ECU DODGE TRUCK 1993 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 21 of 1502

0 - 2

LUBRICATION

AND

MAINTENANCE

• Commercial service

When a vehicle is continuously subjected to severe

driving conditions, lubricate:

• Body components

• All the driveline coupling joints

• Steering linkage More often than normal driving conditions

DUSTY

AREAS

With this type of severe driving condition, special

care should be given to the:

• Engine air cleaner filter

• PCV filter

• Crankcase ventilation system

• Brake booster control valve air filter. Verify that the filters and the associated compo

nents are clean. Also verify that they are functioning

effectively. This will minimize the amount of abra sive particles that enter the engine.

OFF-ROAD

(4WD)

OPERATION

After off-road (4WD) operation, inspect the under

side of the vehicle. Inspect the:

• Tires

• Body structure

• Steering components

• Suspension components • Exhaust system

• Threaded fasteners

HARSH

SURFACE ENVIRONMENTS

After extended operation in harsh environments,

the brake drums, brake linings, and rear wheel bear ings should be inspected and cleaned. This will pre

vent wear and erratic brake action.

ROUTINE MAINTENANCE

The following routine maintenance is recommended

on a monthly basis: TIRES—Inspect the tires for unusual wear/damage.

Determine if the inflation pressure is adequate for

the vehicle load. BATTERY—Inspect and clean the terminals.

Tighten the terminals if necessary. FLUIDS—Determine if the component fluid levels

are acceptable. Add fluid, if necessary. LIGHTS/ELECTRICAL—Test all the electrical sys

tems in the vehicle for proper operation. It is also recommended that the engine oil and the

washer fluid level be determined at each fuel fill-up.

VEHICLE

NOISE CONTROL

Vehicles with a GVWR of 4 535 kg (10,000 lbs), or

more, are required to comply with Federal Exterior Noise Regulations (Fig. 2).

VEHICLE

NOISE

EMISSION

CONTROL INFORMATION

DATE

OF

VEHICLE

MANUFACTURE

THIS

VEHICLE CONFORMS

TO

U.S. EPA REGULATIONS FOR NOISE EMISSION

APPLICABLE

TO

MEDIUM

AND HEAVY

DUTY

TRUCKS. THE

FOLLOWING

ACTS OR THE CAUSING THEREOF BY ANY PERSON ARE PROHIBITED BY THE NOISE CONTROL ACT

OF 1972. (A) THE

REMOVAL

OR

RENDERING

INOPERATIVE, OTHER

THAN

FOR

PURPOSES

OF

MAINTENANCE,

REPAIR.

OR REPLACEMENT, OF ANY NOISE CONTROL DEVICE OR ELEMENT OF

DESIGN

(LISTED

IN

THE

OWNERS

MANUAL)

INCORPORATED

INTO

THIS

VEHICLE

IN COMPLIANCE

WITH

THE NOISE CONTROL

ACT:

(B) THE

USE

OF

THIS

VEHICLE

AFTER SUCH DEVICE

OR

ELEMENT

OF

DESIGN HAS BEEN REMOVED

OR

RENDERED

INOPERATIVE.

PU626D

Fig.

2 Vehicle

Noise

Emission

Control Information

Label

UNAUTHORIZED

DEFEAT

OF

NOISE

CONTROL COMPONENTS

Federal law prohibits removal, altering or other

wise defeating any noise control component. This in

cludes before or after the vehicle is in use. Federal

law also prohibits the use of a vehicle after a noise

control component is defeated.

REQUIRED MAINTENANCE/SERVICE

FOR

NOISE

CONTROL

The following maintenance is required after each

6-month or 9 600 km (6,000 miles) interval. This will

ensure that the vehicle noise control components are

operating properly.

EXHAUST SYSTEM

Inspect exhaust system for exhaust leaks and dam

aged components. The exhaust hangers, clamps and

U-bolts should be attached and in good condition.

Burned or ruptured mufflers, damaged exhaust pipes should be replaced. Refer to Group 11—Exhaust Sys

tem/Intake Manifold for service information.

AIR

FILTER

HOUSING/CANISTER

Inspect the air filter assembly for proper fit. Verify

the cover is securely attached to the housing/canis

ter. Inspect all the air filter housing hoses for con nections. The gasket between the air filter housing and throttle body must be in good condition. The air

filter element should be clean and serviced according

to the maintenance schedule.

FUEL

REQUIREMENTS

GASOLINE

ENGINES

All engines require the use of unleaded gasoline to

reduce the effects of lead to the environment. Also unleaded fuel is necessary to prevent damage to the

catalytic converter/02 sensor. The fuel must have a

minimum octane rating of 87 based on the (R + M)/2

calculation method.

Page 30 of 1502

LUBRICATION

AND

MAINTENANCE

0-11

J

DRIVE-ON

HOIST

I

FRAME

CONTACT

HOIST

TWIN

POST

CHASSIS

HOIST

FLOOR

JACK

RROOD30

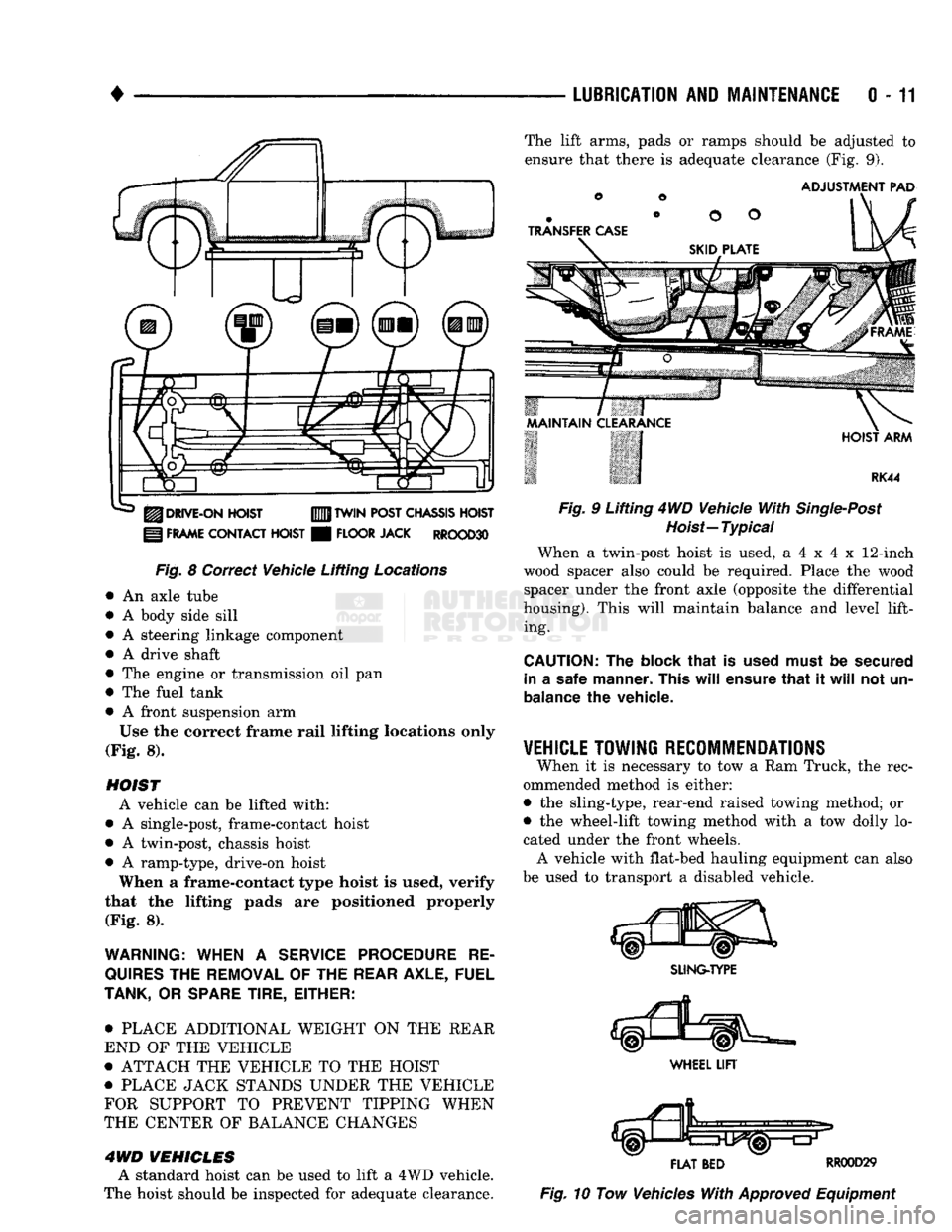

Fig.

