fuel lines DODGE TRUCK 1993 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 191 of 1502

5

- 4

BRAKES

• (3) During road test, make normal and firm brake

stops in 25-40 mph (40-64 Km/h) range. Note faulty

brake operation such as pull, grab, drag, noise, low

pedal, etc.

(4) Inspect suspect brake components and refer to

problem diagnosis information for causes of various

brake conditions.

COMPONENT

INSPECTION

Fluid leak points and dragging brake units can usu

ally be located without removing any components. The

area around a leak point will be wet with fluid. The

components at a dragging brake unit (wheel, tire, rotor)

will be quite warm or hot to the touch.

Other brake problem conditions will require compo

nent removal for proper inspection. Raise the vehicle and remove the necessary wheels for better visual ac

cess.

DIAGNOSING BRAKE

PROBLEMS

PEDAL FALLS

AWAY

A

brake pedal that falls away under steady foot

pressure is the result of a system leak. The leak

point could be at a brakeline, fitting, hose, or caliper. Internal leakage in the master cylinder caused by

worn or damaged piston cups, may also be the prob lem cause.

If leakage is severe, fluid will be evident at or around

the leaking component. However, internal leakage in

the master cylinder may not be physically evident. Re fer to the cylinder test procedure in this section.

LOW PEDAL

If a low pedal is experienced, pump the pedal sev

eral times. If the pedal comes back up, worn lining

and worn rotors or drums are the likely causes.

A decrease in fluid level in the master cylinder res

ervoirs may only be the result of normal lining wear.

Fluid level can be expected to decrease in proportion to wear. It is a result of the outward movement of

caliper and wheel cylinder pistons to compensate for

normal wear. Top off the reservoir fluid level and

check brake operation to verify proper brake action.

SPONGY PEDAL. A spongy pedal is most often caused by air in the sys

tem. Thin brake drums or substandard brake lines and

hoses can also cause a spongy pedal. The proper course

of action is to bleed the system and replace thin drums and suspect quality brake lines and hoses.

HARD PEDAL

OR

HIGH

PEDAL

EFFORT

A hard pedal or high pedal effort may be due to

lining that is water soaked, contaminated, glazed, or

badly worn. The power booster or check valve could also be faulty. On diesel engine models, high pedal effort may be

the result of a low vacuum condition. If the booster and check valve are OK, the problem may be related

to a vacuum pump hose, hose connection, hose fit

ting, pump diaphragm, or drive gear. Vacuum pump output can be checked with a standard vacuum

gauge. Vacuum output should range from 8.5 to 25 inches vacuum. If vacuum pump output is within

limits,

check the power booster and check valve as

described in this section.

BRAKE DRAG

Brake drag occurs when the lining is in constant

contact with the rotor or drum. Drag can occur at

one wheel, all wheels, fronts only, or rears only. It is a product of incomplete brakeshoe release. Drag can

be minor or severe enough to overheat the linings,

rotors and drums.

Brake drag can also effect fuel economy. If undetec

ted, minor brake drag can be misdiagnosed as an en gine or transmission/torque converter problem.

Minor drag will usually cause slight surface charring

of the lining. It can also generate hard spots in rotors and drums from the overheat-cool down process. In most

cases,

the rotors, drums, wheels and tires are quite

warm to the touch after the vehicle is stopped.

Severe drag can char the brake lining all the way

through. It can also distort and score rotors and drums to the point of replacement. The wheels, tires and brake components will be extremely hot. In se

vere cases, the lining may generate smoke as it chars

from overheating.

Some common causes of brake drag are:

• seized or improperly adjusted parking brake cables

• loose/worn wheel bearing

• seized caliper or wheel cylinder piston

• caliper binding on corroded bushings or rusted

slide surfaces

• loose caliper mounting bracket

• drum brakeshoes binding on worn or damaged sup

port plates

• misassembled components. If brake drag occurs at all wheels, the problem may

be related to a blocked master cylinder return port, or faulty power booster that binds and does not release.

BRAKE FADE

Brake fade is a product of overheating caused by

brake drag. However, brake overheating and subse quent fade can also be caused by riding the brake

pedal, making repeated high deceleration stops in a short time span, or constant braking on steep moun

tain roads. Refer to the Brake Drag information in

this section for additional causes.

PEDAL

PULSA

TION

Pedal pulsation is caused by components that are

loose, out of round, or worn beyond tolerance limits.

Page 291 of 1502

7 - 20

COOLING

SYSTEM

•

HOSE

CLAMP

HOSE

J9207-36

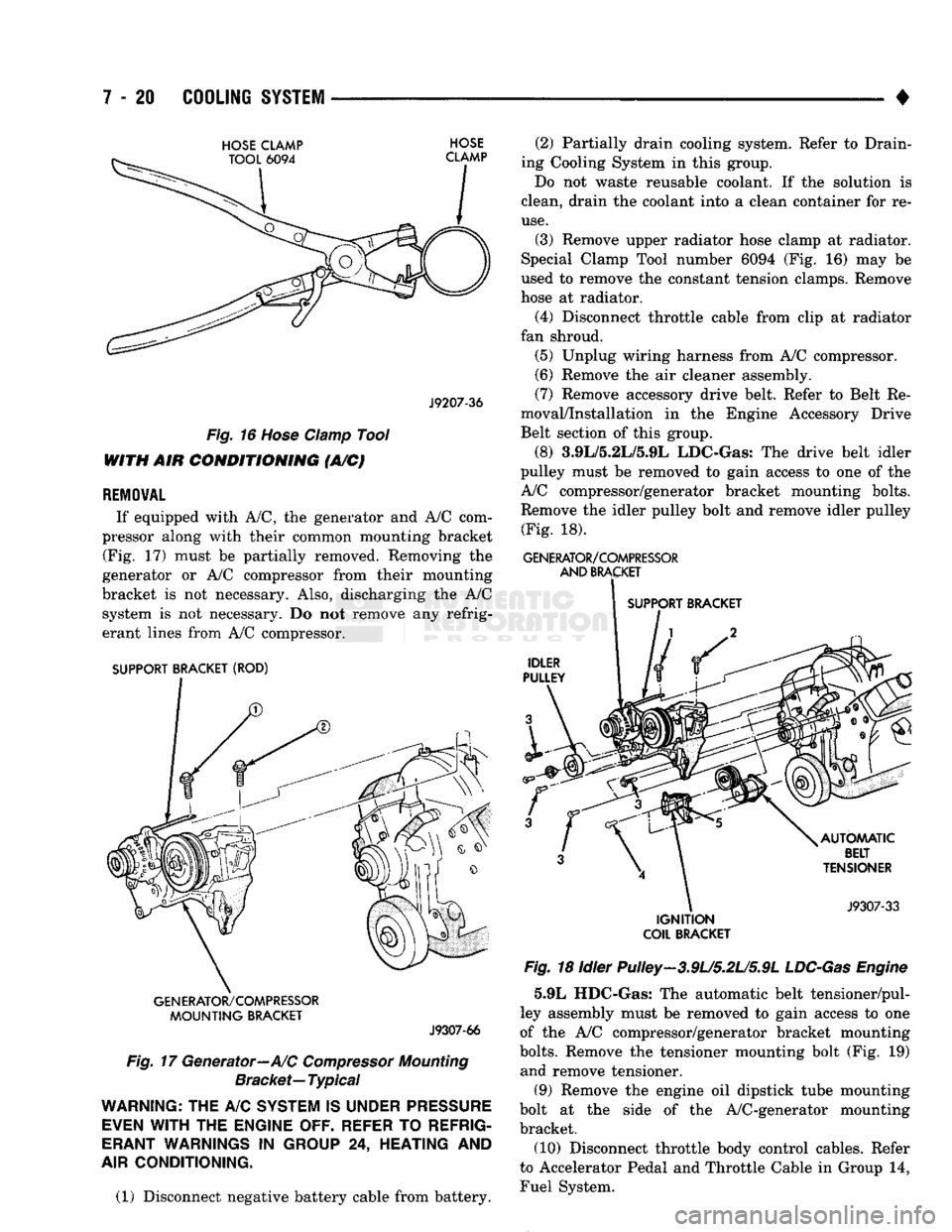

Fig.

