clutch DODGE TOWN AND COUNTRY 2003 User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: TOWN AND COUNTRY, Model: DODGE TOWN AND COUNTRY 2003Pages: 2177, PDF Size: 59.81 MB

Page 35 of 2177

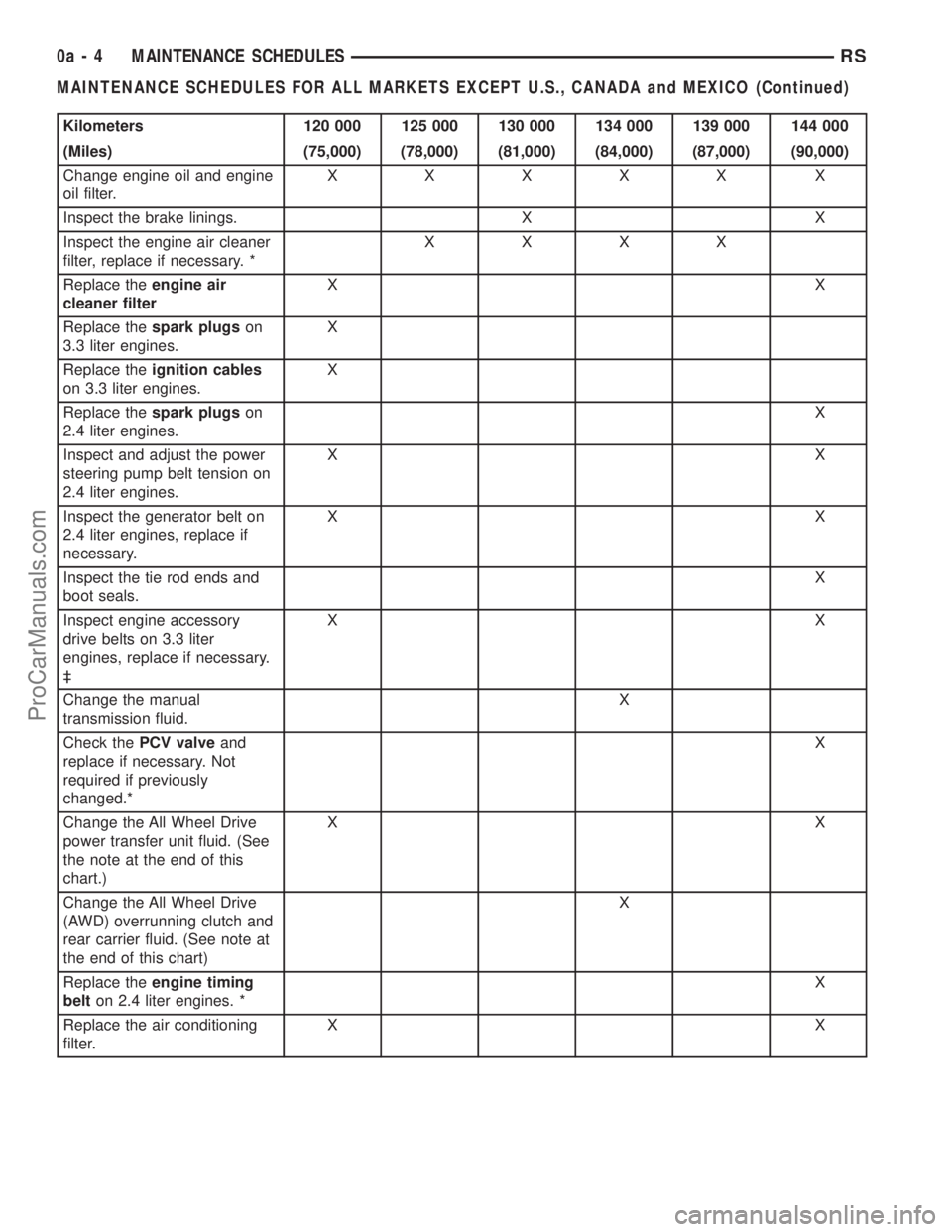

Kilometers 120 000 125 000 130 000 134 000 139 000 144 000

(Miles) (75,000) (78,000) (81,000) (84,000) (87,000) (90,000)

Change engine oil and engine

oil filter.XXXXX X

Inspect the brake linings. X X

Inspect the engine air cleaner

filter, replace if necessary. *XXXX

Replace theengine air

cleaner filterXX

Replace thespark plugson

3.3 liter engines.X

Replace theignition cables

on 3.3 liter engines.X

Replace thespark plugson

2.4 liter engines.X

Inspect and adjust the power

steering pump belt tension on

2.4 liter engines.XX

Inspect the generator belt on

2.4 liter engines, replace if

necessary.XX

Inspect the tie rod ends and

boot seals.X

Inspect engine accessory

drive belts on 3.3 liter

engines, replace if necessary.

³XX

Change the manual

transmission fluid.X

Check thePCV valveand

replace if necessary. Not

required if previously

changed.*X

Change the All Wheel Drive

power transfer unit fluid. (See

the note at the end of this

chart.)XX

Change the All Wheel Drive

(AWD) overrunning clutch and

rear carrier fluid. (See note at

the end of this chart)X

Replace theengine timing

belton 2.4 liter engines. *X

Replace the air conditioning

filter.XX

0a - 4 MAINTENANCE SCHEDULESRS

MAINTENANCE SCHEDULES FOR ALL MARKETS EXCEPT U.S., CANADA and MEXICO (Continued)

