display DODGE TRUCK 1993 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 6 of 1502

INTRODUCTION

INTRODUCTION

DESIGNATIONS,

LABELS/PLATES/DECALS,

CODES

AND DIMENSIONS/WEIGHTS .

CONTENTS

page

MEASUREMENT

AND TORQUE

... 1 SPECIFICATIONS

page

. 11

DESIGNATIONS, LABELS/PLATES/DECALS, CODES

AND

DIMENSIONS/WEIGHTS

INDEX

page

Engine

and

Transmission/Transfer

Case

Identification

2

Engine/Transmission/GVWR

4

Equipment

Identification

Plate

3

International

Vehicle Control

and

Display

Symbols

10

Major Component

Identification 3

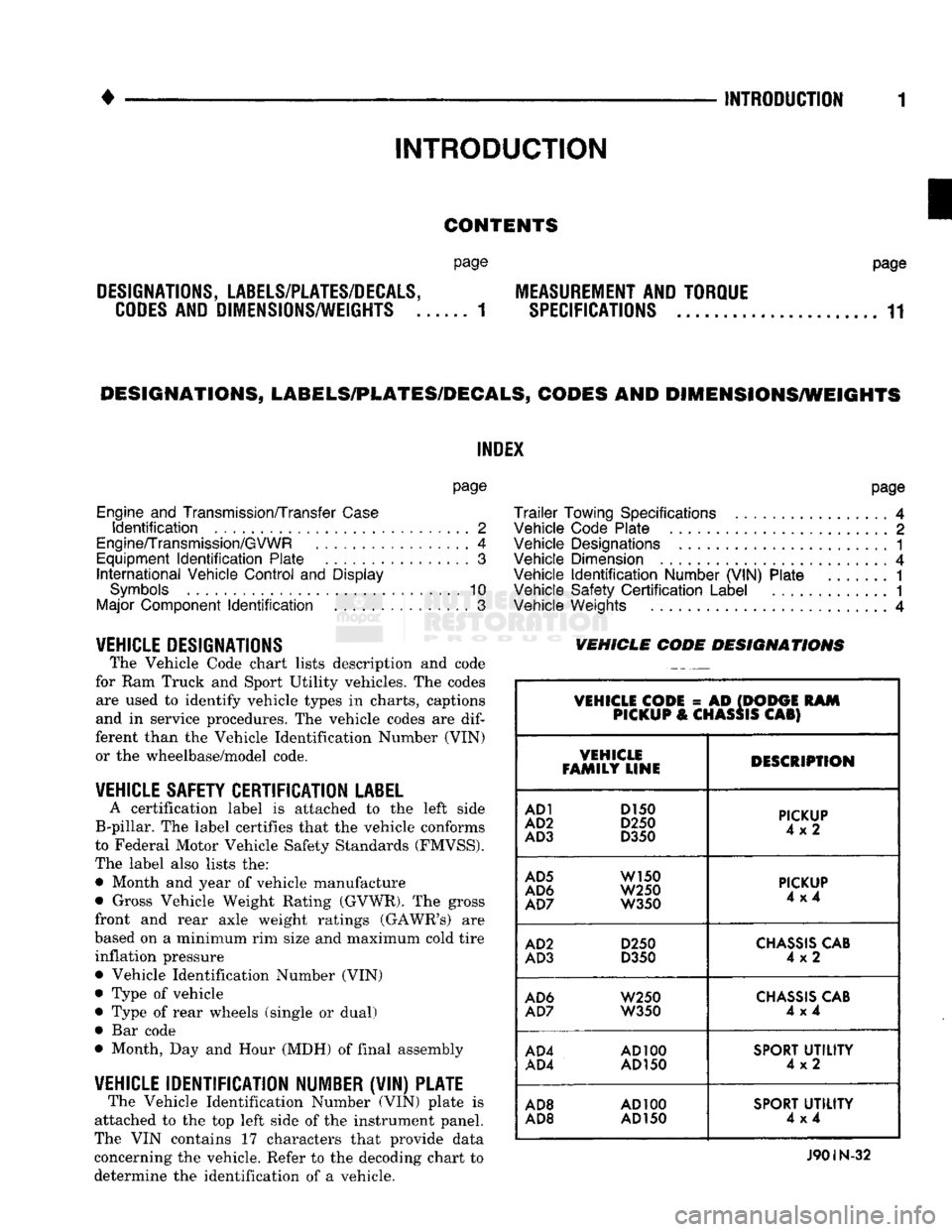

VEHICLE DESIGNATIONS The Vehicle Code chart lists description and code

for Ram Truck and Sport Utility vehicles. The codes are used to identify vehicle types in charts, captions

and in service procedures. The vehicle codes are

dif

ferent than the Vehicle Identification Number (VIN) or the wheelbase/model code.

VEHICLE SAFETY CERTIFICATION

LABEL

A certification label is attached to the left side

B-pillar. The label certifies that the vehicle conforms

to Federal Motor Vehicle Safety Standards (FMVSS).

The label also lists the: • Month and year of vehicle manufacture

• Gross Vehicle Weight Rating (GVWR). The gross

front and rear axle weight ratings (GAWR's) are

based on a minimum rim size and maximum cold tire inflation pressure Vehicle Identification Number (VIN)

Type of vehicle

Type of rear wheels (single or dual) Bar code

Month, Day and Hour (MDH) of final assembly

VEHICLE IDENTIFICATION NUMBER (VIN) PLATE The Vehicle Identification Number (VIN) plate is

attached to the top left side of the instrument panel.

The VIN contains 17 characters that provide data

concerning the vehicle. Refer to the decoding chart to

determine the identification of a vehicle.

page

Trailer

Towing Specifications

4

Vehicle Code Plate

2

Vehicle Designations

1

Vehicle Dimension

4

Vehicle

Identification

Number (VIN) Plate

1

Vehicle Safety

Certification

Label

............. 1

Vehicle Weights

4

VEHICLE CODE

DESIGNATIONS

VEHICLE CODE

= AD

(DODGE

RAM

PICKUP

&

CHASSIS

CAB)

