airbag off DODGE TOWN AND COUNTRY 2003 User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: TOWN AND COUNTRY, Model: DODGE TOWN AND COUNTRY 2003Pages: 2177, PDF Size: 59.81 MB

Page 590 of 2177

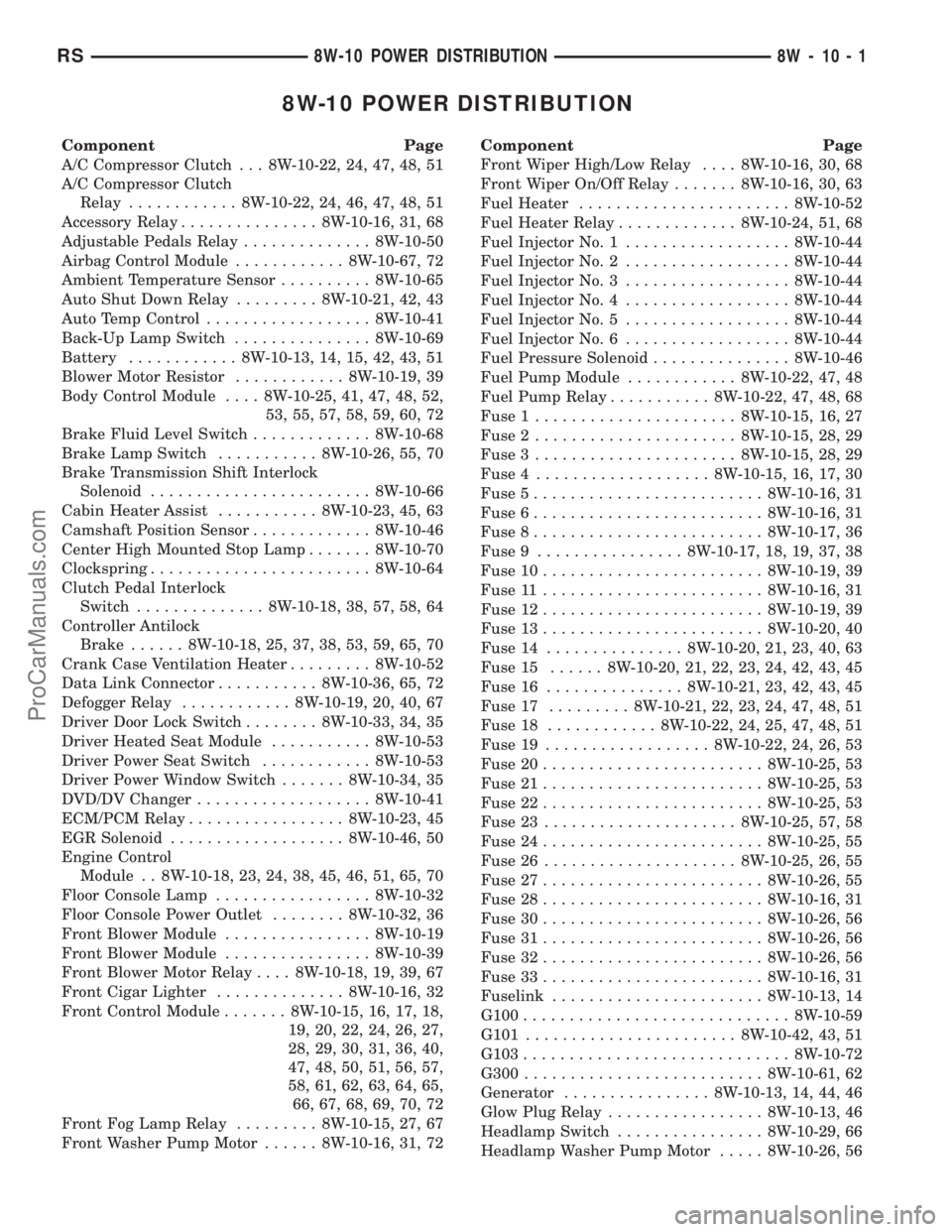

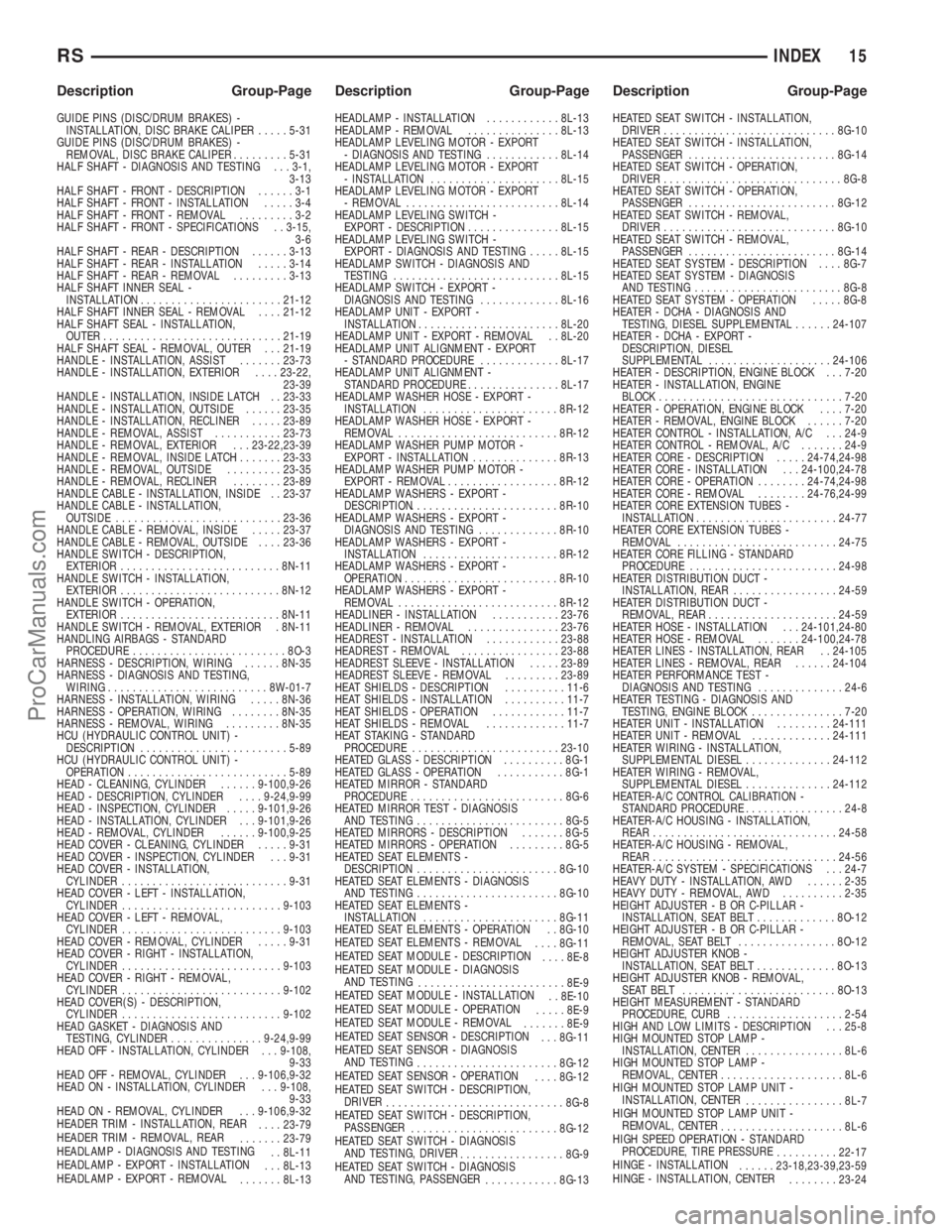

8W-10 POWER DISTRIBUTION

Component Page

A/C Compressor Clutch . . . 8W-10-22, 24, 47, 48, 51

A/C Compressor Clutch

Relay............ 8W-10-22, 24, 46, 47, 48, 51

Accessory Relay............... 8W-10-16, 31, 68

Adjustable Pedals Relay.............. 8W-10-50

Airbag Control Module............ 8W-10-67, 72

Ambient Temperature Sensor.......... 8W-10-65

Auto Shut Down Relay......... 8W-10-21, 42, 43

Auto Temp Control.................. 8W-10-41

Back-Up Lamp Switch............... 8W-10-69

Battery............ 8W-10-13, 14, 15, 42, 43, 51

Blower Motor Resistor............ 8W-10-19, 39

Body Control Module.... 8W-10-25, 41, 47, 48, 52,

53, 55, 57, 58, 59, 60, 72

Brake Fluid Level Switch............. 8W-10-68

Brake Lamp Switch........... 8W-10-26, 55, 70

Brake Transmission Shift Interlock

Solenoid........................ 8W-10-66

Cabin Heater Assist........... 8W-10-23, 45, 63

Camshaft Position Sensor............. 8W-10-46

Center High Mounted Stop Lamp....... 8W-10-70

Clockspring........................ 8W-10-64

Clutch Pedal Interlock

Switch.............. 8W-10-18, 38, 57, 58, 64

Controller Antilock

Brake...... 8W-10-18, 25, 37, 38, 53, 59, 65, 70

Crank Case Ventilation Heater......... 8W-10-52

Data Link Connector........... 8W-10-36, 65, 72

Defogger Relay............ 8W-10-19, 20, 40, 67

Driver Door Lock Switch........ 8W-10-33, 34, 35

Driver Heated Seat Module........... 8W-10-53

Driver Power Seat Switch............ 8W-10-53

Driver Power Window Switch....... 8W-10-34, 35

DVD/DV Changer................... 8W-10-41

ECM/PCM Relay................. 8W-10-23, 45

EGR Solenoid................... 8W-10-46, 50

Engine Control

Module . . 8W-10-18, 23, 24, 38, 45, 46, 51, 65, 70

Floor Console Lamp................. 8W-10-32

Floor Console Power Outlet........ 8W-10-32, 36

Front Blower Module................ 8W-10-19

Front Blower Module................ 8W-10-39

Front Blower Motor Relay.... 8W-10-18, 19, 39, 67

Front Cigar Lighter.............. 8W-10-16, 32

Front Control Module....... 8W-10-15, 16, 17, 18,

19, 20, 22, 24, 26, 27,

28, 29, 30, 31, 36, 40,

47, 48, 50, 51, 56, 57,

58, 61, 62, 63, 64, 65,

66, 67, 68, 69, 70, 72

Front Fog Lamp Relay......... 8W-10-15, 27, 67

Front Washer Pump Motor...... 8W-10-16, 31, 72Component Page

Front Wiper High/Low Relay.... 8W-10-16, 30, 68

Front Wiper On/Off Relay....... 8W-10-16, 30, 63

Fuel Heater....................... 8W-10-52

Fuel Heater Relay............. 8W-10-24, 51, 68

Fuel Injector No. 1.................. 8W-10-44

Fuel Injector No. 2.................. 8W-10-44

Fuel Injector No. 3.................. 8W-10-44

Fuel Injector No. 4.................. 8W-10-44

Fuel Injector No. 5.................. 8W-10-44

Fuel Injector No. 6.................. 8W-10-44

Fuel Pressure Solenoid............... 8W-10-46

Fuel Pump Module............ 8W-10-22, 47, 48

Fuel Pump Relay........... 8W-10-22, 47, 48, 68

Fuse 1...................... 8W-10-15, 16, 27

Fuse 2...................... 8W-10-15, 28, 29

Fuse 3...................... 8W-10-15, 28, 29

Fuse 4................... 8W-10-15, 16, 17, 30

Fuse 5......................... 8W-10-16, 31

Fuse 6......................... 8W-10-16, 31

Fuse 8......................... 8W-10-17, 36

Fuse 9................ 8W-10-17, 18, 19, 37, 38

Fuse 10........................ 8W-10-19, 39

Fuse 11........................ 8W-10-16, 31

Fuse 12........................ 8W-10-19, 39

Fuse 13........................ 8W-10-20, 40

Fuse 14............... 8W-10-20, 21, 23, 40, 63

Fuse 15...... 8W-10-20, 21, 22, 23, 24, 42, 43, 45

Fuse 16............... 8W-10-21, 23, 42, 43, 45

Fuse 17......... 8W-10-21, 22, 23, 24, 47, 48, 51

Fuse 18............ 8W-10-22, 24, 25, 47, 48, 51

Fuse 19.................. 8W-10-22, 24, 26, 53

Fuse 20........................ 8W-10-25, 53

Fuse 21........................ 8W-10-25, 53

Fuse 22........................ 8W-10-25, 53

Fuse 23..................... 8W-10-25, 57, 58

Fuse 24........................ 8W-10-25, 55

Fuse 26..................... 8W-10-25, 26, 55

Fuse 27........................ 8W-10-26, 55

Fuse 28........................ 8W-10-16, 31

Fuse 30........................ 8W-10-26, 56

Fuse 31........................ 8W-10-26, 56

Fuse 32........................ 8W-10-26, 56

Fuse 33........................ 8W-10-16, 31

Fuselink....................... 8W-10-13, 14

G100............................. 8W-10-59

G101....................... 8W-10-42, 43, 51

G103............................. 8W-10-72

G300.......................... 8W-10-61, 62

Generator................ 8W-10-13, 14, 44, 46

Glow Plug Relay................. 8W-10-13, 46

Headlamp Switch................ 8W-10-29, 66

Headlamp Washer Pump Motor..... 8W-10-26, 56

RS8W-10 POWER DISTRIBUTION8W-10-1

ProCarManuals.com

Page 1407 of 2177

WARNING: THE AIR BAG SYSTEM IS A SENSITIVE,

COMPLEX ELECTRO-MECHANICAL UNIT. BEFORE

ATTEMPTING TO DIAGNOSE, REMOVE OR INSTALL

THE AIR BAG SYSTEM COMPONENTS YOU MUST

FIRST DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE. THEN WAIT TWO

MINUTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE. FAILURE TO DO SO COULD RESULT IN

ACCIDENTAL DEPLOYMENT OF THE AIR BAG AND

POSSIBLE PERSONAL INJURY. THE FASTENERS,

SCREWS, AND BOLTS, ORIGINALLY USED FOR

THE AIR BAG COMPONENTS, HAVE SPECIAL

COATINGS AND ARE SPECIFICALLY DESIGNED

FOR THE AIR BAG SYSTEM. THEY MUST NEVER

BE REPLACED WITH ANY SUBSTITUTES. ANYTIME

A NEW FASTENER IS NEEDED, REPLACE WITH

THE CORRECT FASTENERS PROVIDED IN THE

SERVICE PACKAGE OR FASTENERS LISTED IN

THE PARTS BOOKS.

