wheel alignment DODGE TRUCK 1993 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 54 of 1502

•

FRONT SUSPENSION

AND

AXLE

2 - 1

CONTENTS

page

FRONT SUSPENSION—2WD VEHICLES

......

7

FRONT SUSPENSION—4WD VEHICLES

14

FRONT WHEEL

ALIGNMENT

...............

3

GENERAL INFORMATION

1

page

MODEL

44

FRONT AXLE

17

MODEL

80

FRONT AXLE

49

TORQUE SPECIFICATIONS

75

GENERAL

INFORMATION

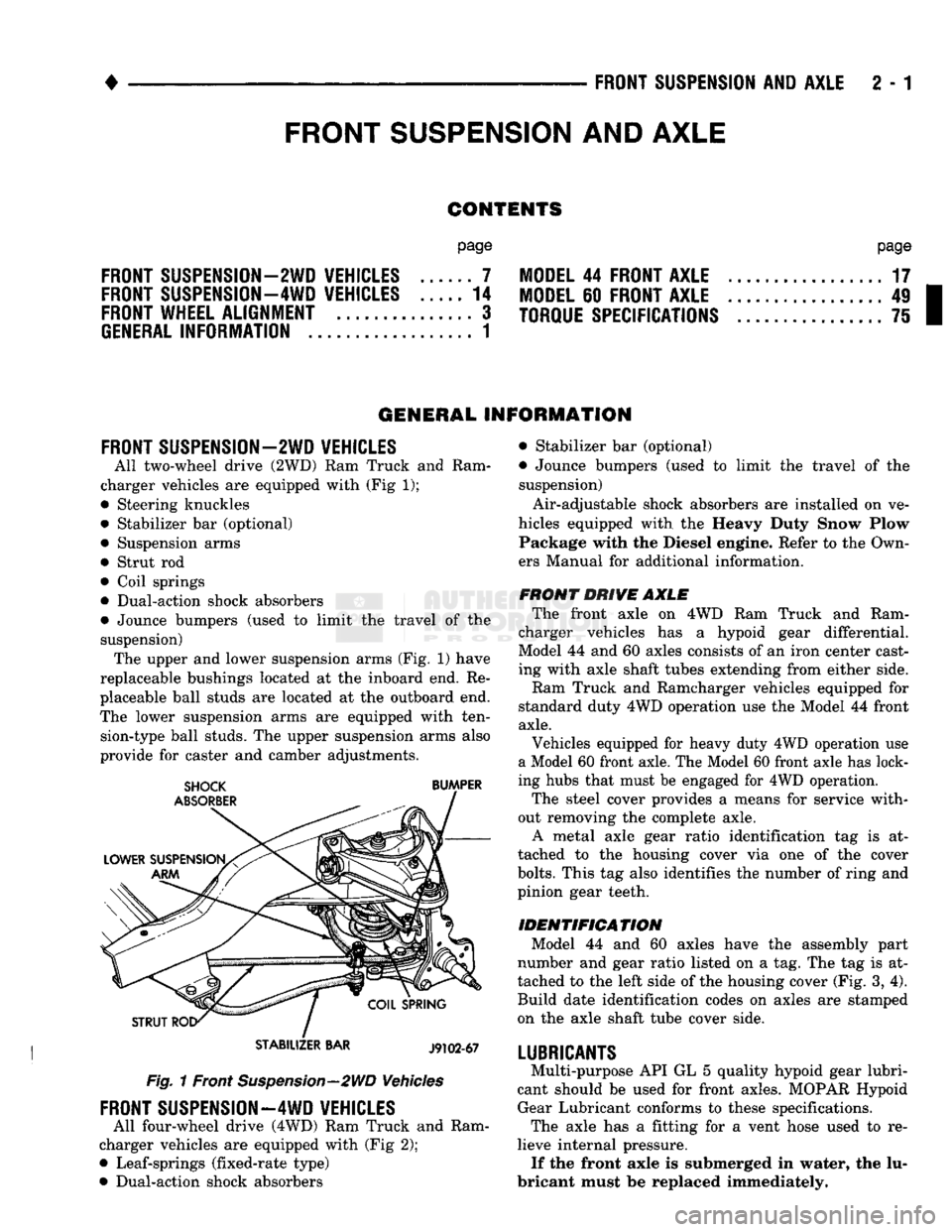

FRONT SUSPENSION—2WD VEHICLES

All two-wheel drive (2WD)

Ram

Truck

and

Ram

charger vehicles

are

equipped with (Fig

1);

• Steering knuckles

• Stabilizer

bar

(optional) • Suspension arms

• Strut

rod

• Coil springs

• Dual-action shock absorbers

• Jounce bumpers (used

to

limit

the

travel

of the

suspension) The upper and lower suspension arms (Fig.

1)

have

replaceable bushings located

at the

inboard end.

Re

placeable ball studs

are

located

at

the

outboard end.

The lower suspension arms

are

equipped with ten sion-type ball studs. The upper suspension arms also

provide

for

caster

and

camber adjustments.

STABILIZER

BAR

J9102-67

Fig. 1 Front Suspension—2WD Vehicles

FRONT SUSPENSION—4WD VEHICLES

All four-wheel drive (4WD) Ram Truck

and

Ram

charger vehicles

are

equipped with (Fig

2);

• Leaf-springs (fixed-rate type)

• Dual-action shock absorbers • Stabilizer

bar

(optional)

• Jounce bumpers (used

to

limit

the

travel

of the

suspension)

Air-adjustable shock absorbers

are

installed

on

ve

hicles equipped with

the

Heavy Duty Snow Plow Package with

the

Diesel engine. Refer

to

the Own

ers Manual

for

additional information.

FRONT DRIVE AXLE The front axle

on 4WD Ram

Truck

and

Ram

charger vehicles

has a

hypoid gear differential.

Model

44

and

60

axles consists

of

an iron center cast

ing with axle shaft tubes extending from either side.

Ram Truck

and

Ramcharger vehicles equipped

for

standard duty 4WD operation use

the

Model

44

front

axle.

Vehicles equipped

for

heavy duty 4WD operation

use

a Model 60 front axle. The Model 60 front axle has lock

ing hubs that must

be

engaged

for

4WD operation.

The steel cover provides

a

means

for

service with

out removing

the

complete axle. A metal axle gear ratio identification

tag is at

tached

to the

housing cover

via one of the

cover

bolts.

This

tag

also identifies

the

number

of

ring and

pinion gear teeth.

IDENTIFICATION Model

44 and 60

axles have

the

assembly part

number

and

gear ratio listed

on a

tag. The

tag

is at

tached

to

the

left side

of

the housing cover (Fig.

3,

4).

Build date identification codes

on

axles

are

stamped

on

the

axle shaft tube cover side.

LUBRICANTS

Multi-purpose API

GL

5

quality hypoid gear lubri

cant should

be

used

for

front axles. MOPAR Hypoid Gear Lubricant conforms

to

these specifications. The axle

has a

fitting

for a

vent hose used

to re

lieve internal pressure. If the front axle

is

submerged

in

water,

the

lu

bricant must

be

replaced immediately.