8 Correct Vehicle Lifting

Locations

An axle tube

A body side sill

A steering linkage component

A drive shaft

The engine or transmission oil pan

The fuel tank

• A front suspension arm Use the correct frame rail lifting locations only

(Fig. 8).

HOIST A vehicle can be lifted with:

• A single-post, frame-contact hoist

• A twin-post, chassis hoist

• A ramp-type, drive-on hoist

When a frame-contact type hoist is used, verify

that the lifting pads are positioned properly (Fig. 8).

WARNING:

WHEN

A

SERVICE

PROCEDURE

RE

QUIRES

THE

REMOVAL

OF

THE

REAR

AXLE,

FUEL

TANK,

OR

SPARE

TIRE,

EITHER:

• PLACE ADDITIONAL WEIGHT ON THE REAR

END OF THE VEHICLE

« ATTACH THE VEHICLE TO THE HOIST

« PLACE JACK STANDS UNDER THE VEHICLE

FOR SUPPORT TO PREVENT TIPPING WHEN

THE CENTER OF BALANCE CHANGES

4WD VEHICLES A standard hoist can be used to lift a 4WD vehicle.

The hoist should be inspected for adequate clearance. The lift arms, pads or ramps should be adjusted to

ensure that there is adequate clearance (Fig. 9).

ADJUSTMENT

PAD

ii 7

MAINTAIN

CLEARANCE

HOIST

ARM

RK44

Fig.

9 Lifting 4WD Vehicle

With

Single-Post

Hoist—

Typical

When a twin-post hoist is used, a 4 x 4 x 12-inch

wood spacer also could be required. Place the wood spacer under the front axle (opposite the differential

housing). This will maintain balance and level lift ing.

CAUTION:

The

block

that

is

used must

be

secured in

a

safe manner. This

will

ensure

that

it

will

not un

balance

the

vehicle.

VEHICLE

TOWING

RECOMMENDATIONS

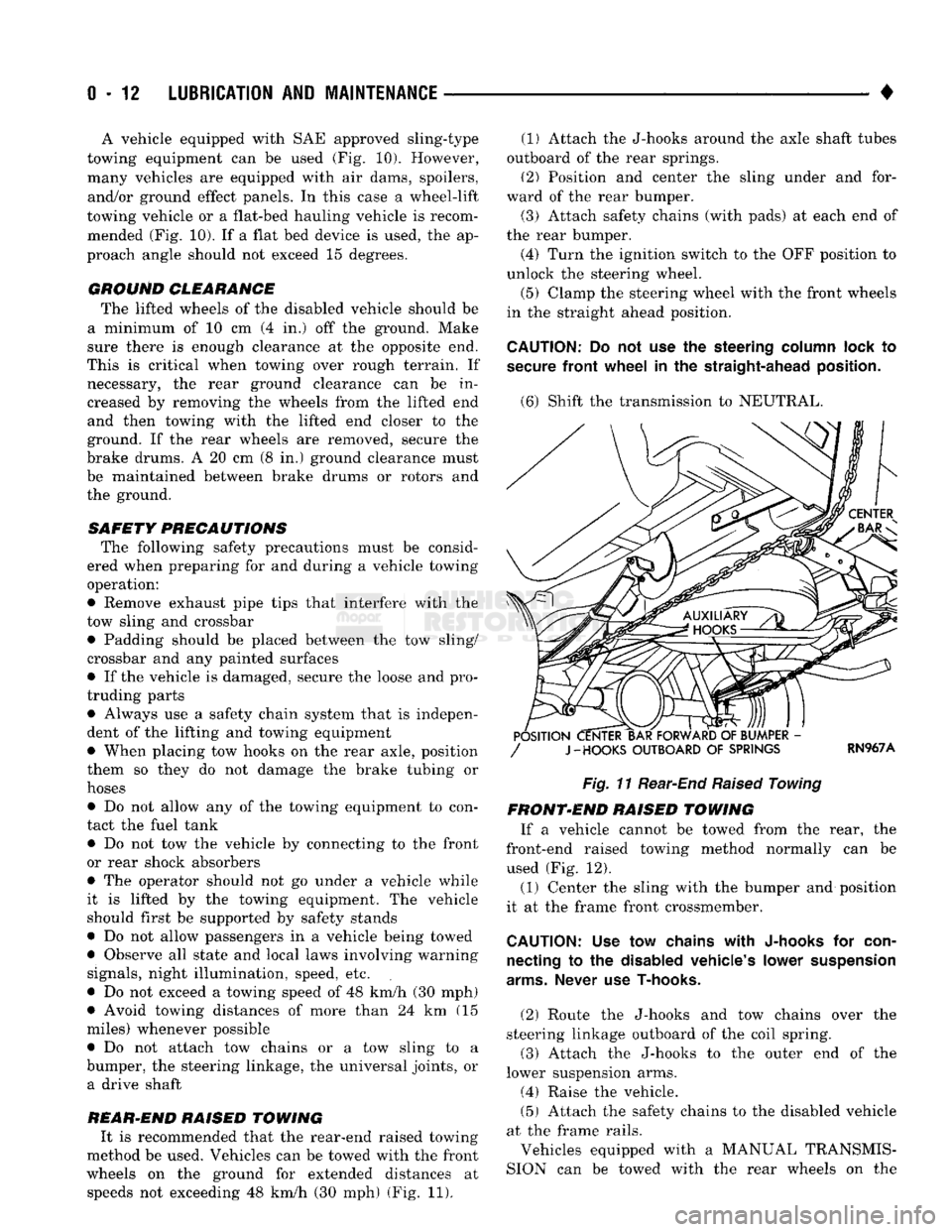

When it is necessary to tow a Ram Truck, the rec

ommended method is either:

• the sling-type, rear-end raised towing method; or

• the wheel-lift towing method with a tow dolly lo

cated under the front wheels. A vehicle with flat-bed hauling equipment can also

be used to transport a disabled vehicle.

SLING-TYPE

FLAT

BED

RR0OD29

Fig.

10 Tow Vehicles

With

Approved

Equipment

Page 31 of 1502

0 - 12

LUBRICATION

AND

MAINTENANCE

• A vehicle equipped with SAE approved sling-type

towing equipment can be used (Fig. 10). However,

many vehicles are equipped with air dams, spoilers, and/or ground effect panels. In this case a wheel-lift

towing vehicle or a flat-bed hauling vehicle is recom mended (Fig. 10). If a flat bed device is used, the ap

proach angle should not exceed 15 degrees.

GROUND CLEARANCE The lifted wheels of the disabled vehicle should be

a minimum of 10 cm (4 in.) off the ground. Make

sure there is enough clearance at the opposite end.

This is critical when towing over rough terrain. If necessary, the rear ground clearance can be increased by removing the wheels from the lifted end

and then towing with the lifted end closer to the

ground. If the rear wheels are removed, secure the

brake drums. A 20 cm (8 in.) ground clearance must

be maintained between brake drums or rotors and the ground.

SAFETY PRECAUTIONS The following safety precautions must be consid

ered when preparing for and during a vehicle towing operation:

• Remove exhaust pipe tips that interfere with the

tow sling and crossbar • Padding should be placed between the tow sling/

crossbar and any painted surfaces

• If the vehicle is damaged, secure the loose and pro

truding parts

• Always use a safety chain system that is indepen dent of the lifting and towing equipment

• When placing tow hooks on the rear axle, position them so they do not damage the brake tubing or

hoses

• Do not allow any of the towing equipment to con

tact the fuel tank

• Do not tow the vehicle by connecting to the front

or rear shock absorbers

• The operator should not go under a vehicle while

it is lifted by the towing equipment. The vehicle

should first be supported by safety stands

• Do not allow passengers in a vehicle being towed

• Observe all state and local laws involving warning signals, night illumination, speed, etc.

• Do not exceed a towing speed of 48 km/h (30 mph)

• Avoid towing distances of more than 24 km (15

miles) whenever possible • Do not attach tow chains or a tow sling to a

bumper, the steering linkage, the universal joints, or a drive shaft

REAR-END RAISED TOWING It is recommended that the rear-end raised towing

method be used. Vehicles can be towed with the front

wheels on the ground for extended distances at speeds not exceeding 48 km/h (30 mph) (Fig. 11). (1) Attach the J-hooks around the axle shaft tubes

outboard of the rear springs. (2) Position and center the sling under and for

ward of the rear bumper. (3) Attach safety chains (with pads) at each end of

the rear bumper.

