roof DODGE TRUCK 1993 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 628 of 1502

•

3.9L

ENGINE

9 - 23 (19) Remove the head bolts from each cylinder

head and remove cylinder heads. Discard the cylin der head gasket.

(20) Remove spark plugs.

CLEANING

Clean all surfaces of cylinder block and cylinder

heads.

Clean cylinder block front and rear gasket surfaces

using a suitable solvent.

INSPECTION

Inspect all surfaces with a straightedge if there is

any reason to suspect leakage. If out-of-flatness ex

ceeds 0.00075 mm/mm (0.00075 inch/inch) times the

span length in any direction, either replace head or

lightly machine the head surface.

FOR EXAMPLE:—A 305 mm (12 inch) span is

0.102 mm (0.004 inch) out-of-flat. The allowable out-

of-flat is 305 x 0,00075 (12 x 0.00075) equals 0.23

mm (0.009 inch). This amount of out-of-flat is accept

able.

The cylinder head surface finish should be 1.78-

3.00 microns (70-125 microinches). Inspect push rods. Replace worn or bent rods.

INSTALLATION

(1) Apply Perfect Sealant No.5, or equivalent, to

both sides of the gasket (Fig. 5).

PERFECT

SEALANT

NO.

5

PERFECT

SEALANT

NO.

5

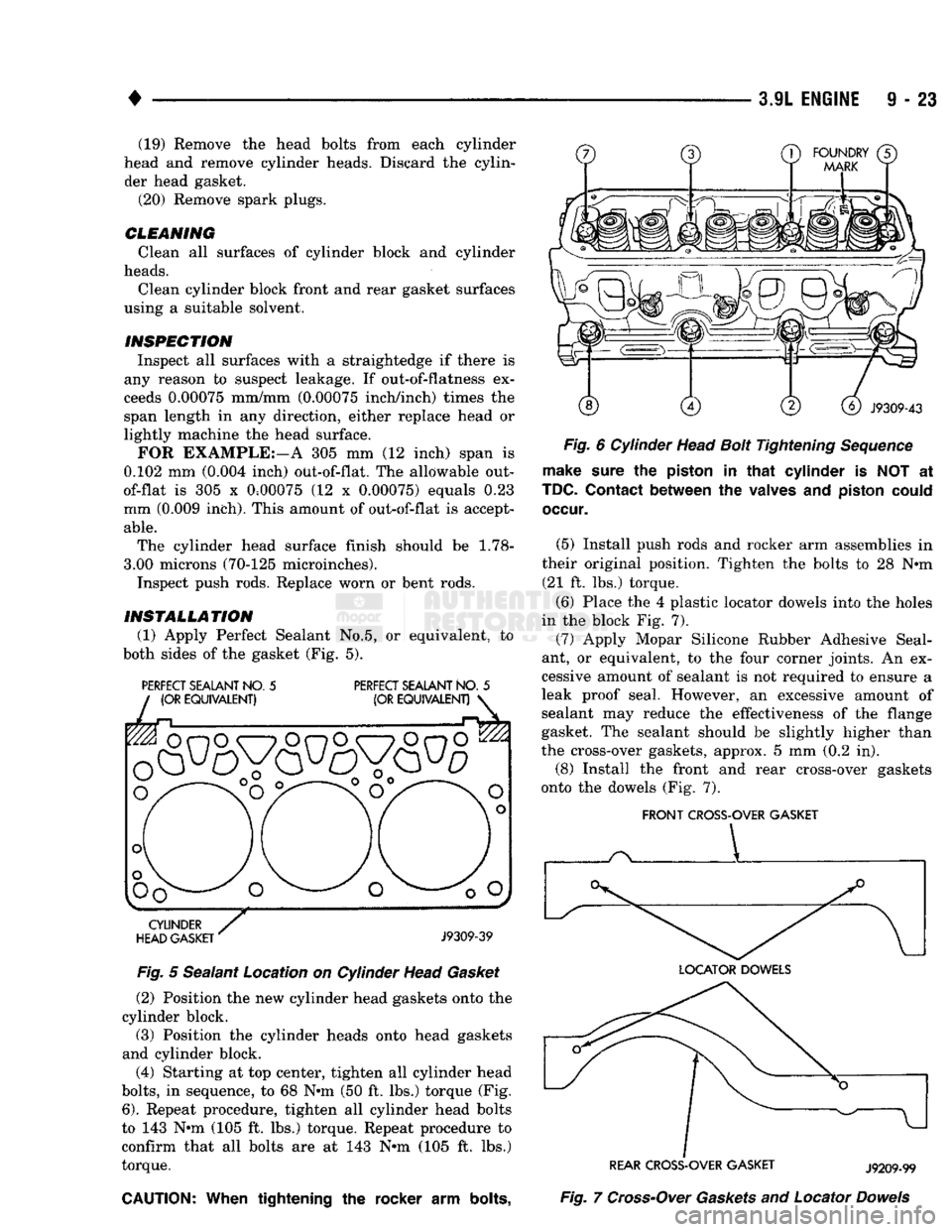

Fig.

5 Sealant Location on Cylinder Head

Gasket

(2) Position the new cylinder head gaskets onto the

cylinder block.

(3) Position the cylinder heads onto head gaskets

and cylinder block.

(4) Starting at top center, tighten all cylinder head

bolts,

in sequence, to 68 N»m (50 ft. lbs.) torque (Fig.

6).

Repeat procedure, tighten all cylinder head bolts

to 143 N»m (105 ft. lbs.) torque. Repeat procedure to

confirm that all bolts are at 143 N*m (105 ft. lbs.)

torque.

CAUTION:

When

tightening the rocker arm

bolts,

Fig.

6 Cylinder Head

Bolt

Tightening

Sequence

make

sure

the

piston

in

that

cylinder is NOT at

TDC.

Contact

between the

valves

and

piston

could

occur.

(5) Install push rods and rocker arm assemblies in

their original position. Tighten the bolts to 28 Nnn (21 ft. lbs.) torque.

(6) Place the 4 plastic locator dowels into the holes

in the block Fig. 7). (7) Apply Mopar Silicone Rubber Adhesive Seal

ant, or equivalent, to the four corner joints. An ex

cessive amount of sealant is not required to ensure a

leak proof seal. However, an excessive amount of sealant may reduce the effectiveness of the flange

gasket. The sealant should be slightly higher than

the cross-over gaskets, approx. 5 mm (0.2 in).

(8) Install the front and rear cross-over gaskets

onto the dowels (Fig. 7).

FRONT

CROSS-OVER

GASKET

REAR

CROSS-OVER

GASKET

J9209-99

Fig.

7

Cross-Over

Gaskets

and Locator

Dowels

Page 658 of 1502

•

5.2L ENGINE

9 - 53

INSPECTION

Inspect all surfaces with a straightedge if there is

any reason to suspect leakage. If out-of-flatness ex

ceeds 0.00075 mm/mm (0.00075 inch/inch) times the span length in inches in any direction, either replace

head or lightly machine the head surface.

FOR EXAMPLE: A 305 mm (12 inch) span is

0.102 mm (0.004 inch) out-of-flat. The allowable out-

of-flat is 305 x 0.00075 (12 x 0.00075) equals 0.23

mm (0.009 inch). This amount of out-of-flat is accept

able.

The cylinder head surface finish should be 1.78-

3.00 microns (70-125 microinches). Inspect push rods. Replace worn or bent rods.

INSTALLATION

(1) Apply Perfect Sealant No.5, or equivalent, to

both sides of the gasket (Fig. 5).

