tire size DODGE TOWN AND COUNTRY 2004 Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2004, Model line: TOWN AND COUNTRY, Model: DODGE TOWN AND COUNTRY 2004Pages: 2585, PDF Size: 62.54 MB

Page 59 of 2585

(6) Back off the forcing screw and remove tool.

(7) Install lower control arm on vehicle. (Refer to 2

- SUSPENSION/FRONT/LOWER CONTROL ARM -

INSTALLATION)

INSTALLATION - LOWER CONTROL ARM

(1) Position lower control arm assembly into front

suspension cradle crossmember guiding bushings into

mounting position (Fig. 22).

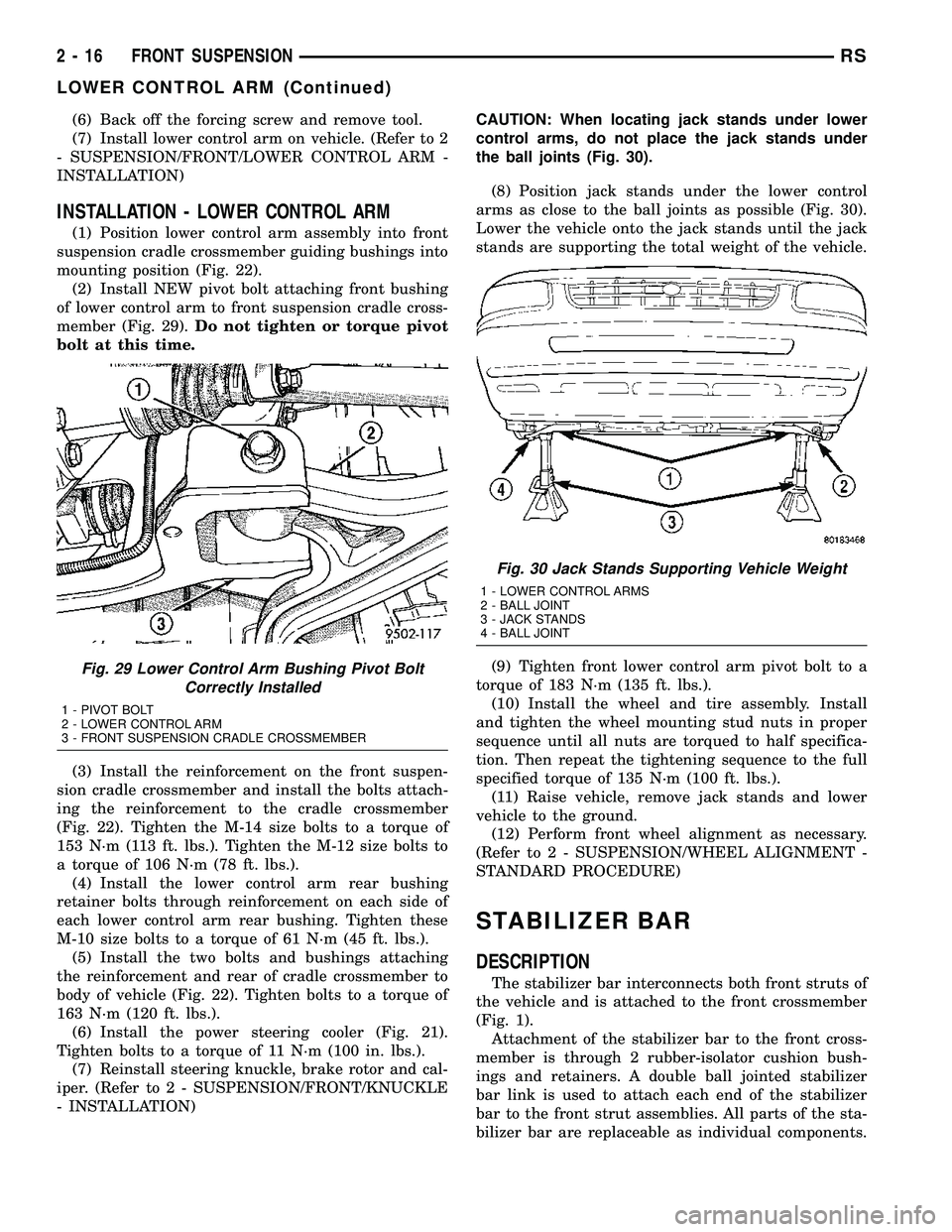

(2) Install NEW pivot bolt attaching front bushing

of lower control arm to front suspension cradle cross-

member (Fig. 29).Do not tighten or torque pivot

bolt at this time.

(3) Install the reinforcement on the front suspen-

sion cradle crossmember and install the bolts attach-

ing the reinforcement to the cradle crossmember

(Fig. 22). Tighten the M-14 size bolts to a torque of

153 N´m (113 ft. lbs.). Tighten the M-12 size bolts to

a torque of 106 N´m (78 ft. lbs.).

(4) Install the lower control arm rear bushing

retainer bolts through reinforcement on each side of

each lower control arm rear bushing. Tighten these

M-10 size bolts to a torque of 61 N´m (45 ft. lbs.).

(5) Install the two bolts and bushings attaching

the reinforcement and rear of cradle crossmember to

body of vehicle (Fig. 22). Tighten bolts to a torque of

163 N´m (120 ft. lbs.).

(6) Install the power steering cooler (Fig. 21).

Tighten bolts to a torque of 11 N´m (100 in. lbs.).

(7) Reinstall steering knuckle, brake rotor and cal-

iper. (Refer to 2 - SUSPENSION/FRONT/KNUCKLE

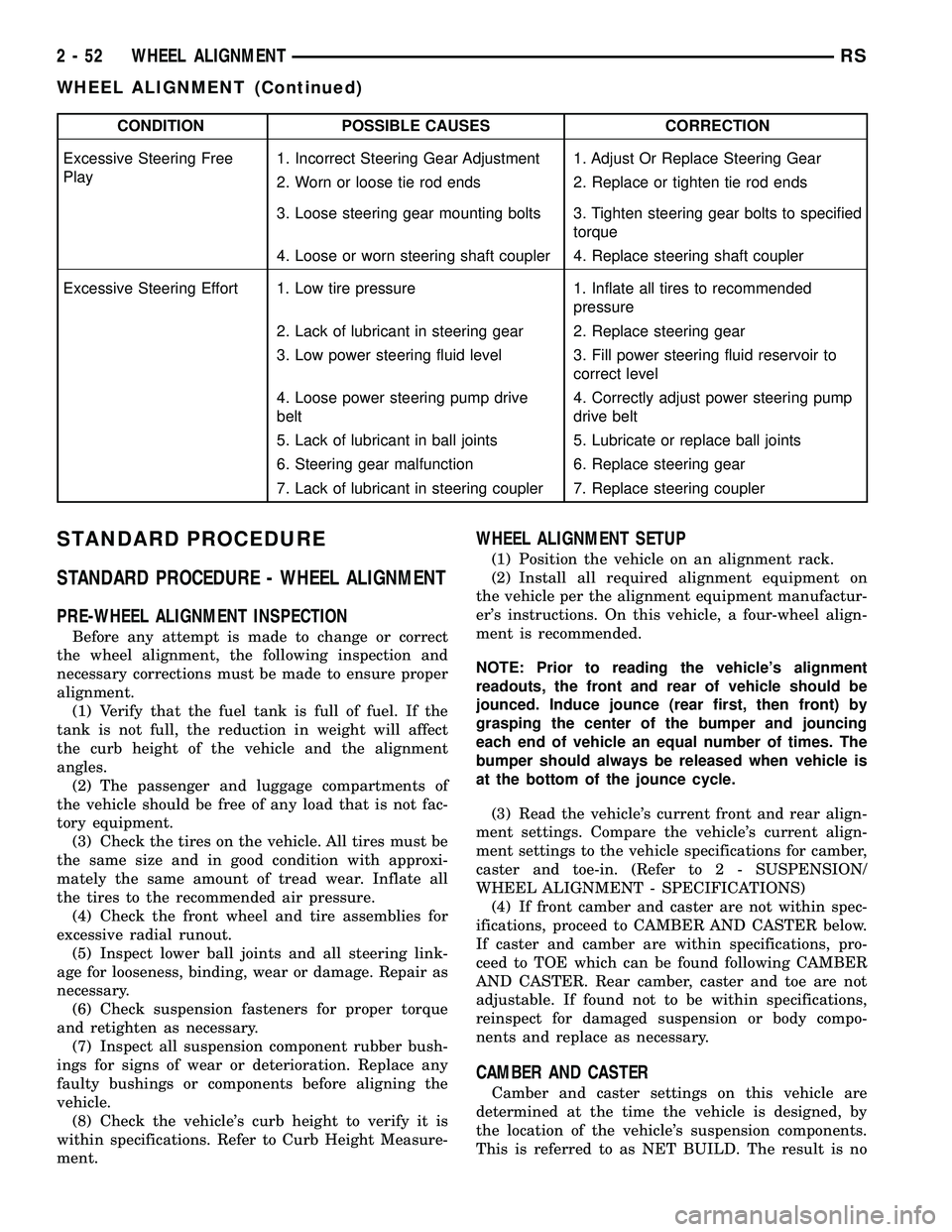

- INSTALLATION)CAUTION: When locating jack stands under lower

control arms, do not place the jack stands under

the ball joints (Fig. 30).

