clock FIAT 124 SPIDER 2017 2.G User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 2017, Model line: 124 SPIDER, Model: FIAT 124 SPIDER 2017 2.GPages: 300, PDF Size: 121.24 MB

Page 193 of 300

Front Side Marker

(If equipped with halogen bulb)

Proceed as follows:

1. Remove the fasteners in the seven

locations and partially peel back the

upper side of the mud guard.2. Turn the socket counterclockwise,

remove socket assembly then remove

the bulb.

3. Install the new bulb in the reverse

order of the removal procedure.

GUID-08020499000011Side Direction Indicator

1 — Fasteners

GUID-07031501210001Side Direction Indicator

2 — Lens Assembly

GUID-07031501211001Side Direction Indicator

3 — Internal Catch

4 — Lens Assembly

08070604-123-100Front Side Marker

1 — Socket

2 — Bulb Assembly

191

Page 195 of 300

5. Turn the socket and bulb assembly

counterclockwise to remove from

taillight housing, and remove bulb.6. Install the new bulb in the reverse

order of the removal procedure.

Reverse Light

Proceed as follows:

1. Make sure the ignition is placed in

the OFF mode, and the headlight

switch is off.

2. Turn the socket assembly

counterclockwise to remove, and

remove bulb.

3. Install the new bulb in the reverse

order of the removal procedure.Rear Side Marker

Proceed as follows:

1. Push the lens assembly rearward to

compress the internal catch, then pull

the lens assembly outwards.

2. Turn the socket and bulb assembly

counterclockwise to remove, and

remove bulb.

07031501-216-001Rear of Vehicle

6 — Taillight Housing

07031501-203-002Taillight Housing

7 — Socket and Bulb Assembly

07031501-219-001Reverse Light

1 — Socket Assembly

2 — Bulb

08070605-123-100Rear Side Marker

1 — Rear Side Marker Lens Assembly

193

Page 196 of 300

3. Install the new bulb and then

reinstall the socket in the reverse order

of the removal procedure.License Plate Lights

Proceed as follows:

1. Make sure the ignition is placed in

the OFF mode, and the headlight

switch is off.

2. Slide the unit as shown in the figure

to remove it.

3. Turn the socket and bulb assembly

counterclockwise and remove, remove

bulb.

4. Install the new bulb in the reverse

order of the removal procedure. Insert

catch and push the housing back into

place.

08070606-123-100Side Marker Housing

2 — Socket and Bulb Assembly

GUID-07031501220001Trunk Lid

1 — License Plate Light Assembly

07031501-221-001License Plate Light Housing

2 — Socket and Bulb Assembly

194

IN CASE OF EMERGENCY

Page 206 of 300

CHANGING A WHEEL

Warning!

Do not attempt to change a tire on the

side of the vehicle close to moving traffic.

Pull far enough off the road to avoid the

danger of being hit when operating the jack

or changing the wheel.

Being under a jacked-up vehicle is

dangerous. The vehicle could slip off the

jack and fall on you. You could be crushed.

Never put any part of your body under a

vehicle that is on a jack. If you need to get

under a raised vehicle, take it to a service

center where it can be raised on a lift.

The jack is designed to be used as a

tool for changing tires only. The jack should

not be used to lift the vehicle for service

purposes. The vehicle should be jacked on

a firm level surface only. Avoid ice or

slippery areas.

Tools Location

Your vehicle may be equipped with a

spare tire, jack, lug wrench, and tow

eyes. For details, contact an Authorized

Dealer.

Tools are stored in the trunk.

Jacking Instructions — If

Equipped

To Remove The Jack

Proceed as follows:

1. In the right side of the trunk, pull on

indentation on side of cover to remove. 2. Turn the wing bolt and jack screw

counterclockwise.

08020100-122-002Jack Tools

1 — Jack Lever

2 — Lug Wrench (If Equipped)

3 — Tow Eyes (If Equipped)

08020101-124-001Jack Location

1 — Indentation On Cover

2 — Jack And Tools Cover

08020101-122-001Jack Components

3 — Wing Bolt

4 — Jack Screw

204

IN CASE OF EMERGENCY

Page 207 of 300

To Secure The Jack

Proceed as follows:

1. Insert the wing bolt into the jack with

the jack screw pointing back, and turn

the wing bolt clockwise to temporarily

tighten it.

2. Turn the jack screw clockwise.

3. Turn the wing bolt completely to

secure the jack.

4. Insert the cover tabs and install the

cover.

Warning!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided. Have the deflated (flat) tire

repaired or replaced immediately.

Maintenance

Always keep the jack clean.