VEHICLE

FAMILY LINE DESCRIPTION

AD1

D150

AD2

D250

AD3

D350

PICKUP

4x2

AD5

W150

AD6

W250

AD7

W350

PICKUP

4x4

AD2

D250

AD3

D350

CHASSIS

CAB

4x2

AD6

W250

AD7

W350

CHASSIS

CAB

4x4

AD4

AD100

AD4

AD150

SPORT

UTILITY

4x2

AD8

AD100

AD8 AD

150

SPORT

UTILITY

4x4

J90IN-32

Page 15 of 1502

10 INTRODUCTION

•

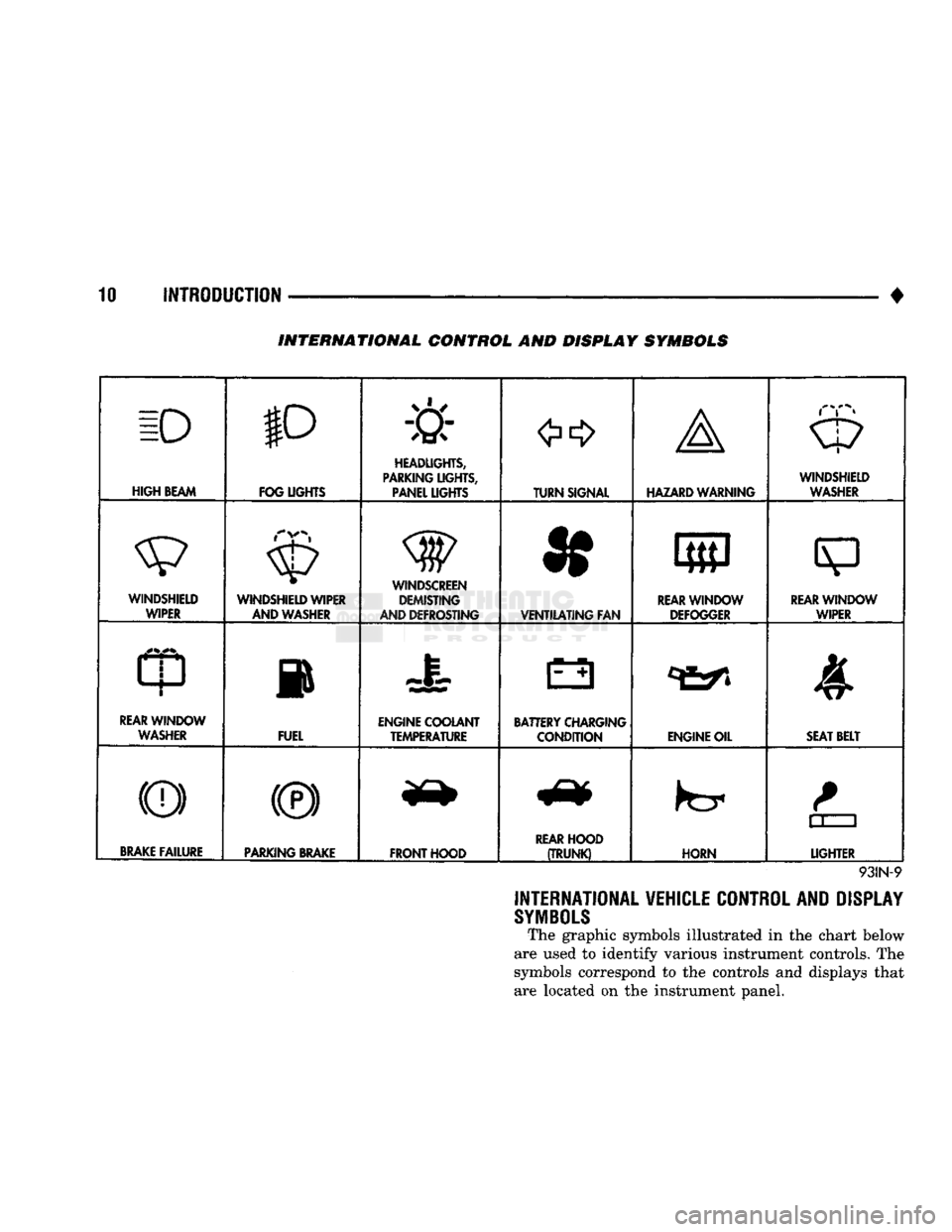

INTERNATIONAL CONTROL AND DISPLAY SYMBOLS

ID

HIGH

BEAM P

FOG UGHTS -&

HEADLIGHTS,

PARKING UGHTS, PANEL UGHTS TURN SIGNAL A

HAZARD WARNING WINDSHIELD

WASHER

WINDSHIELD WIPER WINDSHIELD WIPER

AND WASHER

AND DEFROSTING *

VENTILATING

FAN 8

M f

REAR

WINDOW DEFOGGER

sp

REARWINLX)W WIPER

CD

l

m

REAR

WINDOW WASHER FUEL ENGINE COOLANT

TEMPERATURE BATTERY CHARGING

CONDITION ENGINE OIL

SEAT

BELT

(©) (®) ky

11 J

LIGHTER

BRAKE

FAILURE

PARKING

BRAKE

FRONT HOOD

REAR

HOOD

(TRUNK)

HORN

11 J

LIGHTER

93IN-9

INTERNATIONAL VEHICLE CONTROL AND DISPLAY

SYMBOLS

The graphic symbols illustrated in the chart below

are used to identify various instrument controls. The

symbols correspond to the controls and displays that are located on the instrument panel.

Page 22 of 1502

•

LUBRICATION AND MAINTENANCE

0 - 3

CAUTION: UNLEADED FUEL ONLY must

be

used

in

vehicles equipped

with

a

catalyst emission

control

system.

All

vehicles have reminders

printed

on the

instrument

panel below

the

fuel

gauge

and on the

fuel

filler

door.

The

vehicles also have

fuel

filler

tubes

that

are

specially designed

to

accept only

the

small-diameter nozzles.

It is

illegal

to

bypass

the

design

of an

unleaded

fuel

filler

tube.

DIESEL ENGINES All

Ram

Truck

and Ram

Cab/Chassis Diesel

en

gines normally

can use

number

2D

Diesel fuel

for

most year-round operations.

A

fuel conforming

to

ASTM Specification D-975

is

recommended.

For ex

treme cold-weather, number

ID

Diesel fuel

is

recom mended.

CLASSIFICATION

OF

LUBRICANTS

Lubricating fluids

and

chassis lubricants

are

clas

sified according

to

standards recommended

by the:

• Society

of

Automotive Engineers

(SAE)

• American Petroleum Institute

(API)

• National Lubricating Grease Institute (NLGI)

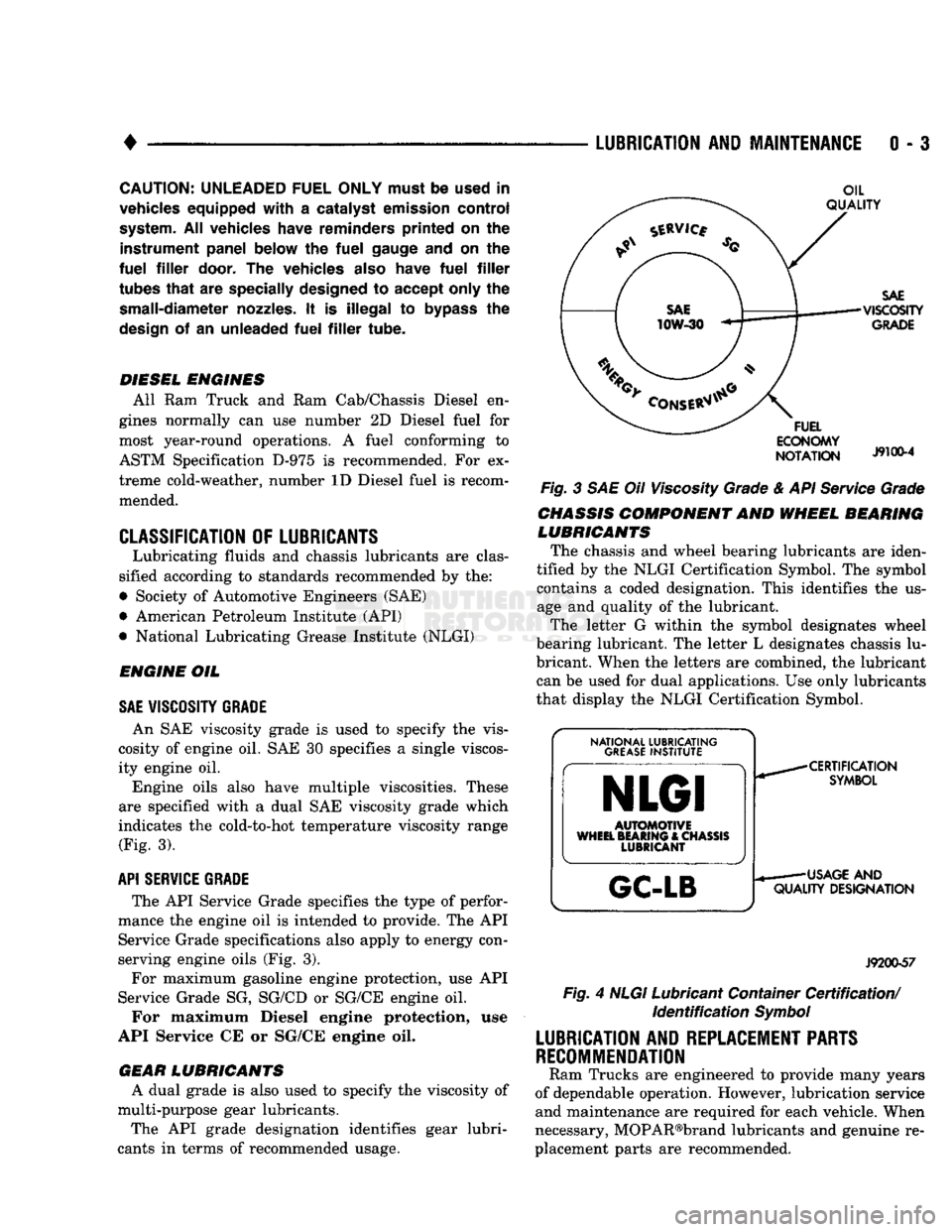

ENGINE

OIL

SAE

VISCOSITY

GRADE

An

SAE

viscosity grade

is

used

to

specify

the

vis

cosity

of

engine

oil. SAE 30

specifies

a

single viscos

ity engine

oil.

