Valve DODGE VIPER 2008 ZB II / 2.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2008, Model line: VIPER, Model: DODGE VIPER 2008 ZB II / 2.GPages: 303, PDF Size: 2.65 MB

Page 160 of 303

check tire pressure. Do not make a visual judgement

when determining proper inflation. Radial tires may look

properly inflated even when they are under inflated.

CAUTION!

After inspecting or adjusting the tire pressure, al-

ways reinstall the valve stem cap (if equipped). This

will prevent moisture and dirt from entering the

valve stem, which could damage the valve stem.

Inflation pressures specified on the placard are always

ªcold tire inflation pressure.º Cold tire inflation pressure

is defined as the tire pressure after the vehicle has not

been driven for at least 3 hours, or driven less than 1 mile

(1 km) after a 3 hour period. The cold tire inflation

pressure must not exceed the maximum inflation pres-

sure molded into the tire sidewall.Check tire pressures more often if subject to a wide range

of outdoor temperatures, as tire pressures vary with

temperature changes.

Tire pressures change by approximately 1 psi (7 kPa) per

12É F (7É C) of air temperature change. Keep this in mind

when checking tire pressure inside a garage, especially in

the winter.

Example: If garage temperature = 68É F (20É C) and the

outside temperature = 32É F (0É C) then the cold tire

inflation pressure should be increased by 3 psi (21 kPa),

which equals 1 psi (7 kPa) for every 12É F (7É C) for this

outside temperature condition.

Tire pressure may increase from 2 to 6 psi (13 to 40 kPa)

during operation. DO NOT reduce this normal pressure

build up or your tire pressure will be too low.