(4) Turn the ignition switch to the OFF position to

unlock the steering wheel. (5) Clamp the steering wheel with the front wheels

in the straight ahead position.

CAUTION:

Do not use the steering

column

lock

to

secure

front

wheel

in the straight-ahead

position.

(6) Shift the transmission to NEUTRAL.

POSITION CENTER BAR FORWARD

OF

BUMPER

-

/

J-HOOKS OUTBOARD

OF

SPRINGS

RN967A

Fig. 11 Rear-End

Raised

Towing

FRONT'END RAISED TOWING If a vehicle cannot be towed from the rear, the

front-end raised towing method normally can be

used (Fig. 12). (1) Center the sling with the bumper and position

it at the frame front crossmember.

CAUTION:

Use tow

chains

with

J-hooks

for

con

necting

to the

disabled

vehicle's

lower

suspension

arms.

Never use

T-hooks.

(2) Route the J-hooks and tow chains over the

steering linkage outboard of the coil spring.

(3) Attach the J-hooks to the outer end of the

lower suspension arms.

(4) Raise the vehicle.

(5.) Attach the safety chains to the disabled vehicle

at the frame rails.

Vehicles equipped with a MANUAL TRANSMIS

SION can be towed with the rear wheels on the

Page 58 of 1502

•

FRONT

SUSPENSION

AND

AXLE

2 - 5 (4) Front wheels for excessive radial, lateral

runout and unbalance. Refer to Group 22, Wheels and Tires for diagnosis information.

(5) Suspension components for wear and noise. Check

components for correct torque. Refer to Groups 2 and 3, Suspension and Axle for additional information.

WHEEL

ALIGNMENT

MEASUREMENTS/ADJUSTMENTS

The front wheel alignment positions must be set to

the specified limits. This will prevent abnormal tire

tread wear. The equipment manufacturer's recommenda

tions for use of their

equipment

should always

be followed. All

damaged

front suspension sys

tem components

should

be replaced. Do not at tempt to straighten any

bent

component.

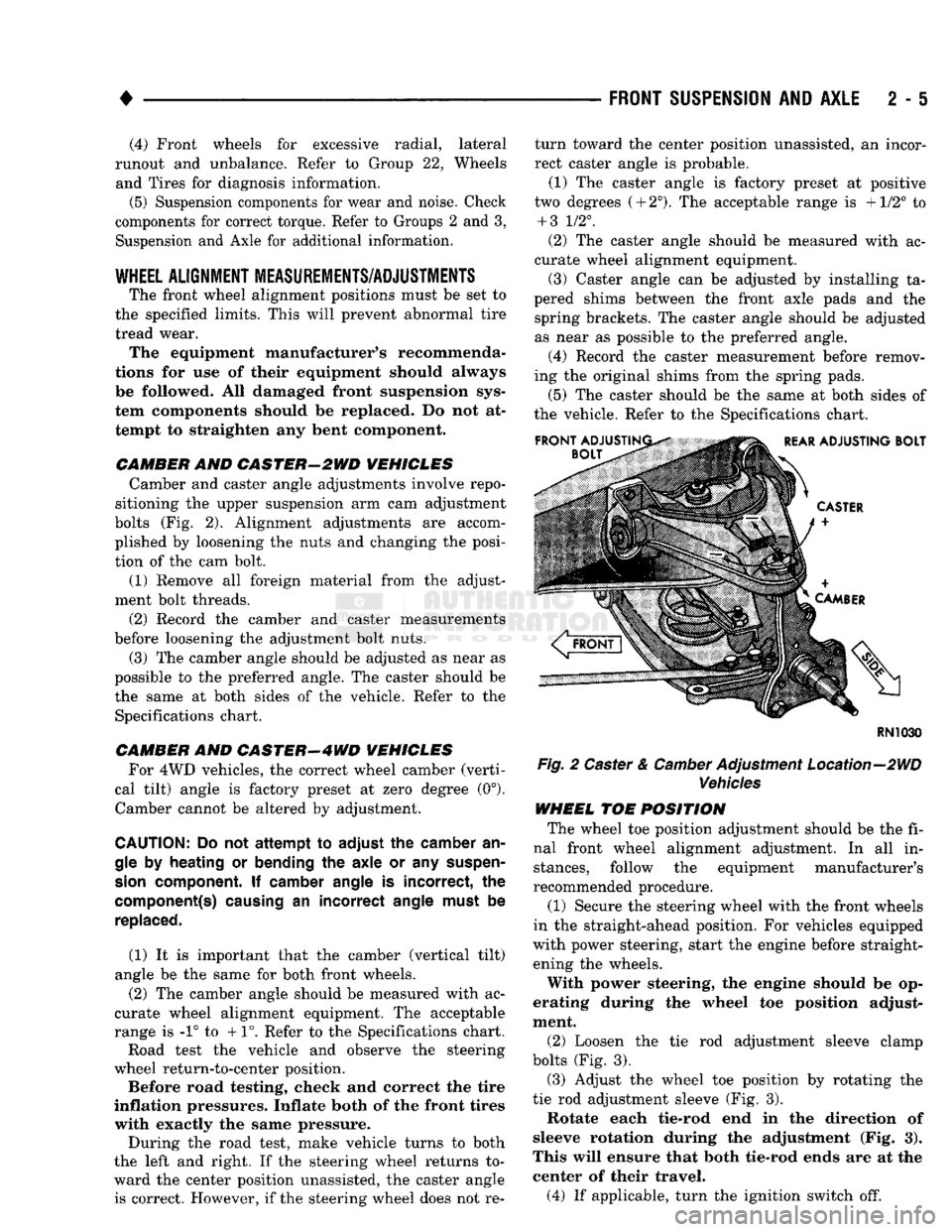

CAMBER AND CASTER-2WD VEHICLES Camber and caster angle adjustments involve repo

sitioning the upper suspension arm cam adjustment

bolts (Fig. 2). Alignment adjustments are accom

plished by loosening the nuts and changing the posi

tion of the cam bolt.

(1) Remove all foreign material from the adjust

ment bolt threads.

(2) Record the camber and caster measurements

before loosening the adjustment bolt nuts.

(3) The camber angle should be adjusted as near as

possible to the preferred angle. The caster should be

the same at both sides of the vehicle. Refer to the Specifications chart.

CAMBER AND CASTER—4WD VEHICLES For 4WD vehicles, the correct wheel camber (verti

cal tilt) angle is factory preset at zero degree (0°).

Camber cannot be altered by adjustment.

CAUTION: Do not attempt to

adjust

the

camber

an

gle by

heating

or bending the axle or any

suspen

sion

component. If camber angle is

incorrect,

the

component(s)

causing

an

incorrect

angle must be replaced.

(1) It is important that the camber (vertical tilt)

angle be the same for both front wheels.

(2) The camber angle should be measured with ac

curate wheel alignment equipment. The acceptable

range is -1° to +1°. Refer to the Specifications chart.

Road test the vehicle and observe the steering

wheel return-to-center position. Before road testing,

check

and

correct

the tire

inflation pressures. Inflate

both

of the front tires

with exactly the

same

pressure.

During the road test, make vehicle turns to both

the left and right. If the steering wheel returns to

ward the center position unassisted, the caster angle is correct. However, if the steering wheel does not re turn toward the center position unassisted, an incor

rect caster angle is probable.

(1) The caster angle is factory preset at positive

two degrees

(

+

2°).

The acceptable range is +1/2° to +

3

1/2°.

(2) The caster angle should be measured with ac

curate wheel alignment equipment.

(3) Caster angle can be adjusted by installing ta

pered shims between the front axle pads and the spring brackets. The caster angle should be adjusted

as near as possible to the preferred angle.

(4) Record the caster measurement before remov

ing the original shims from the spring pads.

(5) The caster should be the same at both sides of

the vehicle. Refer to the Specifications chart.

RN1030

Fig.

2 Caster &

Camber

Adjustment Location—2WD

Vehicles

WHEEL TOE POSITION The wheel toe position adjustment should be the fi

nal front wheel alignment adjustment. In all in stances, follow the equipment manufacturer's

recommended procedure.

