maintenance FIAT 124 SPIDER 2017 2.G Owner's Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2017, Model line: 124 SPIDER, Model: FIAT 124 SPIDER 2017 2.GPages: 300, PDF Size: 121.24 MB

Page 228 of 300

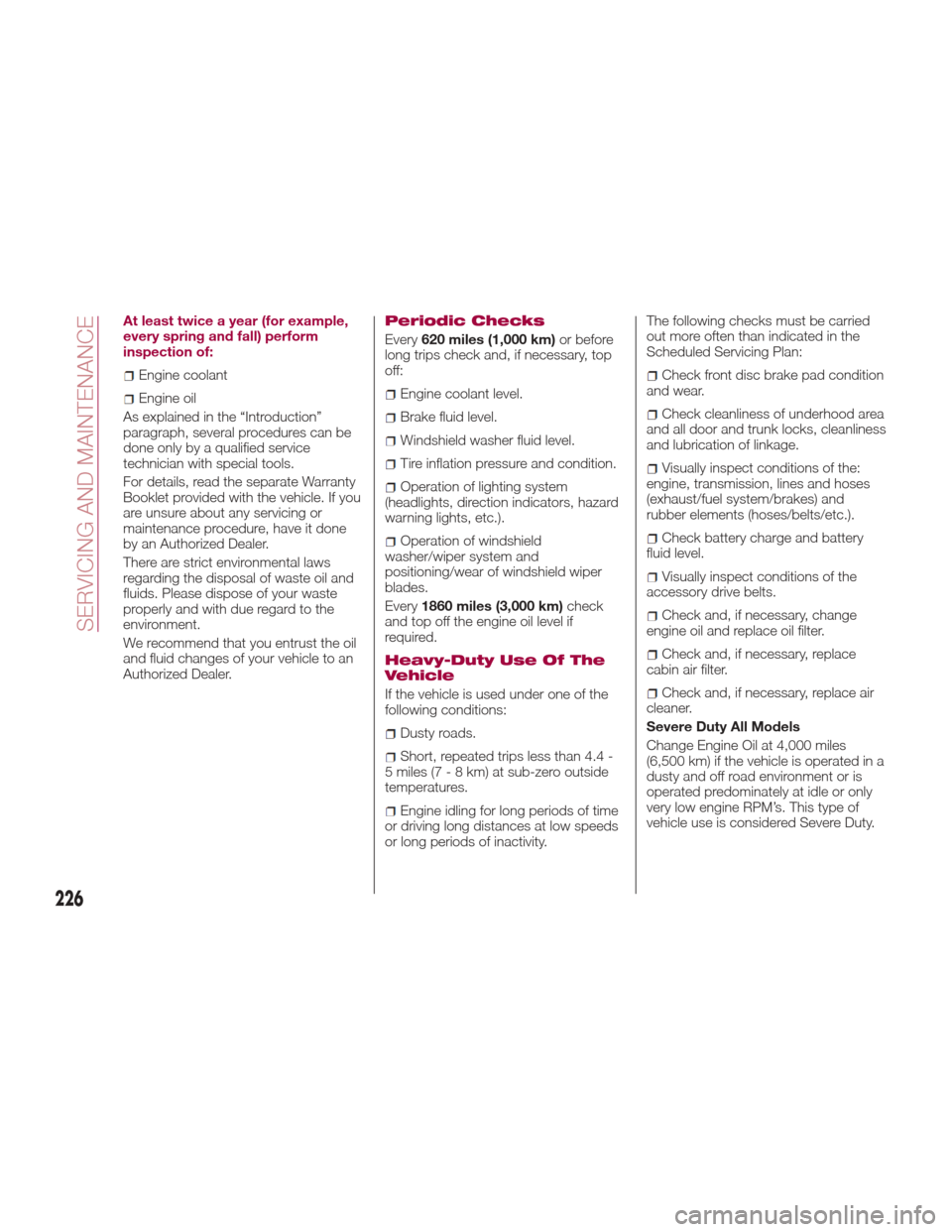

At least twice a year (for example,

every spring and fall) perform

inspection of:

Engine coolant

Engine oil

As explained in the “Introduction”

paragraph, several procedures can be

done only by a qualified service

technician with special tools.

For details, read the separate Warranty

Booklet provided with the vehicle. If you

are unsure about any servicing or

maintenance procedure, have it done

by an Authorized Dealer.

