diag code DODGE TRUCK 1993 Service Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 906 of 1502

•

FUEL

SYSTEM

14 - 87

ENGINE

WARM-UP

• The PCM may start the air intake heater post-heat

cycle depending on intake air temperature. If manifold air temperature was at or below 15°C (59°F) when the

ignition switch was turned on, the cycle is started.

• If intake manifold air temperature is below 32°C

(90°F),

the KSB solenoid will be energized through

the air temperature switch. The solenoid remains en ergized until the air temperature switch opens. The

switch opens when intake manifold air temperature

is above 32°C (90°F).

• If the coolant temperature is below 16°C (60° F),

the transmission will not be allowed to enter over drive (automatic transmission).

• The PCM will turn on the water-in-fuel lamp if a signal is received from the water-in-fuel sensor.

CRUISE

OR

IDLE

• The PCM monitors intake manifold air tempera

ture through the charge temperature sensor input. • If intake manifold air temperature is below 32°C

(90°F),

the KSB solenoid will be energized through

the air temperature switch. The solenoid remains en ergized until the air temperature switch opens. The switch opens when intake manifold air temperature

is above 32°C (90°F).

• The air intake heater post-heat cycle will be com

pleted, if it is not already over.

• The vehicle speed sensor, engine speed sensor and

throttle position sensor inputs are used to control

transmission overdrive operation.

• If the coolant temperature is below 16° C (60° F),

the transmission will not be allowed to enter over drive (automatic transmission).

• If the transmission thermo-switch is open, the

transmission will not be allowed to enter into over

drive (automatic transmission). If the switch opens

when the vehicle is in overdrive, the transmission

will be downshifted. The transmission thermo-switch opens at 134°C (273°F).

• The thermo-switch will close once the transmission

fluid temperature drops to 116°C (240°F). • The PCM will turn on the water-in-fuel lamp if a signal is received from the water-in-fuel sensor.

ACCELERATION

• The vehicle speed sensor, engine speed sensor and

throttle position sensor inputs are used to control

transmission overdrive operation.

• If the coolant temperature is below 16° C (60° F),

the transmission will not be allowed to enter over

drive (automatic transmission).

• If intake manifold air temperature is below 32°C

(90°F),

the KSB solenoid will be energized through

the air temperature switch. The solenoid remains en ergized until the air temperature switch opens. The

switch opens when intake manifold air temperature

is above 32°C (90°F). • If the transmission thermo-switch is open, the

transmission will not be allowed to enter into over

drive (automatic transmission). If the switch opens

when the vehicle is in overdrive, the transmission

will be downshifted. The transmission thermo-switch opens at 134°C (273°F). The thermo-switch will close

once the transmission fluid temperature drops to 116°C (240°F).

• The PCM will turn on the water-in-fuel lamp if a

signal is received from the water-in-fuel sensor.

• If the speed control system resume/accelerate func

tion is being used, the PCM will only allow the vehi

cle to accelerate at a predetermined rate. If a speed

control has been set and the resume/accelerate but

ton is momentarily pushed in, the PCM will increase

vehicle speed by two miles per hour.

• If the brakes are applied, the PCM will disable the

speed control.

DECELERATION

• The vehicle speed sensor, engine speed sensor and

throttle position sensor inputs are used to control

transmission overdrive operation.

• If the coolant temperature is below 16° C (60° F),

the transmission will not be allowed to enter over drive (automatic transmission).

• If the transmission thermo-switch is open, the trans

mission will not be allowed to enter into overdrive (au

tomatic transmission). If the switch opens when the

vehicle is in overdrive, the transmission will be down shifted. The transmission thermo-switch opens at 134°C (273°F). The thermo-switch will close once the transmis

sion fluid temperature drops to 116°C (240°F).

• The PCM will turn on the water-in-fuel lamp if a

signal is received from the water-in-fuel sensor.

• If intake manifold air temperature is below 32°C

(90°F),

the KSB solenoid will be energized through

the air temperature switch. The solenoid remains en ergized until the air temperature switch opens. The

switch opens when intake manifold air temperature

is above 32°C (90°F).

• If the speed control system coast/set function is be

ing used, the PCM will only allow the vehicle to de celerate at a predetermined rate. If the coast/set

switch is pushed while the system is operating, the

PCM will set speed control to the rate the vehicle is

traveling at when the switch is released. • If the brakes are applied, the PCM will disable the speed control.

IGNITION SWITCH

OFF

• When the ignition switch is turned to the off posi

tion, the PCM still receives battery voltage through

the battery input. Battery voltage is needed to keep

PCM memory alive. The PCM memory stores diag nostic trouble code (DTC) messages and the mini

mum TPS value from the previous key-on.

Page 907 of 1502

DIESEL FUEL INJECTION—GENERAL DIAGNOSIS

INDEX

page

Air

in

Fuel System

90

Air Intake Heater

. 90

Diagnostic

Trouble Code (DTC)

. 95

DRB

II

Scan

Tool

95

Engine

Speed

Sensor

91

Fuel Heater

91

Fuel

Injection

Pump

91

Fuel Injectors

92

Fuel Supply Restrictions

92

page

Fuel/Water Separator

Filter 92

High

Pressure Fuel Line Restrictions

93

KSB

Solenoid

. 93

Mechanical

Lift

Pump

93

On-Board

Diagnostics (OBD)

94

System

Schematics—5.9L Diesel Engine

....... 95

Throttle

Position

Sensor

Test

94

Visual

Inspection

88

VISUAL

INSPECTION

A visual inspection for loose, disconnected, or incor

rectly routed wires and hoses should be made before attempting to diagnose or service the fuel injection

system. A visual check will help find these condi

tions.

It also saves unnecessary test and diagnostic

time.