(8) Position jack stands under the lower control

arms as close to the ball joints as possible (Fig. 30).

Lower the vehicle onto the jack stands until the jack

stands are supporting the total weight of the vehicle.

(9) Tighten front lower control arm pivot bolt to a

torque of 183 N´m (135 ft. lbs.).

(10) Install the wheel and tire assembly. Install

and tighten the wheel mounting stud nuts in proper

sequence until all nuts are torqued to half specifica-

tion. Then repeat the tightening sequence to the full

specified torque of 135 N´m (100 ft. lbs.).

(11) Raise vehicle, remove jack stands and lower

vehicle to the ground.

(12) Perform front wheel alignment as necessary.

(Refer to 2 - SUSPENSION/WHEEL ALIGNMENT -

STANDARD PROCEDURE)

STABILIZER BAR

DESCRIPTION

The stabilizer bar interconnects both front struts of

the vehicle and is attached to the front crossmember

(Fig. 1).

Attachment of the stabilizer bar to the front cross-

member is through 2 rubber-isolator cushion bush-

ings and retainers. A double ball jointed stabilizer

bar link is used to attach each end of the stabilizer

bar to the front strut assemblies. All parts of the sta-

bilizer bar are replaceable as individual components.

Fig. 29 Lower Control Arm Bushing Pivot Bolt

Correctly Installed

1 - PIVOT BOLT

2 - LOWER CONTROL ARM

3 - FRONT SUSPENSION CRADLE CROSSMEMBER

Fig. 30 Jack Stands Supporting Vehicle Weight

1 - LOWER CONTROL ARMS

2 - BALL JOINT

3 - JACK STANDS

4 - BALL JOINT

2 - 16 FRONT SUSPENSIONRS

LOWER CONTROL ARM (Continued)

Page 95 of 2585

CONDITION POSSIBLE CAUSES CORRECTION

Excessive Steering Free

Play1. Incorrect Steering Gear Adjustment 1. Adjust Or Replace Steering Gear

2. Worn or loose tie rod ends 2. Replace or tighten tie rod ends

3. Loose steering gear mounting bolts 3. Tighten steering gear bolts to specified

torque

4. Loose or worn steering shaft coupler 4. Replace steering shaft coupler

Excessive Steering Effort 1. Low tire pressure 1. Inflate all tires to recommended

pressure

2. Lack of lubricant in steering gear 2. Replace steering gear

3. Low power steering fluid level 3. Fill power steering fluid reservoir to

correct level

4. Loose power steering pump drive

belt4. Correctly adjust power steering pump

drive belt

5. Lack of lubricant in ball joints 5. Lubricate or replace ball joints

6. Steering gear malfunction 6. Replace steering gear

7. Lack of lubricant in steering coupler 7. Replace steering coupler

STANDARD PROCEDURE

STANDARD PROCEDURE - WHEEL ALIGNMENT

PRE-WHEEL ALIGNMENT INSPECTION

Before any attempt is made to change or correct

the wheel alignment, the following inspection and

necessary corrections must be made to ensure proper

alignment.

(1) Verify that the fuel tank is full of fuel. If the

tank is not full, the reduction in weight will affect

the curb height of the vehicle and the alignment

angles.

(2) The passenger and luggage compartments of

the vehicle should be free of any load that is not fac-

tory equipment.

(3) Check the tires on the vehicle. All tires must be

the same size and in good condition with approxi-

mately the same amount of tread wear. Inflate all

the tires to the recommended air pressure.

(4) Check the front wheel and tire assemblies for

excessive radial runout.

(5) Inspect lower ball joints and all steering link-

age for looseness, binding, wear or damage. Repair as

necessary.

(6) Check suspension fasteners for proper torque

and retighten as necessary.

(7) Inspect all suspension component rubber bush-

ings for signs of wear or deterioration. Replace any

faulty bushings or components before aligning the

vehicle.

(8) Check the vehicle's curb height to verify it is

within specifications. Refer to Curb Height Measure-

ment.

WHEEL ALIGNMENT SETUP

(1) Position the vehicle on an alignment rack.

(2) Install all required alignment equipment on

the vehicle per the alignment equipment manufactur-

er's instructions. On this vehicle, a four-wheel align-

ment is recommended.

NOTE: Prior to reading the vehicle's alignment

readouts, the front and rear of vehicle should be

jounced. Induce jounce (rear first, then front) by

grasping the center of the bumper and jouncing

each end of vehicle an equal number of times. The

bumper should always be released when vehicle is

at the bottom of the jounce cycle.

(3) Read the vehicle's current front and rear align-

ment settings. Compare the vehicle's current align-

ment settings to the vehicle specifications for camber,

caster and toe-in. (Refer to 2 - SUSPENSION/

WHEEL ALIGNMENT - SPECIFICATIONS)

(4) If front camber and caster are not within spec-

ifications, proceed to CAMBER AND CASTER below.

If caster and camber are within specifications, pro-

ceed to TOE which can be found following CAMBER

AND CASTER. Rear camber, caster and toe are not

adjustable. If found not to be within specifications,

reinspect for damaged suspension or body compo-

nents and replace as necessary.

CAMBER AND CASTER

Camber and caster settings on this vehicle are

determined at the time the vehicle is designed, by

the location of the vehicle's suspension components.

This is referred to as NET BUILD. The result is no

2 - 52 WHEEL ALIGNMENTRS

WHEEL ALIGNMENT (Continued)