(1) Secure the steering wheel with the front wheels

in the straight-ahead position. For vehicles equipped

with power steering, start the engine before straight ening the wheels.

With power steering, the engine should be op

erating during the wheel toe position adjust

ment.

(2) Loosen the tie rod adjustment sleeve clamp

bolts (Fig. 3).

(3) Adjust the wheel toe position by rotating the

tie rod adjustment sleeve (Fig. 3). Rotate each tie-rod end in the direction of

sleeve rotation during the adjustment (Fig. 3).

This will ensure that both tie-rod ends are at the center of their travel.

(4) If applicable, turn the ignition switch off.

Page 62 of 1502

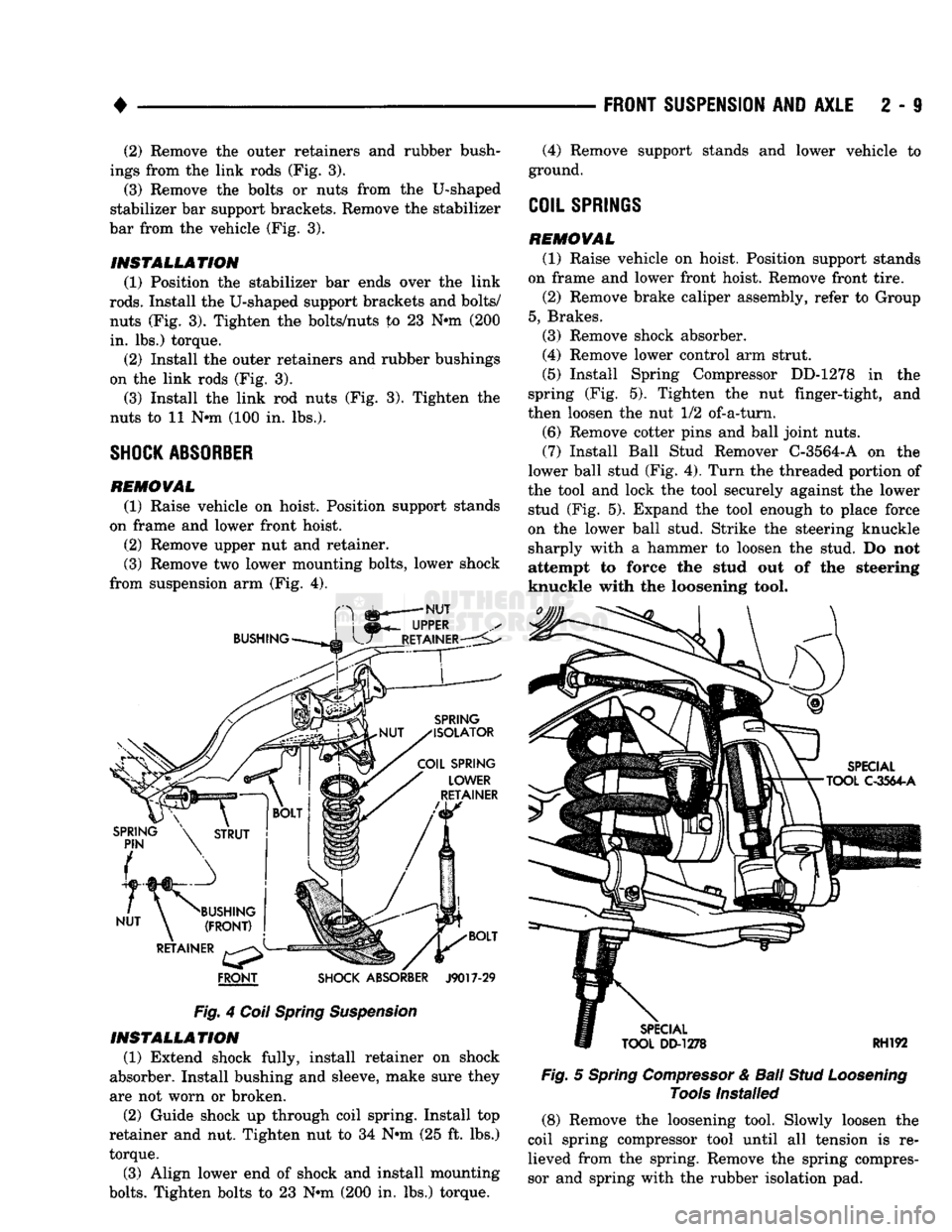

4

FRONT

SHOCK ABSORBER

J9017-29

Fig.

4

Coil Spring Suspension INSTALLATION

(1) Extend shock fully, install retainer on shock

absorber. Install bushing and sleeve, make sure they

are not worn or broken.

(2) Guide shock up through coil spring. Install top

retainer and nut. Tighten nut to 34 Nnn (25 ft. lbs.)

torque.

(3) Align lower end of shock and install mounting

bolts.

Tighten bolts to 23 Nnn (200 in. lbs.) torque.

FRONT SUSPENSION

AND

AXLE

2 - i

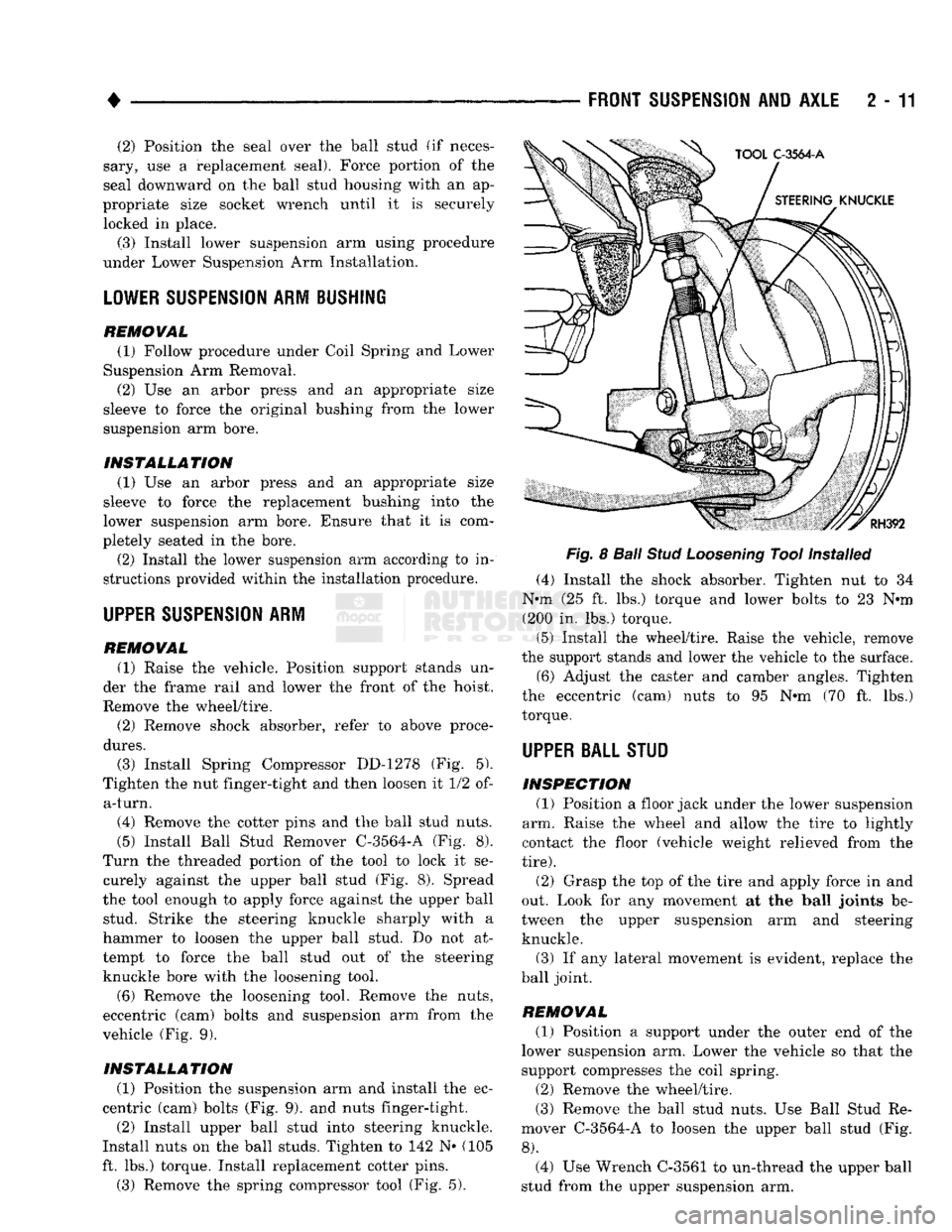

Fig.

