warning DODGE VIPER 2004 ZB / 2.G Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2004, Model line: VIPER, Model: DODGE VIPER 2004 ZB / 2.GPages: 236, PDF Size: 4.18 MB

Page 165 of 236

²Rubber bushings

²Starter bearing

²Throttle control cable

²Water pump bearings

Windshield Washers

The fluid reservoir in the right side engine compartment

should be checked for fluid level at regular intervals. Fill

the reservoir with windshield antifreeze (not radiator

antifreeze).

Exhaust System

The best protection against carbon monoxide entry into

the vehicle body is a properly maintained engine exhaust

system.

If you notice a change in the sound of the exhaust system;

or if exhaust fumes can be detected inside the vehicle; or

when the underside or side of the vehicle is damaged;have a competent mechanic inspect the complete exhaust

system and adjacent body areas for broken, damaged,

deteriorated, or mispositioned parts. Open seams or

loose connections could permit exhaust fumes to seep

into the passenger compartment. In addition, inspect the

exhaust system each time the vehicle is raised for lubri-

cation or oil change. Replace as required.

WARNING!

Exhaust gases can injure or kill. They contain carbon

monoxide which is colorless and odorless. Breathing

it can make you unconscious and can eventually

poison you.

MAINTAINING YOUR VEHICLE 165

7

Page 166 of 236

Cooling System

WARNING!

You or others can be badly burned by hot coolant or

steam from your radiator. If you see or hear steam

coming from under the hood, don't open the hood

until the radiator has had time to cool. Never try to

open a cooling system pressure cap when the radia-

tor is hot.

Inspection

Coolant protection checks should be made every 12

months (before the onset of freezing weather, where

applicable). If coolant is dirty or rusty in appearance, the

system should be drained, flushed and refilled with fresh

coolant. Check the front of the radiator for any accumu-

lation of bugs, leaves, etc.Check the coolant bottle tubing for condition and tight-

ness of connection at reserve tank and radiator. Inspect

the entire system for leaks.

NOTE:Check the front of the radiator for debris (leaves,

paper, etc.) regularly. A build up of such material could

lead to engine overheating.

Do not remove the cooling system pressure cap when the

cooling system is hot.

Cooling System Ð Drain, Flush and Refill

The cooling system should be drained, flushed and

refilled at the intervals shown on the Maintenance Sched-

ules.

If the solution is dirty and contains a considerable

amount of sediment, clean and flush with a reliable

cooling system cleaner. Follow with a thorough rinsing to

remove all deposits and chemicals. Discard old antifreeze

solution according to recommended procedure.

166 MAINTAINING YOUR VEHICLE

Page 168 of 236

Adding Coolant

DO NOT remove the pressure cap when checking cool-

ant. When adding coolant or refilling system, a 50%

solution of ethylene glycol antifreeze coolant in water

should be used. Higher concentrations (not to exceed

65%) are required if temperatures below ±37ÉF are antici-

pated.

Use only high purity water such as distilled or deionized

water when mixing the water / antifreeze solution. The

use of lower quality water will reduce the amount of

corrosion protection in the engine cooling system.

NOTE:It is the owner's responsibility to maintain the

proper level of protection against freezing according to

the temperatures occurring in the area where the vehicle

is operated.WARNING!

Never add coolant to the radiator when the engine is

overheated. Do not loosen or remove pressure cap to

cool overheated engine. The coolant is under pres-

sure and severe scalding could result.

Cooling System Pressure Cap

The cap must be fully tightened to prevent loss of

coolant, and to insure that coolant will return to the

radiator from the coolant reserve tank.

The pressure cap should be inspected and cleaned if there

is any accumulation of foreign material on the sealing

surfaces.

168 MAINTAINING YOUR VEHICLE

Page 169 of 236

WARNING!

The warning words ªDO NOT OPEN HOTº on the

pressure cap are a safety precaution. Never add

coolant to the radiator when the engine is over-

heated. Do not loosen or remove the pressure cap to

cool overheated engine. Heat causes pressure to

build up in the cooling system. To prevent scalding

or injury, do not remove the pressure cap while the

system is hot or under pressure.