Engine oils also have multiple viscosities. These

are specified with

a

dual

SAE

viscosity grade which

indicates

the

cold-to-hot temperature viscosity range (Fig.

3).

API

SERVICE

GRADE

The

API

Service Grade specifies

the

type

of

perfor

mance

the

engine

oil is

intended

to

provide.

The API

Service Grade specifications also apply

to

energy con

serving engine oils

(Fig. 3).

For maximum gasoline engine protection,

use API

Service Grade

SG,

SG/CD

or

SG/CE engine

oil.

For maximum Diesel engine protection,

use

API Service

CE or

SG/CE engine

oil.

GEAR LUBRICANTS A dual grade

is

also used

to

specify

the

viscosity

of

multi-purpose gear lubricants.

The

API

grade designation identifies gear lubri

cants

in

terms

of

recommended usage.

OIL

QUALITY

SAE

VISCOSITY

GRADE

FUEL

ECONOMY

NOTATION

J91004

Fig.

3 SAE Oil

Viscosity Grade

& API

Service

Grade

CHASSIS COMPONENT

AND

WHEEL BEARING

LUBRICANTS The chassis

and

wheel bearing lubricants

are

iden

tified

by the

NLGI Certification Symbol.

The

symbol

contains

a

coded designation. This identifies

the us

age

and

quality

of the

lubricant.

The letter

G

within

the

symbol designates wheel

bearing lubricant.

The

letter

L

designates chassis

lu

bricant. When

the

letters

are

combined,

the

lubricant can

be

used

for

dual applications.

Use

only lubricants

that display

the

NLGI Certification Symbol.

NATIONAL LUBRICATING

GREASE

INSTITUTE

NLGI

AUTOMOTIVE

WHEEL BEARING

&

CHASSIS LUBRICANT

GC-LB

-CERTIFICATION

SYMBOL

—

USAGE

AND

QUALITY

DESIGNATION

J920W7

Fig.

4

NLGI

Lubricant Container

Certification/

Identification

Symbol

LUBRICATION

AND

REPLACEMENT

PARTS

RECOMMENDATION

Ram Trucks

are

engineered

to

provide many years

of dependable operation. However, lubrication service

and maintenance

are

required

for

each vehicle. When

necessary, MOPAR®brand lubricants

and

genuine

re

placement parts

are

recommended.

Page 249 of 1502

i - 62

BRAKES

•

Isolation/Dump

Valve Cycle Times

Activation (opening/closing) of the isolation and

dump valves is continuous during antilock operation.

The valves cycle rapidly in response to speed sensor inputs and control module signal commands. Cycle

times are measured in milliseconds.

As the demand for antilock mode brake operation

is decreased, the module deactivates the hydraulic

valve components to restore normal brake operation.

ANTILOCK

SERVICE

DIAGNOSIS

GENERAL INFORMATION An antilock system malfunction will be indicated

by illumination of the amber antilock warning lamp.

The red brake warning lamp may also illuminate.

If a problem occurs, system diagnosis should begin

with a fluid level check followed by a visual exami

nation of the system electrical and hydraulic connec

tions.

If obvious defects (low fluid, leaks, loose connections, etc.) are not evident, road test the vehi

cle.

A road test should help determine if a malfunc

tion is actually related to an antilock component.

During the road test, note if other conditions are

evident such as a low pedal, pull, grab, or similar condition. Remember that brake malfunctions such as low fluid, system leaks, parking brakes partially

applied, will also affect the antilock system. The idea

is to determine if a malfunction is actually related to

an anti-lock component.

If a road test does reveal a problem, repeat the

road test with the owner driving. Make sure the owner is not riding the brake pedal, or has forgotten

to release the parking brakes. Either situation will

generate a fault and cause the antilock light to illu

minate.

SYSTEM FAULT

CODES

The antilock control module generates flash codes

to help identify the cause of an antilock system fault. Two different control modules are used with the

1992/1993 RWAL system. A type I module is used in

some early production models. All remaining produc

tion models are equipped with a type II module. The type I and II modules are identified by the way

fault codes 9 and 11 are processed. If the vehicle has a type I module, codes 9 and 11 are not erased when

the ignition switch is turned to Off position. If the vehicle has a type II module, codes 9 and 11 are

erased when the switch is turned to Off.

FAULT CODES WITH TYPE I CONTROL

MODULE

The microprocessor in the electronic control module

has a memory and a self test feature. The self test

feature is activated whenever the ignition switch is

turned to Accessory or Run position. If a system fault is detected, the control module il

luminates the antilock light and stores the fault code

in memory. Fault codes are retained in memory even after turning the ignition switch to Off position.

FAULT CODES WITH TYPE II CONTROL

MODULE The microprocessor in the electronic control module

has a memory and a self test feature. The self test

feature is activated whenever the ignition switch is

turned to Accessory or Run position.

If a system fault is detected, the control module

will illuminate the antilock indicator lamp and store

fault codes 1 through 8, 10 and 12 through 15 in the

microprocessor memory. When one of these fault

codes is generated, the control module will retain the code after the ignition switch is turned to the Off po

sition.

When fault code 9 is generated, the code only re

mains in microprocessor memory while the ignition switch is in Run position. Turning the ignition

switch to Off position erases fault code 9. However, if

the problem still exists when the switch is turned

back to Run position, code 9 will reappear in memory after 20 seconds and the antilock light will illumi

nate once again.

When fault code 11 is generated, the antilock light

will illuminate when vehicle speed exceeds approxi mately 60.35 km/h (37.5 mph). Code 11 only remains in memory while the ignition switch is in the Run

position and the fault is present.

When the cause of a fault code 11 is corrected, the

antilock light goes off. Code 11 is erased when the ig

nition switch is turned to Off position. However, if

the problem cause still exists when the ignition switch is turned to Run position, code 11 will reap

pear when vehicle speed exceeds approximately 60.35 km/h (37.5 mph).

FAULT

CODE

CAPACITY

The microprocessor memory will store and display

only one fault code at a time. The stored code can be

displayed by grounding the RWAL diagnostic connec

tor.

FAULT

CODE

IDENTIFICATION

To determine what the fault code is, momentarily

ground the RWAL diagnostic connector and count

the number of times the amber antilock lamp flashes. Fault codes and typical malfunctions are outlined in Figure 8. Note that when a fault code is gen

erated, the red brake warning lamp will also

illuminate. The initial flash will be a long flash followed by a

number of short flashes. The long flash indicates the

beginning of the fault number sequence and the short flashes are a continuation of that sequence.