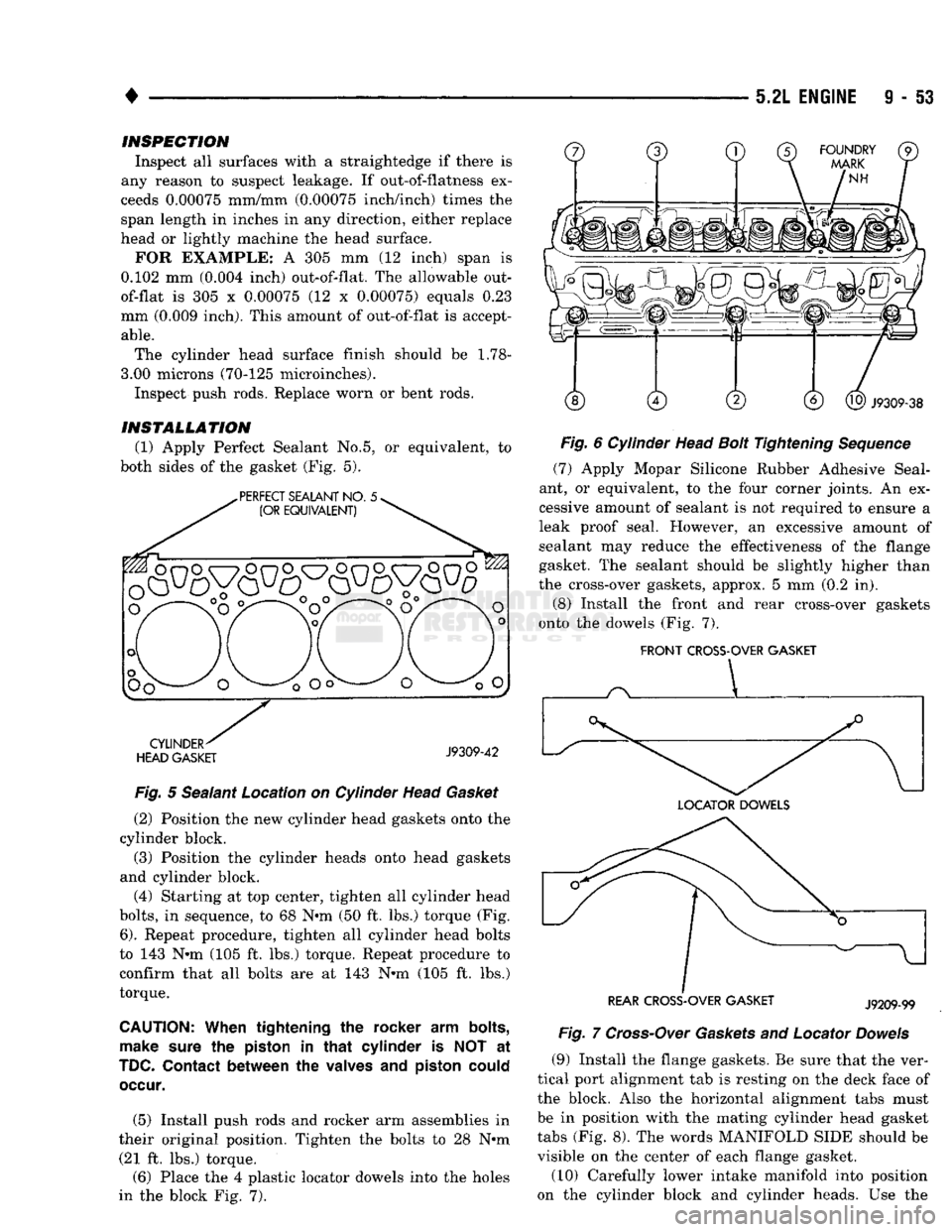

Fig.

5 Sealant Location on Cylinder Head

Gasket

(2) Position the new cylinder head gaskets onto the

cylinder block. (3) Position the cylinder heads onto head gaskets

and cylinder block. (4) Starting at top center, tighten all cylinder head

bolts,

in sequence, to 68 N»m (50 ft. lbs.) torque (Fig.

6).

Repeat procedure, tighten all cylinder head bolts

to 143 N®m (105 ft. lbs.) torque. Repeat procedure to confirm that all bolts are at 143 N-m (105 ft. lbs.)

torque.

CAUTION:

When

tightening the rocker arm

bolts,

make

sure

the

piston

in

that

cylinder is NOT at

TDC.

Contact

between the

valves

and

piston

could

occur.

(5) Install push rods and rocker arm assemblies in

their original position. Tighten the bolts to 28 N»m (21 ft. lbs.) torque. (6) Place the 4 plastic locator dowels into the holes

in the block Fig. 7).

Fig.

6 Cylinder Head

Bolt

Tightening

Sequence

(7) Apply Mopar Silicone Rubber Adhesive Seal

ant, or equivalent, to the four corner joints. An ex

cessive amount of sealant is not required to ensure a

leak proof seal. However, an excessive amount of sealant may reduce the effectiveness of the flange

gasket. The sealant should be slightly higher than

the cross-over gaskets, approx. 5 mm (0.2 in).

(8) Install the front and rear cross-over gaskets

onto the dowels (Fig. 7).

FRONT

CROSS-OVER GASKET

REAR CROSS-OVER GASKET

J9209-99

Fig.

7

Cross-Over

Gaskets

and Locator

Dowels

(9) Install the flange gaskets. Be sure that the ver

tical port alignment tab is resting on the deck face of

the block. Also the horizontal alignment tabs must

be in position with the mating cylinder head gasket

tabs (Fig. 8). The words MANIFOLD SIDE should be visible on the center of each flange gasket.

(10) Carefully lower intake manifold into position

on the cylinder block and cylinder heads. Use the

Page 688 of 1502

•

IJL ENGINE 9 - 83

INSPECTION

Inspect all surfaces with a straightedge if there is

any reason to suspect leakage. If out-of-flatness ex

ceeds 0.00075 mm/mm (0.00075 inch/inch) times the span length in inches in any direction, either replace

head or lightly machine the head surface.

FOR EXAMPLE: A 305 mm (12 inch) span is

0.102 mm (0.004 inch) out-of-flat. The allowable out-

of-flat is 305 x 0.00075 (12 x 0.00075) equals 0.23

mm (0.009 inch). This amount of out-of-flat is accept

able.

The cylinder head surface finish should be 1.78-

4.57 microns (70-180 microinches). Inspect push rods. Replace worn or bent rods.

INSTALLATION

(1) Apply Perfect Sealant No.5, or equivalent, to

both sides of the gasket (Fig. 5).