FRONT

SUSPENSION

AND

AXLE

Page 56 of 1502

FRONT SUSPENSION

AND

AXLE

2 - 3

FRONT

WHEEL

ALIGNMENT

GENERAL

INFORMATION

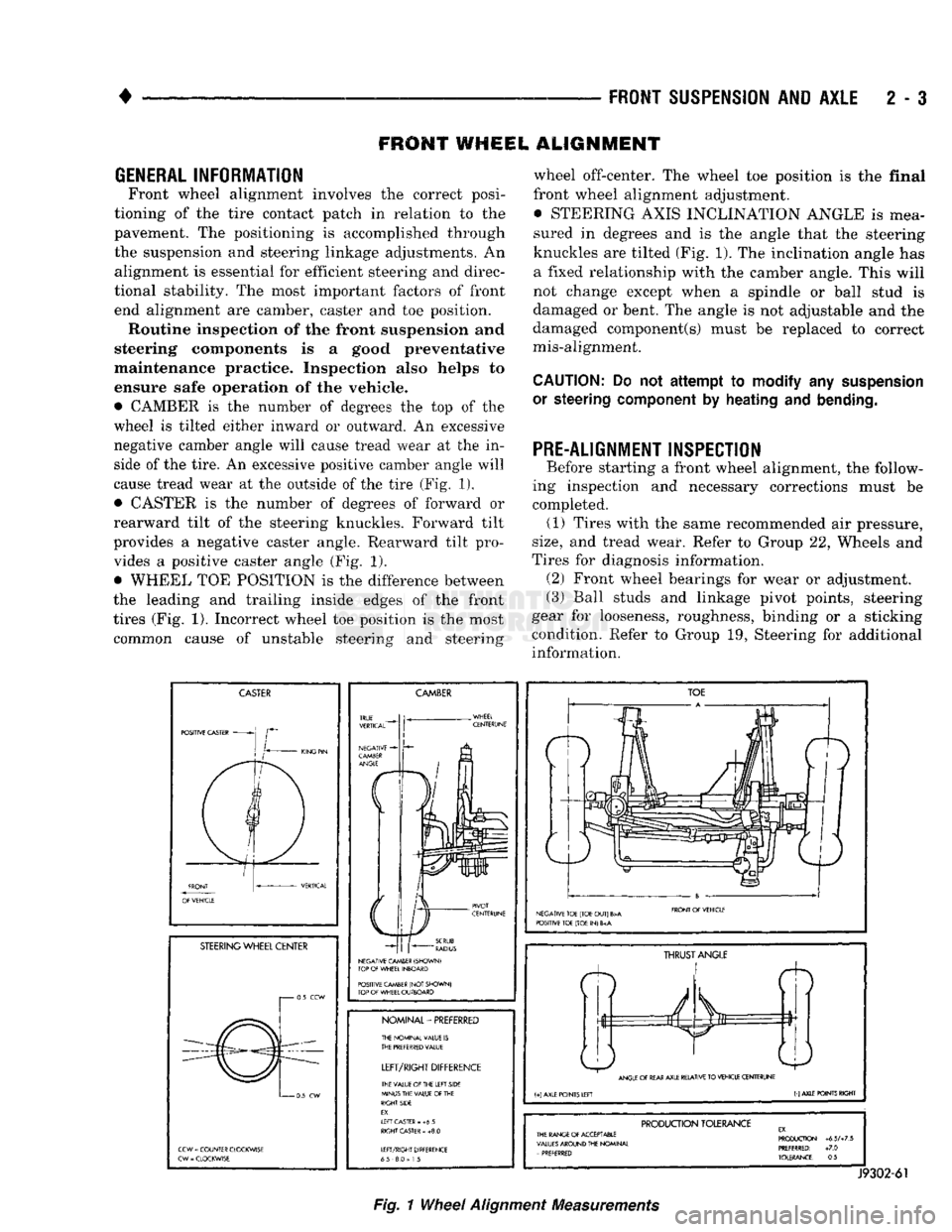

Front wheel alignment involves

the

correct posi

tioning

of the

tire contact patch

in

relation

to the

pavement.

The

positioning

is

accomplished through

the suspension

and

steering linkage adjustments.

An

alignment

is

essential

for

efficient steering

and

direc

tional stability.

The

most important factors

of

front

end alignment

are

camber, caster

and toe

position. Routine inspection

of

the front

suspension

and

steering components

is a

good

preventative

maintenance practice.

Inspection

also

helps

to

ensure

safe operation

of the

vehicle.

• CAMBER

is the

number

of

degrees

the top of the

wheel

is

tilted either inward

or

outward.

An

excessive

negative camber angle will cause tread wear

at the in

side

of

the tire.

An

excessive positive camber angle will

cause tread wear

at the

outside

of

the tire (Fig.

1),

• CASTER

is the

number

of

degrees

of

forward

or

rearward tilt

of the

steering knuckles. Forward tilt

provides

a

negative caster angle. Rearward tilt pro vides

a

positive caster angle

(Fig. 1).

• WHEEL

TOE

POSITION

is the

difference between

the leading

and

trailing inside edges

of the

front

tires (Fig.

1).

Incorrect wheel

toe

position

is the

most common cause

of

unstable steering

and

steering wheel off-center.

The

wheel

toe

position

is the

final

front wheel alignment adjustment. • STEERING AXIS INCLINATION ANGLE

is

mea

sured

in

degrees

and is the

angle that

the

steering

knuckles

are

tilted (Fig. 1).

The

inclination angle

has

a fixed relationship with

the

camber angle. This will

not change except when

a

spindle

or

ball stud

is

damaged

or

bent.

The

angle

is not

adjustable

and the

damaged component(s) must

be

replaced

to

correct

mis-alignment.

CAUTION:

Do not

attempt to modify

any

suspension

or steering

component

by

heating

and

bending.

PRE-ALIGNMENT INSPECTION

Before starting

a

front wheel alignment,

the

follow

ing inspection

and

necessary corrections must

be

completed.

(1)

Tires with

the

same recommended

air

pressure,

size,

and

tread wear. Refer

to

Group

22,

Wheels

and

Tires

for

diagnosis information. (2) Front wheel bearings

for

wear

or

adjustment.

(3) Ball studs

and

linkage pivot points, steering

gear

for

looseness, roughness, binding

or a

sticking

condition. Refer

to

Group

19,

Steering

for

additional information.

CASTER

POSITIVE CASTER

STEERING

WHEEL CENTER

i 0.5

CCW

0

5

CW

CCW

=

COUNTER CLOCKWISE

CW

-

CLOCKWISE

CAMBER

NEGATIVE CAMBER (SHOWN)

TOP

OF

WHEEL INBOARD

POSITIVE CAMBER

(NOT

SHOWN)

TOP

OF

WHEEL OUTBOARD

NOMINAL-PREFERRED

THE NOMINAL VALUE

IS

THE

PREFERRED

VALUE

LEFT/RIGHT

DIFFERENCE

THE VALUE

Of

THE LEFT SIDE

MINUS THE VALUE

OF

THE

RIGHT SIDE

EX.

If

FT CASTER

- +6 5

RIGHT

CASTER

»

+8.0

LEFT/RIGHT DIFFERENCE

65 8.0

=

1

5

TOE

NEGATIVE TOE (TOE

OUT)

B>A

POSITIVE TOE (TOE

IN) 6

FRONT

Of

VEHICLE

ft

THRUST

ANGLE

ANGLE

OF

REAR

AXLE RELATIVE

TO

VEHICLE CENTERUNE

(+)

AXLE POINTS LEFT

(-)

AXLE POINTS RIGHT

PRODUCTION

TOLERANCE

THE RANGE

Of

ACCEPTABLE

VALUES

AROUND THE NOMINAL

-

PREFERRED PRODUCTION

+6.5A7.5

PREFERRED:

+7.0

TOLERANCE:

0.5

J9302-61

Fig.