Page 316 of 1502

•

COOLING

SYSTEM

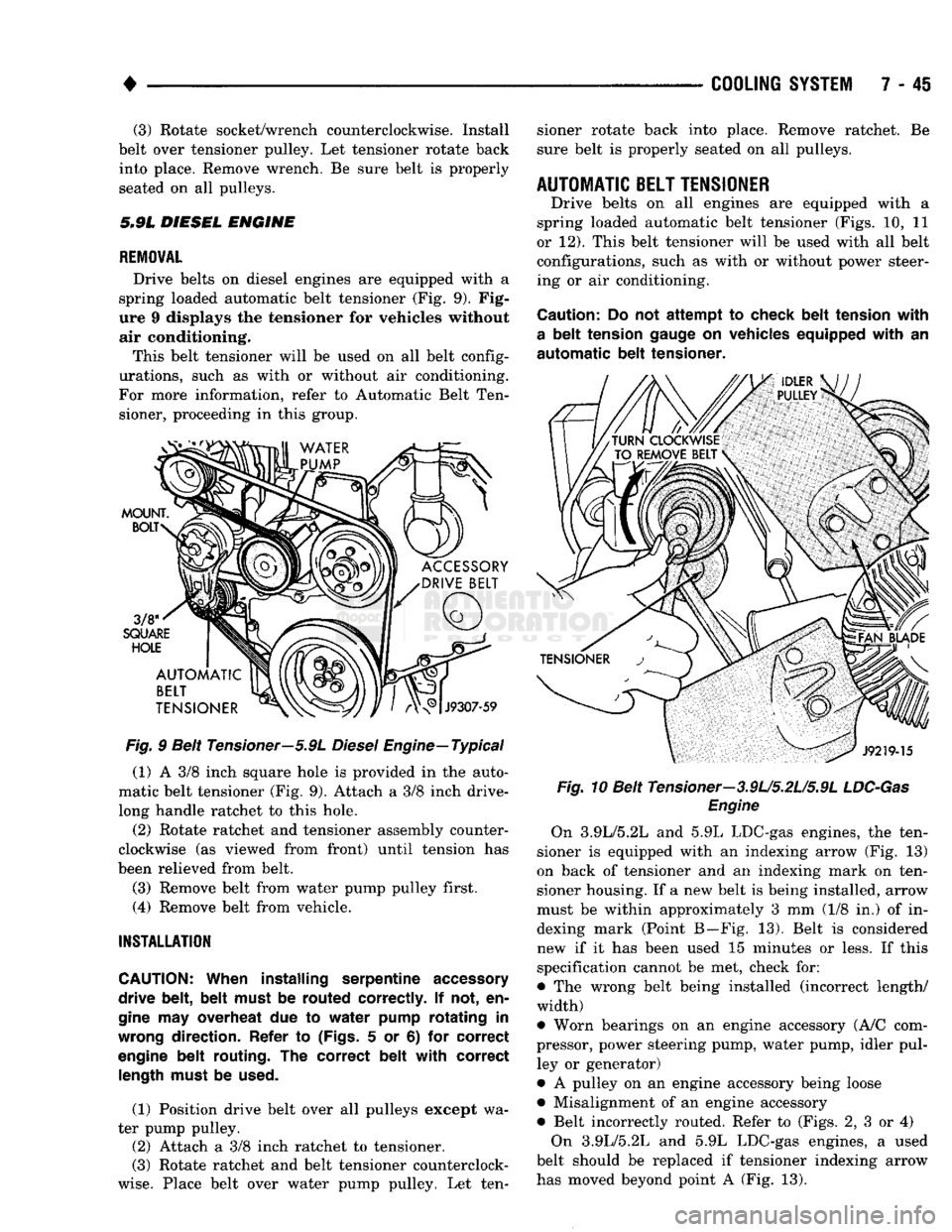

7 - 45 (3) Rotate socket/wrench counterclockwise. Install

belt over tensioner pulley. Let tensioner rotate back into place. Remove wrench. Be sure belt is properly

seated on all pulleys.

5«9L

DIESEL ENGINE

REMOVAL

Drive belts on diesel engines are equipped with a

spring loaded automatic belt tensioner (Fig. 9). Fig

ure 9 displays the tensioner for vehicles without air conditioning.

This belt tensioner will be used on all belt config

urations, such as with or without air conditioning.

For more information, refer to Automatic Belt Ten sioner, proceeding in this group.

Fig.

9 Belt Tensioner—5.9L

Diesel

Engine—Typical

(1) A 3/8 inch square hole is provided in the auto

matic belt tensioner (Fig. 9). Attach a 3/8 inch drive-

long handle ratchet to this hole.

(2) Rotate ratchet and tensioner assembly counter

clockwise (as viewed from front) until tension has

been relieved from belt.

(3) Remove belt from water pump pulley first.

(4) Remove belt from vehicle.

INSTALLATION

CAUTION:

When installing serpentine

accessory

drive belt, belt must

be

routed correctly.

If not, en

gine

may

overheat

due to

water pump rotating

in

wrong

direction. Refer

to

(Figs.

5 or 6) for

correct

engine

belt routing.

The

correct belt with correct

length

must

be

used.

(1) Position drive belt over all pulleys except wa

ter pump pulley. (2) Attach a 3/8 inch ratchet to tensioner.

(3) Rotate ratchet and belt tensioner counterclock

wise.

Place belt over water pump pulley. Let ten sioner rotate back into place. Remove ratchet. Be

sure belt is properly seated on all pulleys.

AUTOMATIC

BELT

TENSIONER

Drive belts on all engines are equipped with a

spring loaded automatic belt tensioner (Figs. 10, 11

or 12). This belt tensioner will be used with all belt configurations, such as with or without power steer

ing or air conditioning.

Caution:

Do not

attempt

to

check belt tension with

a

belt tension

gauge

on

vehicles equipped with

an

automatic

belt tensioner. Fig.

10 Belt Tensioner—3.9U5.2U5.9L

LDC-Gas

Engine

On 3.9L/5.2L and 5.9L LDC-gas engines, the ten

sioner is equipped with an indexing arrow (Fig. 13)

on back of tensioner and an indexing mark on ten

sioner housing. If a new belt is being installed, arrow

must be within approximately 3 mm (1/8 in.) of in dexing mark (Point B—Fig. 13). Belt is considered

new if it has been used 15 minutes or less. If this

specification cannot be met, check for:

• The wrong belt being installed (incorrect length/

width)

• Worn bearings on an engine accessory (A/C com

pressor, power steering pump, water pump, idler pul ley or generator)

• A pulley on an engine accessory being loose

• Misalignment of an engine accessory

• Belt incorrectly routed. Refer to (Figs. 2, 3 or 4) On 3.9L/5.2L and 5.9L LDC-gas engines, a used

belt should be replaced if tensioner indexing arrow

has moved beyond point A (Fig. 13).