Page 98 of 2585

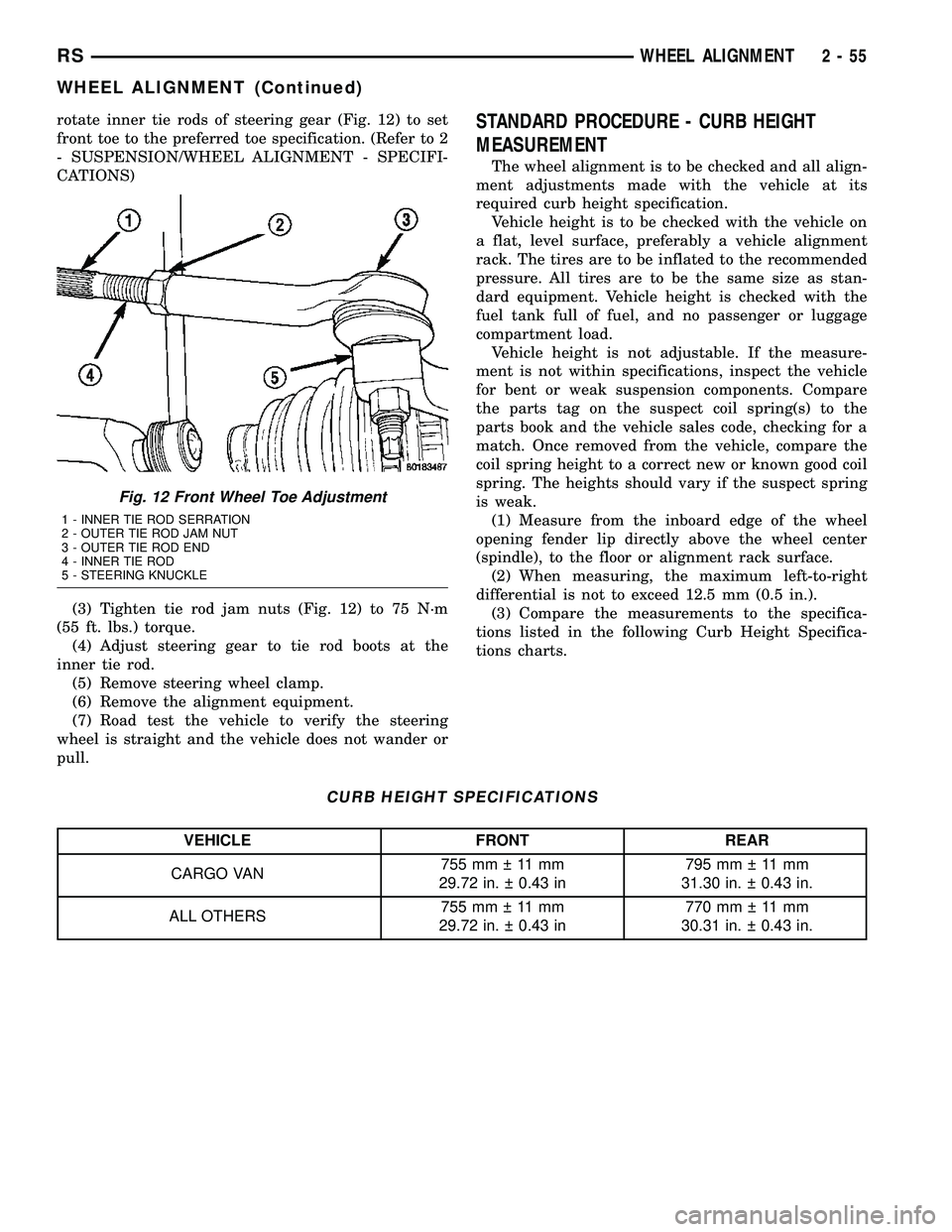

rotate inner tie rods of steering gear (Fig. 12) to set

front toe to the preferred toe specification. (Refer to 2

- SUSPENSION/WHEEL ALIGNMENT - SPECIFI-

CATIONS)

(3) Tighten tie rod jam nuts (Fig. 12) to 75 N´m

(55 ft. lbs.) torque.

(4) Adjust steering gear to tie rod boots at the

inner tie rod.

(5) Remove steering wheel clamp.

(6) Remove the alignment equipment.

(7) Road test the vehicle to verify the steering

wheel is straight and the vehicle does not wander or

pull.STANDARD PROCEDURE - CURB HEIGHT

MEASUREMENT

The wheel alignment is to be checked and all align-

ment adjustments made with the vehicle at its

required curb height specification.

Vehicle height is to be checked with the vehicle on

a flat, level surface, preferably a vehicle alignment

rack. The tires are to be inflated to the recommended

pressure. All tires are to be the same size as stan-

dard equipment. Vehicle height is checked with the

fuel tank full of fuel, and no passenger or luggage

compartment load.

Vehicle height is not adjustable. If the measure-

ment is not within specifications, inspect the vehicle

for bent or weak suspension components. Compare

the parts tag on the suspect coil spring(s) to the

parts book and the vehicle sales code, checking for a

match. Once removed from the vehicle, compare the

coil spring height to a correct new or known good coil

spring. The heights should vary if the suspect spring

is weak.

(1) Measure from the inboard edge of the wheel

opening fender lip directly above the wheel center

(spindle), to the floor or alignment rack surface.

(2) When measuring, the maximum left-to-right

differential is not to exceed 12.5 mm (0.5 in.).

(3) Compare the measurements to the specifica-

tions listed in the following Curb Height Specifica-

tions charts.

CURB HEIGHT SPECIFICATIONS

VEHICLE FRONT REAR

CARGO VAN755mm 11mm

29.72 in. 0.43 in795mm 11mm

31.30 in. 0.43 in.

ALL OTHERS755mm 11mm

29.72 in. 0.43 in770mm 11mm

30.31 in. 0.43 in.

Fig. 12 Front Wheel Toe Adjustment

1 - INNER TIE ROD SERRATION

2 - OUTER TIE ROD JAM NUT

3 - OUTER TIE ROD END

4 - INNER TIE ROD

5 - STEERING KNUCKLE

RSWHEEL ALIGNMENT2-55

WHEEL ALIGNMENT (Continued)

Page 125 of 2585

DIAGNOSIS AND TESTING - REAR DRIVELINE

MODULE OPERATION

Driveline module operation requires relatively

straight-forward diagnosis. Refer to the following

chart:

DRIVELINE MODULE DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

Rear wheels not

overrunning1) Bi-directional overrunning clutch

failure1) Replace overrunning clutch

components as required

No AWD in forward or

reverse directions, propeller

shaft turning1) Bi-directional overrunning clutch

failure1) Replace overrunning clutch

components as required

2) Viscous coupling failure 2) Replace viscous coupling

3) Rear differential failure 3) Replace the rear differential

assembly

No AWD in forward or

reverse directions, propeller

shaft not turning1) Power transfer unit failure. 1) Replace power transfer unit

components as necessary

Vibration at all speeds,

continuous torque transfer1) Mis-matched tires, worn tires on

front axle.1) Replace worn or incorrect

(mis-matched) tires with same

make and size

REMOVAL

(1) Raise vehicle on hoist.

(2) Drain fluid from overrunning clutch housing

and/or differential assembly if necessary.

(3) Remove propeller shaft. (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/PROPELLER SHAFT -

REMOVAL)

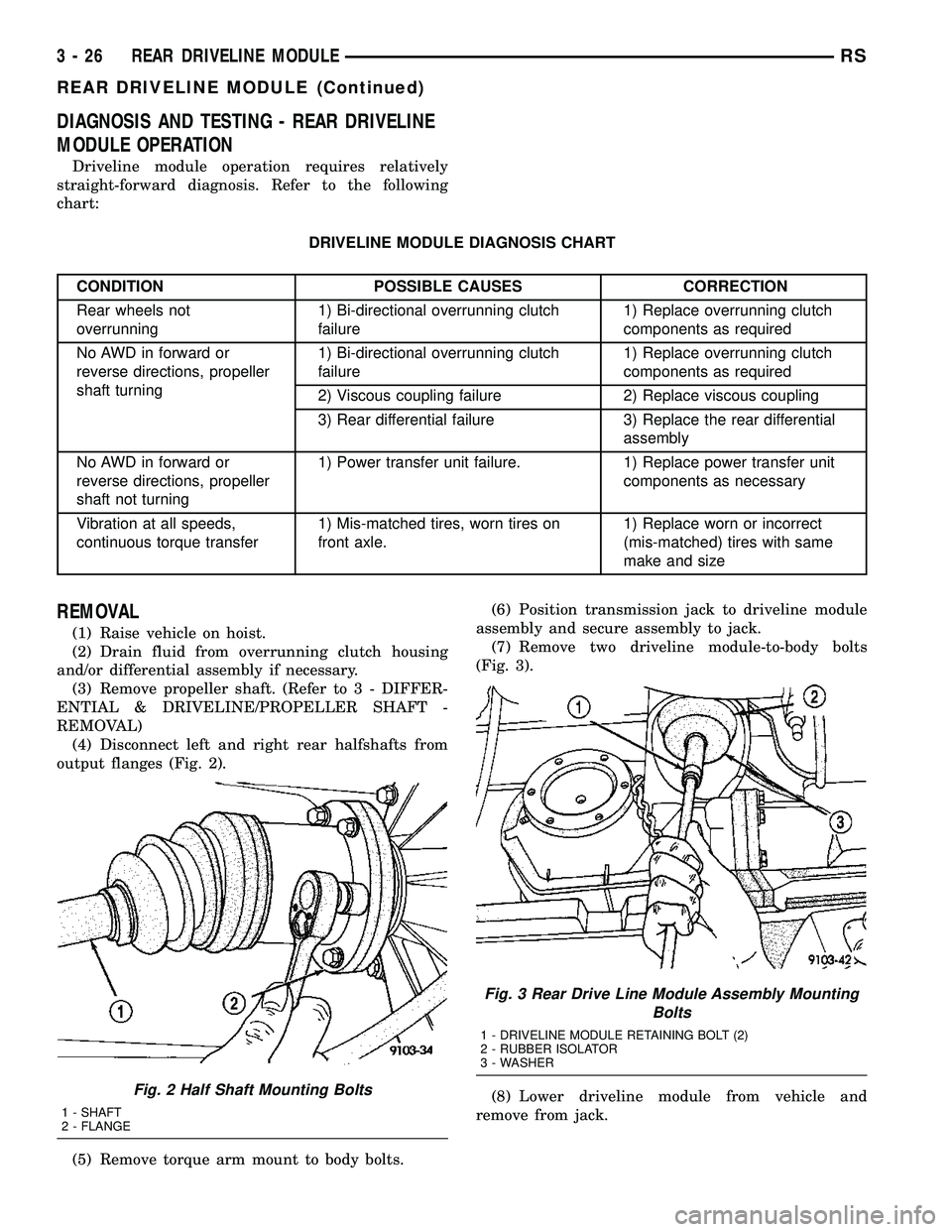

(4) Disconnect left and right rear halfshafts from

output flanges (Fig. 2).