WARNING: SAFETY GOGGLES SHOULD BE WORN

AT ALL TIMES WHEN WORKING ON STEERING

COLUMNS.

CAUTION: Disconnect negative (ground) cable from

the battery before servicing any column compo-

nent.

CAUTION: Do not attempt to remove the pivot pins

to disassemble the tilting mechanism. Damage will

occur.

DIAGNOSIS AND TESTING - STEERING

COLUMN

For diagnosis of conditions relating to the steering

column (Refer to 19 - STEERING - DIAGNOSIS AND

TESTING) and (Refer to 19 - STEERING - DIAGNO-

SIS AND TESTING).

REMOVAL

NOTE: Before proceeding, (Refer to 19 - STEERING/

COLUMN - WARNING).

(1) Make sure the front wheels of the vehicle are

in the STRAIGHT AHEAD position before beginning

the column removal procedure.

(2) Disconnect negative (ground) cable from the

battery and isolate cable from battery terminal.

(3) Remove the lower shroud (Refer to 19 -

STEERING/COLUMN/LOWER SHROUD - REMOV-

AL).

(4) Remove the traction off switch.

(5) Remove the upper shroud.

(6) Remove the cluster trim bezel (Refer to 23 -

BODY/INSTRUMENT PANEL/CLUSTER BEZEL -

REMOVAL).

(7) Remove the knee blocker (Refer to 23 - BODY/

INSTRUMENT PANEL/STEERING COLUMN

OPENING COVER - REMOVAL).

(8) Remove the parking brake handle link.

(9) Remove the knee blocker reinforcement (Refer

to 23 - BODY/INSTRUMENT PANEL/KNEE

BLOCKER - REMOVAL).

(10) Remove the airbag (Refer to 8 - ELECTRI-

CAL/RESTRAINTS/DRIVER AIRBAG - REMOVAL).

(11) Remove the steering wheel retaining nut.

(12) Remove the vibration damper weight.

(13) Remove the steering wheel (Refer to 19 -

STEERING/COLUMN/STEERING WHEEL -

REMOVAL). (Fig. 3)

(14) Disconnect the wiring harness connectors

from the clockspring, multi-function switch, halo

lamp, SKIM module, ignition switch and BTSI sole-

noid.

(15) Disconnect the shift cable at the lever. (Fig. 4)

(16) Remove the pinch side clip, then remove the

cable from the bracket on the column.

(17) Remove the pinch bolt coupling. (Fig. 5)

(18) Loosen the two lower mounting nuts.

(19) Remove the two upper mounting nuts

(20) Remove the steering column.

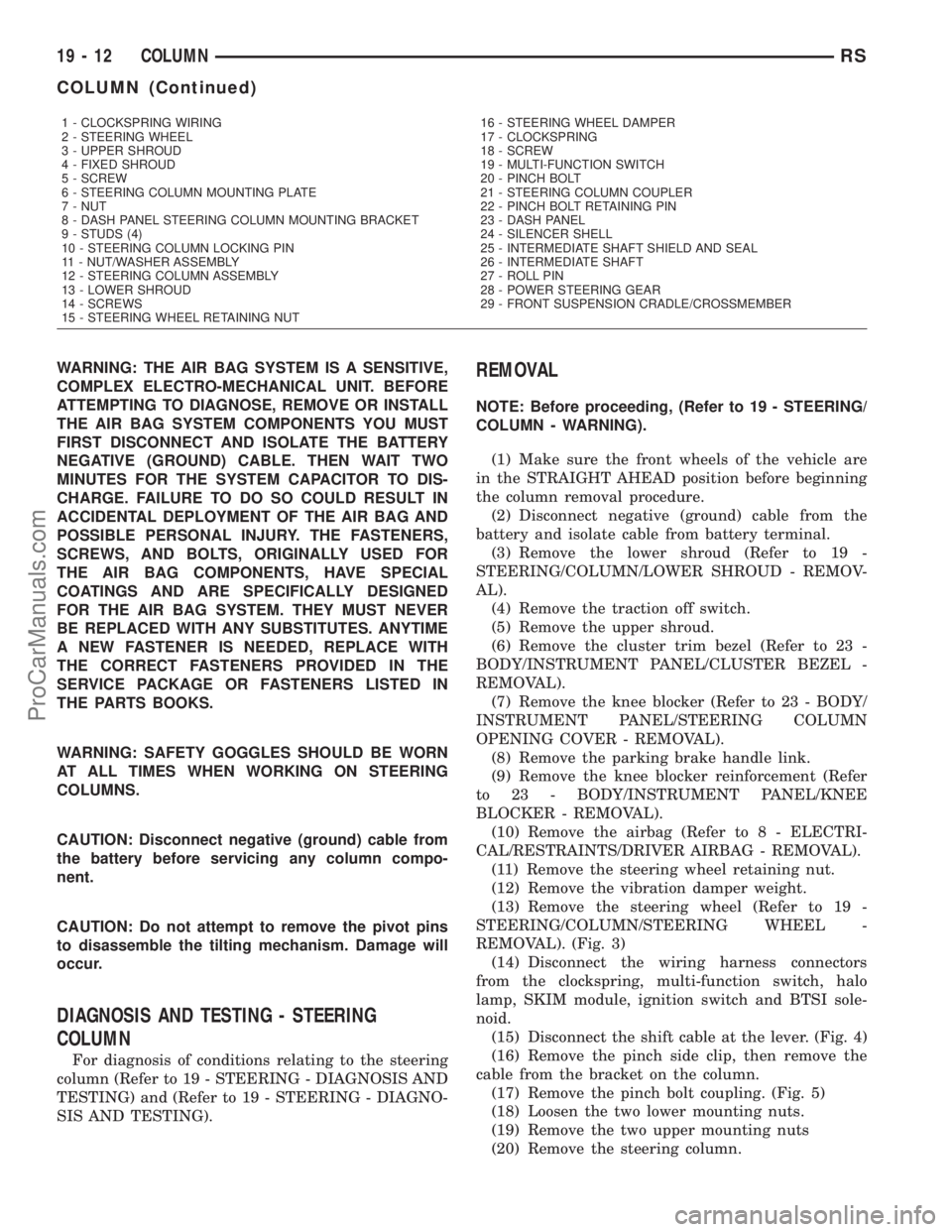

1 - CLOCKSPRING WIRING

2 - STEERING WHEEL

3 - UPPER SHROUD

4 - FIXED SHROUD

5 - SCREW

6 - STEERING COLUMN MOUNTING PLATE

7 - NUT

8 - DASH PANEL STEERING COLUMN MOUNTING BRACKET

9 - STUDS (4)

10 - STEERING COLUMN LOCKING PIN

11 - NUT/WASHER ASSEMBLY

12 - STEERING COLUMN ASSEMBLY

13 - LOWER SHROUD

14 - SCREWS

15 - STEERING WHEEL RETAINING NUT16 - STEERING WHEEL DAMPER

17 - CLOCKSPRING

18 - SCREW

19 - MULTI-FUNCTION SWITCH

20 - PINCH BOLT

21 - STEERING COLUMN COUPLER

22 - PINCH BOLT RETAINING PIN

23 - DASH PANEL

24 - SILENCER SHELL

25 - INTERMEDIATE SHAFT SHIELD AND SEAL

26 - INTERMEDIATE SHAFT

27 - ROLL PIN

28 - POWER STEERING GEAR

29 - FRONT SUSPENSION CRADLE/CROSSMEMBER

19 - 12 COLUMNRS

COLUMN (Continued)

ProCarManuals.com

Page 1409 of 2177

(10) Install the coupling onto the intermediate

shaft and install the pinch bolt. Tighten the pinch

bolt to 28 N´m (250 in. lbs.).

(11) Install the cable from the bracket on the col-

umn, then install the pinch side clips.

(12) Reconnect the shift cable at the lever.

(13) Reconnect the wiring harness connectors to

the clockspring, multi-function switch, halo lamp,

SKIM module, ignition switch and BTSI solenoid.

(14) Install the steering wheel (Refer to 19 -

STEERING/COLUMN/STEERING WHEEL -

INSTALLATION).

(15) Install the vibration damper weight.

(16) Install the steering wheel retaining nut.

Tighten the nut to 61 N´m (45 ft. lbs.)

(17) Install the airbag (Refer to 8 - ELECTRICAL/

RESTRAINTS/DRIVER AIRBAG - INSTALLATION).

(18) Install the knee blocker reinforcement (Refer

to 23 - BODY/INSTRUMENT PANEL/KNEE

BLOCKER - INSTALLATION).

(19) Install the parking brake handle link.

(20) Install the knee blocker (Refer to 23 - BODY/

INSTRUMENT PANEL/STEERING COLUMN

OPENING COVER - INSTALLATION).

(21) Install the cluster trim bezel (Refer to 23 -

BODY/INSTRUMENT PANEL/CLUSTER BEZEL -

INSTALLATION).

(22) Install the upper shroud (Refer to 19 -

STEERING/COLUMN/LOWER SHROUD - INSTAL-

LATION).

(23) Install the traction off switch.

(24) Install the lower shroud.

SPECIFICATIONS

COLUMN TORQUE

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

Driver Airbag Attaching Bolts 10 Ð 90

Steering Column Coupling

Pinch Bolt28 Ð 250

Steering Column Mounting

Nuts12 Ð 105

Steering Wheel Retaining

Nut61 45 Ð

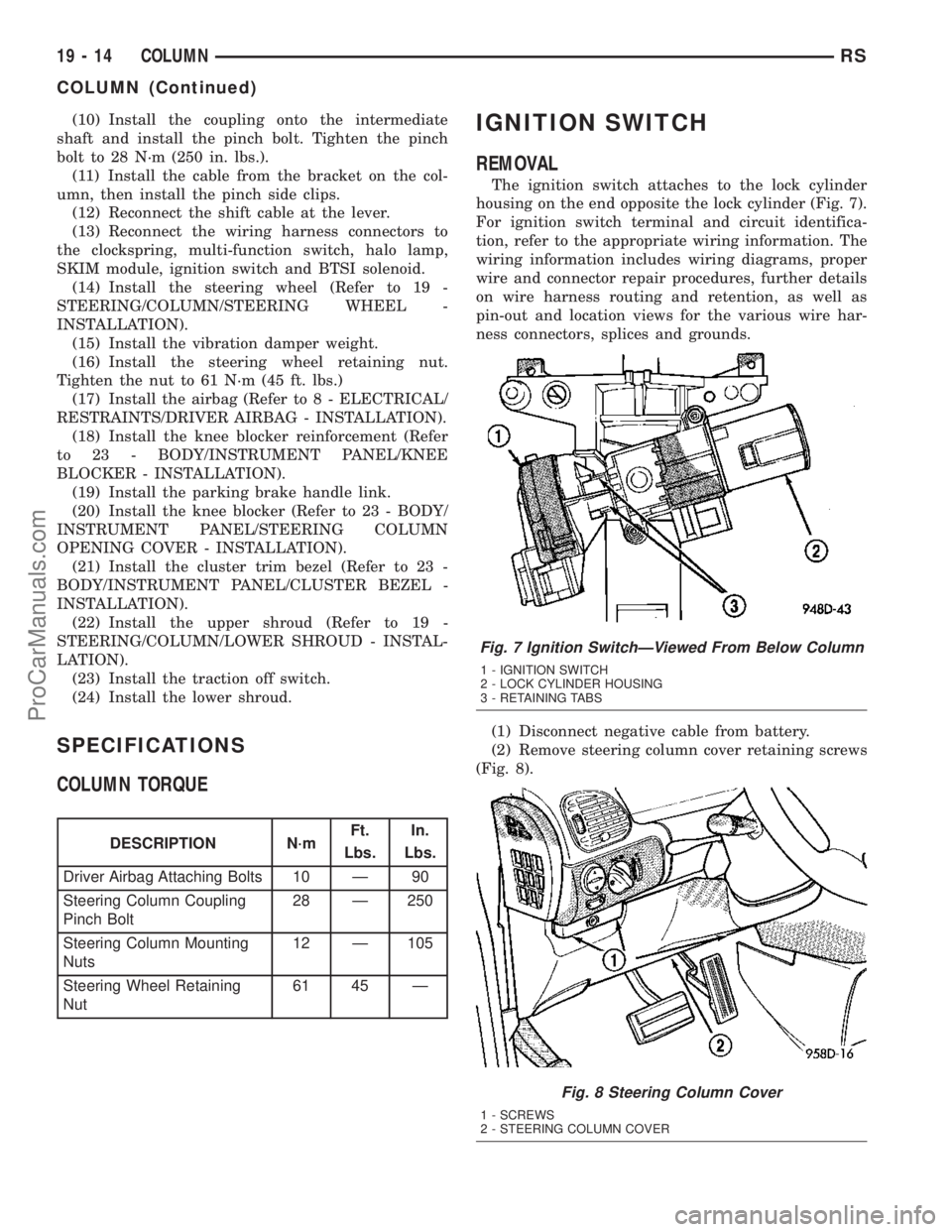

IGNITION SWITCH

REMOVAL

The ignition switch attaches to the lock cylinder

housing on the end opposite the lock cylinder (Fig. 7).