STARTING AND OPERATING 159

5

Page 179 of 303

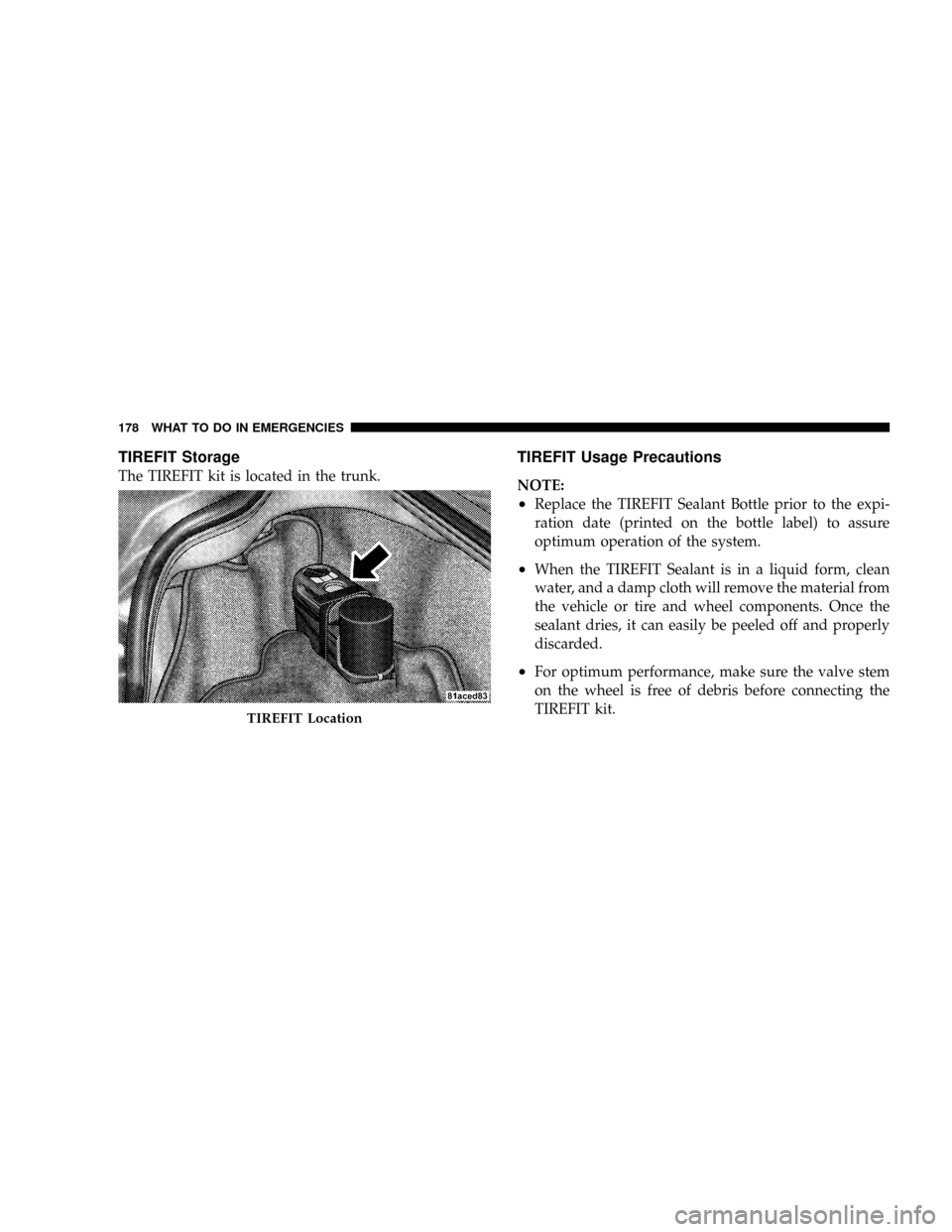

TIREFIT Storage

The TIREFIT kit is located in the trunk.

TIREFIT Usage Precautions

NOTE:

²Replace the TIREFIT Sealant Bottle prior to the expi-

ration date (printed on the bottle label) to assure

optimum operation of the system.

²When the TIREFIT Sealant is in a liquid form, clean

water, and a damp cloth will remove the material from

the vehicle or tire and wheel components. Once the

sealant dries, it can easily be peeled off and properly

discarded.

²For optimum performance, make sure the valve stem

on the wheel is free of debris before connecting the

TIREFIT kit.

TIREFIT Location

178 WHAT TO DO IN EMERGENCIES

Page 182 of 303

6. Air Pump Hose (Black)

7. Sealant Hose (Clear with Yellow Cap)

Using the Mode Select Knob & Hoses

Selecting Air Mode

Turn the Mode Select knob (4) to this position

for air pump operation only. Use the Black Air

Pump Hose (6) when selecting this mode.

Selecting Sealant/Air Mode

Turn the Mode Select knob (4) to this position

to inject the TIREFIT Sealant and to inflate the

tire. Use the Sealant Hose (Clear hose with the

Yellow Cap) (7) when selecting this mode.

Using the Air Pump Power Button

Push and release the button (3) once to turn On

the TIREFIT kit. Push and release the button (3)

again to turn Off the TIREFIT kit.Sealing a Tire with TIREFIT

(A) Whenever You Stop to Use TIREFIT:

Turn on the vehicle's hazard warning flashers.

1. Verify that the valve stem (on the wheel with the

deflated tire) is in a position that is near to the ground.

This will allow the TIREFIT Hoses (6) and (7) to reach the

valve stem and keep the TIREFIT kit flat on the ground.

This will provide the best positioning of the kit when

injecting the sealant into the deflated tire and running the

air pump. Move the vehicle as necessary to place the

valve stem in this position before proceeding.

2. Place the transmission in Park (auto transmission) or

in Gear (manual transmission) and turn off the ignition.

3. Set the parking brake.

WHAT TO DO IN EMERGENCIES 181

6

Page 183 of 303

(B) Setting Up to Use TIREFIT:

Turn the Mode Select knob (4) to the Sealant/

Air Mode position.

1. Uncoil the Clear Sealant Hose (7) and then remove the

Yellow Cap from the fitting at the end of the hose.

2. Place the TIREFIT kit flat on the ground next to the

deflated tire.

3. Remove the cap from the valve stem and then screw

the fitting at the end of the Sealant Hose (7) onto the

valve stem.

4. Uncoil the Power Plug and Cable (5) and then insert

the plug into the vehicle's power outlet.

NOTE:Do not remove foreign objects (e.g., screws or

nails) from the tire.

(C)Injecting TIREFIT Sealant into the deflated tire:

1. Always start the engine before turning on the TIREFIT

kit.

2. After pressing the Air Pump Power Button

(3), the air pump should start to inflate the tire

and the sealant (white fluid) will flow from the

Sealant Bottle (1) through the Sealant Hose (7)

and into the tire.NOTE:Some sealant may leak out

through the puncture in the tire.

3.If the sealant Does Not Flow Through the Clear

Sealant Hose (7):

²Press the Air Pump Power Button (3) to turn off the

TIREFIT kit. Disconnect the Clear Sealant Hose (7)

from the valve stem. Make sure the valve stem is

free of debris. Reconnect the Clear Sealant Hose (7)

to the valve stem. Press the Air Pump Power Button

(3) to turn on the TIREFIT kit.

182 WHAT TO DO IN EMERGENCIES

Page 184 of 303

²Turn the Mode Select knob to the Sealant/Air Mode.

²Connect the Power Plug (5) to a different power

outlet in your vehicle or another vehicle, if available.