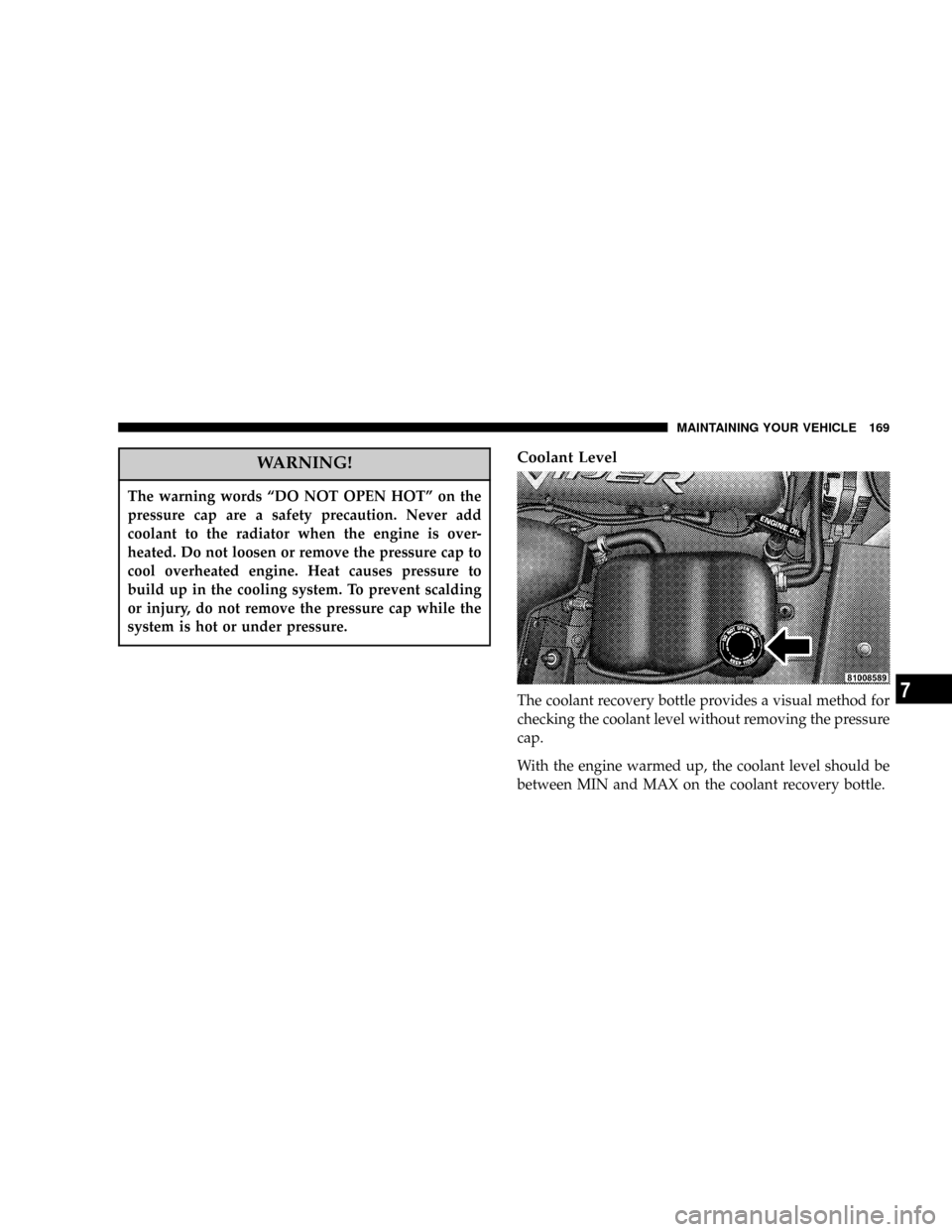

Coolant Level

The coolant recovery bottle provides a visual method for

checking the coolant level without removing the pressure

cap.

With the engine warmed up, the coolant level should be

between MIN and MAX on the coolant recovery bottle.

MAINTAINING YOUR VEHICLE 169

7

Page 171 of 236

hose routing to be sure hoses do not touch any heat

source or moving component that may cause heat dam-

age or mechanical wear.

Insure nylon tubing in these areas has not melted or

collapsed.

