alternator belt DODGE TRUCK 1993 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 331 of 1502

8A

- 10

ELECTRICAL

•

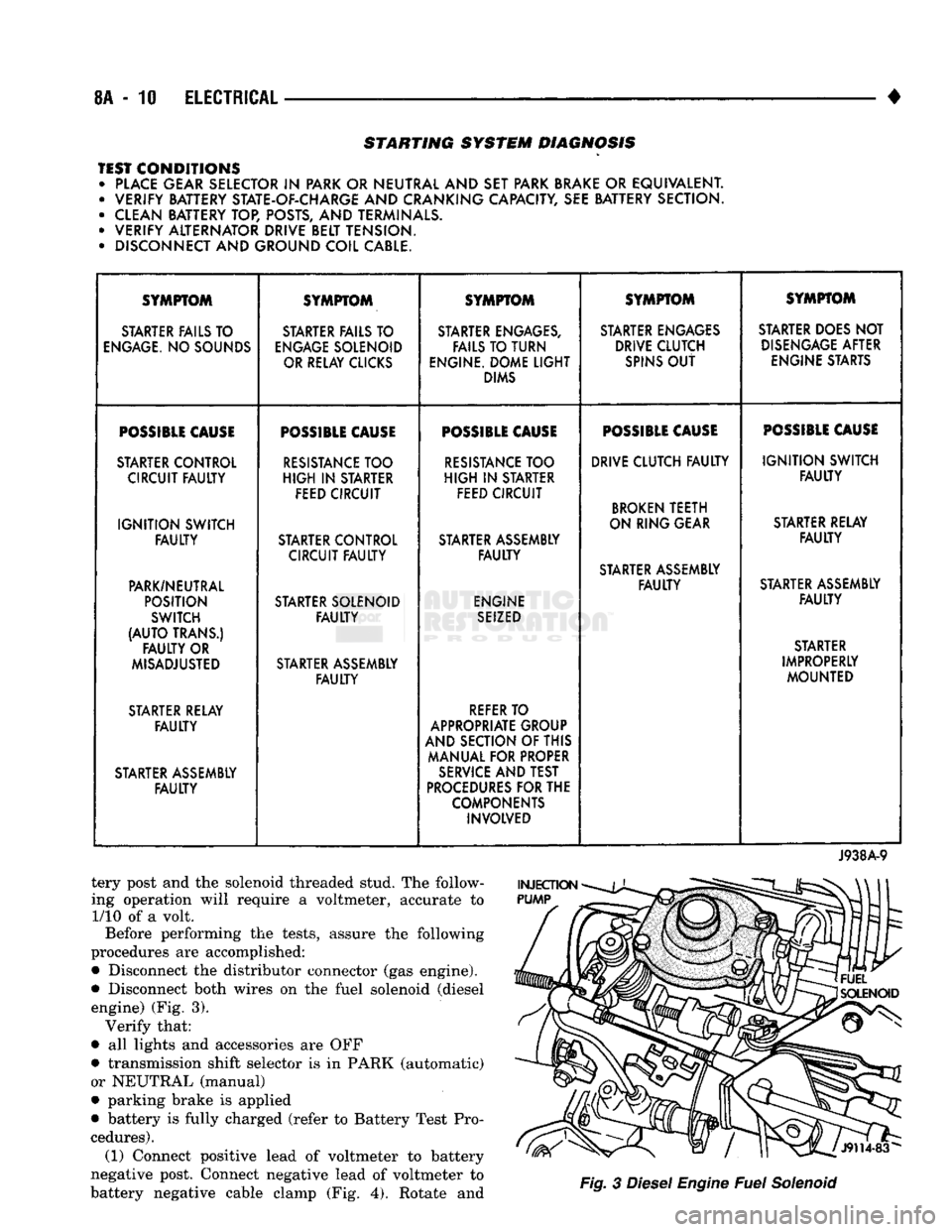

STARTING SYSTEM DIAGNOSIS

TEST CONDITIONS • PLACE GEAR SELECTOR

IN

PARK OR NEUTRAL AND SET PARK BRAKE

OR

EQUIVALENT. • VERIFY BATTERY STATE-OF-CHARGE AND CRANKING CAPACITY, SEE BATTERY SECTION.