A thorough visual inspection of the fuel injec

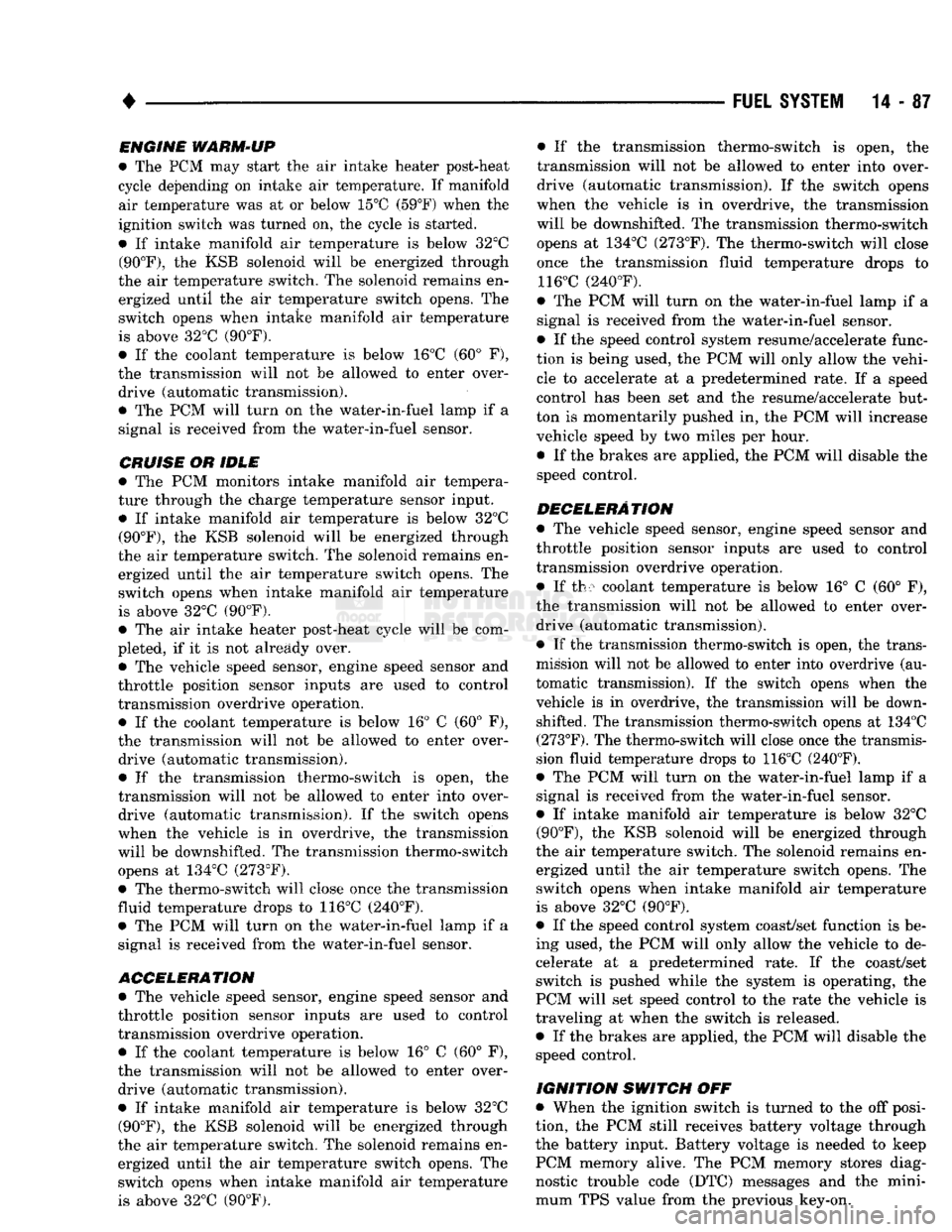

tion system includes the following checks: (1) Be sure that the battery connections are tight

and not corroded (Fig. 1).

• POSITIVE

v^3t

^TERMINAL J91 14

QUICK

DISCONNECT

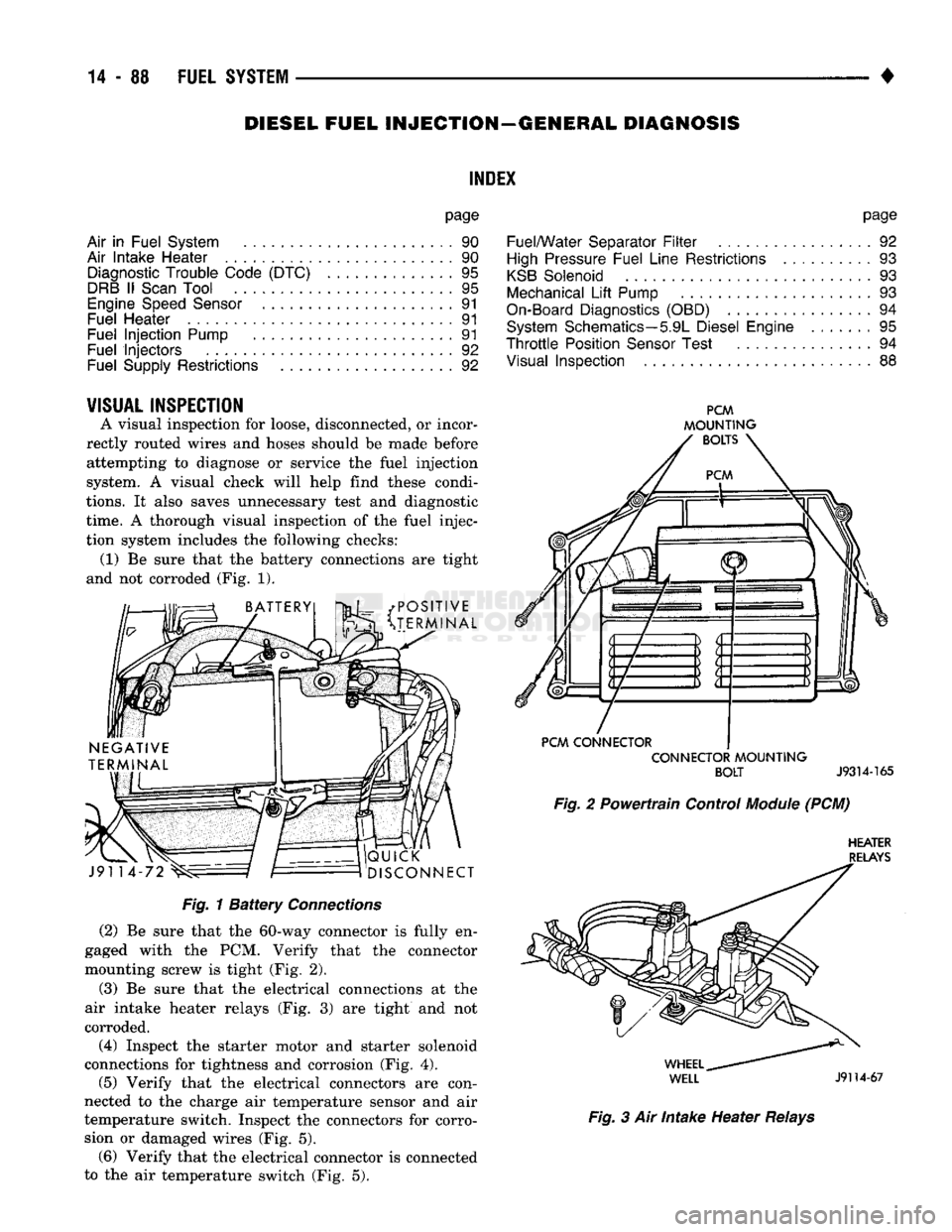

PCM

MOUNTING

BOLTS

PCM

CONNECTOR CONNECTOR

MOUNTING

BOLT

J9314-165

Fig.

2 Powertrain Control

Module

(PCM)

HEATER

RELAYS

Fig.

1

Battery

Connections

(2)

Be sure that the 60-way connector is fully en

gaged with the PCM. Verify that the connector

mounting screw is tight (Fig. 2).

(3)

Be sure that the electrical connections at the

air intake heater relays (Fig. 3) are tight and not

corroded.

(4)

Inspect the starter motor and starter solenoid

connections for tightness and corrosion (Fig. 4).

(5)

Verify that the electrical connectors are con

nected to the charge air temperature sensor and air

temperature switch. Inspect the connectors for corro sion or damaged wires (Fig. 5). (6) Verify that the electrical connector is connected

to the air temperature switch (Fig. 5).

WHEEL

^

WELL

J9114-67

Fig.

3 Air Intake Heater

Relays

Page 913 of 1502

14

- 94

FUEL

SYSTEM

•

THROTTLE POSITION

SENSOR

TEST

CAUTION;

Before checking

the

TPS,

the

throttle

linkage must

be

checked

for

correct

adjustment.

The

throttle

lever must

contact

the low idle

speed screw.

The

throttle

lever must reach breakover when

the

throttle

is

wide

open. Refer

to the

Accelerator Pedal and

Throttle

Cable section

of

Group

14,

Fuel Systems.