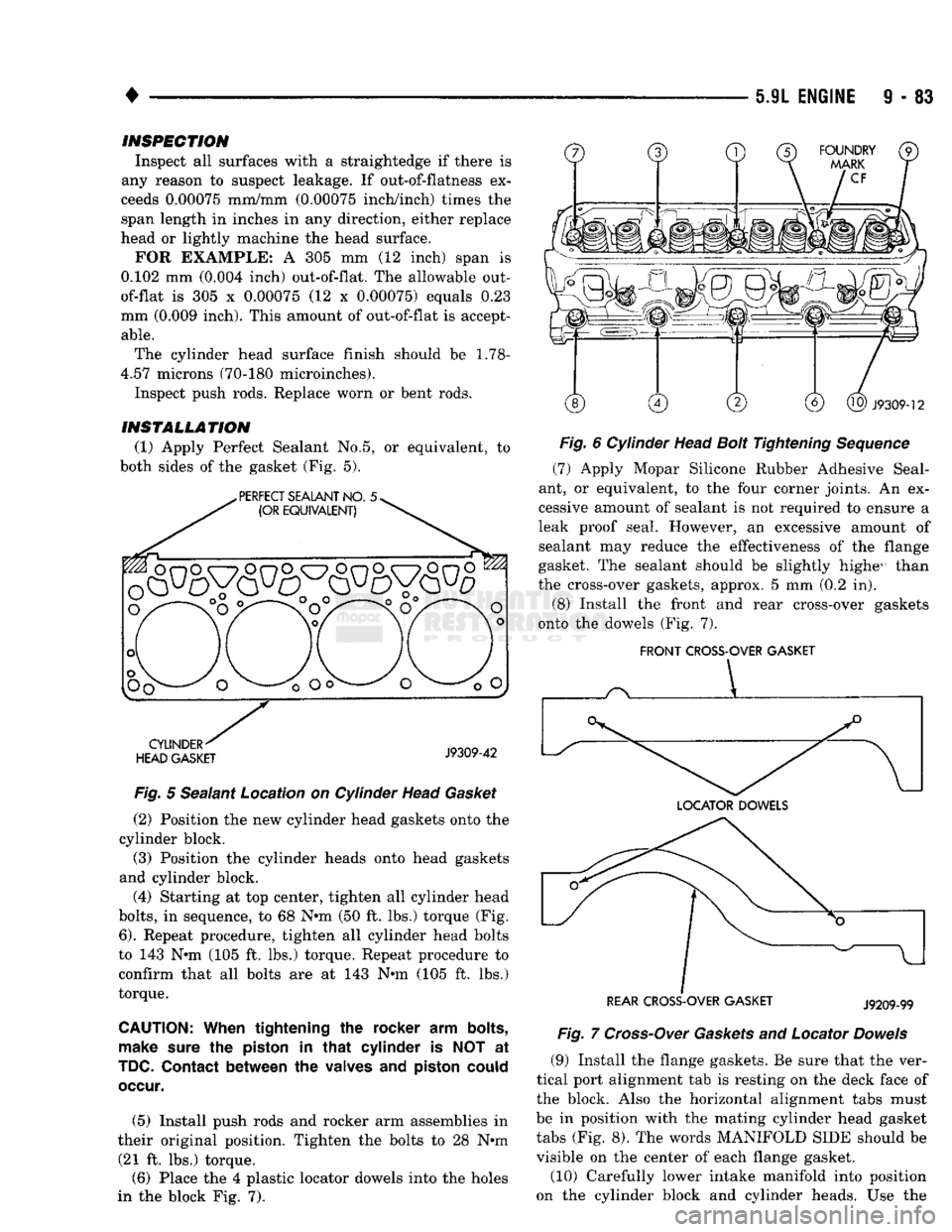

Fig.

5 Sealant Location on Cylinder Head

Gasket

(2) Position the new cylinder head gaskets onto the

cylinder block.

(3) Position the cylinder heads onto head gaskets

and cylinder block. (4) Starting at top center, tighten all cylinder head

bolts,

in sequence, to 68 N-m (50 ft. lbs.) torque (Fig.

6).

Repeat procedure, tighten all cylinder head bolts

to 143 N-m (105 ft. lbs.) torque. Repeat procedure to confirm that all bolts are at 143 N-m (105 ft. lbs.)

torque.

CAUTION:

When

tightening the rocker arm

bolts,

make

sure

the

piston

in

that

cylinder is NOT at

TDC.

Contact

between the

valves

and

piston

could

occur.

(5) Install push rods and rocker arm assemblies in

their original position. Tighten the bolts to 28 N-m (21 ft. lbs.) torque. (6) Place the 4 plastic locator dowels into the holes

in the block Fig. 7).

Fig.

6 Cylinder Head

Bolt

Tightening

Sequence

(7) Apply Mopar Silicone Rubber Adhesive Seal

ant, or equivalent, to the four corner joints. An ex

cessive amount of sealant is not required to ensure a

leak proof seal. However, an excessive amount of sealant may reduce the effectiveness of the flange

gasket. The sealant should be slightly highe^ than

the cross-over gaskets, approx. 5 mm (0.2 in).

(8) Install the front and rear cross-over gaskets

onto the dowels (Fig. 7).

FRONT

CROSS-OVER GASKET

REAR CROSS-OVER GASKET

J9209-99

Fig.

7

Cross-Over

Gaskets

and Locator

Dowels

(9) Install the flange gaskets. Be sure that the ver

tical port alignment tab is resting on the deck face of

the block. Also the horizontal alignment tabs must

be in position with the mating cylinder head gasket tabs (Fig. 8). The words MANIFOLD SIDE should be

visible on the center of each flange gasket.

(10) Carefully lower intake manifold into position

on the cylinder block and cylinder heads. Use the

Page 735 of 1502

9

- 130 5.9L

(DIESEL) ENGINE

• CAMSHAFT BORE DIAMETER

MAX.

54.133

mm

(2.1312

inch)

J9109-78

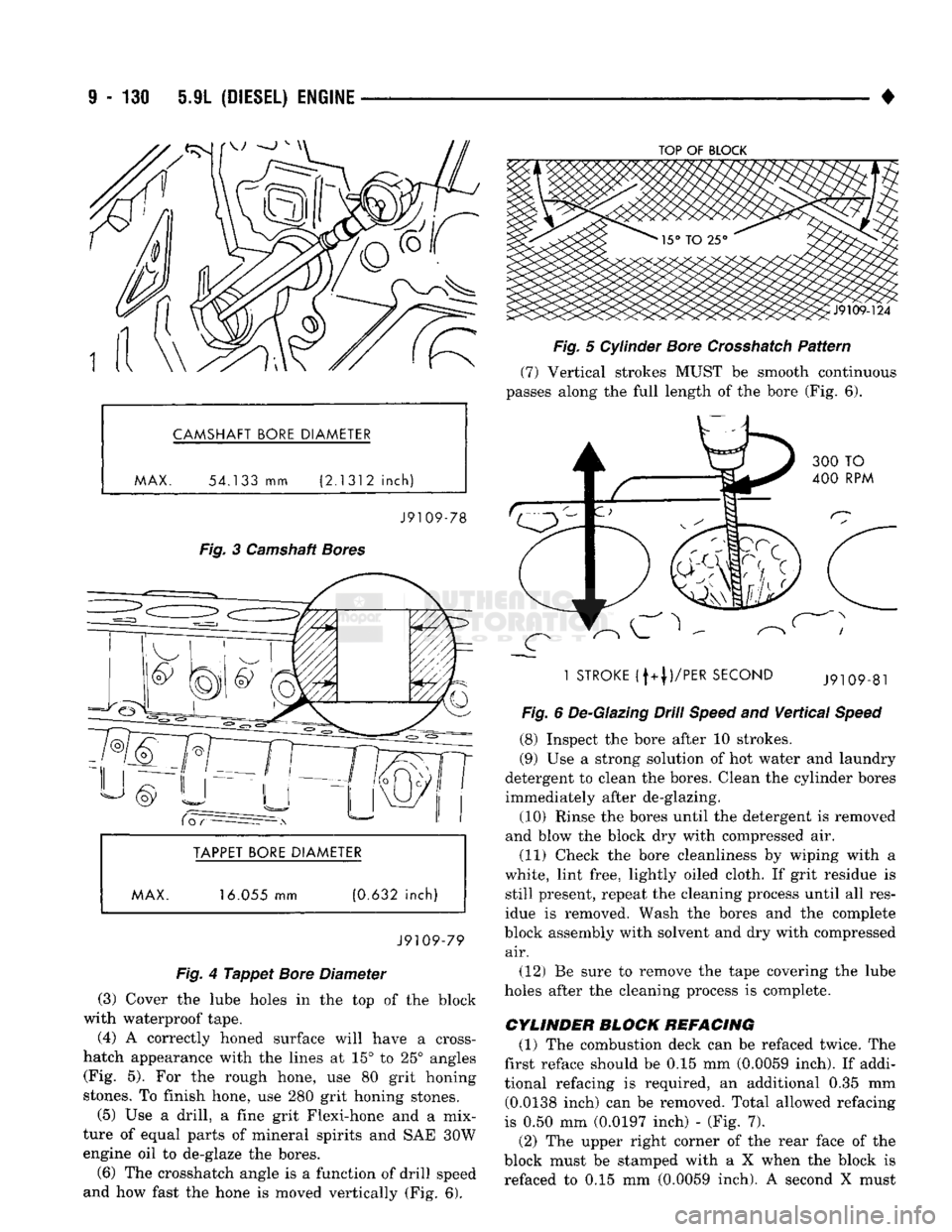

Fig.