Inspect all hose connections such as clamps and cou-

plings to make sure they are secure and no leaks are

present.

Components should be replaced immediately if there is

any evidence of degradation that could result in failure.

Brake System

To assure brake system performance, all brake system

components should be inspected periodically. Suggested

service intervals can be found in Section 8 of this manual.

WARNING!

Riding the brakes can lead to brake failure and

possibly an accident. Driving with your foot resting

or riding on the brake pedal can result in abnormally

high brake temperatures, excessive lining wear, and

possible brake damage. You wouldn't have your full

braking capacity in an emergency.

Brake, Power Steering, and Fuel System Hoses

When servicing the vehicle for scheduled maintenance,

inspect surface of hoses and nylon tubing for evidence of

heat and mechanical damage. Hard and brittle rubber,

cracking, checking, tears, cuts, abrasion, and excessive

swelling suggest deterioration of the rubber. Particular

attention should be made to examining those hose sur-

faces nearest to high heat sources, such as the exhaust

manifold.

MAINTAINING YOUR VEHICLE 171

7

Page 173 of 236

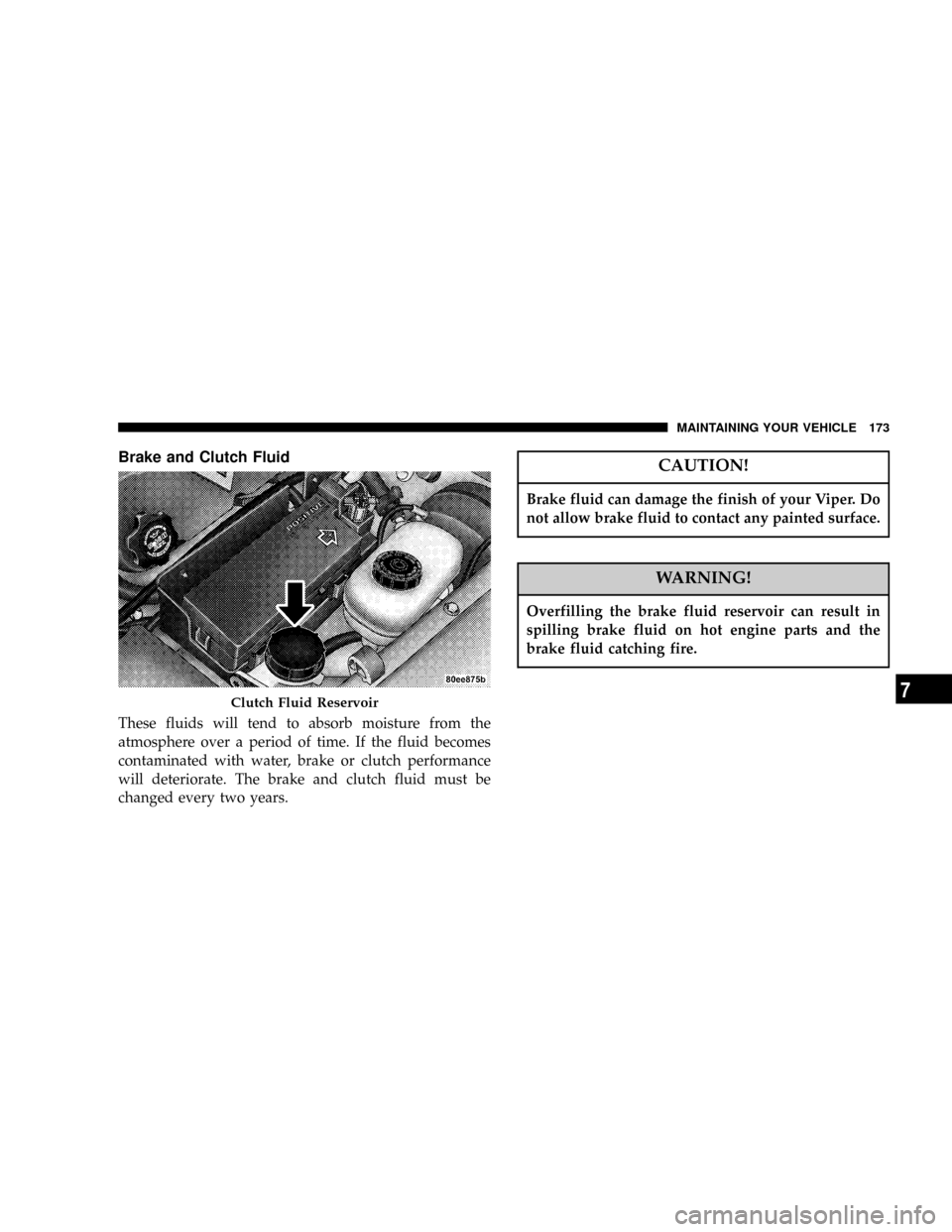

Brake and Clutch Fluid

These fluids will tend to absorb moisture from the

atmosphere over a period of time. If the fluid becomes

contaminated with water, brake or clutch performance

will deteriorate. The brake and clutch fluid must be

changed every two years.

CAUTION!

Brake fluid can damage the finish of your Viper. Do

not allow brake fluid to contact any painted surface.

WARNING!

Overfilling the brake fluid reservoir can result in

spilling brake fluid on hot engine parts and the

brake fluid catching fire.

