fuse chart DODGE TRUCK 1993 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 325 of 1502

8A

- 4

ELECTRICAL

•

IGNITION

OFF

DRAW

(IOD)

Ignition off draw refers to power being drained

from the battery with the ignition turned off. A nor

mal vehicle electrical system will draw from 5 to 20

milliamps. A vehicle that has not been operated for

an extended period of time (approximately 20 days)

may discharge the battery to an inadequate level.

Battery drain should not exceed approximately 20

MA (20 milliamps = 0.020 amps). The 20 MA are needed to supply PCM memory,

digital clock memory, and ETR (electronically tuned

radio) memory. Excessive battery drain is caused by items left

turned on, internally shorted generator, or intermit

tent short in wiring.

If the IOD is excessive (over 20 milliamperes), the

defect must be found and corrected before replacing a

battery. In most cases the battery can be charged and returned to service.

TEST PROCEDURE Testing for higher amperage IOD must be per

formed first to prevent damage to most milliamp

meters.

Verify that all electrical accessories are OFF. Turn

off all lights, remove ignition key, and close all

doors.

If the vehicle is equipped with electronic acces

sories (illuminated entry, high line radio), allow the

systems to automatically shut off (time out), up to 3

minutes.

(1) After determining that the underhood lamp is

operating properly then disconnect bulb. (2) Disconnect negative cable from battery.

(3) Connect a typical 12 volt test light (low watt

age bulb) between the negative cable clamp and the

battery negative terminal. The test light may light brightly for up to 3 min

utes or may not light at all (depending on the elec

trical equipment). The term brightly being used

throughout the following tests, implies the bright ness of the test light will be the same as if it were

connected across the battery.

The test light must be securely clamped to the neg

ative cable and battery terminal. If the test light be

comes disconnected during any of the IOD test, the electronic timer function will be activated and all

tests must be repeated.

(4) After 3 minutes, the test light should turn OFF

or be DIMLY lit (depending on the electrical equip

ment).

If the test light remains brightly lit do not

disconnect it. Remove each fuse or circuit breaker (refer to Group 8 - Wiring Diagrams) until test light

is either OFF or DIMLY lit. This will eliminate the

higher amperage draw.

If test light is still bright after disconnecting each

fuse and circuit breaker, disconnect the wiring har ness from the generator. Refer to Generator Testing

in this group. Do not disconnect the test light. After higher amperage IOD has been corrected, low

amperage IOD may be checked.

It is now safe to install milliamp meter to check for

low amperage IOD.

(5) With test light still connected, securely clamp

an ammeter between battery negative terminal and

negative battery cable.

If the test light or the milliamp meter circuit is

broken the various timer circuits will start. Do

not open any doors or turn on any electrical ac cessories with the test light disconnected or the

meter may be damaged.

(6) Disconnect test light. The current draw should

not exceed 0.020 amp. If it exceeds 20 milliamps iso

late each circuit by removing circuit breakers and

fuses.

The meter reading drops once the high current

problem is found. Repair this section of the circuit,

whether it is a wiring short or component failure.

BATTERY

OPEN CIRCUIT VOLTAGE TEST

A battery voltage (no load) test will indicate the

state of charge of a battery that will pass the Battery

Load Test described in this section. Before proceed

ing with this test or the Battery Load Test the

battery must be completely charged as de scribed in Battery Charging in this section. If a battery has a no load voltage reading of 12.4

volts or greater but will not endure a load test, it is

defective and should be replaced. Refer to Group 8B,

Battery/Starter Service for instructions. To test bat

tery no load voltage, perform the following operation: (1) Before measuring open circuit voltage, the sur

face charge must be removed from plates. Turn head lights on for 15 seconds then allow up to 5 minutes

for voltage to stabilize. (2) Remove both battery cables, negative first.

(3) Using a voltmeter connected to the battery

posts,

see instructions provided with voltmeter, mea sure open circuit voltage (Fig. 6). This voltage reading will indicate state of charge,

but will not reveal cranking capacity. Refer to Bat

tery Open Circuit Voltage chart.

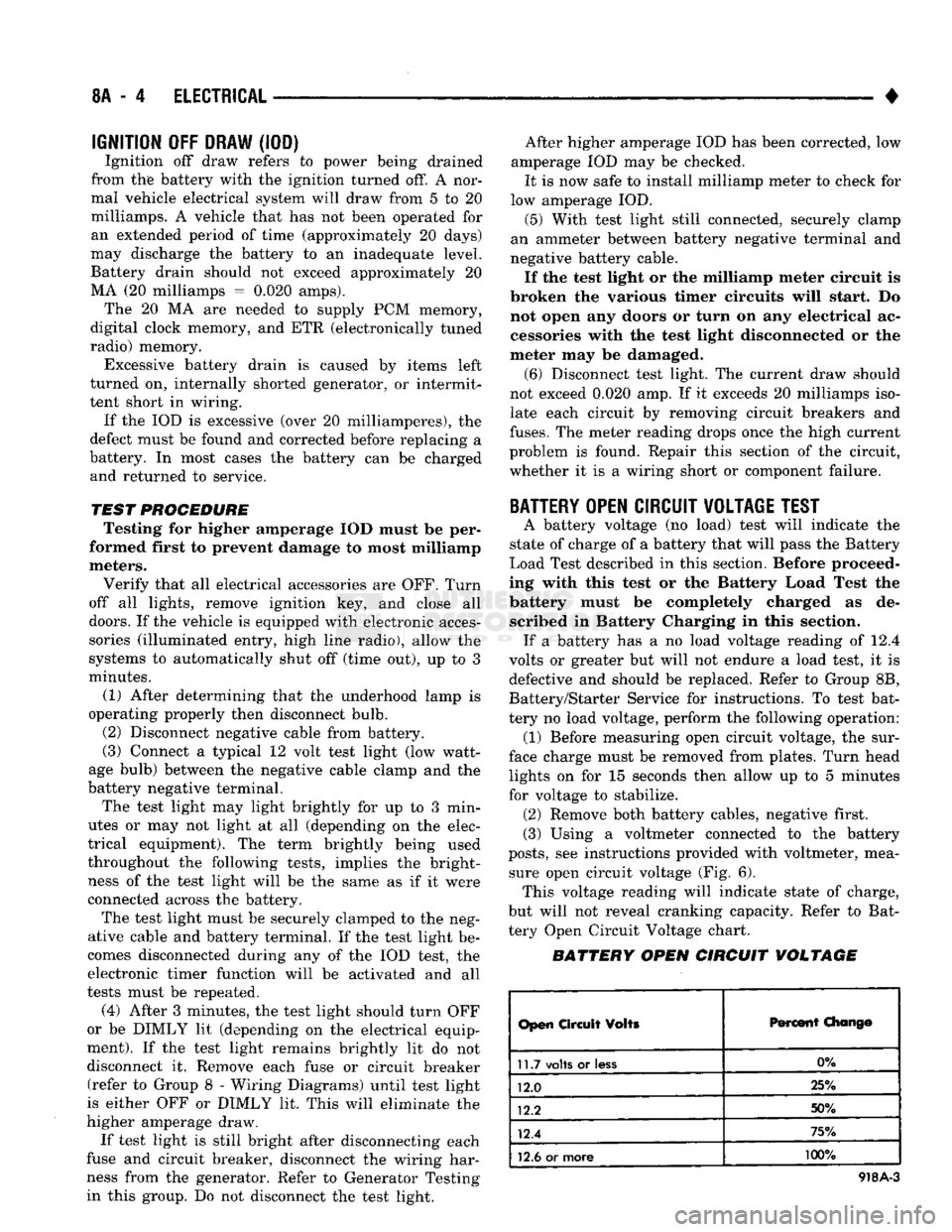

BATTERY OPEN CIRCUIT VOLTAGE

Open

Circuit

Volts

Percent

Chang©

11.7

volts

or

less

0%

12.0 25%

12.2 50%

12.4 75%

12.6

or more 100%

918A-3

Page 412 of 1502

•

HORNS

8G - 1

HORNS

CONTENTS

SERVICE

PROCEDURES

page

.. 3

TEST PROCEDURES

page

.. 1

GENERAL

INFORMATION plied from the fuse block and grounded in the horn The horn system consists of a horn switch, horn re- switch. When the horn switch on the steering column

lay (located on the fuse block), horns, and all their is pressed, the ground circuit is completed, energiz-

wiring and connections. The circuit voltage is sup- ing the relay, and supplying power to the horns.