There are strict environmental laws

regarding the disposal of waste oil and

fluids. Please dispose of your waste

properly and with due regard to the

environment.

We recommend that you entrust the oil

and fluid changes of your vehicle to an

Authorized Dealer.

Periodic Checks

Every 620 miles (1,000 km) or before

long trips check and, if necessary, top

off:

Engine coolant level.

Brake fluid level.

Windshield washer fluid level.

Tire inflation pressure and condition.

Operation of lighting system

(headlights, direction indicators, hazard

warning lights, etc.).

Operation of windshield

washer/wiper system and

positioning/wear of windshield wiper

blades.

Every 1860 miles (3,000 km) check

and top off the engine oil level if

required.

Heavy-Duty Use Of The

Vehicle

If the vehicle is used under one of the

following conditions:

Dusty roads.

Short, repeated trips less than 4.4 -

5 miles (7-8km)atsub -zero outside

temperatures.

Engine idling for long periods of time

or driving long distances at low speeds

or long periods of inactivity. The following checks must be carried

out more often than indicated in the

Scheduled Servicing Plan:

Check front disc brake pad condition

and wear.

Check cleanliness of underhood area

and all door and trunk locks, cleanliness

and lubrication of linkage.

Visually inspect conditions of the:

engine, transmission, lines and hoses

(exhaust/fuel system/brakes) and

rubber elements (hoses/belts/etc.).

Check battery charge and battery

fluid level.

Visually inspect conditions of the

accessory drive belts.

Check and, if necessary, change

engine oil and replace oil filter.

Check and, if necessary, replace

cabin air filter.

Check and, if necessary, replace air

cleaner.

Severe Duty All Models

Change Engine Oil at 4,000 miles

(6,500 km) if the vehicle is operated in a

dusty and off road environment or is

operated predominately at idle or only

very low engine RPM’s. This type of

vehicle use is considered Severe Duty.