Make sure the moving parts are kept

free from dirt or rust.

Make sure the screw thread is

adequately lubricated. Conditions Of Non-Use

Temperatures below -40°F (−40°C)

On sandy or muddy ground

On uneven ground

On steep roads

In extreme weather conditions

In direct contact with the engine or

for repairs under the vehicle

On boats

Changing Procedure

Note: Make sure the jack is well

lubricated before using it.

Warning!

Do not attempt to change a tire on the side

of the vehicle close to moving traffic, pull

far enough off the road to avoid being hit

when operating the jack or changing the

wheel.

Proceed as follows:

1. Stop the vehicle in a position that

does not cause any danger to traffic

and lets you change the tire in safety, as

far as possible from the edge of the

driving lane. The ground must be flat

and sufficiently compact. 2. Turn on the hazard warning lights

and engage the parking brake.

3. For vehicles with automatic

transmission, place the gear selector in

Park (P). For vehicles with manual

transmission, place gear selector in

Reverse (R) and turn off the engine.

4. Stop the engine. The motor must be

kept off as long as the vehicle is lifted

off the ground.

5. Remove the jack and tools.

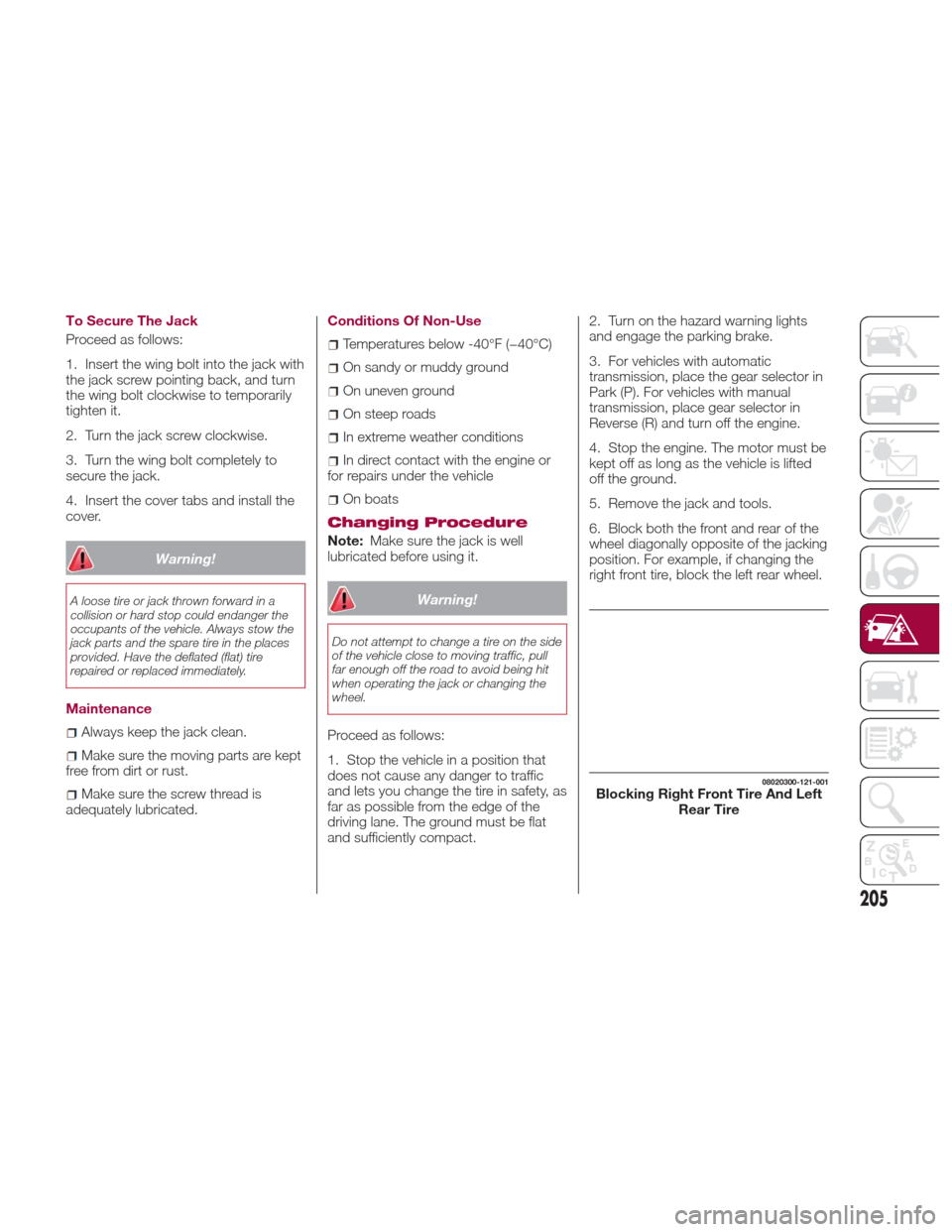

6. Block both the front and rear of the

wheel diagonally opposite of the jacking

position. For example, if changing the

right front tire, block the left rear wheel.