Clutch Fluid Reservoir

MAINTAINING YOUR VEHICLE 173

7

Page 174 of 236

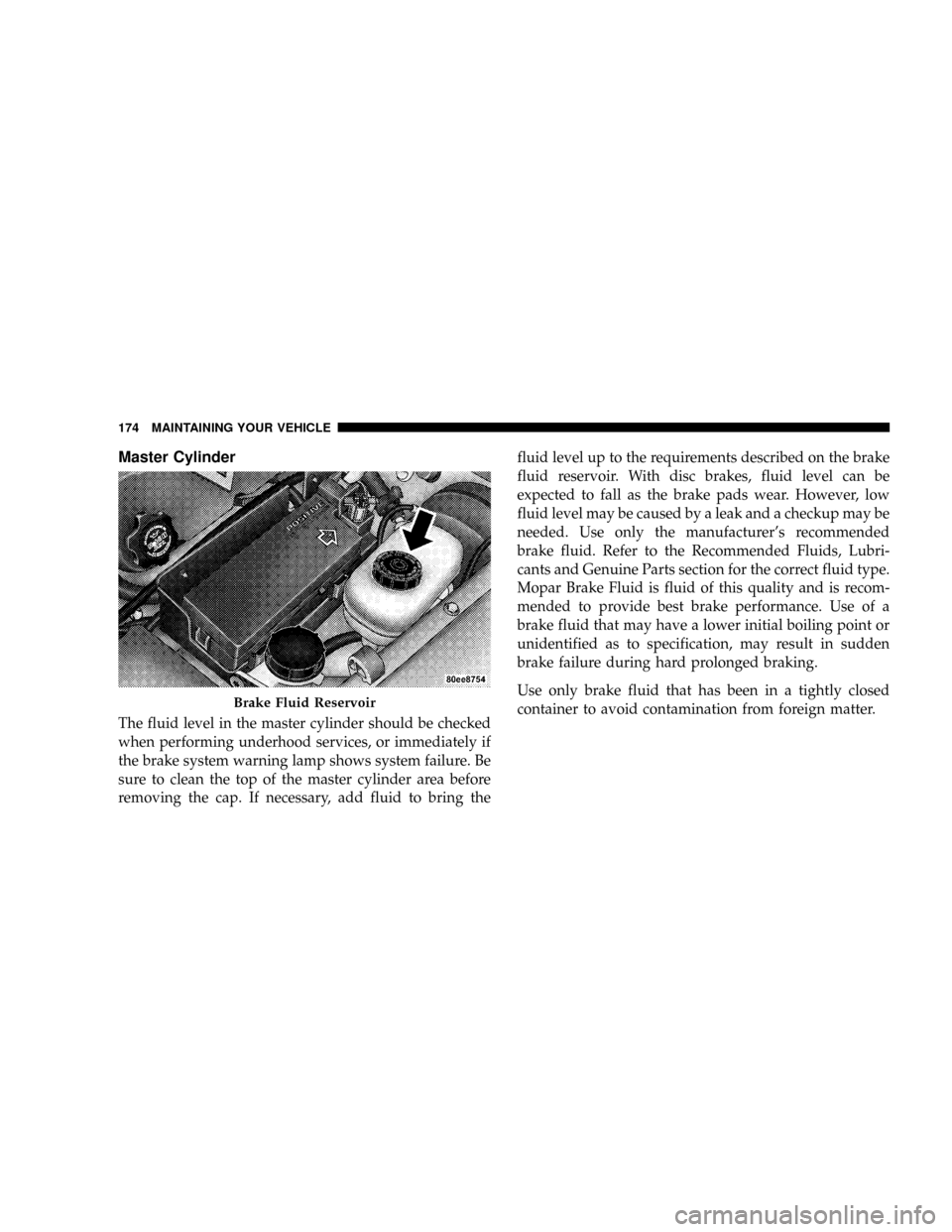

Master Cylinder

The fluid level in the master cylinder should be checked

when performing underhood services, or immediately if

the brake system warning lamp shows system failure. Be

sure to clean the top of the master cylinder area before

removing the cap. If necessary, add fluid to bring thefluid level up to the requirements described on the brake

fluid reservoir. With disc brakes, fluid level can be

expected to fall as the brake pads wear. However, low

fluid level may be caused by a leak and a checkup may be

needed. Use only the manufacturer's recommended

brake fluid. Refer to the Recommended Fluids, Lubri-

cants and Genuine Parts section for the correct fluid type.

Mopar Brake Fluid is fluid of this quality and is recom-

mended to provide best brake performance. Use of a

brake fluid that may have a lower initial boiling point or

unidentified as to specification, may result in sudden

brake failure during hard prolonged braking.

Use only brake fluid that has been in a tightly closed

container to avoid contamination from foreign matter.