16

Hose

Clamp

Tool

WITH AIR

CONDITIONING

(A/C)

REMOVAL

If equipped with A/C, the generator and A/C com

pressor along with their common mounting bracket (Fig. 17) must be partially removed. Removing the

generator or A/C compressor from their mounting

bracket is not necessary. Also, discharging the A/C system is not necessary. Do not remove any refrig

erant lines from A/C compressor.

SUPPORT BRACKET (ROD)

GENERATOR/COMPRESSOR

MOUNTING

BRACKET

J9307-66

Fig.

17 Generator—A/C

Compressor

Mounting

Bracket—

Typical

WARNING;

THE A/C

SYSTEM

IS

UNDER

PRESSURE

EVEN

WITH

THE

ENGINE OFF. REFER

TO

REFRIG

ERANT

WARNINGS

IN

GROUP

24,

HEATING

AND

AIR

CONDITIONING.

(1) Disconnect negative battery cable from battery. (2) Partially drain cooling system. Refer to Drain

ing Cooling System in this group.

Do not waste reusable coolant. If the solution is

clean, drain the coolant into a clean container for re

use.

(3) Remove upper radiator hose clamp at radiator.

Special Clamp Tool number 6094 (Fig. 16) may be

used to remove the constant tension clamps. Remove

hose at radiator.

(4) Disconnect throttle cable from clip at radiator

fan shroud. (5) Unplug wiring harness from A/C compressor.

(6) Remove the air cleaner assembly.

(7) Remove accessory drive belt. Refer to Belt Re

moval/Installation in the Engine Accessory Drive

Belt section of this group.

(8) 3.9L/5.2L/5.9L LDC-Gas: The drive belt idler

pulley must be removed to gain access to one of the

A/C compressor/generator bracket mounting bolts. Remove the idler pulley bolt and remove idler pulley (Fig. 18).

GENERATOR/COMPRESSOR

AND

BRACKET

SUPPORT BRACKET

IGNITION

COIL

BRACKET

Fig.

18 Idler Pulley-3.9U5.2U5.9L

LDC-Gas

Engine

5.9L HDC-Gas: The automatic belt tensioner/pul-

ley assembly must be removed to gain access to one

of the A/C compressor/generator bracket mounting

bolts.

Remove the tensioner mounting bolt (Fig. 19) and remove tensioner.

(9) Remove the engine oil dipstick tube mounting

bolt at the side of the A/C-generator mounting

bracket.

(10) Disconnect throttle body control cables. Refer

to Accelerator Pedal and Throttle Cable in Group 14,

Fuel System.

Page 614 of 1502

•

ENGINES

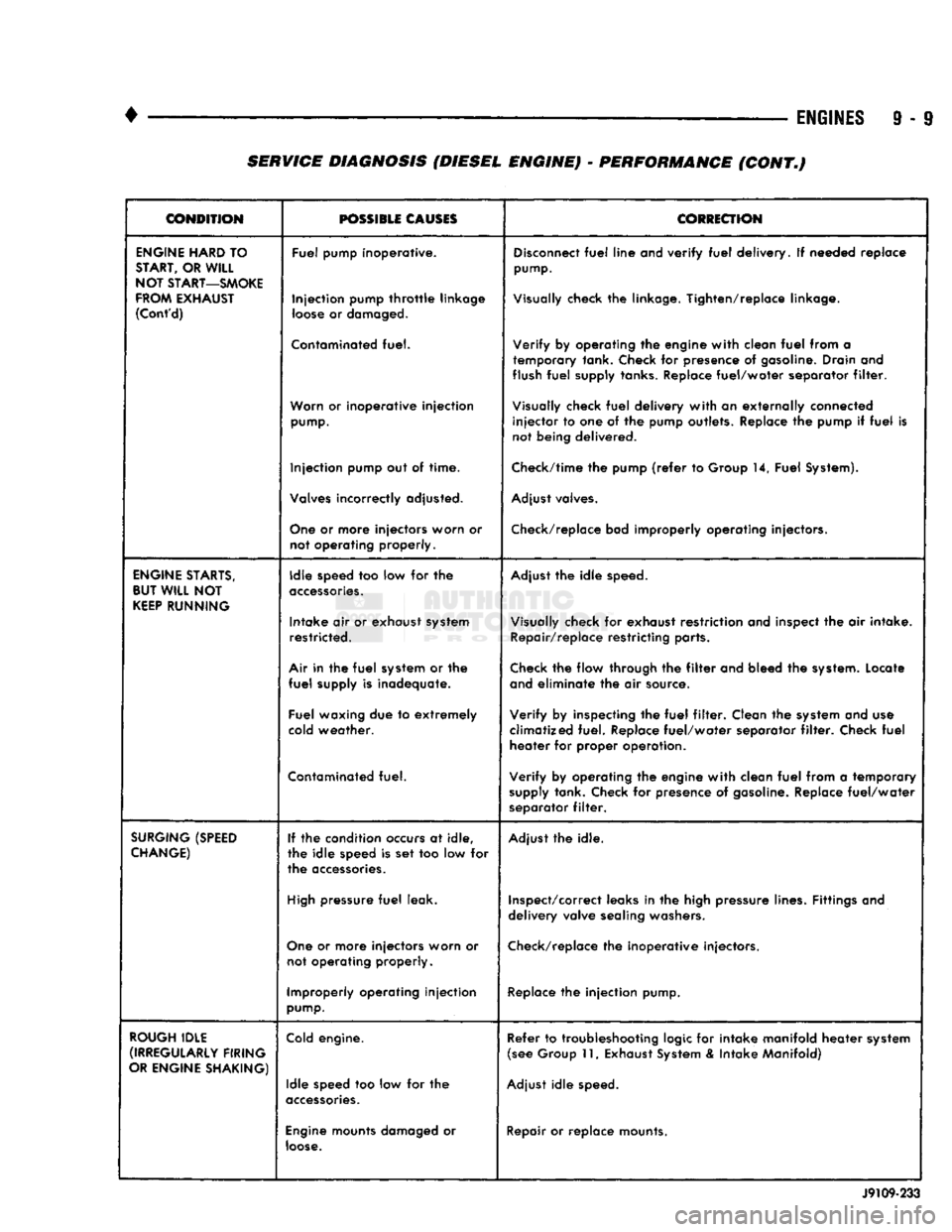

9 - 9 SERVICE DIAGNOSIS (DIESEL ENGINE) • PERFORMANCE (CONT.)

CONDITION

POSSIBLE

CAUSES

CORRECTION

ENGINE

HARD

TO

START,

OR

WILL

NOT

START—SMOKE

FROM

EXHAUST

(Cont'd)

Fuel pump Inoperative.

Injection pump

throttle

linkage

loose

or

damaged.

Contaminated

fuel.

Worn

or inoperative injection

pump.

Injection pump out of time.

Valves

incorrectly adjusted.

One

or more injectors worn or not operating properly.

Disconnect

fuel

line and verify

fuel

delivery. If needed replace

pump.

Visually

check the linkage. Tighten/replace linkage.

Verify by operating the engine with clean

fuel

from a temporary tank. Check for presence of

gasoline.

Drain and

flush

fuel

supply tanks.

Replace

fuel/water separator

filter.

Visually

check

fuel

delivery with an externally connected injector to one of the pump outlets. Replace the pump if

fuel

is

not being delivered.

Check/time

the pump

(refer

to Group 14, Fuel

System).

Adjust

valves.

Check/replace

bad improperly operating injectors.

ENGINE

STARTS,

BUT

WILL

NOT

KEEP

RUNNING

Idle speed too low for the

accessories.

Intake air or exhaust

system

restricted.

Air

in the

fuel

system

or the

fuel

supply is inadequate.

Fuel waxing due to extremely

cold

weather.

Contaminated

fuel.

Adjust

the idle

speed.

Visually

check for exhaust restriction and inspect the air intake.

Repair/replace restricting parts.

Check

the flow through the

filter

and bleed the

system.

Locate

and

eliminate the air source.

Verify by inspecting the

fuel

filter.

Clean the

system

and use

climatized fuel. Replace fuel/water separator

filter.

Check

fuel

heater for proper operation.