5

Spring Compressor

&

Ball

Stud Loosening

Tools

Installed (8) Remove the loosening tool. Slowly loosen the

coil spring compressor tool until all tension is re lieved from the spring. Remove the spring compres

sor and spring with the rubber isolation pad.

(2) Remove the outer retainers and rubber bush

ings from the link rods (Fig. 3).

(3) Remove the bolts or nuts from the U-shaped

stabilizer bar support brackets. Remove the stabilizer

bar from the vehicle (Fig. 3).

INSTALLATION

(1) Position the stabilizer bar ends over the link

rods.

Install the U-shaped support brackets and bolts/ nuts (Fig. 3). Tighten the bolts/nuts to 23 Nnn (200

in.

lbs.) torque. (2) Install the outer retainers and rubber bushings

on the link rods (Fig. 3).

(3) Install the link rod nuts (Fig. 3). Tighten the

nuts to 11 Nnn (100 in. lbs.).

SHOCK ABSORBER

REMOVAL

(1) Raise vehicle on hoist. Position support stands

on frame and lower front hoist.

(2) Remove upper nut and retainer.

(3) Remove two lower mounting bolts, lower shock

from suspension arm (Fig. 4). (4) Remove support stands and lower vehicle to

ground.

COIL

SPRINGS

REMOVAL

(1) Raise vehicle on hoist. Position support stands

on frame and lower front hoist. Remove front tire. (2) Remove brake caliper assembly, refer to Group

5, Brakes. (3) Remove shock absorber.

(4) Remove lower control arm strut.

(5) Install Spring Compressor DD-1278 in the

spring (Fig. 5). Tighten the nut finger-tight, and

then loosen the nut 1/2 of-a-turn.

(6) Remove cotter pins and ball joint nuts.

(7) Install Ball Stud Remover C-3564-A on the

lower ball stud (Fig. 4). Turn the threaded portion of

the tool and lock the tool securely against the lower stud (Fig. 5). Expand the tool enough to place force

on the lower ball stud. Strike the steering knuckle sharply with a hammer to loosen the stud. Do not

attempt to force the stud out of the steering

knuckle with the loosening tool.

Page 64 of 1502

•

FRONT

SUSPENSION

AND

AXLE

2 - 11 (2) Position the seal over the ball stud (if neces

sary, use a replacement seal). Force portion of the

seal downward on the ball stud housing with an ap

propriate size socket wrench until it is securely locked in place.

(3) Install lower suspension arm using procedure

under Lower Suspension Arm Installation.

LOWER SUSPENSION

ARM

BUSHING

REMOVAL (1) Follow procedure under Coil Spring and Lower

Suspension Arm Removal.

(2) Use an arbor press and an appropriate size

sleeve to force the original bushing from the lower

suspension arm bore.

INSTALLATION (1) Use an arbor press and an appropriate size

sleeve to force the replacement bushing into the

lower suspension arm bore. Ensure that it is com

pletely seated in the bore.

(2) Install the lower suspension arm according to in

structions provided within the installation procedure.

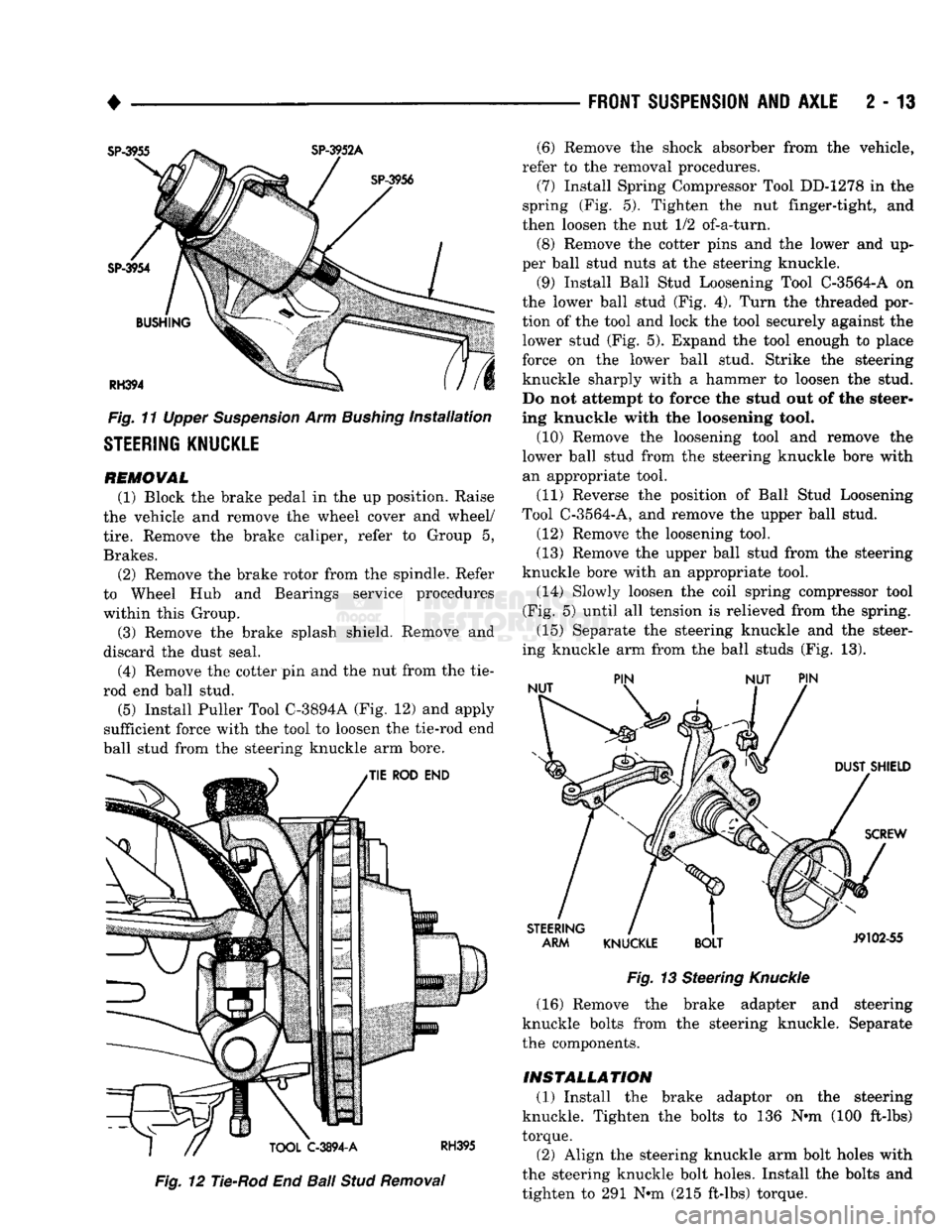

UPPER SUSPENSION

ARM REMOVAL (1) Raise the vehicle. Position support stands un

der the frame rail and lower the front of the hoist.

Remove the wheel/tire.

(2) Remove shock absorber, refer to above proce

dures.

(3) Install Spring Compressor DD-1278 (Fig. 5).

Tighten the nut finger-tight and then loosen it 1/2 of- a-turn.

(4) Remove the cotter pins and the ball stud nuts.

(5) Install Ball Stud Remover C^3564-A (Fig. 8).

Turn the threaded portion of the tool to lock it se curely against the upper ball stud (Fig. 8). Spread

the tool enough to apply force against the upper ball stud. Strike the steering knuckle sharply with a

hammer to loosen the upper ball stud. Do not at

tempt to force the ball stud out of the steering knuckle bore with the loosening tool.

(6) Remove the loosening tool. Remove the nuts,

eccentric (cam) bolts and suspension arm from the

vehicle (Fig. 9).

INSTALLATION (1) Position the suspension arm and install the ec

centric (cam) bolts (Fig. 9). and nuts finger-tight.

(2) Install upper ball stud into steering knuckle.

Install nuts on the ball studs. Tighten to 142 N« (105

ft. lbs.) torque. Install replacement cotter pins.

(3) Remove the spring compressor tool (Fig. 5).

Fig.