08020300-121-001Blocking Right Front Tire And Left

Rear Tire

205

Page 208 of 300

Removing A Tire

Warning!

Carefully follow these tire changing

warnings to help prevent personal injury or

damage to your vehicle:

Always park on a firm, level surface as

far from the edge of the roadway as

possible before raising the vehicle.

Turn on the Hazard Warning flasher.

Block the wheel diagonally opposite the

wheel to be raised.

Set the parking brake firmly and set the

transmission in PARK.

Do not let any passenger sit in the

vehicle when it is on a jack.

Do not get under the vehicle when it is

on a jack. If you need to get under a raised

vehicle, take it to a service center where it

can be raised on a lift.

Only use the jack in the positions

indicated and for lifting this vehicle during a

tire change.

If working on or near a roadway, be

extremely careful of motor traffic.

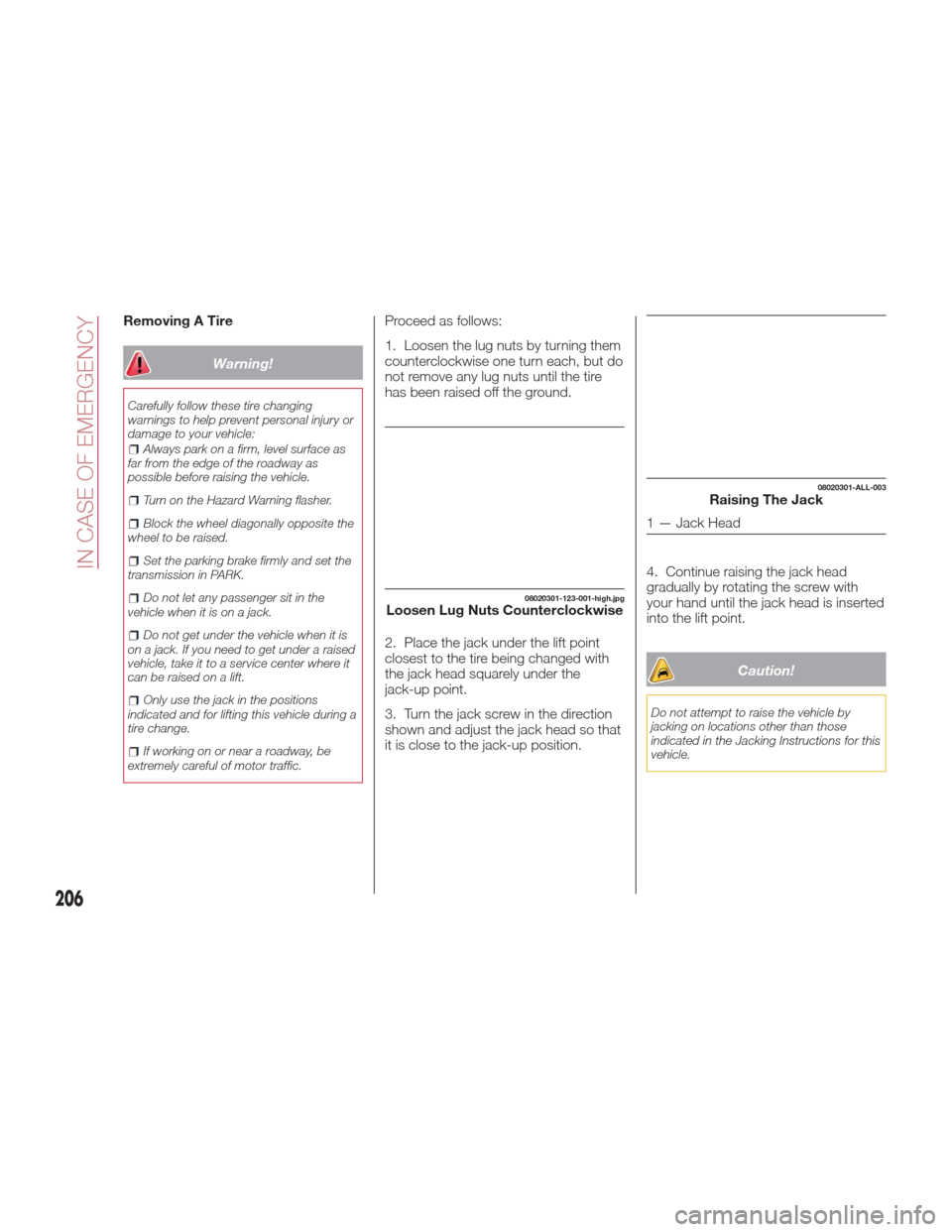

Proceed as follows:

1. Loosen the lug nuts by turning them

counterclockwise one turn each, but do

not remove any lug nuts until the tire

has been raised off the ground.