1

Wheel

Alignment

Measurements

Page 57 of 1502

2 - 4 FRONT SUSPENSION AND AXLE

•

I

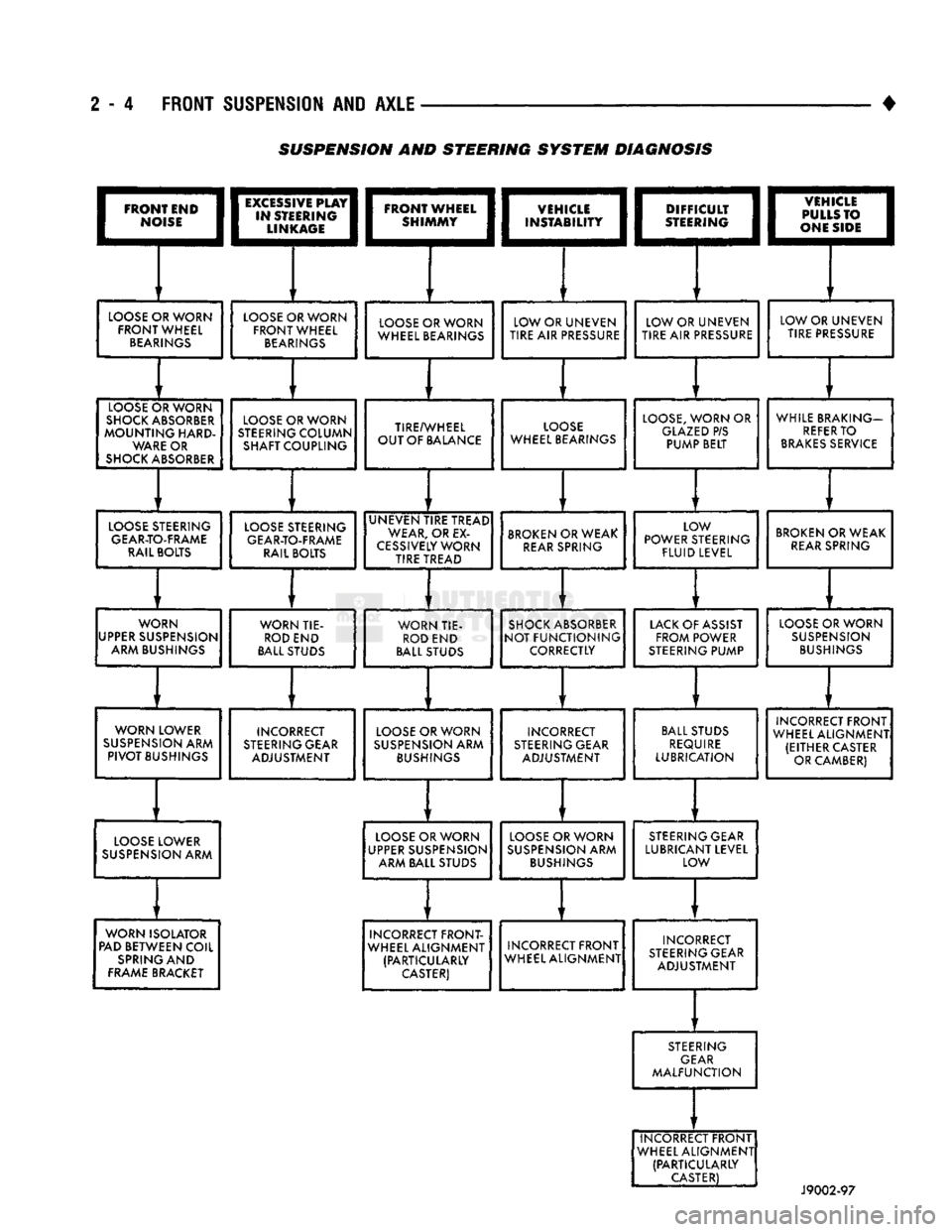

FRONT END

|

|*?£E;

LOOSE

OR WORN

FRONT WHEEL

BEARINGS

LOOSE

C

SHOCKS

MOUNTir

WAR

SHOCK

A )RWORN

JSORBER

nIG

HARD-

E

OR

BSORBER

EXCiSSIVE

PLAY

STEERING

LINKAGE

LOOSE

OR WORN

FRONT WHEEL

BEARINGS

LOOSE

C

STEERINC

SHAFT

C

)RWORN

7

COLUMN

OUPLING

DIFFICULT

STEERING

LOOSE

OR WORN

WHEEL BEARINGS

TIRE/V

OUT OF

f

VHEEL

JA

LANCE

LOW OR UNEVEN

TIRE

AIR

PRESSURE

LO(

WHEEL B

DSE

EARINGS

LOW OR UNEVEN

TIRE AIR

PRESSURE

1vsnciEi

I

1

PULLS

TO I

I

|

ONE SIDE

j

LOOSE,

WORN

OR

GLAZED

P/S PUMP BELT LOW OR UNEVEN

TIRE PRESSURE

WHILE BR

REFE

BRAKES

AKING—

R

TO

SERVICE

LOOSE

STEERING

GEAR-TO-FRAME

RAIL BOLTS

LOOSE

STEERING

GEAR-TO-FRAME

RAIL BOLTS UNEVEN TIRE TREAD

WEAR,

OR

EX

CESSIVELY

WORN TIRE TREAD

BROKEN

OR WEAK

REAR

SPRING LOW

POWER STEERING

FLUID

LEVEL

BROKEN

OR WEAK

REAR

SPRING

WORN

UPPER

SUSPENSION ARM BUSHINGS WORN TIE-

ROD

END

BALL

STUDS WORN TIE-

ROD

END

BALL

STUDS

SHOCK

ABSORBER

NOT FUNCTIONING

CORRECTLY

LACK

OF ASSIST

FROM POWER

STEERING

PUMP

LOOSE

OR WORN

SUSPENSION

BUSHINGS

WORN LOWER

SUSPENSION

ARM

PIVOT

BUSHINGS INCORRECT

STEERING

GEAR ADJUSTMENT

LOOSE

OR WORN

SUSPENSION

ARM

BUSHINGS

INCORRECT

STEERING

GEAR ADJUSTMENT

BALL

STUDS

REQUIRE

LUBRICATION INCORRECT FRONT

WHEEL ALIGNMENT (EITHER CASTER OR CAMBER)

LOOSE

LOWER

SUSPENSION

ARM

LOOSE

OR WORN

UPPER

SUSPENSION ARM BALL STUDS

LOOSE

OR WORN

SUSPENSION

ARM

BUSHINGS

STEERING

GEAR

LUBRICANT LEVEL LOW

WORN ISOLATOR

PAD

BETWEEN COIL

SPRING

AND

FRAME

BRACKET INCORRECT FRONT-

WHEEL ALIGNMENT (PARTICULARLY

CASTER)

INCORRECT FRONT

WHEEL ALIGNMENT INCORRECT

STEERING

GEAR ADJUSTMENT

STEERING

GEAR

MALFUNCTION

INCORRECT FRONT

WHEEL ALIGNMENT (PARTICULARLY

CASTER)

J9002-97

SUSPENSION AND STEERING

SYSTEM

DIAGNOSIS

Page 58 of 1502

•

FRONT

SUSPENSION

AND

AXLE

2 - 5 (4) Front wheels for excessive radial, lateral

runout and unbalance. Refer to Group 22, Wheels and Tires for diagnosis information.

(5) Suspension components for wear and noise. Check

components for correct torque. Refer to Groups 2 and 3, Suspension and Axle for additional information.

WHEEL

ALIGNMENT

MEASUREMENTS/ADJUSTMENTS

The front wheel alignment positions must be set to

the specified limits. This will prevent abnormal tire

tread wear. The equipment manufacturer's recommenda

tions for use of their

equipment

should always

be followed. All

damaged

front suspension sys

tem components

should

be replaced. Do not at tempt to straighten any

bent

component.

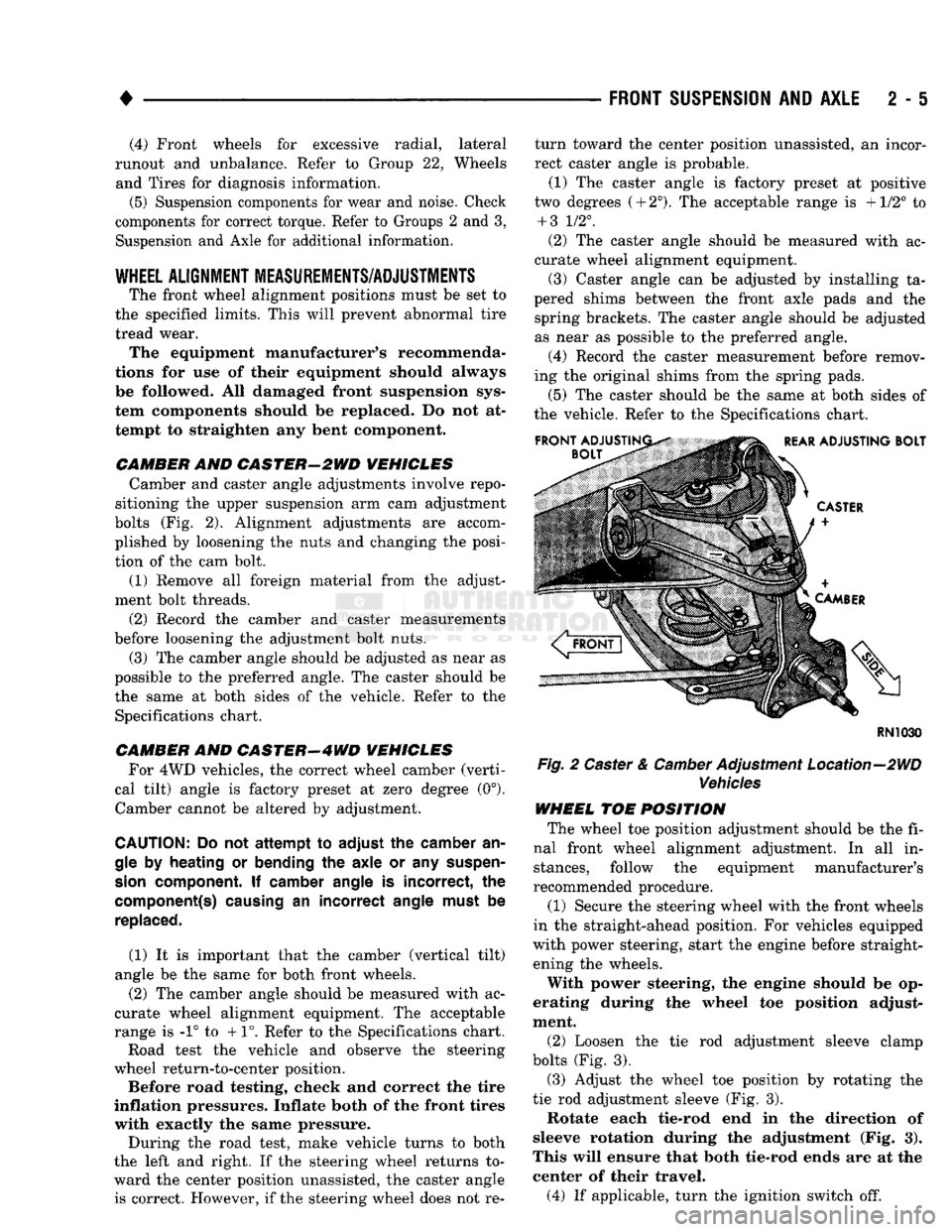

CAMBER AND CASTER-2WD VEHICLES Camber and caster angle adjustments involve repo

sitioning the upper suspension arm cam adjustment

bolts (Fig. 2). Alignment adjustments are accom

plished by loosening the nuts and changing the posi

tion of the cam bolt.