226

SERVICING AND MAINTENANCE

Page 230 of 300

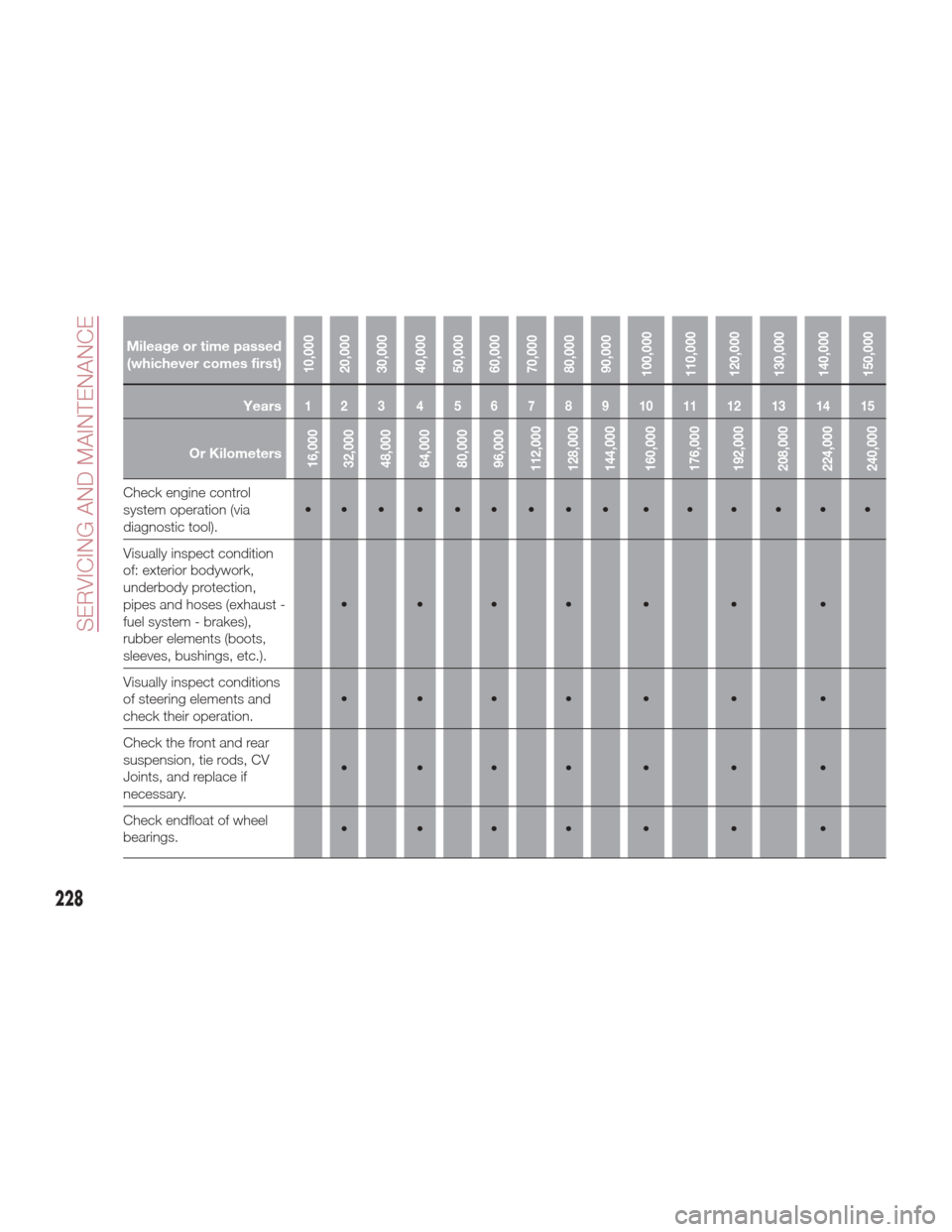

Mileage or time passed(whichever comes first)

