tires DODGE VIPER 2004 ZB / 2.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2004, Model line: VIPER, Model: DODGE VIPER 2004 ZB / 2.GPages: 236, PDF Size: 4.18 MB

Page 48 of 236

Safety Checks You Should Make Inside the

Vehicle

Seat Belts

²

Inspect the belt system periodically, checking for cuts,

frays and loose parts. Damaged parts must be replaced

immediately. Do not disassemble or modify the sys-

tem.

²Seat belt assemblies must be replaced after an accident

if they have been damaged (bent retractor, torn web-

bing, etc.). If there is any question regarding belt or

retractor condition, replace the belt.

Defrosters

Check operation by selecting the defrost mode and place

the blower control on high speed. You should be able to

feel the air directed against the windshield.

Safety Checks You Should Make Outside the

Vehicle

Tires

Examine tires for excessive tread wear or uneven wear

patterns. Check for stones, nails, glass, or other objects

lodged in the tread. Inspect for tread cuts or side wall

cracks. Check wheel nuts for tightness and tires for

proper pressure.

Lights

Have someone observe the operation of exterior lights

while you work the controls. Check turn signal and high

beam indicator lights on the instrument panel.

Fluid Leaks

Check area under vehicle after overnight parking for fuel,

water, oil, or other fluid leaks. Also, if gasoline fumes are

present, the cause should be corrected immediately.

48 THINGS TO KNOW BEFORE STARTING YOUR VEHICLE

Page 95 of 236

STARTING AND OPERATING

CONTENTS

mStarting Procedures......................97

NIf Engine Fails To Start..................98

NAfter Starting........................100

mTransmission Shifting....................100

NRecommended Shift Speeds..............101

NSkip Shift Light.......................101

mParking Brake.........................102

mBrake System..........................104

NBrake Pad Break-In....................107mPower Steering........................107

mTire Safety Information...................108

NTire Markings........................108

NTire Identification Number (TIN)..........111

NTire Loading And Tire Pressure...........112

mTiresÐGeneral Information................116

NTire Pressure.........................116

NTire Inflation Pressures.................117

NRadial-Ply Tires......................120

5

Page 96 of 236

NCompact Spare Tire Ð If Equipped.........120

NTire Spinning........................121

NTread Wear Indicators..................122

NReplacement Tires.....................122

NAlignment And Balance.................123

mLow Tire Pressure (Ltp) System.............124

NLow Tire Indicator....................124

mTire Chains...........................125

mSnow Tires...........................125

mTire Storage...........................126

mTire Rotation Recommendations............126mGround Clearance......................126

mFuel Requirements......................127

NReformulated Gasoline.................127

NGasoline/Oxygenate Blends..............128

NMMT In Gasoline.....................128

NSulfur In Gasoline.....................129

NMaterials Added To Fuel................129

mAdding Fuel..........................129

mVehicle Loading........................130

mTrailer Towing.........................130

96 STARTING AND OPERATING

Page 104 of 236

BRAKE SYSTEM

The Anti-Lock Brake System (ABS) is designed to aid the

driver in maintaining vehicle control under adverse

braking conditions. The system operates with a separate

computer to modulate hydraulic pressure to prevent

wheel lock-up and help avoid skidding on slippery

surfaces.

All vehicle wheels and tires must be the same size and

type as the original equipment wheels and tires must be

properly inflated to produce accurate signals for the

computer.

WARNING!

Significant over or under inflation of tires, or mixing

sizes of front or rear tires or wheels on the vehicle

can lead to loss of braking effectiveness.

The Anti-Lock Brake System conducts a low-speed self-

test at about 12 mph (20 km/h). If you have your foot

lightly on the brake while this test is occurring, you may

feel slight pedal movement. The movement can be more

apparent on ice and snow. This is normal.

The Anti-Lock Brake System pump motor runs during

the self-test at 12 mph (20 km/h) and during an ABS stop.

The pump motor makes a low humming noise during

operation, which is normal.

WARNING!

Pumping of the Anti-Lock Brakes will diminish

their effectiveness and may lead to an accident.

Pumping makes the stopping distance longer. Just

press firmly on your brake pedal when you need to

slow down or stop.

104 STARTING AND OPERATING

Page 105 of 236

CAUTION!

The Anti-Lock Brake System is subject to possible

detrimental effects of electronic interference caused

by improperly installed after-market radios or tele-

phones.

WARNING!