3 Camshaft

Bores

BORE DIAMETER

MAX. 16.055 mm (0.632 inch)

J9109-79

Fig.

4

Tappet

Bore

Diameter

(3) Cover the lube holes in the top of the block

with waterproof tape.

(4) A correctly honed surface will have a cross-

hatch appearance with the lines at 15° to 25° angles (Fig. 5). For the rough hone, use 80 grit honing

stones. To finish hone, use 280 grit honing stones.

(5) Use a drill, a fine grit Flexi-hone and a mix

ture of equal parts of mineral spirits and SAE 30W engine oil to de-glaze the bores.

(6) The Crosshatch angle is a function of drill speed

and how fast the hone is moved vertically (Fig. 6).

TOP

OF

BLOCK

Fig.

5 Cylinder

Bore

Crosshatch

Pattern

(7) Vertical strokes MUST be smooth continuous

passes along the full length of the bore (Fig. 6).

1

STROKE

(f+|)/PER

SECOND

Fig.

6 De-Glazing Drill

Speed

and

Vertical

Speed

(8) Inspect the bore after 10 strokes.

(9) Use a strong solution of hot water and laundry

detergent to clean the bores. Clean the cylinder bores

immediately after de-glazing.

(10) Rinse the bores until the detergent is removed

and blow the block dry with compressed air. (11) Check the bore cleanliness by wiping with a

white, lint free, lightly oiled cloth. If grit residue is still present, repeat the cleaning process until all res

idue is removed. Wash the bores and the complete

block assembly with solvent and dry with compressed air.

(12) Be sure to remove the tape covering the lube

holes after the cleaning process is complete.

CYLINDER BLOCK REFACING

(1) The combustion deck can be refaced twice. The

first reface should be 0.15 mm (0.0059 inch). If addi

tional refacing is required, an additional 0.35 mm (0.0138 inch) can be removed. Total allowed refacing

is 0.50 mm (0.0197 inch) - (Fig. 7).

(2) The upper right corner of the rear face of the

block must be stamped with a X when the block is refaced to 0.15 mm (0.0059 inch). A second X must

Page 773 of 1502

11-14

EXHAUST

SYSTEM

AND

INTAKE

MANIFOLD

• The plenum pan rail must be clean and dry (free of

all foreign material).

INSPECTION

Inspect manifold for cracks.

Inspect mating surfaces of manifold for flatness

with a straightedge.

INSTALLATION

(1) Install the plenum pan, if removed, as follows: (a) Turn the intake manifold upside down. Sup

port the manifold.

(b) Place a new plenum pan gasket onto the seal

rail of the intake manifold. Position the pan over

the gasket. Align all the gasket and pan holes with

the intake manifold. (c) Hand start all bolts.

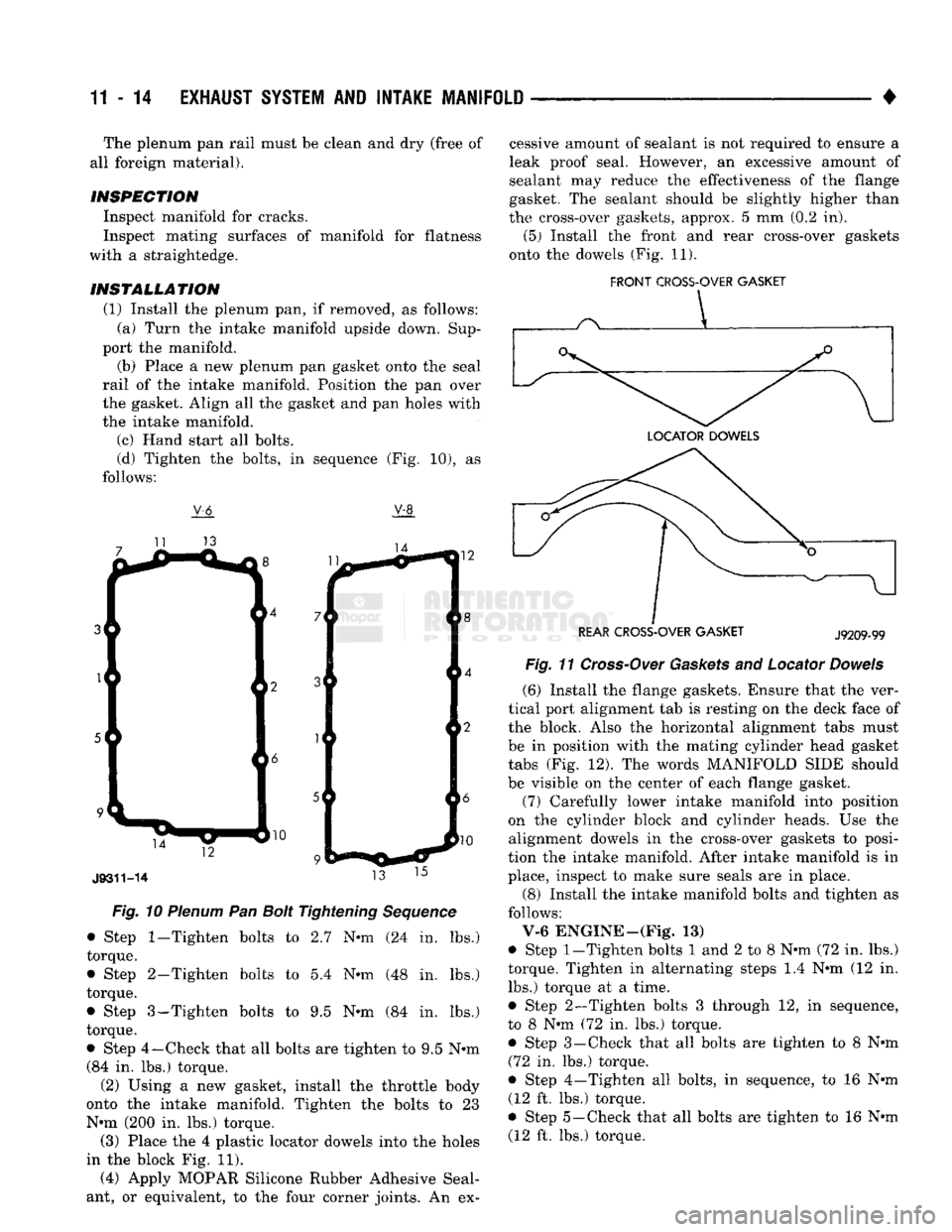

(d) Tighten the bolts, in sequence (Fig. 10), as

follows:

V-6

V-8

Fig.