Make sure the engine is running before turning on

the TIREFIT kit.

²The Sealant Bottle (1) may be empty due to previous

use. Call for assistance.

(D) After Injecting TIREFIT Sealant:

1. Allow the air pump to inflate the tire to the pressure

indicated on the tire pressure label on the driver-side

latch pillar. Check the pressure in the tire by looking at

the Pressure Gauge (2).

²If the tire inflates to at least 26 psi (1.8 bar) within 15

minutes, proceed to Step 2 of this procedure.

²If tire fails to inflate to 26 psi (1.8 bar) within 15

minutes, perform the procedure steps described

under ª(G) Distributing TIREFIT Sealant to Better

Enable Tire Inflation.º

²Press the Air Pump Power Button (3) to

turn off the TIREFIT kit.

2. Remove the Speed Limit sticker from the top of the

Sealant Bottle (1) and place the sticker on the steering

wheel.

3. Disconnect the TIREFIT kit from the valve stem and

place it in the vehicle.

(E) Securing TIREFIT Sealant in the Tire

Drive the vehicle for approximately 5 miles (8 km) to

ensure distribution of the TIREFIT Sealant within the tire.

WHAT TO DO IN EMERGENCIES 183

6

Page 185 of 303

WARNING!

TIREFIT is not a permanent flat tire repair. Have the

tire inspected and repaired or replaced after using

TIREFIT. Do not exceed 55 mph (90 km/h) until

having the tire repaired or replaced. Failure to follow

this warning can result in injuries that are serious or

fatal to you, your passengers, and others around you.

(F) After Securing TIREFIT Sealant in the Tire:

Turn the Mode Select knob (4) to the Air Mode

position.

1. Uncoil the Black Air Pump Hose (6) and connect it to

the valve stem.2. Check the pressure in the tire by reading the Pressure

Gauge (2).

²If the pressure is less than 19 psi (1.3 bar), the tire is

too badly damaged. Do not attempt to drive the

vehicle further. Call for assistance.

²If the pressure is equal to or greater than 19 psi (1.3

bar), but less than the level indicated on the tire

pressure label, proceed to Step 4 of this procedure.

²If the pressure is at the level indicated on the tire

pressure label on the driver-side latch pillar, proceed

to Step 5 of this procedure.

3. Inflate the tire to the pressure indicated on the tire

pressure label on the driver-side latch pillar.

4. Disconnect the TIREFIT kit from the valve stem and

then reinstall the cap on the valve stem.

184 WHAT TO DO IN EMERGENCIES

Page 186 of 303

5. Place the TIREFIT kit in its proper storage area in the

vehicle.

6. Have the tire inspected and repaired or replaced at the

earliest opportunity at an authorized dealer or tire ser-

vice center.

7. Replace the Sealant Bottle (1) at your nearest autho-

rized Mopartparts dealership as soon as possible.

(G) Distributing TIREFIT Sealant to Better Enable

Tire Inflation

NOTE:Use this procedure only if directed here from

Step 1 of ª(D) After Injecting TIREFIT Sealant.º

Press the Air Pump Power Button (3) to turn off

the TIREFIT kit. Then, disconnect the kit from

the valve stem and place it in the vehicle.1. Drive the vehicle forward approximately 30 to 50 feet

(9 to 15 m) to distribute the sealant more evenly within

the tire.

2. Return to Step 1 of ª(D) After Injecting TIREFIT

Sealantº and attempt to inflate the tire. However, this

time, if the tire fails to inflate to 26 psi (1.8 bar) within 15

minutes, the tire is too badly damaged. Do not attempt to

drive the vehicle further. Call for assistance.

WHAT TO DO IN EMERGENCIES 185

6

Page 207 of 303

NOTE:

²Because of the plastic body shell on your vehicle,

ignition cables should be replaced with the specially

designed RFI cables available at your dealer.

²The ignition timing cannot be set on this engine.

Crankcase Emission Control System

Proper operation of this system depends on freedom

from plugging due to deposits. As vehicle mileage builds

up, the Crankcase Ventilation Valve orifice may accumu-

late deposits. If a valve is not working properly, it should

be replaced with a new orifice. DO NOT ATTEMPT TO

CLEAN THE OLD ORIFICE!

Check the ventilation hose for indication of damage or

plugging deposits and replace if necessary. See your

authorized dealer for service.

Maintenance-Free Battery

The top of the MAINTENANCE-FREE battery is perma-

nently sealed. You will never have to add water, nor is

periodic maintenance required.

The battery is located underneath an access panel inside

the rear compartment on the left side of the vehicle. A

remote battery terminal is located in the engine compart-

ment for jump-starting.