For ignition switch terminal and circuit identifica-

tion, refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices and grounds.

(1) Disconnect negative cable from battery.

(2) Remove steering column cover retaining screws

(Fig. 8).

Fig. 7 Ignition SwitchÐViewed From Below Column

1 - IGNITION SWITCH

2 - LOCK CYLINDER HOUSING

3 - RETAINING TABS

Fig. 8 Steering Column Cover

1 - SCREWS

2 - STEERING COLUMN COVER

19 - 14 COLUMNRS

COLUMN (Continued)

ProCarManuals.com

Page 1418 of 2177

SHROUD - UPPER

REMOVAL

(1) Remove the two shroud-to-shroud mounting

screws from the lower shroud (Fig. 32).

(2) Unsnap the upper shroud from the lower on

the left side as follows:

(a) Hook a finger on the left hand around the

rear of the shrouds at the seam (Fig. 33), near the

snap points.

(b) Grasp the upper shroud at the rear using the

right hand (Fig. 33).

(c) As the left hand's hooked finger is pulled out-

ward against the seam, pull the upper shroud

upward using the right hand, disconnecting the

shroud snaps.

(3) Unsnap the upper shroud from the lower on

the right side as follows:

(a) Hook a finger on the right hand around the

rear of the shrouds at the seam (Fig. 34), near the

snap points.

(b) Grasp the upper shroud at the rear using the

left hand (Fig. 34).

(c) As the right hand's hooked finger is pulled

outward against the seam, pull the upper shroud

upward using the left hand, disconnecting the

shroud snaps.

(4) Lift the upper shroud straight up off the steer-

ing column. If vehicle is equipped with traction con-

trol, disconnect wiring connector at traction control

switch pig tail. If vehicle is equipped with power fold-

away mirrors (Export), disconnect wiring connector

at mirror switch pig tail. Remove upper shroud.

(5) If vehicle is equipped with traction control,

remove traction control switch from shroud.

(6) If vehicle is equipped with power foldaway mir-

rors (Export), remove power fold-away switch from

upper shroud.

INSTALLATION

(1) If the vehicle is equipped with power foldaway

mirrors (Export), install the power fold-away switch

in the upper shroud.

(2) If vehicle is equipped with traction control,

install the traction control switch in the upper

shroud.

(3) Place the upper shroud over the lower shroud,

aligning the snap clips and alignment tabs. If the

vehicle is equipped with traction control, connect the

wiring connector at the traction control switch pig

tail before lining the shrouds up to one another.

(4) Snap the upper shroud to the lower shroud.

Once snapped into place, verify there are no gaps

between the two mating surfaces of the shrouds.(5) Install the two shroud-to-shroud mounting

screws (Fig. 32). Tighten the screws to 2 N´m (17 in.

lbs.) torque.

(6) Ensure that the shrouds are snug and fit is

acceptable.

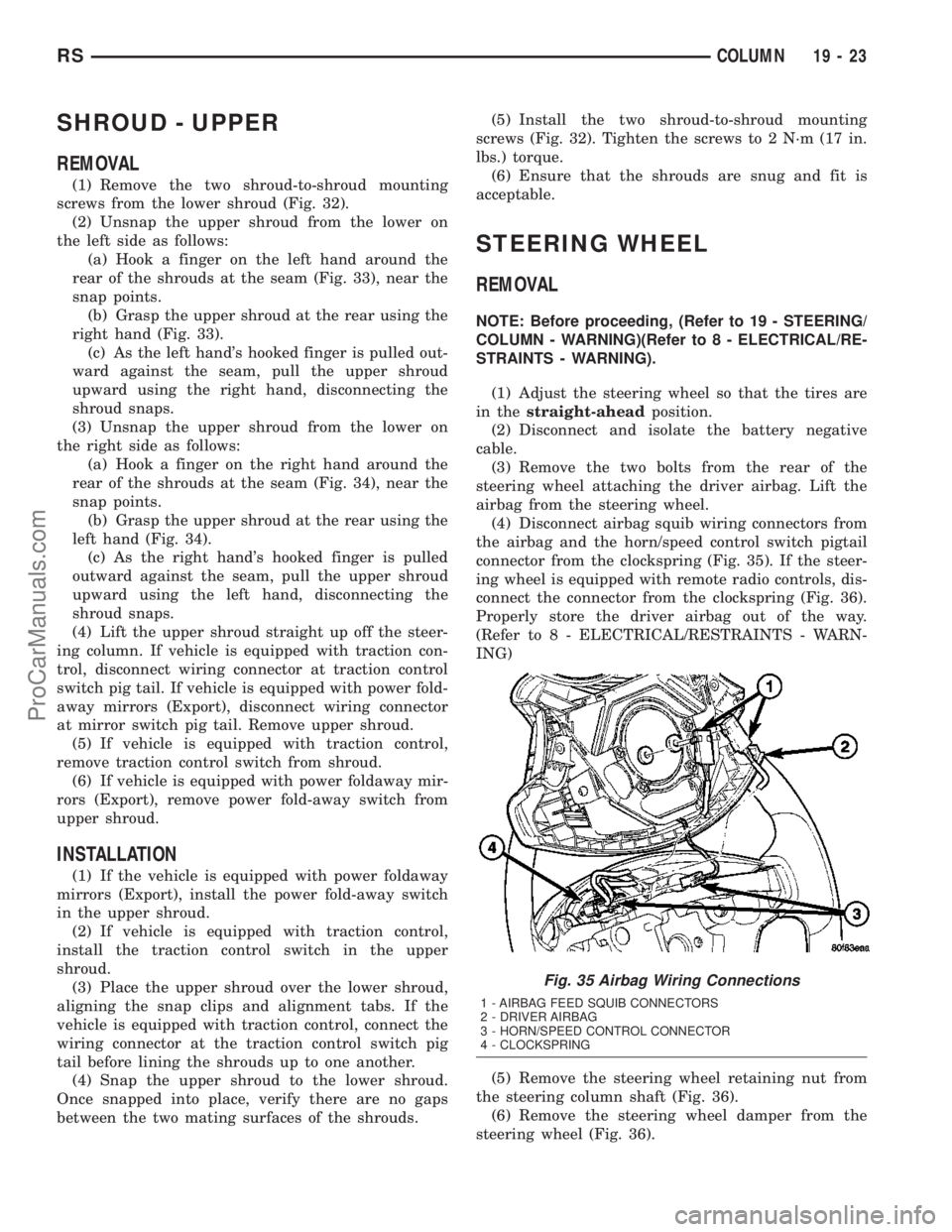

STEERING WHEEL

REMOVAL

NOTE: Before proceeding, (Refer to 19 - STEERING/

COLUMN - WARNING)(Refer to 8 - ELECTRICAL/RE-

STRAINTS - WARNING).

(1) Adjust the steering wheel so that the tires are

in thestraight-aheadposition.

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the two bolts from the rear of the

steering wheel attaching the driver airbag. Lift the

airbag from the steering wheel.

(4) Disconnect airbag squib wiring connectors from

the airbag and the horn/speed control switch pigtail

connector from the clockspring (Fig. 35). If the steer-

ing wheel is equipped with remote radio controls, dis-

connect the connector from the clockspring (Fig. 36).

Properly store the driver airbag out of the way.

(Refer to 8 - ELECTRICAL/RESTRAINTS - WARN-

ING)

(5) Remove the steering wheel retaining nut from

the steering column shaft (Fig. 36).

(6) Remove the steering wheel damper from the

steering wheel (Fig. 36).

Fig. 35 Airbag Wiring Connections

1 - AIRBAG FEED SQUIB CONNECTORS

2 - DRIVER AIRBAG

3 - HORN/SPEED CONTROL CONNECTOR

4 - CLOCKSPRING

RSCOLUMN19-23

ProCarManuals.com

Page 2006 of 2177

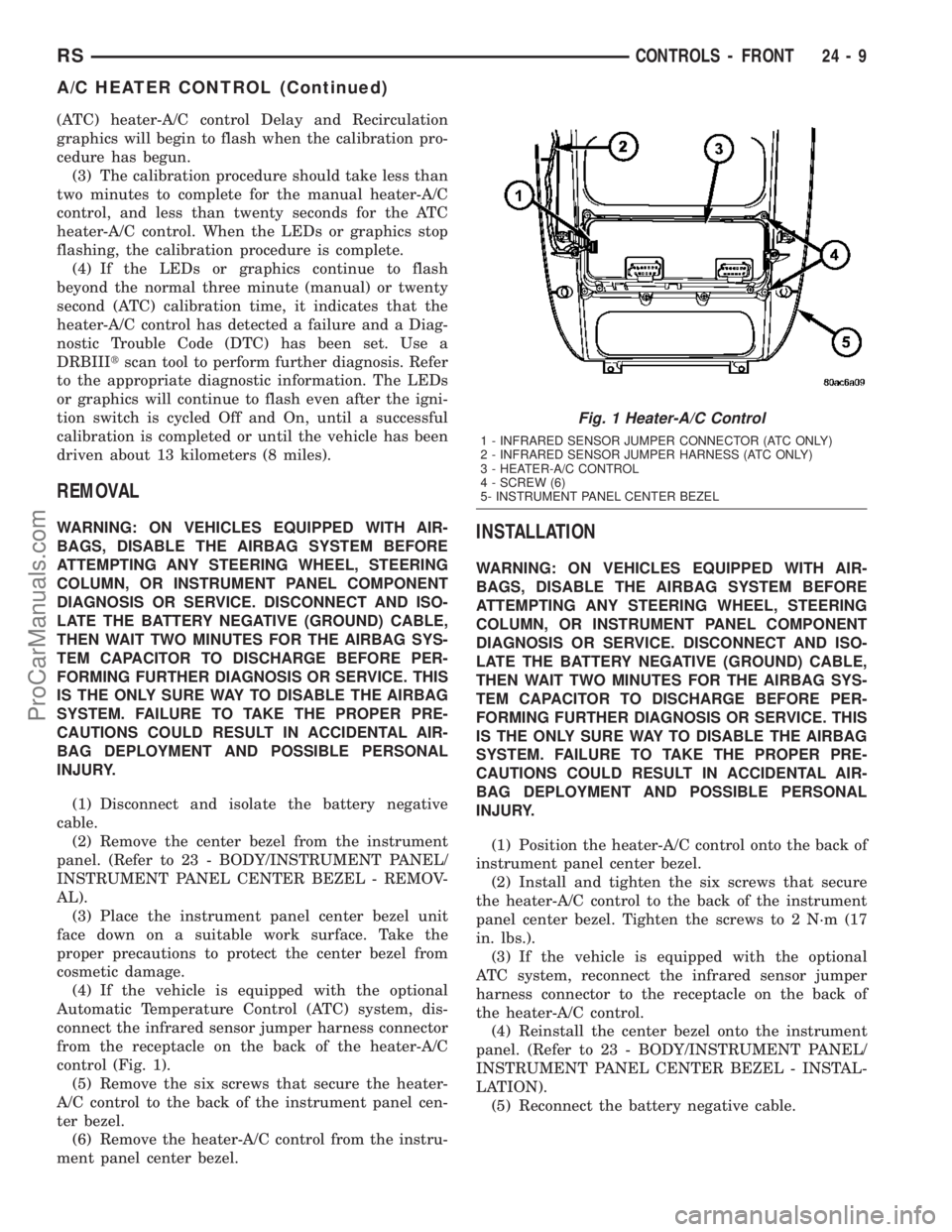

(ATC) heater-A/C control Delay and Recirculation

graphics will begin to flash when the calibration pro-

cedure has begun.

(3) The calibration procedure should take less than

two minutes to complete for the manual heater-A/C

control, and less than twenty seconds for the ATC

heater-A/C control. When the LEDs or graphics stop

flashing, the calibration procedure is complete.

(4) If the LEDs or graphics continue to flash

beyond the normal three minute (manual) or twenty

second (ATC) calibration time, it indicates that the

heater-A/C control has detected a failure and a Diag-

nostic Trouble Code (DTC) has been set. Use a

DRBIIItscan tool to perform further diagnosis. Refer

to the appropriate diagnostic information. The LEDs

or graphics will continue to flash even after the igni-

tion switch is cycled Off and On, until a successful

calibration is completed or until the vehicle has been

driven about 13 kilometers (8 miles).