(1) Remove all foreign material from the adjust

ment bolt threads.

(2) Record the camber and caster measurements

before loosening the adjustment bolt nuts.

(3) The camber angle should be adjusted as near as

possible to the preferred angle. The caster should be

the same at both sides of the vehicle. Refer to the Specifications chart.

CAMBER AND CASTER—4WD VEHICLES For 4WD vehicles, the correct wheel camber (verti

cal tilt) angle is factory preset at zero degree (0°).

Camber cannot be altered by adjustment.

CAUTION: Do not attempt to

adjust

the

camber

an

gle by

heating

or bending the axle or any

suspen

sion

component. If camber angle is

incorrect,

the

component(s)

causing

an

incorrect

angle must be replaced.

(1) It is important that the camber (vertical tilt)

angle be the same for both front wheels.

(2) The camber angle should be measured with ac

curate wheel alignment equipment. The acceptable

range is -1° to +1°. Refer to the Specifications chart.

Road test the vehicle and observe the steering

wheel return-to-center position. Before road testing,

check

and

correct

the tire

inflation pressures. Inflate

both

of the front tires

with exactly the

same

pressure.

During the road test, make vehicle turns to both

the left and right. If the steering wheel returns to

ward the center position unassisted, the caster angle is correct. However, if the steering wheel does not re turn toward the center position unassisted, an incor

rect caster angle is probable.

(1) The caster angle is factory preset at positive

two degrees

(

+

2°).

The acceptable range is +1/2° to +

3

1/2°.

(2) The caster angle should be measured with ac

curate wheel alignment equipment.

(3) Caster angle can be adjusted by installing ta

pered shims between the front axle pads and the spring brackets. The caster angle should be adjusted

as near as possible to the preferred angle.

(4) Record the caster measurement before remov

ing the original shims from the spring pads.

(5) The caster should be the same at both sides of

the vehicle. Refer to the Specifications chart.

RN1030

Fig.

2 Caster &

Camber

Adjustment Location—2WD

Vehicles

WHEEL TOE POSITION The wheel toe position adjustment should be the fi

nal front wheel alignment adjustment. In all in stances, follow the equipment manufacturer's

recommended procedure.

(1) Secure the steering wheel with the front wheels

in the straight-ahead position. For vehicles equipped

with power steering, start the engine before straight ening the wheels.

With power steering, the engine should be op

erating during the wheel toe position adjust

ment.

(2) Loosen the tie rod adjustment sleeve clamp

bolts (Fig. 3).

(3) Adjust the wheel toe position by rotating the

tie rod adjustment sleeve (Fig. 3). Rotate each tie-rod end in the direction of

sleeve rotation during the adjustment (Fig. 3).

This will ensure that both tie-rod ends are at the center of their travel.

(4) If applicable, turn the ignition switch off.

Page 84 of 1502

•

FRONT SUSPENSION

AND

AXLE

2 - 31

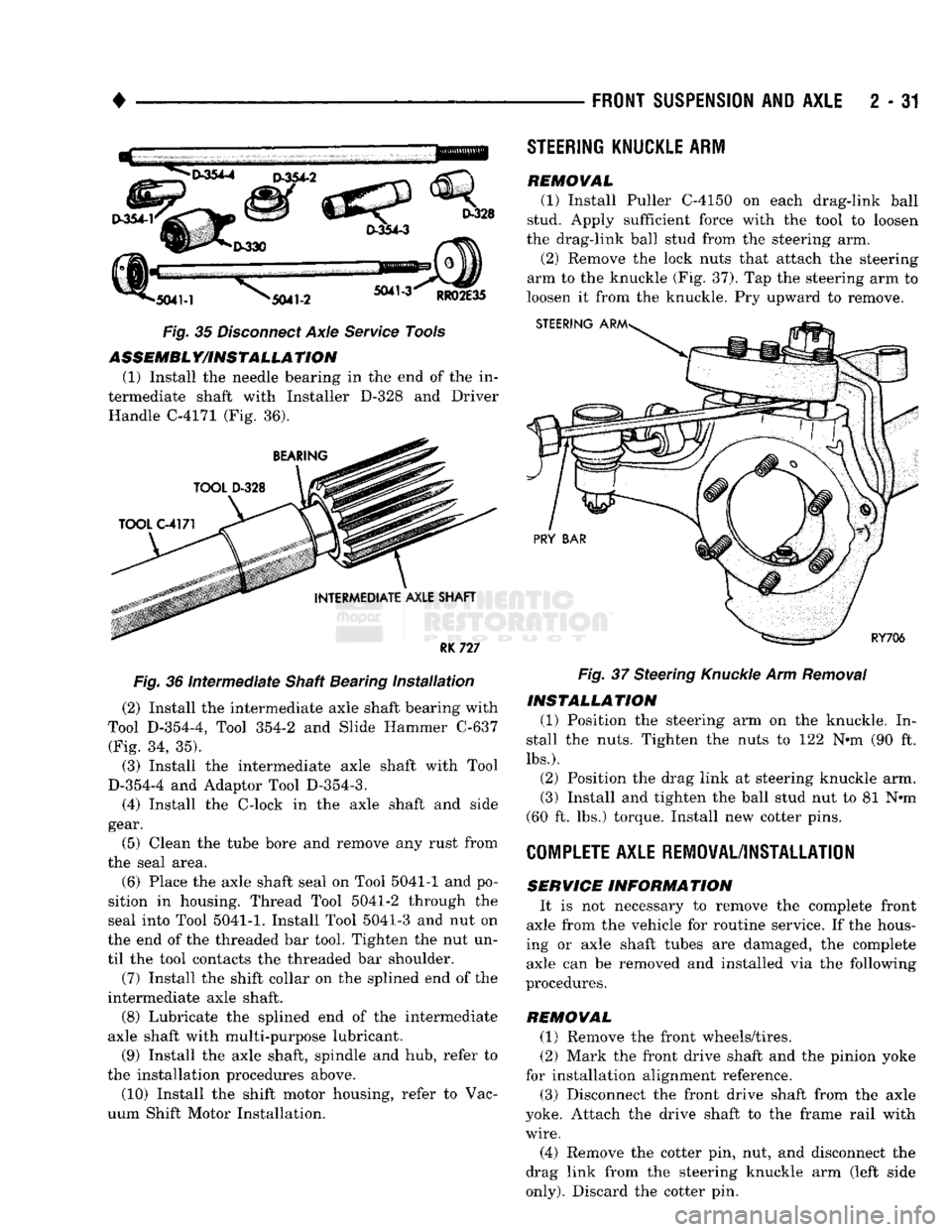

Fig. 35 Disconnect Axle Service Tools ASSEMBLY/INSTALLATION

(1) Install the needle bearing in the end of the in

termediate shaft with Installer D-328 and Driver Handle C-4171 (Fig. 36).

RK

727

Fig. 36 Intermediate Shaft Bearing installation (2) Install the intermediate axle shaft bearing with

Tool D-354-4, Tool 354-2 and Slide Hammer C-637 (Fig. 34, 35).

(3) Install the intermediate axle shaft with Tool

D-354-4 and Adaptor Tool D-354-3.

(4) Install the C-lock in the axle shaft and side

gear.

(5) Clean the tube bore and remove any rust from

the seal area.