8

Ball

Stud

Loosening

Tool Installed

(4) Install the shock absorber. Tighten nut to 34

N*m (25 ft. lbs.) torque and lower bolts to 23 N*m (200 in. lbs.) torque.

(5) Install the wheel/tire. Raise the vehicle, remove

the support stands and lower the vehicle to the surface.

(6) Adjust the caster and camber angles. Tighten

the eccentric (cam) nuts to 95 N*m (70 ft. lbs.)

torque.

UPPER BALL STUD

INSPECTION (1) Position a floor jack under the lower suspension

arm. Raise the wheel and allow the tire to lightly

contact the floor (vehicle weight relieved from the

tire).

(2) Grasp the top of the tire and apply force in and

out. Look for any movement at the ball joints be

tween the upper suspension arm and steering knuckle.

(3) If any lateral movement is evident, replace the

ball joint.

REMOVAL (1) Position a support under the outer end of the

lower suspension arm. Lower the vehicle so that the

support compresses the coil spring.

(2) Remove the wheel/tire.

(3) Remove the ball stud nuts. Use Ball Stud Re

mover C-3564-A to loosen the upper ball stud (Fig.

8).

(4) Use Wrench C-3561 to un-thread the upper ball

stud from the upper suspension arm.

Page 66 of 1502

•

Fig.

11 Upper Suspension Arm Bushing installation

STEERING KNUCKLE

REMOVAL

(1) Block the brake pedal in the up position. Raise

the vehicle and remove the wheel cover and wheel/

tire.

Remove the brake caliper, refer to Group 5,

Brakes. (2) Remove the brake rotor from the spindle. Refer

to Wheel Hub and Bearings service procedures

within this Group.

(3) Remove the brake splash shield. Remove and

discard the dust seal.

(4) Remove the cotter pin and the nut from the tie-

rod end ball stud.

(5)

Install Puller Tool C-3894A (Fig. 12) and apply

sufficient force with the tool to loosen the tie-rod end

ball stud from the steering knuckle arm bore.

Fig.

12 Tie-Rod End

Ball

Stud

Removal

FRONT SUSPENSION

AND

AXLE

2 - 13

Fig.

13 Steering

Knuckle

(16) Remove the brake adapter and steering

knuckle bolts from the steering knuckle. Separate

the components.

INSTALLATION (1) Install the brake adaptor on the steering

knuckle. Tighten the bolts to 136 Nnn (100 ft-lbs)

torque.

(2) Align the steering knuckle arm bolt holes with

the steering knuckle bolt holes. Install the bolts and

tighten to 291 Nnn (215 ft-lbs) torque. (6) Remove the shock absorber from the vehicle,

refer to the removal procedures. (7) Install Spring Compressor Tool DD-1278 in the

spring (Fig. 5). Tighten the nut finger-tight, and

then loosen the nut 1/2 of-a-turn.

(8) Remove the cotter pins and the lower and up

per ball stud nuts at the steering knuckle.

(9) Install Ball Stud Loosening Tool C-3564-A on

the lower ball stud (Fig. 4). Turn the threaded por

tion of the tool and lock the tool securely against the lower stud (Fig. 5). Expand the tool enough to place

force on the lower ball stud. Strike the steering

knuckle sharply with a hammer to loosen the stud.

Do not attempt to force the stud out of the steer

ing knuckle with the loosening tool.

(10) Remove the loosening tool and remove the

lower ball stud from the steering knuckle bore with an appropriate tool.

(11) Reverse the position of Ball Stud Loosening

Tool C-3564-A, and remove the upper ball stud.

(12) Remove the loosening tool.

(13) Remove the upper ball stud from the steering

knuckle bore with an appropriate tool. (14) Slowly loosen the coil spring compressor tool

(Fig. 5) until all tension is relieved from the spring.

(15) Separate the steering knuckle and the steer

ing knuckle arm from the ball studs (Fig. 13).

Page 72 of 1502

FRONT

SUSPENSION

AND

AXLE

2 - 19

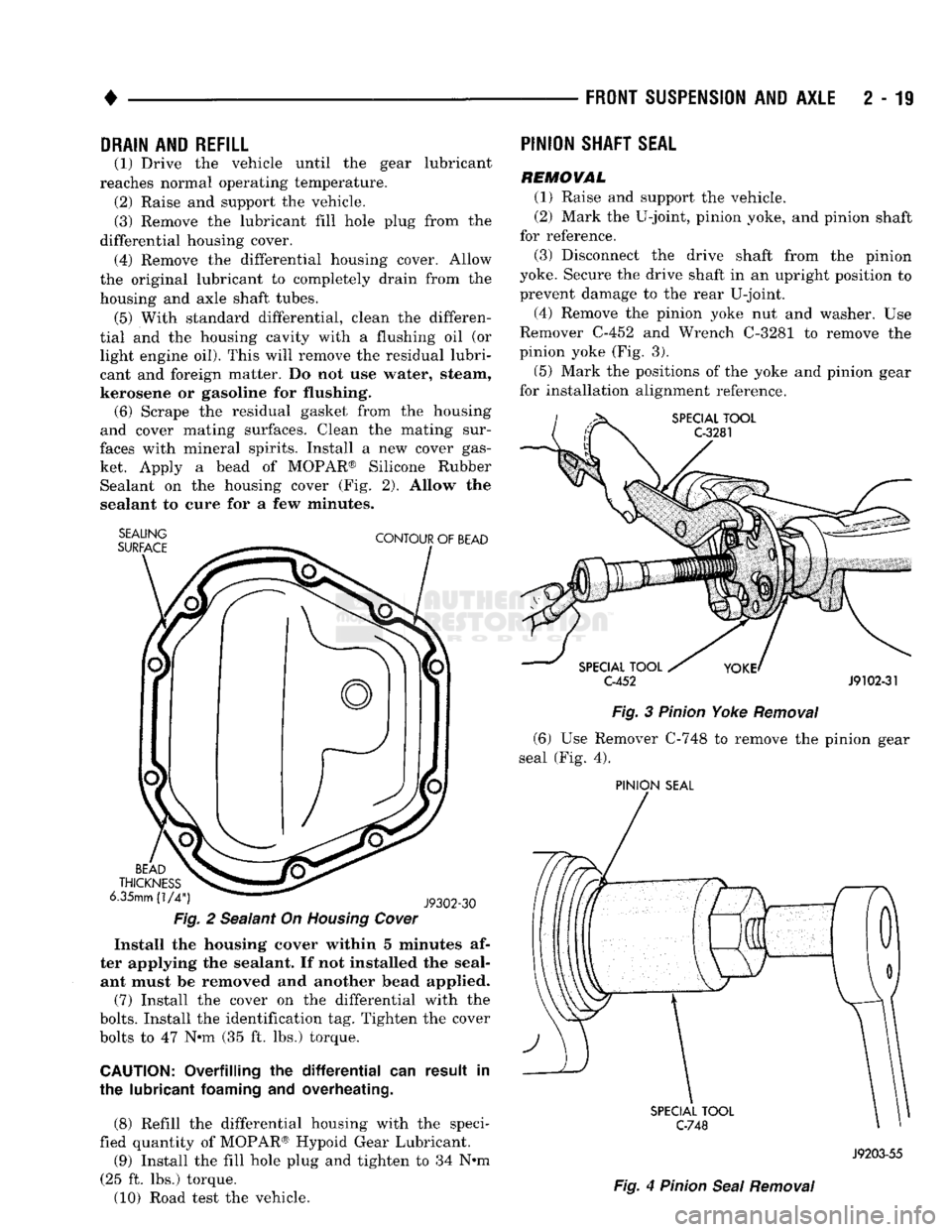

DRAIN

AND

REFILL

(1) Drive the vehicle until the gear lubricant

reaches normal operating temperature. (2) Raise and support the vehicle.

(3) Remove the lubricant fill hole plug from the

differential housing cover.

(4) Remove the differential housing cover. Allow

the original lubricant to completely drain from the

housing and axle shaft tubes.

(5) With standard differential, clean the differen

tial and the housing cavity with a flushing oil (or light engine oil). This will remove the residual lubricant and foreign matter. Do not use water, steam,

kerosene or gasoline for flushing. (6) Scrape the residual gasket from the housing

and cover mating surfaces. Clean the mating sur

faces with mineral spirits. Install a new cover gas ket. Apply a bead of MOPAR® Silicone Rubber Sealant on the housing cover (Fig. 2). Allow the

sealant to cure for a few minutes.