Page 338 of 1502

•

ELECTRICAL

8A - 17

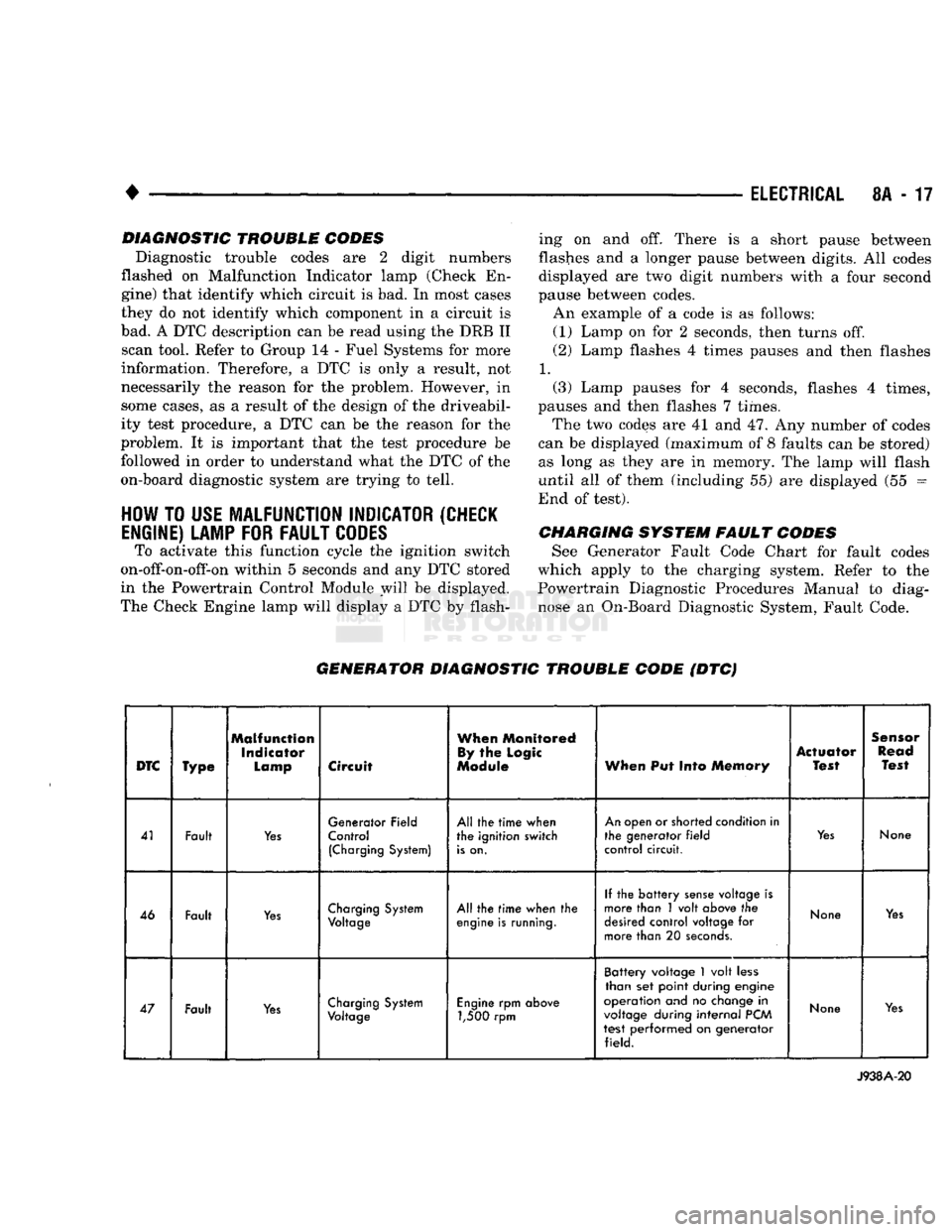

DIAGNOSTIC

TROUBLE

CODES

Diagnostic trouble codes are 2 digit numbers

flashed on Malfunction Indicator lamp (Check En

gine) that identify which circuit is bad. In most cases

they do not identify which component in a circuit is

bad. A DTC description can be read using the DRB II scan tool. Refer to Group 14 - Fuel Systems for more

information. Therefore, a DTC is only a result, not

necessarily the reason for the problem. However, in

some cases, as a result of the design of the driveabil- ity test procedure, a DTC can be the reason for the

problem. It is important that the test procedure be followed in order to understand what the DTC of the

on-board diagnostic system are trying to tell.

HOW

TO

USE

MALFUNCTION

INDICATOR

(CHECK

ENGINE)

LAMP

FOR

FAULT

CODES

To activate this function cycle the ignition switch

on-off-on-off-on within 5 seconds and any DTC stored

in the Powertrain Control Module will be displayed.

The Check Engine lamp will display a DTC by flash ing on and off. There is a short pause between

flashes and a longer pause between digits. All codes

displayed are two digit numbers with a four second

pause between codes. An example of a code is as follows:

(1) Lamp on for 2 seconds, then turns off.

(2) Lamp flashes 4 times pauses and then flashes

1.

(3) Lamp pauses for 4 seconds, flashes 4 times,

pauses and then flashes 7 times.

The two codes are 41 and 47. Any number of codes

can be displayed (maximum of 8 faults can be stored) as long as they are in memory. The lamp will flash

until all of them (including 55) are displayed (55 =

End of test).

CHARGING

SYSTEM

FAULT

CODES

See Generator Fault Code Chart for fault codes

which apply to the charging system. Refer to the

Powertrain Diagnostic Procedures Manual to diag

nose an On-Board Diagnostic System, Fault Code.

GENERATOR

DIAGNOSTIC

TROUBLE

CODE

(DTC)

DTC

Type

Malfunction

Indicator

Lamp

Circuit

When

Monitored

By

the

Logic

Module

When

Put Into

Memory

Actuator

Test

Sensor

Read

Test

41 Fault

Yes

Generator Field

Control

(Charging

System)

All the

time

when

the ignition switch

is

on.

An

open or shorted condition in

the generator

field

control circuit.

Yes

None

46 Fault

Yes

Charging

System

Voltage

All the

time

when the

engine

is

running.

If the

battery

sense

voltage is

more than 1 volt

above

the

desired

control voltage for

more than 20

seconds.

None

Yes

47 Fault

Yes

Charging

System

Voltage

Engine

rpm

above

1,500 rpm Battery voltage

1

volt

less

than set point during engine

operation and no

change

in

voltage

during

internal

PCM

test performed on generator field.