²Anti-lock system (ABS) cannot prevent the natu-

ral laws of physics from acting on the vehicle, nor

can it increase braking or steering efficiency be-

yond that afforded by the condition of the vehicle

brakes and tires or the traction afforded.

²The ABS cannot prevent accidents, including

those resulting from excessive speed in turns,

following another vehicle too closely, or hydro-

planing. Only a safe, attentive, and skillful driver

can prevent accidents.

²The capabilities of an ABS equipped vehicle must

never be exploited in a reckless or dangerous

manner which could jeopardize the user's safety

or the safety of others.

STARTING AND OPERATING 105

5

Page 108 of 236

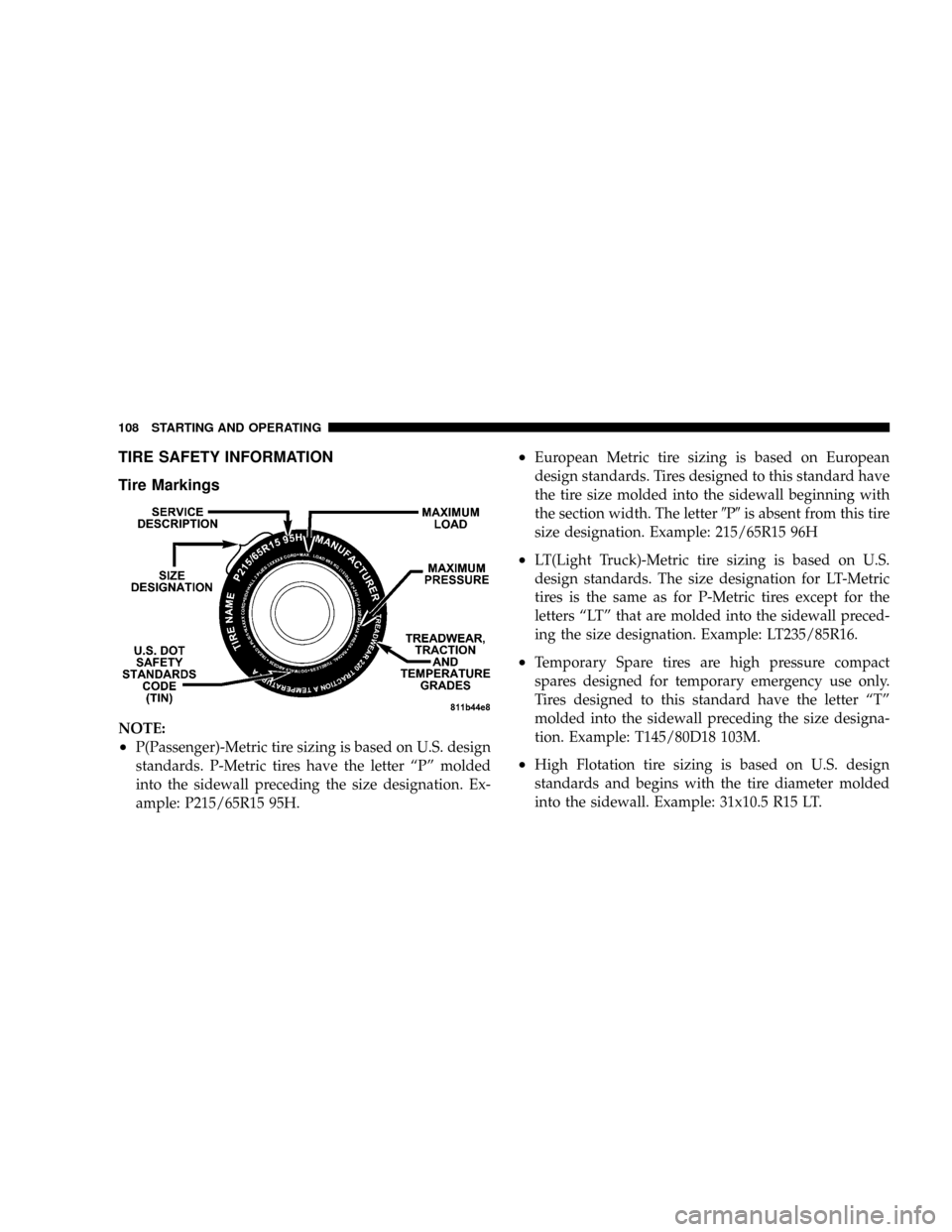

TIRE SAFETY INFORMATION

Tire Markings

NOTE:

²P(Passenger)-Metric tire sizing is based on U.S. design

standards. P-Metric tires have the letter ªPº molded

into the sidewall preceding the size designation. Ex-

ample: P215/65R15 95H.