(6) Place the axle shaft seal on Tool 5041-1 and po

sition in housing. Thread Tool 5041-2 through the

seal into Tool

5041-1.

Install Tool 5041-3 and nut on

the end of the threaded bar tool. Tighten the nut un

til the tool contacts the threaded bar shoulder.

(7) Install the shift collar on the splined end of the

intermediate axle shaft.

(8) Lubricate the splined end of the intermediate

axle shaft with multi-purpose lubricant.

(9) Install the axle shaft, spindle and hub, refer to

the installation procedures above. (10) Install the shift motor housing, refer to Vac

uum Shift Motor Installation.

STEERING

KNUCKLE

ARM

REMOVAL

(1) Install Puller C-4150 on each drag-link ball

stud. Apply sufficient force with the tool to loosen

the drag-link ball stud from the steering arm.

(2) Remove the lock nuts that attach the steering

arm to the knuckle (Fig. 37). Tap the steering arm to

loosen it from the knuckle. Pry upward to remove. Fig. 37 Steering Knuckle Arm Removal

INSTALLATION

(1) Position the steering arm on the knuckle. In

stall the nuts. Tighten the nuts to 122 N«m (90 ft.

lbs.).

(2) Position the drag link at steering knuckle arm.

(3) Install and tighten the ball stud nut to 81 N*m

(60 ft. lbs.) torque. Install new cotter pins.

COMPLETE

AXLE REMOVAL/INSTALLATION

SERVICE

INFORMATION

It is not necessary to remove the complete front

axle from the vehicle for routine service. If the hous

ing or axle shaft tubes are damaged, the complete axle can be removed and installed via the following

procedures.

REMOVAL (1) Remove the front wheels/tires.

(2) Mark the front drive shaft and the pinion yoke

for installation alignment reference.

(3) Disconnect the front drive shaft from the axle

yoke. Attach the drive shaft to the frame rail with

wire.

(4) Remove the cotter pin, nut, and disconnect the

drag link from the steering knuckle arm (left side

only).

Discard the cotter pin.

Page 112 of 1502

•

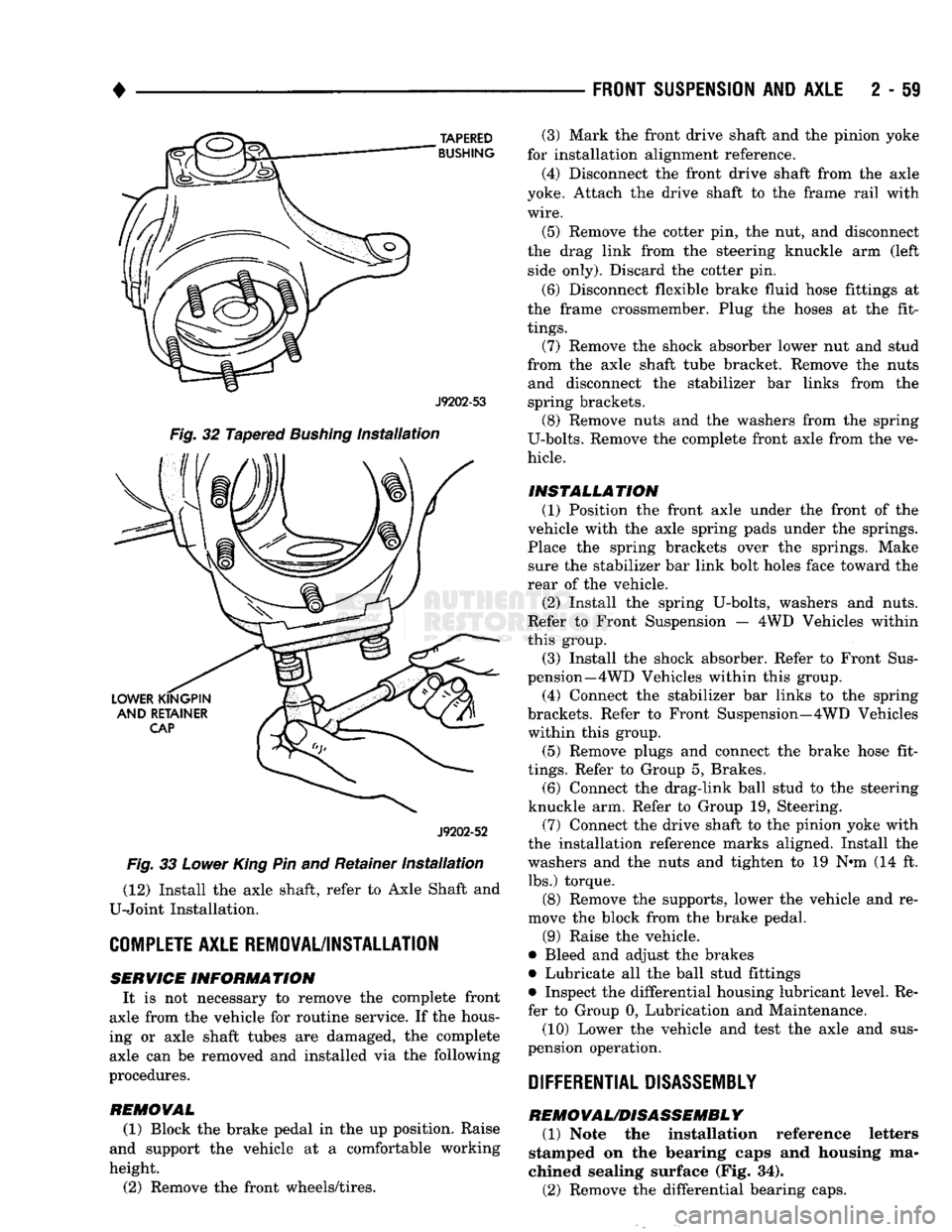

TAPERED

BUSHING

J9202-53

Fig.

32 Tapered

Bushing

Installation

J9202-52

Fig.

33

Lower

King

Pin and Retainer

Installation

(12) Install the axle shaft, refer to Axle Shaft and

U-Joint Installation.

COMPLETE

AXLE REMOVAL/INSTALLATION SERVICE

INFORMATION

It is not necessary to remove the complete front

axle from the vehicle for routine service. If the hous

ing or axle shaft tubes are damaged, the complete axle can be removed and installed via the following

procedures.

REMOVAL

(1) Block the brake pedal in the up position. Raise

and support the vehicle at a comfortable working

height.

(2) Remove the front wheels/tires.

FRONT SUSPENSION

AND

AXLE

2 - 59

(3) Mark the front drive shaft and the pinion yoke

for installation alignment reference.

(4) Disconnect the front drive shaft from the axle

yoke. Attach the drive shaft to the frame rail with

wire.

(5) Remove the cotter pin, the nut, and disconnect

the drag link from the steering knuckle arm (left side only). Discard the cotter pin.

(6) Disconnect flexible brake fluid hose fittings at

the frame crossmember. Plug the hoses at the fit

tings.

(7) Remove the shock absorber lower nut and stud

from the axle shaft tube bracket. Remove the nuts and disconnect the stabilizer bar links from the

spring brackets. (8) Remove nuts and the washers from the spring

U-bolts. Remove the complete front axle from the ve

hicle.

INSTALLATION (1) Position the front axle under the front of the

vehicle with the axle spring pads under the springs.

Place the spring brackets over the springs. Make sure the stabilizer bar link bolt holes face toward the

rear of the vehicle.

(2) Install the spring U-bolts, washers and nuts.

Refer to Front Suspension — 4WD Vehicles within

this group. (3) Install the shock absorber. Refer to Front Sus

pension—4 WD Vehicles within this group.

(4) Connect the stabilizer bar links to the spring

brackets. Refer to Front Suspension—4WD Vehicles within this group.

(5) Remove plugs and connect the brake hose fit

tings.

Refer to Group 5, Brakes. (6) Connect the drag-link ball stud to the steering

knuckle arm. Refer to Group 19, Steering. (7) Connect the drive shaft to the pinion yoke with

the installation reference marks aligned. Install the

washers and the nuts and tighten to 19 N-m (14 ft. lbs.) torque.

(8) Remove the supports, lower the vehicle and re

move the block from the brake pedal.

(9) Raise the vehicle.

• Bleed and adjust the brakes

• Lubricate all the ball stud fittings

• Inspect the differential housing lubricant level. Re

fer to Group 0, Lubrication and Maintenance.

(10) Lower the vehicle and test the axle and sus

pension operation.

DIFFERENTIAL DISASSEMBLY

REMOVAL/DISASSEMBLY

(1) Note the installation reference letters

stamped on the bearing caps and housing ma

chined sealing surface (Fig. 34).