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the center bezel from the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL - REMOV-

AL).

(3) Place the instrument panel center bezel unit

face down on a suitable work surface. Take the

proper precautions to protect the center bezel from

cosmetic damage.

(4) If the vehicle is equipped with the optional

Automatic Temperature Control (ATC) system, dis-

connect the infrared sensor jumper harness connector

from the receptacle on the back of the heater-A/C

control (Fig. 1).

(5) Remove the six screws that secure the heater-

A/C control to the back of the instrument panel cen-

ter bezel.

(6) Remove the heater-A/C control from the instru-

ment panel center bezel.INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Position the heater-A/C control onto the back of

instrument panel center bezel.

(2) Install and tighten the six screws that secure

the heater-A/C control to the back of the instrument

panel center bezel. Tighten the screws to 2 N´m (17

in. lbs.).

(3) If the vehicle is equipped with the optional

ATC system, reconnect the infrared sensor jumper

harness connector to the receptacle on the back of

the heater-A/C control.

(4) Reinstall the center bezel onto the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL - INSTAL-

LATION).

(5) Reconnect the battery negative cable.

Fig. 1 Heater-A/C Control

1 - INFRARED SENSOR JUMPER CONNECTOR (ATC ONLY)

2 - INFRARED SENSOR JUMPER HARNESS (ATC ONLY)

3 - HEATER-A/C CONTROL

4 - SCREW (6)

5- INSTRUMENT PANEL CENTER BEZEL

RSCONTROLS - FRONT24-9

A/C HEATER CONTROL (Continued)

ProCarManuals.com

Page 2040 of 2177

BLOWER MOTOR

DESCRIPTION

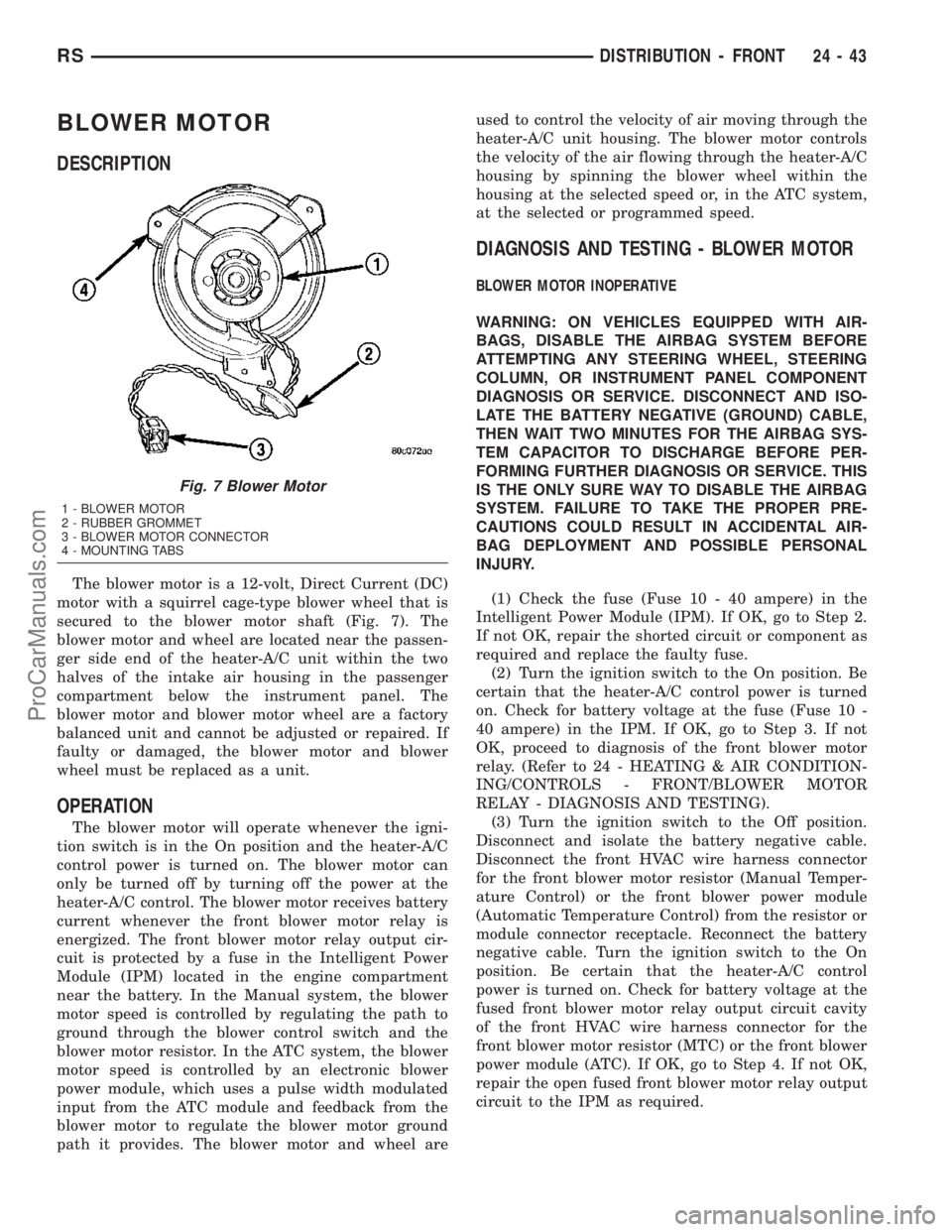

The blower motor is a 12-volt, Direct Current (DC)

motor with a squirrel cage-type blower wheel that is

secured to the blower motor shaft (Fig. 7). The

blower motor and wheel are located near the passen-

ger side end of the heater-A/C unit within the two

halves of the intake air housing in the passenger

compartment below the instrument panel. The

blower motor and blower motor wheel are a factory

balanced unit and cannot be adjusted or repaired. If

faulty or damaged, the blower motor and blower

wheel must be replaced as a unit.

OPERATION

The blower motor will operate whenever the igni-

tion switch is in the On position and the heater-A/C

control power is turned on. The blower motor can

only be turned off by turning off the power at the

heater-A/C control. The blower motor receives battery

current whenever the front blower motor relay is

energized. The front blower motor relay output cir-

cuit is protected by a fuse in the Intelligent Power

Module (IPM) located in the engine compartment

near the battery. In the Manual system, the blower

motor speed is controlled by regulating the path to

ground through the blower control switch and the

blower motor resistor. In the ATC system, the blower

motor speed is controlled by an electronic blower

power module, which uses a pulse width modulated

input from the ATC module and feedback from the

blower motor to regulate the blower motor ground

path it provides. The blower motor and wheel areused to control the velocity of air moving through the

heater-A/C unit housing. The blower motor controls

the velocity of the air flowing through the heater-A/C

housing by spinning the blower wheel within the

housing at the selected speed or, in the ATC system,

at the selected or programmed speed.

DIAGNOSIS AND TESTING - BLOWER MOTOR

BLOWER MOTOR INOPERATIVE

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Check the fuse (Fuse 10 - 40 ampere) in the

Intelligent Power Module (IPM). If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Turn the ignition switch to the On position. Be

certain that the heater-A/C control power is turned

on. Check for battery voltage at the fuse (Fuse 10 -

40 ampere) in the IPM. If OK, go to Step 3. If not

OK, proceed to diagnosis of the front blower motor

relay. (Refer to 24 - HEATING & AIR CONDITION-

ING/CONTROLS - FRONT/BLOWER MOTOR

RELAY - DIAGNOSIS AND TESTING).

(3) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the front HVAC wire harness connector

for the front blower motor resistor (Manual Temper-

ature Control) or the front blower power module

(Automatic Temperature Control) from the resistor or

module connector receptacle. Reconnect the battery

negative cable. Turn the ignition switch to the On

position. Be certain that the heater-A/C control

power is turned on. Check for battery voltage at the

fused front blower motor relay output circuit cavity

of the front HVAC wire harness connector for the

front blower motor resistor (MTC) or the front blower

power module (ATC). If OK, go to Step 4. If not OK,

repair the open fused front blower motor relay output

circuit to the IPM as required.