10

Plenum

Pan

Bolt

Tightening

Sequence

• Step

1-Tighten

bolts to 2.7 N*m (24 in. lbs.)

torque.

• Step 2-Tighten bolts to 5.4 N«m (48 in. lbs.)

torque.

• Step 3-Tighten bolts to 9.5 Nnn (84 in. lbs.)

torque.

• Step 4—Check that all bolts are tighten to 9.5 N®m (84 in. lbs.) torque.

(2) Using a new gasket, install the throttle body

onto the intake manifold. Tighten the bolts to 23

Nun (200 in. lbs.) torque. (3) Place the 4 plastic locator dowels into the holes

in the block Fig. 11).

(4) Apply MOPAR Silicone Rubber Adhesive Seal

ant, or equivalent, to the four corner joints. An ex cessive amount of sealant is not required to ensure a

leak proof seal. However, an excessive amount of

sealant may reduce the effectiveness of the flange

gasket. The sealant should be slightly higher than

the cross-over gaskets, approx. 5 mm (0.2 in).

(5) Install the front and rear cross-over gaskets

onto the dowels (Fig. 11).

FRONT

CROSS-OVER

GASKET

REAR

CROSS-OVER

GASKET

J9209-99

Fig

11

Cross-Over

Gaskets

and Locator

Dowels

(6) Install the flange gaskets. Ensure that the ver

tical port alignment tab is resting on the deck face of

the block. Also the horizontal alignment tabs must

be in position with the mating cylinder head gasket

tabs (Fig. 12). The words MANIFOLD SIDE should

be visible on the center of each flange gasket.

(7) Carefully lower intake manifold into position

on the cylinder block and cylinder heads. Use the alignment dowels in the cross-over gaskets to posi

tion the intake manifold. After intake manifold is in

place, inspect to make sure seals are in place.

(8) Install the intake manifold bolts and tighten as

follows:

V-6 ENGINE—(Fig. 13)

• Step

1-Tighten

bolts 1 and 2 to 8 Nun (72 in. lbs.)

torque. Tighten in alternating steps 1.4 Nun (12 in. lbs.) torque at a time.

• Step 2—Tighten bolts 3 through 12, in sequence,

to 8 Nun (72 in. lbs.) torque.

• Step 3—Check that all bolts are tighten to 8 Nun (72 in. lbs.) torque.

• Step 4—Tighten all bolts, in sequence, to 16 Nun (12 ft. lbs.) torque.

• Step 5—Check that all bolts are tighten to 16 Nun (12 ft. lbs.) torque.

Page 1384 of 1502

•

BODY

COMPONENTS

23 - 1

CONTENTS

page

page

CAB/BODY

INTERIOR COMPONENTS

35

FIXED

GLASS

. 29

DOORS

21

PAINT

CODE

CHART

54

EXTERIOR

COMPONENTS

1

REFINISHING

PROCEDURES

54

EXTERIOR COMPONENTS

INDEX

page

Battery

Tray

7

Blower Motor Housing

Insulation

Panel—Diesel

Engine

Only

7

Body

Mouldings, Nameplates

and

Decals .......

9

Cab

. 14

Cab/Body

and

Cargo

Box

Stripes

11

Cargo

Box

19

Cowl

Grille

7

Front

Fenders

8

Fuel

Filler

Door

and

Nozzle/Tubes

12

Grille

and

Grille

Extension Panel

1

Grille

Extension Panel Support Bracket

(With

Diesel Engine Only)

3

page

Grille

Opening Panel (GOP)

and

Radiator Support Panel

3

Hatchgate

and

Components

16

Hood

5

Hood

Inside Release Cable

5

Hood

Latch

4

Labels/Decals/Plates

1

Outside Mirrors

13

Roof

Vent—Ramcharger

. 20

Splash

Shields—Front Fender

9

Sport

Bar

18

Tailgate

14

LABELS/DECALS/PLATES

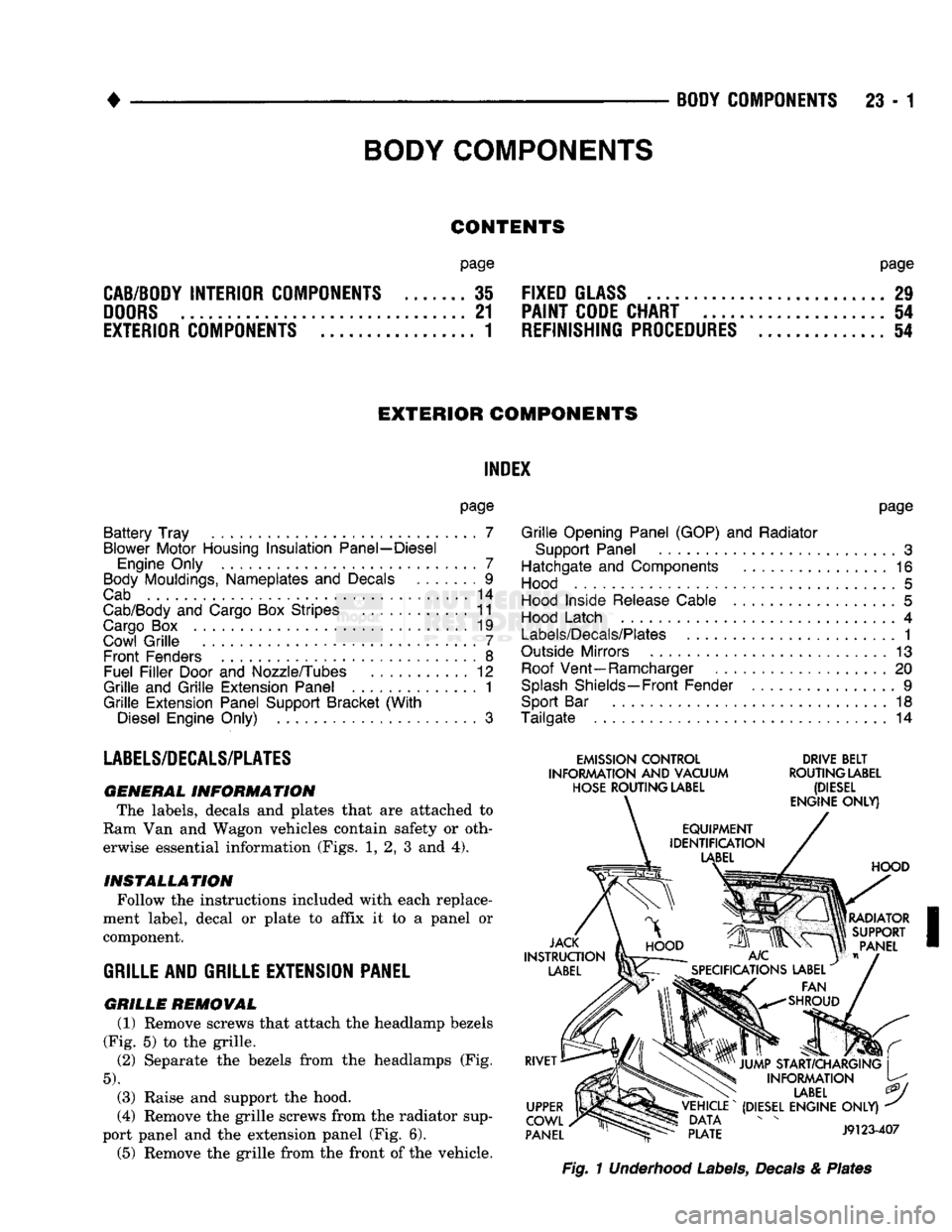

GENERAL

INFORMATION The labels, decals

and

plates that

are

attached

to

Ram Van

and

Wagon vehicles contain safety

or

oth erwise essential information (Figs.