TEST PROCEDURES

HORNS

WILL

NOT

SOUND

If the horns do not sound, check for a blown horn

fuse in cavity number 4 of the fuse block. If the fuse is blown, replace it with the same type fuse. If the

horns fail to sound and the newly replaced fuse blows

the horn switch is depressed, check for one of the fol lowing:

• a short circuit in the horn

• the horn wiring between the fuse terminal and the

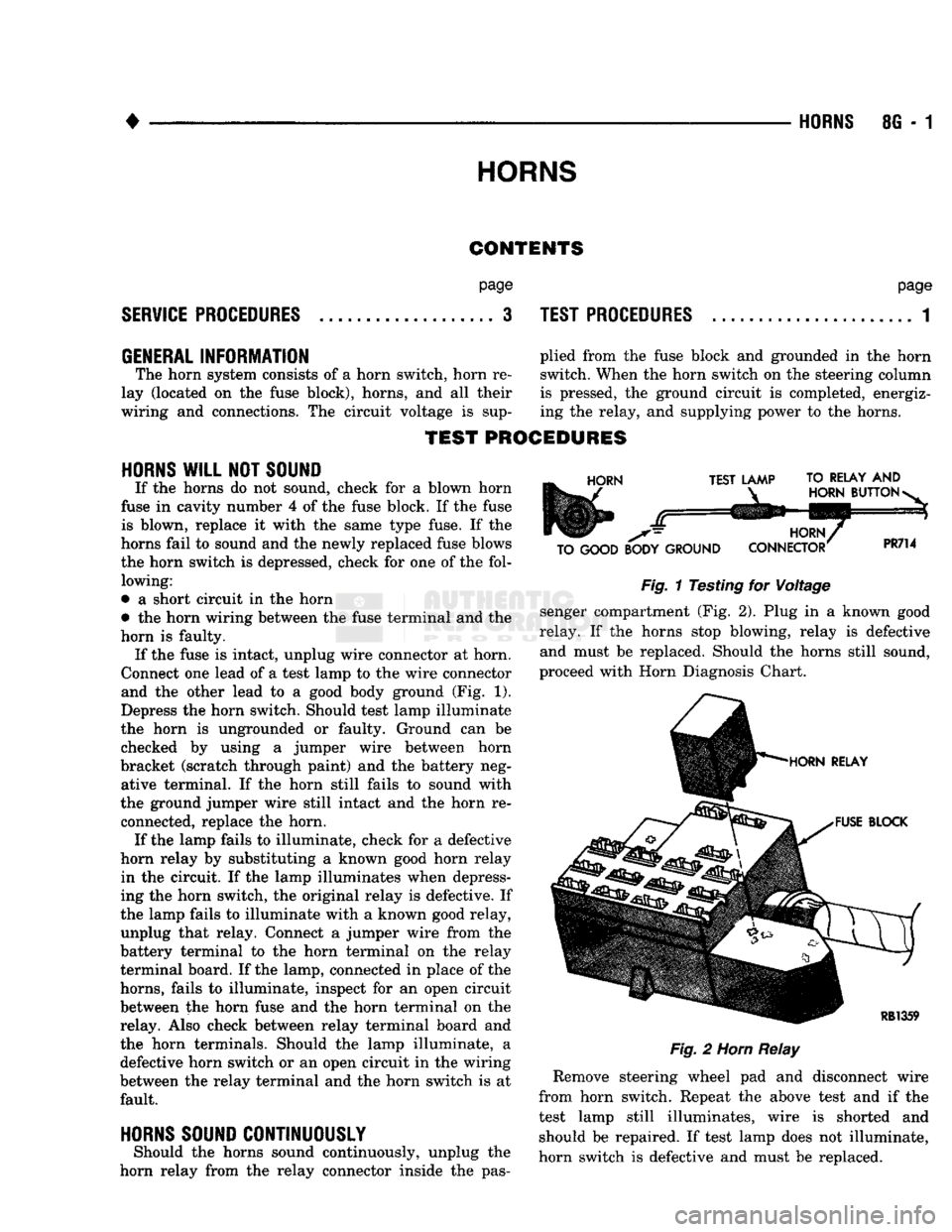

horn is faulty. If the fuse is intact, unplug wire connector at horn.

Connect one lead of a test lamp to the wire connector and the other lead to a good body ground (Fig. 1).

Depress the horn switch. Should test lamp illuminate

the horn is ungrounded or faulty. Ground can be checked by using a jumper wire between horn

bracket (scratch through paint) and the battery neg ative terminal. If the horn still fails to sound with

the ground jumper wire still intact and the horn re connected, replace the horn. If the lamp fails to illuminate, check for a defective

horn relay by substituting a known good horn relay in the circuit. If the lamp illuminates when depress

ing the horn switch, the original relay is defective. If

the lamp fails to illuminate with a known good relay, unplug that relay. Connect a jumper wire from the

battery terminal to the horn terminal on the relay

terminal board. If the lamp, connected in place of the

horns, fails to illuminate, inspect for an open circuit

between the horn fuse and the horn terminal on the relay. Also check between relay terminal board and

the horn terminals. Should the lamp illuminate, a defective horn switch or an open circuit in the wiring

between the relay terminal and the horn switch is at fault.

HORNS SOUND CONTINUOUSLY

Should the horns sound continuously, unplug the

horn relay from the relay connector inside the pas-

HORN

TEST LAMP TO RELAY

AND

HORN

BUTTON

-

TO GOOD BODY GROUND HORN,

CONNECTOR

PR714

Fig.

1 Testing for Voltage

senger compartment (Fig. 2). Plug in a known good

relay. If the horns stop blowing, relay is defective and must be replaced. Should the horns still sound,

proceed with Horn Diagnosis Chart.

HORN RELAY

FUSE BLOCK

RB1359

Fig.

2

Horn

Relay

Remove steering wheel pad and disconnect wire

from horn switch. Repeat the above test and if the

test lamp still illuminates, wire is shorted and should be repaired. If test lamp does not illuminate,

horn switch is defective and must be replaced.

Page 435 of 1502

8K - 4

WINDSHIELD WIPER

AND

WASHER

SYSTEMS

•

PROCEDURE (1) Remove wiring harness. Connect jumper from

Terminal P2 to terminal "L" of wiper motor (Fig, 4).

TERMINALS

Fig. 4 Om Jumper Wire Between Terminal "P2" and

"L".

One Jumper Wire Between Terminal "P1" and "B+" (2) Connect second jumper from terminal "PI" to

battery. If motor runs to PARK position and stops,

wiper switch is faulty. If motor keeps running and

does not park, replace motor assembly.

CONDITION Motor will stop wherever it is, when column

switch is put in OFF position. (Wipers do not

continue running to PARK position).

PROCEDURE

(1) Remove motor wiring connector and clean ter

minals. Reconnect connector and test motor. If prob lem persists, proceed to step No. 2.

(2) Put wiper switch to OFF and ignition switch to

ACC position. Disconnect motor wiring connector. Connect a voltmeter or test lamp to the motor

ground strap. Connect the other lead to terminal

"PI"

of wiring connector.

(a) If voltage is not present, check for an open

circuit in the wiring harness or wiper control

switch or fuse. (b) If voltage is present, proceed to step (3).

(3) Remove wiper motor from vehicle and connect

an ohmmeter or continuity tester between terminals

"L"

and "P2" (Fig. 5).

(a) If there is continuity between these termi

nals,

the problem is a defective motor. Fig. 5 Ohmmeter Between Terminal "L" and "P2"

(b) If there is no continuity, the problem is an

open circuit in the wiper control switch or wiring

harness.

MULTIFUNCTION

(TWO

SPEED WIPER) SWITCH

TESTING PROCEDURES

The multifunction switch contains circuitry for:

• turn signal

• hazard warning

• headlamp beam select

• headlamp optical horn

• windshield wiper

• pulse wipe

• and windshield washer switching. This integrated switch assembly is mounted to the

left-hand side of the steering column. Should any

function of the switch fail, the entire switch assem

bly must be replaced. To test the switch: (1) Disconnect negative cable from battery.

(2) Remove tilt lever (Tilt column only).

(3)

Remove upper and lower column covers to gain

access to the switch connector (Fig. 6). (4) Remove lower fixed column cover.

(5) Loosen steering column upper bracket nuts. Do

Not remove nuts.

(6)

Move upper fixed column cover to gain access

to rear of multifunction switch.

(7)

Remove switch connector (Figs. 7 and 8).

(8)

Using an ohmmeter, test for continuity (no re

sistance) between the terminals of the switch as

shown in the following continuity chart (Fig. 9).