Verify by operating the engine with clean

fuel

from a temporary

supply

tank. Check for presence of

gasoline.

Replace fuel/water

separator

filter.

SURGING

(SPEED

CHANGE)

If the condition

occurs

at idle,

the idle speed is set too low for

the

accessories.

High

pressure

fuel

leak.

One

or more injectors worn or not operating properly.

Improperly operating injection

pump.

Adjust

the idle.

Inspect/correct

leaks in the high pressure lines. Fittings and

delivery valve

sealing

washers.

Check/replace

the inoperative injectors.

Replace

the injection pump.

ROUGH

IDLE

(IRREGULARLY

FIRING

OR

ENGINE

SHAKING)

Cold

engine.

Idle speed too low for the

accessories.

Engine

mounts

damaged

or

loose.

Refer to troubleshooting

logic

for intake manifold heater

system

(see

Group 11,

Exhaust

System

& Intake Manifold)

Adjust

idle

speed.

Repair

or replace mounts. J9109-233

Page 615 of 1502

9

- 10

ENGINES

— _

•

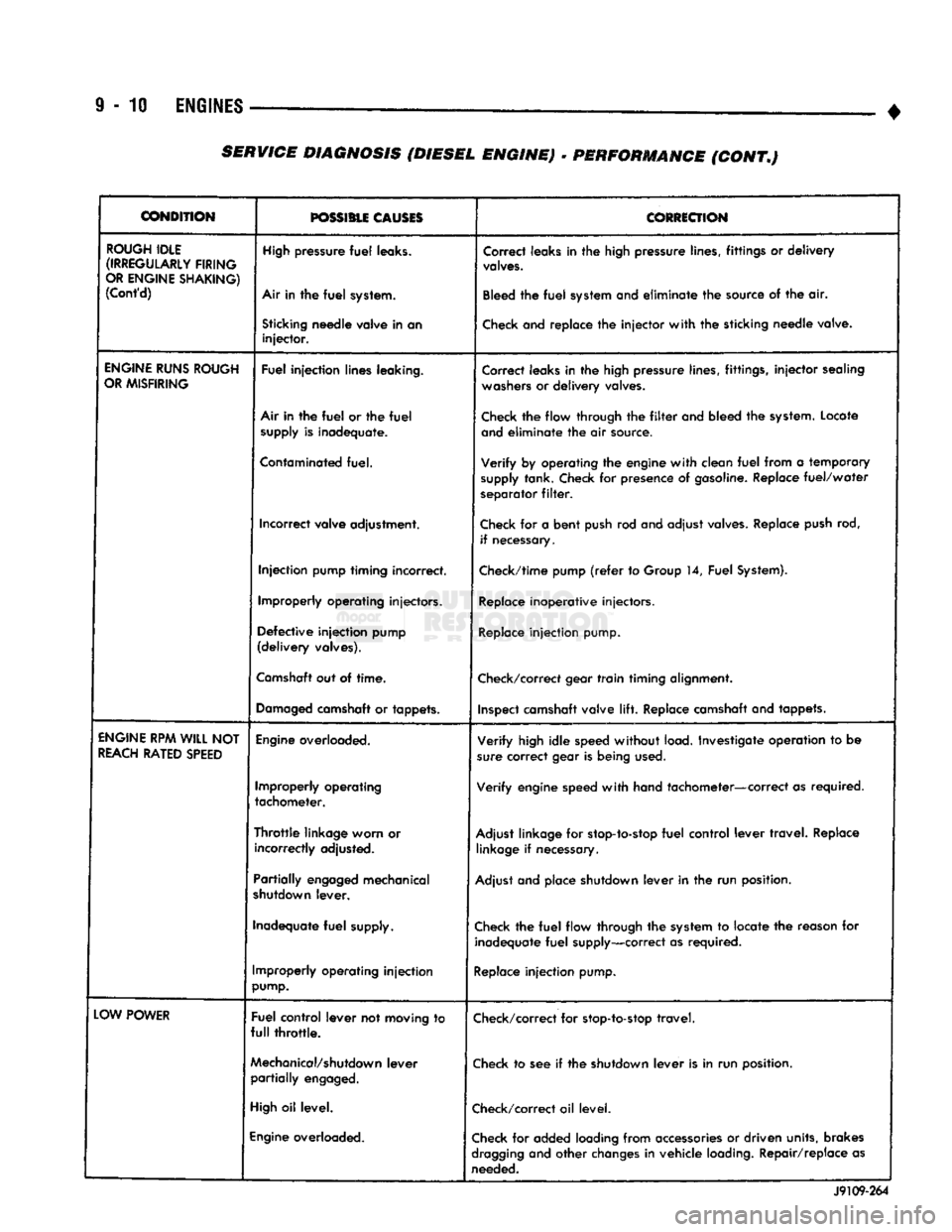

CONDITION

possmu

CLOSES

CORRECTION

ROUGH

IDLE

(IRREGULARLY

FIRING

OR

ENGINE

SHAKING)

(Cont'd)

High

pressure

fuel

leaks.

Air In the

fuel

system.

Correct leaks in the high pressure lines, fittings or

delivery

valves.

Bleed the

fuel

system and

eliminate

the source of the air.

Sticking

needle

valve

in an

injector.

Check and replace the

injector

with

the sticking

needle

valve.

ENGINE

RUNS

ROUGH

OR

MISFIRING

Fuel

injection

lines

leaking.

Correct leaks in the high pressure lines, fittings,

injector

sealing

washers

or

delivery

valves.

Air in the

fuel

or the

fuel

supply

is

inadequate.

Check the flow through the

filter

and bleed the system. Locate

and

eliminate

the air source.

Contaminated

fuel.

Verify

by operating the engine

with

clean

fuel

from a temporary

supply

tank. Check for presence of gasoline. Replace

fuel/water

separator

filter.

Incorrect

valve

adjustment.

Check for a

bent

push rod and adjust valves. Replace push rod,

if necessary.

Injection

pump

timing

incorrect.

Check/time pump

(refer

to Group 14,

Fuel

System).

Improperly

operating

injectors.

Replace inoperative injectors.

Defective

injection

pump

(delivery

valves).

Replace

injection

pump.

Camshaft

out of

time.

Check/correct gear

train

timing alignment.

Damaged

camshaft or

tappets.

Inspect camshaft valve

lift.

Replace camshaft and tappets.

ENGINE

RPM WILL NOT

REACH

RATED

SPEED

Engine

overloaded.

Verify

high

idle

speed

without

load. Investigate operation to be

sure correct gear is being used.

Improperly

operating

tachometer.

Verify

engine speed

with

hand tachometer—correct as required.

Throttle

linkage

worn

or

incorrectly

adjusted.

Adjust linkage for stop-to-stop

fuel

control

lever

travel.

Replace

linkage if necessary.

Partially

engaged

mechanical

shutdown

lever.

Adjust and place shutdown

lever

in the run position.

Inadequate

fuel

supply. Check the

fuel

flow through the system to locate the reason for

inadequate

fuel

supply—correct as required.

Improperly

operating

injection

pump.

Replace

injection

pump.

LOW

POWER

Fuel

control

lever

not

moving

to

full

throttle.

Check/correct for stop-to-stop

travel.

Mechanical/shutdown

lever

partially

engaged.

Check to see if the shutdown

lever

is in run position.

High

oil

level.

Check/correct oil level.

Engine

overloaded.

Check for added loading from accessories or driven units, brakes

dragging

and

other

changes in vehicle loading. Repair/replace as

needed.

J9109-264

SERVICE

DIAGNOSIS (DIESEL ENGINE)

•

PERFORMANCE (CONT.)

Page 616 of 1502

•

ENGINES

9 - 11 SERVICE DIAGNOSIS (DIESEL ENGINE) - PERFORMANCE (CONT.)