1, 2, 3 and 4).

INSTALLATION

Follow the instructions included with each replace

ment label, decal

or

plate

to

affix

it to a

panel

or

component.

GRILLE

AND GRILLE EXTENSION PANEL

GRILLE

REMOVAL (1) Remove screws that attach the headlamp bezels

(Fig.

5) to the

grille.

(2)

Separate

the

bezels from

the

headlamps

(Fig.

5).

(3) Raise

and

support

the

hood.

(4) Remove the grille screws from the radiator sup

port panel

and the

extension panel (Fig.

6).

(5) Remove

the

grille from the front

of

the vehicle.

EMISSION

CONTROL

DRIVE

BELT

INFORMATION

AND

VACUUM

ROUTING

LABEL

HOSE

ROUTING

LABEL

(DIESEL

Fig.

1 Underhood Labels, Decals & Plates

BODY

COMPONENTS

Page 1394 of 1502

•

BODY COMPONENTS

23 - 11 (3) Apply additional heat to any location where the

decal remains adhered to the panel.

(4) Remove the extra adhesive from the panel with

a cloth saturated with an adhesive remover.

INSTALLATION

(1) Clean the panel surface with a commercial wax

and silicone removal solution. Wipe the surface with

a clean cloth. (2) Remove the backing from the decal. Position it

on the panel.

(3) Verify that the decal is properly aligned.

(4) Press the decal onto the panel with a roller to

ensure complete adhesion.

Fig.

28

Tailgate

&

Cargo

Box

Decals

TMILGA

TE/HA

TCHGA

TE

APPLIQUE

REMOVAL

(1) Open the tailgate/hatchgate.

(2) If applicable, remove the hatchgate trim panel.

(3) Remove the applique screws (Figs. 29 and 30).

(4) Pry the applique from the tailgate/hatchgate to

separate the corner studs from the retainers. (5) Remove the applique from the tailgate/hatch

gate.

INSTALLATION

(1) Position the applique on the tailgate/hatchgate

with the corner studs mated with the retainers.

(2) Install the applique screws in the tailgate/

hatchgate (Figs. 29 and 30). Tighten the screws to 2 N-m (20 in. lbs.) torque. (3) If applicable, install the hatchgate trim panel.

(4) Close the tailgate/hatchgate.

ROOF

MOULDING

REMOVAL

(1) Remove the moulding end caps.

(2) Pry the moulding from the drip rail. Remove

the moulding from the roof edge.

RETAINER

APPLIQUE

J9123-538

Fig.

29

Tailgate

Applique

Fig.

30 Hatchgate Applique

INSTALLATION

(1) Position the roof moulding with retainers at

the roof drip rail. (2) Force the moulding onto the drip rail until it is

seated against the roof edge.

(3) Install the moulding end caps.

CAB/BODY

AND

CARGO

BOX

STRIPES

GENERAL

INFORMATION

The cab/body and cargo box stripes are durable,

weather-resistant tape stripes with pressure-sensitive

backing (Figs. 32 and 33). The tape stripe is pro tected by a carrier until installed on a body panel.

The carrier also is an installation alignment aid.

Page 1395 of 1502

23

- 12

BODY COMPONENTS

•

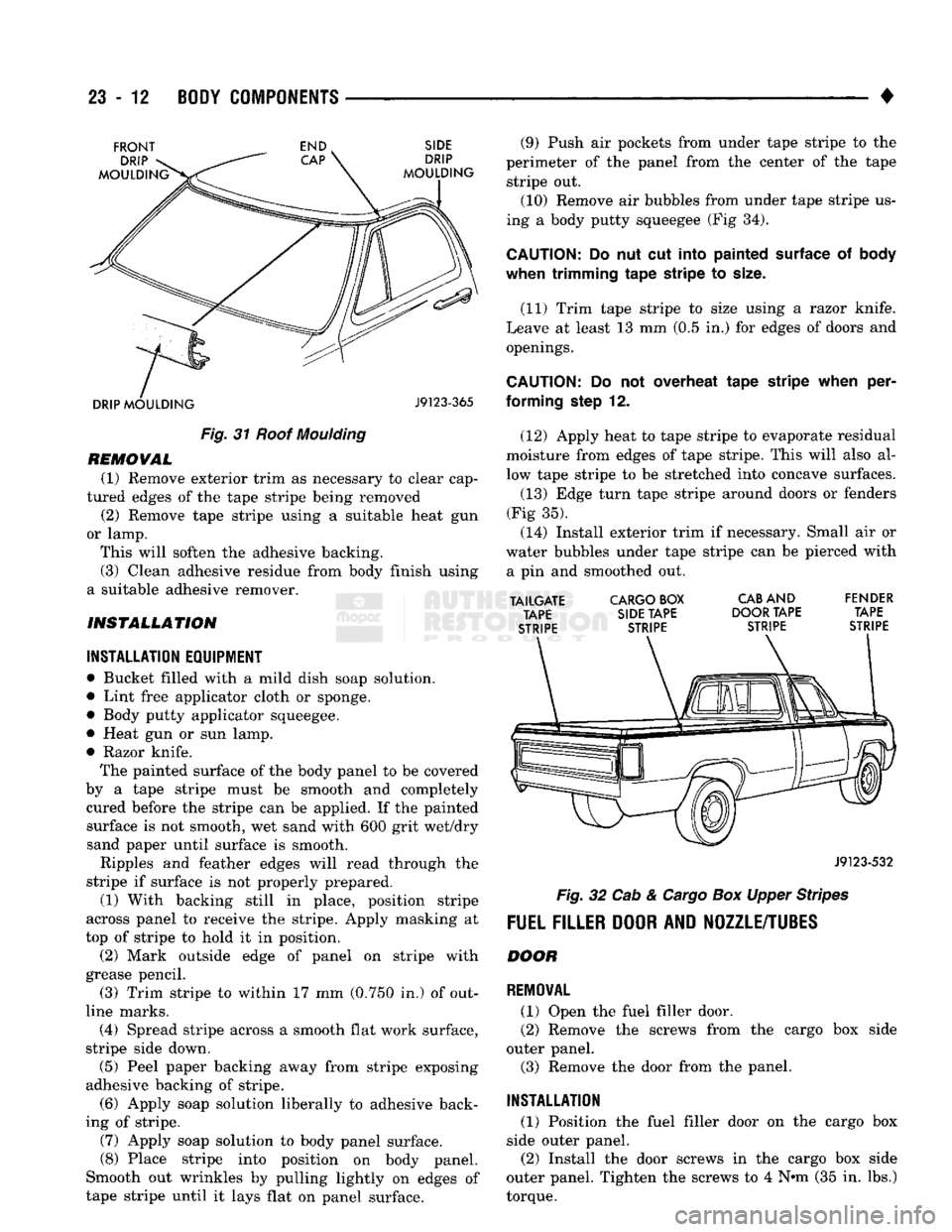

Fig.

31

Roof

Moulding

REMOVAL

(1) Remove exterior trim as necessary to clear cap

tured edges of the tape stripe being removed

(2) Remove tape stripe using a suitable heat gun

or lamp. This will soften the adhesive backing.

(3) Clean adhesive residue from body finish using

a suitable adhesive remover.

INSTALLATION

INSTALLATION EQUIPMENT

• Bucket filled with a mild dish soap solution.