None

Yes

J938A-20

Page 342 of 1502

• BATTERY/STARTER/GENERATOR

SERVICE

8B - 1

CONTENTS

page page

BATTERY

SERVICE

PROCEDURES

1 SPECIFICATIONS 9

GENERATOR

SERVICE

6 STARTER

SERVICE

PROCEDURES

4

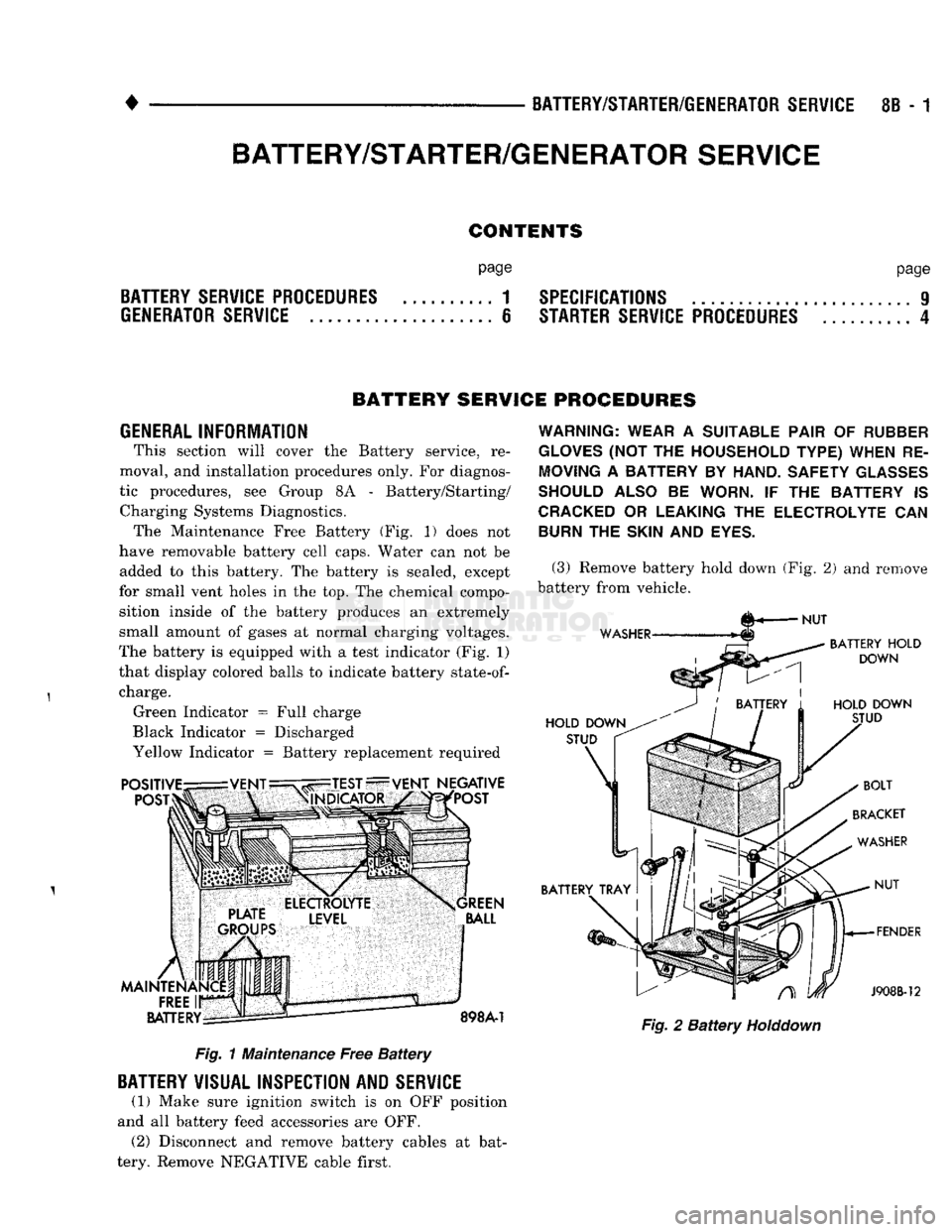

BATTERY SERVICE PROCEDURES

GENERAL

INFORMATION This section will cover the Battery service, re

moval, and installation procedures only. For diagnos

tic procedures, see Group 8A - Battery/Starting/ Charging Systems Diagnostics. The Maintenance Free Battery (Fig. 1) does not

have removable battery cell caps. Water can not be added to this battery. The battery is sealed, except

for small vent holes in the top. The chemical compo sition inside of the battery produces an extremely

small amount of gases at normal charging voltages.

The battery is equipped with a test indicator (Fig. 1)

that display colored balls to indicate battery

state-of-

charge. Green Indicator = Full charge

Black Indicator = Discharged

Yellow Indicator = Battery replacement required Fig. 1 Maintenance Free Battery

BATTERY

VISUAL INSPECTION AND

SERVICE

(1) Make sure ignition switch is on OFF position

and all battery feed accessories are OFF. (2) Disconnect and remove battery cables at bat

tery. Remove NEGATIVE cable first.

WARNING: WEAR

A

SUITABLE PAIR

OF

RUBBER

GLOVES

(NOT THE

HOUSEHOLD TYPE) WHEN

RE

MOVING

A

BATTERY

BY

HAND. SAFETY

GLASSES

SHOULD ALSO

BE

WORN.

IF THE

BATTERY

IS

CRACKED

OR

LEAKING

THE

ELECTROLYTE

CAN

BURN

THE

SKIN

AND

EYES.

(3) Remove battery hold down (Fig. 2) and remove

battery from vehicle. Fig. 2 Battery

Holddown

BATTERY/STARTER/GENERATOR

SERVICE

Page 359 of 1502

8D

- 8

IGNITION

SYSTEMS

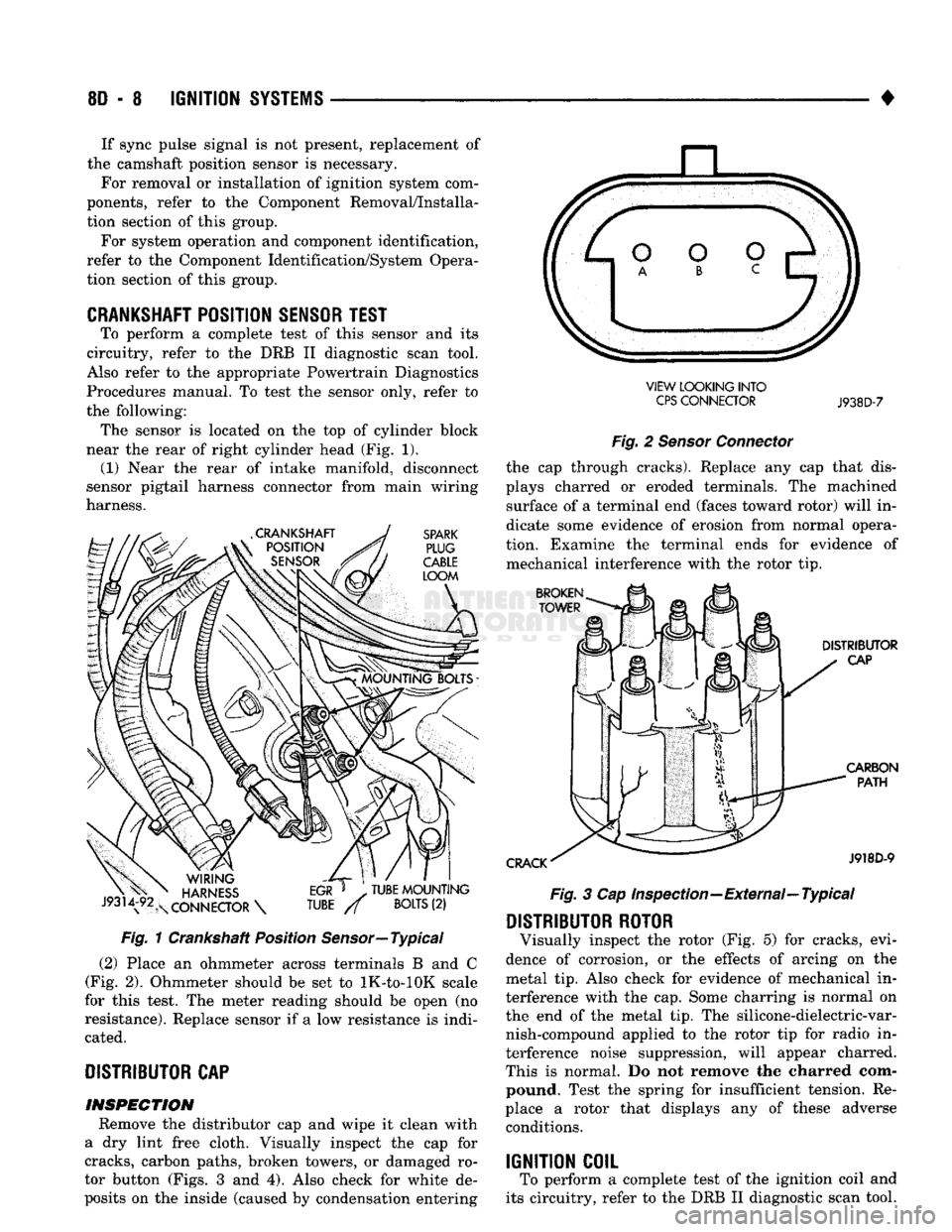

• If sync pulse signal is not present, replacement of

the camshaft position sensor is necessary. For removal or installation of ignition system com

ponents, refer to the Component Removal/Installa

tion section of this group.

For system operation and component identification,

refer to the Component Identification/System Opera

tion section of this group.

CRANKSHAFT POSITION

SENSOR

TEST

To perform a complete test of this sensor and its

circuitry, refer to the DRB II diagnostic scan tool.