Fig. 7 Blower Motor

1 - BLOWER MOTOR

2 - RUBBER GROMMET

3 - BLOWER MOTOR CONNECTOR

4 - MOUNTING TABS

RSDISTRIBUTION - FRONT24-43

ProCarManuals.com

Page 2148 of 2177

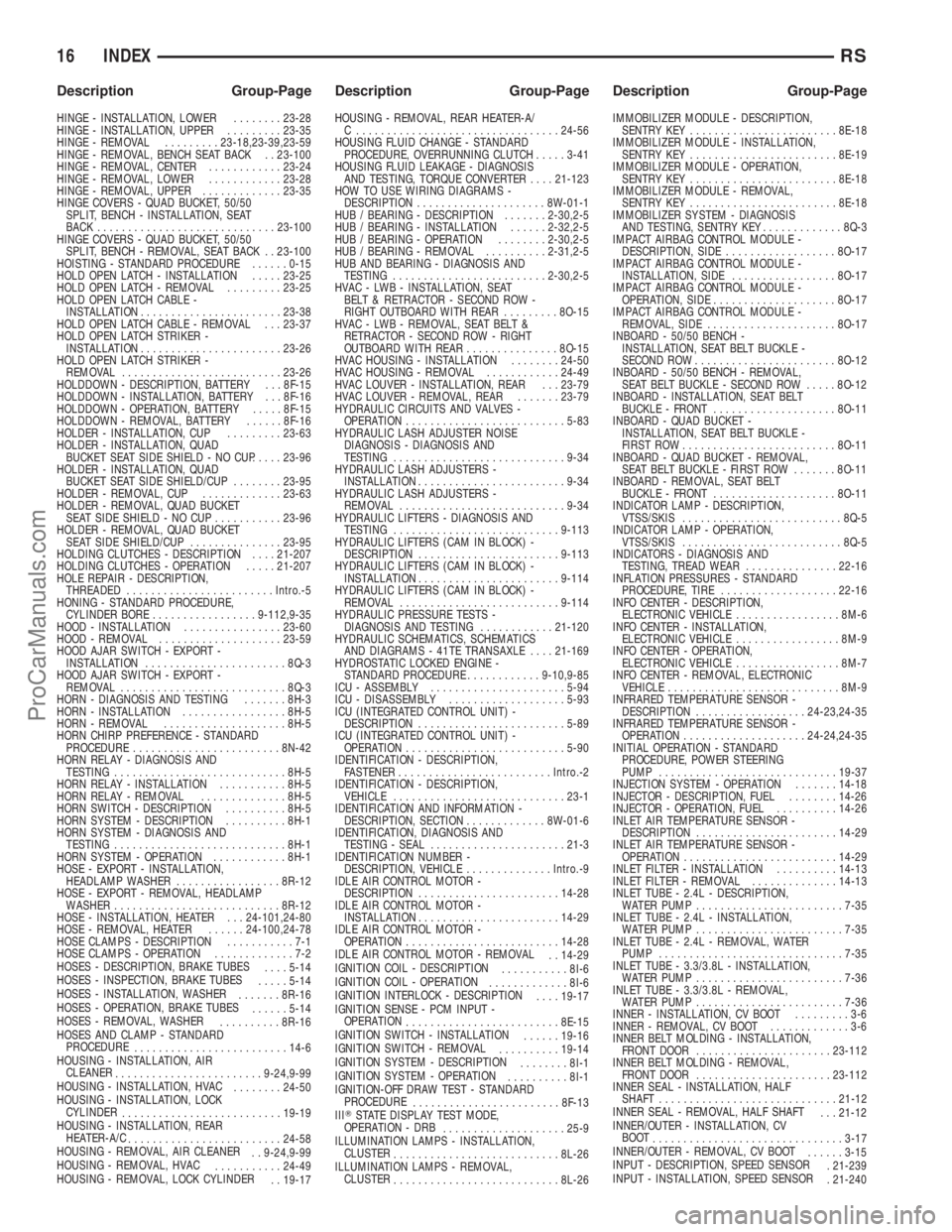

CUSHION SIDE COVER - INSTALLATION,

FRONT SEAT........................23-93

CUSHION SIDE COVER - REMOVAL,

FRONT SEAT........................23-93

CV BOOT - INNER - INSTALLATION........3-6

CV BOOT - INNER - REMOVAL............3-6

CV BOOT - INNER/OUTER -

INSTALLATION........................3-17

CV BOOT - INNER/OUTER - REMOVAL.....3-15

CV BOOT - OUTER - INSTALLATION.......3-10

CV BOOT - OUTER - REMOVAL...........3-10

CYCLE - STANDARD PROCEDURE,

POWER DOOR LEARN................8N-28

CYCLE - STANDARD PROCEDURE,

POWER LIFTGATE LEARN...............8N-9

CYLINDER - DESCRIPTION, KEY/LOCK....19-20

CYLINDER - DESCRIPTION, STANDARD 4 . . . 8I-9

CYLINDER - INSTALLATION, KEY/LOCK . . . 19-20

CYLINDER - INSTALLATION, LOCK . . 23-20,23-41

CYLINDER - INSTALLATION, SLAVE.......6-11

CYLINDER - INSTALLATION, SUPPORT....23-42

CYLINDER - LHD - INSTALLATION,

MASTER............................6-10

CYLINDER - LHD - REMOVAL, MASTER.....6-9

CYLINDER - OPERATION, KEY/LOCK......19-20

CYLINDER - REMOVAL, KEY/LOCK.......19-20

CYLINDER - REMOVAL, LOCK......23-19,23-41

CYLINDER - REMOVAL, SLAVE...........6-11

CYLINDER - REMOVAL, SUPPORT.......23-42

CYLINDER - RHD - INSTALLATION,

MASTER.............................6-9

CYLINDER - RHD - REMOVAL, MASTER.....6-8

CYLINDER BLEEDING - STANDARD

PROCEDURE, MASTER.................5-35

CYLINDER BORE FITTING - STANDARD

PROCEDURE, PISTON TO...............9-42

CYLINDER BORE HONING - STANDARD

PROCEDURE....................9-112,9-35

CYLINDER COMBUSTION PRESSURE

LEAKAGE TEST - DIAGNOSIS AND

TESTING.........................9-83,9-9

CYLINDER COMPRESSION PRESSURE

TEST - DIAGNOSIS AND TESTING.....9-83,9-9

CYLINDER (FLUID RESERVOIR) -

ASSEMBLY, MASTER...................5-38

CYLINDER (FLUID RESERVOIR) -

DISASSEMBLY, MASTER................5-37

CYLINDER HEAD - CLEANING.......9-100,9-26

CYLINDER HEAD - DESCRIPTION.....9-24,9-99

CYLINDER HEAD - INSPECTION.....9-101,9-26

CYLINDER HEAD - INSTALLATION . . . 9-101,9-26

CYLINDER HEAD - REMOVAL.......9-100,9-25

CYLINDER HEAD COVER - CLEANING......9-31

CYLINDER HEAD COVER - INSPECTION....9-31

CYLINDER HEAD COVER -

INSTALLATION........................9-31

CYLINDER HEAD COVER - LEFT -

INSTALLATION.......................9-103

CYLINDER HEAD COVER - LEFT -

REMOVAL..........................9-103

CYLINDER HEAD COVER - REMOVAL......9-31

CYLINDER HEAD COVER - RIGHT -

INSTALLATION.......................9-103

CYLINDER HEAD COVER - RIGHT -

REMOVAL..........................9-102

CYLINDER HEAD COVER(S) -

DESCRIPTION.......................9-102

CYLINDER HEAD GASKET - DIAGNOSIS

AND TESTING....................9-24,9-99

CYLINDER HEAD OFF - INSTALLATION . . . 9-108,

9-33

CYLINDER HEAD OFF - REMOVAL . . . 9-106,9-32

CYLINDER HEAD ON - INSTALLATION....9-108,

9-33

CYLINDER HEAD ON - REMOVAL....9-106,9-32

CYLINDER HOUSING - INSTALLATION,

LOCK..............................19-19

CYLINDER HOUSING - REMOVAL, LOCK . . 19-17

CYLINDER LOCK SWITCH -

DESCRIPTION, DOOR

.................8N-40

CYLINDER LOCK SWITCH - DIAGNOSIS

AND TESTING, DOOR

.................8N-40

CYLINDER LOCK SWITCH -

INSTALLATION, DOOR

.................8N-41

CYLINDER LOCK SWITCH - OPERATION,

DOOR

.............................8N-40

CYLINDER LOCK SWITCH - REMOVAL,

DOOR

.............................8N-41CYLINDERS - INSPECTION, WHEEL.......5-57

CYLINDERS - INSTALLATION, WHEEL.....5-57

CYLINDERS - REMOVAL, WHEEL.........5-57

DAMAGED OR WORN THREADS -

STANDARD PROCEDURE, REPAIR OF . . 9-10,9-86

DAMPER - INSTALLATION, VIBRATION . . . 9-130,

9-47

DAMPER - REMOVAL, VIBRATION . . . 9-130,9-47

DATA BUS COMMUNICATION RECEIVE -

PCM INPUT - OPERATION..............8E-15

DATA LINK CONNECTOR - DESCRIPTION . . . 8E-6

DATA LINK CONNECTOR - OPERATION.....8E-7

DAY / NIGHT MIRROR - DESCRIPTION,

AUTOMATIC........................8N-47

DAY / NIGHT MIRROR - DIAGNOSIS AND

TESTING, AUTOMATIC................8N-47

DAY / NIGHT MIRROR - OPERATION,

AUTOMATIC........................8N-47

DCHA - DIAGNOSIS AND TESTING,

DIESEL SUPPLEMENTAL HEATER.......24-107

DCHA - EXPORT - DESCRIPTION, DIESEL

SUPPLEMENTAL HEATER.............24-106

DEAERATION - DIAGNOSIS AND

TESTING, COOLING SYSTEM.............7-4

DECOUPLER PULLEY - DESCRIPTION,

GENERATOR........................8F-25

DECOUPLER PULLEY - DIAGNOSIS AND

TESTING, GENERATOR................8F-25

DECOUPLER PULLEY - INSTALLATION,

GENERATOR........................8F-26

DECOUPLER PULLEY - OPERATION,

GENERATOR..........................8F-25

DECOUPLER PULLEY - REMOVAL,

GENERATOR........................8F-26

DEFINITION - DESCRIPTION, TRIP........25-1

DEFLECTOR - INSTALLATION, WIND.....23-118

DEFLECTOR - REMOVAL, WIND........23-118

DEFOGGER RELAY - DESCRIPTION.......8G-2

DEFOGGER SWITCH - DESCRIPTION,

REAR WINDOW.......................8G-2

DEFOGGER SWITCH - OPERATION, REAR

WINDOW............................8G-2

DEFROSTER DUCT - INSTALLATION......24-48

DEFROSTER DUCT - REMOVAL..........24-47

DEMAGNETIZING - STANDARD

PROCEDURE, COMPASS...............8M-4

DEMISTER DUCTS - INSTALLATION......24-48

DEMISTER DUCTS - REMOVAL..........24-48

DEMISTER OUTLET - INSTALLATION.....24-42

DEMISTER OUTLET - REMOVAL.........24-41

DEPLOYMENT - STANDARD

PROCEDURE, SERVICE AFTER AN

AIRBAG.............................8O-3

DETECTION ASSY - INSTALLATION,

NATURAL VAC LEAK..................25-13

DETECTION ASSY - REMOVAL, NATURAL

VAC LEAK..........................25-13

DETECTION PUMP - INSTALLATION,

LEAK..............................25-13

DETECTION PUMP - REMOVAL, LEAK....25-13

DEVICES - STANDARD PROCEDURE,

ELECTROSTATIC DISCHARGE (ESD)