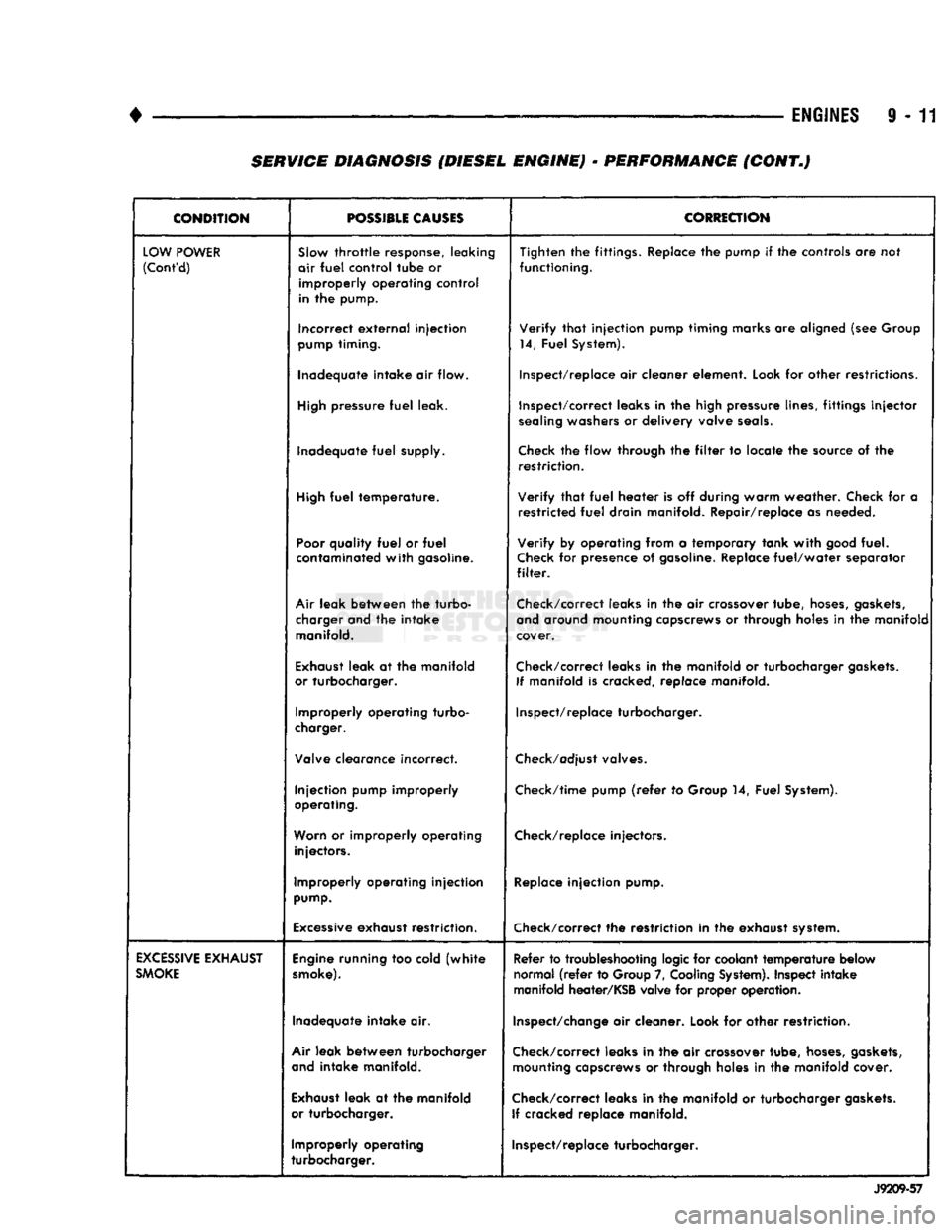

CONDITION

POSSIBLE

CAUSES

CORRECTION

LOW

POWER

(Cont'd)

SJow

throttle

response, leaking

air

fuel

control

tube

or

improperly

operating

control

in the pump. Tighten the fittings. Replace the pump if the controls are not

functioning.

Incorrect

external

injection

pump

timing. Verify

that

injection pump timing marks are aligned (see Group

14, Fuel System).

Inadequate intake air flow. Inspect/replace air cleaner element. Look for other restrictions.

High

pressure

fuel

leak. Inspect/correct leaks in the high pressure lines, fittings

injector

sealing

washers or delivery valve

seals.

Inadequate

fuel

supply.

Check

the flow through the

filter

to locate the source of the

restriction.

High

fuel

temperature. Verify

that

fuel

heater is off during warm weather. Check for a

restricted

fuel

drain manifold. Repair/replace as needed.

Poor

quality

fuel

or

fuel

contaminated

with

gasoline. Verify by operating from a temporary tank

with

good

fuel.

Check

for presence of

gasoline.

Replace

fuel/water

separator

filter.

Air

leak between the turbo- charger and the intake manifold. Check/correct leaks in the air crossover tube,

hoses,

gaskets,

and

around mounting capscrews or through holes in the manifold

cover.

Exhaust

leak at the manifold

or turbocharger. Check/correct leaks in the manifold or turbocharger

gaskets.

If manifold is cracked, replace manifold.

Improperly operating turbo-

charger. Inspect/replace turbocharger.

Valve clearance incorrect.

Check/adjust

valves.

Injection pump improperly

operating. Check/time pump

(refer

to Group 14, Fuel System).

Worn

or improperly operating injectors. Check/replace injectors.

Improperly operating injection

pump.

Replace

injection pump.

Excessive

exhaust restriction. Check/correct the restriction in the exhaust system.

EXCESSIVE

EXHAUST

SMOKE

Engine

running too cold

(white

smoke).

Refer to troubleshooting logic for coolant

temperature

below

normal

(refer

to Group 7,

Cooling

System).

Inspect intake

manifold heater/KSB valve for proper operation.

Inadequate intake air.

Inspect/change

air cleaner. Look for other restriction.

Air

leak between turbocharger

and

intake manifold. Check/correct leaks in the air crossover tube,

hoses,

gaskets,

mounting capscrews or through holes in the manifold cover.

Exhaust

leak at the manifold

or turbocharger. Check/correct leaks in the manifold or turbocharger

gaskets.

If cracked replace manifold.

Improperly operating

turbocharger. Inspect/replace turbocharger.