(2) Remove the differential bearing caps.

Page 135 of 1502

3

- 6

REAR SUSPENSION

AND

AXLE

•

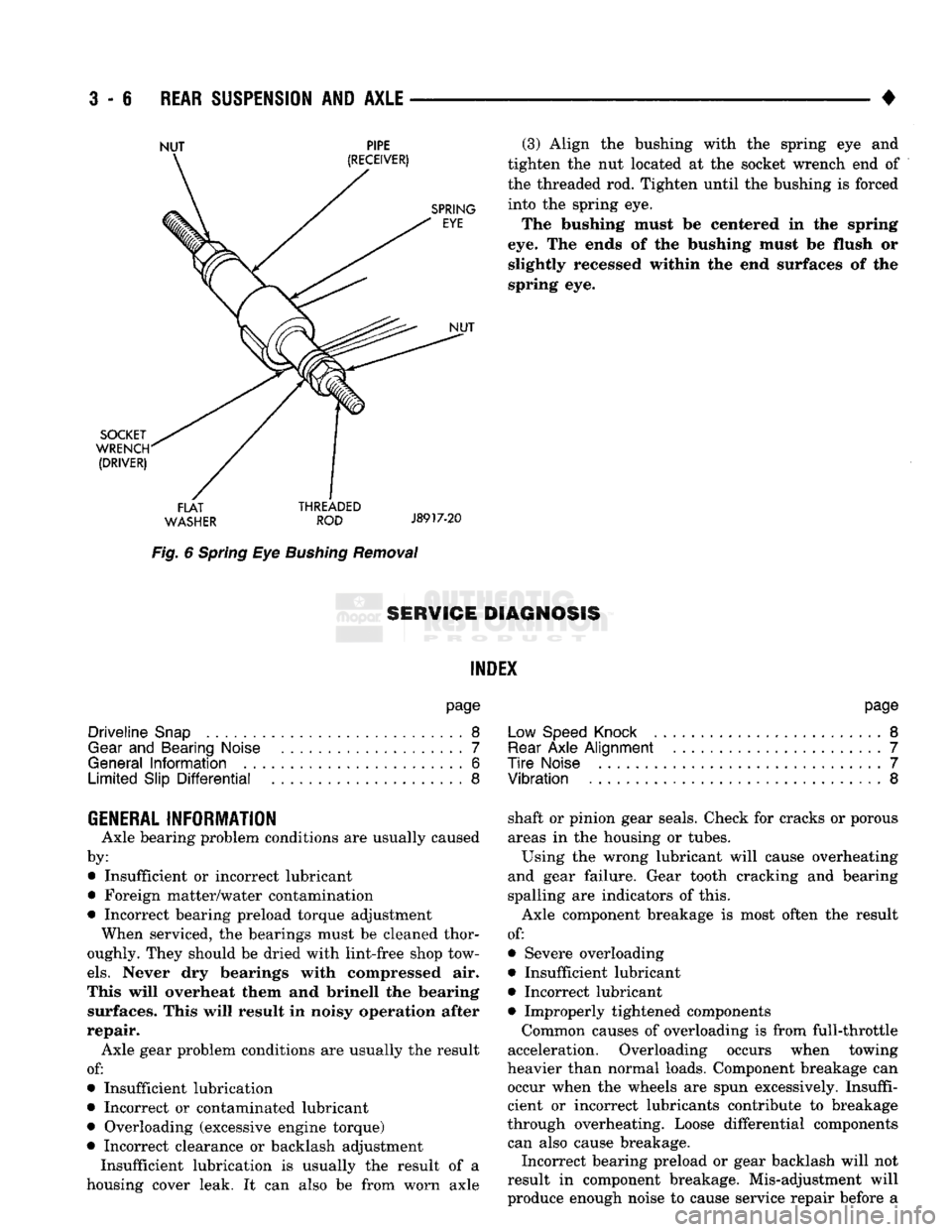

NUT PIPE

SOCKET

WRENCH

(DRIVER)

FLAT

THREADED

WASHER

ROD

J8917-20

Fig.

6

Spring

Eye

Bushing

Removal

(3) Align

the

bushing with

the

spring

eye and

tighten

the nut

located

at the

socket wrench

end of

the threaded

rod.

Tighten until

the

bushing

is

forced into

the

spring

eye.

The bushing must

be

centered

in the

spring

eye.

The

ends

of the

bushing must

be

flush

or

slightly recessed within

the end

surfaces

of the

spring

eye.

8ERW1GE DIAGNOSIS

INDEX

page

Driveline

Snap

8

Gear

and

Bearing Noise

7

General

Information

6

Limited

Slip

Differential

8

page

Low Speed Knock

.........................

8

Rear

Axle

Alignment

.......................

7

Tire

Noise

7

Vibration

8

GENERAL INFORMATION

Axle bearing problem conditions

are

usually caused

by: • Insufficient

or

incorrect lubricant

• Foreign matter/water contamination

• Incorrect bearing preload torque adjustment When serviced,

the

bearings must

be

cleaned thor

oughly. They should

be

dried with lint-free shop tow

els.

Never

dry

bearings with compressed

air.

This will overheat them

and

brinell

the

bearing surfaces. This will result

in

noisy operation after

repair. Axle gear problem conditions

are

usually

the

result

of:

• Insufficient lubrication

• Incorrect

or

contaminated lubricant

• Overloading (excessive engine torque)

• Incorrect clearance

or

backlash adjustment Insufficient lubrication

is

usually

the

result

of a

housing cover leak.

It can

also

be

from worn axle shaft

or

pinion gear seals. Check

for

cracks

or

porous

areas

in the

housing

or

tubes.

Using

the

wrong lubricant will cause overheating

and gear failure. Gear tooth cracking

and

bearing

spalling

are

indicators

of

this.

Axle component breakage

is

most often

the

result

of:

• Severe overloading

• Insufficient lubricant

• Incorrect lubricant • Improperly tightened components

Common causes

of

overloading

is

from full-throttle

acceleration. Overloading occurs when towing

heavier than normal loads. Component breakage

can

occur when

the

wheels

are

spun excessively. Insuffi

cient

or

incorrect lubricants contribute

to

breakage

through overheating. Loose differential components can also cause breakage. Incorrect bearing preload

or

gear backlash will

not

result

in

component breakage. Mis-adjustment will

produce enough noise

to

cause service repair before

a

Page 136 of 1502

•

RfAR SUSPENSION

AND

AXLE

3 - 7 failure occurs. If a mis-adjustment condition is not

corrected, component failure can result.

REAR

AXLE ALIGNMENT

MEASUREMENT The following procedure can be used to determine

if abnormal rear tire tread wear is the result of a

bent or deformed rear axle shaft.

(1) Raise both rear wheels off the surface with a

frame contact hoist. (2) Attach a one-inch long piece of masking tape at

the center of each tire tread for use as reference marks.

(3) Rotate the rear wheels until both reference

marks face the front of the vehicle. Measure the dis

tance between the outside edges of the two pieces of

tape.

Record this measurement as the front of tire (FTR) measurement.

(4) Rotate the rear wheels until both reference

marks face the rear of the vehicle. Measure the dis

tance between the outside edges of the two pieces of

tape.

Record this measurement as the rear of tire (RTR) measurement.

(5) Subtract the (RTR) measurement from the

(FTR) measurement to obtain the amount of wheel

toe.

The acceptable rear wheel toe-in position is 1/16 inch (1.6 mm) to 3/16 inch (4.8 mm) toe-out.

(6) Rotate the rear wheels until the reference

marks are facing downward. Measure the distance

between the outside edges of the two pieces of tape. Record this measurement as the bottom of tire (BTR)

measurement.

(7) Average the (FTR) and the (RTR) distance

measurements. Subtract the (BTR) measurement

from this average distance to obtain the camber. The acceptable amount of camber is 1/16 inch to 3/32 inch

(1.6 to 2.4 mm).

(FTR + RTR) DIVIDED BY 2 (TWO) MINUS

BTR EQUALS CAMBER

If the (BTR) distance measurement is less than

the average FTR and RTR distance measure

ment, the camber will be positive ( + ). If the (BTR) distance measurement is greater than the average FTR and RTR distance, the camber will

be negative ( - ).

If the toe position or camber is not acceptable, a

bent or deformed rear axle shaft is most likely the cause.

TIRE

NOISE

Check tires that are damaged, unbalanced, incor

rectly inflated. Tires that have deep treads can emit sounds like axle noise. Differentiate between tire and

axle noise during a road test. Tire noise will usually vary with different road

conditions. Tire noise is sensitive to inflation pres

sure.