(5) Remove torque arm mount to body bolts.(6) Position transmission jack to driveline module

assembly and secure assembly to jack.

(7) Remove two driveline module-to-body bolts

(Fig. 3).

(8) Lower driveline module from vehicle and

remove from jack.

Fig. 2 Half Shaft Mounting Bolts

1 - SHAFT

2 - FLANGE

Fig. 3 Rear Drive Line Module Assembly Mounting

Bolts

1 - DRIVELINE MODULE RETAINING BOLT (2)

2 - RUBBER ISOLATOR

3 - WASHER

3 - 26 REAR DRIVELINE MODULERS

REAR DRIVELINE MODULE (Continued)

Page 182 of 2585

CAUTION: When replacing a master cylinder, be

sure to use the correct master cylinder for the type

of brake system the vehicle is equipped with.

The body of the master cylinder is an anodized alu-

minum casting. It has a machined bore to accept the

master cylinder pistons and threaded ports with

seats for the hydraulic brake line connections.

The brake fluid reservoir is mounted on the top of

the master cylinder. It is made of a see-through

polypropylene type plastic for easy fluid level view-

ing. A brake fluid level switch is attached to the

brake fluid reservoir.

The master cylinder is not a repairable component

and must be replaced if diagnosed to be functioning

improperly. The brake fluid reservoir and brake fluid

level switch can be replaced separately.

CAUTION: Do not hone the bore of the cylinder as

this will remove the anodized surface from the bore.

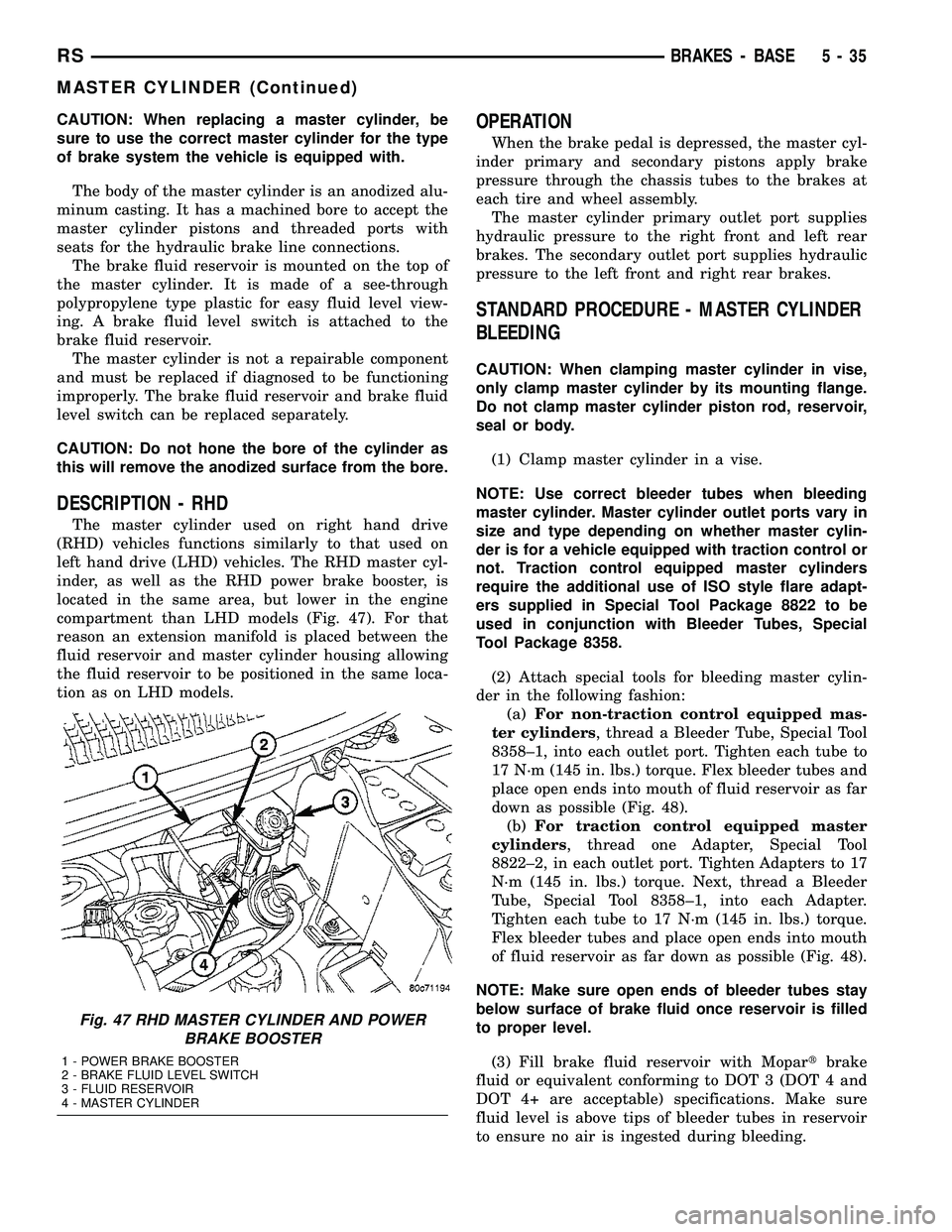

DESCRIPTION - RHD

The master cylinder used on right hand drive

(RHD) vehicles functions similarly to that used on

left hand drive (LHD) vehicles. The RHD master cyl-

inder, as well as the RHD power brake booster, is

located in the same area, but lower in the engine

compartment than LHD models (Fig. 47). For that

reason an extension manifold is placed between the

fluid reservoir and master cylinder housing allowing

the fluid reservoir to be positioned in the same loca-

tion as on LHD models.

OPERATION

When the brake pedal is depressed, the master cyl-

inder primary and secondary pistons apply brake

pressure through the chassis tubes to the brakes at

each tire and wheel assembly.

The master cylinder primary outlet port supplies

hydraulic pressure to the right front and left rear

brakes. The secondary outlet port supplies hydraulic

pressure to the left front and right rear brakes.

STANDARD PROCEDURE - MASTER CYLINDER

BLEEDING

CAUTION: When clamping master cylinder in vise,

only clamp master cylinder by its mounting flange.

Do not clamp master cylinder piston rod, reservoir,

seal or body.

(1) Clamp master cylinder in a vise.

NOTE: Use correct bleeder tubes when bleeding

master cylinder. Master cylinder outlet ports vary in

size and type depending on whether master cylin-

der is for a vehicle equipped with traction control or

not. Traction control equipped master cylinders

require the additional use of ISO style flare adapt-

ers supplied in Special Tool Package 8822 to be

used in conjunction with Bleeder Tubes, Special

Tool Package 8358.

(2) Attach special tools for bleeding master cylin-

der in the following fashion:

(a)For non-traction control equipped mas-

ter cylinders, thread a Bleeder Tube, Special Tool

8358±1, into each outlet port. Tighten each tube to

17 N´m (145 in. lbs.) torque. Flex bleeder tubes and

place open ends into mouth of fluid reservoir as far

down as possible (Fig. 48).

(b)For traction control equipped master

cylinders, thread one Adapter, Special Tool

8822±2, in each outlet port. Tighten Adapters to 17

N´m (145 in. lbs.) torque. Next, thread a Bleeder

Tube, Special Tool 8358±1, into each Adapter.

Tighten each tube to 17 N´m (145 in. lbs.) torque.

Flex bleeder tubes and place open ends into mouth

of fluid reservoir as far down as possible (Fig. 48).

NOTE: Make sure open ends of bleeder tubes stay

below surface of brake fluid once reservoir is filled

to proper level.

(3) Fill brake fluid reservoir with Mopartbrake

fluid or equivalent conforming to DOT 3 (DOT 4 and

DOT 4+ are acceptable) specifications. Make sure

fluid level is above tips of bleeder tubes in reservoir

to ensure no air is ingested during bleeding.