J9209-57

Page 625 of 1502

TRANSFER

CASE

INSULATOR

MOUNTING PLATE

NUT(B

RAIL

ASSEMBLY

SPACER

UPPER

INSULATOR

NUT®

LOWER

INSULATOR

J9109-242

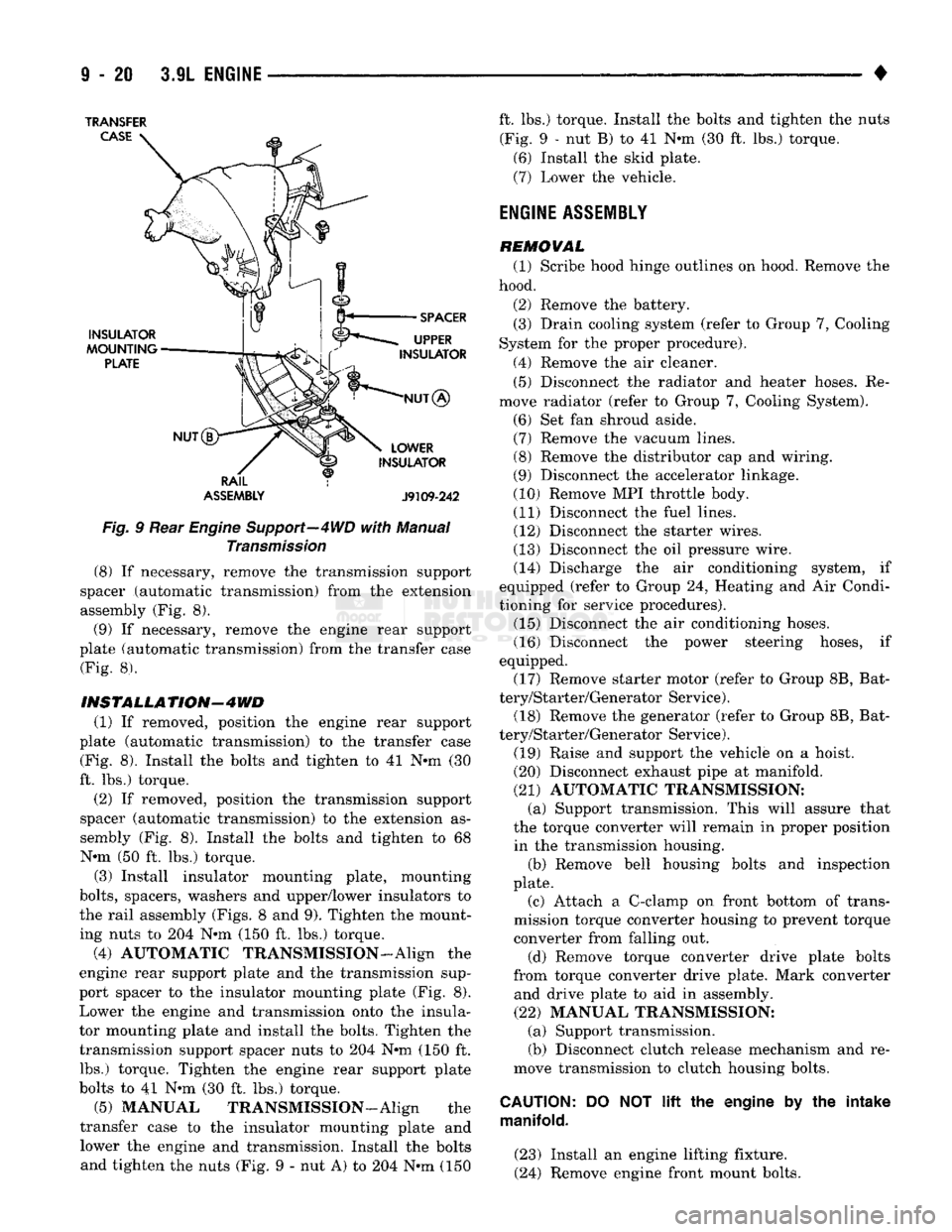

Fig.

9 Rear

Engine

Support—4WD

with

Manual

Transmission

(8) If necessary, remove the transmission support

spacer (automatic transmission) from the extension

assembly (Fig. 8).

(9) If necessary, remove the engine rear support

plate (automatic transmission) from the transfer case (Fig. 8).

INSTALLATION-4WD

(1) If removed, position the engine rear support

plate (automatic transmission) to the transfer case (Fig. 8). Install the bolts and tighten to 41 N-m (30

ft. lbs.) torque.

(2) If removed, position the transmission support

spacer (automatic transmission) to the extension as

sembly (Fig. 8). Install the bolts and tighten to 68 N-m (50 ft. lbs.) torque.

(3) Install insulator mounting plate, mounting

bolts,

spacers, washers and upper/lower insulators to

the rail assembly (Figs. 8 and 9). Tighten the mount

ing nuts to 204 N*m (150 ft. lbs.) torque.

(4) AUTOMATIC TRANSMISSION-Align the

engine rear support plate and the transmission sup

port spacer to the insulator mounting plate (Fig. 8). Lower the engine and transmission onto the insula

tor mounting plate and install the bolts. Tighten the transmission support spacer nuts to 204 N-m (150 ft. lbs.) torque. Tighten the engine rear support plate

bolts to 41 N-m (30 ft. lbs.) torque.

(5) MANUAL TRANSMISSION—Align the

transfer case to the insulator mounting plate and lower the engine and transmission. Install the bolts and tighten the nuts (Fig. 9 - nut A) to 204 N-m (150 ft. lbs.) torque. Install the bolts and tighten the nuts

(Fig. 9 - nut B) to 41 N-m (30 ft. lbs.) torque. (6) Install the skid plate.

(7) Lower the vehicle.

ENGINE

ASSEMBLY

REMOVAL (1) Scribe hood hinge outlines on hood. Remove the

hood.

(2) Remove the battery. (3) Drain cooling system (refer to Group 7, Cooling

System for the proper procedure).

(4) Remove the air cleaner. (5) Disconnect the radiator and heater hoses. Re

move radiator (refer to Group 7, Cooling System).

(6) Set fan shroud aside. (7) Remove the vacuum lines. (8) Remove the distributor cap and wiring.

(9) Disconnect the accelerator linkage.

(10) Remove MPI throttle body. (11) Disconnect the fuel lines. (12) Disconnect the starter wires.

(13) Disconnect the oil pressure wire. (14) Discharge the air conditioning system, if

equipped (refer to Group 24, Heating and Air Condi

tioning for service procedures). (15) Disconnect the air conditioning hoses.

(16) Disconnect the power steering hoses, if

equipped. (17) Remove starter motor (refer to Group 8B, Bat

tery/Starter/Generator Service). (18) Remove the generator (refer to Group 8B, Bat

tery/Starter/Generator Service).

(19) Raise and support the vehicle on a hoist.

(20) Disconnect exhaust pipe at manifold.

(21) AUTOMATIC TRANSMISSION: (a) Support transmission. This will assure that

the torque converter will remain in proper position in the transmission housing. (b) Remove bell housing bolts and inspection

plate.

(c) Attach a C-clamp on front bottom of trans

mission torque converter housing to prevent torque

converter from falling out.

(d) Remove torque converter drive plate bolts

from torque converter drive plate. Mark converter and drive plate to aid in assembly.

(22) MANUAL TRANSMISSION: (a) Support transmission.

(b) Disconnect clutch release mechanism and re

move transmission to clutch housing bolts.

CAUTION:

DO NOT

lift

the engine by the intake

manifold.

(23) Install an engine lifting fixture.

(24) Remove engine front mount bolts.

Page 626 of 1502

•

3.9L

ENGINE

9 - 21 (25) Lower the vehicle.

(26) On automatic transmission vehicles, discon

nect the engine from the torque converter drive

plate. On manual transmission vehicles, move engine forward until drive pinion shaft clears the clutch

disc.

Remove engine from engine compartment. (27) Install engine assembly on engine repair

stand.

INSTALLATION (1) Remove engine from the repair stand and posi

tion in the engine compartment.

(2) Install engine support fixture.

(3) Raise and support the vehicle on a hoist.

(4)

AUTOMATIC TRANSMISSION: (a) Position the torque converter and drive plate.

Install torque converter drive plate bolts. Tighten

the bolts to 31 Nnn (270 in. lbs.) torque.

(b) Install the engine front mounts.

(c) Install bell housing bolts. Tighten the bolts to

41 N-m (30 ft. lbs.) torque.

(d) Remove C-clamp.

(e) Install the inspection plate.

(5) MANUAL TRANSMISSION: (a) Position the drive pinion shaft to the clutch

disc.

(b) Connect the clutch release mechanism and

install the transmission to clutch bolts. Tighten the

bolts to 68 N-m (50 ft. lbs.) torque.

(c) Install the engine front mounts.

(6) Remove transmission support.

(7) Install exhaust pipe to manifold.

(8) Lower the vehicle.

(9) Remove engine lifting fixture.

(10) Install the generator (refer to Group 8B, Bat

tery/Starter/Generator Service). (11) Install starter motor (refer to Group 8B, Bat

tery/Starter/Generator Service). (12) Connect power steering hoses, if equipped.

(13) Connect air conditioning hoses.

(14) Evacuate and charge the air conditioning sys

tem, if equipped (refer to Group 24, Heater and Air Conditioning for service procedures). (15) Using a new gasket, install MPI throttle body.

Tighten the throttle body bolts to 23 N-m (200 in. lbs.) torque. (16) Connect the accelerator linkage.

(17) Connect the starter wires. (18) Connect the oil pressure wire.

(19) Install the distributor cap and wiring.

(20) Connect the vacuum lines.

(21) Connect the fuel lines.

(22) Install the radiator (refer to Group 7, Cooling

System). Connect the radiator hoses and heater

hoses.

(23) Install fan shroud in position. (24) Fill cooling system (refer to Group 7, Cooling

System for the proper procedures). (25) Install the air cleaner.

(26) Install the battery.

(27) Warm engine and adjust.

(28) Install hood and line up with the scribe

marks. (29) Road test vehicle.