Also refer to the appropriate Powertrain Diagnostics

Procedures manual. To test the sensor only, refer to

the following: The sensor is located on the top of cylinder block

near the rear of right cylinder head (Fig. 1). (1) Near the rear of intake manifold, disconnect

sensor pigtail harness connector from main wiring

harness. Fig. 1 Crankshaft Position Sensor—Typical

(2) Place an ohmmeter across terminals B and C

(Fig. 2). Ohmmeter should be set to lK-to-lOK scale

for this test. The meter reading should be open (no

resistance). Replace sensor if a low resistance is indi cated.

DISTRIBUTOR

CAP INSPECTION Remove the distributor cap and wipe it clean with

a dry lint free cloth. Visually inspect the cap for

cracks, carbon paths, broken towers, or damaged ro

tor button (Figs. 3 and 4). Also check for white de

posits on the inside (caused by condensation entering VIEW LOOKING INTO

CPS

CONNECTOR

J938D-7

Fig. 2 Sensor Connector the cap through cracks). Replace any cap that dis

plays charred or eroded terminals. The machined surface of a terminal end (faces toward rotor) will in

dicate some evidence of erosion from normal opera

tion. Examine the terminal ends for evidence of mechanical interference with the rotor tip. Fig. 3 Cap Inspection—External—Typical

DISTRIBUTOR ROTOR

Visually inspect the rotor (Fig. 5) for cracks, evi

dence of corrosion, or the effects of arcing on the

metal tip. Also check for evidence of mechanical in

terference with the cap. Some charring is normal on

the end of the metal tip. The silicone-dielectric-var nish-compound applied to the rotor tip for radio in

terference noise suppression, will appear charred.

This is normal. Do not remove the charred com pound. Test the spring for insufficient tension. Re

place a rotor that displays any of these adverse conditions.

IGNITION COIL

To perform a complete test of the ignition coil and

its circuitry, refer to the DRB II diagnostic scan tool.

Page 365 of 1502

8D

- 14

IGNITION SYSTEMS

• (5) Test the MAP sensor ground circuit at sensor

connector terminal-A (Fig. 19) and PCM connector

terminal-4. Repair the wire harness if necessary.

(6) Test the MAP sensor ground circuit at the

PCM connector between terminal-4 and terminal-11

with an ohmmeter. If the ohmmeter indicates an

open circuit, inspect for a defective sensor ground

connection. Refer to Group 8W, Wiring for location of

this connection. If the ground connection is good, re

place the PCM. If terminal-4 has a short circuit to 12 volts +, correct this condition before replacing the

PCM.

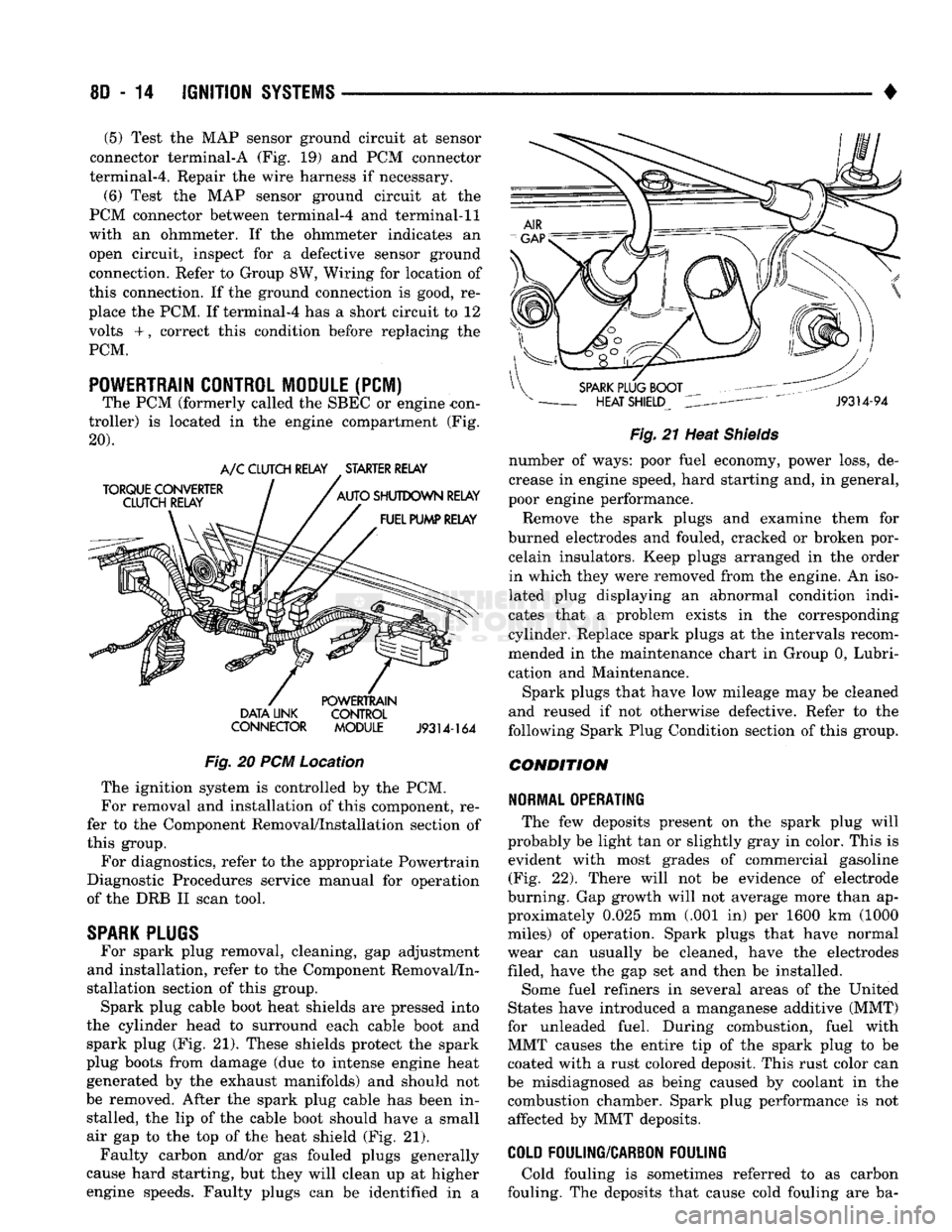

POWERTRAIN

CONTROL MODULE {PCM)

The PCM (formerly called the SBEC or engine -con

troller) is located in the engine compartment (Fig.

20). DATA UNK CONTROL

CONNECTOR MODULE

J9314-164

Fig.

20 PCM Location The ignition system is controlled by the PCM.

For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

For diagnostics, refer to the appropriate Powertrain

Diagnostic Procedures service manual for operation

of the DRB II scan tool.

SPARK

PLUGS

For spark plug removal, cleaning, gap adjustment

and installation, refer to the Component Removal/In

stallation section of this group. Spark plug cable boot heat shields are pressed into

the cylinder head to surround each cable boot and

spark plug (Fig. 21). These shields protect the spark

plug boots from damage (due to intense engine heat

generated by the exhaust manifolds) and should not

be removed. After the spark plug cable has been in stalled, the lip of the cable boot should have a small

air gap to the top of the heat shield (Fig. 21). Faulty carbon and/or gas fouled plugs generally

cause hard starting, but they will clean up at higher

engine speeds. Faulty plugs can be identified in a

Fig.

21 Heat

Shields

number of ways: poor fuel economy, power loss, de

crease in engine speed, hard starting and, in general,

poor engine performance.

Remove the spark plugs and examine them for

burned electrodes and fouled, cracked or broken por celain insulators. Keep plugs arranged in the order

in which they were removed from the engine. An iso

lated plug displaying an abnormal condition indi

cates that a problem exists in the corresponding

cylinder. Replace spark plugs at the intervals recom

mended in the maintenance chart in Group 0, Lubri

cation and Maintenance.

Spark plugs that have low mileage may be cleaned

and reused if not otherwise defective. Refer to the

following Spark Plug Condition section of this group.