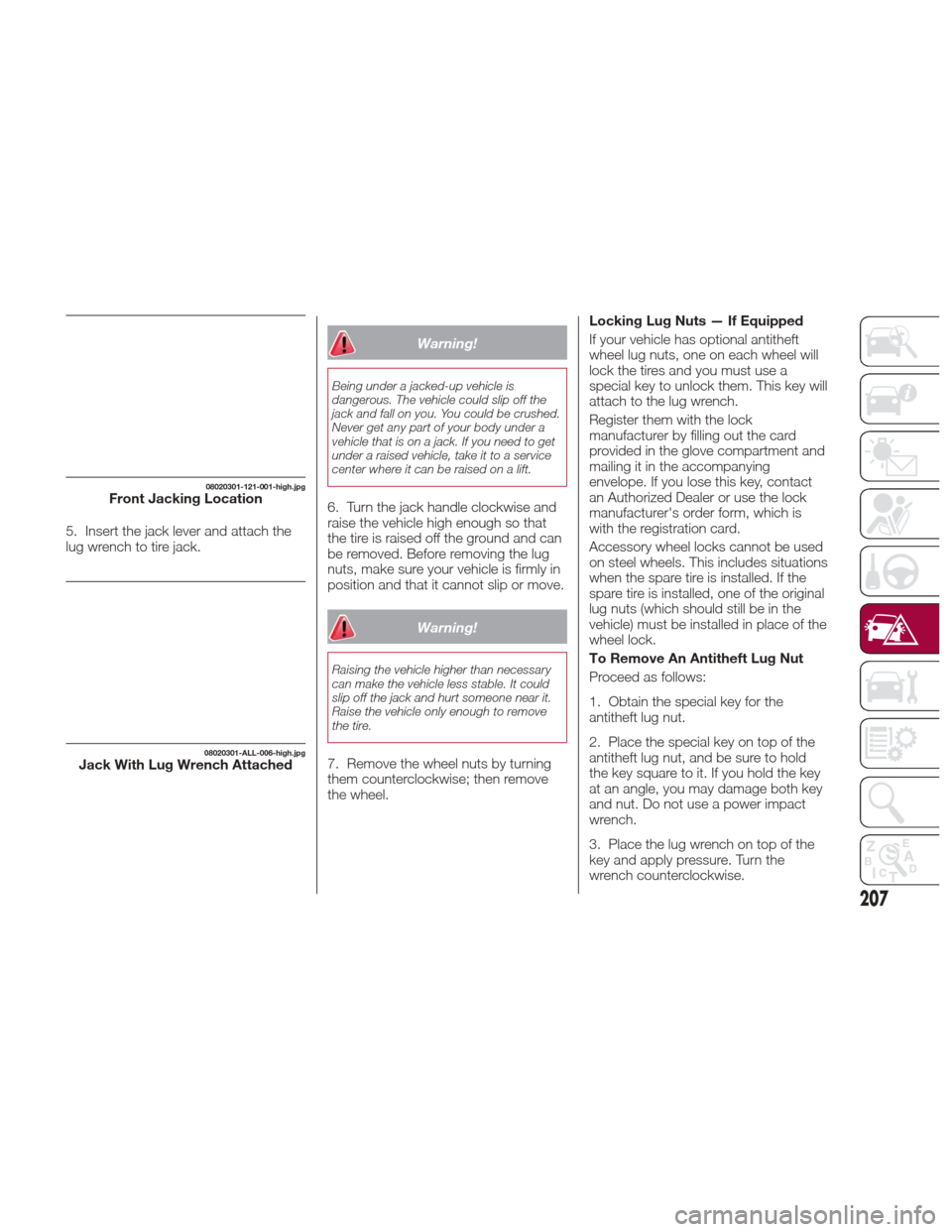

2. Place the jack under the lift point

closest to the tire being changed with

the jack head squarely under the

jack-up point.

3. Turn the jack screw in the direction

shown and adjust the jack head so that

it is close to the jack-up position. 4. Continue raising the jack head

gradually by rotating the screw with

your hand until the jack head is inserted

into the lift point.