• CLEAN BATTERY TOP, POSTS, AND TERMINALS.

• VERIFY ALTERNATOR DRIVE BELT TENSION.

• DISCONNECT AND GROUND COIL CABLE. SYMPTOM

SYMPTOM SYMPTOM SYMPTOM SYMPTOM

STARTER FAILS TO STARTER FAILS TO STARTER ENGAGES, STARTER ENGAGES STARTER DOES NOT

ENGAGE.

NO SOUNDS

ENGAGE

SOLENOID FAILS TO TURN DRIVE CLUTCH

DISENGAGE

AFTER

OR RELAY CLICKS ENGINE. DOME

LIGHT

SPINS

OUT

ENGINE STARTS

DIMS

POSSIBLE

CAUSE

POSSIBLE

CAUSE

POSSIBLE

CAUSE

POSSIBLE

CAUSE

POSSIBLE

CAUSE

STARTER CONTROL

RESISTANCE

TOO

RESISTANCE

TOO DRIVE CLUTCH

FAULTY

IGNITION

SWITCH

CIRCUIT

FAULTY

HIGH

IN

STARTER

HIGH

IN

STARTER

FAULTY

FEED CIRCUIT FEED CIRCUIT

BROKEN

TEETH

IGNITION

SWITCH ON RING GEAR

STARTER RELAY

FAULTY

STARTER CONTROL STARTER ASSEMBLY

FAULTY

CIRCUIT

FAULTY FAULTY

STARTER ASSEMBLY

PARK/NEUTRAL

FAULTY

STARTER ASSEMBLY

POSITION STARTER SOLENOID ENGINE

FAULTY

SWITCH

FAULTY

SEIZED

(AUTO

TRANS.) STARTER

FAULTY

OR STARTER

MISADJUSTED STARTER ASSEMBLY IMPROPERLY

FAULTY

MOUNTED

STARTER RELAY

REFER

TO

FAULTY

APPROPRIATE GROUP

AND SECTION OF THIS

MANUAL FOR PROPER

STARTER ASSEMBLY

SERVICE

AND TEST

FAULTY

PROCEDURES

FOR THE

COMPONENTS INVOLVED

J938A-9

tery post and the solenoid threaded stud. The follow

ing operation will require a voltmeter, accurate to 1/10 of a volt.

Before performing the tests, assure the following

procedures are accomplished:

•

Disconnect the distributor connector (gas engine).

•

Disconnect both wires on the fuel solenoid (diesel engine) (Fig. 3). Verify that:

•

all lights and accessories are OFF

•

transmission shift selector is in PARK (automatic)

or NEUTRAL (manual)

•

parking brake is applied

•

battery is fully charged (refer to Battery Test Pro

cedures). (1) Connect positive lead of voltmeter to battery

negative post. Connect negative lead of voltmeter to

battery negative cable clamp (Fig. 4). Rotate and

Fig.