Fig. 47 RHD MASTER CYLINDER AND POWER

BRAKE BOOSTER

1 - POWER BRAKE BOOSTER

2 - BRAKE FLUID LEVEL SWITCH

3 - FLUID RESERVOIR

4 - MASTER CYLINDER

RSBRAKES - BASE5-35

MASTER CYLINDER (Continued)

Page 277 of 2585

CAUTION: When replacing a master cylinder, be

sure to use the correct master cylinder for the type

of brake system the vehicle is equipped with.The body of the master cylinder is an anodized alu-

minum casting. It has a machined bore to accept the

master cylinder pistons and threaded ports with

seats for the hydraulic brake line connections. The brake fluid reservoir is mounted on the top of

the master cylinder. It is made of a see-through

polypropylene type plastic for easy fluid level view-

ing. A brake fluid level switch is attached to the

brake fluid reservoir. The master cylinder is not a repairable component

and must be replaced if diagnosed to be functioning

improperly. The brake fluid reservoir and brake fluid

level switch can be replaced separately.

CAUTION: Do not hone the bore of the cylinder as

this will remove the anodized surface from the bore.

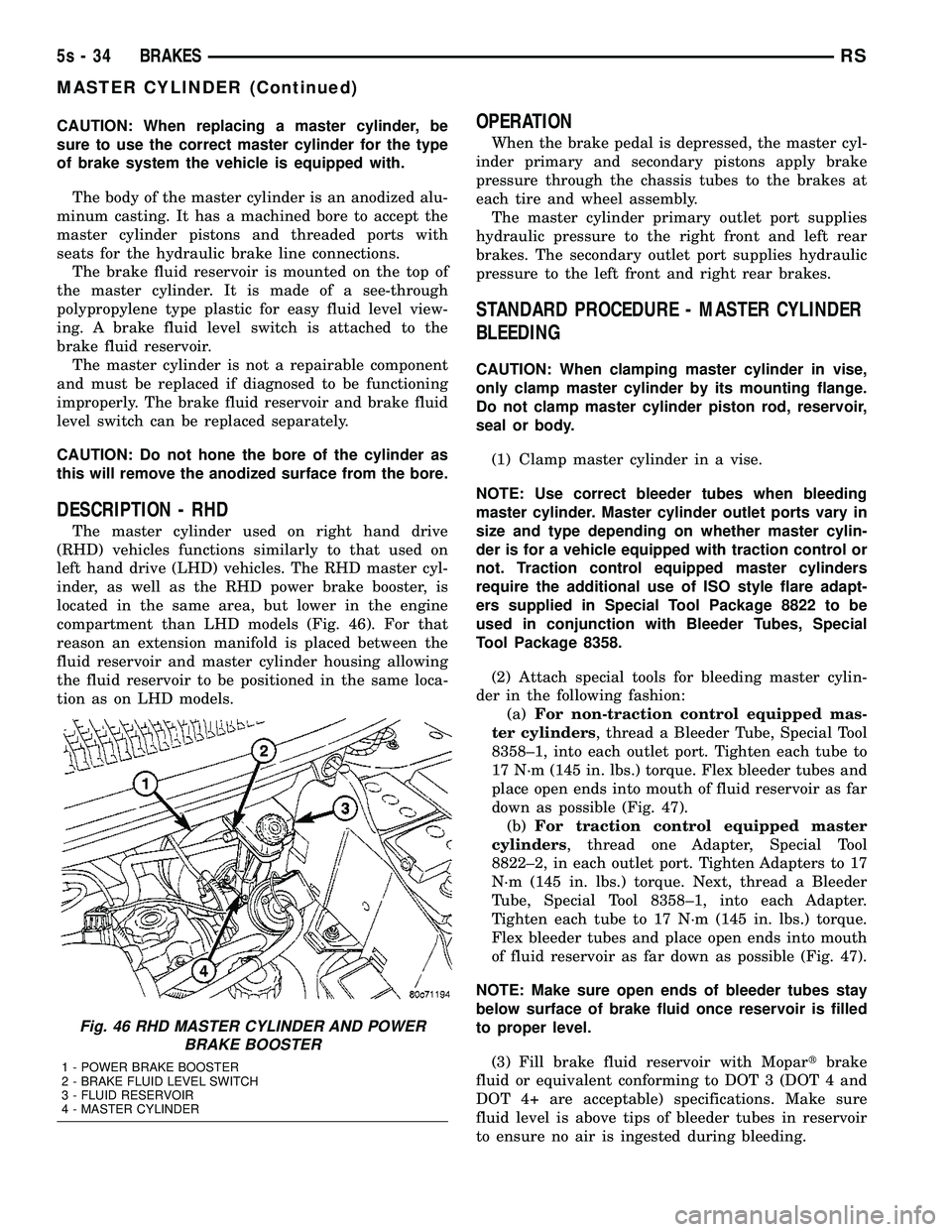

DESCRIPTION - RHD

The master cylinder used on right hand drive

(RHD) vehicles functions similarly to that used on

left hand drive (LHD) vehicles. The RHD master cyl-

inder, as well as the RHD power brake booster, is

located in the same area, but lower in the engine

compartment than LHD models (Fig. 46). For that

reason an extension manifold is placed between the

fluid reservoir and master cylinder housing allowing

the fluid reservoir to be positioned in the same loca-

tion as on LHD models.

OPERATION

When the brake pedal is depressed, the master cyl-

inder primary and secondary pistons apply brake

pressure through the chassis tubes to the brakes at

each tire and wheel assembly. The master cylinder primary outlet port supplies

hydraulic pressure to the right front and left rear

brakes. The secondary outlet port supplies hydraulic

pressure to the left front and right rear brakes.

STANDARD PROCEDURE - MASTER CYLINDER

BLEEDING

CAUTION: When clamping master cylinder in vise,

only clamp master cylinder by its mounting flange.

Do not clamp master cylinder piston rod, reservoir,

seal or body.

(1) Clamp master cylinder in a vise.

NOTE: Use correct bleeder tubes when bleeding

master cylinder. Master cylinder outlet ports vary in

size and type depending on whether master cylin-

der is for a vehicle equipped with traction control or

not. Traction control equipped master cylinders

require the additional use of ISO style flare adapt-

ers supplied in Special Tool Package 8822 to be

used in conjunction with Bleeder Tubes, Special

Tool Package 8358. (2) Attach special tools for bleeding master cylin-

der in the following fashion: (a)For non-traction control equipped mas-

ter cylinders , thread a Bleeder Tube, Special Tool

8358±1, into each outlet port. Tighten each tube to

17 N´m (145 in. lbs.) torque. Flex bleeder tubes and

place open ends into mouth of fluid reservoir as far

down as possible (Fig. 47). (b) For traction control equipped master

cylinders , thread one Adapter, Special Tool

8822±2, in each outlet port. Tighten Adapters to 17

N´m (145 in. lbs.) torque. Next, thread a Bleeder

Tube, Special Tool 8358±1, into each Adapter.

Tighten each tube to 17 N´m (145 in. lbs.) torque.

Flex bleeder tubes and place open ends into mouth

of fluid reservoir as far down as possible (Fig. 47).

NOTE: Make sure open ends of bleeder tubes stay

below surface of brake fluid once reservoir is filled

to proper level. (3) Fill brake fluid reservoir with Mopar tbrake

fluid or equivalent conforming to DOT 3 (DOT 4 and

DOT 4+ are acceptable) specifications. Make sure

fluid level is above tips of bleeder tubes in reservoir

to ensure no air is ingested during bleeding.