ProCarManuals.com

Page 36 of 2177

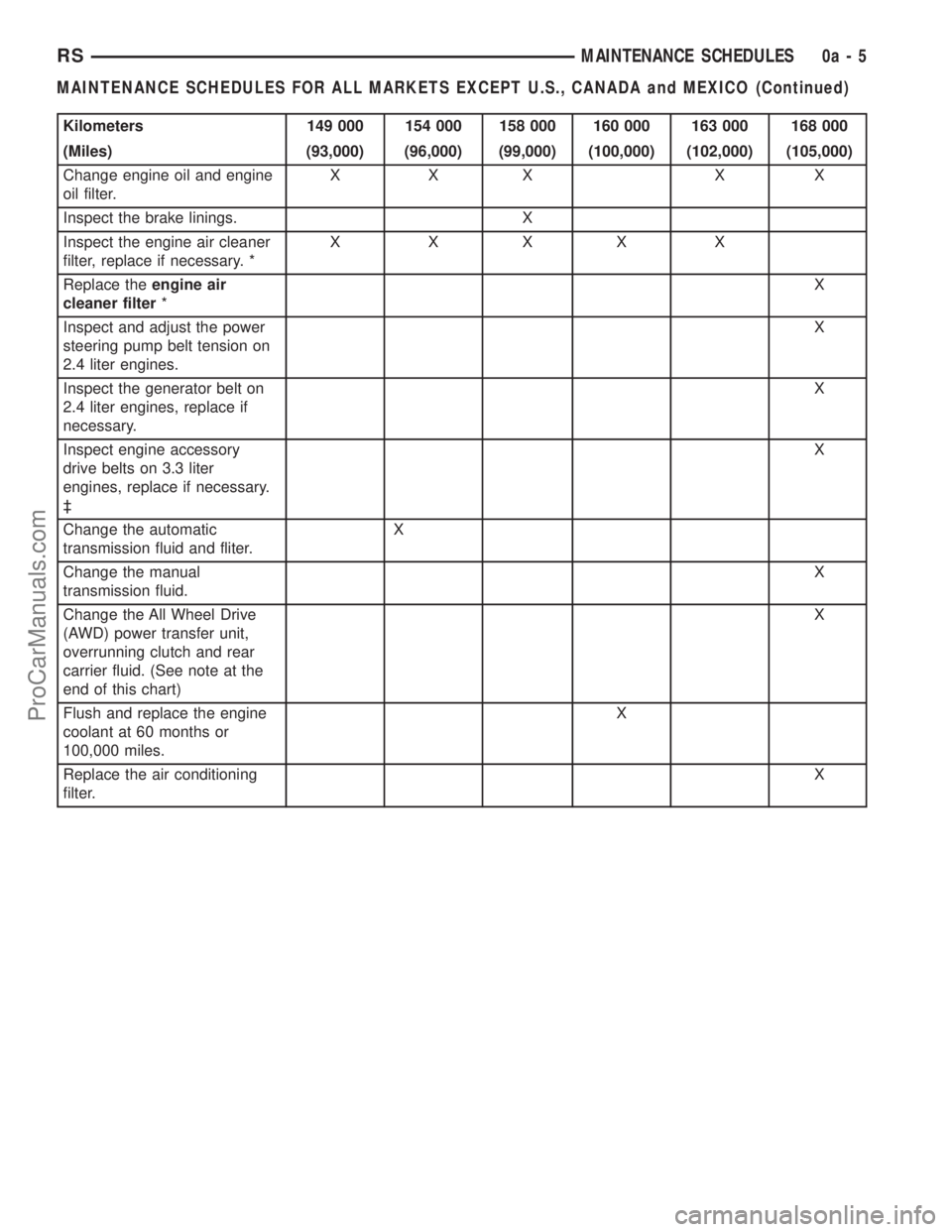

Kilometers 149 000 154 000 158 000 160 000 163 000 168 000

(Miles) (93,000) (96,000) (99,000) (100,000) (102,000) (105,000)

Change engine oil and engine

oil filter.XXX X X

Inspect the brake linings. X

Inspect the engine air cleaner

filter, replace if necessary. *X XXX X

Replace theengine air

cleaner filter*X

Inspect and adjust the power

steering pump belt tension on

2.4 liter engines.X

Inspect the generator belt on

2.4 liter engines, replace if

necessary.X

Inspect engine accessory

drive belts on 3.3 liter

engines, replace if necessary.

³X

Change the automatic

transmission fluid and fliter.X

Change the manual

transmission fluid.X

Change the All Wheel Drive

(AWD) power transfer unit,

overrunning clutch and rear

carrier fluid. (See note at the

end of this chart)X

Flush and replace the engine

coolant at 60 months or

100,000 miles.X

Replace the air conditioning

filter.X

RSMAINTENANCE SCHEDULES0a-5

MAINTENANCE SCHEDULES FOR ALL MARKETS EXCEPT U.S., CANADA and MEXICO (Continued)

ProCarManuals.com

Page 37 of 2177

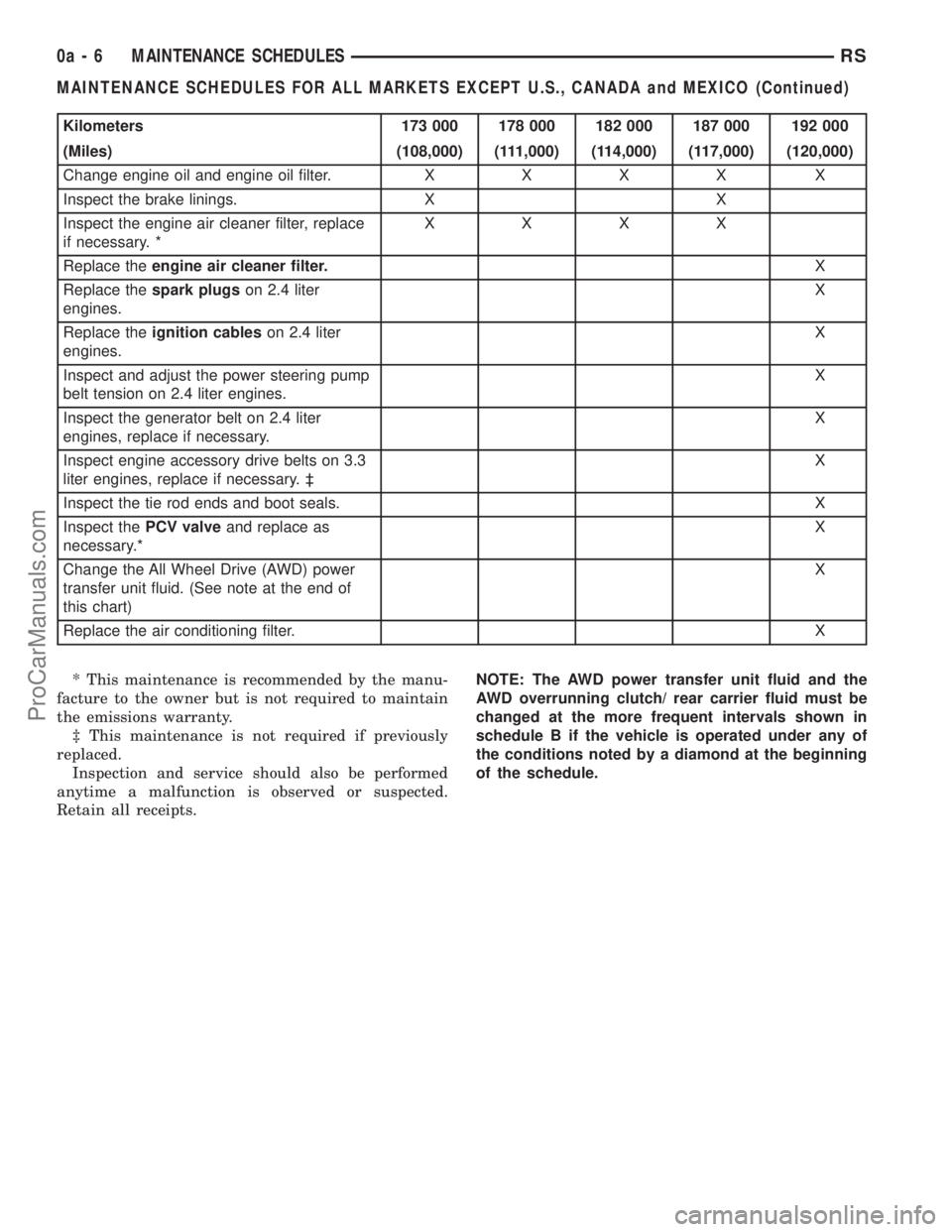

Kilometers 173 000 178 000 182 000 187 000 192 000

(Miles) (108,000) (111,000) (114,000) (117,000) (120,000)