10,000

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Years123 456789101112131415

Or Kilometers16,000

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

Check engine control

system operation (via

diagnostic tool). •••••••••••••••

Visually inspect condition

of: exterior bodywork,

underbody protection,

pipes and hoses (exhaust -

fuel system - brakes),

rubber elements (boots,

sleeves, bushings, etc.). •••• • • •

Visually inspect conditions

of steering elements and

check their operation. •••• • • •

Check the front and rear

suspension, tie rods, CV

Joints, and replace if

necessary. •••• • • •

Check endfloat of wheel

bearings. •••• • • •

228

SERVICING AND MAINTENANCE

Page 232 of 300

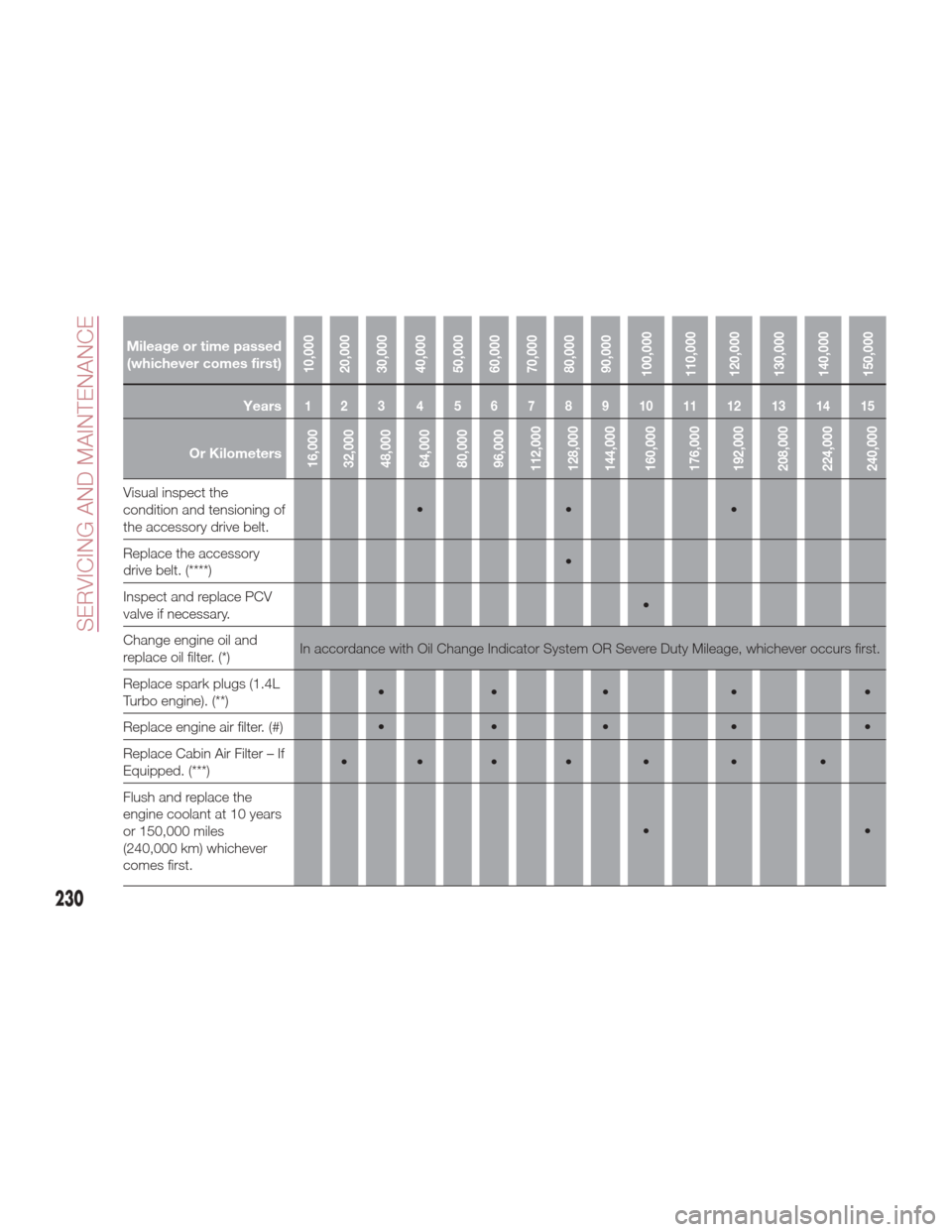

Mileage or time passed(whichever comes first)

10,000

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Years123 456789101112131415

Or Kilometers16,000

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

Visual inspect the

condition and tensioning of

the accessory drive belt. •• •

Replace the accessory

drive belt. (****) •

Inspect and replace PCV

valve if necessary. •

Change engine oil and

replace oil filter. (*) In accordance with Oil Change Indicator System OR Severe Duty Mileage, whichever occurs first.

