maintenance schedule DODGE VIPER 2008 ZB II / 2.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2008, Model line: VIPER, Model: DODGE VIPER 2008 ZB II / 2.GPages: 303, PDF Size: 2.65 MB

Page 2 of 303

TABLE OF CONTENTSSECTIONPAGE

1INTRODUCTION.............................................................3

2THINGS TO KNOW BEFORE STARTING YOUR VEHICLE...............................9

3UNDERSTANDING THE FEATURES OF YOUR VEHICLE...............................61

4UNDERSTANDING YOUR INSTRUMENT PANEL.................................... 93

5STARTING AND OPERATING................................................. 129

6WHAT TO DO IN EMERGENCIES...............................................175

7MAINTAINING YOUR VEHICLE............................................... 191

8MAINTENANCE SCHEDULES.................................................. 255

9IF YOU NEED CONSUMER ASSISTANCE..........................................275

10INDEX....................................................................285

1

2

3

4

5

6

7

8

9

10

Page 166 of 303

aggressive tread designs such as those on all season type

tires. Rotation will increase tread life, help to maintain

mud, snow, and wet traction levels, and contribute to a

smooth, quiet ride.

Follow the ªMaintenance Schedulesº in Section 8 of this

manual for the recommended tire rotation frequency for

your type of driving. Remember, more frequent rotation is

permissible if desired. Also, correct for anything causing

rapid or unusual wear prior to performing the tire rotation.