SENSITIVE........................8W-01-8

DIAGNOSTIC SYSTEM - DIAGNOSIS AND

TESTING, ON-BOARD.................8F-21

DIAGNOSTIC TROUBLE CODES -

STANDARD PROCEDURE, OBTAINING.....8E-15

DIAGRAMS - 41TE TRANSAXLE

HYDRAULIC SCHEMATICS,

SCHEMATICS.......................21-169

DIAGRAMS - DESCRIPTION, HOW TO

USE WIRING......................8W-01-1

DIESEL - DESCRIPTION, 2.5L...........19-51

DIESEL - INSTALLATION, 2.5L..........19-52

DIESEL - REMOVAL, 2.5L..............19-51

DIESEL ENGINE - DESCRIPTION, FUEL

REQUIREMENTS.......................0-6

DIESEL ENGINES - DESCRIPTION,

ENGINE OIL...........................0-6

DIESEL HEATER WIRING -

INSTALLATION, SUPPLEMENTAL

........24-112

DIESEL HEATER WIRING - REMOVAL,

SUPPLEMENTAL

....................24-112

DIESEL SUPPLEMENTAL HEATER - DCHA

- DIAGNOSIS AND TESTING

...........24-107

DIESEL SUPPLEMENTAL HEATER - DCHA

- EXPORT - DESCRIPTION

............24-106

DIFFERENTIAL - ASSEMBLY

............21-66DIFFERENTIAL - DESCRIPTION..........21-62

DIFFERENTIAL - DISASSEMBLY.........21-62

DIFFERENTIAL - OPERATION............21-62

DIFFERENTIAL ASSEMBLY -

DESCRIPTION........................3-39

DIFFERENTIAL ASSEMBLY - OPERATION . . . 3-39

DIFFERENTIAL ASSEMBLY FLUID

CHANGE - STANDARD PROCEDURE.......3-40

DIFFERENTIAL BEARING PRELOAD -

ADJUSTMENT......................21-199

DIFFERENTIAL CARRIER SEAL -

INSTALLATION........................21-9

DIFFERENTIAL CARRIER SEAL -

REMOVAL...........................21-9

DIFFERENTIAL SIDE GEAR END PLAY -

ADJUSTMENT.......................21-70

DIFFERENTIAL TURNING TORQUE -

ADJUSTMENT.......................21-69

DIMENSIONS - SPECIFICATIONS, BODY

OPENING..........................23-124

DIMENSIONS, SPECIFICATIONS - FRAME . . . 13-4

DIODE - INSTALLATION............8W-01-14

DIODE - REMOVAL................8W-01-14

DISC AND PRESSURE PLATE - 2.5L TD -

INSTALLATION, CLUTCH................6-12

DISC AND PRESSURE PLATE - 2.5L TD -

REMOVAL, CLUTCH....................6-11

DISC BRAKE CALIPER - INSTALLATION,

REAR...............................5-30

DISC BRAKE CALIPER - REMOVAL,

REAR...............................5-27

DISC BRAKE CALIPER ADAPTER -

INSTALLATION, FRONT.................5-31

DISC BRAKE CALIPER ADAPTER -

REMOVAL, FRONT.....................5-31

DISC BRAKE CALIPER (DISC/DISC

BRAKES) - INSTALLATION, FRONT........5-27

DISC BRAKE CALIPER (DISC/DISC

BRAKES) - REMOVAL, FRONT............5-24

DISC BRAKE CALIPER (DISC/DRUM

BRAKES) - INSTALLATION, FRONT........5-27

DISC BRAKE CALIPER (DISC/DRUM

BRAKES) - REMOVAL, FRONT............5-24

DISC BRAKE CALIPER GUIDE PINS

(DISC/DRUM BRAKES) -

INSTALLATION........................5-31

DISC BRAKE CALIPER GUIDE PINS

(DISC/DRUM BRAKES) - REMOVAL.......5-31

DISC BRAKE SHOES - CLEANING.....5-16,5-18

DISC BRAKE SHOES - INSPECTION . . . 5-16,5-18

DISC BRAKE SHOES - INSTALLATION,

REAR...............................5-19

DISC BRAKE SHOES - REMOVAL, REAR....5-17

DISC BRAKE SHOES (DISC/DISC

BRAKES) - INSTALLATION, FRONT........5-16

DISC BRAKE SHOES (DISC/DISC

BRAKES) - REMOVAL, FRONT............5-14

DISC BRAKE SHOES (DISC/DRUM

BRAKES) - INSTALLATION, FRONT........5-17

DISC BRAKE SHOES (DISC/DRUM

BRAKES) - REMOVAL, FRONT............5-15

DISC BRAKES (EXPORT) - DESCRIPTION . . . 5-13

DISC BRAKES (FRONT) - DESCRIPTION....5-11

DISC BRAKES (FRONT) - OPERATION......5-13

DISC BRAKES (REAR) - DESCRIPTION.....5-12

DISC BRAKES (REAR) - OPERATION......5-13

DISC RUNOUT - DIAGNOSIS AND

TESTING, CLUTCH COVER...............6-6

DISCHARGE (ESD) SENSITIVE DEVICES -

STANDARD PROCEDURE,

ELECTROSTATIC...................8W-01-8

DISCHARGE LINE - INSTALLATION.......24-69

DISCHARGE LINE - REMOVAL..........24-68

DISPLAY TEST MODE, OPERATION - DRB

IIITSTATE ...........................25-9

DISTRIBUTION DUCT - INSTALLATION,

A/C................................24-53

DISTRIBUTION DUCT - INSTALLATION,

REAR HEATER.......................24-59

DISTRIBUTION DUCT - REMOVAL, A/C

....24-53

DISTRIBUTION DUCT - REMOVAL, REAR

HEATER

............................24-59

DISTRIBUTION DUCTS - INSTALLATION,

FLOOR

.............................24-49

DISTRIBUTION DUCTS - REMOVAL,

FLOOR

.............................24-48

DISTRIBUTION SYSTEM - DESCRIPTION,

POWER

..........................8W-97-1

RSINDEX9

Description Group-Page Description Group-Page Description Group-Page

ProCarManuals.com

Page 2149 of 2177

DISTRIBUTION SYSTEM - OPERATION,

POWER..........................8W-97-1

DISTRIBUTION SYSTEMS, SPECIAL

TOOLS - POWER...................8W-97-2

DOES NOT FILL - DIAGNOSIS AND

TESTING, VEHICLE...................25-16

DOME/CARGO LAMP - INSTALLATION....8L-26

DOME/CARGO LAMP - REMOVAL........8L-26

DOOR - INSTALLATION................23-16

DOOR - INSTALLATION, FUEL FILL.......23-51

DOOR - INSTALLATION, SLIDING........23-29

DOOR - REMOVAL....................23-15

DOOR - REMOVAL, FUEL FILL..........23-51

DOOR - REMOVAL, SLIDING............23-29

DOOR ACTUATOR - DESCRIPTION,

BLEND........................24-11,24-30

DOOR ACTUATOR - DESCRIPTION,

MODE.............................24-24

DOOR ACTUATOR - DESCRIPTION,

RECIRCULATION.....................24-27

DOOR ACTUATOR - INSTALLATION,

BLEND........................24-12,24-31

DOOR ACTUATOR - INSTALLATION,

MODE........................24-25,24-36

DOOR ACTUATOR - INSTALLATION,

RECIRCULATION.....................24-28

DOOR ACTUATOR - OPERATION, BLEND . . 24-11,

24-30

DOOR ACTUATOR - OPERATION, MODE . . . 24-24

DOOR ACTUATOR - OPERATION,

RECIRCULATION.......................24-27

DOOR ACTUATOR - REMOVAL, BLEND . . . 24-12,

24-31

DOOR ACTUATOR - REMOVAL, MODE....24-25,

24-36

DOOR ACTUATOR - REMOVAL,

RECIRCULATION.....................24-27

DOOR ADJUSTMENT - STANDARD

PROCEDURE, SLIDING................8N-28

DOOR ADJUSTMENTS, ADJUSTMENTS -

SLIDING............................23-30

DOOR BLOCKER LATCH - INSTALLATION,

FUEL FILL..........................23-52

DOOR BLOCKER LATCH - REMOVAL,

FUEL FILL..........................23-52

DOOR BLOCKER LATCH STRIKER -

INSTALLATION, FUEL FILL.............23-52

DOOR BLOCKER LATCH STRIKER -

REMOVAL, FUEL FILL.................23-52

DOOR BLOCKER LOCKOUT LINK -

INSTALLATION, FUEL FILL.............23-53

DOOR BLOCKER LOCKOUT LINK -

REMOVAL, FUEL FILL.................23-52

DOOR CONTROL MODULE -

DESCRIPTION, SLIDING...............8E-19

DOOR CONTROL MODULE -

INSTALLATION, SLIDING...............8E-20

DOOR CONTROL MODULE - OPERATION,

SLIDING............................8E-19

DOOR CONTROL MODULE - REMOVAL,

SLIDING............................8E-19

DOOR CYLINDER LOCK SWITCH -

DESCRIPTION.......................8N-40

DOOR CYLINDER LOCK SWITCH -

DIAGNOSIS AND TESTING.............8N-40

DOOR CYLINDER LOCK SWITCH -

INSTALLATION......................8N-41

DOOR CYLINDER LOCK SWITCH -

OPERATION

.........................8N-40

DOOR CYLINDER LOCK SWITCH -

REMOVAL

..........................8N-41

DOOR GLASS - INSTALLATION

..........23-17

DOOR GLASS - INSTALLATION, REAR

. . . 23-108

DOOR GLASS - INSTALLATION, SLIDING

. 23-107

DOOR GLASS - REMOVAL

.............23-17

DOOR GLASS - REMOVAL, REAR

.......23-108

DOOR GLASS - REMOVAL, SLIDING

.....23-107

DOOR GLASS RUN WEATHERSTRIP -

INSTALLATION, FRONT

...............23-110

DOOR GLASS RUN WEATHERSTRIP -

REMOVAL, FRONT

...................23-110

DOOR INNER BELT MOLDING -

INSTALLATION, FRONT

...............23-112

DOOR INNER BELT MOLDING -

REMOVAL, FRONT

...................23-112

DOOR LEARN CYCLE - STANDARD

PROCEDURE, POWER

.................8N-28DOOR LOCK MOTOR - DIAGNOSIS AND

TESTING...........................8N-41

DOOR LOCK MOTOR - INSTALLATION,

SLIDING...........................8N-44

DOOR LOCK MOTOR - REMOVAL,

SLIDING...........................8N-44

DOOR LOCK SWITCH - DIAGNOSIS AND

TESTING...........................8N-41

DOOR LOCK SWITCH - INSTALLATION....8N-42

DOOR LOCK SWITCH - REMOVAL.......8N-42

DOOR MOTOR - DESCRIPTION, SLIDING . . 8N-30

DOOR MOTOR - INSTALLATION, SLIDING . 8N-31

DOOR MOTOR - OPERATION, SLIDING . . . 8N-30

DOOR MOTOR - REMOVAL, SLIDING.....8N-30

DOOR OUTER BELT MOLDING -

INSTALLATION, FRONT...............23-110

DOOR OUTER BELT MOLDING -

REMOVAL, FRONT...................23-110

DOOR REAR OUTLET - INSTALLATION,

FRONT.............................24-42

DOOR REAR OUTLET - REMOVAL,

FRONT.............................24-41

DOOR SILL PLATE - INSTALLATION,

SLIDING............................23-80

DOOR SILL PLATE - REMOVAL, SLIDING . . 23-80

DOOR SILL TRIM PLATE -

INSTALLATION.......................23-76

DOOR SILL TRIM PLATE - REMOVAL.....23-76

DOOR STOP BUMPER BEZEL -

INSTALLATION, SLIDING...............23-25

DOOR STOP BUMPER BEZEL -

REMOVAL, SLIDING..................23-25

DOOR SYSTEM - DESCRIPTION, POWER

SLIDING...........................8N-19

DOOR SYSTEM - DIAGNOSIS AND

TESTING, POWER SLIDING.............8N-22

DOOR SYSTEM - OPERATION, POWER

SLIDING...........................8N-21

DOOR WEATHERSTRIP - INSTALLATION,

FRONT............................23-111

DOOR WEATHERSTRIP - INSTALLATION,

SLIDING...........................23-112

DOOR WEATHERSTRIP - REMOVAL,

FRONT............................23-111

DOOR WEATHERSTRIP - REMOVAL,

SLIDING...........................23-112

DOSING PUMP - DESCRIPTION, FUEL . . . 24-108

DOSING PUMP - INSTALLATION, FUEL . . . 24-108

DOSING PUMP - OPERATION, FUEL.....24-108

DOSING PUMP - REMOVAL, FUEL......24-108

DOWNSTREAM 1/2 - 2.4/3.3/3.8L -

REMOVAL..........................14-33

DOWNSTREAM 2/1, 2.4/3.3/3.8L -

INSTALLATION.......................14-34

D-PILLAR TRIM PANEL - INSTALLATION,

LEFT..............................23-77

D-PILLAR TRIM PANEL - INSTALLATION,

RIGHT.............................23-80

D-PILLAR TRIM PANEL - REMOVAL,

LEFT..............................23-77

D-PILLAR TRIM PANEL - REMOVAL,

RIGHT.............................23-80

DRAIN AND FILL - STANDARD

PROCEDURE, FLUID..................21-71

DRAIN TUBE - INSTALLATION..........23-117

DRAIN TUBE - REMOVAL.............23-116

DRAINCOCK - INSTALLATION, RADIATOR . . . 7-26

DRAINCOCK - REMOVAL, RADIATOR......7-26

DRAINING - STANDARD PROCEDURE,

COOLING SYSTEM.....................7-4

DRAINING FUEL TANK - STANDARD

PROCEDURE.........................14-2

DRAW TEST - STANDARD PROCEDURE,

IGNITION-OFF.......................8F-13

DRB IIITSTATE DISPLAY TEST MODE,

OPERATION..........................25-9

DRIVE - ASSEMBLY, FINAL............21-195

DRIVE - DESCRIPTION, FLEX...........8N-36

DRIVE - DISASSEMBLY, FINAL.........21-190

DRIVE - INSTALLATION, FLEX..........8N-37

DRIVE - OPERATION, FLEX.............8N-36

DRIVE - REMOVAL, FLEX

..............8N-37

DRIVE BELT - DIAGNOSIS AND TESTING,

ACCESSORY

..........................7-7

DRIVE BELT TENSION, SPECIFICATIONS -

ACCESSORY

..........................7-5

DRIVE BELTS - 2.4L - ADJUSTMENTS

.....7-10

DRIVE BELTS - 2.4L - CLEANING

..........7-9DRIVE BELTS - 2.4L - INSPECTION........7-9

DRIVE BELTS - 2.4L - INSTALLATION......7-10

DRIVE BELTS - 2.4L - REMOVAL..........7-8

DRIVE BELTS - 3.3/3.8L - CLEANING......7-11

DRIVE BELTS - 3.3/3.8L - INSPECTION....7-11

DRIVE BELTS - 3.3/3.8L - INSTALLATION . . . 7-12

DRIVE BELTS - 3.3/3.8L - REMOVAL......7-11

DRIVE PLATE MISALIGNMENT -

DIAGNOSIS AND TESTING...............6-6

DRIVE UNIT - DESCRIPTION, LOWER....8N-32

DRIVE UNIT - INSTALLATION, LOWER....8N-33

DRIVE UNIT - OPERATION, LOWER......8N-32

DRIVE UNIT - REMOVAL, LOWER.......8N-33