Replace spark plugs (1.4L

Turbo engine). (**) ••• • •

Replace engine air filter. (#) • • • • •

Replace Cabin Air Filter – If

Equipped. (***) •••• • • •

Flush and replace the

engine coolant at 10 years

or 150,000 miles

(240,000 km) whichever

comes first. ••

230

SERVICING AND MAINTENANCE

Page 233 of 300

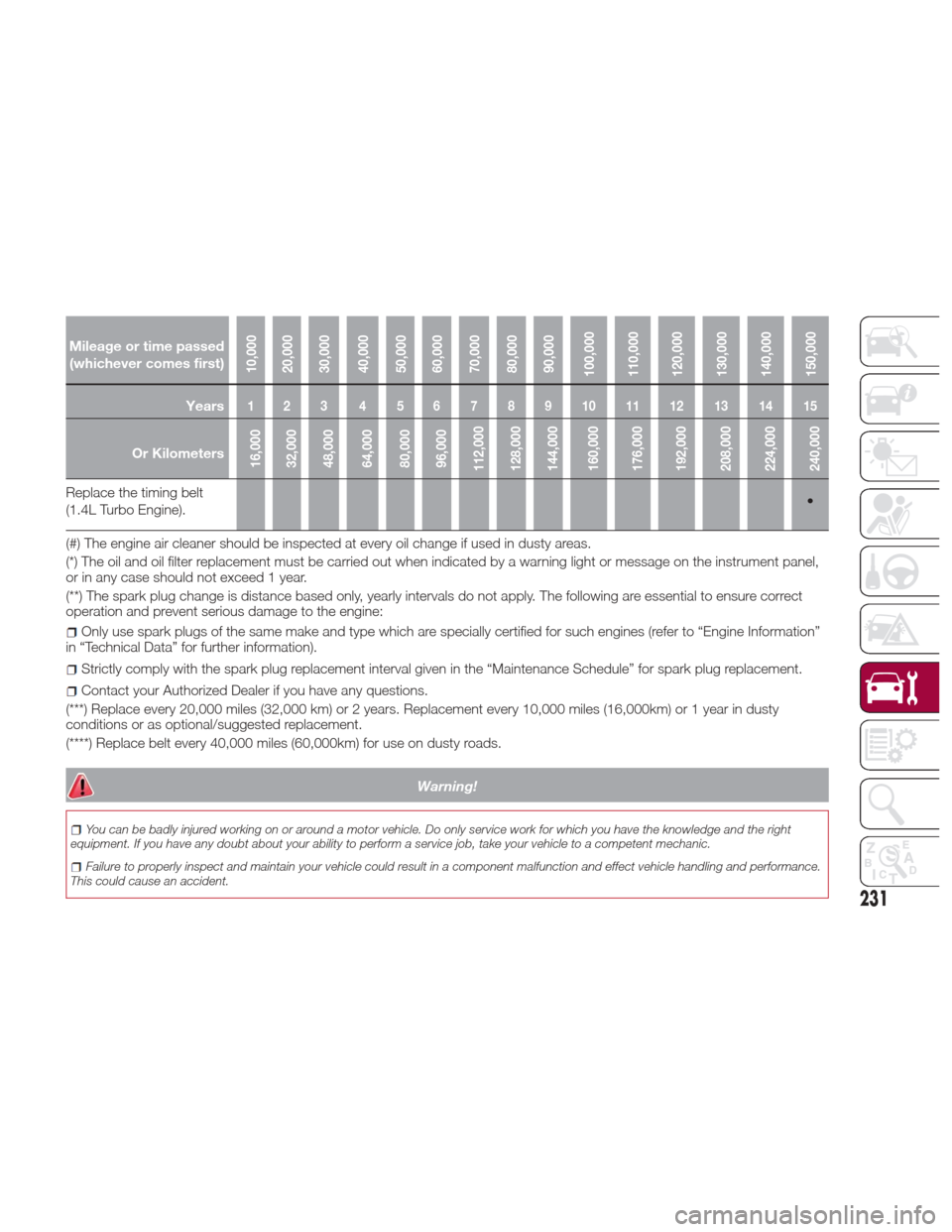

Mileage or time passed(whichever comes first)

10,000

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Years123 456789101112131415

Or Kilometers16,000

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

Replace the timing belt

(1.4L Turbo Engine). •

(#) The engine air cleaner should be inspected at every oil change if used in dusty areas.

(*) The oil and oil filter replacement must be carried out when indicated by a warning light or message on the instrument panel,

or in any case should not exceed 1 year.

(**) The spark plug change is distance based only, yearly intervals do not apply. The following are essential to ensure correct

operation and prevent serious damage to the engine:

Only use spark plugs of the same make and type which are specially certified for such engines (refer to “Engine Information”

in “Technical Data” for further information).

Strictly comply with the spark plug replacement interval given in the “Maintenance Schedule” for spark plug replacement.

Contact your Authorized Dealer if you have any questions.

(***) Replace every 20,000 miles (32,000 km) or 2 years. Replacement every 10,000 miles (16,000km) or 1 year in dusty

conditions or as optional/suggested replacement.

(****) Replace belt every 40,000 miles (60,000km) for use on dusty roads.

Warning!

You can be badly injured working on or around a motor vehicle. Do only service work for which you have the knowledge and the right

equipment. If you have any doubt about your ability to perform a service job, take your vehicle to a competent mechanic.

Failure to properly inspect and maintain your vehicle could result in a component malfunction and effect vehicle handling and performance.

This could cause an accident.