(9)

Refer to Service Procedures for assembly.

Page 476 of 1502

•

WIRING DIAGRAMS

8W

- 1

CONTENTS

page page

COMPONENT IDENTIFICATION

.............

9

SPLICE LOCATIONS

29

GENERAL

INFORMATION

1

WIRING DIAGRAMS AD-BODY

37

GENERAL

INFORMATION

INDEX

page

Circuit

Identification

2

Component

Identification

3

Connectors

3

Fusible Links

3

Harness

Repair

3

Locating

A

System

or

Component

2

page

Secondary

Ignition

Wiring

1

Splice Locations

3

Symbols

and

Fuses

5

Troubleshooting

Wiring

Problems

3

Wire Code

Identification

2

Wiring

Diagram Sheets

and

Indexes

1

The wiring diagrams contain

the

latest information

available

at

time

of

publication. Throughout

out

this

group references

may

be

made

to a

particular vehicle

by letter

or

number designation.

A

chart showing

the

breakdown

of

these designations

is

included

in the

Introduction Section

of

this service manual.

SECONDARY

IGNITION WIRING

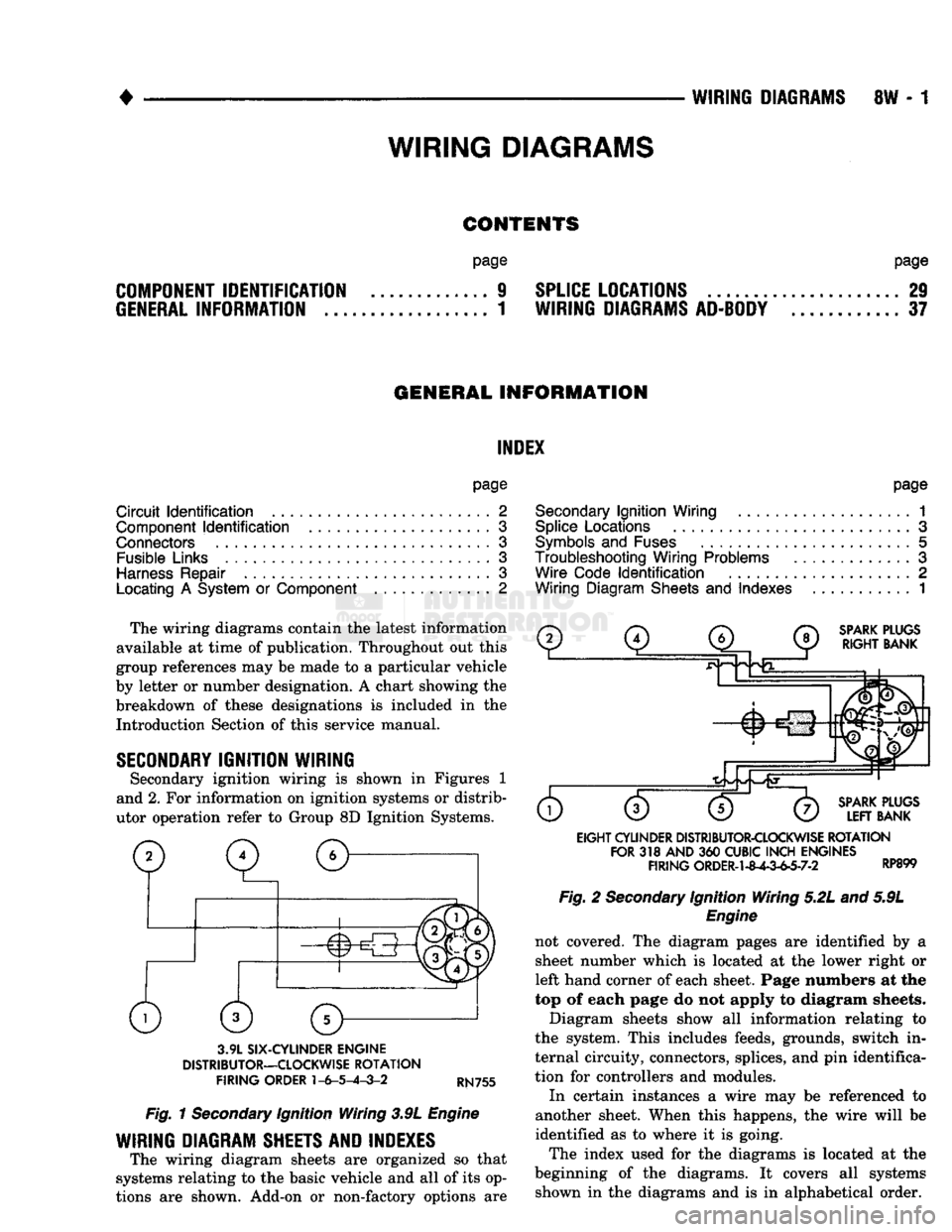

Secondary ignition wiring

is

shown

in

Figures

1

and 2.

For

information

on

ignition systems

or

distrib

utor operation refer

to

Group

8D

Ignition Systems.

SPARK

PLUGS

RIGHT

BANK

3.9L

SIX-CYLINDER

ENGINE

DISTRIBUTOR—CLOCKWISE

ROTATION

FIRING

ORDER

1-6-5-4-3-2

RN755

Fig.

1

Secondary

Ignition Wiring 3.9L

Engine

WIRING DIAGRAM SHEETS AND INDEXES

The wiring diagram sheets

are

organized

so

that

systems relating

to the

basic vehicle

and all of

its op

tions

are

shown. Add-on

or

non-factory options

are

SPARK

PLUGS

LEFT

BANK

EIGHT

CYLINDER

DISTRIBUTOR-CLOCKWISE

ROTATION

FOR

318

AND

360

CUBIC

INCH

ENGINES

FIRING

ORDER-1-8^-3-63-7-2 RP899 Fig.

2

Secondary

Ignition Wiring 5.2L and 5.9L

Engine

not covered.

The

diagram pages

are

identified

by a

sheet number which

is

located

at the

lower right

or

left hand corner

of

each sheet. Page numbers

at the

top

of

each page

do not

apply

to

diagram sheets.

Diagram sheets show

all

information relating

to

the system. This includes feeds, grounds, switch

in

ternal circuity, connectors, splices,

and

pin

identifica

tion

for

controllers

and

modules.

In certain instances

a

wire

may be

referenced

to

another sheet. When this happens,

the

wire will

be

identified

as to

where

it is

going.

The index used

for the

diagrams

is

located

at the

beginning

of the

diagrams.

It

covers

all

systems shown

in the

diagrams

and is in

alphabetical order.