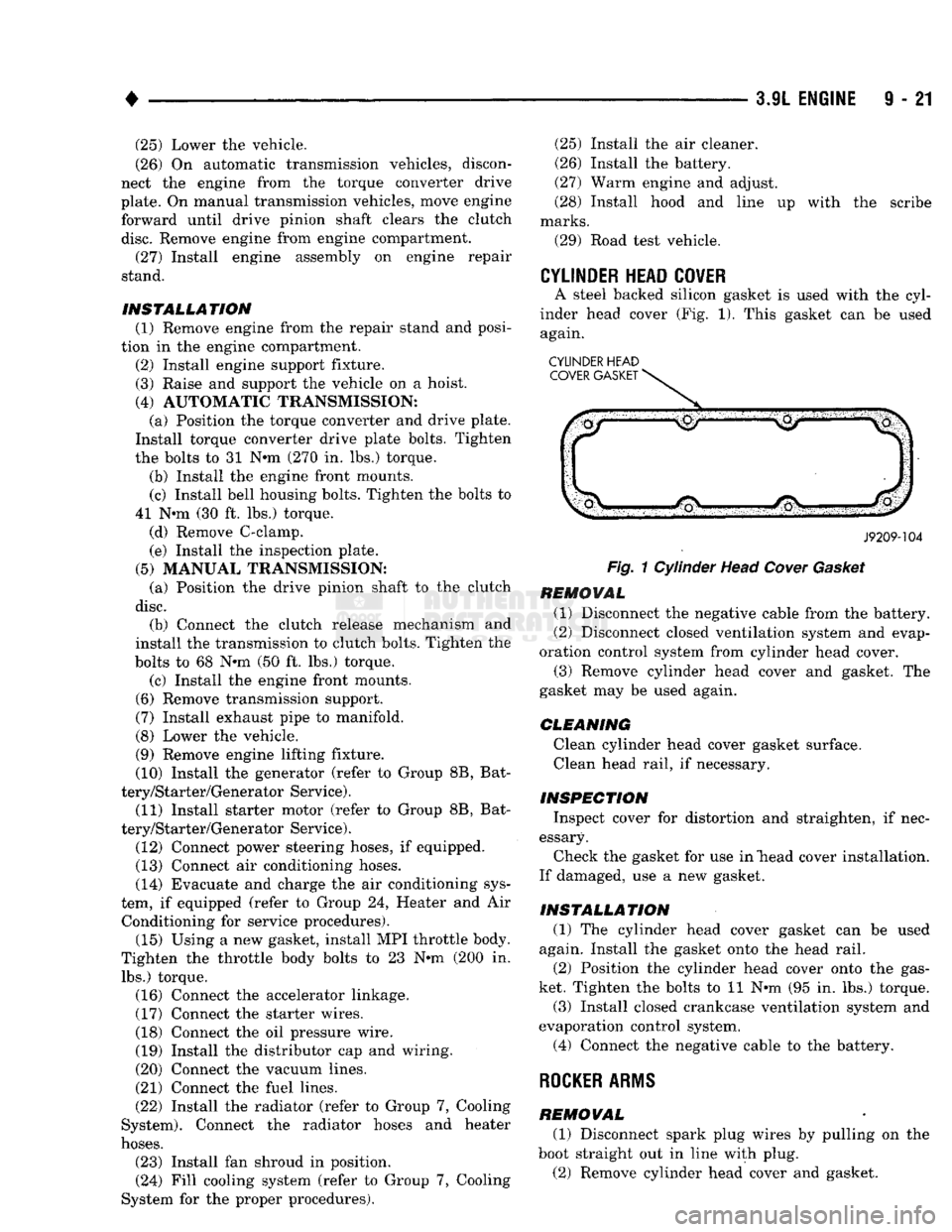

CYLINDER

HEAD COVER

A steel backed silicon gasket is used with the cyl

inder head cover (Fig. 1). This gasket can be used again.

CYLINDER HEAD COVER GASKET

J9209-104

Fig.

1 Cylinder Head

Cover

Gasket

REMOVAL (1) Disconnect the negative cable from the battery.

(2) Disconnect closed ventilation system and evap

oration control system from cylinder head cover. (3) Remove cylinder head cover and gasket. The

gasket may be used again.

CLEANING Clean cylinder head cover gasket surface. Clean head rail, if necessary.

INSPECTION Inspect cover for distortion and straighten, if nec

essary. Check the gasket for use in "head cover installation.

If damaged, use a new gasket.

INSTALLATION (1) The cylinder head cover gasket can be used

again. Install the gasket onto the head rail.

(2) Position the cylinder head cover onto the gas

ket. Tighten the bolts to 11 N-m (95 in. lbs.) torque. (3) Install closed crankcase ventilation system and

evaporation control system.

(4) Connect the negative cable to the battery.

ROCKER

ARMS

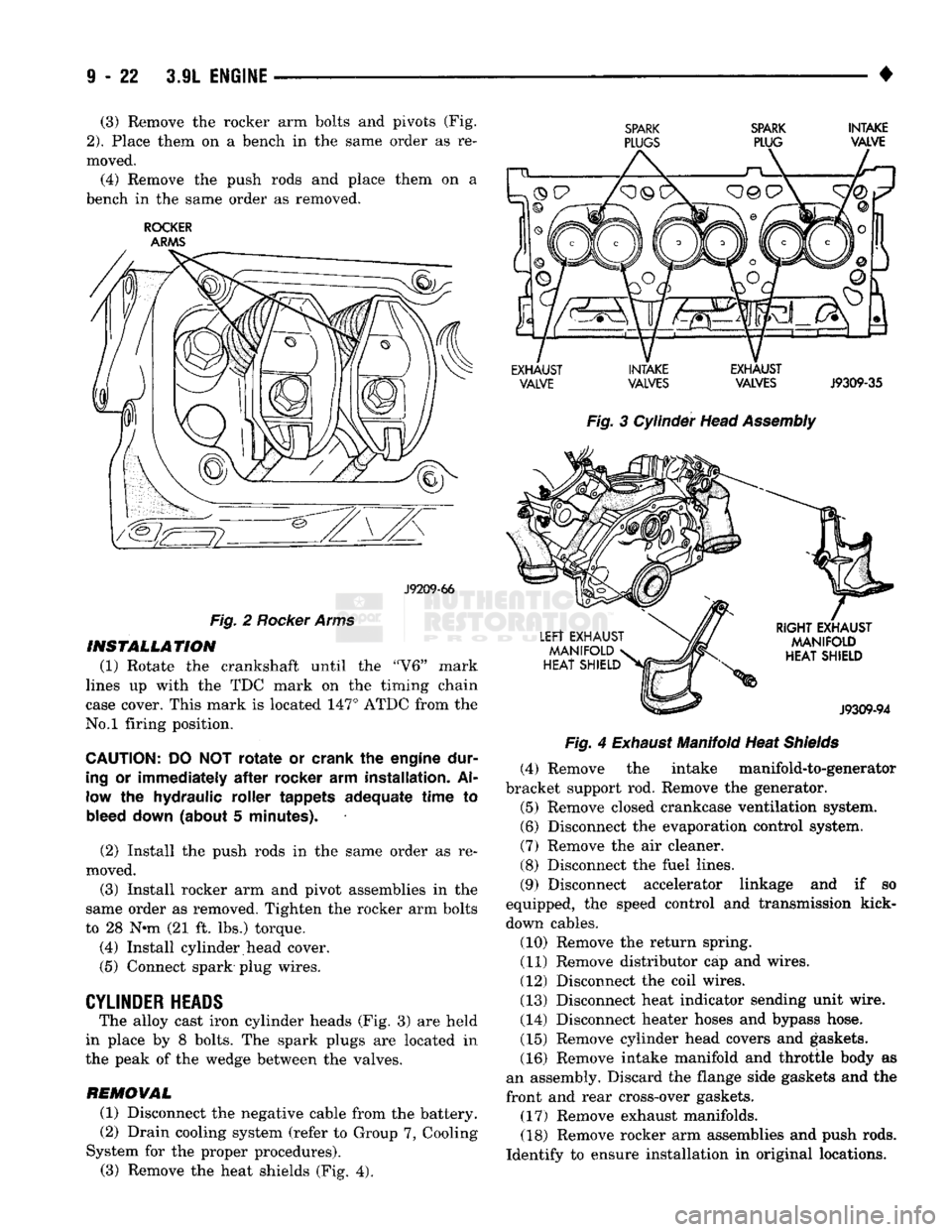

REMOVAL (1) Disconnect spark plug wires by pulling on the

boot straight out in line with plug.