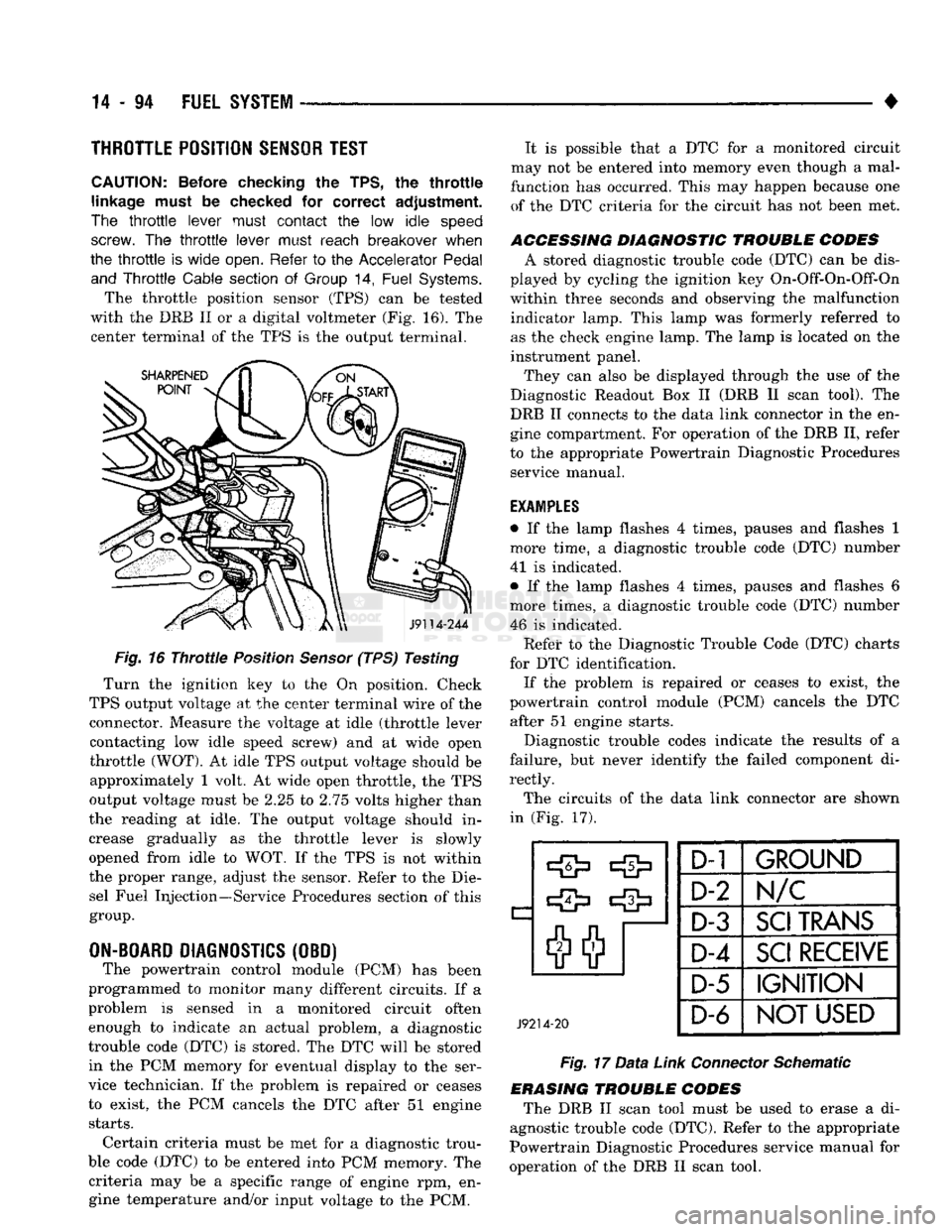

The throttle position sensor (TPS) can be tested

with the DRB II or a digital voltmeter (Fig. 16). The center terminal of the TPS is the output terminal.

J9114-244

Fig.

16

Throttle

Position

Sensor

(TPS) Testing

Turn the ignition key to the On position. Check

TPS output voltage at the center terminal wire of the connector. Measure the voltage at idle (throttle lever contacting low idle speed screw) and at wide open

throttle

(WOT).

At idle TPS output voltage should be approximately 1 volt. At wide open throttle, the TPS

output voltage must be 2.25 to 2.75 volts higher than

the reading at idle. The output voltage should in

crease gradually as the throttle lever is slowly

opened from idle to WOT. If the TPS is not within

the proper range, adjust the sensor. Refer to the Die sel Fuel Injection—Service Procedures section of this

group.

ON-BOARD

DIAGNOSTICS

(OBD) The powertrain control module (PCM) has been

programmed to monitor many different circuits. If a

problem is sensed in a monitored circuit often enough to indicate an actual problem, a diagnostic

trouble code (DTC) is stored. The DTC will be stored in the PCM memory for eventual display to the ser

vice technician. If the problem is repaired or ceases

to exist, the PCM cancels the DTC after 51 engine

starts.

Certain criteria must be met for a diagnostic trou

ble code (DTC) to be entered into PCM memory. The criteria may be a specific range of engine rpm, engine temperature and/or input voltage to the PCM. It is possible that a DTC for a monitored circuit

may not be entered into memory even though a mal

function has occurred. This may happen because one of the DTC criteria for the circuit has not been met.

ACCESSING DIAGNOSTIC TROUBLE CODES A stored diagnostic trouble code (DTC) can be dis

played by cycling the ignition key On-Off-On-Off-On

within three seconds and observing the malfunction indicator lamp. This lamp was formerly referred to

as the check engine lamp. The lamp is located on the

instrument panel.

They can also be displayed through the use of the

Diagnostic Readout Box II (DRB II scan tool). The

DRB II connects to the data link connector in the en

gine compartment. For operation of the DRB II, refer

to the appropriate Powertrain Diagnostic Procedures service manual.

EXAMPLES

• If the lamp flashes 4 times, pauses and flashes 1

more time, a diagnostic trouble code (DTC) number

41 is indicated.

• If the lamp flashes 4 times, pauses and flashes 6

more times, a diagnostic trouble code (DTC) number 46 is indicated. Refet* to the Diagnostic Trouble Code (DTC) charts

for DTC identification. If the problem is repaired or ceases to exist, the

powertrain control module (PCM) cancels the DTC after 51 engine starts.

Diagnostic trouble codes indicate the results of a

failure, but never identify the failed component di

rectly.