Caution!

Do not attempt to raise the vehicle by

jacking on locations other than those

indicated in the Jacking Instructions for this

vehicle.

08020301-123-001-high.jpgLoosen Lug Nuts Counterclockwise

08020301-ALL-003Raising The Jack

1 — Jack Head

206

IN CASE OF EMERGENCY

Page 209 of 300

5. Insert the jack lever and attach the

lug wrench to tire jack.

Warning!

Being under a jacked-up vehicle is

dangerous. The vehicle could slip off the

jack and fall on you. You could be crushed.

Never get any part of your body under a

vehicle that is on a jack. If you need to get

under a raised vehicle, take it to a service

center where it can be raised on a lift.

6. Turn the jack handle clockwise and

raise the vehicle high enough so that

the tire is raised off the ground and can

be removed. Before removing the lug

nuts, make sure your vehicle is firmly in

position and that it cannot slip or move.

Warning!

Raising the vehicle higher than necessary

can make the vehicle less stable. It could

slip off the jack and hurt someone near it.

Raise the vehicle only enough to remove

the tire.

7. Remove the wheel nuts by turning

them counterclockwise; then remove

the wheel.Locking Lug Nuts — If Equipped

If your vehicle has optional antitheft

wheel lug nuts, one on each wheel will

lock the tires and you must use a

special key to unlock them. This key will

attach to the lug wrench.

Register them with the lock

manufacturer by filling out the card

provided in the glove compartment and

mailing it in the accompanying

envelope. If you lose this key, contact

an Authorized Dealer or use the lock

manufacturer's order form, which is

with the registration card.

Accessory wheel locks cannot be used

on steel wheels. This includes situations

when the spare tire is installed. If the

spare tire is installed, one of the original

lug nuts (which should still be in the

vehicle) must be installed in place of the

wheel lock.

To Remove An Antitheft Lug Nut

Proceed as follows:

1. Obtain the special key for the

antitheft lug nut.

2. Place the special key on top of the

antitheft lug nut, and be sure to hold

the key square to it. If you hold the key

at an angle, you may damage both key

and nut. Do not use a power impact

wrench.

3. Place the lug wrench on top of the

key and apply pressure. Turn the

wrench counterclockwise.

08020301-121-001-high.jpgFront Jacking Location

08020301-ALL-006-high.jpgJack With Lug Wrench Attached

207

Page 210 of 300

To Install The Antitheft Lug Nut

Proceed as follows:

1. Place the special key on top of the

nut, and be sure to hold the key square

to it. If you hold the key at an angle, you

may damage both key and nut. Do not

use a power impact wrench.

2. Place the lug wrench on top of the

special key, apply pressure, and turn it

clockwise.

Mounting The Tire

Proceed as follows:

1. Remove dirt and grime from the

mounting surfaces of the wheel and

hub, including the hub bolts, with a

cloth.

2. Mount the tire and install the wheel

nuts with the beveled edge inward;

tighten them by hand.

Caution!

Be sure to mount the spare tire with the

valve stem facing outward. The vehicle

could be damaged if the spare tire is

mounted incorrectly.