Fig. 46 RHD MASTER CYLINDER AND POWER BRAKE BOOSTER

1 - POWER BRAKE BOOSTER

2 - BRAKE FLUID LEVEL SWITCH

3 - FLUID RESERVOIR

4 - MASTER CYLINDER

5s - 34 BRAKESRS

MASTER CYLINDER (Continued)

Page 530 of 2585

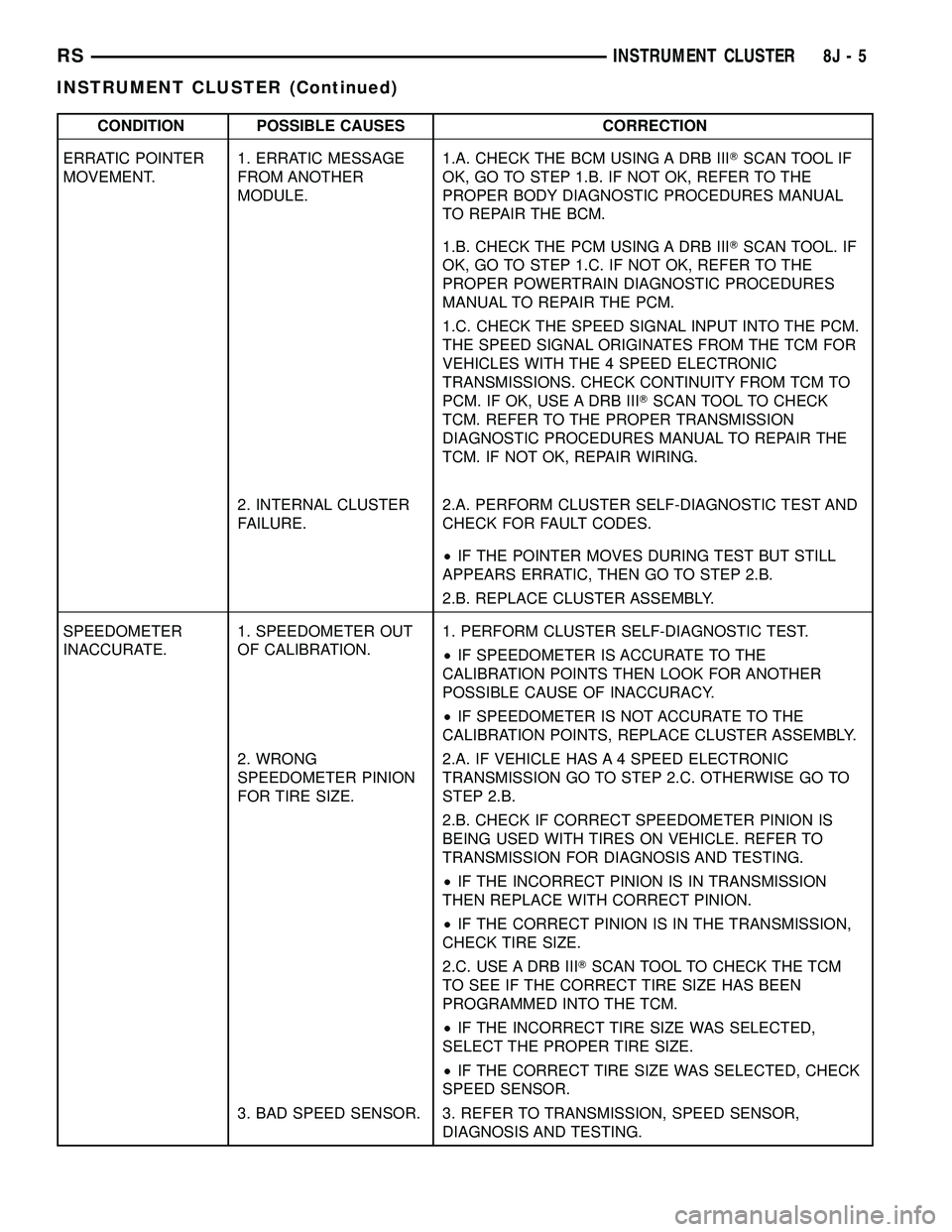

CONDITION POSSIBLE CAUSES CORRECTION

ERRATIC POINTER

MOVEMENT.1. ERRATIC MESSAGE

FROM ANOTHER

MODULE.1.A. CHECK THE BCM USING A DRB IIITSCAN TOOL IF

OK, GO TO STEP 1.B. IF NOT OK, REFER TO THE

PROPER BODY DIAGNOSTIC PROCEDURES MANUAL

TO REPAIR THE BCM.

1.B. CHECK THE PCM USING A DRB IIITSCAN TOOL. IF

OK, GO TO STEP 1.C. IF NOT OK, REFER TO THE

PROPER POWERTRAIN DIAGNOSTIC PROCEDURES

MANUAL TO REPAIR THE PCM.

1.C. CHECK THE SPEED SIGNAL INPUT INTO THE PCM.

THE SPEED SIGNAL ORIGINATES FROM THE TCM FOR

VEHICLES WITH THE 4 SPEED ELECTRONIC

TRANSMISSIONS. CHECK CONTINUITY FROM TCM TO

PCM. IF OK, USE A DRB IIITSCAN TOOL TO CHECK

TCM. REFER TO THE PROPER TRANSMISSION

DIAGNOSTIC PROCEDURES MANUAL TO REPAIR THE

TCM. IF NOT OK, REPAIR WIRING.

2. INTERNAL CLUSTER

FAILURE.2.A. PERFORM CLUSTER SELF-DIAGNOSTIC TEST AND

CHECK FOR FAULT CODES.

²IF THE POINTER MOVES DURING TEST BUT STILL

APPEARS ERRATIC, THEN GO TO STEP 2.B.

2.B. REPLACE CLUSTER ASSEMBLY.

SPEEDOMETER

INACCURATE.1. SPEEDOMETER OUT

OF CALIBRATION.1. PERFORM CLUSTER SELF-DIAGNOSTIC TEST.

²IF SPEEDOMETER IS ACCURATE TO THE

CALIBRATION POINTS THEN LOOK FOR ANOTHER

POSSIBLE CAUSE OF INACCURACY.

²IF SPEEDOMETER IS NOT ACCURATE TO THE

CALIBRATION POINTS, REPLACE CLUSTER ASSEMBLY.

2. WRONG

SPEEDOMETER PINION

FOR TIRE SIZE.2.A. IF VEHICLE HAS A 4 SPEED ELECTRONIC

TRANSMISSION GO TO STEP 2.C. OTHERWISE GO TO

STEP 2.B.

2.B. CHECK IF CORRECT SPEEDOMETER PINION IS

BEING USED WITH TIRES ON VEHICLE. REFER TO

TRANSMISSION FOR DIAGNOSIS AND TESTING.

²IF THE INCORRECT PINION IS IN TRANSMISSION

THEN REPLACE WITH CORRECT PINION.

²IF THE CORRECT PINION IS IN THE TRANSMISSION,

CHECK TIRE SIZE.

2.C. USE A DRB IIITSCAN TOOL TO CHECK THE TCM

TO SEE IF THE CORRECT TIRE SIZE HAS BEEN

PROGRAMMED INTO THE TCM.

²IF THE INCORRECT TIRE SIZE WAS SELECTED,

SELECT THE PROPER TIRE SIZE.

²IF THE CORRECT TIRE SIZE WAS SELECTED, CHECK

SPEED SENSOR.

3. BAD SPEED SENSOR. 3. REFER TO TRANSMISSION, SPEED SENSOR,

DIAGNOSIS AND TESTING.

RSINSTRUMENT CLUSTER8J-5

INSTRUMENT CLUSTER (Continued)

Page 1381 of 2585

Calibrate the tester according to the manufactur-

er's instructions. The shop air source for testing

should maintain 483 kPa (70 psi) minimum, 1,379

kPa (200 psi) maximum, with 552 kPa (80 psi) rec-

ommended.

Perform the test procedures on each cylinder

according to the tester manufacturer's instructions.

While testing, listen for pressurized air escaping

through the throttle body, tailpipe and oil filler cap

opening. Check for bubbles in the coolant.

All gauge pressure indications should be equal,

with no more than 25% leakage per cylinder.

FOR EXAMPLE:At 552 kPa (80 psi) input pres-

sure, a minimum of 414 kPa (60 psi) should be main-

tained in the cylinder.