DRIVE UNIT TRACK & RACK -

DESCRIPTION, LOWER................8N-34

DRIVE UNIT TRACK & RACK -

INSTALLATION, LOWER...............8N-34

DRIVE UNIT TRACK & RACK -

OPERATION, LOWER..................8N-34

DRIVE UNIT TRACK & RACK -

REMOVAL, LOWER...................8N-34

DRIVELINE MODULE - DESCRIPTION,

REAR...............................3-23

DRIVELINE MODULE - OPERATION,

REAR...............................3-23

DRIVELINE MODULE - SPECIFICATIONS,

REAR...............................3-34

DRIVELINE MODULE NOISE -

DIAGNOSIS AND TESTING, REAR.........3-24

DRIVELINE MODULE OPERATION -

DIAGNOSIS AND TESTING, REAR.........3-26

DRIVER AIRBAG - DESCRIPTION.........8O-5

DRIVER AIRBAG - INSTALLATION........8O-6

DRIVER AIRBAG - OPERATION...........8O-5

DRIVER AIRBAG - REMOVAL............8O-5

DRIVER AIRBAG TRIM COVER -

INSTALLATION.......................8O-7

DRIVER AIRBAG TRIM COVER -

REMOVAL...........................8O-6

DRIVER HEATED SEAT SWITCH -

DESCRIPTION........................8G-8

DRIVER HEATED SEAT SWITCH -

DIAGNOSIS AND TESTING..............8G-9

DRIVER HEATED SEAT SWITCH -

INSTALLATION......................8G-10

DRIVER HEATED SEAT SWITCH -

OPERATION..........................8G-8

DRIVER HEATED SEAT SWITCH -

REMOVAL..........................8G-10

DRIVER POWER SEAT TRACK -

DESCRIPTION.......................8N-58

DRIVER POWER SEAT TRACK -

DIAGNOSIS AND TESTING.............8N-58

DRIVER POWER SEAT TRACK -

INSTALLATION......................8N-59

DRIVER POWER SEAT TRACK -

OPERATION.........................8N-58

DRIVER POWER SEAT TRACK -

REMOVAL..........................8N-59

DRIVER SEAT SWITCH - DESCRIPTION . . . 8N-53

DRIVER SEAT SWITCH - DIAGNOSIS

AND TESTING.......................8N-54

DRIVER SEAT SWITCH - INSTALLATION . . 8N-55

DRIVER SEAT SWITCH - OPERATION.....8N-54

DRIVER SEAT SWITCH - REMOVAL......8N-55

DRIVING CLUTCHES - DESCRIPTION....21-190

DRIVING CLUTCHES - OPERATION......21-190

DROP - STANDARD PROCEDURE,

TESTING FOR A VOLTAGE

...........8W-01-10

DRUM - INSTALLATION

.................5-32

DRUM - REMOVAL

....................5-32

DRUM BRAKE - INSTALLATION,

SUPPORT PLATE

......................5-56

DRUM BRAKE - REMOVAL, SUPPORT

PLATE

..............................5-56

DRUM BRAKE AUTOMATIC ADJUSTER -

DIAGNOSIS AND TESTING

..............5-13

DRUM BRAKE SHOE LINING -

INSPECTION, REAR

....................5-22

DRUM BRAKE SHOES - ADJUSTMENT,

REAR

...............................5-23

DRUM BRAKE SHOES - INSTALLATION,

REAR

...............................5-22

DRUM BRAKE SHOES - REMOVAL, REAR

. . 5-19

DRUM BRAKES (REAR) - DESCRIPTION

....5-13

DUAL ZONE - DESCRIPTION

.............24-1

DUAL ZONE - OPERATION

...............24-3

10 INDEXRS

Description Group-Page Description Group-Page Description Group-Page

ProCarManuals.com

Page 2154 of 2177

GUIDE PINS (DISC/DRUM BRAKES) -

INSTALLATION, DISC BRAKE CALIPER.....5-31

GUIDE PINS (DISC/DRUM BRAKES) -

REMOVAL, DISC BRAKE CALIPER.........5-31

HALF SHAFT - DIAGNOSIS AND TESTING . . . 3-1,

3-13

HALF SHAFT - FRONT - DESCRIPTION......3-1

HALF SHAFT - FRONT - INSTALLATION.....3-4

HALF SHAFT - FRONT - REMOVAL.........3-2

HALF SHAFT - FRONT - SPECIFICATIONS . . 3-15,

3-6

HALF SHAFT - REAR - DESCRIPTION......3-13

HALF SHAFT - REAR - INSTALLATION.....3-14

HALF SHAFT - REAR - REMOVAL.........3-13

HALF SHAFT INNER SEAL -

INSTALLATION.......................21-12

HALF SHAFT INNER SEAL - REMOVAL....21-12

HALF SHAFT SEAL - INSTALLATION,

OUTER.............................21-19

HALF SHAFT SEAL - REMOVAL, OUTER . . . 21-19

HANDLE - INSTALLATION, ASSIST.......23-73

HANDLE - INSTALLATION, EXTERIOR....23-22,

23-39

HANDLE - INSTALLATION, INSIDE LATCH . . 23-33

HANDLE - INSTALLATION, OUTSIDE......23-35

HANDLE - INSTALLATION, RECLINER.....23-89

HANDLE - REMOVAL, ASSIST...........23-73

HANDLE - REMOVAL, EXTERIOR . . . 23-22,23-39

HANDLE - REMOVAL, INSIDE LATCH.......23-33

HANDLE - REMOVAL, OUTSIDE.........23-35

HANDLE - REMOVAL, RECLINER........23-89

HANDLE CABLE - INSTALLATION, INSIDE . . 23-37

HANDLE CABLE - INSTALLATION,

OUTSIDE...........................23-36

HANDLE CABLE - REMOVAL, INSIDE.....23-37

HANDLE CABLE - REMOVAL, OUTSIDE....23-36

HANDLE SWITCH - DESCRIPTION,

EXTERIOR..........................8N-11

HANDLE SWITCH - INSTALLATION,

EXTERIOR..........................8N-12

HANDLE SWITCH - OPERATION,

EXTERIOR..........................8N-11

HANDLE SWITCH - REMOVAL, EXTERIOR . 8N-11

HANDLING AIRBAGS - STANDARD

PROCEDURE.........................8O-3

HARNESS - DESCRIPTION, WIRING......8N-35

HARNESS - DIAGNOSIS AND TESTING,

WIRING..........................8W-01-7

HARNESS - INSTALLATION, WIRING.....8N-36

HARNESS - OPERATION, WIRING........8N-35

HARNESS - REMOVAL, WIRING.........8N-35

HCU (HYDRAULIC CONTROL UNIT) -

DESCRIPTION........................5-89

HCU (HYDRAULIC CONTROL UNIT) -

OPERATION..........................5-89

HEAD - CLEANING, CYLINDER......9-100,9-26

HEAD - DESCRIPTION, CYLINDER....9-24,9-99

HEAD - INSPECTION, CYLINDER.....9-101,9-26

HEAD - INSTALLATION, CYLINDER . . . 9-101,9-26

HEAD - REMOVAL, CYLINDER......9-100,9-25

HEAD COVER - CLEANING, CYLINDER.....9-31

HEAD COVER - INSPECTION, CYLINDER . . . 9-31

HEAD COVER - INSTALLATION,

CYLINDER...........................9-31

HEAD COVER - LEFT - INSTALLATION,

CYLINDER..........................9-103

HEAD COVER - LEFT - REMOVAL,

CYLINDER..........................9-103

HEAD COVER - REMOVAL, CYLINDER.....9-31

HEAD COVER - RIGHT - INSTALLATION,

CYLINDER..........................9-103

HEAD COVER - RIGHT - REMOVAL,

CYLINDER..........................9-102

HEAD COVER(S) - DESCRIPTION,

CYLINDER..........................9-102

HEAD GASKET - DIAGNOSIS AND

TESTING, CYLINDER...............9-24,9-99

HEAD OFF - INSTALLATION, CYLINDER . . . 9-108,

9-33

HEAD OFF - REMOVAL, CYLINDER . . . 9-106,9-32

HEAD ON - INSTALLATION, CYLINDER . . . 9-108,

9-33

HEAD ON - REMOVAL, CYLINDER . . . 9-106,9-32

HEADER TRIM - INSTALLATION, REAR

....23-79

HEADER TRIM - REMOVAL, REAR

.......23-79

HEADLAMP - DIAGNOSIS AND TESTING

. . 8L-11

HEADLAMP - EXPORT - INSTALLATION

. . . 8L-13

HEADLAMP - EXPORT - REMOVAL

.......8L-13HEADLAMP - INSTALLATION............8L-13

HEADLAMP - REMOVAL...............8L-13

HEADLAMP LEVELING MOTOR - EXPORT

- DIAGNOSIS AND TESTING............8L-14

HEADLAMP LEVELING MOTOR - EXPORT

- INSTALLATION.....................8L-15

HEADLAMP LEVELING MOTOR - EXPORT

- REMOVAL.........................8L-14

HEADLAMP LEVELING SWITCH -

EXPORT - DESCRIPTION...............8L-15

HEADLAMP LEVELING SWITCH -

EXPORT - DIAGNOSIS AND TESTING.....8L-15

HEADLAMP SWITCH - DIAGNOSIS AND

TESTING...........................8L-15

HEADLAMP SWITCH - EXPORT -

DIAGNOSIS AND TESTING.............8L-16

HEADLAMP UNIT - EXPORT -

INSTALLATION.......................8L-20

HEADLAMP UNIT - EXPORT - REMOVAL . . 8L-20

HEADLAMP UNIT ALIGNMENT - EXPORT

- STANDARD PROCEDURE.............8L-17

HEADLAMP UNIT ALIGNMENT -

STANDARD PROCEDURE...............8L-17

HEADLAMP WASHER HOSE - EXPORT -

INSTALLATION......................8R-12

HEADLAMP WASHER HOSE - EXPORT -

REMOVAL..........................8R-12

HEADLAMP WASHER PUMP MOTOR -

EXPORT - INSTALLATION..............8R-13

HEADLAMP WASHER PUMP MOTOR -

EXPORT - REMOVAL..................8R-12

HEADLAMP WASHERS - EXPORT -

DESCRIPTION........................8R-10

HEADLAMP WASHERS - EXPORT -

DIAGNOSIS AND TESTING.............8R-10

HEADLAMP WASHERS - EXPORT -

INSTALLATION......................8R-12

HEADLAMP WASHERS - EXPORT -

OPERATION.........................8R-10

HEADLAMP WASHERS - EXPORT -

REMOVAL..........................8R-12

HEADLINER - INSTALLATION...........23-76

HEADLINER - REMOVAL...............23-76

HEADREST - INSTALLATION............23-88

HEADREST - REMOVAL................23-88

HEADREST SLEEVE - INSTALLATION.....23-89

HEADREST SLEEVE - REMOVAL.........23-89

HEAT SHIELDS - DESCRIPTION..........11-6

HEAT SHIELDS - INSTALLATION..........11-7

HEAT SHIELDS - OPERATION............11-7

HEAT SHIELDS - REMOVAL.............11-7

HEAT STAKING - STANDARD

PROCEDURE........................23-10

HEATED GLASS - DESCRIPTION..........8G-1

HEATED GLASS - OPERATION...........8G-1

HEATED MIRROR - STANDARD

PROCEDURE.........................8G-6

HEATED MIRROR TEST - DIAGNOSIS

AND TESTING........................8G-5

HEATED MIRRORS - DESCRIPTION.......8G-5

HEATED MIRRORS - OPERATION.........8G-5

HEATED SEAT ELEMENTS -

DESCRIPTION.......................8G-10

HEATED SEAT ELEMENTS - DIAGNOSIS

AND TESTING.......................8G-10

HEATED SEAT ELEMENTS -

INSTALLATION......................8G-11

HEATED SEAT ELEMENTS - OPERATION . . 8G-10

HEATED SEAT ELEMENTS - REMOVAL

....8G-11

HEATED SEAT MODULE - DESCRIPTION

....8E-8

HEATED SEAT MODULE - DIAGNOSIS

AND TESTING

........................8E-9

HEATED SEAT MODULE - INSTALLATION

. . 8E-10

HEATED SEAT MODULE - OPERATION

.....8E-9

HEATED SEAT MODULE - REMOVAL

.......8E-9

HEATED SEAT SENSOR - DESCRIPTION

. . . 8G-11

HEATED SEAT SENSOR - DIAGNOSIS

AND TESTING

.......................8G-12

HEATED SEAT SENSOR - OPERATION

....8G-12

HEATED SEAT SWITCH - DESCRIPTION,

DRIVER

.............................8G-8

HEATED SEAT SWITCH - DESCRIPTION,

PASSENGER

........................8G-12

HEATED SEAT SWITCH - DIAGNOSIS

AND TESTING, DRIVER

.................8G-9

HEATED SEAT SWITCH - DIAGNOSIS

AND TESTING, PASSENGER

............8G-13HEATED SEAT SWITCH - INSTALLATION,

DRIVER............................8G-10

HEATED SEAT SWITCH - INSTALLATION,

PASSENGER........................8G-14

HEATED SEAT SWITCH - OPERATION,

DRIVER.............................8G-8

HEATED SEAT SWITCH - OPERATION,

PASSENGER........................8G-12

HEATED SEAT SWITCH - REMOVAL,

DRIVER............................8G-10

HEATED SEAT SWITCH - REMOVAL,

PASSENGER........................8G-14

HEATED SEAT SYSTEM - DESCRIPTION....8G-7

HEATED SEAT SYSTEM - DIAGNOSIS

AND TESTING........................8G-8

HEATED SEAT SYSTEM - OPERATION.....8G-8

HEATER - DCHA - DIAGNOSIS AND

TESTING, DIESEL SUPPLEMENTAL......24-107

HEATER - DCHA - EXPORT -

DESCRIPTION, DIESEL

SUPPLEMENTAL....................24-106

HEATER - DESCRIPTION, ENGINE BLOCK . . . 7-20

HEATER - INSTALLATION, ENGINE

BLOCK..............................7-20

HEATER - OPERATION, ENGINE BLOCK....7-20

HEATER - REMOVAL, ENGINE BLOCK......7-20

HEATER CONTROL - INSTALLATION, A/C . . . 24-9

HEATER CONTROL - REMOVAL, A/C.......24-9

HEATER CORE - DESCRIPTION.....24-74,24-98

HEATER CORE - INSTALLATION . . . 24-100,24-78

HEATER CORE - OPERATION........24-74,24-98

HEATER CORE - REMOVAL........24-76,24-99

HEATER CORE EXTENSION TUBES -

INSTALLATION.......................24-77

HEATER CORE EXTENSION TUBES -

REMOVAL..........................24-75

HEATER CORE FILLING - STANDARD

PROCEDURE........................24-98

HEATER DISTRIBUTION DUCT -

INSTALLATION, REAR.................24-59

HEATER DISTRIBUTION DUCT -

REMOVAL, REAR.....................24-59

HEATER HOSE - INSTALLATION . . . 24-101,24-80

HEATER HOSE - REMOVAL.......24-100,24-78

HEATER LINES - INSTALLATION, REAR . . 24-105

HEATER LINES - REMOVAL, REAR......24-104

HEATER PERFORMANCE TEST -

DIAGNOSIS AND TESTING..............24-6

HEATER TESTING - DIAGNOSIS AND

TESTING, ENGINE BLOCK...............7-20

HEATER UNIT - INSTALLATION.........24-111

HEATER UNIT - REMOVAL.............24-111

HEATER WIRING - INSTALLATION,