3

Diesel

Engine

Fuel

Solenoid

Page 621 of 1502

9 - 16

ENGINES

•

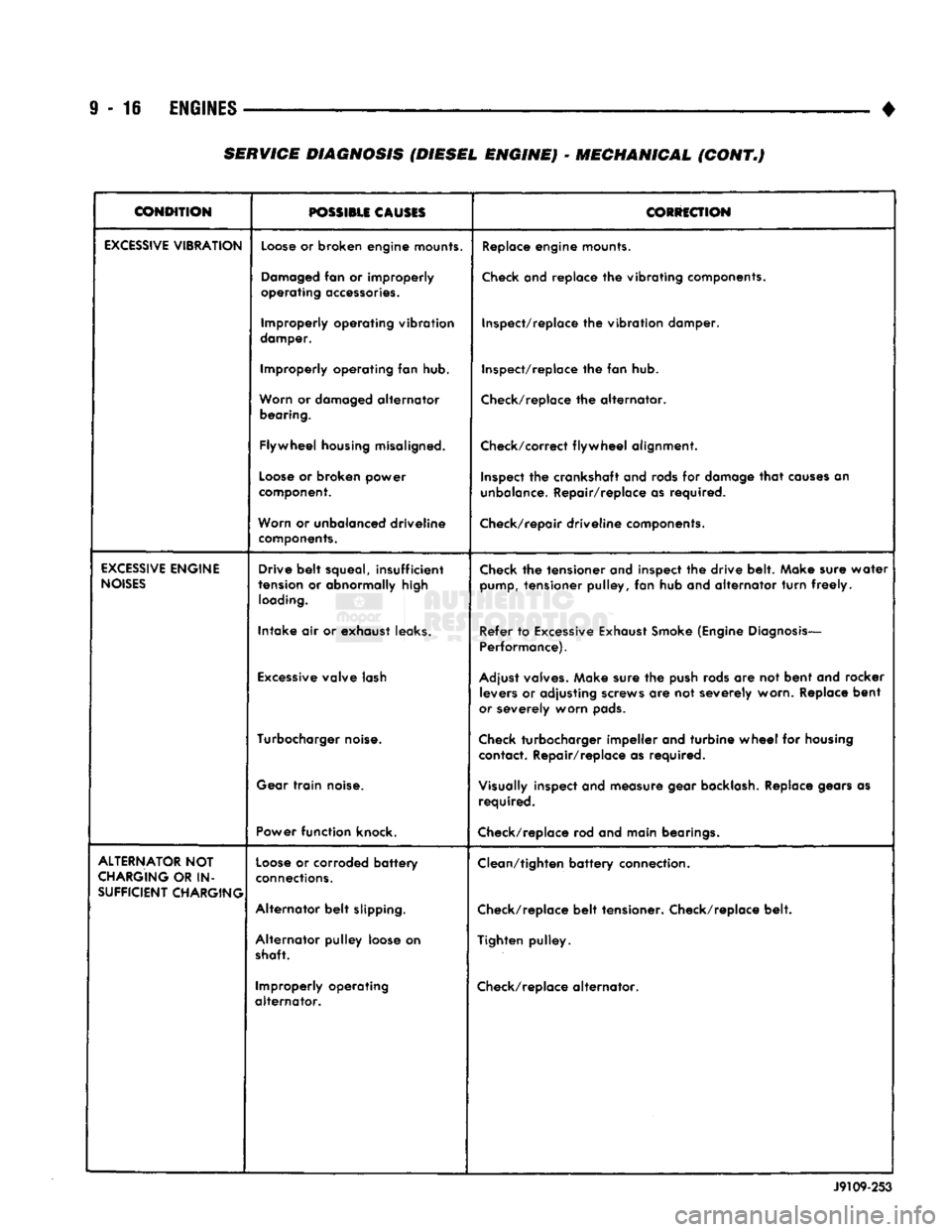

CONDITION

POSSIBLE

CAUSES

CORRECTION

EXCESSIVE

VIBRATION

Loose

or broken engine mounts.

Replace

engine mounts.

Damaged

fan or improperly

operating

accessories.

Check

and replace the vibrating components.

Improperly operating vibration

clamper. Inspect/replace the vibration damper.

Improperly operating fan hub. Inspect/replace the fan hub.

Worn

or

damaged

alternator

bearing.

Check/replace

the alternator.

Flywheel

housing

misaligned. Check/correct flywheel alignment.

Loose

or broken power

component.

Inspect

the crankshaft and rods for damage

that

causes

an

unbalance.

Repair/replace as required.

Worn

or unbalanced driveline

components.

Check/repair driveline components.

EXCESSIVE

ENGINE

NOISES

Drive belt squeal, insufficient

tension

or abnormally high

loading.

Check

the tensioner and inspect the drive belt. Make sure water

pump,

tensioner pulley, fan hub and alternator turn

freely.

Intake air or exhaust leaks. Refer to

Excessive

Exhaust

Smoke

(Engine

Diagnosis—

Performance).

Excessive

valve

lash

Adjust

valves.

Make sure the

push

rods are not bent and rocker

levers or adjusting screws are not severely worn. Replace bent

or

severely worn

pads.

Turbocharger

noise.

Check

turbocharger impeller and turbine wheel for housing

contact. Repair/replace as required.

Gear

train

noise.

Visually

inspect and measure gear

backlash.

Replace gears as

required.

Power

function knock.

Check/replace

rod and main bearings.

ALTERNATOR

NOT

CHARGING

OR IN-

SUFFICIENT

CHARGING

Loose

or corroded battery

connections.