CONDITION

NORMAL OPERATING

The few deposits present on the spark plug will

probably be light tan or slightly gray in color. This is evident with most grades of commercial gasoline (Fig. 22). There will not be evidence of electrode

burning. Gap growth will not average more than ap proximately 0.025 mm (.001 in) per 1600 km (1000

miles) of operation. Spark plugs that have normal

wear can usually be cleaned, have the electrodes filed, have the gap set and then be installed.

Some fuel refiners in several areas of the United

States have introduced a manganese additive (MMT)

for unleaded fuel. During combustion, fuel with

MMT causes the entire tip of the spark plug to be coated with a rust colored deposit. This rust color can

be misdiagnosed as being caused by coolant in the combustion chamber. Spark plug performance is not affected by MMT deposits.

COLD

FOULING/CARBON FOULING

Cold fouling is sometimes referred to as carbon

fouling. The deposits that cause cold fouling are ba-

Page 384 of 1502

•

INSTRUMENT PANEL

AND

GAUGES

8E - 3

MALFUNCTION INDICATOR (CHECK ENGINE)

Fig.

5

Distance Sensor

If

the

input from

one of the

following sensors fails

an internal Powertrain Control Module

(PCM)

self

check,

the PCM

turns

on the

Check Engine Lamp. The

PCM

then substitutes

a

modified signal

in

place

of

the one

that failed until

a

repair

is

made:

• Manifold Absolute Pressure (MAP) Sensor

• Throttle Position Sensor

• Coolant Temperature Sensor

• Battery Voltage Sense

• Battery Voltage

Too

High

Refer

to the

appropriate Powertrain Diagnostic

Test Procedures manual

for

further information.

ELECTRONIC DIGITAL CLOCK

The electronic digital clock

is in the

radio.

The

clock

and

radio each

use the

display panel built into

the radio.

A

digital readout indicates

the

time

in

hours

and

minutes whenever

the

ignition switch

is in

the

ON or ACC

position. When

the

ignition switch

is in the OFF

position

or

when

the

radio frequency

is

being displayed, time keeping

is

accurately maintained. The procedure

for

setting

the

clock varies slightly

with each radio.

The

correct procedure

is

described under

the

individual radio operating instructions

re

ferred

to in the

Owner Manual supplied with

the ve

hicle.

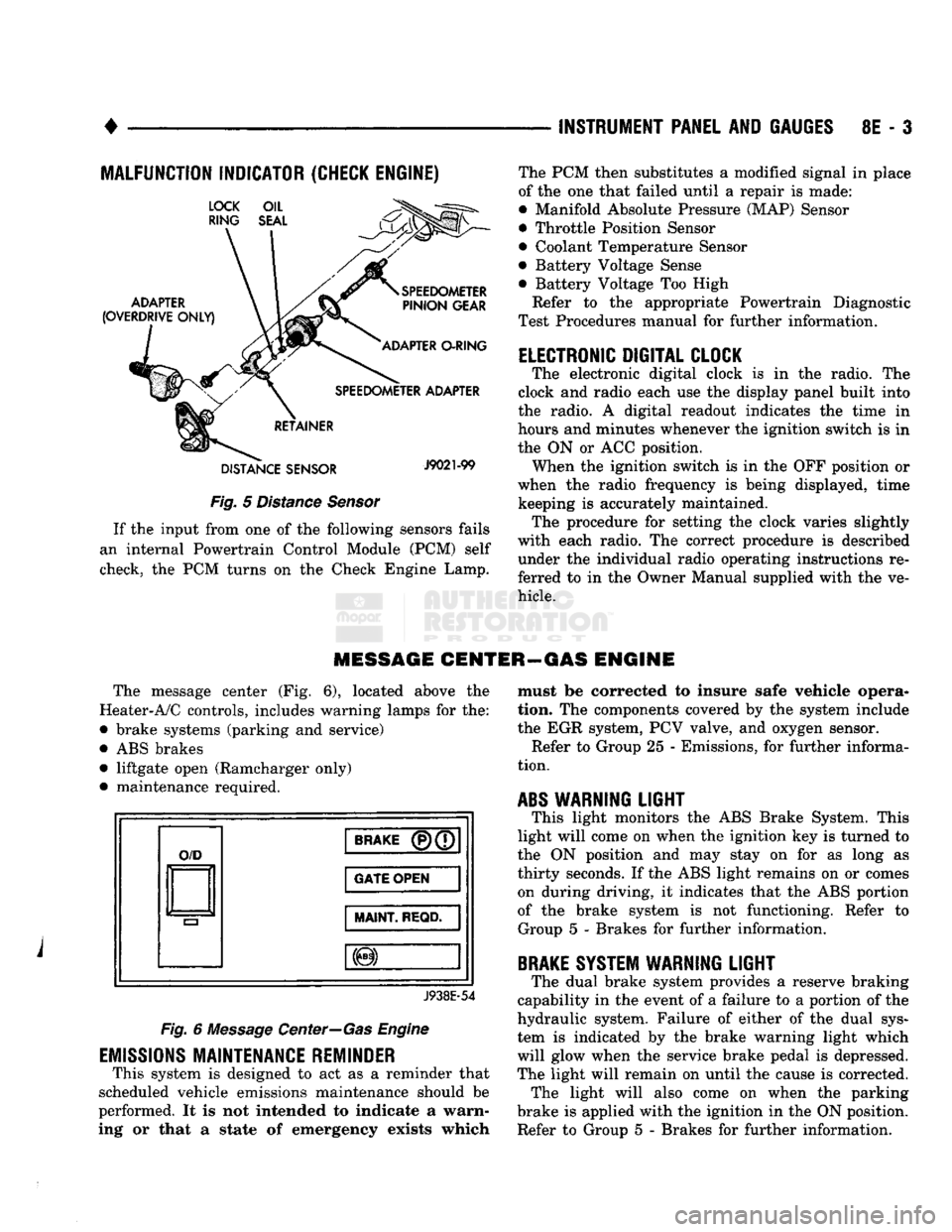

MESSAGE CENTER—GAS ENGINE

The message center

(Fig. 6),

located above

the

Heater-A/C controls, includes warning lamps

for the:

• brake systems (parking

and

service)

•

ABS

brakes • liftgate open (Ramcharger only)

• maintenance required.

O/D

BRAKE

(P)(7

GATE OPEN

MAINT

REQD.

J938E-54

Fig.

6

Message Center—Gas Engine

EMISSIONS

MAINTENANCE REMINDER

This system

is

designed

to act as a

reminder that

scheduled vehicle emissions maintenance should

be

performed.

It is not

intended

to

indicate

a

warn

ing

or

that

a

state

of

emergency exists which must

be

corrected

to

insure safe vehicle opera

tion.

The

components covered

by the

system include

the

EGR

system,

PCV

valve,

and

oxygen sensor. Refer

to

Group

25 -

Emissions,

for

further informa

tion.

ABS

WARNING

LIGHT

This light monitors

the ABS

Brake System. This

light will come

on

when

the

ignition

key is

turned

to

the

ON

position

and may

stay

on for as

long

as

thirty seconds.

If the ABS

light remains

on or

comes on during driving,

it

indicates that

the ABS

portion

of

the

brake system

is not

functioning. Refer

to

Group

5 -

Brakes

for

further information.

BRAKE

SYSTEM WARNING

LIGHT

The dual brake system provides

a

reserve braking

capability

in the

event

of a

failure

to a

portion

of the

hydraulic system. Failure

of

either

of the

dual sys

tem

is

indicated

by the

brake warning light which

will glow when

the

service brake pedal

is

depressed.

The light will remain

on

until

the

cause

is

corrected. The light will also come

on

when

the

parking

brake

is

applied with

the

ignition

in the ON

position.

Refer

to

Group

5 -

Brakes

for

further information.