WIRING

DIAGRAMS

Page 477 of 1502

8W

- 2

WIRING

DIAGRAMS

•

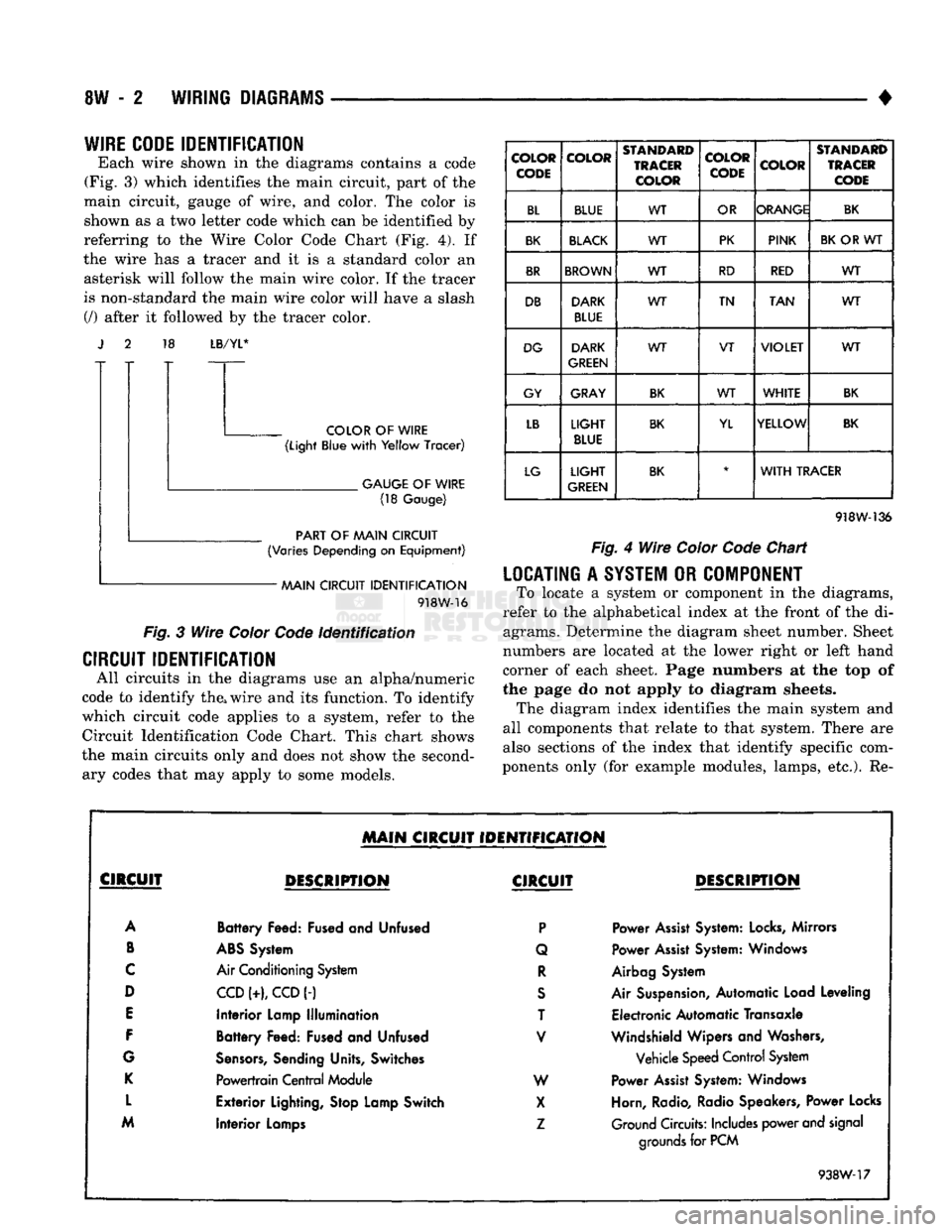

WIRE CODE

IDENTIFICATION

Each wire shown in the diagrams contains a code

(Fig. 3) which identifies the main circuit, part of the

main circuit, gauge of wire, and color. The color is shown as a two letter code which can be identified by

referring to the Wire Color Code Chart (Fig. 4). If

the wire has a tracer and it is a standard color an asterisk will follow the main wire color. If the tracer

is non-standard the main wire color will have a slash (/) after it followed by the tracer color. 18

LB/YL*

COLOR

OF

WIRE

(Light

Blue

with

Yellow

Tracer)

.

GAUGE

OF

WIRE

(18

Gauge)

PART

OF

AAAIN CIRCUIT

(Varies

Depending

on

Equipment)

AAAIN CIRCUIT

IDENTIFICATION

918W-16

Fig.

3

Wire

Color

Code

Identification

CIRCUIT IDENTIFICATION

All circuits in the diagrams use an alpha/numeric

code to identify the, wire and its function. To identify

which circuit code applies to a system, refer to the

Circuit Identification Code Chart. This chart shows

the main circuits only and does not show the second ary codes that may apply to some models.

COLOR

CODE COLOR

STANDARD

TRACER

COLOR COLOR

CODE

COLOR

STANDARD

TRACER

CODE

BL BLUE WT

OR ORANGE

BK

BK

BLACK

WT PK

PINK

BK

OR WT

BR

BROWN

WT RD

RED WT

DB DARK

BLUE WT

TN

TAN WT

DG DARK

GREEN WT

VT

VIOLET

WT

GY GRAY

BK

WT

WHITE

BK

LB

LIGHT

BLUE

BK

YL YELLOW

BK

LG

LIGHT

GREEN

BK

*

WITH

TRACER

918W-136

Fig.

4

Wire

Color

Code

Chart

LOCATING

A

SYSTEM

OR

COMPONENT

To locate a system or component in the diagrams,

refer to the alphabetical index at the front of the di agrams. Determine the diagram sheet number. Sheet

numbers are located at the lower right or left hand

corner of each sheet. Page numbers at the top of

the page do not apply to diagram sheets. The diagram index identifies the main system and

all components that relate to that system. There are

also sections of the index that identify specific com

ponents only (for example modules, lamps, etc.). Re-

MAIN

CIRCUIT IDENTIFICATION

CIRCUIT

DESCRIPTION

CIRCUIT

DESCRIPTION

A

Battery

Feed: Fused and Unfused

P

Power

Assist

System:

Locks,

Mirrors

B

ABS

System Q Power

Assist

System: Windows

C

Air Conditioning System

R

Airbag System

D

CCD

(+),

CCD

(-)

S

Air Suspension, Automatic Load Leveling

E

Interior

Lamp

Illumination

T Electronic Automatic Transaxle

F

Battery

Feed: Fused and Unfused

V

Windshield Wipers and Washers,

G

Sensors,

Sending Units, Switches Vehicle Speed Control System

K

Powertrain

Central

Module W Power

Assist

System: Windows

L

Exterior

Lighting, Stop Lamp Switch

X

Horn, Radio, Radio Speakers, Power Locks

M

Interior

Lamps

Z

Ground Circuits: Includes power and signal

Interior

Lamps

grounds

for PCM

938W-17

Page 478 of 1502

•

WIRING

DIAGRAMS

8W - 3 fer to a components name in the index if you are

unclear as to what a system may be called.

Diagram pages are arranged starting with the bat

tery and fuses. Then working into charging, starting, and ignition systems. After this they start at the

front of the vehicle and work to rear of the vehicle.

The diagrams end with connector identification

pages.

COMPONENT

IDENTIFICATION

To find a components actual location on the vehicle

refer to the wiring and components section index. This section shows the wire harness routing and the compo

nents location in the vehicle. When using this section

refer to the wiring diagrams for the general location of

the component. Then use the component identification index to locate the proper figure number.

SPLICE

LOCATIONS

Splices are indicated in the wiring diagrams by a

diamond with splice circuit code within it (Fig. 5 ex ample 1). If there is more than one splice per circuit

splice code a small box will be connected to the dia

mond with the splice number in it (Fig. 5 example 2). To locate a splice in the wire harness determine

the splice number from the wiring diagrams, then re

fer to the splice location index. This section shows

the general location of the splice in the harness.

EXAMPLE

1

EXAMPLE

2 918W-18

Fig.

5 Wiring

Splice

Examples

CONNECTORS

The connectors shown in the diagram are viewed from

the terminal end unless otherwise specified. For view ing bulkhead and engine controller connectors refer to

the back of the wiring diagrams. This area shows major connectors for pin and cavity identification.

TROUBLESHOOTING

WIRING

PROBLEMS

When troubleshooting wiring problems there are

six steps which can aid in the procedure. The steps

are listed and explained below. (1) Verify the problem.

(2) Verify any related symptoms. Perform opera

tional checks on components in the same circuit as the problem area. Refer to the wiring diagram fuse

application chart for circuit information. (3) Analyze the symptoms. Use the wiring dia

grams to determine what the circuit is doing, where

the problem most likely is occurring and where the diagnosis will continue. (4) Isolate the problem area. (5) Repair the problem.

(6) Verify proper operation. For this step check for

proper operation of all items on the circuit repaired. Refer to the wiring diagram fuse application chart.