Change engine oil and engine oil filter.XXXX X

Inspect the brake linings. X X

Inspect the engine air cleaner filter, replace

if necessary. *XXXX

Replace theengine air cleaner filter.X

Replace thespark plugson 2.4 liter

engines.X

Replace theignition cableson 2.4 liter

engines.X

Inspect and adjust the power steering pump

belt tension on 2.4 liter engines.X

Inspect the generator belt on 2.4 liter

engines, replace if necessary.X

Inspect engine accessory drive belts on 3.3

liter engines, replace if necessary. ³X

Inspect the tie rod ends and boot seals. X

Inspect thePCV valveand replace as

necessary.*X

Change the All Wheel Drive (AWD) power

transfer unit fluid. (See note at the end of

this chart)X

Replace the air conditioning filter.X

* This maintenance is recommended by the manu-

facture to the owner but is not required to maintain

the emissions warranty.

³ This maintenance is not required if previously

replaced.

Inspection and service should also be performed

anytime a malfunction is observed or suspected.

Retain all receipts.NOTE: The AWD power transfer unit fluid and the

AWD overrunning clutch/ rear carrier fluid must be

changed at the more frequent intervals shown in

schedule B if the vehicle is operated under any of

the conditions noted by a diamond at the beginning

of the schedule.

0a - 6 MAINTENANCE SCHEDULESRS

MAINTENANCE SCHEDULES FOR ALL MARKETS EXCEPT U.S., CANADA and MEXICO (Continued)