• Lint free applicator cloth or sponge. • Body putty applicator squeegee.

• Heat gun or sun lamp.

• Razor knife.

The painted surface of the body panel to be covered

by a tape stripe must be smooth and completely cured before the stripe can be applied. If the painted surface is not smooth, wet sand with 600 grit wet/dry

sand paper until surface is smooth.

Ripples and feather edges will read through the

stripe if surface is not properly prepared. (1) With backing still in place, position stripe

across panel to receive the stripe. Apply masking at

top of stripe to hold it in position. (2) Mark outside edge of panel on stripe with

grease pencil. (3) Trim stripe to within 17 mm (0.750 in.) of out

line marks.

(4) Spread stripe across a smooth flat work surface,

stripe side down. (5) Peel paper backing away from stripe exposing

adhesive backing of stripe.

(6) Apply soap solution liberally to adhesive back

ing of stripe. (7) Apply soap solution to body panel surface.

(8) Place stripe into position on body panel.

Smooth out wrinkles by pulling lightly on edges of

tape stripe until it lays flat on panel surface. (9) Push air pockets from under tape stripe to the

perimeter of the panel from the center of the tape stripe out. (10) Remove air bubbles from under tape stripe us

ing a body putty squeegee (Fig 34).

CAUTION:

Do nut cut

Into

painted surface

of body

when trimming

tape

stripe

to

size.

(11) Trim tape stripe to size using a razor knife.

Leave at least 13 mm (0.5 in.) for edges of doors and openings.

CAUTION;

Do not overheat

tape

stripe

when

per

forming

step

12.

(12) Apply heat to tape stripe to evaporate residual

moisture from edges of tape stripe. This will also al

low tape stripe to be stretched into concave surfaces.

(13) Edge turn tape stripe around doors or fenders

(Fig 35). (14) Install exterior trim if necessary. Small air or

water bubbles under tape stripe can be pierced with a pin and smoothed out.

TAILGATE

CARGO BOX

CAB

AND FENDER TAPE SIDE TAPE DOOR TAPE TAPE

STRIPE STRIPE STRIPE STRIPE

J9123-532

Fig.

32 Cab &

Cargo

Box Upper Stripes

FUEL FILLER DOOR AND NOZZLE/TUBES

DOOR

REMOVAL

(1) Open the fuel filler door.

(2) Remove the screws from the cargo box side

outer panel. (3) Remove the door from the panel.

INSTALLATION

(1) Position the fuel filler door on the cargo box

side outer panel.

(2) Install the door screws in the cargo box side

outer panel. Tighten the screws to 4 Nnn (35 in. lbs.)

torque.

Page 1400 of 1502

•

BODY

COMPONENTS

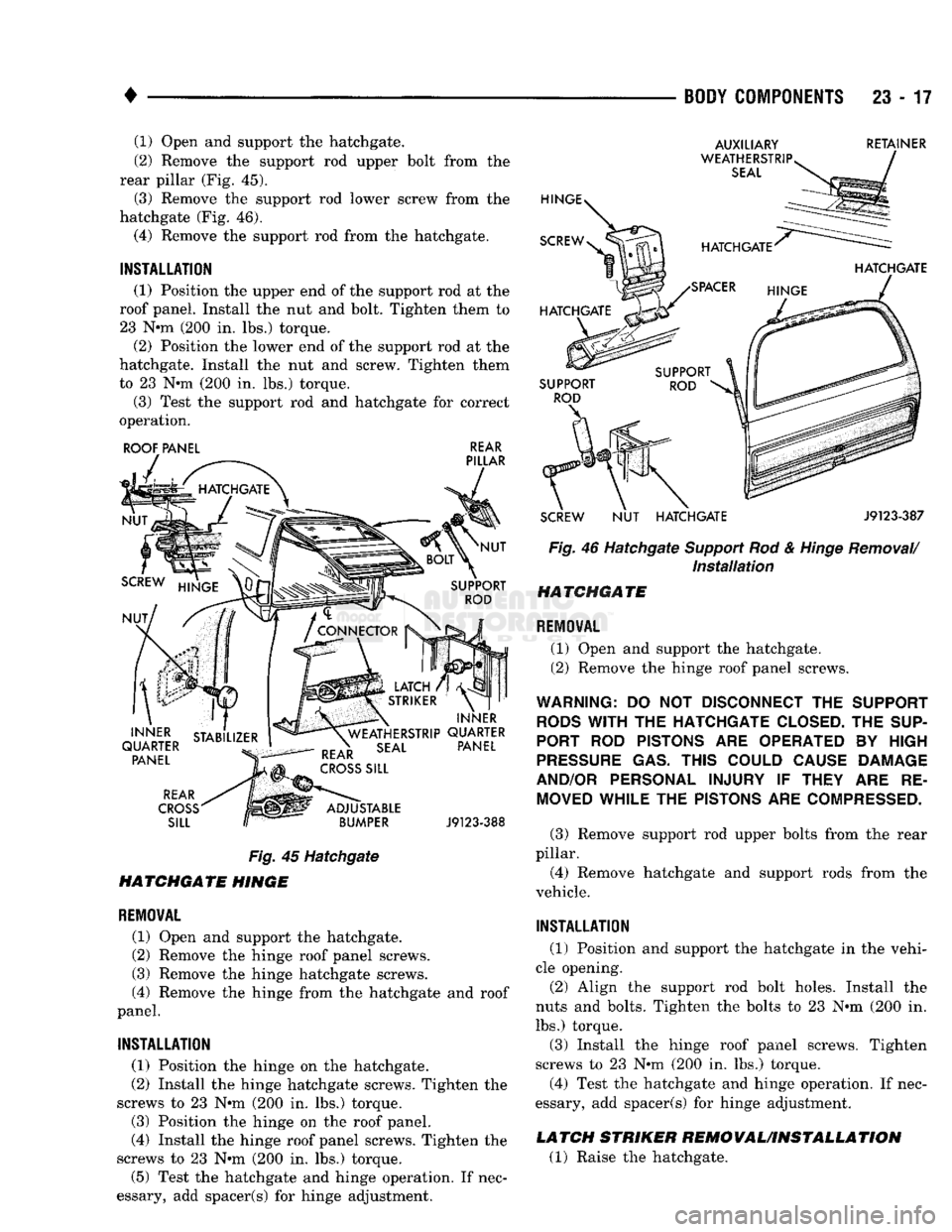

23 - 17 (1) Open and support the hatchgate.

(2) Remove the support rod upper bolt from the

rear pillar (Fig. 45).

(3) Remove the support rod lower screw from the

hatchgate (Fig. 46). (4) Remove the support rod from the hatchgate.

INSTALLATION

(1) Position the upper end of the support rod at the

roof panel. Install the nut and bolt. Tighten them to 23 N'm (200 in. lbs.) torque.

(2) Position the lower end of the support rod at the

hatchgate. Install the nut and screw. Tighten them

to 23 N-m (200 in. lbs.) torque.

(3) Test the support rod and hatchgate for correct

operation.

ROOF PANEL REAR

Fig.

45 Hatchgate

HATCHGATE

HINGE

REMOVAL

(1) Open and support the hatchgate.

(2) Remove the hinge roof panel screws.

(3) Remove the hinge hatchgate screws.

(4) Remove the hinge from the hatchgate and roof

panel.

INSTALLATION

(1) Position the hinge on the hatchgate.

(2) Install the hinge hatchgate screws. Tighten the

screws to 23 N*m (200 in. lbs.) torque.

(3) Position the hinge on the roof panel.