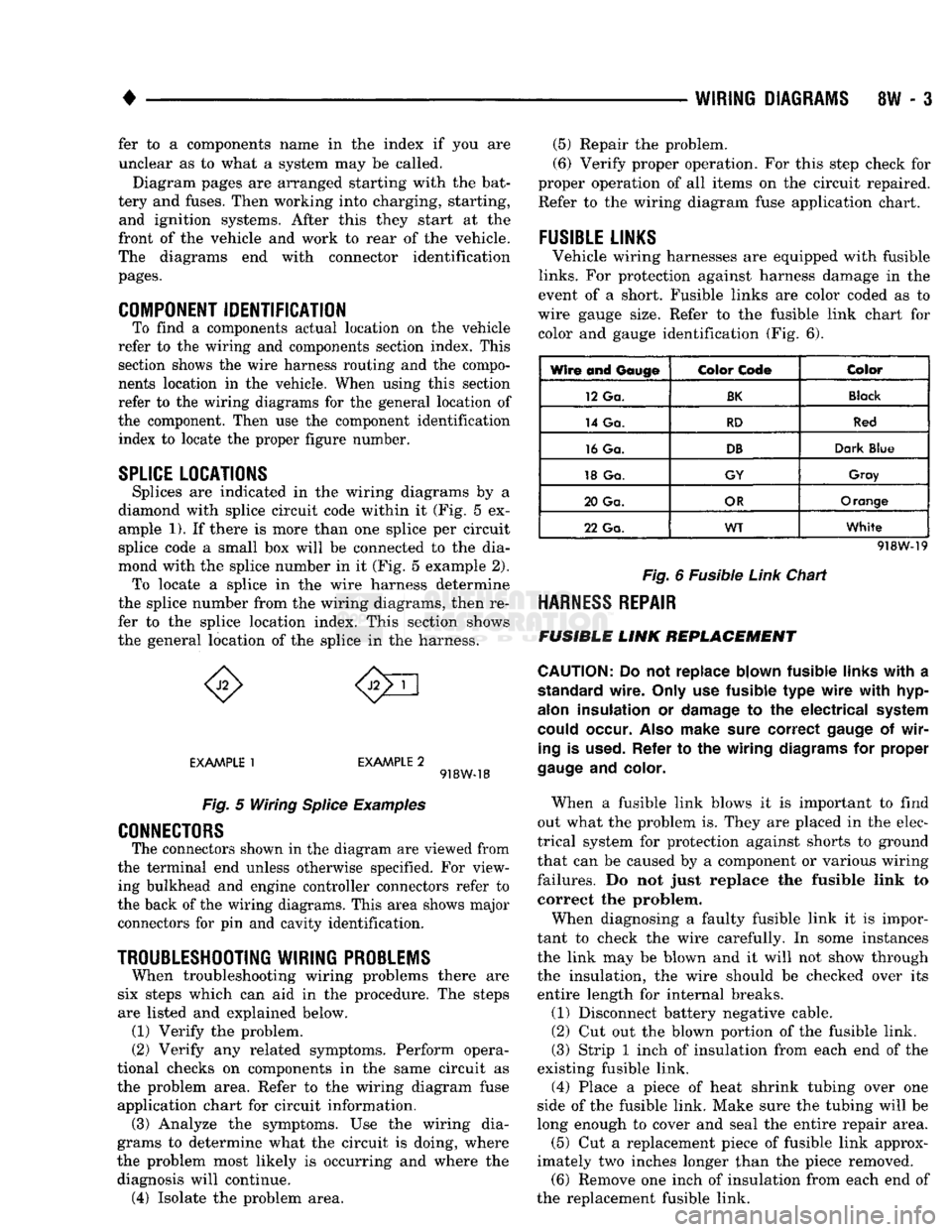

FUSIBLE

LINKS

Vehicle wiring harnesses are equipped with fusible

links.

For protection against harness damage in the

event of a short. Fusible links are color coded as to

wire gauge size. Refer to the fusible link chart for color and gauge identification (Fig. 6).

Wire and

Gauge

Color

Code

Color

12 Ga.

BK

Black

14 Ga.

RD

Red

16 Ga.

DB

Dark

Blue

18 Ga.

GY

Gray

20 Ga.

OR

Orange

22 Ga.

WT

White

918W-19

Fig.

6 Fusible

Link

Chart

HARNESS

REPAIR

FUSIBLE

LINK

REPLACEMENT

CAUTION:

Do not replace blown fusible

links

with

a

standard

wire.

Only

use fusible type

wire

with

hyp-

alon

insulation or

damage

to the electrical

system

could

occur.

Also

make

sure

correct

gauge

of

wir

ing

is

used.

Refer to the wiring

diagrams

for proper

gauge

and

color.

When a fusible link blows it is important to find

out what the problem is. They are placed in the elec

trical system for protection against shorts to ground

that can be caused by a component or various wiring

failures. Do not just replace the fusible link to correct the problem.

When diagnosing a faulty fusible link it is impor

tant to check the wire carefully. In some instances

the link may be blown and it will not show through the insulation, the wire should be checked over its

entire length for internal breaks.

(1) Disconnect battery negative cable.

(2) Cut out the blown portion of the fusible link.

(3) Strip 1 inch of insulation from each end of the

existing fusible link.

(4) Place a piece of heat shrink tubing over one

side of the fusible link. Make sure the tubing will be

long enough to cover and seal the entire repair area.

(5) Cut a replacement piece of fusible link approx

imately two inches longer than the piece removed. (6) Remove one inch of insulation from each end of

the replacement fusible link.

Page 480 of 1502

WIRING DIAGRAMS

SW - 5

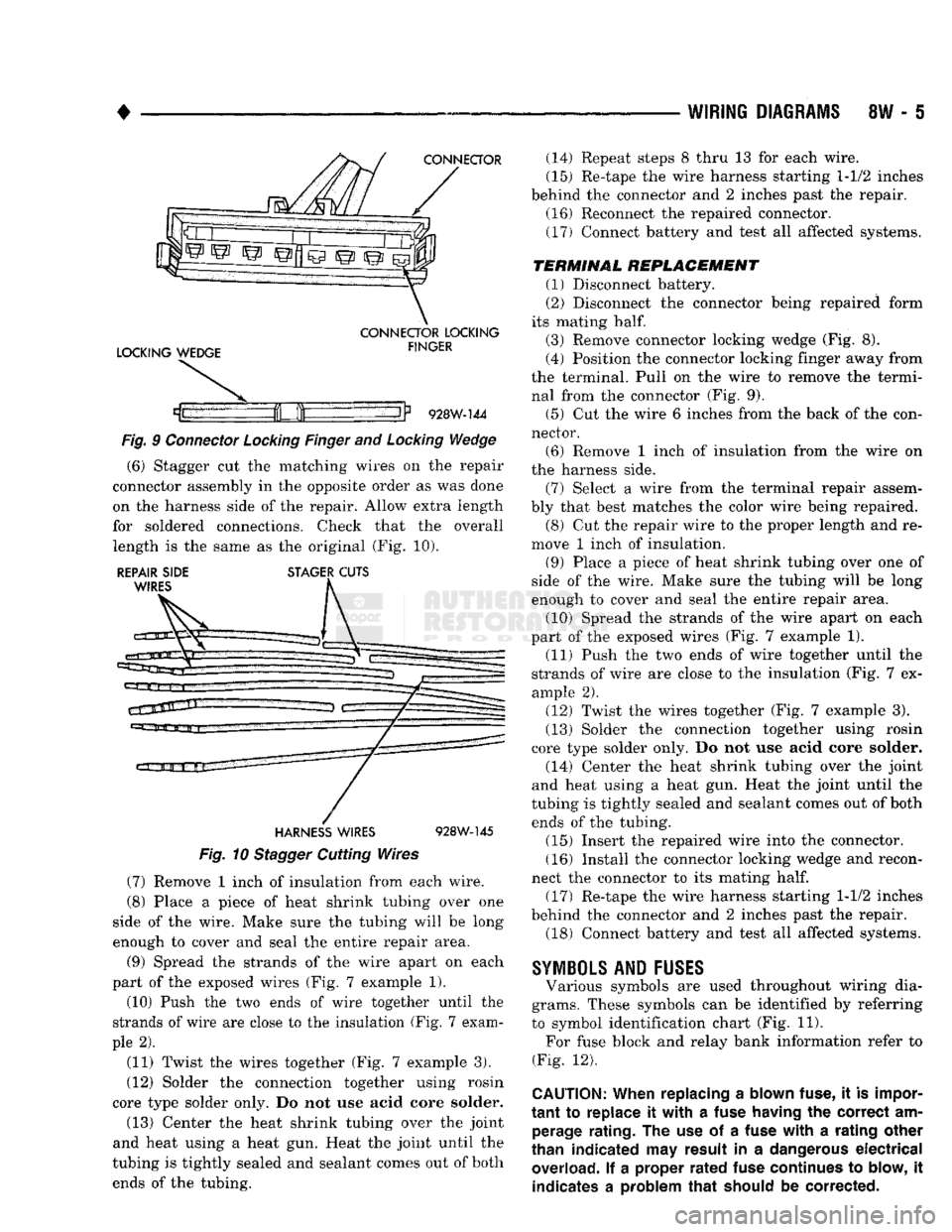

CONNECTOR

LOCKING WEDGE

CONNECTOR

LOCKING

FINGER

If

928W-144

Fig.

9

Connector

Locking

Finger

and

Locking

Wedge

(6) Stagger cut the matching wires on the repair

connector assembly in the opposite order as was done

on the harness side of the repair. Allow extra length

for soldered connections. Check that the overall length is the same as the original (Fig. 10).

REPAIR SIDE STAGER CUTS WIRES

HARNESS

WIRES

928W-145

Fig.