ProCarManuals.com

Page 122 of 2177

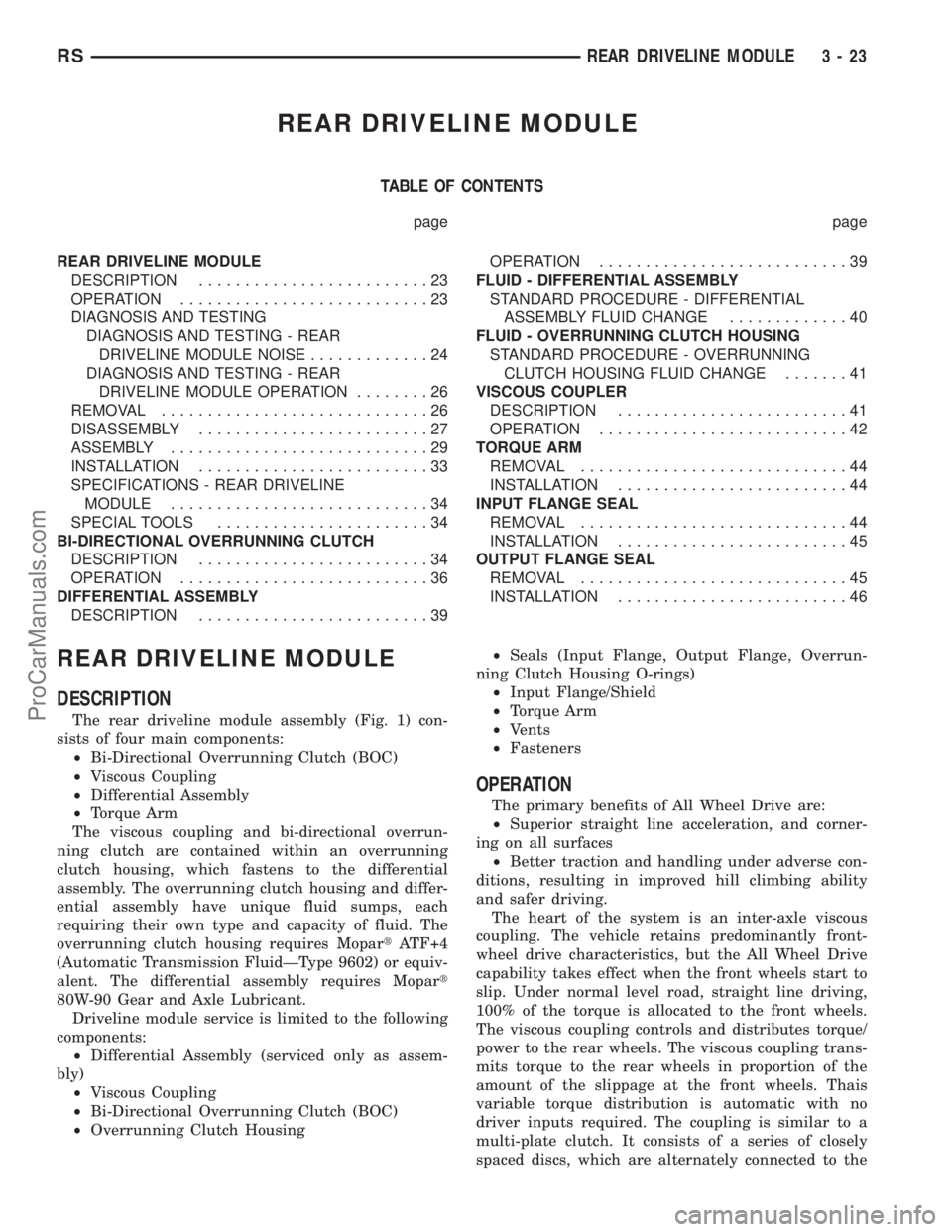

REAR DRIVELINE MODULE

TABLE OF CONTENTS

page page

REAR DRIVELINE MODULE

DESCRIPTION.........................23

OPERATION...........................23

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - REAR

DRIVELINE MODULE NOISE.............24

DIAGNOSIS AND TESTING - REAR

DRIVELINE MODULE OPERATION........26

REMOVAL.............................26

DISASSEMBLY.........................27

ASSEMBLY............................29

INSTALLATION.........................33

SPECIFICATIONS - REAR DRIVELINE

MODULE............................34

SPECIAL TOOLS.......................34

BI-DIRECTIONAL OVERRUNNING CLUTCH

DESCRIPTION.........................34

OPERATION...........................36

DIFFERENTIAL ASSEMBLY

DESCRIPTION.........................39OPERATION...........................39

FLUID - DIFFERENTIAL ASSEMBLY

STANDARD PROCEDURE - DIFFERENTIAL

ASSEMBLY FLUID CHANGE.............40

FLUID - OVERRUNNING CLUTCH HOUSING

STANDARD PROCEDURE - OVERRUNNING

CLUTCH HOUSING FLUID CHANGE.......41

VISCOUS COUPLER

DESCRIPTION.........................41

OPERATION...........................42

TORQUE ARM

REMOVAL.............................44

INSTALLATION.........................44

INPUT FLANGE SEAL

REMOVAL.............................44

INSTALLATION.........................45

OUTPUT FLANGE SEAL

REMOVAL.............................45

INSTALLATION.........................46

REAR DRIVELINE MODULE

DESCRIPTION

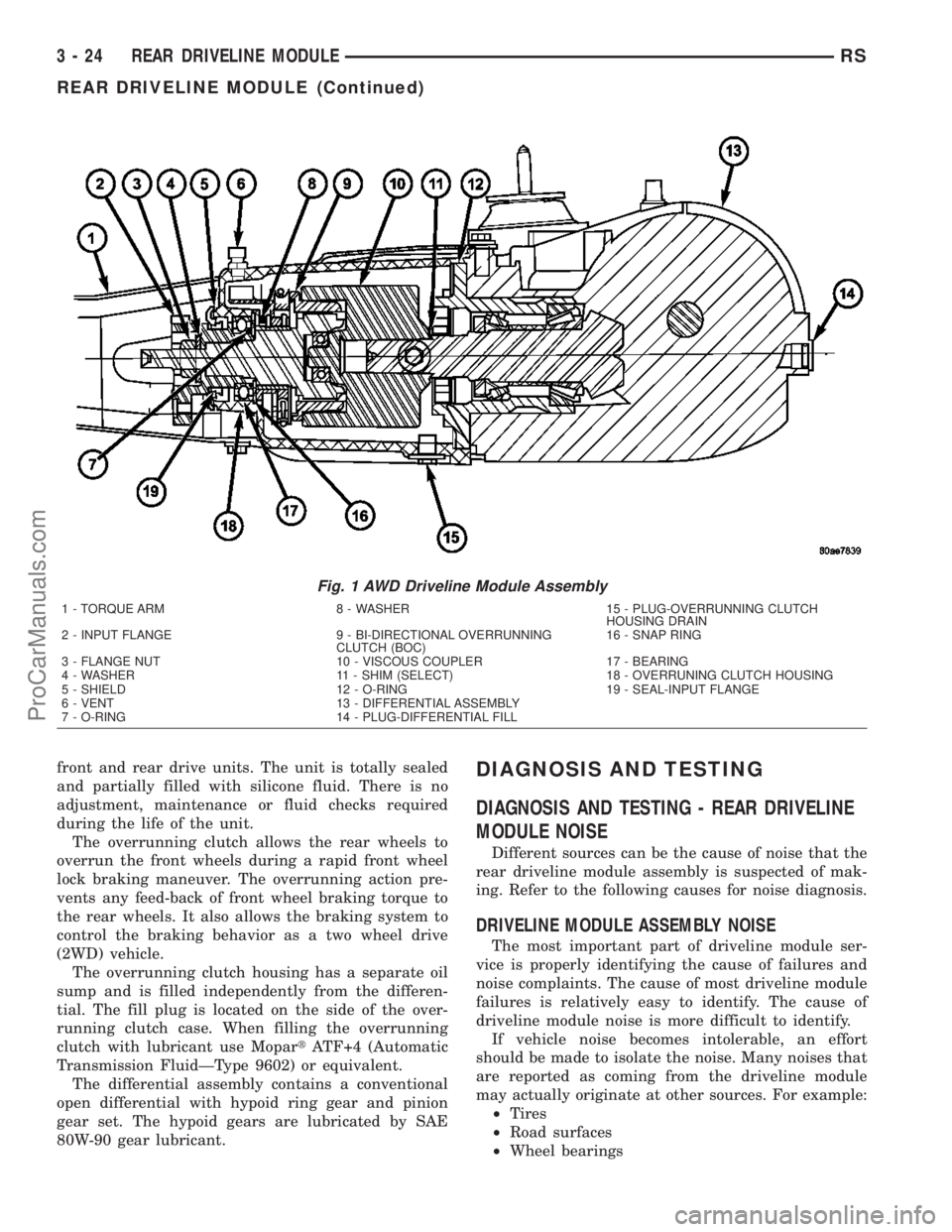

The rear driveline module assembly (Fig. 1) con-

sists of four main components:

²Bi-Directional Overrunning Clutch (BOC)

²Viscous Coupling

²Differential Assembly

²Torque Arm

The viscous coupling and bi-directional overrun-

ning clutch are contained within an overrunning

clutch housing, which fastens to the differential

assembly. The overrunning clutch housing and differ-

ential assembly have unique fluid sumps, each

requiring their own type and capacity of fluid. The

overrunning clutch housing requires MopartATF+4

(Automatic Transmission FluidÐType 9602) or equiv-

alent. The differential assembly requires Mopart

80W-90 Gear and Axle Lubricant.

Driveline module service is limited to the following

components:

²Differential Assembly (serviced only as assem-

bly)

²Viscous Coupling

²Bi-Directional Overrunning Clutch (BOC)

²Overrunning Clutch Housing²Seals (Input Flange, Output Flange, Overrun-

ning Clutch Housing O-rings)

²Input Flange/Shield

²Torque Arm

²Vents

²Fasteners

OPERATION

The primary benefits of All Wheel Drive are:

²Superior straight line acceleration, and corner-

ing on all surfaces

²Better traction and handling under adverse con-

ditions, resulting in improved hill climbing ability

and safer driving.

The heart of the system is an inter-axle viscous

coupling. The vehicle retains predominantly front-

wheel drive characteristics, but the All Wheel Drive

capability takes effect when the front wheels start to

slip. Under normal level road, straight line driving,

100% of the torque is allocated to the front wheels.

The viscous coupling controls and distributes torque/

power to the rear wheels. The viscous coupling trans-

mits torque to the rear wheels in proportion of the

amount of the slippage at the front wheels. Thais

variable torque distribution is automatic with no

driver inputs required. The coupling is similar to a

multi-plate clutch. It consists of a series of closely

spaced discs, which are alternately connected to the

RSREAR DRIVELINE MODULE3-23

ProCarManuals.com

Page 123 of 2177

front and rear drive units. The unit is totally sealed

and partially filled with silicone fluid. There is no

adjustment, maintenance or fluid checks required

during the life of the unit.