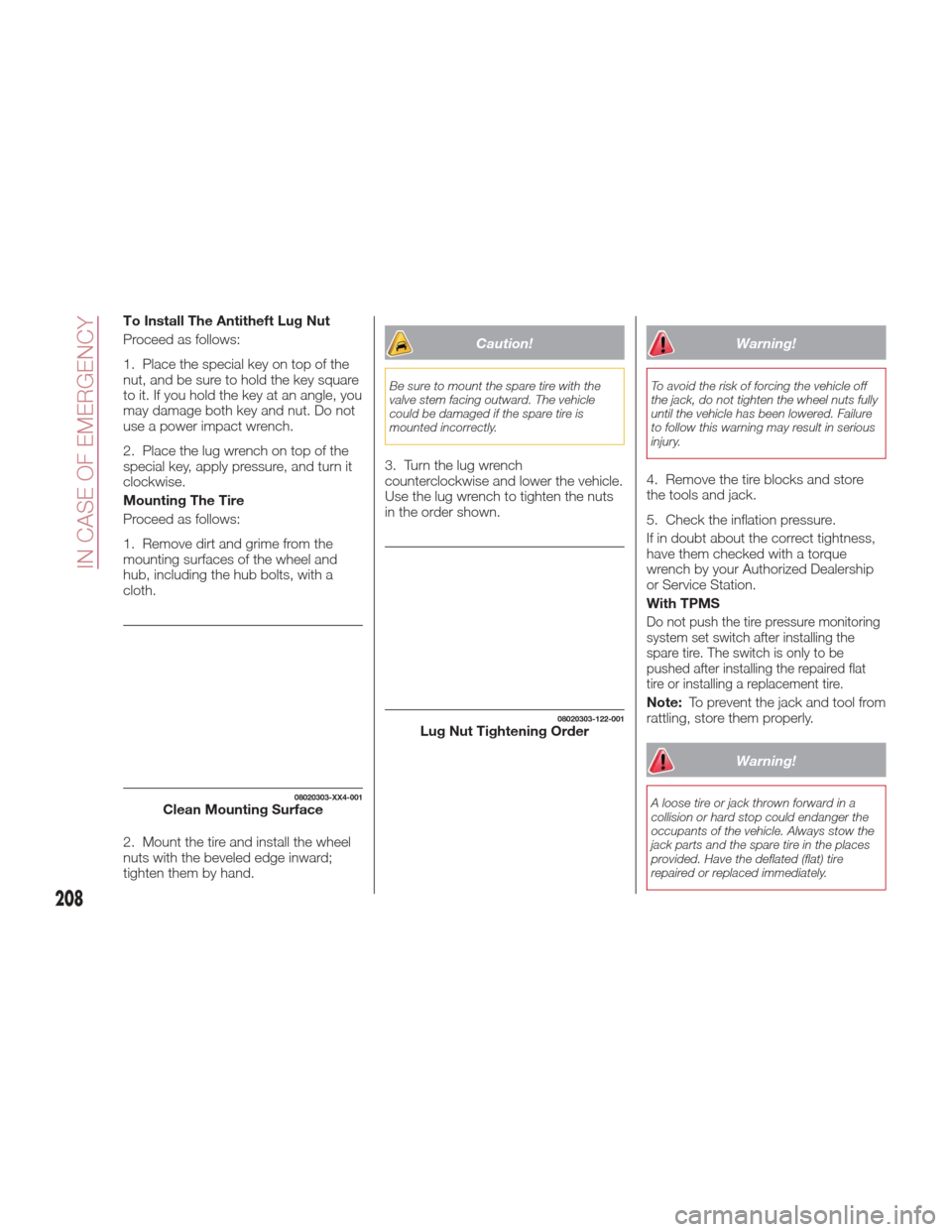

3. Turn the lug wrench

counterclockwise and lower the vehicle.

Use the lug wrench to tighten the nuts

in the order shown.

Warning!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel nuts fully

until the vehicle has been lowered. Failure

to follow this warning may result in serious

injury.

4. Remove the tire blocks and store

the tools and jack.

5. Check the inflation pressure.

If in doubt about the correct tightness,

have them checked with a torque

wrench by your Authorized Dealership

or Service Station.

With TPMS

Do not push the tire pressure monitoring

system set switch after installing the

spare tire. The switch is only to be

pushed after installing the repaired flat

tire or installing a replacement tire.

Note:To prevent the jack and tool from

rattling, store them properly.

Warning!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided. Have the deflated (flat) tire