SEALING

SURFACE

CONTOUR

OF

BEAD

BEAD

THICKNESS

6.35mm

(1/4")

J9302-30

Fig.

2 Sealant On

Housing

Cover

Install the housing cover within 5 minutes af

ter applying the sealant. If not installed the seal ant must be removed and another bead applied.

(7) Install the cover on the differential with the

bolts.

Install the identification tag. Tighten the cover

bolts to 47 Nnn (35 ft. lbs.) torque.

CAUTION:

Overfilling the

differential

can result in

the lubricant

foaming

and overheating.

(8) Refill the differential housing with the speci

fied quantity of MOPAR® Hypoid Gear Lubricant.

(9) Install the fill hole plug and tighten to 34 N#m

(25 ft. lbs.) torque.

(10) Road test the vehicle.

PINION

SHAFT

SEAL

REMOVAL

(1) Raise and support the vehicle.

(2) Mark the U-joint, pinion yoke, and pinion shaft

for reference.

(3) Disconnect the drive shaft from the pinion

yoke. Secure the drive shaft in an upright position to prevent damage to the rear U-joint.

(4) Remove the pinion yoke nut and washer. Use

Remover C-452 and Wrench C-3281 to remove the

pinion yoke (Fig. 3).

(5) Mark the positions of the yoke and pinion gear

for installation alignment reference.

SPECIAL

TOOL

C-3281

SPECIAL

TOOL

C-452

J9102-31

Fig.

3

Pinion

Yoke

Removal

(6) Use Remover C-748 to remove the pinion gear

seal (Fig. 4).

PINION

SEAL

SPECIAL

TOOL

C-748

Fig.

4

Pinion

Seal

Removal

J9203-55

Page 143 of 1502

3

- 14

REAR SUSPENSION

AND

AXLE

3

- 18

REAR SUSPENSION Fig.

6 Bearing

Removal

(9

1/4-Axle)

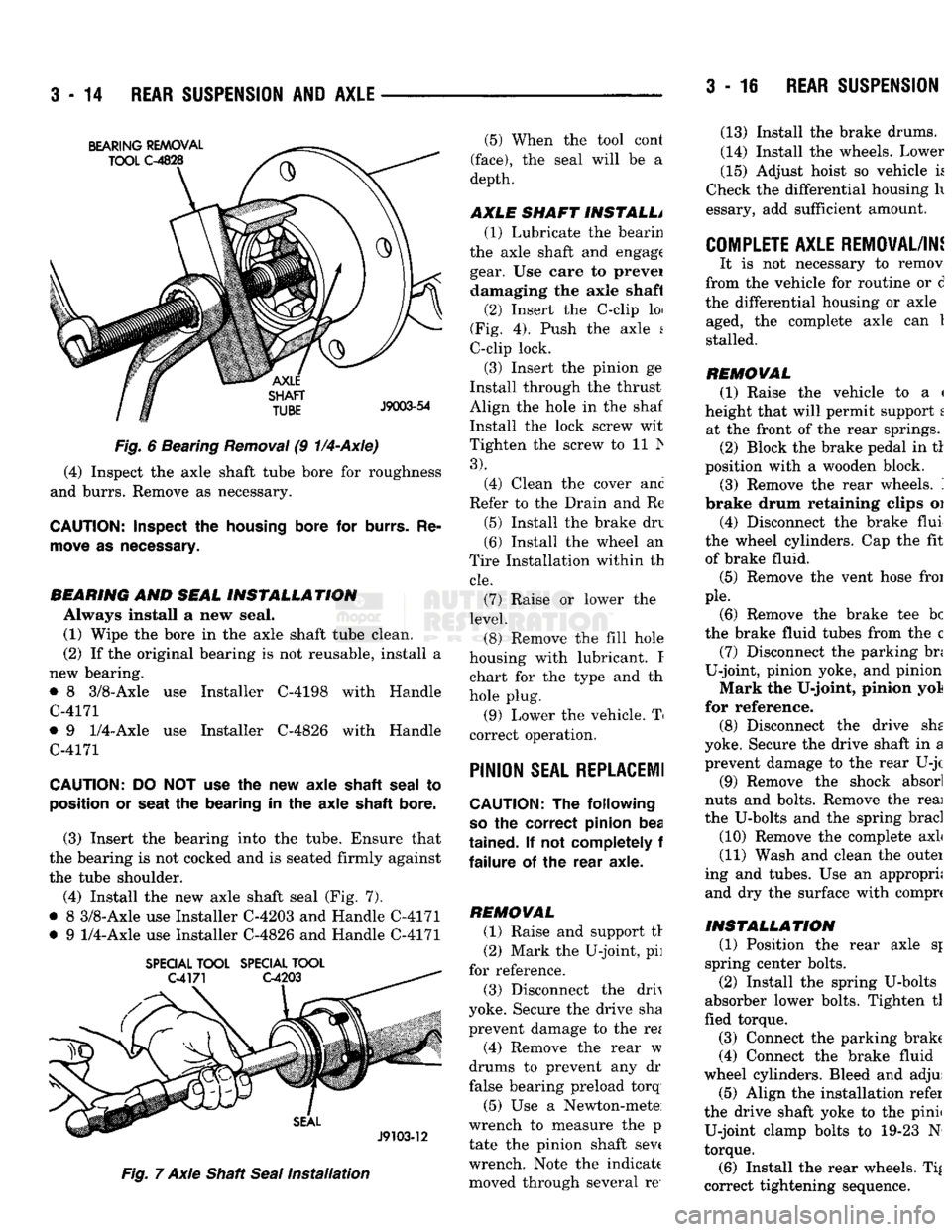

(4) Inspect the axle shaft tube bore for roughness

and burrs. Remove as necessary.

CAUTION:

Inspect

the

housing

bore for

burrs.

Re

move

as

necessary.

BEARING

AND

SEAL

INSTALLATION

Always install a new seal. (1) Wipe the bore in the axle shaft tube clean.

(2) If the original bearing is not reusable, install a

new bearing.

• 8 3/8-Axle use Installer C-4198 with Handle

C-4171

• 9

1/4-Axle

use Installer C-4826 with Handle

C-4171

CAUTION:

DO NOT use the new axle

shaft

seal

to

position

or

seat

the bearing in the axle

shaft

bore.

(3) Insert the bearing into the tube. Ensure that

the bearing is not cocked and is seated firmly against

the tube shoulder.

(4) Install the new axle shaft seal (Fig. 7).

• 8 3/8-Axle use Installer C-4203 and Handle C-4171

• 9

1/4-Axle

use Installer C-4826 and Handle C-4171

SPECIAL

TOOL

SPECIAL

TOOL

Fig.

7 Axle Shaft

Seal

Installation

(5) When the tool cont

(face),

the seal will be a

depth.

AXLE SHAFT INSTALL* (1) Lubricate the bearin

the axle shaft and engage gear. Use care to prevei damaging the axle shaft

(2) Insert the C-clip loi

(Fig. 4). Push the axle s

C-clip lock.

(3) Insert the pinion ge

Install through the thrust

Align the hole in the shaf

Install the lock screw wit

Tighten the screw to 11 Is

3).

(4) Clean the cover anc

Refer to the Drain and Re

(5) Install the brake drv

(6) Install the wheel an

Tire Installation within th

cle.

(7) Raise or lower the

level.

(8) Remove the fill hole

housing with lubricant. I chart for the type and th

hole plug.

(9) Lower the vehicle. T

correct operation.

PINION

SEAL REPLACE!!

CAUTION:

The following

so

the correct pinion bea

tained.

If not completely f

failure

of the rear axle.

REMOVAL (1) Raise and support tr

(2) Mark the U-joint, pi]

for reference.

(3) Disconnect the drh

yoke. Secure the drive sha

prevent damage to the re*

(4) Remove the rear w

drums to prevent any dr

false bearing preload torq

(5) Use a Newton-mete

wrench to measure the p

tate the pinion shaft sev( wrench. Note the indicate moved through several re' (13) Install the brake drums.

(14) Install the wheels. Lower

(15) Adjust hoist so vehicle k

Check the differential housing h

essary, add sufficient amount.

COMPLETE AXLE REMOVAL/IN!

It is not necessary to remov

from the vehicle for routine or d

the differential housing or axle aged, the complete axle can 1

stalled.