The overrunning clutch allows the rear wheels to

overrun the front wheels during a rapid front wheel

lock braking maneuver. The overrunning action pre-

vents any feed-back of front wheel braking torque to

the rear wheels. It also allows the braking system to

control the braking behavior as a two wheel drive

(2WD) vehicle.

The overrunning clutch housing has a separate oil

sump and is filled independently from the differen-

tial. The fill plug is located on the side of the over-

running clutch case. When filling the overrunning

clutch with lubricant use MopartATF+4 (Automatic

Transmission FluidÐType 9602) or equivalent.

The differential assembly contains a conventional

open differential with hypoid ring gear and pinion

gear set. The hypoid gears are lubricated by SAE

80W-90 gear lubricant.DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - REAR DRIVELINE

MODULE NOISE

Different sources can be the cause of noise that the

rear driveline module assembly is suspected of mak-

ing. Refer to the following causes for noise diagnosis.

DRIVELINE MODULE ASSEMBLY NOISE

The most important part of driveline module ser-

vice is properly identifying the cause of failures and

noise complaints. The cause of most driveline module

failures is relatively easy to identify. The cause of

driveline module noise is more difficult to identify.

If vehicle noise becomes intolerable, an effort

should be made to isolate the noise. Many noises that

are reported as coming from the driveline module

may actually originate at other sources. For example:

²Tires

²Road surfaces

²Wheel bearings

Fig. 1 AWD Driveline Module Assembly

1 - TORQUE ARM 8 - WASHER 15 - PLUG-OVERRUNNING CLUTCH

HOUSING DRAIN

2 - INPUT FLANGE 9 - BI-DIRECTIONAL OVERRUNNING

CLUTCH (BOC)16 - SNAP RING

3 - FLANGE NUT 10 - VISCOUS COUPLER 17 - BEARING

4 - WASHER 11 - SHIM (SELECT) 18 - OVERRUNING CLUTCH HOUSING

5 - SHIELD 12 - O-RING 19 - SEAL-INPUT FLANGE

6 - VENT 13 - DIFFERENTIAL ASSEMBLY

7 - O-RING 14 - PLUG-DIFFERENTIAL FILL

3 - 24 REAR DRIVELINE MODULERS

REAR DRIVELINE MODULE (Continued)

ProCarManuals.com

Page 125 of 2177

DIAGNOSIS AND TESTING - REAR DRIVELINE

MODULE OPERATION

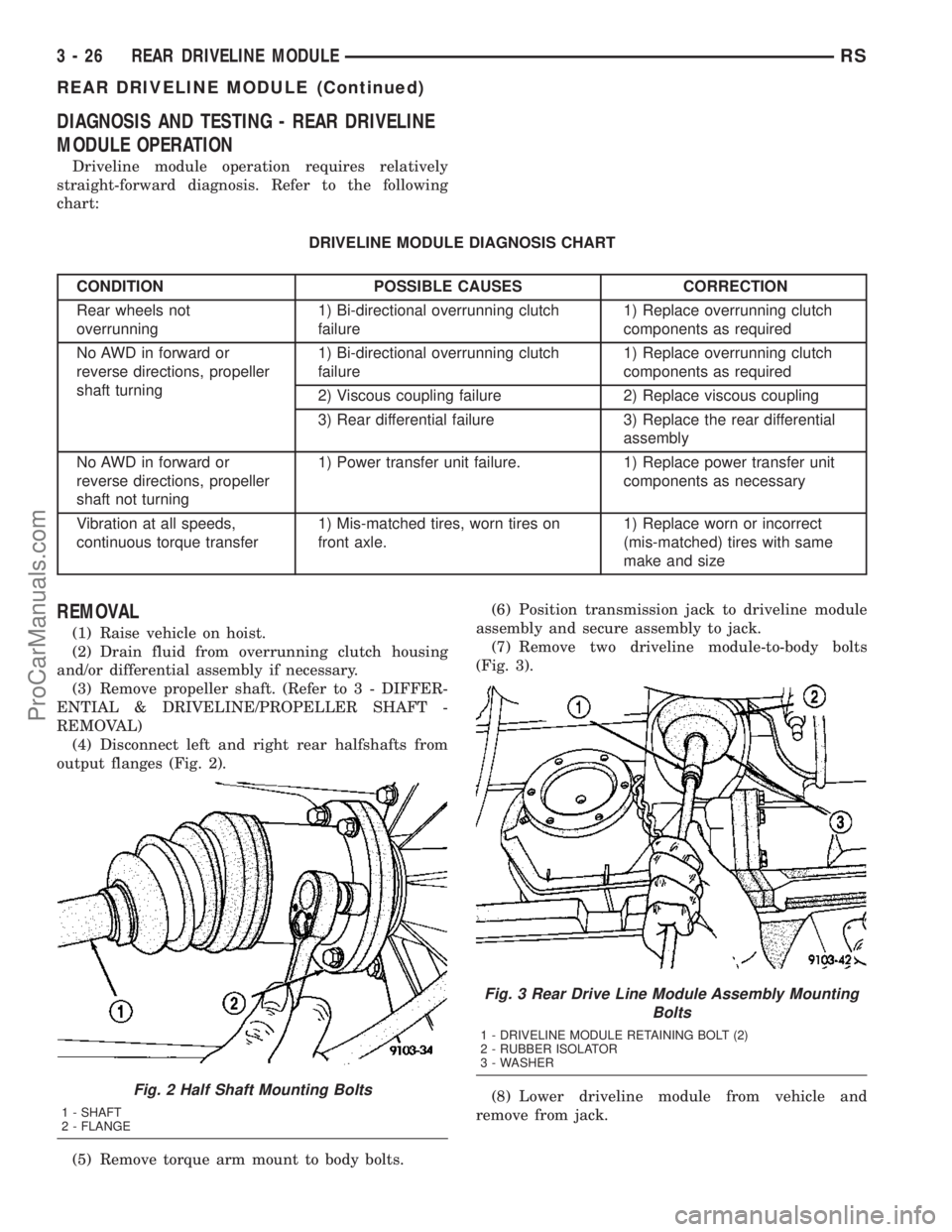

Driveline module operation requires relatively

straight-forward diagnosis. Refer to the following

chart:

DRIVELINE MODULE DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

Rear wheels not

overrunning1) Bi-directional overrunning clutch

failure1) Replace overrunning clutch

components as required

No AWD in forward or

reverse directions, propeller

shaft turning1) Bi-directional overrunning clutch

failure1) Replace overrunning clutch

components as required

2) Viscous coupling failure 2) Replace viscous coupling

3) Rear differential failure 3) Replace the rear differential

assembly

No AWD in forward or

reverse directions, propeller

shaft not turning1) Power transfer unit failure. 1) Replace power transfer unit

components as necessary

Vibration at all speeds,

continuous torque transfer1) Mis-matched tires, worn tires on

front axle.1) Replace worn or incorrect

(mis-matched) tires with same

make and size

REMOVAL

(1) Raise vehicle on hoist.

