ECU DODGE VIPER 2004 ZB / 2.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2004, Model line: VIPER, Model: DODGE VIPER 2004 ZB / 2.GPages: 236, PDF Size: 4.18 MB

Page 46 of 236

You will want to have the airbags ready for your protec-

tion in a collision. While the airbag Supplemental Re-

straint System (SRS) is designed to be maintenance free,

if any of the following occurs, have an authorized dealer

service the system immediately.

²The AIRBAG light does not come on or flickers during

the 6 to 8 seconds when the ignition switch is first

turned on.

²The light remains on or flickers after the 6 to 8 second

interval.

²The light flickers or comes on and remains on while

driving.

Transporting Pets

Deploying airbags could harm your pet. An unrestrained

pet will be thrown about and possibly injured, or injure a

passenger during panic braking or in a collision.Pets should be restrained in pet harnesses or pet carriers

that are secured by seat belts.

ENGINE BREAK-IN RECOMMENDATIONS

The engine in your new Viper does not require a long

break-in period. Following these few simple guidelines is

all that is necessary for a good break-in:

For the first 500 miles (800 km):

²Keep your vehicle speed below the legal, posted speed

limit and your engine speed below 4,000 rpm.

²Avoid driving at a constant speed, either fast or slow,

for long periods of time.

²Do not make any full throttle starts and avoid full

throttle acceleration.

²Use the proper gear for your speed range.

46 THINGS TO KNOW BEFORE STARTING YOUR VEHICLE

Page 77 of 236

CAUTION!

Prolonged driving with the light on could cause

further damage to the emission control system. It

could also affect fuel economy and driveability. The

vehicle must be serviced before any state emissions

tests can be performed.

If the light is flashing, severe catalytic converter damage

and power loss will soon occur. Immediate service is

required.

If the gas cap is not secured properly, the light may come

on. Be sure the gas cap is tightened every time you add

fuel.

High Beam Indicator

This light shows that the headlights are on high

beam. Pull the turn signal lever toward the steer-

ing wheel to switch the headlights from high or low

beam.

Seat Belt Indicator Light

This system alerts the driver to fasten the seat belt

if not done so within 60 seconds of starting the

vehicle and if the vehicle is moving faster than 5

mph (8 km/h). The system will cause a chime to sound

repeatedly and will flash the seat belt warning light for 96

seconds or until the driver's seat belt is fastened. The

reminder system will be reactivated if the driver's seat

belt is unfastened for more than 10 seconds and the

vehicle speed is greater than 5 mph (8 km/hr). Refer to

Enhanced Seat Belt Use Reminder System (BeltAlertŸ) in

the Occupant Restraints section for deactivating the

system.