repaired or replaced immediately.08020303-XX4-001Clean Mounting Surface

08020303-122-001Lug Nut Tightening Order

208

IN CASE OF EMERGENCY

Page 218 of 300

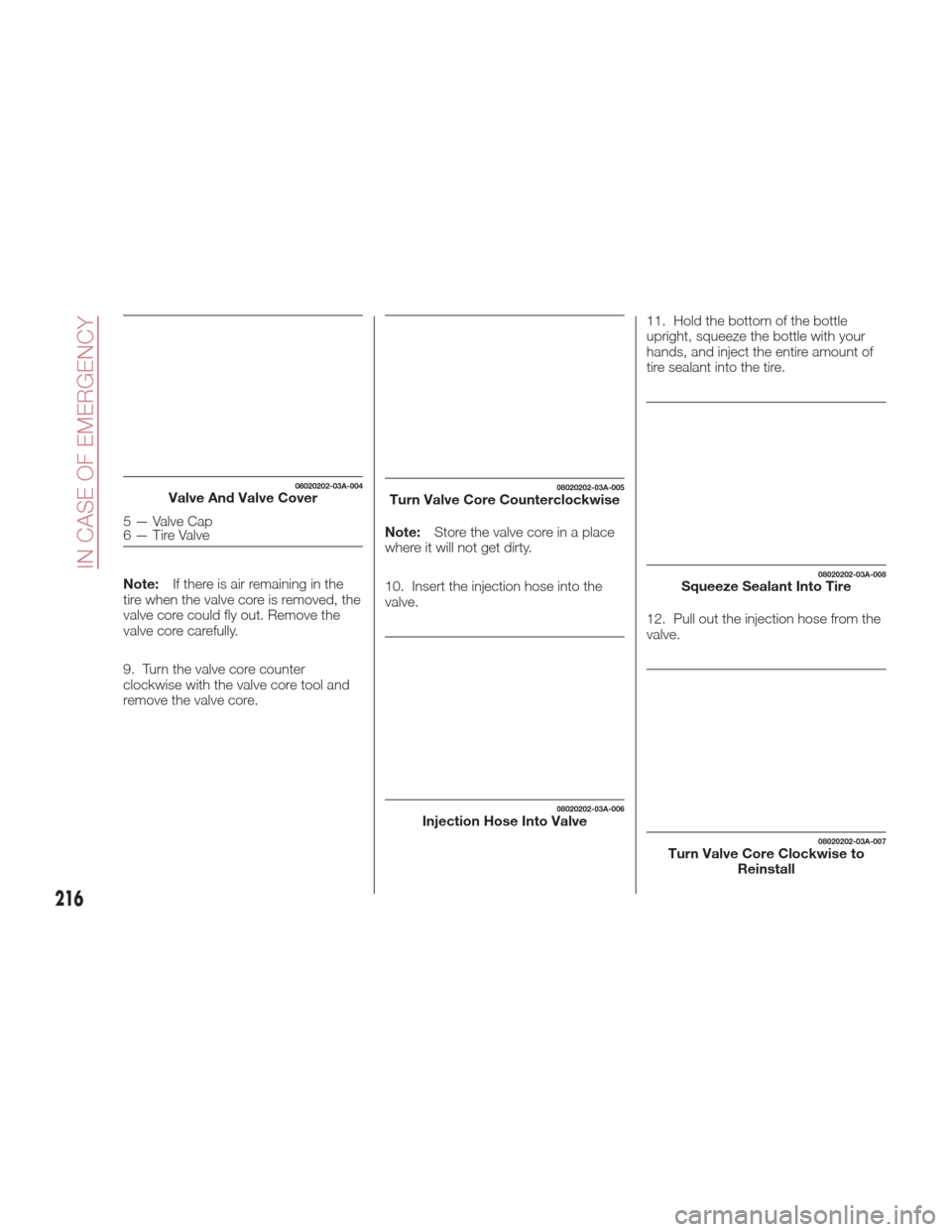

Note:If there is air remaining in the

tire when the valve core is removed, the

valve core could fly out. Remove the

valve core carefully.

9. Turn the valve core counter

clockwise with the valve core tool and

remove the valve core. Note:

Store the valve core in a place

where it will not get dirty.

10. Insert the injection hose into the

valve. 11. Hold the bottom of the bottle

upright, squeeze the bottle with your

hands, and inject the entire amount of

tire sealant into the tire.

12. Pull out the injection hose from the

valve.

08020202-03A-004Valve And Valve Cover

5 — Valve Cap

6 — Tire Valve

08020202-03A-005Turn Valve Core Counterclockwise

08020202-03A-006Injection Hose Into Valve

08020202-03A-008Squeeze Sealant Into Tire

08020202-03A-007Turn Valve Core Clockwise to

Reinstall

216

IN CASE OF EMERGENCY

Page 219 of 300

13. Reinsert the valve core into the

valve and turn it clockwise to install.

Note:

The tire sealant cannot be reused.

If the tire sealant kit has been used, or

is expired, purchase new one at an

Authorized Dealer.

Do not throw away the empty tire

sealant bottle after use. Return the

empty tire sealant bottle to an

Authorized Dealer when replacing the

tire. The empty tire sealant bottle will

need to be used to extract and dispose

of the used sealant from the tire.

14. Install the injection hose to the tab

of the bottle to prevent leakage of any

remaining sealant.

15. Adhere the speed restriction sticker

to an area where it can be viewed easily

by the driver.

Warning!

Do not adhere the speed restriction sticker

to the padded area on the steering wheel.

Adhering the speed restriction sticker to

the padded area on the steering wheel is

dangerous because the air bag may not

operate (deploy) normally resulting in

serious injury. In addition, do not adhere

the sticker to areas where warning lights or

the speedometer cannot be viewed.