(2) Drain fluid from overrunning clutch housing

and/or differential assembly if necessary.

(3) Remove propeller shaft. (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/PROPELLER SHAFT -

REMOVAL)

(4) Disconnect left and right rear halfshafts from

output flanges (Fig. 2).

(5) Remove torque arm mount to body bolts.(6) Position transmission jack to driveline module

assembly and secure assembly to jack.

(7) Remove two driveline module-to-body bolts

(Fig. 3).

(8) Lower driveline module from vehicle and

remove from jack.

Fig. 2 Half Shaft Mounting Bolts

1 - SHAFT

2 - FLANGE

Fig. 3 Rear Drive Line Module Assembly Mounting

Bolts

1 - DRIVELINE MODULE RETAINING BOLT (2)

2 - RUBBER ISOLATOR

3 - WASHER

3 - 26 REAR DRIVELINE MODULERS

REAR DRIVELINE MODULE (Continued)

ProCarManuals.com

Page 126 of 2177

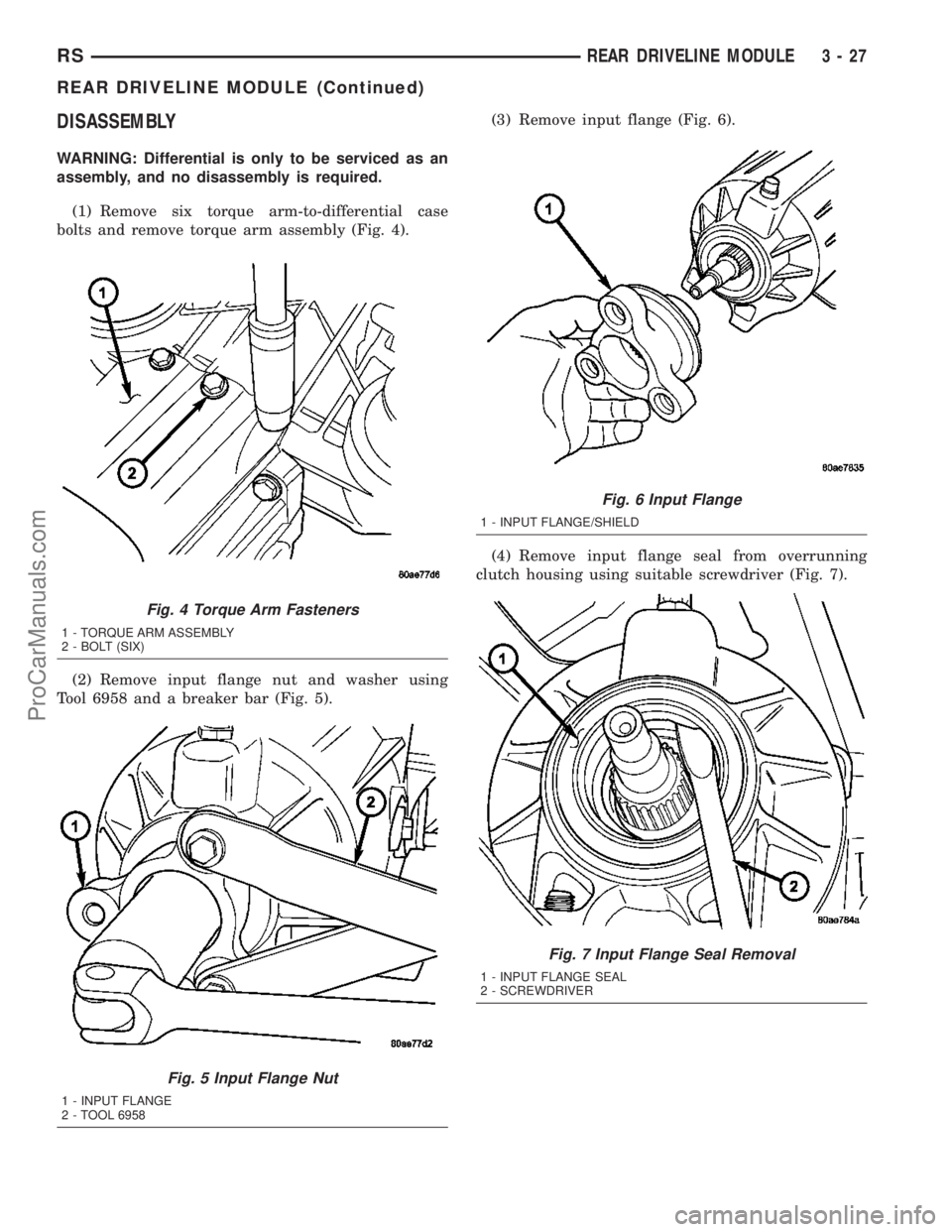

DISASSEMBLY

WARNING: Differential is only to be serviced as an

assembly, and no disassembly is required.

(1) Remove six torque arm-to-differential case

bolts and remove torque arm assembly (Fig. 4).

(2) Remove input flange nut and washer using

Tool 6958 and a breaker bar (Fig. 5).(3) Remove input flange (Fig. 6).

(4) Remove input flange seal from overrunning

clutch housing using suitable screwdriver (Fig. 7).

Fig. 4 Torque Arm Fasteners

1 - TORQUE ARM ASSEMBLY

2 - BOLT (SIX)

Fig. 5 Input Flange Nut

1 - INPUT FLANGE

2 - TOOL 6958

Fig. 6 Input Flange

1 - INPUT FLANGE/SHIELD

Fig. 7 Input Flange Seal Removal

1 - INPUT FLANGE SEAL

2 - SCREWDRIVER

RSREAR DRIVELINE MODULE3-27

REAR DRIVELINE MODULE (Continued)