REMOVAL (1) Raise the vehicle to a <

height that will permit support t at the front of the rear springs. (2) Block the brake pedal in tl

position with a wooden block. (3) Remove the rear wheels. '.

brake drum retaining clips oi

(4) Disconnect the brake flui

the wheel cylinders. Cap the fit of brake fluid.

(5) Remove the vent hose froi

pie.

(6) Remove the brake tee be

the brake fluid tubes from the c (7) Disconnect the parking bn

U-joint, pinion yoke, and pinion

Mark the U-joint, pinion yol

for reference. (8) Disconnect the drive she

yoke. Secure the drive shaft in a prevent damage to the rear U-jc

(9) Remove the shock absorl

nuts and bolts. Remove the reai

the U-bolts and the spring brad

(10) Remove the complete axL

(11) Wash and clean the outei

ing and tubes. Use an appropri; and dry the surface with comprc

INSTALLATION

(1) Position the rear axle sj

spring center bolts.

(2) Install the spring U-bolts

absorber lower bolts. Tighten tl

fled torque.

(3) Connect the parking brake

(4) Connect the brake fluid

wheel cylinders. Bleed and adjui (5) Align the installation refer

the drive shaft yoke to the pinii U-joint clamp bolts to 19-23 N

torque.

(6) Install the rear wheels. Ti|

correct tightening sequence.

Page 158 of 1502

•

REAR

SUSPENSION

AND

AXLE

3 - 31

LUBRICANT

Hypoid gear lubricant, as defined by MIL-L-2105-B

and API GL 5 is the specified lube. MOPAR Hypoid

Gear Lubricant conforms with both of these specifica

tions and is highly recommended.

CAUTION:

If a

rear

axle

is

submerged

in

water,

the

axle

lubricant

must

be

replaced

immediately,

DRAIN

AND

REFILL

(1) Drive the vehicle until the gear lubricant

reaches normal operating temperature. (2) Raise and support the vehicle. (3) Remove the lubricant fill hole plug from the

differential housing cover. (4) Remove the differential housing cover. Allow

the lubricant to completely drain from the housing and axle shaft tubes. (5) Flush the differential and the housing cavity

with a flushing oil to remove residual lubricant and

foreign matter. Do not use water,

steam,

kerosene

or

gasoline for

flushing,

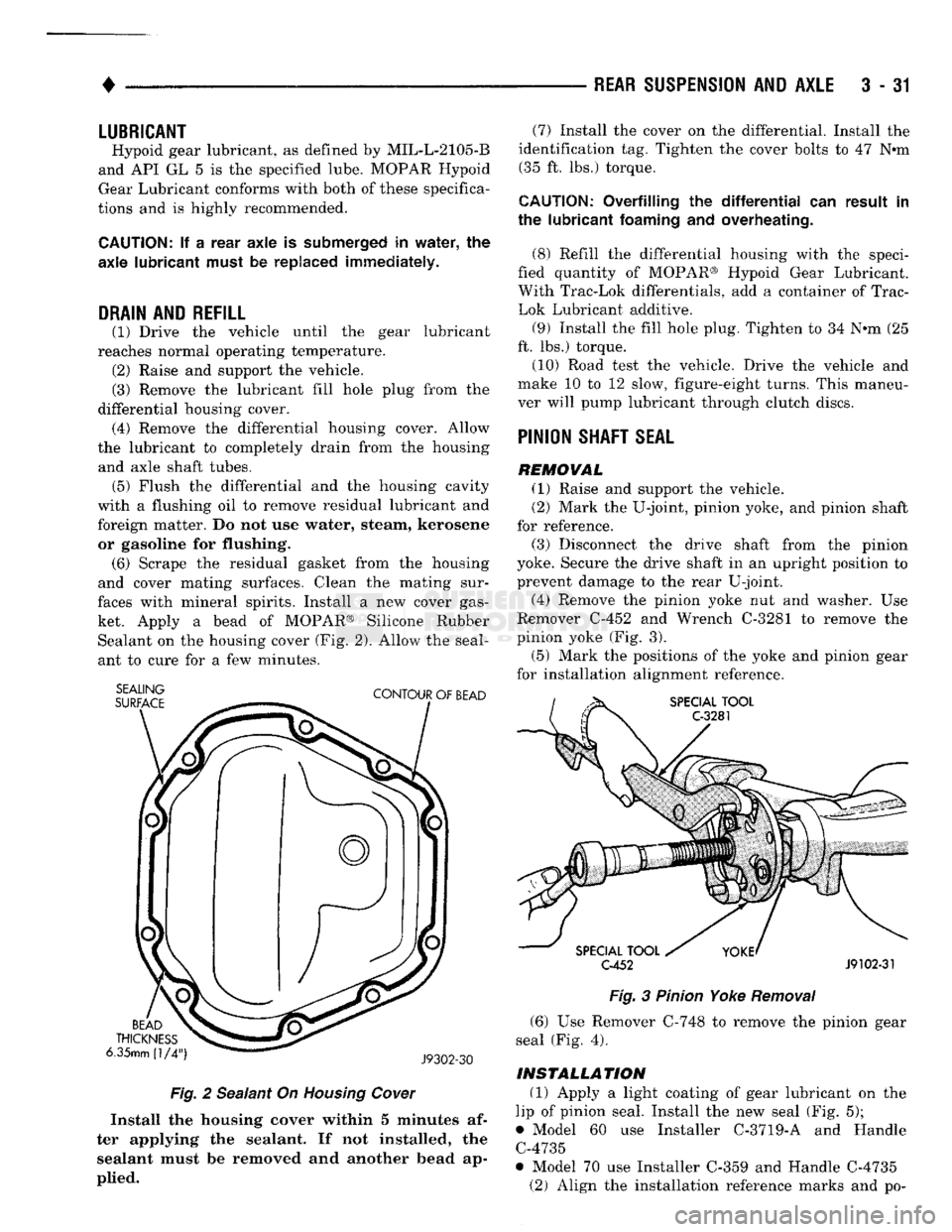

(6) Scrape the residual gasket from the housing

and cover mating surfaces. Clean the mating sur

faces with mineral spirits. Install a new cover gas

ket. Apply a bead of MOPAR® Silicone Rubber Sealant on the housing cover (Fig. 2). Allow the seal

ant to cure for a few minutes.

SEALING

SURFACE

CONTOUR

OF

BEAD

BEAD

THICKNESS

6.35mm

(1/4")

J9302-30

Fig.

2 Sealant On Housing Cower

Install

the

housing

cover

within 5

minutes

af

ter

applying

the

sealant.

If not

installed,

the

sealant

must be

removed

and another

bead

ap

plied.

(7) Install the cover on the differential. Install the

identification tag. Tighten the cover bolts to 47 Nem (35 ft. lbs.) torque.

CAUTION:

Overfilling

the differential" can

result

in

the

lubricant

foaming

and

overheating.

(8) Refill the differential housing with the speci

fied quantity of MOPAR® Hypoid Gear Lubricant.

With Trac-Lok differentials, add a container of Trac-

Lok Lubricant additive.

(9) Install the fill hole plug. Tighten to 34 N-m (25

ft. lbs.) torque.

(10) Road test the vehicle. Drive the vehicle and

make 10 to 12 slow, figure-eight turns. This maneu

ver will pump lubricant through clutch discs.

PINION

SHAFT

SEAL

REMOVAL

(1) Raise and support the vehicle.

(2) Mark the U-joint, pinion yoke, and pinion shaft

for reference.

(3) Disconnect the drive shaft from the pinion

yoke. Secure the drive shaft in an upright position to

prevent damage to the rear U-joint.

(4) Remove the pinion yoke nut and washer. Use

Remover C-452 and Wrench C-3281 to remove the

pinion yoke (Fig. 3).

(5) Mark the positions of the yoke and pinion gear

for installation alignment reference.

SPECIAL

TOOL

C-3281

SPECIAL

TOOL

C-452

J9102-31

Fig.

3 Pinion Yoke

Removal

(6) Use Remover C-748 to remove the pinion gear

seal (Fig. 4).

INSTALLATION

(1) Apply a light coating of gear lubricant on the

lip of pinion seal. Install the new seal (Fig. 5);

• Model 60 use Installer C-3719-A and Handle C-4735

• Model 70 use Installer C-359 and Handle C-4735 (2) Align the installation reference marks and po-