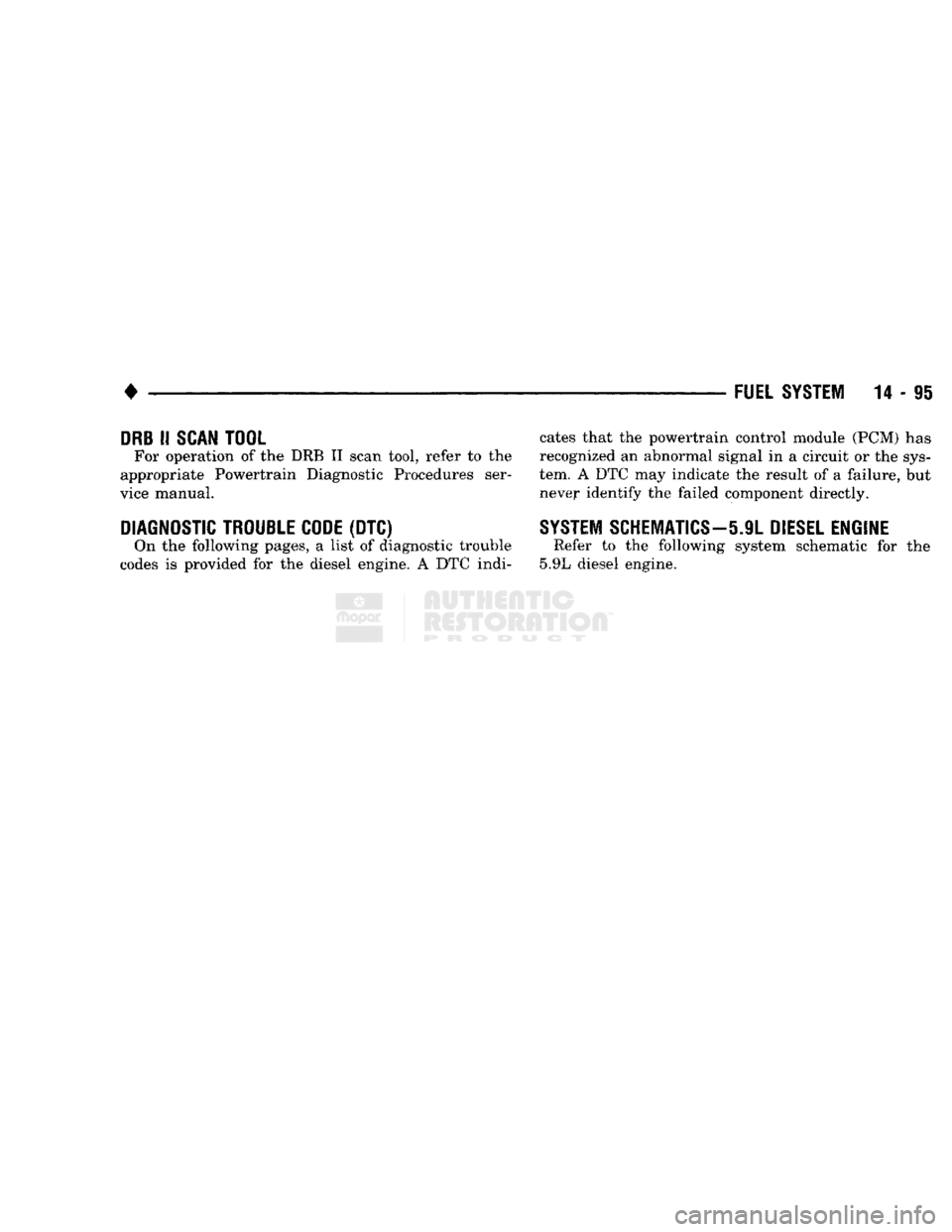

The circuits of the data link connector are shown

in (Fig. 17).

J9214-20

D-1

1

GROUND

D-2

N/C

D-3

SCI

TRANS

D-4

SCI

RECEIVE

D-5 IGNITION

D-6

NOT USED

Fig.

17

Data

Link

Connector

Schematic

ERASING TROUBLE CODES The DRB II scan tool must be used to erase a di

agnostic trouble code (DTC). Refer to the appropriate

Powertrain Diagnostic Procedures service manual for

operation of the DRB II scan tool.

Page 914 of 1502

•

FUEL SYSTEM

14 - 95

DRB

II

SCAN

TOOL

For operation

of the DRB II

scan tool, refer

to the

appropriate Powertrain Diagnostic Procedures ser

vice manual.

DIAGNOSTIC TROUBLE CODE (DTC)

On

the

following pages,

a

list

of

diagnostic trouble

codes

is

provided

for the

diesel engine.

A DTC

indi cates that

the

powertrain control module

(PCM) has

recognized

an

abnormal signal

in a

circuit

or the

sys

tem.

A DTC may

indicate

the

result

of a

failure,

but

never identify

the

failed component directly.

SYSTEM SCHEMATICS—5.9L DIESEL ENGINE

Refer

to the

following system schematic

for the

5.9L diesel engine.

Page 915 of 1502

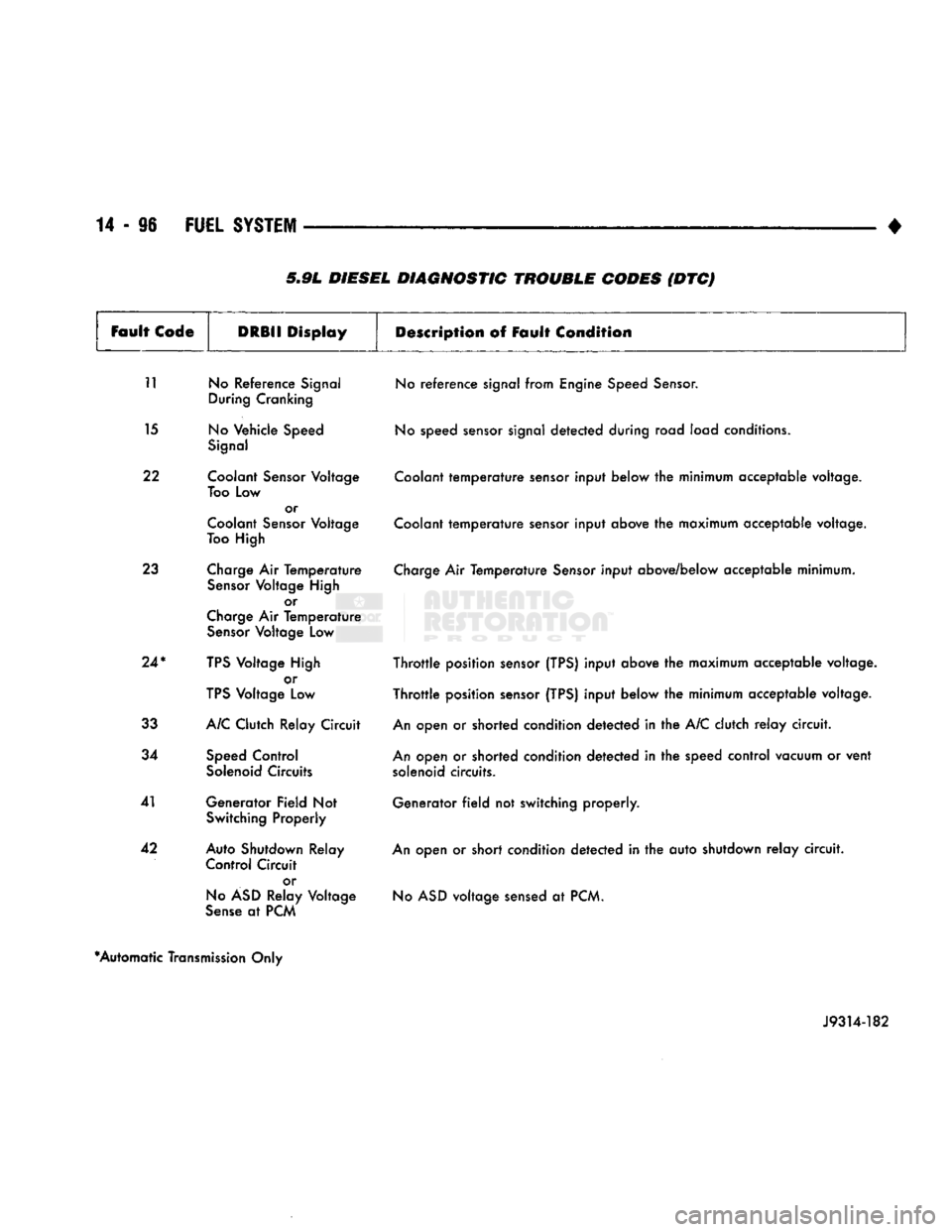

5.9L DIESEL DIAGNOSTIC TROUBLE CODES (DTC)

Fault

Code

DRBII

Display

Description

of Fault

Condition

11 No Reference Signal During Cranking

15 No Vehicle Speed Signal

22 Coolant Sensor Voltage Too Low or

Coolant Sensor Voltage

Too High

23 Charge Air Temperature Sensor Voltage High or

Charge Air Temperature Sensor Voltage Low

24*

TPS Voltage High or

TPS Voltage Low

33 A/C Clutch Relay Circuit

34 Speed Control Solenoid Circuits

41 Generator Field Not Switching Properly

42 Auto Shutdown Relay Control Circuit

or

No ASD Relay Voltage

Sense at PCM No reference signal from Engine Speed Sensor.