SUPPLEMENTAL DIESEL..............24-112

HEATER WIRING - REMOVAL,

SUPPLEMENTAL DIESEL..............24-112

HEATER-A/C CONTROL CALIBRATION -

STANDARD PROCEDURE................24-8

HEATER-A/C HOUSING - INSTALLATION,

REAR..............................24-58

HEATER-A/C HOUSING - REMOVAL,

REAR..............................24-56

HEATER-A/C SYSTEM - SPECIFICATIONS . . . 24-7

HEAVY DUTY - INSTALLATION, AWD......2-35

HEAVY DUTY - REMOVAL, AWD..........2-35

HEIGHT ADJUSTER-BORC-PILLAR -

INSTALLATION, SEAT BELT.............8O-12

HEIGHT ADJUSTER-BORC-PILLAR -

REMOVAL, SEAT BELT................8O-12

HEIGHT ADJUSTER KNOB -

INSTALLATION, SEAT BELT.............8O-13

HEIGHT ADJUSTER KNOB - REMOVAL,

SEAT BELT .........................8O-13

HEIGHT MEASUREMENT - STANDARD

PROCEDURE, CURB...................2-54

HIGH AND LOW LIMITS - DESCRIPTION . . . 25-8

HIGH MOUNTED STOP LAMP -

INSTALLATION, CENTER................8L-6

HIGH MOUNTED STOP LAMP -

REMOVAL, CENTER....................8L-6

HIGH MOUNTED STOP LAMP UNIT -

INSTALLATION, CENTER

................8L-7

HIGH MOUNTED STOP LAMP UNIT -

REMOVAL, CENTER

....................8L-6

HIGH SPEED OPERATION - STANDARD

PROCEDURE, TIRE PRESSURE

..........22-17

HINGE - INSTALLATION

......23-18,23-39,23-59

HINGE - INSTALLATION, CENTER

........23-24

RSINDEX15

Description Group-Page Description Group-Page Description Group-Page

ProCarManuals.com

Page 2155 of 2177

HINGE - INSTALLATION, LOWER........23-28

HINGE - INSTALLATION, UPPER.........23-35

HINGE - REMOVAL.........23-18,23-39,23-59

HINGE - REMOVAL, BENCH SEAT BACK . . 23-100

HINGE - REMOVAL, CENTER............23-24

HINGE - REMOVAL, LOWER............23-28

HINGE - REMOVAL, UPPER.............23-35

HINGE COVERS - QUAD BUCKET, 50/50

SPLIT, BENCH - INSTALLATION, SEAT

BACK.............................23-100

HINGE COVERS - QUAD BUCKET, 50/50

SPLIT, BENCH - REMOVAL, SEAT BACK . . 23-100

HOISTING - STANDARD PROCEDURE......0-15

HOLD OPEN LATCH - INSTALLATION.....23-25

HOLD OPEN LATCH - REMOVAL.........23-25

HOLD OPEN LATCH CABLE -

INSTALLATION.......................23-38

HOLD OPEN LATCH CABLE - REMOVAL . . . 23-37

HOLD OPEN LATCH STRIKER -

INSTALLATION.......................23-26

HOLD OPEN LATCH STRIKER -

REMOVAL..........................23-26

HOLDDOWN - DESCRIPTION, BATTERY . . . 8F-15

HOLDDOWN - INSTALLATION, BATTERY . . . 8F-16

HOLDDOWN - OPERATION, BATTERY.....8F-15

HOLDDOWN - REMOVAL, BATTERY......8F-16

HOLDER - INSTALLATION, CUP.........23-63

HOLDER - INSTALLATION, QUAD

BUCKET SEAT SIDE SHIELD - NO CUP.....23-96

HOLDER - INSTALLATION, QUAD

BUCKET SEAT SIDE SHIELD/CUP........23-95

HOLDER - REMOVAL, CUP.............23-63

HOLDER - REMOVAL, QUAD BUCKET

SEAT SIDE SHIELD - NO CUP...........23-96

HOLDER - REMOVAL, QUAD BUCKET

SEAT SIDE SHIELD/CUP...............23-95

HOLDING CLUTCHES - DESCRIPTION....21-207

HOLDING CLUTCHES - OPERATION.....21-207

HOLE REPAIR - DESCRIPTION,

THREADED........................Intro.-5

HONING - STANDARD PROCEDURE,

CYLINDER BORE.................9-112,9-35

HOOD - INSTALLATION................23-60

HOOD - REMOVAL....................23-59

HOOD AJAR SWITCH - EXPORT -

INSTALLATION.......................8Q-3

HOOD AJAR SWITCH - EXPORT -

REMOVAL...........................8Q-3

HORN - DIAGNOSIS AND TESTING.......8H-3

HORN - INSTALLATION.................8H-5

HORN - REMOVAL....................8H-5

HORN CHIRP PREFERENCE - STANDARD

PROCEDURE........................8N-42

HORN RELAY - DIAGNOSIS AND

TESTING............................8H-5

HORN RELAY - INSTALLATION...........8H-5

HORN RELAY - REMOVAL..............8H-5

HORN SWITCH - DESCRIPTION..........8H-5

HORN SYSTEM - DESCRIPTION..........8H-1

HORN SYSTEM - DIAGNOSIS AND

TESTING............................8H-1

HORN SYSTEM - OPERATION............8H-1

HOSE - EXPORT - INSTALLATION,

HEADLAMP WASHER.................8R-12

HOSE - EXPORT - REMOVAL, HEADLAMP

WASHER...........................8R-12

HOSE - INSTALLATION, HEATER . . . 24-101,24-80

HOSE - REMOVAL, HEATER......24-100,24-78

HOSE CLAMPS - DESCRIPTION...........7-1

HOSE CLAMPS - OPERATION.............7-2

HOSES - DESCRIPTION, BRAKE TUBES

....5-14

HOSES - INSPECTION, BRAKE TUBES

.....5-14

HOSES - INSTALLATION, WASHER

.......8R-16

HOSES - OPERATION, BRAKE TUBES

......5-14

HOSES - REMOVAL, WASHER

..........8R-16

HOSES AND CLAMP - STANDARD

PROCEDURE

.........................14-6

HOUSING - INSTALLATION, AIR

CLEANER

........................9-24,9-99

HOUSING - INSTALLATION, HVAC

........24-50

HOUSING - INSTALLATION, LOCK

CYLINDER

..........................19-19

HOUSING - INSTALLATION, REAR

HEATER-A/C

.........................24-58

HOUSING - REMOVAL, AIR CLEANER

. . 9-24,9-99

HOUSING - REMOVAL, HVAC

...........24-49

HOUSING - REMOVAL, LOCK CYLINDER

. . 19-17HOUSING - REMOVAL, REAR HEATER-A/

C .................................24-56

HOUSING FLUID CHANGE - STANDARD

PROCEDURE, OVERRUNNING CLUTCH.....3-41

HOUSING FLUID LEAKAGE - DIAGNOSIS

AND TESTING, TORQUE CONVERTER....21-123

HOW TO USE WIRING DIAGRAMS -

DESCRIPTION.....................8W-01-1

HUB / BEARING - DESCRIPTION.......2-30,2-5

HUB / BEARING - INSTALLATION......2-32,2-5

HUB / BEARING - OPERATION........2-30,2-5

HUB / BEARING - REMOVAL..........2-31,2-5

HUB AND BEARING - DIAGNOSIS AND

TESTING.........................2-30,2-5

HVAC - LWB - INSTALLATION, SEAT

BELT & RETRACTOR - SECOND ROW -

RIGHT OUTBOARD WITH REAR.........8O-15

HVAC - LWB - REMOVAL, SEAT BELT &

RETRACTOR - SECOND ROW - RIGHT

OUTBOARD WITH REAR...............8O-15

HVAC HOUSING - INSTALLATION........24-50

HVAC HOUSING - REMOVAL............24-49

HVAC LOUVER - INSTALLATION, REAR . . . 23-79

HVAC LOUVER - REMOVAL, REAR.......23-79

HYDRAULIC CIRCUITS AND VALVES -

OPERATION..........................5-83

HYDRAULIC LASH ADJUSTER NOISE

DIAGNOSIS - DIAGNOSIS AND

TESTING............................9-34

HYDRAULIC LASH ADJUSTERS -

INSTALLATION........................9-34

HYDRAULIC LASH ADJUSTERS -

REMOVAL...........................9-34

HYDRAULIC LIFTERS - DIAGNOSIS AND

TESTING...........................9-113

HYDRAULIC LIFTERS (CAM IN BLOCK) -

DESCRIPTION.......................9-113

HYDRAULIC LIFTERS (CAM IN BLOCK) -

INSTALLATION.......................9-114

HYDRAULIC LIFTERS (CAM IN BLOCK) -

REMOVAL..........................9-114

HYDRAULIC PRESSURE TESTS -

DIAGNOSIS AND TESTING............21-120

HYDRAULIC SCHEMATICS, SCHEMATICS

AND DIAGRAMS - 41TE TRANSAXLE....21-169

HYDROSTATIC LOCKED ENGINE -

STANDARD PROCEDURE............9-10,9-85

ICU - ASSEMBLY......................5-94

ICU - DISASSEMBLY...................5-93

ICU (INTEGRATED CONTROL UNIT) -

DESCRIPTION........................5-89

ICU (INTEGRATED CONTROL UNIT) -

OPERATION..........................5-90

IDENTIFICATION - DESCRIPTION,

FASTENER.........................Intro.-2

IDENTIFICATION - DESCRIPTION,

VEHICLE............................23-1

IDENTIFICATION AND INFORMATION -

DESCRIPTION, SECTION.............8W-01-6

IDENTIFICATION, DIAGNOSIS AND

TESTING - SEAL......................21-3

IDENTIFICATION NUMBER -

DESCRIPTION, VEHICLE..............Intro.-9

IDLE AIR CONTROL MOTOR -

DESCRIPTION.......................14-28

IDLE AIR CONTROL MOTOR -

INSTALLATION.......................14-29

IDLE AIR CONTROL MOTOR -

OPERATION.........................14-28

IDLE AIR CONTROL MOTOR - REMOVAL

. . 14-29

IGNITION COIL - DESCRIPTION

...........8I-6

IGNITION COIL - OPERATION

.............8I-6

IGNITION INTERLOCK - DESCRIPTION

....19-17

IGNITION SENSE - PCM INPUT -

OPERATION

.........................8E-15

IGNITION SWITCH - INSTALLATION

......19-16

IGNITION SWITCH - REMOVAL

..........19-14

IGNITION SYSTEM - DESCRIPTION

........8I-1

IGNITION SYSTEM - OPERATION

..........8I-1

IGNITION-OFF DRAW TEST - STANDARD

PROCEDURE

........................8F-13

IIITSTATE DISPLAY TEST MODE,

OPERATION - DRB

....................25-9

ILLUMINATION LAMPS - INSTALLATION,

CLUSTER

...........................8L-26

ILLUMINATION LAMPS - REMOVAL,

CLUSTER

...........................8L-26IMMOBILIZER MODULE - DESCRIPTION,

SENTRY KEY........................8E-18

IMMOBILIZER MODULE - INSTALLATION,

SENTRY KEY........................8E-19

IMMOBILIZER MODULE - OPERATION,

SENTRY KEY........................8E-18

IMMOBILIZER MODULE - REMOVAL,

SENTRY KEY........................8E-18

IMMOBILIZER SYSTEM - DIAGNOSIS

AND TESTING, SENTRY KEY.............8Q-3

IMPACT AIRBAG CONTROL MODULE -

DESCRIPTION, SIDE..................8O-17

IMPACT AIRBAG CONTROL MODULE -

INSTALLATION, SIDE.................8O-17

IMPACT AIRBAG CONTROL MODULE -

OPERATION, SIDE....................8O-17

IMPACT AIRBAG CONTROL MODULE -

REMOVAL, SIDE.....................8O-17

INBOARD - 50/50 BENCH -

INSTALLATION, SEAT BELT BUCKLE -

SECOND ROW.......................8O-12

INBOARD - 50/50 BENCH - REMOVAL,

SEAT BELT BUCKLE - SECOND ROW.....8O-12

INBOARD - INSTALLATION, SEAT BELT

BUCKLE - FRONT....................8O-11

INBOARD - QUAD BUCKET -

INSTALLATION, SEAT BELT BUCKLE -

FIRST ROW.........................8O-11

INBOARD - QUAD BUCKET - REMOVAL,

SEAT BELT BUCKLE - FIRST ROW.......8O-11

INBOARD - REMOVAL, SEAT BELT

BUCKLE - FRONT....................8O-11

INDICATOR LAMP - DESCRIPTION,

VTSS/SKIS..........................8Q-5

INDICATOR LAMP - OPERATION,

VTSS/SKIS..........................8Q-5

INDICATORS - DIAGNOSIS AND

TESTING, TREAD WEAR...............22-16

INFLATION PRESSURES - STANDARD

PROCEDURE, TIRE...................22-16

INFO CENTER - DESCRIPTION,

ELECTRONIC VEHICLE.................8M-6

INFO CENTER - INSTALLATION,

ELECTRONIC VEHICLE.................8M-9

INFO CENTER - OPERATION,

ELECTRONIC VEHICLE.................8M-7

INFO CENTER - REMOVAL, ELECTRONIC

VEHICLE............................8M-9

INFRARED TEMPERATURE SENSOR -

DESCRIPTION..................24-23,24-35

INFRARED TEMPERATURE SENSOR -

OPERATION....................24-24,24-35

INITIAL OPERATION - STANDARD

PROCEDURE, POWER STEERING

PUMP.............................19-37

INJECTION SYSTEM - OPERATION.......14-18

INJECTOR - DESCRIPTION, FUEL........14-26

INJECTOR - OPERATION, FUEL..........14-26

INLET AIR TEMPERATURE SENSOR -

DESCRIPTION.......................14-29

INLET AIR TEMPERATURE SENSOR -

OPERATION.........................14-29

INLET FILTER - INSTALLATION..........14-13

INLET FILTER - REMOVAL..............14-13

INLET TUBE - 2.4L - DESCRIPTION,

WATER PUMP........................7-35

INLET TUBE - 2.4L - INSTALLATION,

WATER PUMP........................7-35

INLET TUBE - 2.4L - REMOVAL, WATER

PUMP..............................7-35

INLET TUBE - 3.3/3.8L - INSTALLATION,

WATER PUMP........................7-36

INLET TUBE - 3.3/3.8L - REMOVAL,

WATER PUMP........................7-36

INNER - INSTALLATION, CV BOOT.........3-6

INNER - REMOVAL, CV BOOT.............3-6

INNER BELT MOLDING - INSTALLATION,

FRONT DOOR......................23-112

INNER BELT MOLDING - REMOVAL,

FRONT DOOR......................23-112

INNER SEAL - INSTALLATION, HALF

SHAFT.............................21-12

INNER SEAL - REMOVAL, HALF SHAFT

. . . 21-12

INNER/OUTER - INSTALLATION, CV

BOOT

...............................3-17

INNER/OUTER - REMOVAL, CV BOOT

......3-15

INPUT - DESCRIPTION, SPEED SENSOR

. 21-239

INPUT - INSTALLATION, SPEED SENSOR

. 21-240

16 INDEXRS

Description Group-Page Description Group-Page Description Group-Page

ProCarManuals.com