To gain access to the battery, remove the floor portion of

the rear compartment carpet.

206 MAINTAINING YOUR VEHICLE

Page 262 of 303

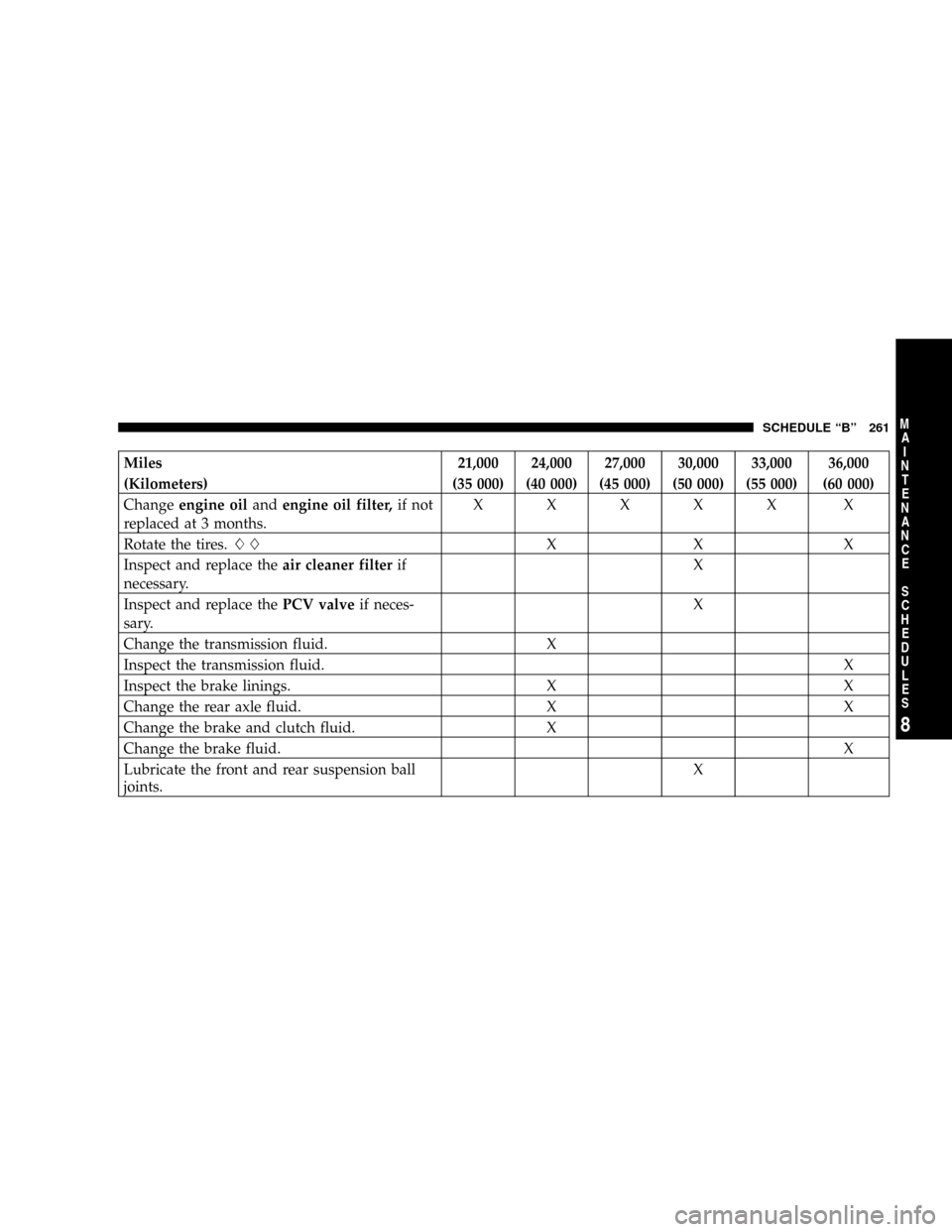

Miles 21,000 24,000 27,000 30,000 33,000 36,000

(Kilometers) (35 000) (40 000) (45 000) (50 000) (55 000) (60 000)