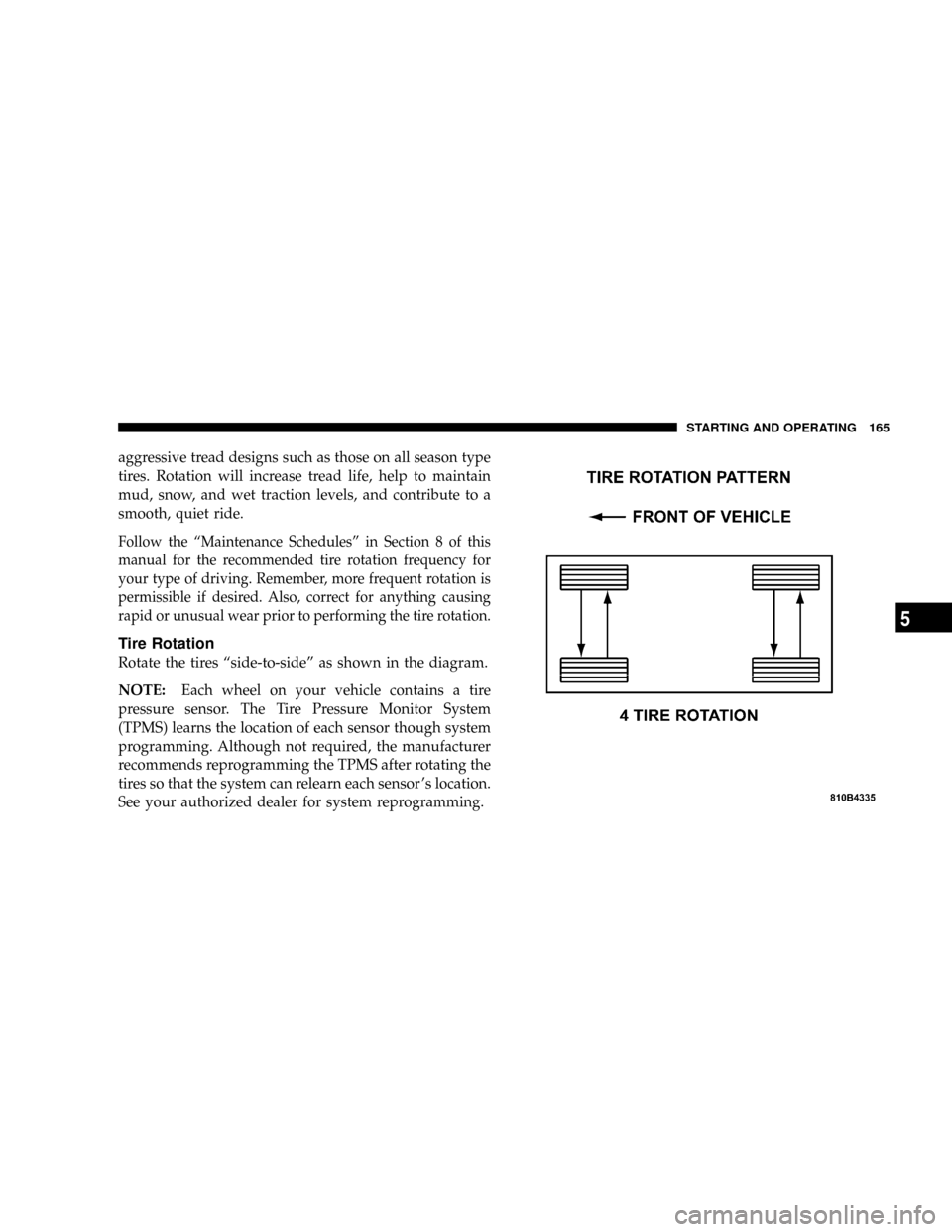

Tire Rotation

Rotate the tires ªside-to-sideº as shown in the diagram.

NOTE:Each wheel on your vehicle contains a tire

pressure sensor. The Tire Pressure Monitor System

(TPMS) learns the location of each sensor though system

programming. Although not required, the manufacturer

recommends reprogramming the TPMS after rotating the

tires so that the system can relearn each sensor 's location.

See your authorized dealer for system reprogramming.

STARTING AND OPERATING 165

5

Page 198 of 303

5. Approximately 15 seconds later, one of two things will

happen:

a. The MIL will flash for about 10 seconds and then

return to being fully illuminated until you turn off the

ignition key or start the engine. This means that your

vehicle's OBD system isnot readyand you shouldnot

proceed to the I/M station.

b. The MIL will not flash at all and will remain fully

illuminated until you turn OFF the ignition key or start

the engine. This means that your vehicle's OBD system

isreadyand you can proceed to the I/M station.

If your OBD system isnot ready,you should see your

authorized dealer or repair facility. If your vehicle was

recently serviced or had a battery failure or replacement,

you may need to do nothing more than drive your

vehicle as you normally would in order for your OBD

system to update. A recheck with the above test routine

may then indicate that the system is now ready.Regardless of whether your vehicle's OBD system is

ready or not ready, if the MIL symbol is illuminated

during normal vehicle operation, you should have your

vehicle serviced before going to the I/M station. The I/M

station can fail your vehicle because the MIL symbol is on

with the engine running.

REPLACEMENT PARTS

Use of genuine Mopartparts for normal/scheduled

maintenance and repairs is highly recommended to en-

sure the designed performance. Damage or failures

caused by the use of non-Mopartparts for maintenance

and repairs will not be covered by the manufacturer's

warranty.

MAINTAINING YOUR VEHICLE 197

7

Page 201 of 303

²More than 50% of your driving is at sustained high

speeds during hot weather, above 90ÉF (32ÉC)

²Trailer towing

²Taxi, Police, or delivery service (commercial service)

²Off-road or desert driving

²If equipped for and operating with E-85 (ethanol) fuel

NOTE:IfANYof these apply to you, then change your

engine oil every 3,000 miles (5 000 km) or 3 months,

whichever comes first, and follow schedule ªBº in the

9Maintenance Schedules9in this manual.

If none of these applies to you, then change your engine

oil at every interval shown on schedule9A9in the

9Maintenance Schedules9in this manual.

NOTE:Under no circumstances should oil change in-

tervals exceed 6,000 miles (10 000 km) or 6 months,

whichever comes first.

Engine Oil Selection

For best performance and maximum protection under all

types of operating conditions, the manufacturer only

recommends full synthetic engine oils that meet the

American Petroleum Institute (API) categories of SM or

SM/CF, and meet the requirements of DaimlerChrysler

Material Standard MS-10725.