No speed sensor signal detected during road load conditions.

Coolant temperature sensor input below the minimum acceptable voltage.

Coolant temperature sensor input above the maximum acceptable voltage.

Charge Air Temperature Sensor input above/below acceptable minimum.

Throttle position sensor (TPS) input above the maximum acceptable voltage.

Throttle position sensor (TPS) input below the minimum acceptable voltage.

An open or shorted condition detected in the A/C clutch relay circuit.

An open or shorted condition detected in the speed control vacuum or vent solenoid circuits.

Generator field not switching properly.

An open or short condition detected in the auto shutdown relay circuit. No ASD voltage sensed at PCM.

*Automatic Transmission Only

J9314-182

Page 916 of 1502

FUEL

SYSTEM

14 - 97

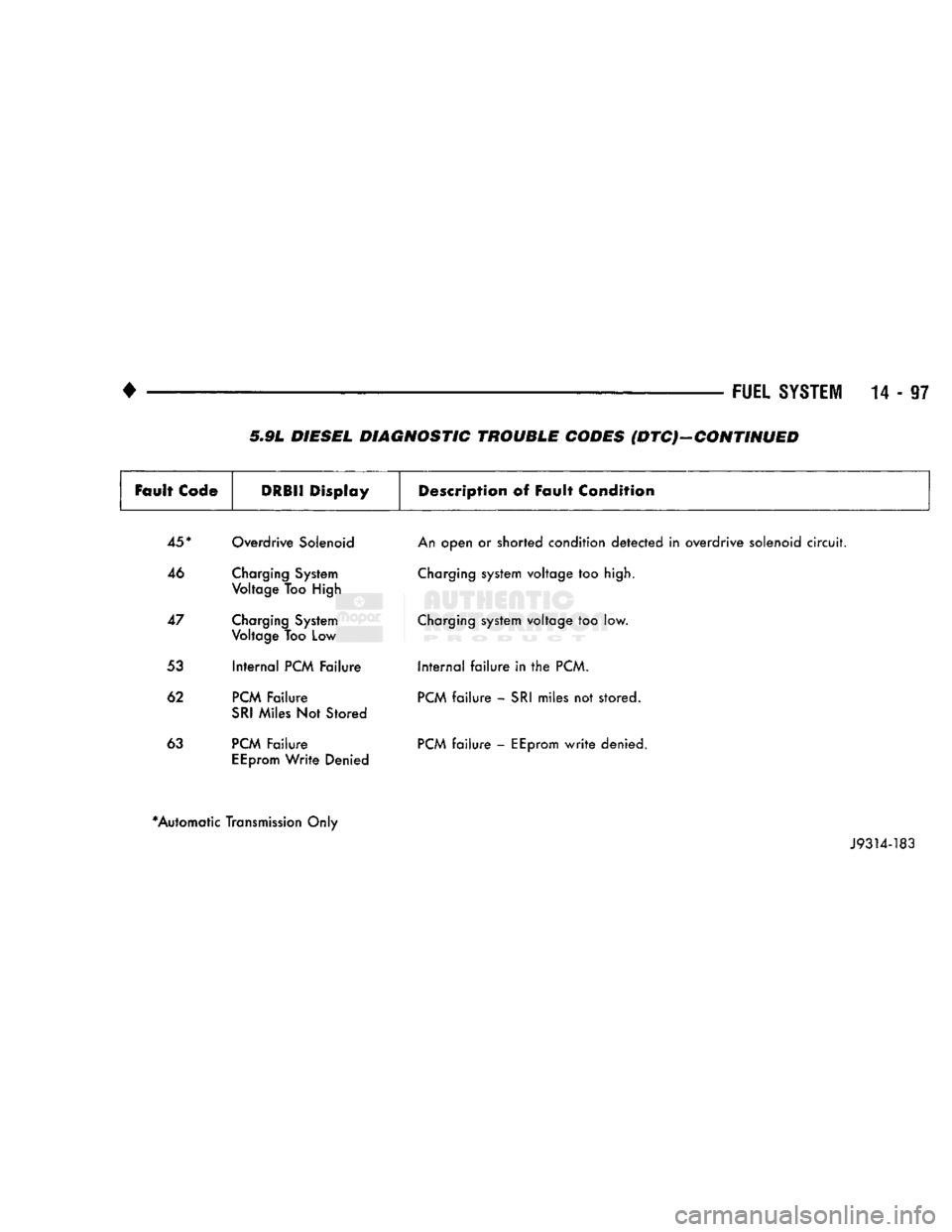

5„9L DIESEL DIAGNOSTIC TROUBLE CODES {DTC}-CONTINUED

Fault

Code

DRBII Display

Description

of Fault Condition

45*

Overdrive Solenoid

46 Charging System Voltage Too High

47 Charging System Voltage Too Low

53 Internal PCM Failure

62 PCM Failure SRI Miles Not Stored

63 PCM Failure EEprom Write Denied An open or shorted condition detected in overdrive solenoid circuit.

Charging system voltage too high.

Charging system voltage too low. Internal failure in the PCM.

PCM failure - SRI miles not stored.

PCM failure - EEprom write denied.

*Automatic Transmission Only J9314-183

Page 962 of 1502

•

STEERING STEERING

19-1

CONTENTS

page

GENERAL INFORMATION

1

POWER STEERING PUMP

11

POWER STEERING SYSTEM DIAGNOSIS

..... 2

RECIRCULATING

BALL

POWER STEERING GEAR

. 20

page

STEERING COLUMN

3i

STEERING LINKAGE

17

TORQUE SPECIFICATIONS

40

GENERAL

INFORMATION

STEERING SYSTEM COMPONENTS

Dodge Trucks

use a

power

assisted recirculating-

ball

type steering gear

(Fig.

1). The

gear

is

used with

four

wheel drive

and two

wheel

drive

vehicles. Power steering systems

use;

•

Steering

gear • Steering linkage

• Pressure

and

return fluid hoses

and

fittings

• Belt driven hydraulic steering pump with

fluid

reservoir

J9219-65

Fig.

1

Power

Steering

Systems

The steering linkage consists

of a

pitman

arm,

idler

arm, tie

rods,

and

center link. Adjustment

sleeves

are

used

on the tie

rods

for toe and

steering

wheel alignment.