10

Stagger

Cutting Wires (7) Remove 1 inch of insulation from each wire.

(8) Place a piece of heat shrink tubing over one

side of the wire. Make sure the tubing will be long

enough to cover and seal the entire repair area.

(9) Spread the strands of the wire apart on each

part of the exposed wires (Fig. 7 example 1).

(10) Push the two ends of wire together until the

strands of wire are close to the insulation (Fig. 7 exam

ple 2).

(11) Twist the wires together (Fig. 7 example 3).

(12) Solder the connection together using rosin

core type solder only. Do not use acid core solder.

(13) Center the heat shrink tubing over the joint

and heat using a heat gun. Heat the joint until the

tubing is tightly sealed and sealant comes out of both ends of the tubing. (14) Repeat steps 8 thru 13 for each wire.

(15) Re-tape the wire harness starting 1-1/2 inches

behind the connector and 2 inches past the repair. (16) Reconnect the repaired connector.

(17) Connect battery and test all affected systems.

TERMINAL

REPLACEMENT

(1) Disconnect battery.

(2) Disconnect the connector being repaired form

its mating

half.

(3) Remove connector locking wedge (Fig. 8).

(4) Position the connector locking finger away from

the terminal. Pull on the wire to remove the termi nal from the connector (Fig. 9).

(5) Cut the wire 6 inches from the back of the con

nector. (6) Remove 1 inch of insulation from the wire on

the harness side.

(7) Select a wire from the terminal repair assem

bly that best matches the color wire being repaired. (8) Cut the repair wire to the proper length and re

move 1 inch of insulation.

(9) Place a piece of heat shrink tubing over one of

side of the wire. Make sure the tubing will be long

enough to cover and seal the entire repair area.

(10) Spread the strands of the wire apart on each

part of the exposed wires (Fig. 7 example 1). (11) Push the two ends of wire together until the

strands of wire are close to the insulation (Fig. 7 ex

ample 2).

(12) Twist the wires together (Fig. 7 example 3).

(13) Solder the connection together using rosin

core type solder only. Do not use acid core solder.

(14) Center the heat shrink tubing over the joint

and heat using a heat gun. Heat the joint until the

tubing is tightly sealed and sealant comes out of both ends of the tubing.

(15) Insert the repaired wire into the connector.

(16) Install the connector locking wedge and recon

nect the connector to its mating

half.

(17) Re-tape the wire harness starting 1-1/2 inches

behind the connector and 2 inches past the repair. (18) Connect battery and test all affected systems.

SYMBOLS

AND

FUSES

Various symbols are used throughout wiring dia

grams. These symbols can be identified by referring

to symbol identification chart (Fig. 11). For fuse block and relay bank information refer to

(Fig. 12).

CAUTION:

When replacing

a

blown fuse,

it is

impor

tant

to

replace

it

with

a

fuse having

the

correct

am

perage rating.

The use of a

fuse

with

a

rating other

than indicated

may

result

in a

dangerous

electrical

overload.

If a

proper

rated

fuse continues

to

blow,

it

indicates

a

problem

that

should

be

corrected.

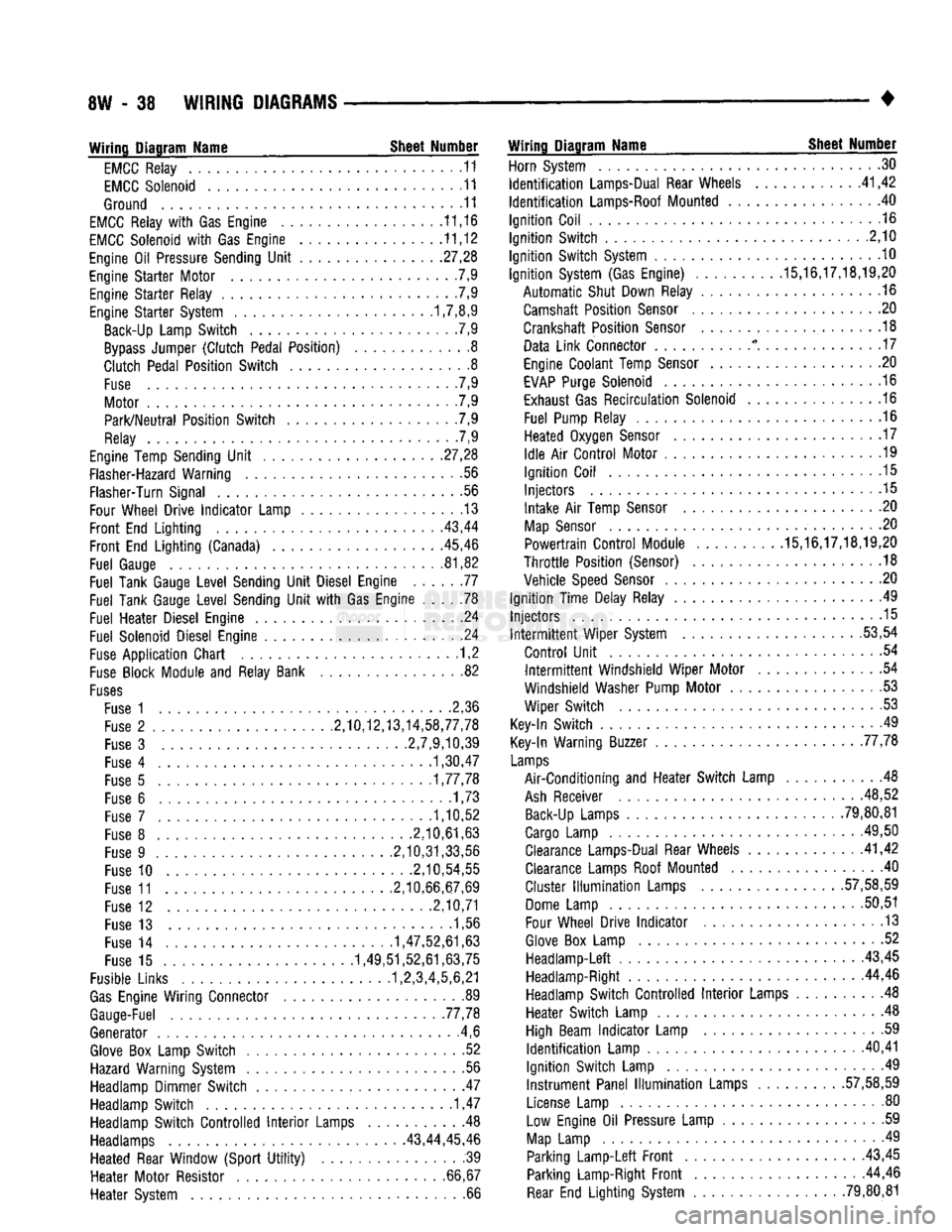

Page 513 of 1502

8W

- 38

WIRING

DIAGRAMS

• Wiring Diagram Name Sheet Number

EMCC

Relay

11

EMCC

Solenoid

11

Ground

11

EMCC

Relay

with Gas

Engine

11,16

EMCC

Solenoid

with Gas

Engine

11,12

Engine

Oil

Pressure Sending

Unit

.27,28

Engine

Starter

Motor

7,9

Engine

Starter

Relay

.7,9

Engine

Starter

System 1,7,8,9 Back-Up Lamp

Switch

.7,9

Bypass

Jumper

(Clutch

Pedal

Position)

8

Clutch

Pedal

Position

Switch

8

Fuse

. 7,9

Motor

7,9

Park/Neutral

Position

Switch

. .7,9

Relay

7,9

Engine Temp Sending

Unit

.

.27,28

Flasher-Hazard Warning

.56

Flasher-Turn Signal

56

Four Wheel

Drive

Indicator

Lamp

13

Front

End

Lighting

. .

.43,44

Front

End

Lighting

(Canada) 45,46

Fuel

Gauge

81,82

Fuel

Tank Gauge

Level

Sending

Unit

Diesel Engine

77

Fuel

Tank Gauge

Level

Sending

Unit

with Gas

Engine

78

Fuel

Heater

Diesel Engine

24

Fuel

Solenoid Diesel Engine

.24

Fuse

Application

Chart

1,2

Fuse

Block Module

and

Relay Bank

82

Fuses

Fuse

1 2,36

Fuse

2

.........

2,10,12,13,14,58,77,78

Fuse

3

2,7,9,10,39

Fuse

4

1,30,47

Fuse

5

1,77,78

Fuse

6

......