STANDARD PROCEDURE

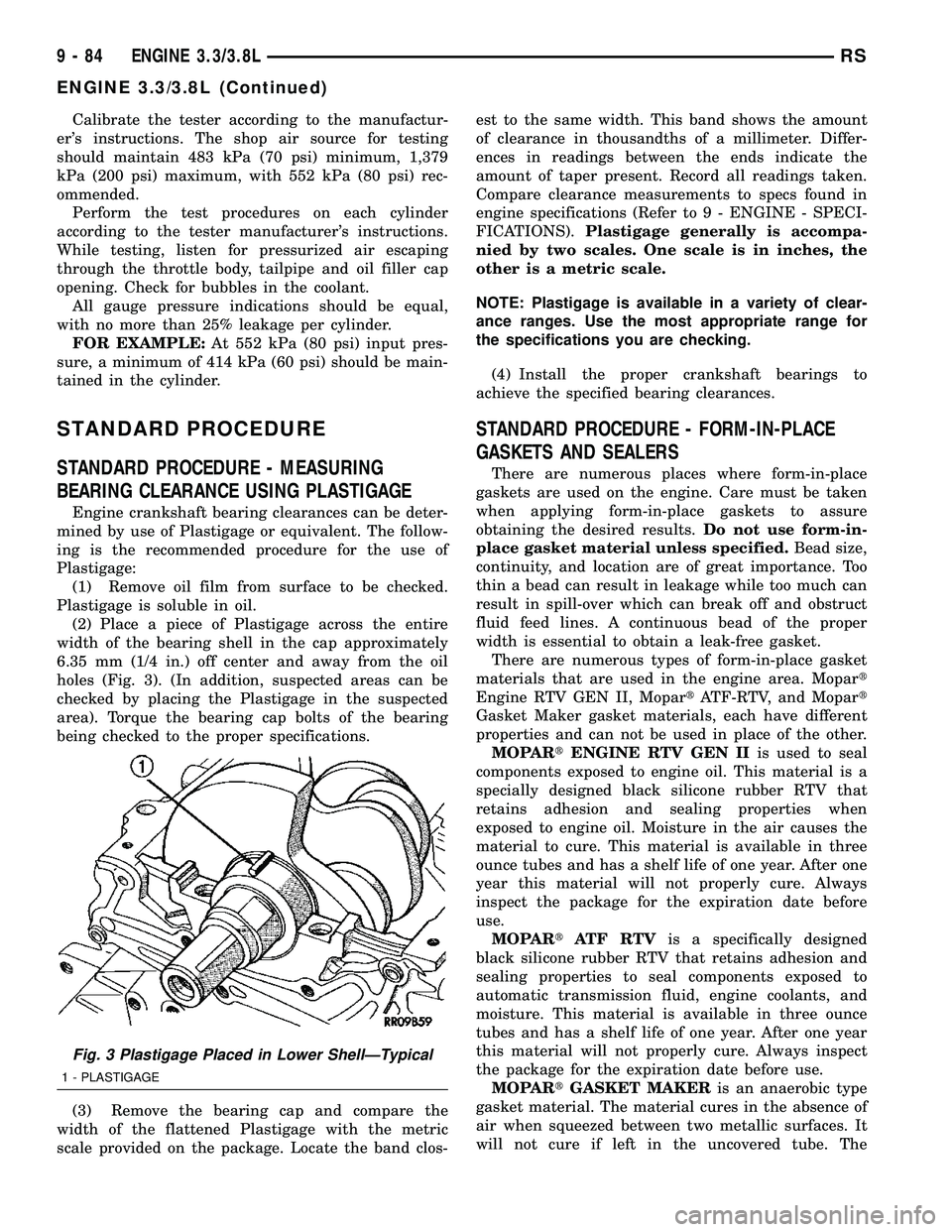

STANDARD PROCEDURE - MEASURING

BEARING CLEARANCE USING PLASTIGAGE

Engine crankshaft bearing clearances can be deter-

mined by use of Plastigage or equivalent. The follow-

ing is the recommended procedure for the use of

Plastigage:

(1) Remove oil film from surface to be checked.

Plastigage is soluble in oil.

(2) Place a piece of Plastigage across the entire

width of the bearing shell in the cap approximately

6.35 mm (1/4 in.) off center and away from the oil

holes (Fig. 3). (In addition, suspected areas can be

checked by placing the Plastigage in the suspected

area). Torque the bearing cap bolts of the bearing

being checked to the proper specifications.

(3) Remove the bearing cap and compare the

width of the flattened Plastigage with the metric

scale provided on the package. Locate the band clos-est to the same width. This band shows the amount

of clearance in thousandths of a millimeter. Differ-

ences in readings between the ends indicate the

amount of taper present. Record all readings taken.

Compare clearance measurements to specs found in

engine specifications (Refer to 9 - ENGINE - SPECI-

FICATIONS).Plastigage generally is accompa-

nied by two scales. One scale is in inches, the

other is a metric scale.

NOTE: Plastigage is available in a variety of clear-

ance ranges. Use the most appropriate range for

the specifications you are checking.

(4) Install the proper crankshaft bearings to

achieve the specified bearing clearances.

STANDARD PROCEDURE - FORM-IN-PLACE

GASKETS AND SEALERS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Too

thin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and Mopart

Gasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN IIis used to seal

components exposed to engine oil. This material is a

specially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

material to cure. This material is available in three

ounce tubes and has a shelf life of one year. After one

year this material will not properly cure. Always

inspect the package for the expiration date before

use.

MOPARtATF RTVis a specifically designed

black silicone rubber RTV that retains adhesion and

sealing properties to seal components exposed to

automatic transmission fluid, engine coolants, and

moisture. This material is available in three ounce

tubes and has a shelf life of one year. After one year

this material will not properly cure. Always inspect

the package for the expiration date before use.

MOPARtGASKET MAKERis an anaerobic type

gasket material. The material cures in the absence of

air when squeezed between two metallic surfaces. It

will not cure if left in the uncovered tube. The

Fig. 3 Plastigage Placed in Lower ShellÐTypical

1 - PLASTIGAGE

9 - 84 ENGINE 3.3/3.8LRS

ENGINE 3.3/3.8L (Continued)

Page 1417 of 2585

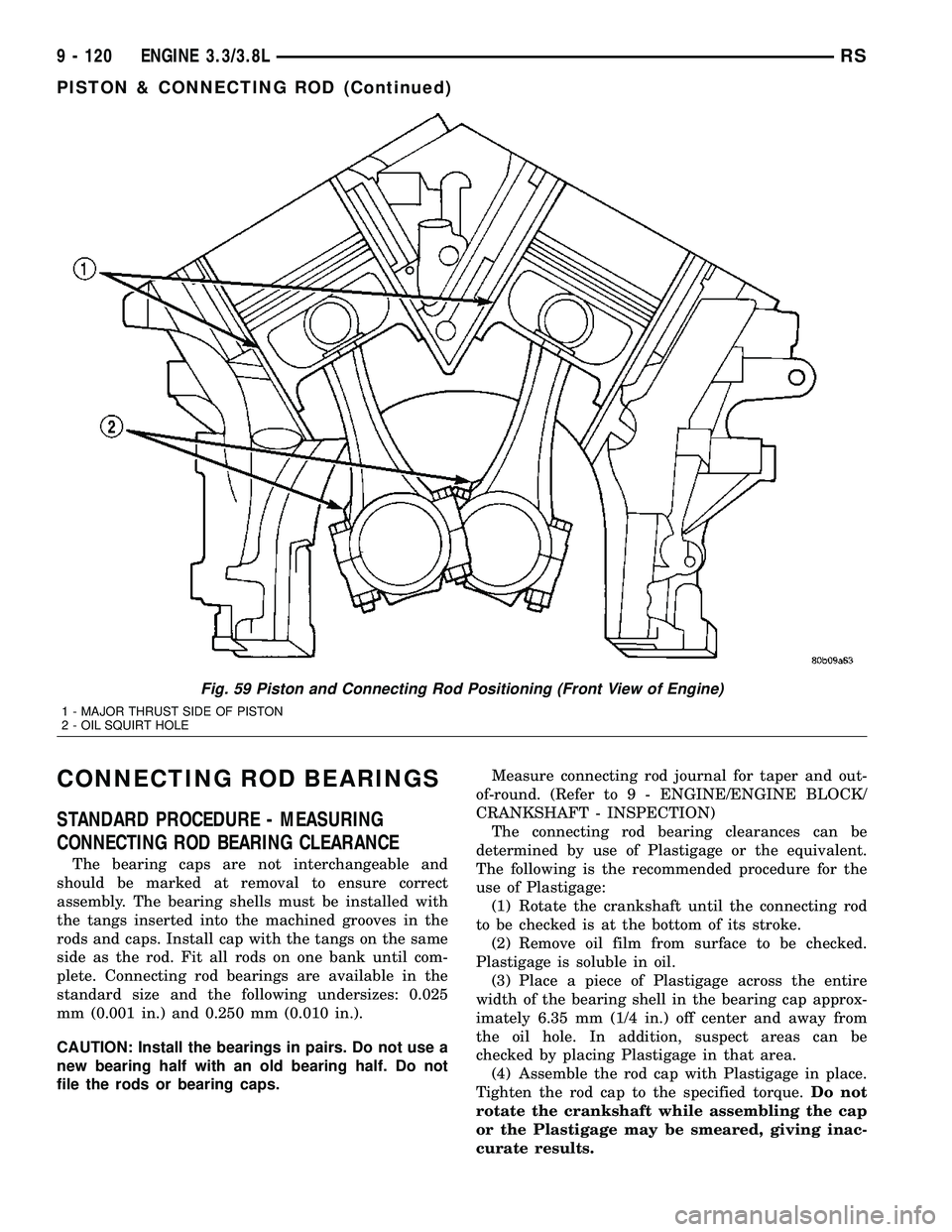

CONNECTING ROD BEARINGS

STANDARD PROCEDURE - MEASURING

CONNECTING ROD BEARING CLEARANCE

The bearing caps are not interchangeable and

should be marked at removal to ensure correct

assembly. The bearing shells must be installed with

the tangs inserted into the machined grooves in the

rods and caps. Install cap with the tangs on the same

side as the rod. Fit all rods on one bank until com-

plete. Connecting rod bearings are available in the

standard size and the following undersizes: 0.025

mm (0.001 in.) and 0.250 mm (0.010 in.).