²European Metric tire sizing is based on European

design standards. Tires designed to this standard have

the tire size molded into the sidewall beginning with

the section width. The letter9P9is absent from this tire

size designation. Example: 215/65R15 96H

²LT(Light Truck)-Metric tire sizing is based on U.S.

design standards. The size designation for LT-Metric

tires is the same as for P-Metric tires except for the

letters ªLTº that are molded into the sidewall preced-

ing the size designation. Example: LT235/85R16.

²Temporary Spare tires are high pressure compact

spares designed for temporary emergency use only.

Tires designed to this standard have the letter ªTº

molded into the sidewall preceding the size designa-

tion. Example: T145/80D18 103M.

²High Flotation tire sizing is based on U.S. design

standards and begins with the tire diameter molded

into the sidewall. Example: 31x10.5 R15 LT.

108 STARTING AND OPERATING

Page 111 of 236

Tire Identification Number (TIN)

The TIN may be found on one or both sides of the tire

however the date code may only be on one side. Tires

with white sidewalls will have the full TIN including

date code located on the white sidewall side of the tire.Look for the TIN on the outboard side of black sidewall

tires as mounted on the vehicle. If the TIN is not found on

the outboard side then you will find it on the inboard side

of the tire.

EXAMPLE:

DOT MA L9 ABCD 0301

DOT= Department of Transportation

ÐThis symbol certifies that the tire is in compliance with the U.S. Department of Transportation tire

safety standards, and is approved for highway use.

MA= Code representing the tire manufacturing location.(2 digits)

L9= Code representing the tire size.(2 digits)

ABCD= Code used by tire manufacturer.(1 to 4 digits)

03= Number representing the week in which the tire was manufactured.(2 digits)

Ð03 means the 3rd week.

01= Number representing the year in which the tire was manufactured.(2 digits)

Ð01 means the year 2001.

ÐPrior to July 2000, tire manufacturers were only required to have 1 number to represent the year in

which the tire was manufactured. Example: 031 could represent the 3rd week of 1981 or 1991.