The manufacturer recommends the use of a full synthetic

engine oil, such as Mobil 1tSAE 0W-40 or equivalent.

Engine Oil Viscosity (SAE Grade)

The proper SAE viscosity grade of engine oil should be

selected based on the following recommendation and be

within the operating temperature shown in the engine oil

viscosity chart.

200 MAINTAINING YOUR VEHICLE

Page 204 of 303

Spark Plugs

Spark plugs must fire properly to assure engine perfor-

mance and emission control. New plugs should be in-

stalled at the specified mileage. The entire set should be

replaced if there is any malfunction due to a faulty spark

plug. Malfunctioning spark plugs can damage the cata-

lytic converter. Refer to ªFluids, Lubricants, and Genuine

Partsº in this section for the proper type of spark plug for

use in your vehicle.

Engine Air Cleaner Filter

For normal driving conditions, inspect and replace the

engine air cleaner filter at the intervals shown on Sched-

ule ªA.º For vehicles driven frequently in dusty or under

severe conditions, inspect and replace the engine air

cleaner filter at the intervals shown on Schedule ªB.º

WARNING!

The air induction system (air cleaner, hoses, etc) can

provide a measure of protection in the case of engine

backfire. Do not remove the air induction system (air

cleaner, hoses, etc) unless such removal is necessary

for repair or maintenance. Make sure that no one is

near the engine compartment before starting the

vehicle with the air induction system (air cleaner,

hoses, etc) removed. Failure to do so can result in

serious personal injury.

MAINTAINING YOUR VEHICLE 203

7

Page 215 of 303

WARNING!

Overfilling the power steering fluid reservoir can

result in spilling power steering fluid on hot engine

parts and the power steering fluid catching fire.

Front & Rear Suspension Ball Joints

This vehicle has suspension ball joints that require peri-

odic inspection and lubrication.

Inspection

The ball joints should be inspected whenever other

service or maintenance is performed on the vehicle.

Damaged seals should be replaced to prevent leakage or

contamination of the grease. If there is any movement

within the ball joint, the knuckle or control arm must be

replaced, as the ball joints are not serviceable by them-

selves. See your authorized dealer for service.

Lubrication

The ball joints are lubricated at the factory with special

grease. Therefore, when lubricating the ball joints, use

only special long life chassis grease such as Multi-

Mileage Lubricant, which is intended for this purpose.

Refer to the ªMaintenance Schedulesº in this manual for

the specified lubrication intervals.

Steering Linkage

There are two tie rod end ball joints that require periodic

inspection.

Inspection

The ball joint seals on the tie rod ends should be

inspected whenever other service or maintenance is

performed on the vehicle. Damaged seals should be

replaced to prevent leakage or contamination of the

grease. If damaged, the tie rod end must be replaced, as

the seals are not serviceable by themselves. See your

authorized dealer for service.

214 MAINTAINING YOUR VEHICLE

Page 221 of 303

drain from the coolant recovery bottle. DO NOT RE-

MOVE THE COOLANT PRESSURE CAP WHEN THE

COOLING SYSTEM IS HOT.

Cooling System Ð Drain, Flush, and Refill

The system should be drained, flushed, and refilled at the

intervals shown on the ªMaintenance Schedulesº in this

manual.

If the solution is dirty or contains a considerable amount

of sediment, clean and flush with a reliable cooling

system cleaner. Follow with a thorough rinsing to remove

all deposits and chemicals. Properly dispose of old

antifreeze solution.

Selection Of Coolant

Use only the manufacturer's recommended coolant. Re-

fer to ªFluids, Lubricants, and Genuine Partsº for the

correct coolant type.

CAUTION!

²Mixing of coolants other than specified HOAT

engine coolants, may result in engine damage and

may decrease corrosion protection. If a non-HOAT

coolant is introduced into the cooling system in an

emergency, it should be replaced with the speci-

fied coolant as soon as possible.