.1,73

Fuse

7

1,10,52

Fuse

8

.2,10,61,63

Fuse

9

.2,10,31,33,56

Fuse

10

.2,10,54,55

Fuse

11

2,10,66,67,69

Fuse

12

2,10,71

Fuse

13 1,56

Fuse

14

1,47,52,61,63

Fuse

15

1,49,51,52,61,63,75

Fusible Links 1,2,3,4,5,6,21

Gas

Engine

Wiring

Connector

89

Gauge-Fuel .77,78

Generator

.4,6

Glove

Box

Lamp

Switch

52

Hazard Warning System

. .56

Headlamp Dimmer

Switch

47

Headlamp

Switch

1,47

Headlamp

Switch

Controlled

Interior

Lamps

Headlamps 43,44,

Heated

Rear Window

(Sport

Utility)

Heater

Motor

Resistor

Heater

System Wiring Diagram Name Sheet Number

Horn System

30

Identification

Lamps-Dual Rear Wheels

41,42

Identification

Lamps-Roof Mounted

. 40

Ignition

Coil

.16

Ignition

Switch

.2,10

Ignition

Switch

System

10

Ignition

System (Gas Engine)

.........

.15,16,17,18,19,20

Automatic

Shut Down Relay

.16

Camshaft

Position

Sensor

20

Crankshaft

Position

Sensor

.18

Data

Link

Connector

* . . .17

Engine Coolant Temp

Sensor

20

EVAP

Purge Solenoid

16

Exhaust Gas

Recirculation

Solenoid

16

Fuel

Pump Relay

.16

Heated

Oxygen

Sensor

. . . 17

Idle

Air

Control

Motor

.19

Ignition

Coil

.15

Injectors

.15

Intake

Air

Temp

Sensor

. .20

Map

Sensor

. .20

Powertrain

Control

Module .15,16,17,18,19,20

Throttle

Position

(Sensor)

.18

Vehicle

Speed

Sensor

.20

Ignition

Time

Delay Relay

49

Injectors

.15 Intermittent

Wiper

System .53,54

Control

Unit

.54 Intermittent

Windshield

Wiper

Motor

54

Windshield

Washer Pump

Motor

53

Wiper

Switch

53

Key-In

Switch

49

Key-In Warning Buzzer 77,78

Lamps

Air-Conditioning

and

Heater

Switch

Lamp

48

Ash

Receiver .48,52 Back-Up Lamps

......

79,80,81

Cargo Lamp

.

.49,50 Clearance Lamps-Dual Rear Wheels .41,42

Clearance Lamps Roof Mounted

.40

Cluster

Illumination

Lamps

.

.57,58,59

Dome Lamp

50,51

Four Wheel

Drive

Indicator

.13

Glove

Box

Lamp

52

Headlamp-Left

43,45 Headlamp-Right 44,46

Headlamp

Switch

Controlled

Interior

Lamps

. 48

Heater

Switch

Lamp

.48

High Beam

Indicator

Lamp

.59

Identification

Lamp

.

.40,41

Ignition

Switch

Lamp

.49

Instrument

Panel

Illumination

Lamps

.

.57,58,59

License Lamp

. . . 80

.

.48 Low

Engine

Oil

Pressure Lamp

59

45,46

Map

Lamp

49

.

.39

Parking

Lamp-Left

Front

43,45

66,67 Parking Lamp-Right

Front

44,46 .

.66

Rear

End

Lighting

System .79,80,81

Page 517 of 1502

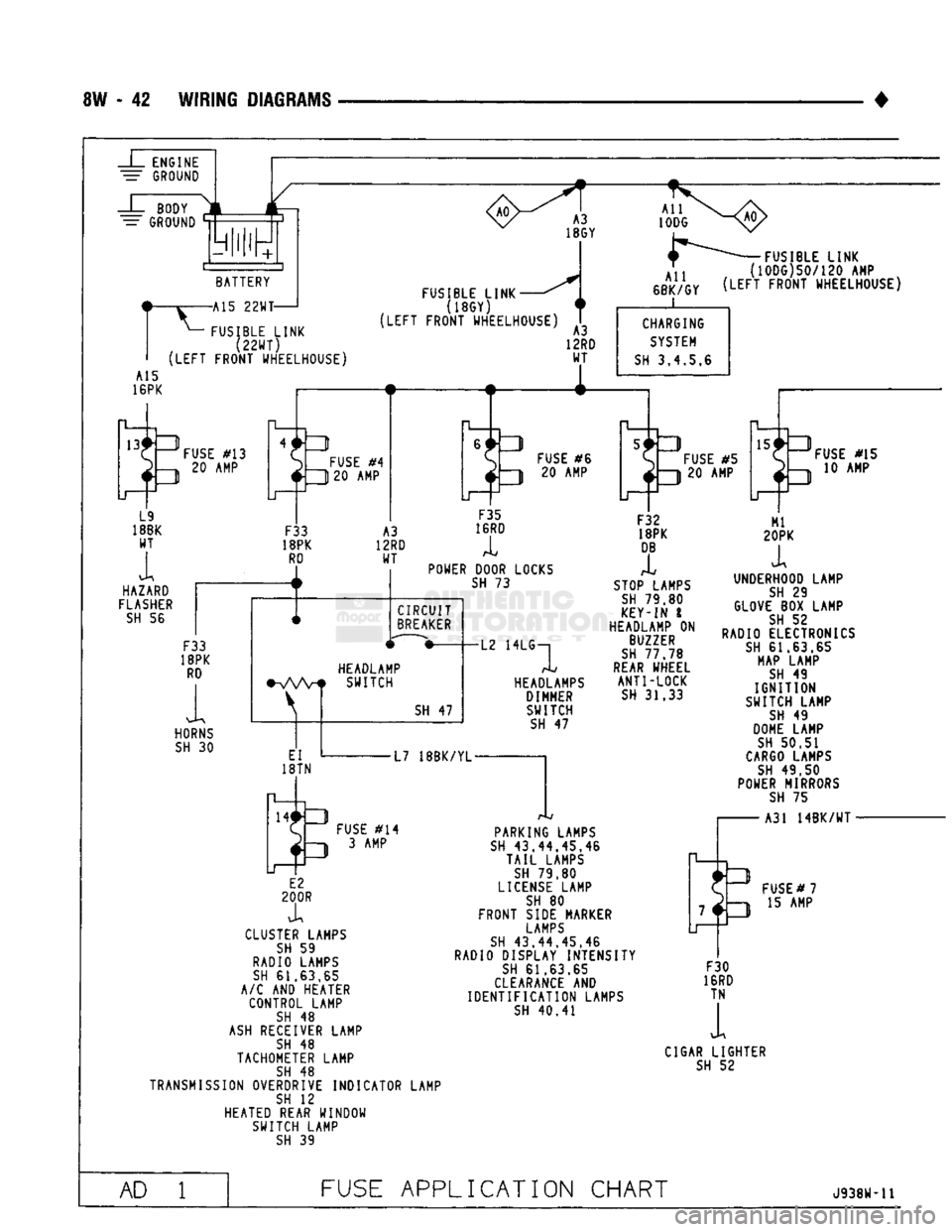

8W

- 42

WIRING DIAGRAMS

-J_

ENGINE

=

GROUND

BODY

—

GROUND

BATTERY

-A

15

22WT-

^—

FUSIBLE LINK

(22WT)

(LEFT

FRONT WHEELHOUSE) FUSIBLE LINK

(18GY)

(LEFT

FRONT WHEELHOUSE)