The pitch of tire noise changes when the vehi

cle speed is varied.

Drive the vehicle over different road surfaces. Note

the changes in the noise. If the noise changes, the

tires are the source of the noise.

Refer to Group 22, Wheels and Tires for additional

information.

GEAR

AND BEARING NOISE

GEAR

NOISE

Axle gear noise can be caused by insufficient lubri

cant. Incorrect backlash, tooth contact, or worn/dam aged gears can cause noise.

Gear noise usually happens at a specific speed

range. The range is 30 to 40 mph, or above 50 mph.

The noise can also occur during a specific type of driving condition. These conditions are, acceleration,

deceleration, coast, or constant load.

When road testing, accelerate the vehicle to the

speed range where the noise is the greatest. Shift

out-of-gear and coast through the peak-noise range.

If the noise stops or changes greatly, check for

insuf

ficient lubricant. Incorrect ring gear backlash, or gear damage can cause noise changes.

Differential side and pinion gears can be checked

by turning the vehicle. They usually do not cause noise in straight-ahead driving. These gears are

loaded during vehicle turns. If noise does occur dur

ing vehicle turns, the side or pinion gears could be

worn or damaged. A worn pinion gear mate shaft can also cause a snapping or a knocking noise.

BEARING NOISE

The axle shaft, differential and pinion gear bear

ings can all produce noise when worn or damaged.

Bearing noise can be either a whining, or a growling sound.

Pinion gear bearings have a constant-pitch noise.

This noise changes only with vehicle speed. Pinion

bearing noise will be higher because it rotates at a faster rate. Drive the vehicle and load the differen

tial.

If bearing noise occurs the pinion rear bearing is the source of the noise. If the bearing noise is heard during a coast, front bearing is the source.

Worn, damaged differential bearings usually pro

duce a low pitch noise. Differential bearing noise is

similar to pinion bearing. The pitch of differential

bearing noise is also constant and varies only with vehicle speed.

Axle shaft bearings produce noise and vibration

when worn or damaged. The noise generally changes

when the bearings are loaded. Road test the vehicle. Turn the vehicle sharply to the left and to the right.

This will load the bearings and change the noise

Page 138 of 1502

REAR

SUSPENSION

AND

AXLE

3 - 9

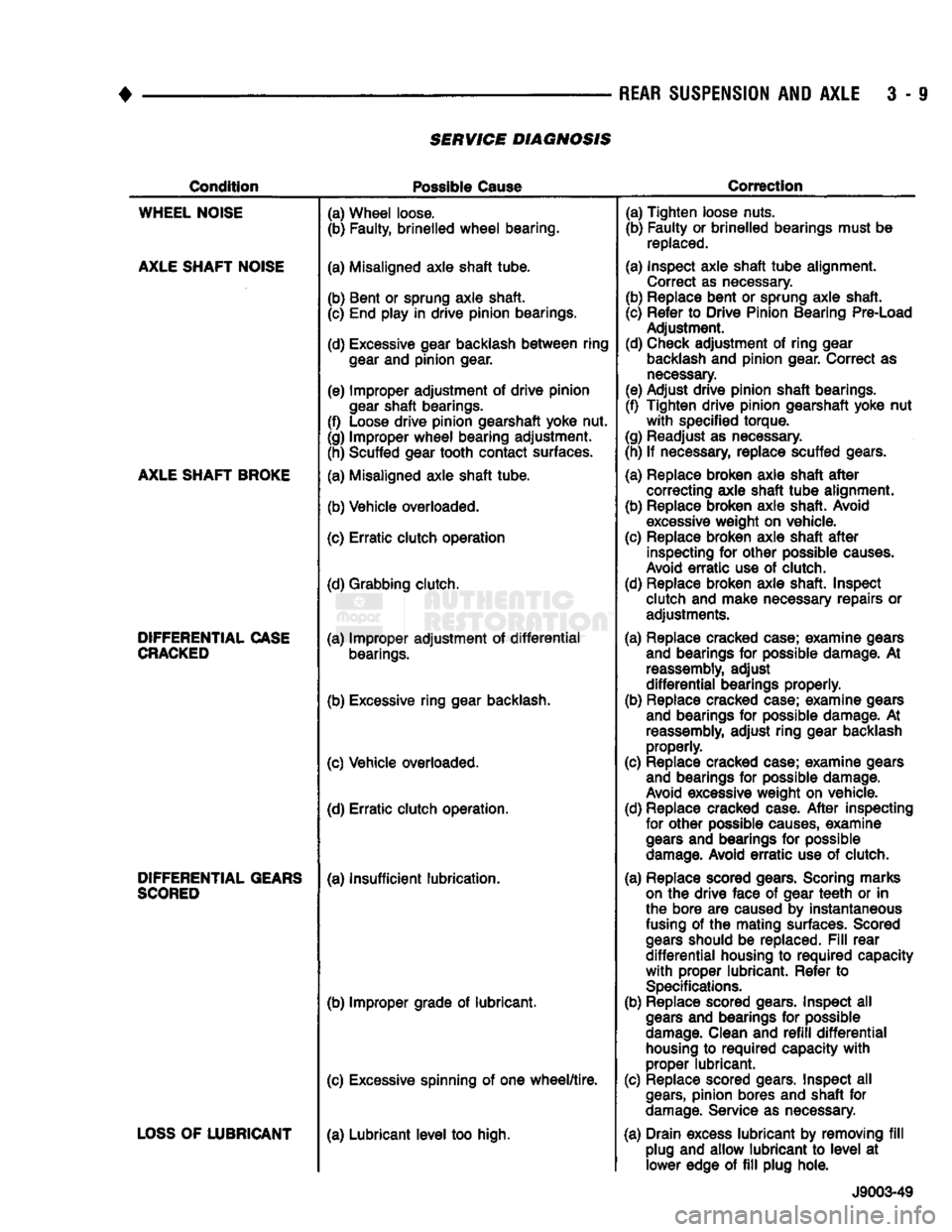

SERVICE DIAGNOSIS

Condition

Possible

Cause

Correction

WHEEL

NOISE

AXLE

SHAFT

NOISE

AXLE

SHAFT

BROKE

DIFFERENTIAL

CASE

CRACKED

DIFFERENTIAL

GEARS

SCORED

LOSS

OF

LUBRICANT

(a) Wheel loose.

(b) Faulty, brinelled

wheel

bearing.

(a) Misaligned axle shaft tube.

(b) Bent or sprung axle shaft. (c) End play in drive pinion bearings.

(d) Excessive gear backlash

between

ring

gear

and pinion gear.

(e) Improper adjustment of drive pinion

gear

shaft bearings.

(f) Loose drive pinion gearshaft yoke nut.

(g) Improper

wheel

bearing adjustment. (h) Scuffed gear tooth contact surfaces.

(a) Misaligned axle shaft tube.

(b) Vehicle overloaded.

(c) Erratic clutch operation

(d) Grabbing clutch.

(a) Improper adjustment of

differential

bearings.

(b) Excessive ring gear backlash.

(c) Vehicle overloaded. (d) Erratic clutch operation.

(a) Insufficient lubrication.

(b) Improper grade of lubricant.

(c) Excessive spinning of one

wheel/tire.

(a) Lubricant

level

too high. (a) Tighten loose nuts.

(b) Faulty or brinelled bearings must be

replaced.

(a) Inspect axle shaft

tube

alignment. Correct as necessary.

(b) Replace bent or sprung axle shaft.

(c) Refer to Drive Pinion Bearing Pre-Load Adjustment.

(d) Check adjustment of ring gear

backlash

and pinion gear. Correct as

necessary.

(e) Adjust drive pinion shaft bearings.

(f) Tighten drive pinion gearshaft yoke nut

with

specified torque.

(g) Readjust as necessary.

(h) If necessary, replace scuffed gears.

(a) Replace broken axle shaft

after

correcting axle shaft

tube

alignment.

(b) Replace broken axle shaft. Avoid

excessive

weight on vehicle.

(c) Replace broken axle shaft

after

inspecting for other possible

causes.

Avoid

erratic

use of clutch.

(d) Replace broken axle shaft. Inspect clutch and make necessary repairs or adjustments.

(a) Replace cracked case; examine gears and bearings for possible damage. At

reassembly,

adjust

differential

bearings properly.

(b) Replace cracked case; examine gears and bearings for possible damage. At

reassembly,

adjust ring gear backlash properly.