For

additional wheel alignment

in

formation refer

to

Group

2,

Front Suspension. RECIRCULA TING-BALL

POWER

STEERING

GEARS

The recirculating ball system acts

as a

rolling

thread between

the

worm shaft

and

rack piston.

The

worm shaft

is

supported

by a

thrust bearing

at the

lower

end

and a

bearing assembly

at

the

upper

end.

When

the

worm shaft

is

turned

the

rack piston

moves.

The

rack piston teeth mesh with

the

pitman (sector) shaft. Turning

the

worm shaft turns

the

pit

man shaft, which turns

the

steering linkage.

The steering gears

can be

adjusted

and

internally

serviced.

An identification code

on the

upper adjustment

cover designates

the

ratio.

• Code

XS

designates 13-16:1 ratio used

in

Dodge

Ram Truck vehicles

POWER

STEERING

PUMP

Hydraulic pressure

is

provided

by a

belt driven

power steering pump.

The

power steering pump

is a

constant flow rate

and

displacement, vane-type

pump.

The

internal parts that

are

inside

the

housing operate submerged

in

fluid.

The

flow control orifice

is

part

of

the

pressure line union.

The

pressure relief

valve inside

the

flow control valve limits

the

pump

pressure.

The power steering pump

is

connected

to

the

steer

ing gear

via the

pressure hose

and the

return hose.

The pump shaft

has

a

pressed-on pulley that

is

belt driven

by the

crankshaft pulley.

Trailer

tow

option vehicles

are

equipped with

a

power steering pump

oil

cooler.

The oil

cooler

is

mounted

to the

engine block under

the

steering

pump cast aluminum mounting bracket.

The power steering pump

on

the

DODGE TURBO

DIESEL engine

is

bolted onto

the

rear

of

the

vac

uum pump.

The

pump

is

driven

by the

accessory drive through

a

common shaft.

Page 1084 of 1502

•

AUTOMATIC TRANSiISSIO|-32RH/8iRH/37RH/42RH/4iRH

21 - 83 plate. The overdrive clutch also disengages the direct

clutch during 3-4 upshifts. As fluid pressure extends

the overdrive piston, the piston contacts the direct clutch hub pressing it rearward. This action com

presses the direct clutch spring relieving spring load on the clutch pack. The clutch is disengaged once

spring load is relieved.

The 3-4 accumulator cushions overdrive clutch en

gagement to smooth the transition into fourth gear.

The accumulator is charged at the same time as ap

ply pressure acts against the overdrive piston.

Converter clutch engagement in overdrive fourth

gear is controlled by sensor inputs to the powertrain

control module. In third gear above 25 mph, sensor inputs to the control module that determine clutch

engagement and shift timing are:

• coolant temperature (verifies minimum of 60° F)

• engine speed • vehicle speed

• throttle position

• manifold vacuum (MAP sensor)

Gearshift

Mechanism

The gear shift mechanism provides the same shift

positions used with 3-speed Chrysler transmissions

(P-R-N-D-2-1).

The shift into overdrive fourth gear range occurs

only after the transmission has completed the shift into D third gear range. No further movement of the

shift mechanism is required to complete the 3-4 shift.

The fourth gear upshift occurs automatically when

the overdrive control switch is in the ON position. Shift timing is determined by sensor inputs to the

engine controller.

Overdrive Control

Switch

The overdrive control switch is located in the in

strument panel. In the On position, automatic shifts

into fourth gear overdrive will occur. In the Off posi

tion, the switch overrides the engine controller pre

venting a shift to overdrive fourth gear range.

The switch has an indicator light that illuminates

when overdrive is turned off. The switch also resets

when the ignition key is turned to the OFF position so that the automatic overdrive feature is restored.

The use of fault codes is employed to help diagnose

the electronic components that operate the overdrive

unit and converter clutch.

HYDRAULIC

CONTROLS

The 42REJ/46RH hydraulic control system provides

fully automatic operation. The system performs five

basic functions which are: pressure supply, pressure regulation, flow control, clutch/band application, and

lubrication. 42RH/46RH system operation is similar to that de

scribed in the 32RH/36RH/37RH General Informa tion section. The main difference being fourth gear

operation which is covered here.

Pressure

Regulation

The pressure regulator valve maintains line pres

sure.

The amount of pressure developed is controlled

by throttle pressure which is dependent on the de gree of throttle opening. The regulator valve is lo

cated in the valve body.

The throttle valve determines line pressure and

shift speed. Governor pressure increases in propor

tion to vehicle speed. The throttle valve controls up shift and downshift speeds by regulating pressure

according to throttle position.

Flow

Control And Lubrication The manual valve is operated by the gearshift link

age and provides the operating range selected by the

driver.

The 1-2 shift valve provides 1-2 or 2-1 shifts and

the 2-3 shift valve provides 2-3 or 3-2 shifts.

The kickdown valve provides forced 3-2 or 3-1

downshifts depending on vehicle speed. Downshifts

occur when the throttle is opened beyond downshift

detent position which is just before wide open throt

tle.

The 2-3 valve throttle pressure plug provides 3-2

downshifts at varying throttle openings depending on

vehicle speed.

The 1-2 shift control valve transmits 1-2 shift pres

sure to the accumulator piston. This controls kick-

down band capacity on 1-2 upshifts and 3-2 downshifts.

The 3-4 shift valve, shuttle valve, timing valve and

accumulator are only actuated when the overdrive

solenoid is energized.

The solenoid contains a check ball that controls a

vent port to the 3-4 valve. The check ball either di

verts line pressure away from or directly to, the 3-4 shift valve. Energizing the solenoid causes the check

ball to close the vent port allowing line pressure to act upon the 3-4 upshift valve.

The limit valve determines maximum speed at

which a 3-2 part throttle kickdown can be made. Some transmissions do not have the limit valve and

maximum speed for a 3-2 kickdown is at the detent

position.

The 2-3 shuttle valve has two functions. First is

fast front band release and smooth engagement dur ing lift-foot 2-3 upshifts. The second is to regulate

front clutch and band application during 3-2 down

shifts.

The 3-4 shuttle valve uses a combination of throt

tle and governor pressure to control the rate of over

drive piston apply and release. This is done to

maintain shift quality at varying throttle openings.