(2) Remove cylinder head cover and gasket.

Page 627 of 1502

(3) Remove the rocker arm bolts and pivots (Fig.

2).

Place them on a bench in the same order as re

moved.

(4) Remove the push rods and place them on a

bench in the same order as removed.

ROCKER

ARMS

J9209-66

Fig.

2

Rocker Arms

INSTALLATION

(1) Rotate the crankshaft until the "V6" mark

lines up with the TDC mark on the timing chain

case cover. This mark is located 147° ATDC from the

No.l firing position.

CAUTION:

DO NOT

rotate

or

crank

the

engine dur

ing

or

immediately

after

rocker

arm

installation.

Al

low

the

hydraulic roller tappets adequate time

to

bleed down (about

5

minutes).

(2) Install the push rods in the same order as re

moved.

(3) Install rocker arm and pivot assemblies in the

same order as removed. Tighten the rocker arm bolts

to 28 N*m (21 ft. lbs.) torque.

(4) Install cylinder head cover.

(5) Connect spark plug wires.

CYLINDER

HEADS

The alloy cast iron cylinder heads (Fig. 3) are held

in place by 8 bolts. The spark plugs are located in

the peak of the wedge between the valves.

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Drain cooling system (refer to Group 7, Cooling

System for the proper procedures). (3) Remove the heat shields (Fig. 4).

SPARK SPARK

INTAKE

PLUGS

PLUG VALVE

EXHAUST INTAKE EXHAUST VALVE VALVES VALVES

J9309-35

Fig.

3 Cylinder Head

Assembly Fig.

4

Exhaust

Manifold Heat

Shields

(4) Remove the intake manifold-to-generator

bracket support rod. Remove the generator.

(5) Remove closed crankcase ventilation system.

(6) Disconnect the evaporation control system.

(7) Remove the air cleaner.

(8) Disconnect the fuel lines.

(9) Disconnect accelerator linkage and if so

equipped, the speed control and transmission kick-

down cables. (10) Remove the return spring.

(11) Remove distributor cap and wires.

(12) Disconnect the coil wires.

(13) Disconnect heat indicator sending unit wire.

(14) Disconnect heater hoses and bypass hose.

(15) Remove cylinder head covers and gaskets.

(16) Remove intake manifold and throttle body as

an assembly. Discard the flange side gaskets and the

front and rear cross-over gaskets.

(17) Remove exhaust manifolds.

(18) Remove rocker arm assemblies and push rods.

Identify to ensure installation in original locations.

Page 629 of 1502

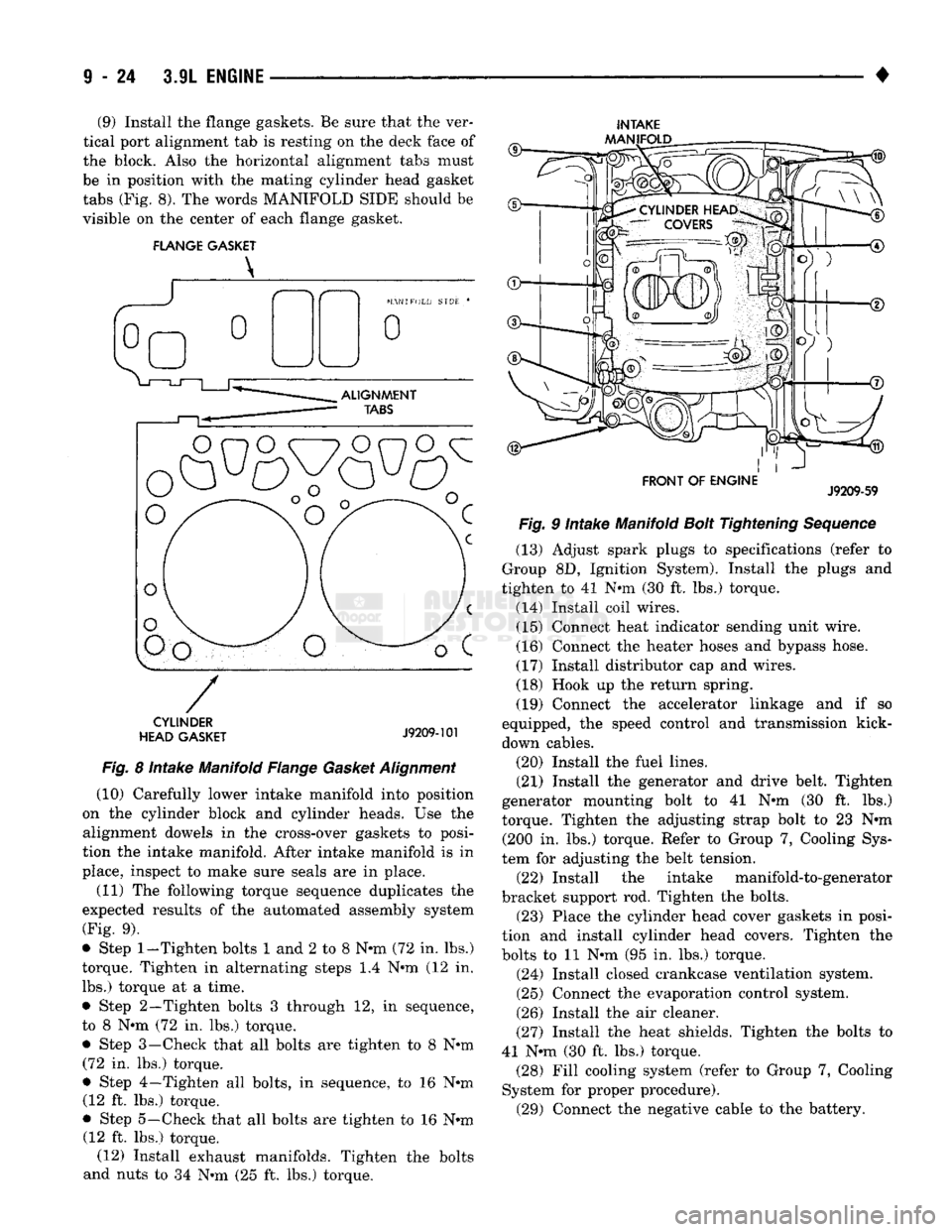

(9) Install the flange gaskets. Be sure that the ver

tical port alignment tab is resting on the deck face of

the block. Also the horizontal alignment tabs must

be in position with the mating cylinder head gasket

tabs (Fig. 8). The words MANIFOLD SIDE should be

visible on the center of each flange gasket.

FLANGE GASKET

INTAKE

AAANIFOLD

CYLINDER

HEAD GASKET

J9209-101

Fig.

8 Intake Manifold Flange

Gasket

Alignment

(10) Carefully lower intake manifold into position

on the cylinder block and cylinder heads. Use the alignment dowels in the cross-over gaskets to posi

tion the intake manifold. After intake manifold is in

place, inspect to make sure seals are in place.

(11) The following torque sequence duplicates the

expected results of the automated assembly system

(Fig. 9).

• Step

1-Tighten

bolts 1 and 2 to 8 N-m (72 in. lbs.)

torque. Tighten in alternating steps 1.4 N-m (12 in. lbs.) torque at a time.

• Step 2—Tighten bolts 3 through 12, in sequence,

to 8 N-m (72 in. lbs.) torque.

• Step 3—Check that all bolts are tighten to 8 N-m (72 in. lbs.) torque.

• Step 4—Tighten all bolts, in sequence, to 16 N-m (12 ft. lbs.) torque.

• Step 5—Check that all bolts are tighten to 16 N-m (12 ft. lbs.) torque. (12) Install exhaust manifolds. Tighten the bolts

and nuts to 34 N-m (25 ft. lbs.) torque.

FRONT OF ENGINE

J9209-59

Fig.

9 Intake Manifold

Bolt

Tightening

Sequence

(13) Adjust spark plugs to specifications (refer to

Group 8D, Ignition System). Install the plugs and

tighten to 41 N-m (30 ft. lbs.) torque.