Brake Fluid Reservoir

174 MAINTAINING YOUR VEHICLE

Page 188 of 236

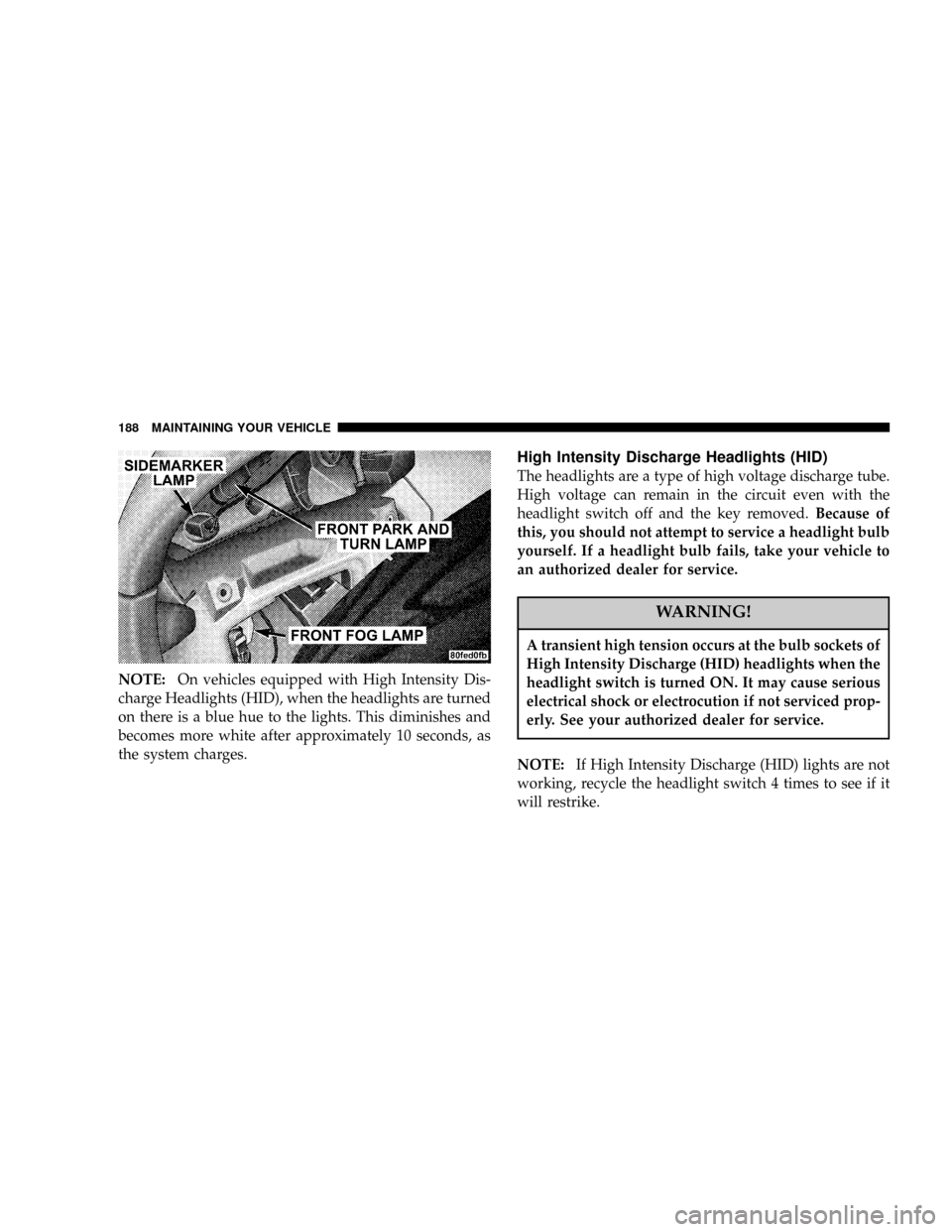

NOTE:On vehicles equipped with High Intensity Dis-

charge Headlights (HID), when the headlights are turned

on there is a blue hue to the lights. This diminishes and

becomes more white after approximately 10 seconds, as

the system charges.

High Intensity Discharge Headlights (HID)

The headlights are a type of high voltage discharge tube.

High voltage can remain in the circuit even with the

headlight switch off and the key removed.Because of

this, you should not attempt to service a headlight bulb

yourself. If a headlight bulb fails, take your vehicle to

an authorized dealer for service.

WARNING!

A transient high tension occurs at the bulb sockets of

High Intensity Discharge (HID) headlights when the

headlight switch is turned ON. It may cause serious

electrical shock or electrocution if not serviced prop-

erly. See your authorized dealer for service.

NOTE:If High Intensity Discharge (HID) lights are not

working, recycle the headlight switch 4 times to see if it

will restrike.

188 MAINTAINING YOUR VEHICLE

Page 213 of 236

* This maintenance is recommended by DaimlerChrysler

Corporation to the owner but is not required to maintain

the warranty on the PCV orifice.

³ This maintenance is not required if previously replaced.

Inspection and service should also be performed anytime

a malfunction is observed or suspected. Retain all re-

ceipts.WARNING!

You can be badly injured working on or around a

motor vehicle. Do only that service work for which

you have the knowledge and the right equipment. If

