid...................8Wa-10-18, 32

Rear Wiper Motor..........................8Wa-10-28

Remote Keyless Entry Module....................8Wa-10-33

Right B-Pillar Switch........................8Wa-10-28

Right Combination Relay......................8Wa-10-60

Right Fog Lamp.........................8Wa-10-14, 22

Right Front Park/ Turn Signal Lamp...........8Wa-10-14, 23, 49, 53

Right Headlamp...........................8Wa-10-50

Right Headlamp Leveling Motor...............8Wa-10-24, 53, 55

Right High Beam Lamp.......................8Wa-10-51

Right Low Beam Lamp.......................8Wa-10-51

Right Park Lamp........................8Wa-10-24, 53

Right Power Mirror.........................8Wa-10-32

Right Rear Lamp Assembly................8Wa-10-14, 23, 24, 59

Right Repeater Lamp........................8Wa-10-44

Right Side Impact Airbag Control Module..............8Wa-10-55

Right Sliding Door Control Module.................8Wa-10-45

Right Stop/ Turn Signal Relay....................8Wa-10-60

Right Turn Signal Lamp.......................8Wa-10-49

Sentry Key Immobilizer Module...........8Wa-10-33, 39, 41, 46, 47

Solenoid/ Pressure Switch Assy...................8Wa-10-34

Starter Motor.......................8Wa-10-12, 13, 16, 30

Starter Motor Relay...................8Wa-10-16, 30, 46, 47

Thatcham Alarm Module.................8Wa-10-39, 41, 47, 61

Torque Converter Clutch Solenoid..................8Wa-10-39

Trailer Tow Connector......................8Wa-10-23, 58

Transmission Control Module...........8Wa-10-16, 19, 30, 34, 54, 55

Transmission Control Relay...................8Wa-10-19, 34

Transmission Range Sensor.....................8Wa-10-58

TXV Solenoid............................8Wa-10-31

Vehicle Speed Sensor........................8Wa-10-36

Washer Fluid Level Switch.....................8Wa-10-53

Wiper Module........................8Wa-10-15, 25, 52

RG8W-10 POWER DISTRIBUTION8Wa-10-1

ProCarManuals.com

Page 732 of 2321

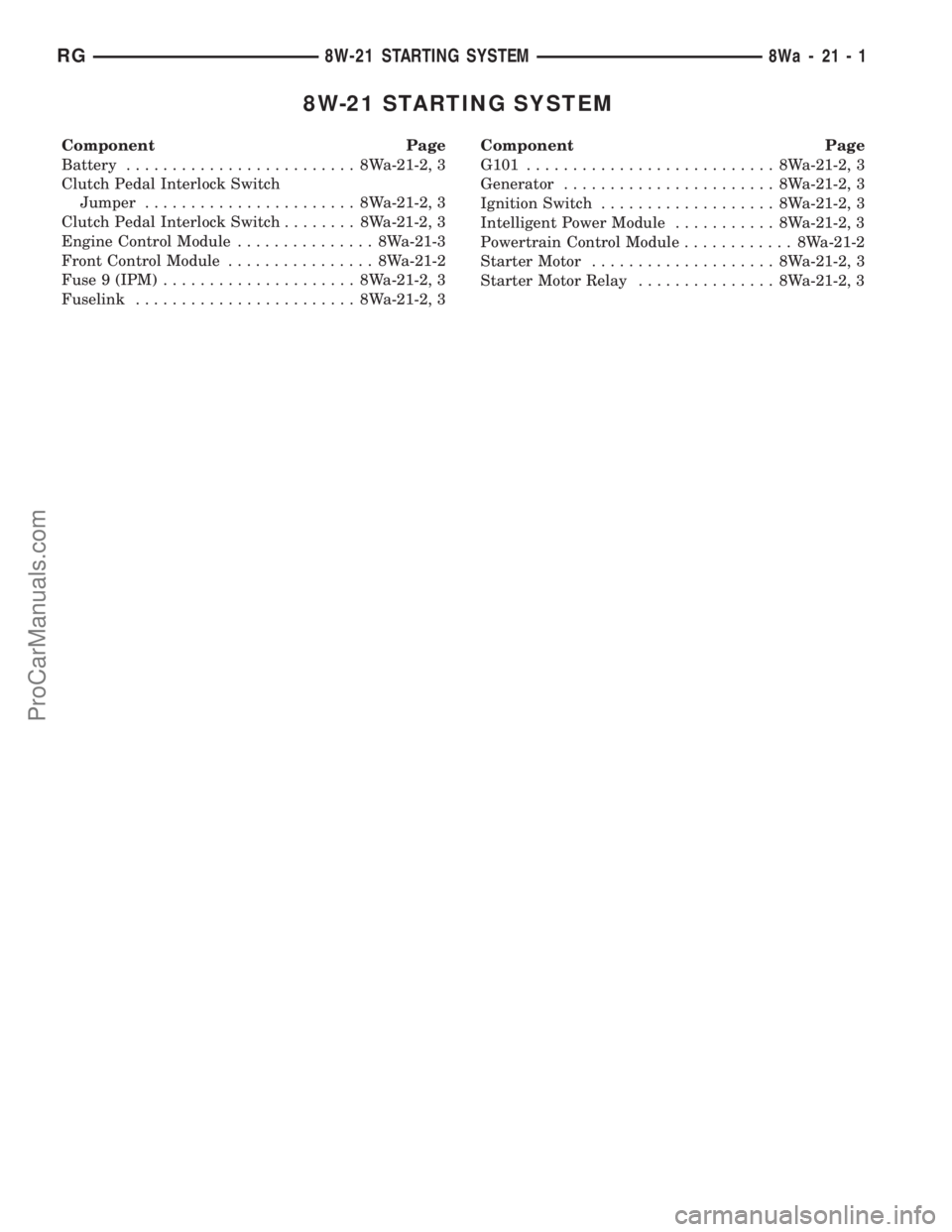

8W-21 STARTING SYSTEM

Component Page

Battery......................... 8Wa-21-2, 3

Clutch Pedal Interlock Switch

Jumper....................... 8Wa-21-2, 3

Clutch Pedal Interlock Switch........ 8Wa-21-2, 3

Engine Control Module............... 8Wa-21-3

Front Control Module................ 8Wa-21-2

Fuse 9 (IPM)..................... 8Wa-21-2, 3

Fuselink........................ 8Wa-21-2, 3Component Page

G101........................... 8Wa-21-2, 3

Generator....................... 8Wa-21-2, 3

Ignition Switch................... 8Wa-21-2, 3

Intelligent Power Module........... 8Wa-21-2, 3

Powertrain Control Module............ 8Wa-21-2

Starter Motor.................... 8Wa-21-2, 3

Starter Motor Relay............... 8Wa-21-2, 3

RG8W-21 STARTING SYSTEM8Wa-21-1

ProCarManuals.com