(4) Install the hinge roof panel screws. Tighten the

screws to 23 N»m (200 in. lbs.) torque.

(5) Test the hatchgate and hinge operation. If nec

essary, add spacer(s) for hinge adjustment.

AUXILIARY RETAINER

SCREW

NUT

HATCHGATE

J9123-387

Fig.

46 Hatchgate

Support

Rod &

Hinge

Removal/

Installation

HATCHGATE

REMOVAL

(1) Open and support the hatchgate.

(2) Remove the hinge roof panel screws.

WARNING:

DO NOT

DISCONNECT

THE

SUPPORT

RODS

WITH

THE

HATCHGATE CLOSED.

THE

SUP

PORT

ROD

PISTONS

ARE

OPERATED

BY

HIGH

PRESSURE

GAS.

THIS COULD CAUSE DAMAGE

AND/OR PERSONAL INJURY

IF

THEY

ARE RE

MOVED WHILE

THE

PISTONS

ARE

COMPRESSED.

(3) Remove support rod upper bolts from the rear

pillar.

(4) Remove hatchgate and support rods from the

vehicle.

INSTALLATION

(1) Position and support the hatchgate in the vehi

cle opening. (2) Align the support rod bolt holes. Install the

nuts and bolts. Tighten the bolts to 23 N*m (200 in.

lbs.) torque.

(3) Install the hinge roof panel screws. Tighten

screws to 23 N«m (200 in. lbs.) torque. (4) Test the hatchgate and hinge operation. If nec

essary, add spacer(s) for hinge adjustment.

LATCH

STRIKER

REMOVAL/INSTALLATION

(1) Raise the hatchgate.

Page 1403 of 1502

23

- 20

BODY COMPONENTS

•

Fig.

52

Cargo

Box

Side

Panel

Braces

ROOF

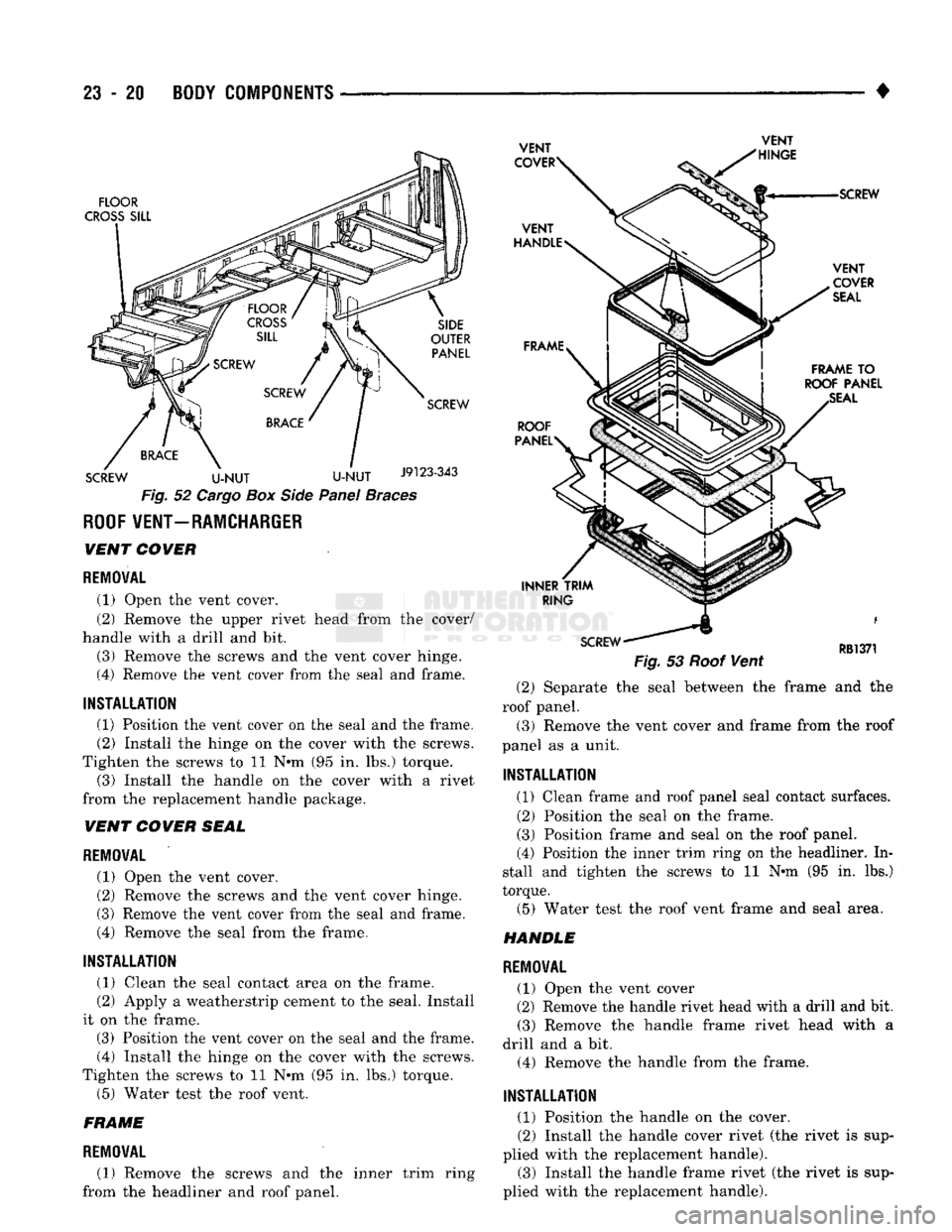

VENT—RAMCHARGER

WENT

COWER

REMOVAL

(1) Open the vent cover.

(2) Remove the upper rivet head from the cover/

handle with a drill and bit. (3) Remove the screws and the vent cover hinge.

(4) Remove the vent cover from the seal and frame.

INSTALLATION

(1) Position the vent cover on the seal and the frame. (2) Install the hinge on the cover with the screws.

Tighten the screws to 11 N-m (95 in. lbs.) torque.

(3) Install the handle on the cover with a rivet

from the replacement handle package.

WENT

COWER

SEAL

REMOVAL

(1) Open the vent cover.

(2) Remove the screws and the vent cover hinge.

(3) Remove the vent cover from the seal and frame.

(4) Remove the seal from the frame.

INSTALLATION

(1) Clean the seal contact area on the frame.

(2) Apply a weatherstrip cement to the seal. Install

it on the frame. (3) Position the vent cover on the seal and the frame.

(4) Install the hinge on the cover with the screws.

Tighten the screws to 11 N-m (95 in. lbs.) torque. (5) Water test the roof vent.

FRAME

REMOVAL

(1) Remove the screws and the inner trim ring

from the headliner and roof panel.

Fig.

53

Roof

Vent

(2) Separate the seal between the frame and the

roof panel. (3) Remove the vent cover and frame from the roof

panel as a unit.

INSTALLATION

(1) Clean frame and roof panel seal contact surfaces. (2) Position the seal on the frame.

(3) Position frame and seal on the roof panel.

(4) Position the inner trim ring on the headliner. In

stall and tighten the screws to 11 N-m (95 in. lbs.)

torque.

(5) Water test the roof vent frame and seal area.

HANDLE

REMOVAL

(1) Open the vent cover

(2) Remove the handle rivet head with a drill and bit.

(3) Remove the handle frame rivet head with a

drill and a bit. (4) Remove the handle from the frame.

INSTALLATION

(1) Position the handle on the cover. (2) Install the handle cover rivet (the rivet is sup

plied with the replacement handle).

(3) Install the handle frame rivet (the rivet is sup

plied with the replacement handle).