you have any doubt about your ability to perform a

service job, take your vehicle to a competent me-

chanic.

SCHEDULE ªAº 213

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

Page 222 of 236

DEPARTMENT OF TRANSPORTATION UNIFORM

TIRE QUALITY GRADES

The following describes the tire grading categories estab-

lished by the National highway Traffic Safety Adminis-

tration. The specific grade rating assigned by the tire's

manufacturer in each category is shown on the sidewall

of the tires on your car.

All Passenger Car Tires Must Conform to Federal Safety

Requirements in Addition to These Grades.

Treadwear

The treadwear grade is a comparative rating based on the

wear rate of the tire when tested under controlled con-

ditions on a specified government test course. For ex-

ample, a tire graded 150 would wear one and a half (1

1/2) times as well on the government course as a tire

graded 100. The relative performance of tires depends

upon the actual conditions of their use, however, andmay depart significantly from the norm due to variations

in driving habits, service practices and differences in road

characteristics and climate.

Traction Grades

The traction grades, from highest to lowest, are A, B, and

C, and they represent the tire's ability to stop on wet

pavement as measured under controlled conditions on

specified government test surfaces of asphalt and con-

crete. A tire marked C may have poor traction perfor-

mance.

WARNING!

The traction grade is based on braking (straight-

ahead) traction tests and does not include cornering

(turning) performance.

222 IF YOU NEED CONSUMER ASSISTANCE