(14) Install coil wires. (15) Connect heat indicator sending unit wire.

(16) Connect the heater hoses and bypass hose.

(17) Install distributor cap and wires.

(18) Hook up the return spring.

(19) Connect the accelerator linkage and if so

equipped, the speed control and transmission kick-

down cables.

(20) Install the fuel lines.

(21) Install the generator and drive belt. Tighten

generator mounting bolt to 41 N-m (30 ft. lbs.)

torque. Tighten the adjusting strap bolt to 23 N-m (200 in. lbs.) torque. Refer to Group 7, Cooling Sys

tem for adjusting the belt tension. (22) Install the intake manifold-to-generator

bracket support rod. Tighten the bolts. (23) Place the cylinder head cover gaskets in posi

tion and install cylinder head covers. Tighten the

bolts to 11 N-m (95 in. lbs.) torque.

(24) Install closed crankcase ventilation system.

(25) Connect the evaporation control system.

(26) Install the air cleaner.

(27) Install the heat shields. Tighten the bolts to

41 N-m (30 ft. lbs.) torque. (28) Fill cooling system (refer to Group 7, Cooling

System for proper procedure). (29) Connect the negative cable to the battery.

Page 634 of 1502

•

3.9L

ENGINE

I - 21

VIBRATION

DAMPER

REMOVAL

(1) Disconnect the negative cable from the battery,

(2) Remove fan shroud retainer bolts and set

shroud back over engine.

(3) Remove the cooling system fan.

(4) Remove the serpentine belt (refer to Group 7,

Cooling System).

(5) Remove the vibration damper pulley.

(6) Remove vibration damper bolt and washer from

end of crankshaft.

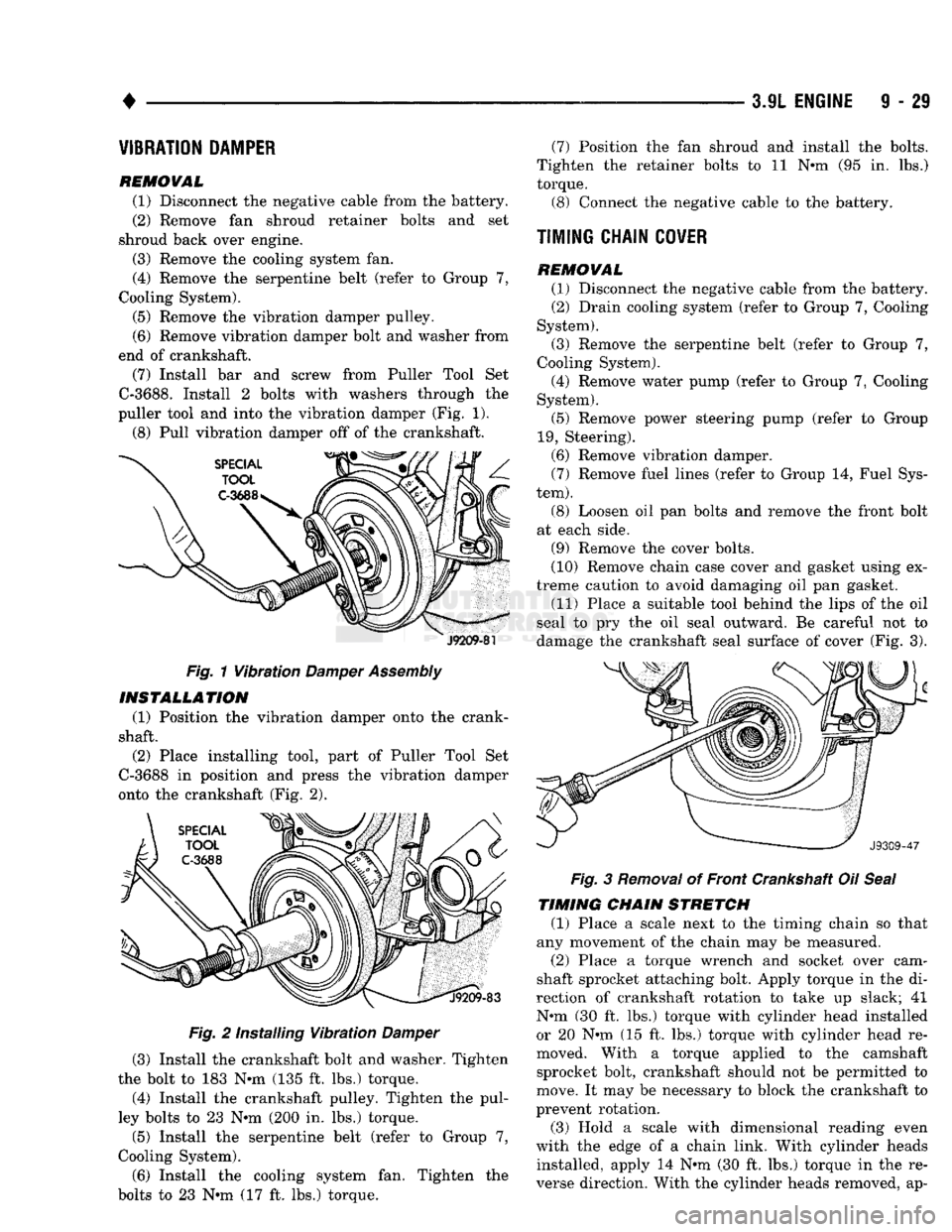

(7) Install bar and screw from Puller Tool Set

C-3688.

Install 2 bolts with washers through the

puller tool and into the vibration damper (Fig. 1).

(8) Pull vibration damper off of the crankshaft.

J9209-81

Fig. 1 Vibration

Damper

Assembly INSTALLATION

(1) Position the vibration damper onto the crank

shaft.

(2) Place installing tool, part of Puller Tool Set

C-3688 in position and press the vibration damper

onto the crankshaft (Fig. 2).

Fig. 2 Installing Vibration Damper

(3) Install the crankshaft bolt and washer. Tighten

the bolt to 183 N*m (135 ft. lbs.) torque.

(4) Install the crankshaft pulley. Tighten the pul

ley bolts to 23 N*m (200 in. lbs.) torque.

(5) Install the serpentine belt (refer to Group 7,

Cooling System).

(6) Install the cooling system fan. Tighten the

bolts to 23 N*m (17 ft. lbs.) torque. (7) Position the fan shroud and install the bolts.

Tighten the retainer bolts to 11 N*m (95 in. lbs.)

torque.

(3)

Connect the negative cable to the battery.

TIMING CHAIN

COVER

REMOVAL (1)

Disconnect the negative cable from the battery.

(2)

Drain cooling system (refer to Group 7, Cooling

System).

(3)

Remove the serpentine belt (refer to Group 7,

Cooling System).

(4)

Remove water pump (refer to Group 7, Cooling

System).

(5)

Remove power steering pump (refer to Group

19,

Steering).

(6)

Remove vibration damper. (7) Remove fuel lines (refer to Group 14, Fuel Sys

tem).

(8) Loosen oil pan bolts and remove the front bolt

at each side.

(9)

Remove the cover bolts.

(10)

Remove chain case cover and gasket using ex

treme caution to avoid damaging oil pan gasket.

(11)

Place a suitable tool behind the lips of the oil

seal to pry the oil seal outward. Be careful not to

damage the crankshaft seal surface of cover (Fig. 3). Fig. 3 Removal of Front Crankshaft Oil Seal

TIMING CHAIN STRETCH

(1) Place a scale next to the timing chain so that

any movement of the chain may be measured.

(2)

Place a torque wrench and socket over cam

shaft sprocket attaching bolt. Apply torque in the di

rection of crankshaft rotation to take up slack; 41

N#m (30 ft. lbs.) torque with cylinder head installed or 20 N»m (15 ft. lbs.) torque with cylinder head re

moved. With a torque applied to the camshaft sprocket bolt, crankshaft should not be permitted to

move. It may be necessary to block the crankshaft to

prevent rotation.

(3)

Hold a scale with dimensional reading even

with the edge of a chain link. With cylinder heads installed, apply 14 N*m (30 ft. lbs.) torque in the re

verse direction. With the cylinder heads removed, ap-