(c) Replace cracked case; examine gears and bearings for possible damage.

Avoid

excessive weight on vehicle.

(d) Replace cracked case.

After

inspecting for other possible

causes,

examine

gears

and bearings for possible

damage.

Avoid

erratic

use of clutch.

(a) Replace scored gears. Scoring marks

on

the drive face of gear

teeth

or in

the bore are caused by instantaneous

fusing

of the mating surfaces. Scored

gears

should be replaced.

Fill

rear

differential

housing to

required

capacity

with

proper lubricant. Refer to

Specifications.

(b) Replace scored gears. Inspect all

gears

and bearings for possible

damage.

Clean and

refill

differential

housing

to

required

capacity

with

proper lubricant.

(c) Replace scored gears. Inspect all

gears,

pinion bores and shaft for

damage.

Service as necessary.

(a) Drain excess lubricant by removing

fill

plug and allow lubricant to

level

at lower edge of

fill

plug hole.

J9003-49

Page 140 of 1502

•

REAR

SUSPENSION

AND

AXLE

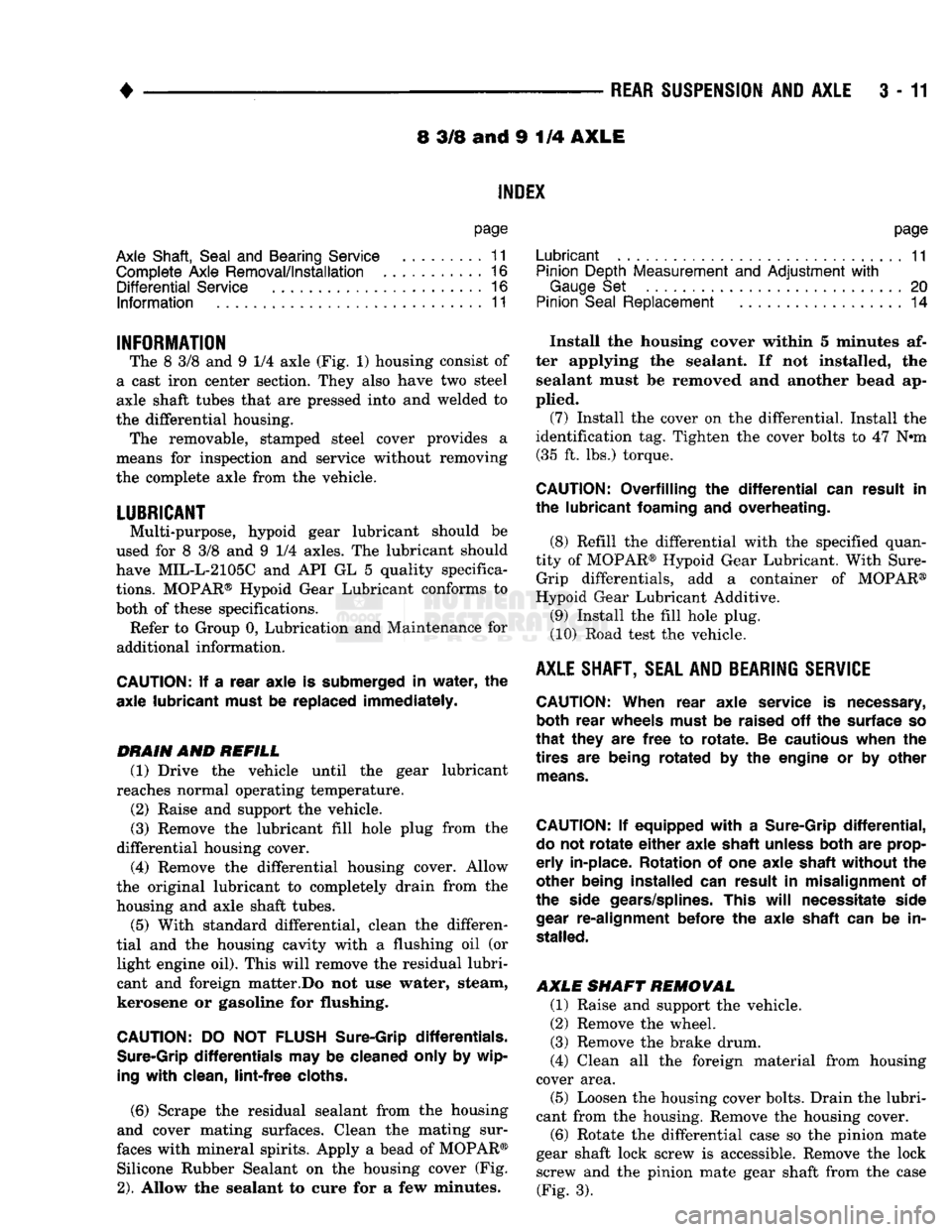

3 - 11 8 3/8 and 9 1/4

AXLE

INDEX

page

Axle Shaft, Seal

and

Bearing Service

......... 11

Complete Axle Removal/Installation

16

Differential

Service

16

Information

11

INFORMATION

The 8 3/8 and 9 1/4 axle (Fig. 1) housing consist of

a cast iron center section. They also have two steel

axle shaft tubes that are pressed into and welded to

the differential housing. The removable, stamped steel cover provides a

means for inspection and service without removing

the complete axle from the vehicle.

LUBRICANT

Multi-purpose, hypoid gear lubricant should be

used for 8 3/8 and 9 1/4 axles. The lubricant should

have MIL-L-2105C and API GL 5 quality specifica

tions.

MOPAR® Hypoid Gear Lubricant conforms to

both of these specifications.

Refer to Group 0, Lubrication and Maintenance for

additional information.

CAUTION:

If a

rear axle

is

submerged

in

water,

the

axle lubricant must

be

replaced immediately.

DRAIN

AND

REFILL

(1) Drive the vehicle until the gear lubricant

reaches normal operating temperature.

(2) Raise and support the vehicle.

(3) Remove the lubricant fill hole plug from the

differential housing cover.

(4) Remove the differential housing cover. Allow

the original lubricant to completely drain from the

housing and axle shaft tubes. (5) With standard differential, clean the differen

tial and the housing cavity with a flushing oil (or light engine oil). This will remove the residual lubri

cant and foreign matter.Do not use water, steam,

kerosene or gasoline for flushing.

CAUTION:

DO NOT

FLUSH

Sure-Grip differentials.

Sure-Grip

differentials

may be

cleaned only

by

wip

ing

with

clean,

lint-free

cloths.

(6)

Scrape the residual sealant from the housing

and cover mating surfaces. Clean the mating sur

faces with mineral spirits. Apply a bead of MOPAR® Silicone Rubber Sealant on the housing cover (Fig.

2).

Allow the sealant to cure for a few minutes.

page

Lubricant

11

Pinion Depth Measurement

and

Adjustment

with

Gauge

Set 20

Pinion

Seal

Replacement

14

Install the housing cover within 5 minutes af

ter applying the sealant. If not installed, the sealant must be removed and another bead ap

plied. (7) Install the cover on the differential. Install the

identification tag. Tighten the cover bolts to 47 N#m (35 ft. lbs.) torque.

CAUTION:

Overfilling

the

differential

can

result

in

the lubricant foaming

and

overheating.

(8) Refill the differential with the specified quan

tity of MOPAR® Hypoid Gear Lubricant. With Sure- Grip differentials, add a container of MOPAR®

Hypoid Gear Lubricant Additive.

(9) Install the fill hole plug.

(10) Road test the vehicle.

AXLE

SHAFT, SEAL AND BEARING

SERVICE

CAUTION:

When rear axle service

is

necessary, both rear wheels must

be

raised

off the

surface

so

that

they

are

free

to

rotate.

Be

cautious when

the

tires

are

being rotated

by the

engine

or by

other

means.

CAUTION:

If

equipped

with

a

Sure-Grip

differential,

do

not

rotate

either

axle shaft unless both

are

prop

erly

in-place. Rotation

of one

axle shaft without

the

other being installed

can

result

in

misalignment

of

the side gears/splines. This

will

necessitate side

gear

re-alignment before

the

axle shaft

can be in

stalled.

AXLE SHAFT REMOVAL

(1) Raise and support the vehicle.

(2) Remove the wheel.

(3) Remove the brake drum.

(4) Clean all the foreign material from housing

cover area.

(5) Loosen the housing cover bolts. Drain the lubri

cant from the housing. Remove the housing cover.

(6)

Rotate the differential case so the pinion mate

gear shaft lock screw is accessible. Remove the lock screw and the pinion mate gear shaft from the case (Fig. 3).