ProCarManuals.com

Page 127 of 2177

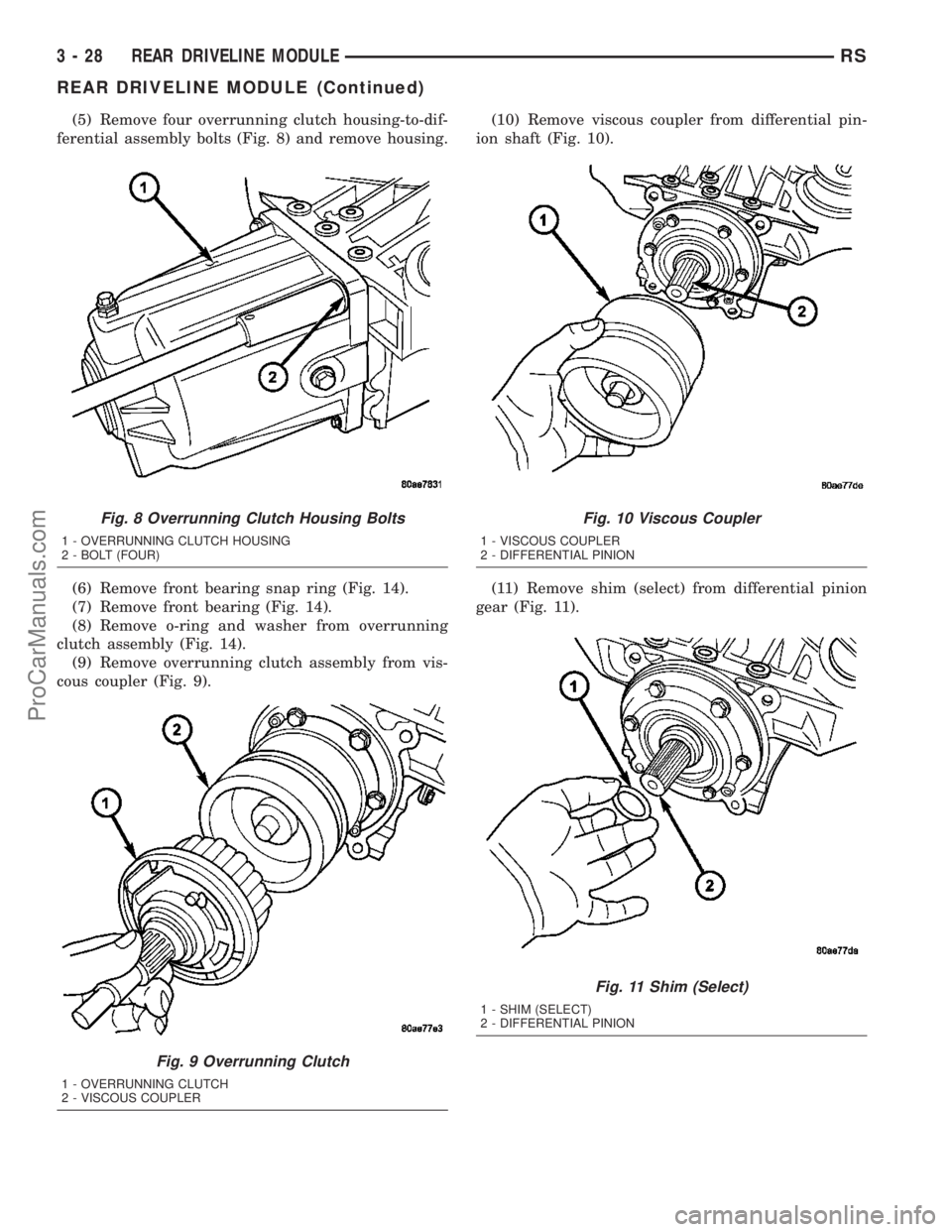

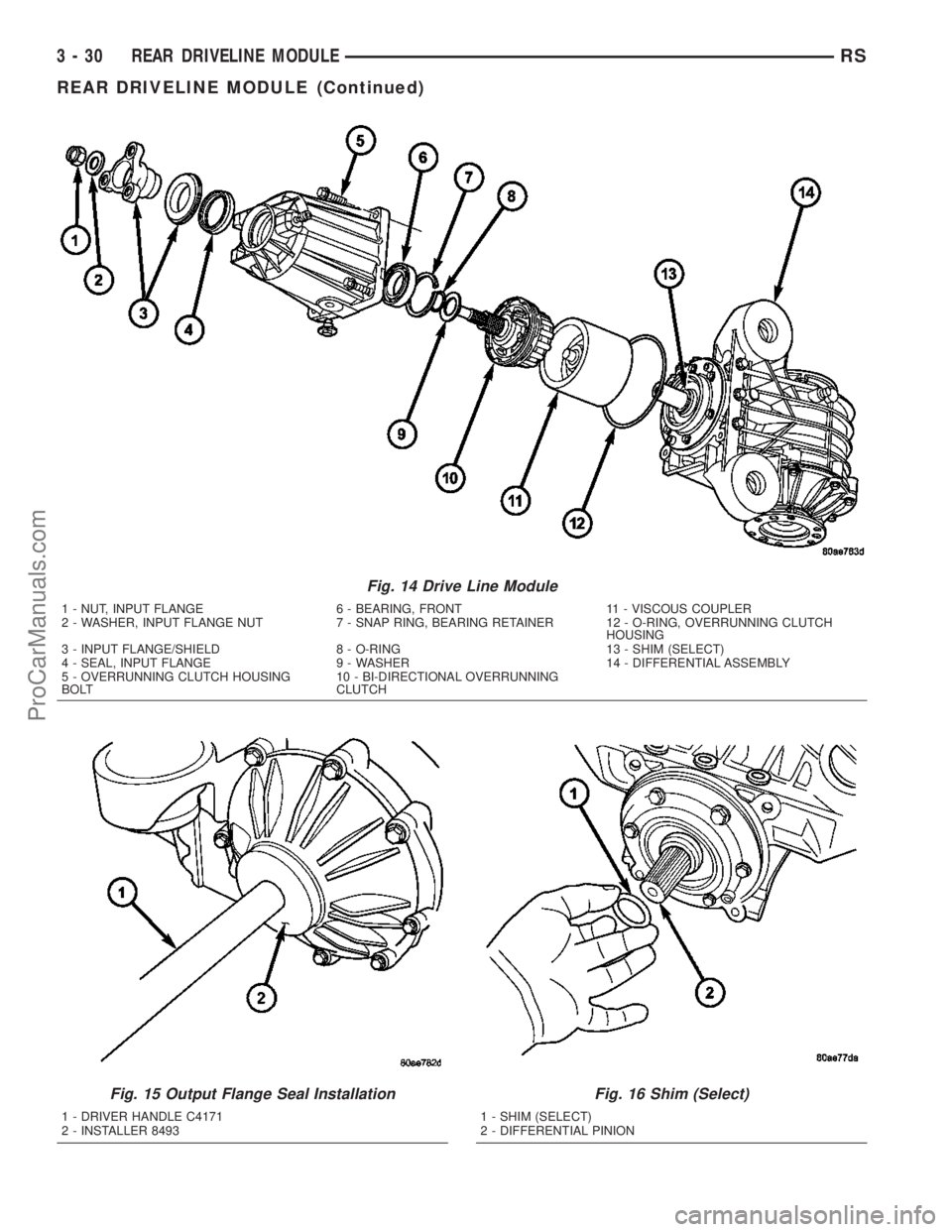

(5) Remove four overrunning clutch housing-to-dif-

ferential assembly bolts (Fig. 8) and remove housing.

(6) Remove front bearing snap ring (Fig. 14).

(7) Remove front bearing (Fig. 14).