UNDERSTANDING YOUR INSTRUMENT PANEL 77

4

Page 98 of 236

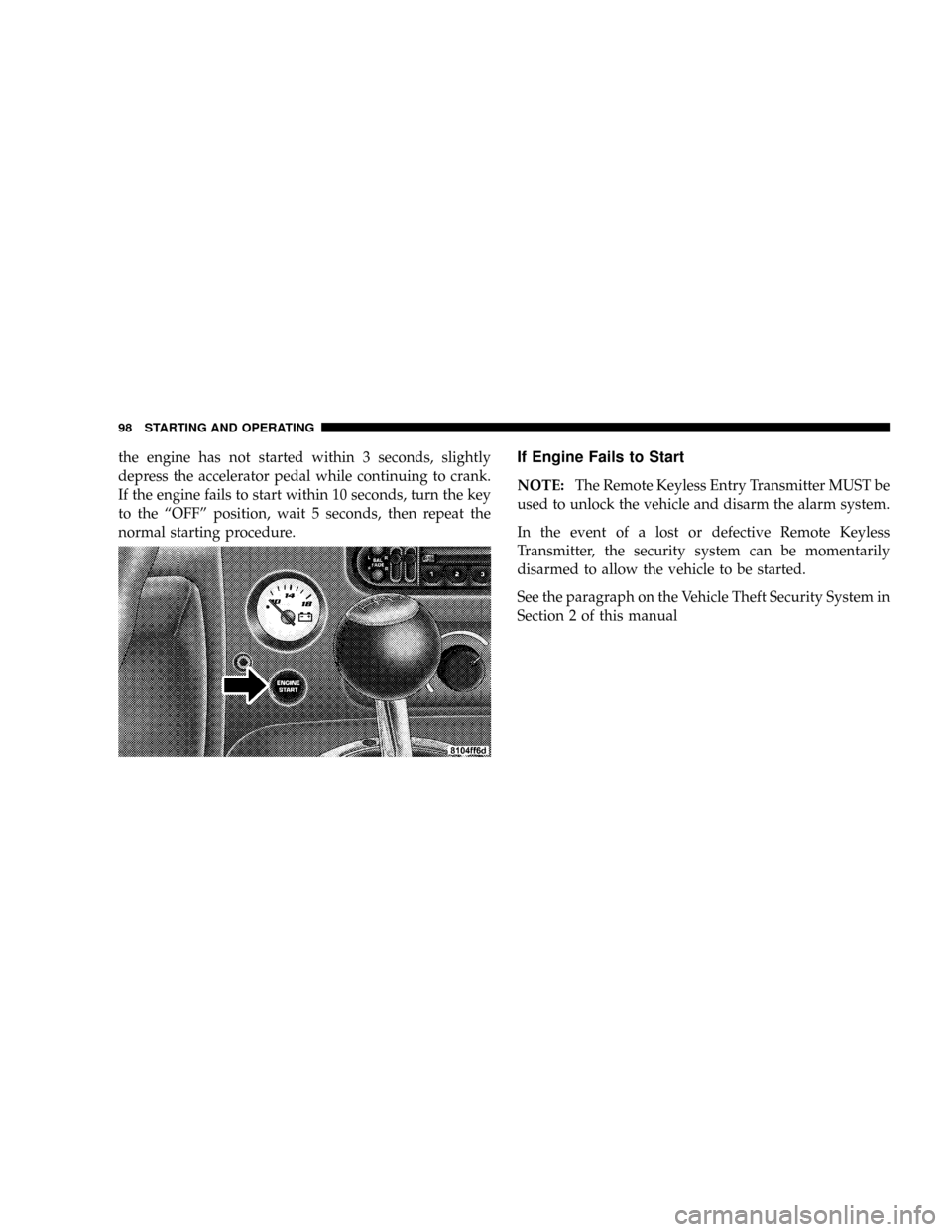

the engine has not started within 3 seconds, slightly

depress the accelerator pedal while continuing to crank.

If the engine fails to start within 10 seconds, turn the key

to the ªOFFº position, wait 5 seconds, then repeat the

normal starting procedure.If Engine Fails to Start

NOTE:The Remote Keyless Entry Transmitter MUST be

used to unlock the vehicle and disarm the alarm system.

In the event of a lost or defective Remote Keyless

Transmitter, the security system can be momentarily

disarmed to allow the vehicle to be started.

See the paragraph on the Vehicle Theft Security System in

Section 2 of this manual

98 STARTING AND OPERATING

Page 137 of 236

and the other end to the engine of the other vehicle. Make

sure that you have a good contact on the engines.

NOTE:When using another vehicle as the power

source, turn off all accessories.

8. Turn off the Theft Security System.

NOTE:If system is not turned off, the Theft System

electronics will prevent the engine from starting.

9. Allow battery to charge to at least 12.4 volts before

attempting to start engine.

10. Start the engine in the booster vehicle and let the

engine idle for a few minutes. Then start the Viper

engine. If engine does not start in 15 seconds, stop

cranking engine and allow starter to cool down before

cranking again.

11. When removing the booster cables, reverse the above

sequence exactly.DRIVING ON SLIPPERY SURFACES

WARNING!

Rapid acceleration on slippery surfaces is danger-

ous. You could lose control of the vehicle and possi-

bly have an accident. Accelerate slowly and carefully

whenever there is likely to be poor traction (ice,

snow, wet, mud, loose sand, etc.).

Traction

When driving on wet or slushy roads, it is possible for a

wedge of water to build up between the tire and road

surface. This is hydroplaning and may cause partial or

complete loss of vehicle control and stopping ability. To

reduce this possibility, the following precautions should

be observed:

WHAT TO DO IN EMERGENCIES 137

6

Page 171 of 236

hose routing to be sure hoses do not touch any heat

source or moving component that may cause heat dam-

age or mechanical wear.

Insure nylon tubing in these areas has not melted or

collapsed.

Inspect all hose connections such as clamps and cou-

plings to make sure they are secure and no leaks are

present.

Components should be replaced immediately if there is

any evidence of degradation that could result in failure.

Brake System

To assure brake system performance, all brake system

components should be inspected periodically. Suggested

service intervals can be found in Section 8 of this manual.

WARNING!

Riding the brakes can lead to brake failure and

possibly an accident. Driving with your foot resting

or riding on the brake pedal can result in abnormally

high brake temperatures, excessive lining wear, and

possible brake damage. You wouldn't have your full

braking capacity in an emergency.

Brake, Power Steering, and Fuel System Hoses

When servicing the vehicle for scheduled maintenance,

inspect surface of hoses and nylon tubing for evidence of

heat and mechanical damage. Hard and brittle rubber,

cracking, checking, tears, cuts, abrasion, and excessive

swelling suggest deterioration of the rubber. Particular

attention should be made to examining those hose sur-

faces nearest to high heat sources, such as the exhaust

manifold.

MAINTAINING YOUR VEHICLE 171

7

Page 172 of 236

Inspect all hose clamps and couplings to make sure they

are secure and no leaks are present.

Insure nylon tubing in these areas has not melted or

collapsed.

NOTE:Often, fluids are used during assembly plant

operations to ease the assembly of hoses to couplings.

Therefore, oil wetness at the hose-coupling area is not

necessarily an indication of leakage. Actual dripping of

hot fluid when systems are under pressure (during

vehicle operation) should be noted before hose is re-

placed based on leakage.

High pressure fuel system hoses have unique material

characteristics that provide adequate sealing and resist

attack by deteriorated gasoline.Use only manufacturer specified hoses or their equiva-

lent in material and specification, in any fuel system

servicing. It is mandatory to replace all clamps that have

been loosened or removed during service.

NOTE:Inspection of brake hoses should be done when-

ever the brake system is serviced and at every engine oil

change. If there is any evidence of cracking, scuffing, or

worn spots, the hose should be replaced immediately!

Eventual deterioration of the hose can take place with

possible burst failure.

172 MAINTAINING YOUR VEHICLE