Alternator belt slipping. Clean/tighten battery connection.

Check/replace

belt tensioner. Check/replace belt.

Alternator pulley loose on

shaft.

Tighten pulley.

Improperly operating

alternator.

Check/replace

alternator.

J9109-253

SERVICE DIAGNOSIS (DIESEL ENGINE) - MECHANICAL (CONT.)

Page 756 of 1502

5.9L

(DIESEL)

ENGINE

9-153

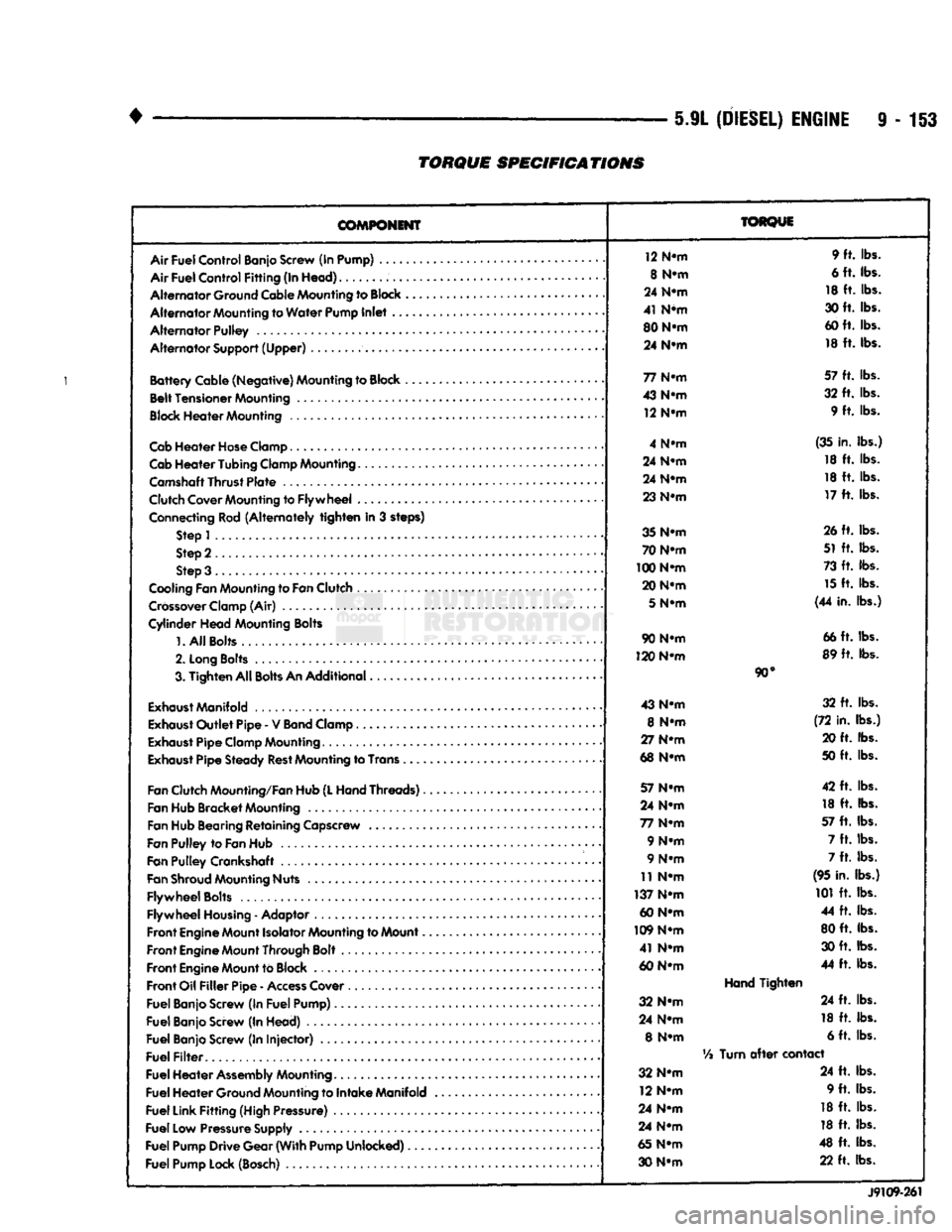

TORQUE

SPECIFICATIONS

COMPONENT

Air

Fuel

Control

Banjo Screw (In Pump) ....