²Do not use plain water alone or alcohol-base

engine coolant (antifreeze) products. Do not use

additional rust inhibitors or antirust products, as

they may not be compatible with the radiator

engine coolant and may plug the radiator.

²This vehicle has not been designed for use with

Propylene Glycol based coolants. Use of Propy-

lene Glycol based coolants is not recommended.

220 MAINTAINING YOUR VEHICLE

Page 226 of 303

Brake System

In order to assure brake system performance, all brake

system components should be inspected periodically.

Recommended service intervals can be found in the

ªMaintenance Schedulesº in this manual.

WARNING!

Riding the brakes can lead to brake failure and

possibly an accident. Driving with your foot resting

or riding on the brake pedal can result in abnormally

high brake temperatures, excessive lining wear, and

possible brake damage. You wouldn't have your full

braking capacity in an emergency.

Brake and Power Steering Hoses

When servicing the vehicle for scheduled maintenance,

inspect surface of hoses and nylon tubing for evidence of

heat and mechanical damage. Hard and brittle rubber,cracking, checking, tears, cuts, abrasion, and excessive

swelling suggest deterioration of the rubber. Particular

attention should be made to examining those hose sur-

faces nearest to high heat sources, such as the exhaust

manifold.

Insure nylon tubing in these areas has not melted or

collapsed.

Inspect all hose clamps and couplings to make sure they

are secure and no leaks are present.

NOTE:

²Often, fluid such as oil, power steering fluid, and

brake fluid are used during assembly plant operations

to facilitate the assembly of hoses to couplings. There-

fore, oil wetness at the hose-coupling area is not

necessarily an indication of leakage. Actual dripping

of hot fluid when systems are under pressure (during

vehicle operation), should be noted before a hose is

replaced based on leakage.

MAINTAINING YOUR VEHICLE 225

7

Page 228 of 303

Use only the manufacturer's recommended brake fluid.

Refer to ªFluids, Lubricants, and Genuine Partsº for the

correct fluid type. Use of a brake fluid that may have a

lower initial boiling point or unidentified as to specifica-

tion, may result in sudden brake failure during hard

prolonged braking.

WARNING!

Overfilling the brake fluid reservoir can result in

spilling brake fluid on hot engine parts and the

brake fluid catching fire.

Use only brake fluid that has been in a tightly closed

container to avoid contamination from foreign matter.

CAUTION!

²Do not allow petroleum base fluid to contaminate

the brake fluid, all brake seal components could

be damaged causing partial or complete brake

failure.

²Brake fluid can damage the finish of your vehicle.

Do not allow brake fluid to contact any painted

surface.

Change Brake Fluid

Brake fluid will tend to absorb moisture from the atmo-

sphere over time. If the fluid becomes contaminated with

water, brake performance will deteriorate. Therefore, the

brake fluid must be changed at the intervals specified in

the ªMaintenance Schedulesº in this manual. See your

authorized dealer for service.

MAINTAINING YOUR VEHICLE 227

7

Page 230 of 303

Use only the manufacturer's recommended clutch fluid.

Refer to ªFluids, Lubricants, and Genuine Partsº for the

correct fluid type.

WARNING!

Overfilling the clutch fluid reservoir can result in

spilling clutch fluid on hot engine parts and the

clutch fluid catching fire.

Use only clutch fluid that has been in a tightly closed

container to avoid contamination from foreign matter.

CAUTION!

²Do not allow petroleum base fluid to contaminate

the clutch fluid, all clutch seal components could

be damaged causing partial or complete clutch

failure.

²Clutch fluid can damage the finish of your vehicle.

Do not allow clutch fluid to contact any painted

surface.

Change Clutch Fluid

Clutch fluid will tend to absorb moisture from the

atmosphere over time. If the fluid becomes contaminated

with water, clutch performance will deteriorate. There-

fore, the clutch fluid must be changed at the intervals

specified in the ªMaintenance Schedulesº in this manu-

al.See your authorized dealer for service.

MAINTAINING YOUR VEHICLE 229

7