CAUTION: Install the bearings in pairs. Do not use a

new bearing half with an old bearing half. Do not

file the rods or bearing caps.Measure connecting rod journal for taper and out-

of-round. (Refer to 9 - ENGINE/ENGINE BLOCK/

CRANKSHAFT - INSPECTION)

The connecting rod bearing clearances can be

determined by use of Plastigage or the equivalent.

The following is the recommended procedure for the

use of Plastigage:

(1) Rotate the crankshaft until the connecting rod

to be checked is at the bottom of its stroke.

(2) Remove oil film from surface to be checked.

Plastigage is soluble in oil.

(3) Place a piece of Plastigage across the entire

width of the bearing shell in the bearing cap approx-

imately 6.35 mm (1/4 in.) off center and away from

the oil hole. In addition, suspect areas can be

checked by placing Plastigage in that area.

(4) Assemble the rod cap with Plastigage in place.

Tighten the rod cap to the specified torque.Do not

rotate the crankshaft while assembling the cap

or the Plastigage may be smeared, giving inac-

curate results.

Fig. 59 Piston and Connecting Rod Positioning (Front View of Engine)

1 - MAJOR THRUST SIDE OF PISTON

2 - OIL SQUIRT HOLE

9 - 120 ENGINE 3.3/3.8LRS

PISTON & CONNECTING ROD (Continued)

Page 1421 of 2585

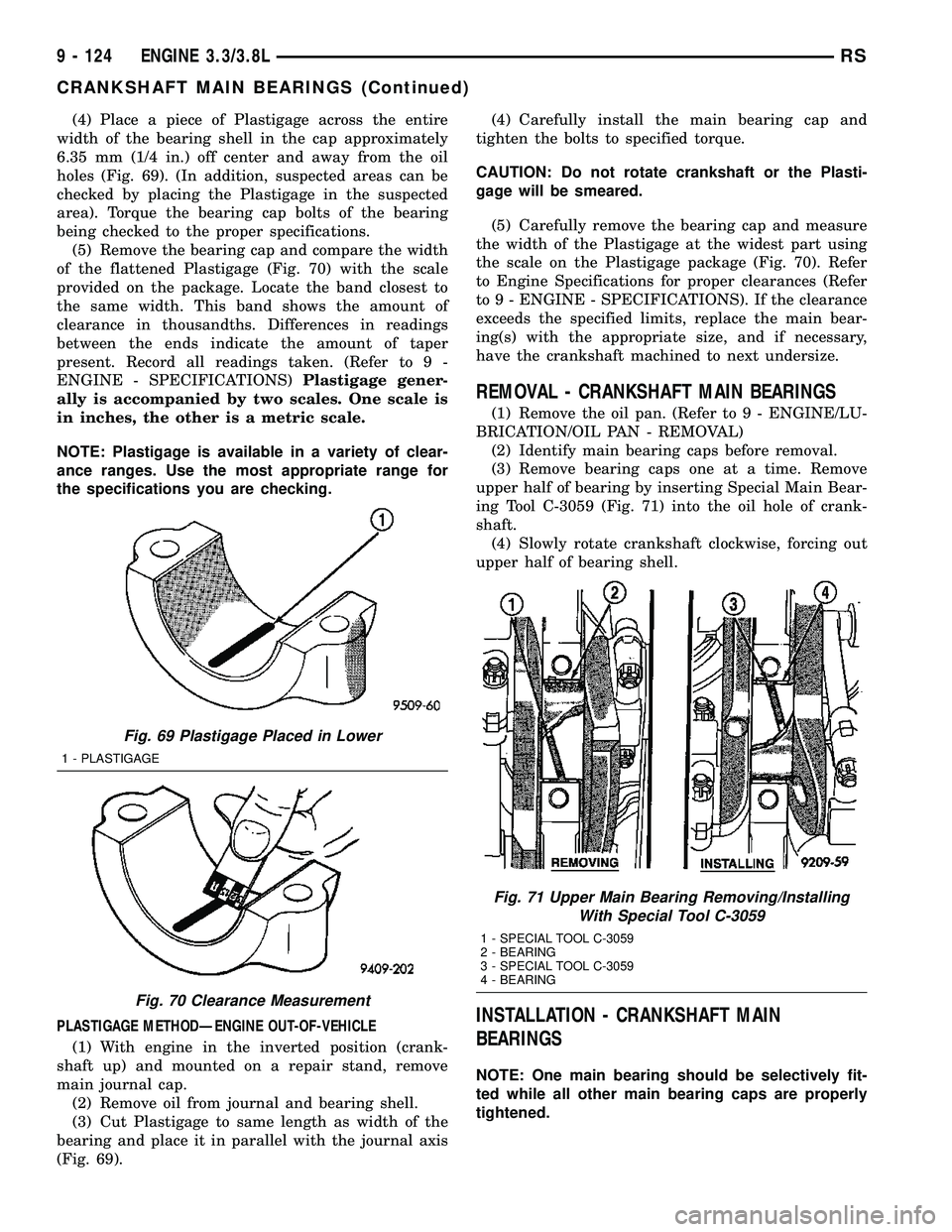

(4) Place a piece of Plastigage across the entire

width of the bearing shell in the cap approximately

6.35 mm (1/4 in.) off center and away from the oil

holes (Fig. 69). (In addition, suspected areas can be

checked by placing the Plastigage in the suspected

area). Torque the bearing cap bolts of the bearing

being checked to the proper specifications.

(5) Remove the bearing cap and compare the width

of the flattened Plastigage (Fig. 70) with the scale

provided on the package. Locate the band closest to

the same width. This band shows the amount of

clearance in thousandths. Differences in readings

between the ends indicate the amount of taper

present. Record all readings taken. (Refer to 9 -

ENGINE - SPECIFICATIONS)Plastigage gener-

ally is accompanied by two scales. One scale is

in inches, the other is a metric scale.

NOTE: Plastigage is available in a variety of clear-

ance ranges. Use the most appropriate range for

the specifications you are checking.

PLASTIGAGE METHODÐENGINE OUT-OF-VEHICLE

(1) With engine in the inverted position (crank-

shaft up) and mounted on a repair stand, remove

main journal cap.

(2) Remove oil from journal and bearing shell.

(3) Cut Plastigage to same length as width of the

bearing and place it in parallel with the journal axis

(Fig. 69).(4) Carefully install the main bearing cap and

tighten the bolts to specified torque.

CAUTION: Do not rotate crankshaft or the Plasti-

gage will be smeared.

(5) Carefully remove the bearing cap and measure

the width of the Plastigage at the widest part using

the scale on the Plastigage package (Fig. 70). Refer

to Engine Specifications for proper clearances (Refer

to 9 - ENGINE - SPECIFICATIONS). If the clearance

exceeds the specified limits, replace the main bear-

ing(s) with the appropriate size, and if necessary,

have the crankshaft machined to next undersize.

REMOVAL - CRANKSHAFT MAIN BEARINGS

(1) Remove the oil pan. (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL)

(2) Identify main bearing caps before removal.

(3) Remove bearing caps one at a time. Remove

upper half of bearing by inserting Special Main Bear-

ing Tool C-3059 (Fig. 71) into the oil hole of crank-

shaft.

(4) Slowly rotate crankshaft clockwise, forcing out

upper half of bearing shell.

INSTALLATION - CRANKSHAFT MAIN

BEARINGS

NOTE: One main bearing should be selectively fit-

ted while all other main bearing caps are properly

tightened.

Fig. 69 Plastigage Placed in Lower

1 - PLASTIGAGE

Fig. 70 Clearance Measurement

Fig. 71 Upper Main Bearing Removing/Installing

With Special Tool C-3059

1 - SPECIAL TOOL C-3059

2 - BEARING

3 - SPECIAL TOOL C-3059

4 - BEARING

9 - 124 ENGINE 3.3/3.8LRS

CRANKSHAFT MAIN BEARINGS (Continued)