Changeengine oilandengine oil filter,if not

replaced at 3 months.XXXXX X

Rotate the tires.LLXX X

Inspect and replace theair cleaner filterif

necessary.X

Inspect and replace thePCV valveif neces-

sary.X

Change the transmission fluid. X

Inspect the transmission fluid.X

Inspect the brake linings. X X

Change the rear axle fluid. X X

Change the brake and clutch fluid. X

Change the brake fluid.X

Lubricate the front and rear suspension ball

joints.X

SCHEDULE ªBº 261

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

Page 264 of 303

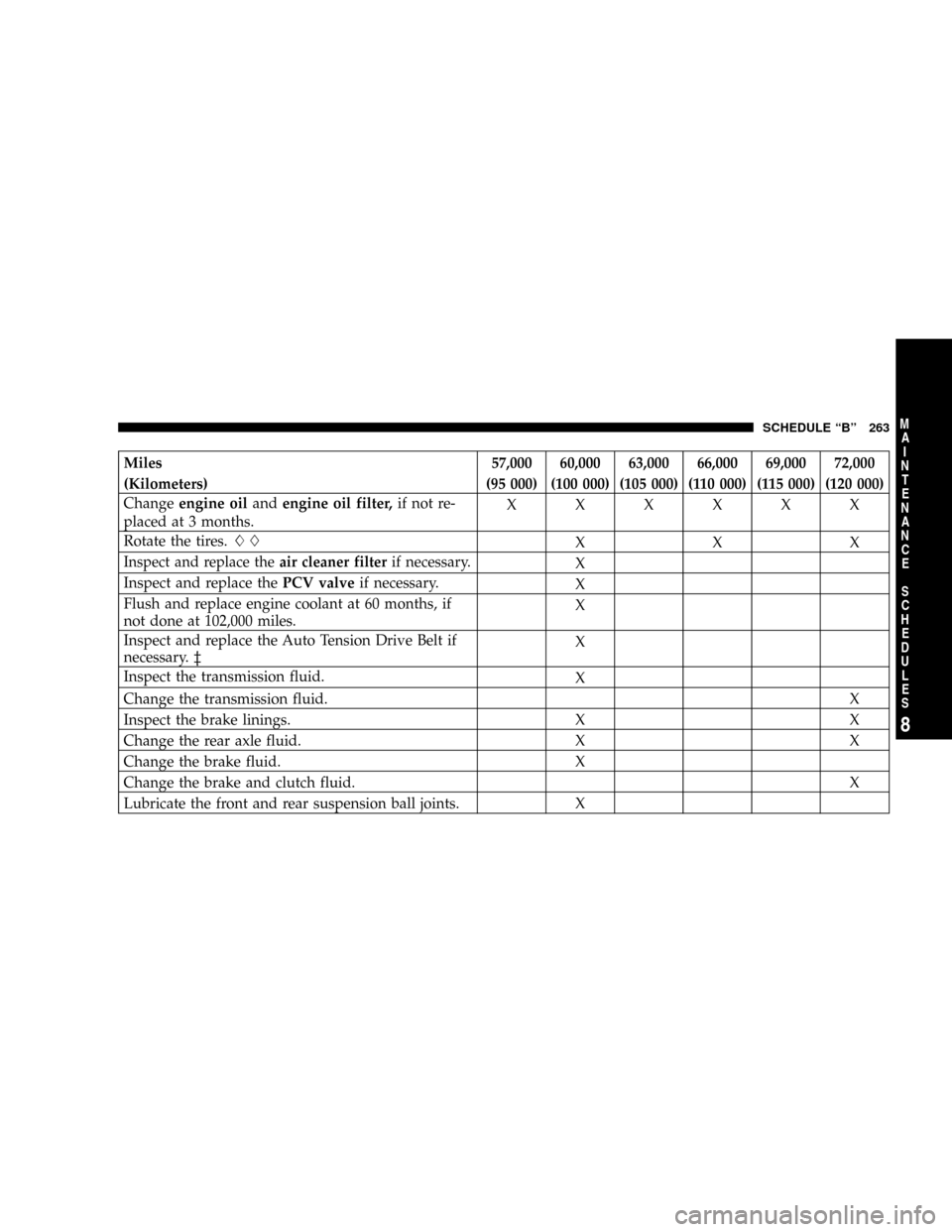

Miles 57,000 60,000 63,000 66,000 69,000 72,000

(Kilometers) (95 000) (100 000) (105 000) (110 000) (115 000) (120 000)

Changeengine oilandengine oil filter,if not re-

placed at 3 months.XXXXXX

Rotate the tires.LL

XXX

Inspect and replace theair cleaner filterif necessary.

X

Inspect and replace thePCV valveif necessary.

X

Flush and replace engine coolant at 60 months, if

not done at 102,000 miles.X

Inspect and replace the Auto Tension Drive Belt if

necessary. ³X

Inspect the transmission fluid.

X

Change the transmission fluid.X

Inspect the brake linings. X X

Change the rear axle fluid. X X

Change the brake fluid. X

Change the brake and clutch fluid.X

Lubricate the front and rear suspension ball joints. X

SCHEDULE ªBº 263

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S