STARTING AND OPERATING 111

5

Page 112 of 236

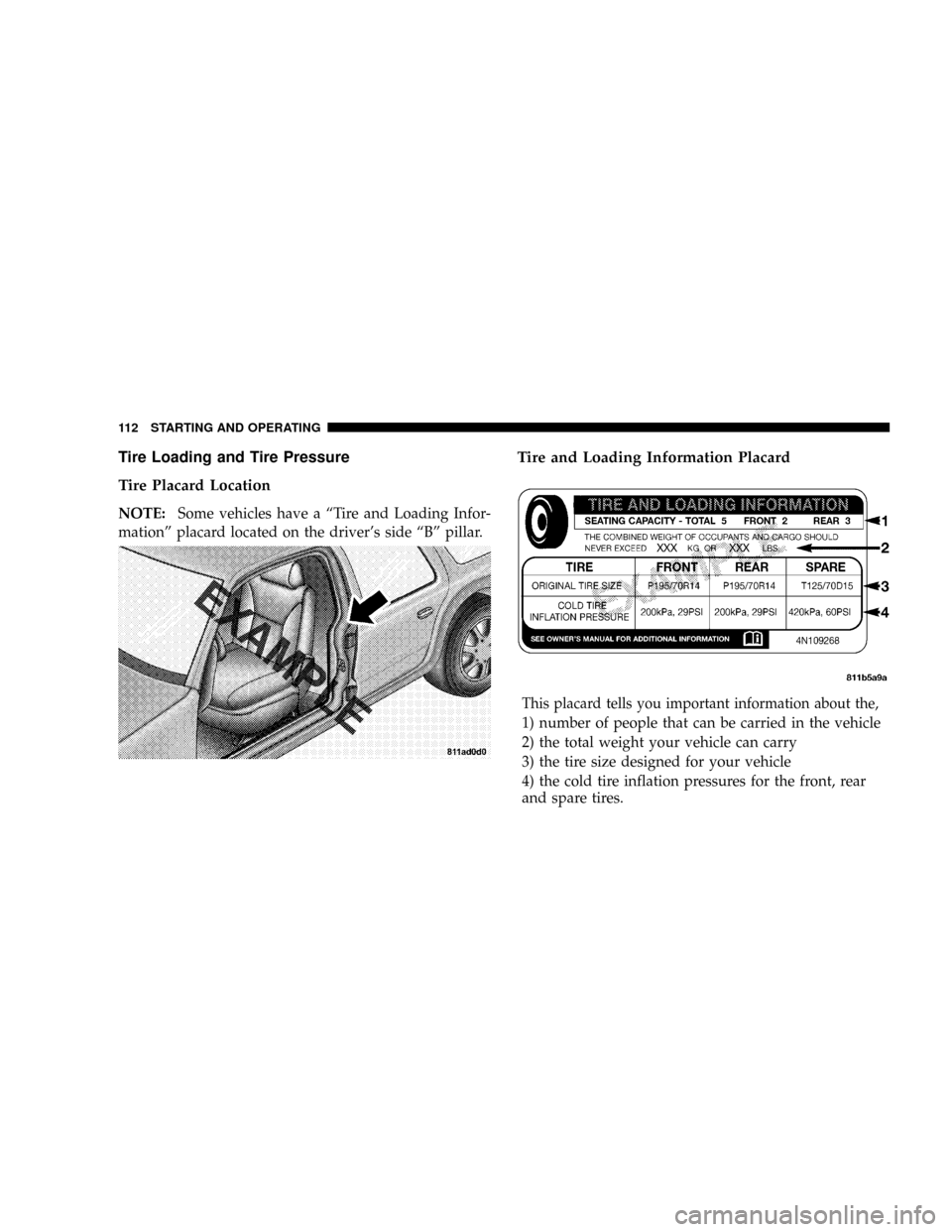

Tire Loading and Tire Pressure

Tire Placard Location

NOTE:Some vehicles have a ªTire and Loading Infor-

mationº placard located on the driver's side ªBº pillar.

Tire and Loading Information Placard

This placard tells you important information about the,

1) number of people that can be carried in the vehicle

2) the total weight your vehicle can carry

3) the tire size designed for your vehicle

4) the cold tire inflation pressures for the front, rear

and spare tires.

112 STARTING AND OPERATING

Page 116 of 236

WARNING!

Overloading of your tire is dangerous. Overloading

can cause tire failure, affect vehicle handling, and

increase your stopping distance. Use tires of the

recommended load capacity for your vehicle. Never

overload them.

TIRESÐGENERAL INFORMATION

Tire Pressure

Proper tire inflation pressure is essential to the safe and

satisfactory operation of your vehicle. Three primary

areas are affected by improper tire pressure:1. SafetyÐ

WARNING!

Improperly inflated tires are dangerous and can cause

accidents.

²Under inflation increases tire flexing and can result in

tire failure.

²Over inflation reduces a tire's ability to cushion

shock. Objects on the road and chuck holes can cause

damage that results in tire failure.

²Unequal tire pressures can cause steering problems.

You could lose control of your vehicle.

²Over inflated or under inflated tires can affect vehicle

handling and can fail suddenly, resulting in loss of

vehicle control.

²Unequal tire pressures from one side of the vehicle to

the other can cause the vehicle to drift to the right or left.

Always drive with each tire inflated to the recom-

mended cold tire inflation pressure.

116 STARTING AND OPERATING

Page 118 of 236

The pressure should be checked and adjusted as well as

inspecting for signs of tire wear or visible damage at least

once a month. Use a good quality pocket-type gauge to

check tire pressure. Do not make a visual judgement

when determining proper inflation. Radial tires may look

properly inflated even when they are underinflated.

CAUTION!

After inspecting or adjusting the tire pressure al-

ways reinstall the valve stem cap±if equipped. This

will prevent moisture and dirt from entering the

valve stem, which could damage the valve stem.

Inflation pressures specified on the placard are always

ªcold tire inflation pressureº. Cold tire inflation pressure

is defined as the tire pressure after the vehicle has not

been driven for at least 3 hours, or driven less than 1mile(1 km) after a 3 hour period. The cold tire inflation

pressure must not exceed the maximum inflation pres-

sure molded into the tire side wall.

Check tire pressures more often if subject to a wide range

of outdoor temperatures, as tire pressures vary with

temperature changes.

Tire pressures change by approximately 1 psi (7 kPa) per

12É F (7É C) of air temperature change. Keep this in mind

when checking tire pressure inside a garage especially in

the winter.

Example: If garage temperature = 68É F (20É C) and the

outside temperature = 32É F (0É C) then the cold tire

inflation pressure should be increased by 3 psi (21 kPa),

which equals 1 psi (7 kPa) for every 12É F (7É C) for this

outside temperature condition.

118 STARTING AND OPERATING