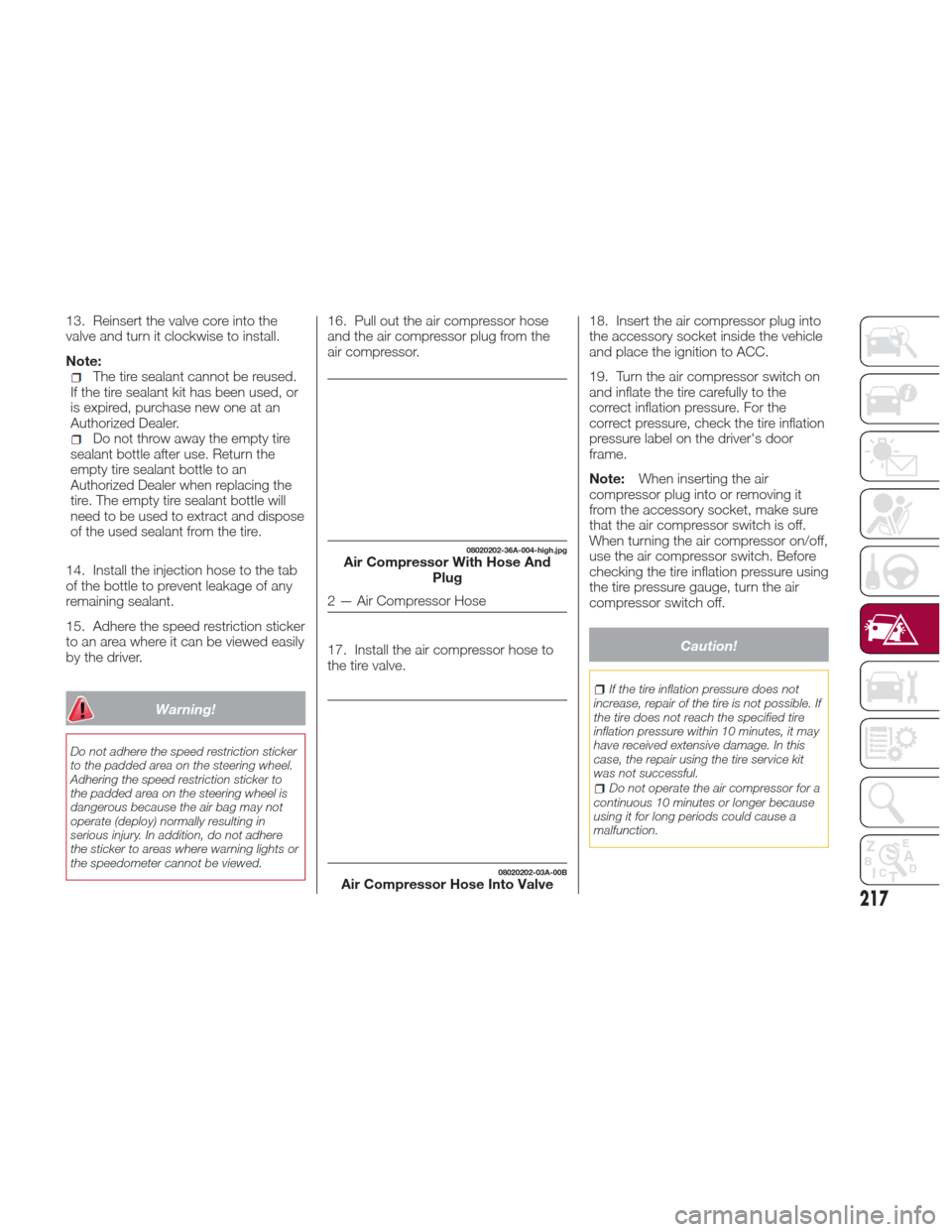

16. Pull out the air compressor hose

and the air compressor plug from the

air compressor.

17. Install the air compressor hose to

the tire valve. 18. Insert the air compressor plug into

the accessory socket inside the vehicle

and place the ignition to ACC.

19. Turn the air compressor switch on

and inflate the tire carefully to the

correct inflation pressure. For the

correct pressure, check the tire inflation

pressure label on the driver's door

frame.

Note:

When inserting the air

compressor plug into or removing it

from the accessory socket, make sure

that the air compressor switch is off.

When turning the air compressor on/off,

use the air compressor switch. Before

checking the tire inflation pressure using

the tire pressure gauge, turn the air

compressor switch off.

Caution!

If the tire inflation pressure does not

increase, repair of the tire is not possible. If

the tire does not reach the specified tire

inflation pressure within 10 minutes, it may

have received extensive damage. In this

case, the repair using the tire service kit

was not successful.

Do not operate the air compressor for a

continuous 10 minutes or longer because

using it for long periods could cause a

malfunction.

08020202-36A-004-high.jpgAir Compressor With Hose And Plug

2 — Air Compressor Hose

08020202-03A-00BAir Compressor Hose Into Valve

217