Page 1380 of 1502

•

WHEELS

AND

TIRES

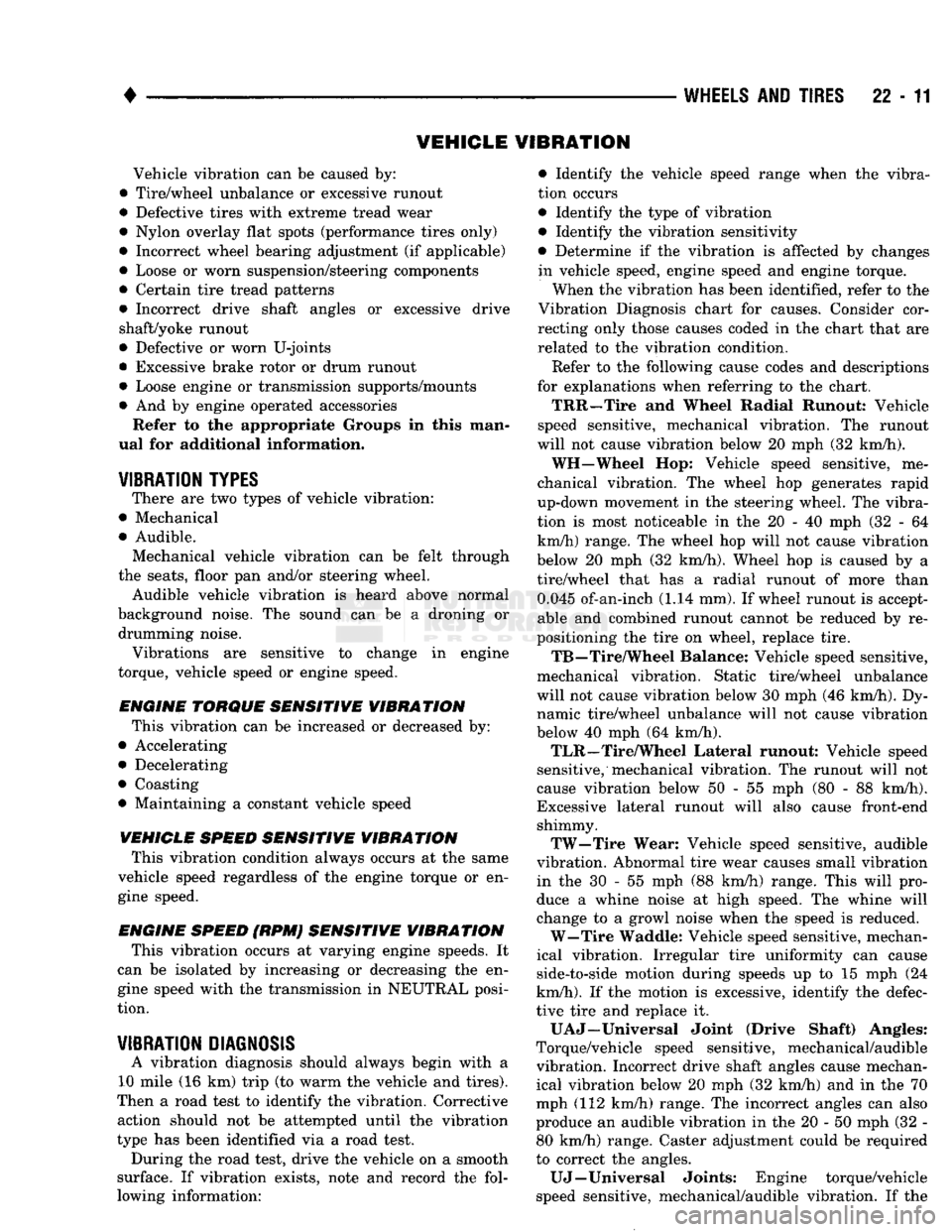

22-11 VEHICLE VIBRATION

Vehicle vibration can

be

caused by:

• Tire/wheel unbalance

or

excessive runout

• Defective tires with extreme tread wear

• Nylon overlay flat spots (performance tires only)

• Incorrect wheel bearing adjustment

(if

applicable)

• Loose

or

worn suspension/steering components

• Certain tire tread patterns

• Incorrect drive shaft angles

or

excessive drive

shaft/yoke runout

• Defective

or

worn U-joints

• Excessive brake rotor

or

drum runout

• Loose engine

or

transmission supports/mounts

• And

by

engine operated accessories Refer

to the

appropriate Groups

in

this man

ual for additional information.

VIBRATION

TYPES

There are two types

of

vehicle vibration:

• Mechanical

• Audible. Mechanical vehicle vibration

can be

felt through

the seats, floor pan and/or steering wheel. Audible vehicle vibration

is

heard above normal

background noise.

The

sound

can be a

droning

or

drumming noise. Vibrations

are

sensitive

to

change

in

engine

torque, vehicle speed

or

engine speed.

ENGINE TORQUE SENSITIVE VIBRATION

This vibration can

be

increased

or

decreased by:

• Accelerating

• Decelerating

• Coasting

• Maintaining

a

constant vehicle speed

VEHICLE SPEED SENSITIVE VIBRATION

This vibration condition always occurs

at

the same

vehicle speed regardless

of

the engine torque

or en

gine speed.

ENGINE SPEED

{RPM}

SENSITIVE VIBRATION

This vibration occurs

at

varying engine speeds.

It

can

be

isolated

by

increasing

or

decreasing

the en

gine speed with the transmission

in

NEUTRAL posi

tion.

VIBRATION

DIAGNOSIS

A vibration diagnosis should always begin with

a

10 mile (16 km) trip (to warm the vehicle and tires).

Then

a

road test

to

identify the vibration. Corrective action should

not be

attempted until

the

vibration

type has been identified

via a

road test. During the road test, drive the vehicle

on a

smooth

surface.

