LUBRICATION

AND

MAINTENANCE

0-11

J

DRIVE-ON

HOIST

I

FRAME

CONTACT

HOIST

TWIN

POST

CHASSIS

HOIST

FLOOR

JACK

RROOD30

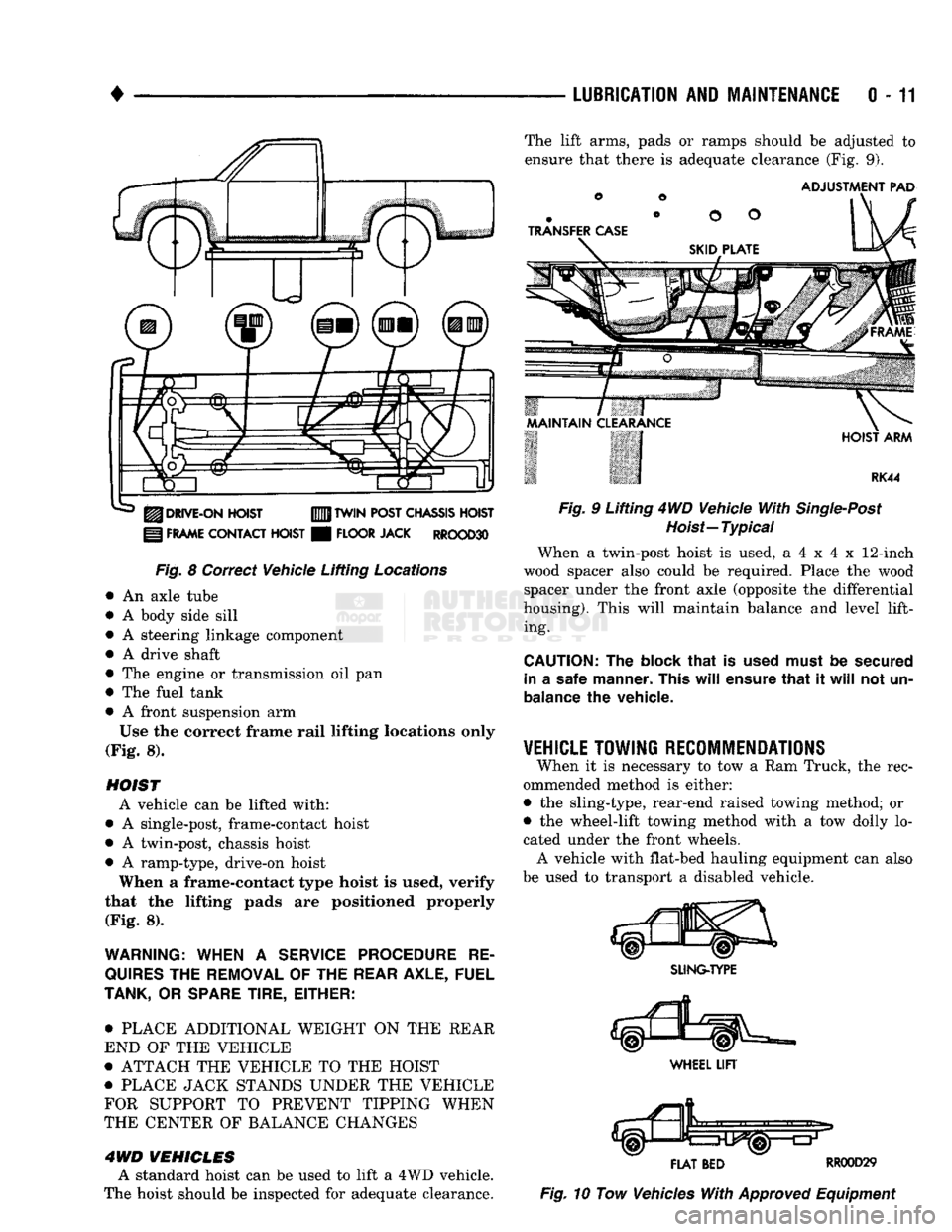

Fig.

8 Correct Vehicle Lifting

Locations

An axle tube

A body side sill

A steering linkage component

A drive shaft

The engine or transmission oil pan

The fuel tank

• A front suspension arm Use the correct frame rail lifting locations only

(Fig. 8).

HOIST A vehicle can be lifted with:

• A single-post, frame-contact hoist

• A twin-post, chassis hoist

• A ramp-type, drive-on hoist

When a frame-contact type hoist is used, verify

that the lifting pads are positioned properly (Fig. 8).

WARNING:

WHEN

A

SERVICE

PROCEDURE

RE

QUIRES

THE

REMOVAL

OF

THE

REAR

AXLE,

FUEL

TANK,

OR

SPARE

TIRE,

EITHER:

• PLACE ADDITIONAL WEIGHT ON THE REAR

END OF THE VEHICLE

« ATTACH THE VEHICLE TO THE HOIST

« PLACE JACK STANDS UNDER THE VEHICLE

FOR SUPPORT TO PREVENT TIPPING WHEN

THE CENTER OF BALANCE CHANGES

4WD VEHICLES A standard hoist can be used to lift a 4WD vehicle.

The hoist should be inspected for adequate clearance. The lift arms, pads or ramps should be adjusted to

ensure that there is adequate clearance (Fig. 9).

ADJUSTMENT

PAD

ii 7

MAINTAIN

CLEARANCE

HOIST

ARM

RK44

Fig.

9 Lifting 4WD Vehicle

With

Single-Post

Hoist—

Typical

When a twin-post hoist is used, a 4 x 4 x 12-inch

wood spacer also could be required. Place the wood spacer under the front axle (opposite the differential

housing). This will maintain balance and level lift ing.

CAUTION:

The

block

that

is

used must

be

secured in

a

safe manner. This

will

ensure

that

it

will

not un

balance

the

vehicle.

VEHICLE

TOWING

RECOMMENDATIONS

When it is necessary to tow a Ram Truck, the rec

ommended method is either:

• the sling-type, rear-end raised towing method; or

• the wheel-lift towing method with a tow dolly lo

cated under the front wheels. A vehicle with flat-bed hauling equipment can also

be used to transport a disabled vehicle.

SLING-TYPE

FLAT

BED

RR0OD29

Fig.

10 Tow Vehicles

With

Approved

Equipment