All

6BK/GY FUSIBLE LINK

{1000)50/120 AMP

(LEFT

FRONT WHEELHOUSE) A15

16PK

13#-ZI

L9

18BK WT

i

HAZARD

FLASHER

SH

56

IT-

FUSE

#13

20 AMP

O

FUSE

#4

|

ft 20 AMP

F33

18PK

RD

A3

12RD WT A3

12RD WT

4-

CHARGING

SYSTEM

SH

3,4,5.6

FUSE

#6 20 AMP

FUSE

#5

J—1| 20 AMP

F33

18PK

RD

HORNS

SH

30

POWER DOOR LOCKS

SH

73

CIRCUIT

BREAKER

HEADLAMP

•VWf

SWITCH

EI

18TN

SH

47

-L2 HEADLAMPS

DIMMER SWITCH

SH

47

F32

18PK

DB

I

STOP LAMPS

SH

79,80

KEY-IN

I

HEADLAMP

ON

BUZZER

SH

77.78

REAR

WHEEL ANTI-LOCK

SH

31.33

FUSE

#15

10 AMP

L7

18BK/YL-

3

FUSE

#14

D 3AMP

E2

200R

X

CLUSTER LAMPS

SH

59

RADIO LAMPS

SH

61.63.65

A/C

AND

HEATER CONTROL LAMP

SH

48

ASH

RECEIVER LAMP

SH

48

TACHOMETER LAMP

SH

48

TRANSMISSION OVERDRIVE INDICATOR LAMP

SH

12

HEATED REAR WINDOW SWITCH LAMP

SH

39

PARKING LAMPS

SH

43.44.45,46

TAIL

LAMPS

SH

79.80

LICENSE

LAMP

SH

80

FRONT SIDE MARKER

LAMPS

SH

43.44.45.46

RADIO DISPLAY INTENSITY

SH

61.63.65

CLEARANCE

AND

IDENTIFICATION

LAMPS

SH

40.41

UNDERHOOD LAMP

SH

29

GLOVE

BOX

LAMP

SH

52

RADIO ELECTRONICS

SH

61.63.65

MAP LAMP

SH

49

IGNITION

SWITCH LAMP

SH

49

DOME LAMP

SH

50.51

CARGO

LAMPS

SH

49.50

POWER MIRRORS

SH

75

A31

14BK/WT

-

7*3

LI FUSE

#7

2h-i

15 AMP

F30

16RD TN

1

CIGAR LIGHTER

SH

52

AD

1

FUSE

APPLICATION CHART

J938W-U

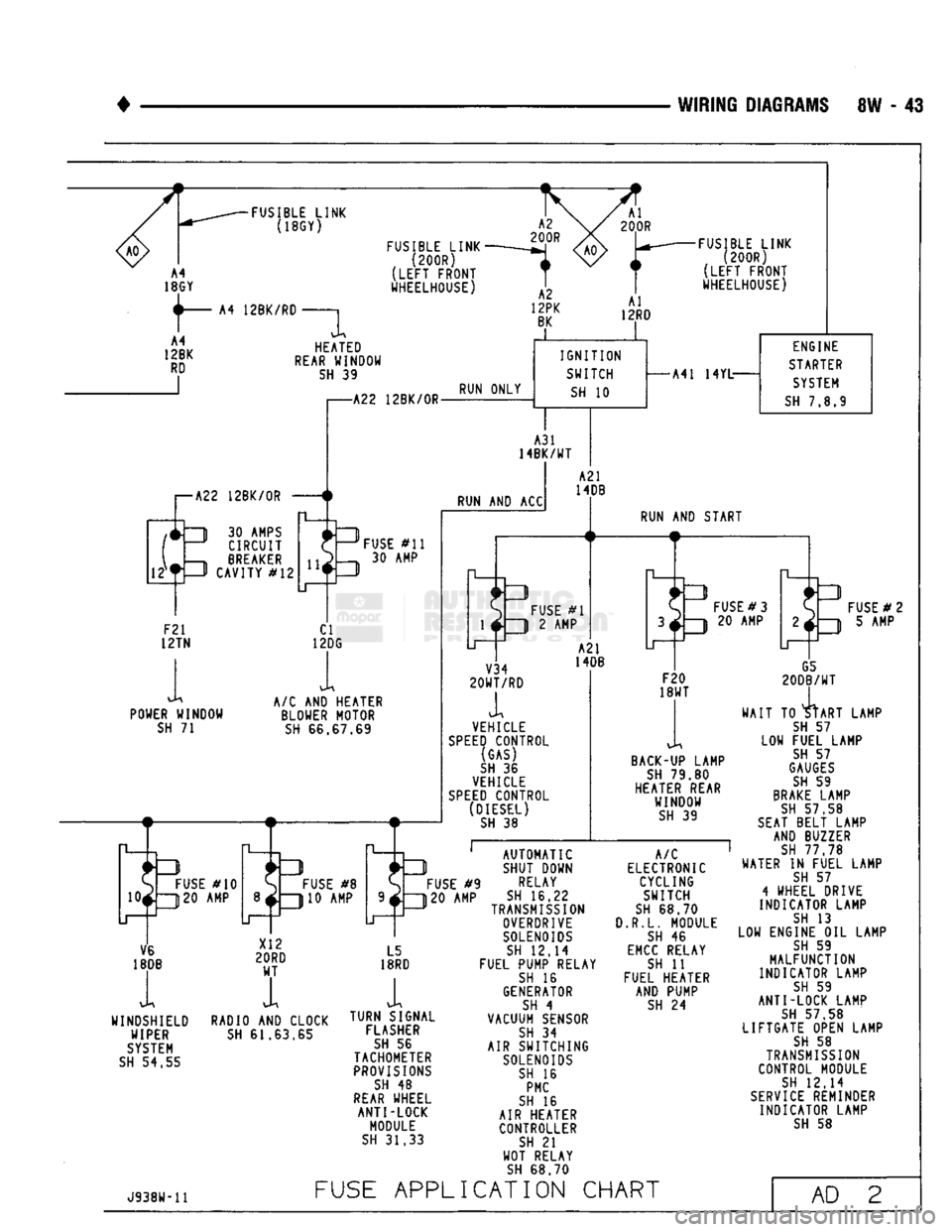

Page 518 of 1502

WIRING

DIAGRAMS

8W - 43

FUSIBLE

LINK

(18GY)

12BK/RD

FUSIBLE

LINK

(200R)

(LEFT

FRONT

WHEELHOUSE) HEATED

REAR

WINDOW

SH

39

FUSIBLE

LINK

(200R)

(LEFT

FRONT

WHEELHOUSE)

I—A22

12BK/0R

IT

1

30

AMPS

J CIRCUIT

,—h BREAKER —P CAVITY

#12

-A22

12BK/0R-

RUN ONLY

IGNITION

SWITCH

SH

10

A31

14BK/WT

RUN

AND ACC

F21

12TN

POWER WINDOW

SH

71

FUSE

#11

30 AMP

CI

12DG

A/C

AND

HEATER BLOWER MOTOR

SH

66.67.69

S

FUSE

#10

10*ZJ20

AMP

O

FUSE

#8

310 AMP

-A41

14YL-

ENGINE

STARTER

SYSTEM

SH

7.8.9

A21

14DB

FUSE

#1

3

2 AMP

RUN

AND

START

V34

20WT/RD

A2I

14DB

VEHICLE

SPEED

CONTROL (GAS)

SH

36

VEHICLE

SPEED

CONTROL (DIESEL)

SH

38

FUSE

#3

20 AMP

F20

18WT

BACK-UP

LAMP

SH

79.80

HEATER REAR WINDOW

SH

39

G5

20DB/WT

TO

4tART

D

FUSE

# 2

3

5 AMP

LAMP LOW

FUSE

#9

120 AMP

V6

18DB

WINDSHIELD WIPER

SYSTEM

SH

54.55

RADIO

AND

CLOCK

SH

61.63.65

L5

18RD

i

TURN SIGNAL FLASHER

SH

56

TACHOMETER

PROVISIONS

SH

48

REAR

WHEEL ANTI-LOCK

MODULE

SH

31.33

AUTOMATIC

SHUT DOWN

RELAY

SH

16.22

TRANSMISSION

OVERDRIVE

SOLENOIDS

SH

12.14

FUEL PUMP RELAY

SH

16

GENERATOR

SH

4

VACUUM SENSOR

SH

34

AIR SWITCHING

SOLENOIDS

SH

16

PMC

SH

16

AIR HEATER CONTROLLER

SH

21

WOT RELAY

SH

68.70

A/C

ELECTRONIC CYCLING SWITCH

SH

68.70

3.R.L.

MODULE

SH

46

EMCC

RELAY

SH

11

FUEL HEATER AND PUMP

SH

24

WAIT

TO

START

SH

57

FUEL LAMP

SH

57

GAUGES

SH

59

BRAKE

LAMP

SH

57.58

SEAT

BELT LAMP AND BUZZER

SH

77 78

WATER

IN

FUEL LAMP

SH

57

4

WHEEL DRIVE

INDICATOR LAMP

SH

13

LOW ENGINE

OIL

LAMP

SH

59

MALFUNCTION

INDICATOR LAMP

SH

59

ANTI-LOCK LAMP

SH

57 58

LIFTGATE OPEN LAMP

SH

58

TRANSMISSION

CONTROL MODULE

SH

12.14

SERVICE

REMINDER INDICATOR LAMP

SH

58

J938W-11

FUSE

APPLICATION

CHART

AD

2