Air

Fuel

Control

Fitting

(In

Head)

Alternator

Ground Cable Mounting to

Block

Alternator

Mounting to

Water

Pump

Inlet

..

Alternator

Pulley

Alternator

Support

(Upper)

Battery

Cable

(Negative)

Mounting to Block ,

Belt

Tensioner

Mounting

Block

Heater

Mounting

Cab

Heater

Hose

Clamp

Cab

Heater

Tubing

Clamp Mounting.......

Camshaft

Thrust

Plate

Clutch Cover Mounting to

Flywheel

...

Connecting Rod

(Alternately

tighten

in 3 steps) Step 1

Step 2

Step 3 .

Cooling Fan Mounting to

Fan

Clutch

Crossover

Clamp (Air)

Cylinder

Head

Mounting Bolts

1.

All

Bolts....

2.

Long

Bolts

.........

3.

Tighten

All

Bolts

An

Additional

Exhaust

Manifold

Exhaust

Outlet

Pipe

- V

Band

Clamp

Exhaust

Pipe

Clamp Mounting

Exhaust

Pipe

Steady

Rest

Mounting to Trans .

Fan

Clutch Mounting/Fan Hub

(L

Hand

Threads)..

Fan Hub

Bracket

Mounting

Fan Hub Bearing

Retaining

Capscrew

Fan

Pulley

to

Fan

Hub

Fan

Pulley

Crankshaft .

Fan

Shroud

Mounting Nuts

Flywheel

Bolts

Flywheel

Housing

- Adaptor

Front

Engine

Mount Isolator Mounting to Mount..

Front

Engine

Mount Through Bolt

Front

Engine

Mount to Block

Front

Oil

Filler

Pipe

-

Access

Cover

Fuel

Banjo Screw (In

Fuel

Pump)

Fuel

Banjo Screw (In

Head)

Fuel

Banjo Screw (In

Injector)

Fuel

Filter

Fuel

Heater

Assembly

Mounting

Fuel

Heater

Ground Mounting to

Intake

Manifold

Fuel

Link

Fitting

(High Pressure)

Fuel

Low Pressure Supply

Fuel

Pump

Drive

Gear

(With

Pump

Unlocked)

Fuel

Pump Lock (Bosch)

TORQUE

12 N-m 9 ft. lbs.

8 N-m 6 ft. lbs.

24 N-m 18 ft. lbs.

41 N*m 30 ft. lbs.

80 N-m 60 ft. lbs.

24 N-m 18 ft. lbs.

77 N-m 57 ft. lbs.

43 N-m 32 ft. lbs.

12 N-m 9 ft. lbs.

4 N-m (35 in. lbs.)

24 N-m 18 ft. lbs.

24 N-m 18 ft. lbs.

23 N-m 17 ft. lbs.

35 N-m 26 ft. lbs.

70 N-m 51 ft. lbs.

100 N-m 73 ft. lbs.

20 N-m 15 ft. lbs.

5

N-m (44 in. lbs.)

90 N-m 66 ft. lbs.

120 N-m 89 ft. lbs.

90°

43 N-m 32 ft. lbs.

8 N-m (72 in. lbs.)

27 N-m 20 ft. lbs.

68 N-m 50 ft. lbs.

57 N-m 42 ft. lbs.

24 N-m 18 ft. lbs.

77 N-m 57 ft. lbs.

9 N-m 7 ft. lbs.

9 N-m 7 ft. lbs.

11 N-m (95 in. lbs.)

137 N-m 101 ft. lbs.

60 N-m 44 ft. lbs.

109 N-m 80 ft. lbs.

41 N-m 30 ft. lbs.

60 N-m 44 ft. lbs.

Hand

Tighten

32 N-m 24 ft. lbs.

24 N-m 18 ft. lbs.

8 N-m 6 ft. lbs.

Vi

Turn

after

contact

32 N-m 24 ft. lbs.

12 N-m 9 ft. lbs.

24 N-m 18 ft. lbs.

24 N-m 18 ft. lbs.

65 N-m 48 ft. lbs.

30 N-m 22 ft. lbs.

J9109-261