(8) Remove o-ring and washer from overrunning

clutch assembly (Fig. 14).

(9) Remove overrunning clutch assembly from vis-

cous coupler (Fig. 9).(10) Remove viscous coupler from differential pin-

ion shaft (Fig. 10).

(11) Remove shim (select) from differential pinion

gear (Fig. 11).

Fig. 8 Overrunning Clutch Housing Bolts

1 - OVERRUNNING CLUTCH HOUSING

2 - BOLT (FOUR)

Fig. 9 Overrunning Clutch

1 - OVERRUNNING CLUTCH

2 - VISCOUS COUPLER

Fig. 10 Viscous Coupler

1 - VISCOUS COUPLER

2 - DIFFERENTIAL PINION

Fig. 11 Shim (Select)

1 - SHIM (SELECT)

2 - DIFFERENTIAL PINION

3 - 28 REAR DRIVELINE MODULERS

REAR DRIVELINE MODULE (Continued)

ProCarManuals.com

Page 128 of 2177

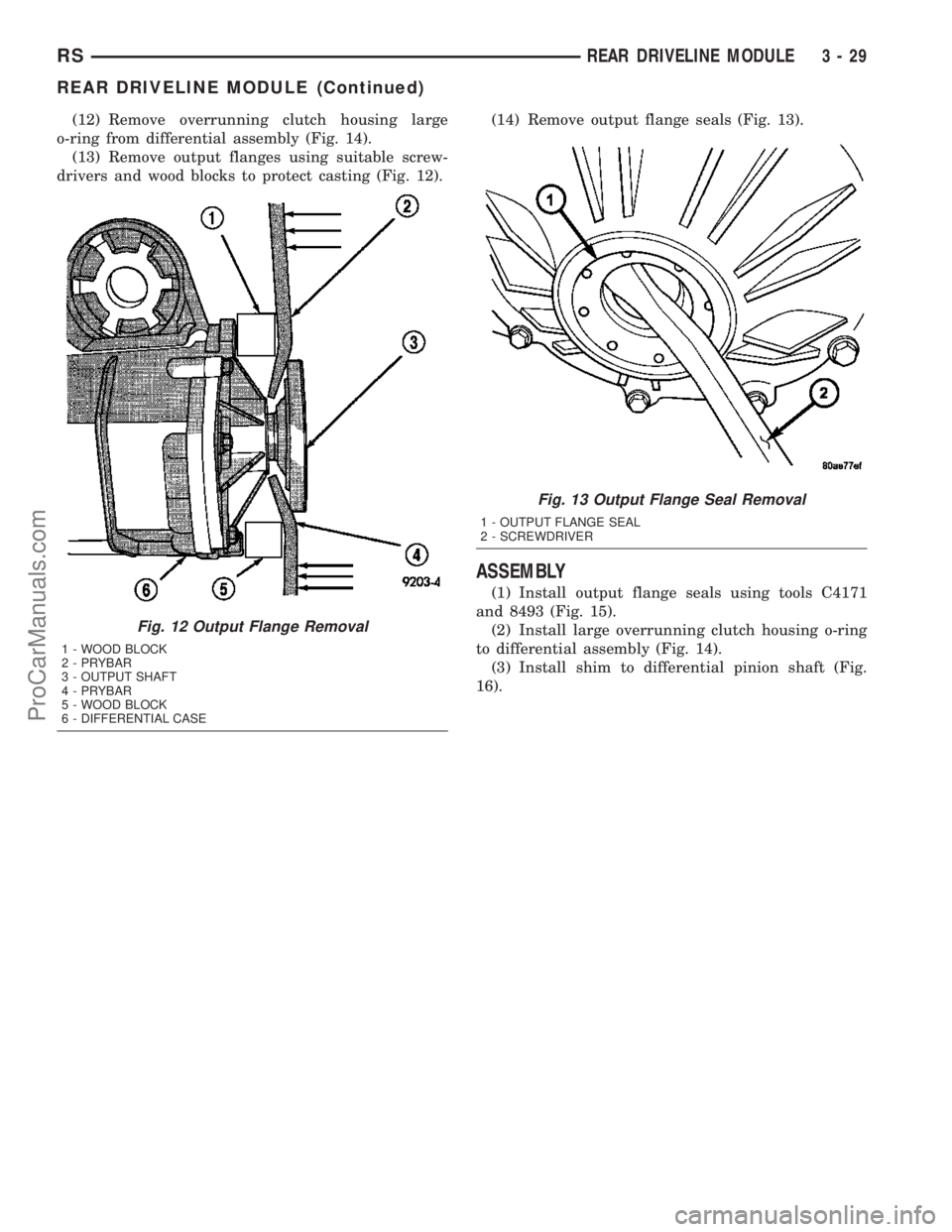

(12) Remove overrunning clutch housing large

o-ring from differential assembly (Fig. 14).

(13) Remove output flanges using suitable screw-

drivers and wood blocks to protect casting (Fig. 12).(14) Remove output flange seals (Fig. 13).

ASSEMBLY

(1) Install output flange seals using tools C4171

and 8493 (Fig. 15).

(2) Install large overrunning clutch housing o-ring

to differential assembly (Fig. 14).

(3) Install shim to differential pinion shaft (Fig.

16).

Fig. 12 Output Flange Removal

1 - WOOD BLOCK

2 - PRYBAR

3 - OUTPUT SHAFT

4 - PRYBAR

5 - WOOD BLOCK

6 - DIFFERENTIAL CASE

Fig. 13 Output Flange Seal Removal

1 - OUTPUT FLANGE SEAL

2 - SCREWDRIVER

RSREAR DRIVELINE MODULE3-29

REAR DRIVELINE MODULE (Continued)

ProCarManuals.com

Page 129 of 2177

Fig. 14 Drive Line Module

1 - NUT, INPUT FLANGE 6 - BEARING, FRONT 11 - VISCOUS COUPLER

2 - WASHER, INPUT FLANGE NUT 7 - SNAP RING, BEARING RETAINER 12 - O-RING, OVERRUNNING CLUTCH

HOUSING

3 - INPUT FLANGE/SHIELD 8 - O-RING 13 - SHIM (SELECT)

4 - SEAL, INPUT FLANGE 9 - WASHER 14 - DIFFERENTIAL ASSEMBLY

5 - OVERRUNNING CLUTCH HOUSING

BOLT10 - BI-DIRECTIONAL OVERRUNNING

CLUTCH

Fig. 15 Output Flange Seal Installation

1 - DRIVER HANDLE C4171

2 - INSTALLER 8493

Fig. 16 Shim (Select)

1 - SHIM (SELECT)

2 - DIFFERENTIAL PINION

3 - 30 REAR DRIVELINE MODULERS

REAR DRIVELINE MODULE (Continued)

ProCarManuals.com