If

vibration exists, note

and

record

the

fol

lowing information: • Identify

the

vehicle speed range when

the

vibra

tion occurs

• Identify the type

of

vibration

• Identify the vibration sensitivity

• Determine

if

the vibration

is

affected

by

changes

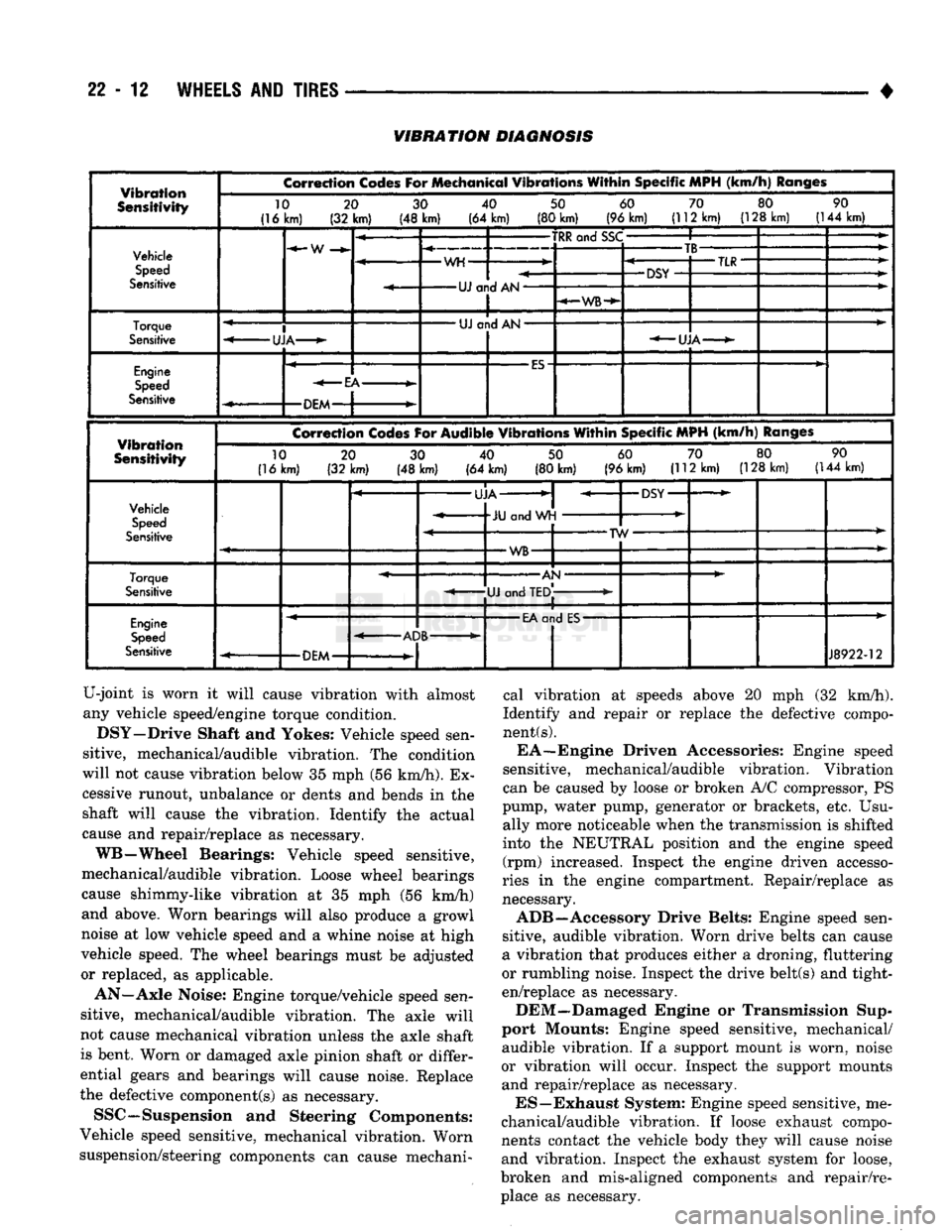

in vehicle speed, engine speed and engine torque. When the vibration has been identified, refer to the

Vibration Diagnosis chart

for

causes. Consider cor

recting only those causes coded

in

the chart that

are

related

to

the vibration condition.

Refer

to

the following cause codes and descriptions

for explanations when referring

to

the chart.

TRR—Tire

and

Wheel Radial Runout: Vehicle

speed sensitive, mechanical vibration.

The

runout

will not cause vibration below

20

mph (32 km/h).

WH—Wheel Hop: Vehicle speed sensitive,

me

chanical vibration.

The

wheel

hop

generates rapid

up-down movement

in

the steering wheel. The vibra

tion

is

most noticeable

in the 20 - 40

mph

(32 - 64

km/h) range. The wheel hop will not cause vibration

below

20

mph (32 km/h). Wheel hop

is

caused

by a

tire/wheel that

has a

radial runout

of

more than 0.045 of-an-inch (1.14 mm).

If

wheel runout

is

accept

able

and

combined runout cannot

be

reduced

by re

positioning the tire

on

wheel, replace tire.

TB—Tire/Wheel Balance: Vehicle speed sensitive,

mechanical vibration. Static tire/wheel unbalance

will not cause vibration below 30 mph (46 km/h). Dy

namic tire/wheel unbalance will

not

cause vibration

below

40

mph (64 km/h). TLR—Tire/Wheel Lateral runout: Vehicle speed

sensitive, mechanical vibration. The runout will

not

cause vibration below

50 - 55 mph (80 - 88

km/h).

Excessive lateral runout will also cause front-end shimmy. TW—Tire Wear: Vehicle speed sensitive, audible

vibration. Abnormal tire wear causes small vibration in

the 30 - 55

mph

(88

km/h) range. This will pro

duce

a

whine noise

at

high speed.

The

whine will

change

to a

growl noise when the speed

is

reduced. W—Tire Waddle: Vehicle speed sensitive, mechan

ical vibration. Irregular tire uniformity

can

cause

side-to-side motion during speeds

up to 15

mph

(24

km/h).

If

the motion

is

excessive, identify

the

defec

tive tire and replace

it.

U A J—Universal Joint (Drive Shaft) Angles:

Torque/vehicle speed sensitive, mechanical/audible

vibration. Incorrect drive shaft angles cause mechan ical vibration below

20

mph (32 km/h) and

in

the

70

mph (112 km/h) range. The incorrect angles can also

produce

an

audible vibration

in

the 20

-

50 mph (32

-

80 km/h) range. Caster adjustment could

be

required

to correct the angles. UJ—Universal Joints: Engine torque/vehicle

speed sensitive, mechanical/audible vibration.

If

the

Page 1381 of 1502

22-12

WHEELS

AND

TIRES

VIBRATION

DIAGNOSIS

Vibration

Sensitivity

Correction

Codes

For

Mechanical

Vibrations

Within

Specific

MPH

(km/h)

Ranges

10

(16km)

20

(32 km) 30

(48 km) 40

(64 km) 50

(80 km) 60

(96 km) 70

(112 km) 80

(128 km) 90

(144 km) Vehicle

Speed

Sensitive

•W

-WH-

-TRR

and

SSC-

-UJ

and AN-

-WB-

-TB-

-DSY

•TLR-

Torque

Sensitive

I

-UJA-

•

UJ

and AN

•

•UJA-

Engine

Speed

Sensitive

•ES

•EA-

•DEM-

Vibration

Sensitivity

Correction

Codes

For

Audible

Vibrations

Within

Specific

MPH

(km/h)

Ranges

10

(16 km) 20

(32 km) 30

(48 km) 40

(64 km) 50

(80 km) 60

(96 km) 70

(112 km) 80

(128 km) 90

(144 km)

Vehicle

Speed

Sensitive

•UJA-

JU

and WH

•DSY"

-TW-

•WB-

Torque

Sensitive

-AN

*

-UJ

and

TED,

Engine

Speed

Sensitive

•

EA

and

ES-

-ADB-

-DEM-

J8922-12

U-joint is worn it will cause vibration with almost

any vehicle speed/engine torque condition. DSY—Drive Shaft and Yokes: Vehicle speed sen

sitive, mechanical/audible vibration. The condition

will not cause vibration below 35 mph (56 km/h). Ex

cessive runout, unbalance or dents and bends in the shaft will cause the vibration. Identify the actual

cause and repair/replace as necessary.

WB—Wheel Bearings: Vehicle speed sensitive,

mechanical/audible vibration. Loose wheel bearings

cause shimmy-like vibration at 35 mph (56 km/h)

and above. Worn bearings will also produce a growl

noise at low vehicle speed and a whine noise at high

vehicle speed. The wheel bearings must be adjusted

or replaced, as applicable.

AN—Axle Noise: Engine torque/vehicle speed sen

sitive, mechanical/audible vibration. The axle will

not cause mechanical vibration unless the axle shaft

is bent. Worn or damaged axle pinion shaft or differ

ential gears and bearings will cause noise. Replace

the defective component(s) as necessary.

SSC—Suspension and Steering Components:

Vehicle speed sensitive, mechanical vibration. Worn

suspension/steering components can cause mechani cal vibration at speeds above 20 mph (32 km/h).

Identify and repair or replace the defective compo

nent

(s).

EA—Engine Driven Accessories: Engine speed

sensitive, mechanical/audible vibration. Vibration

can be caused by loose or broken A/C compressor, PS

pump, water pump, generator or brackets, etc. Usu ally more noticeable when the transmission is shifted

into the NEUTRAL position and the engine speed (rpm) increased. Inspect the engine driven accesso

ries in the engine compartment. Repair/replace as

necessary.

ADB—Accessory Drive Belts: Engine speed sen

sitive, audible vibration. Worn drive belts can cause

a vibration that produces either a droning, fluttering

or rumbling noise. Inspect the drive belt(s) and tight

en/replace as necessary.

DEM—Damaged Engine or Transmission Sup

port Mounts: Engine speed sensitive, mechanical/ audible vibration. If a support mount is worn, noise

or vibration will occur. Inspect the support mounts and repair/replace as necessary.

ES—Exhaust System: Engine speed sensitive, me

chanical/audible vibration. If loose exhaust compo

nents contact the vehicle body they will cause noise

and vibration. Inspect the exhaust system for loose,

broken and mis-aligned components and repair/re place as necessary.