231

Page 234 of 300

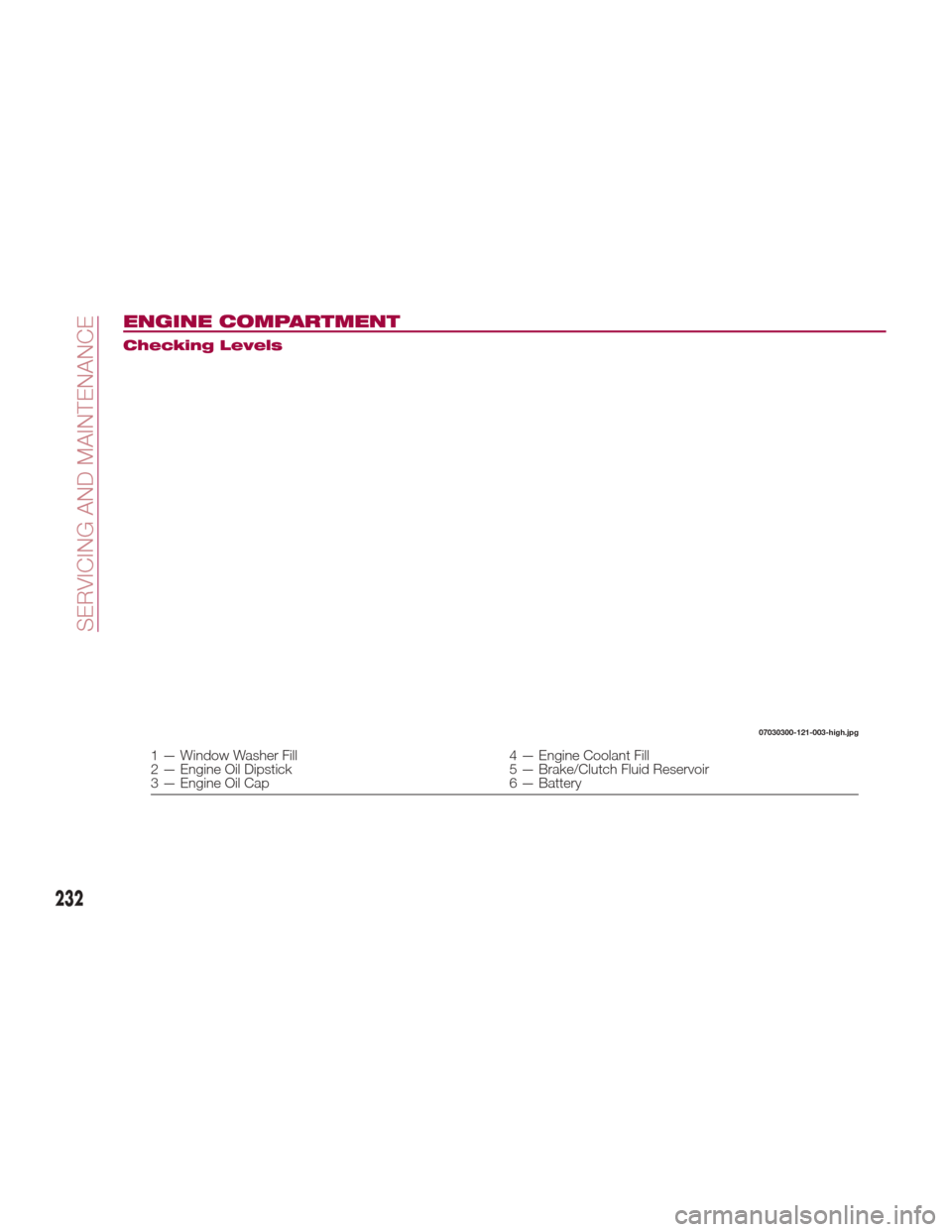

ENGINE COMPARTMENT

Checking Levels

07030300-121-003-high.jpg

1 — Window Washer Fill4 — Engine Coolant Fill

2 — Engine Oil Dipstick 5 — Brake/Clutch Fluid Reservoir

3 — Engine Oil Cap 6 — Battery

232

SERVICING AND MAINTENANCE

Page 236 of 300

Warning!

Do not open hot engine cooling system.

Never add engine coolant (antifreeze) when

the engine is overheated. Do not loosen or

remove the cap to cool an overheated

engine. Heat causes pressure to build up in

the cooling system. To prevent scalding or

injury, do not remove the pressure cap

while the system is hot or under pressure.

Do not use a pressure cap other than

the one specified for your vehicle. Personal

injury or engine damage may result.

The coolant should be at full in the

radiator and between the F (Full) and L

(Low) marks on the coolant reservoir

when the engine is cool. If it is at or near L (Low), add coolant by

mixing a minimum solution of 50%

Mopar Long Life Coolant Concentrate

for FIAT Spider. Use higher

concentrations (not to exceed 70%) if

temperatures below −34°F (−37°C) are

anticipated. Bring the level to F (Full).

Please contact your Authorized Dealer

for assistance.

Securely tighten the coolant reservoir

tank cap after adding coolant.

If the coolant reservoir is empty or new

coolant is required frequently, contact

your Authorized Dealer.

Brake/Clutch Fluid

Inspecting Brake/Clutch Fluid Level

The brakes and clutch draw fluid

from the same reservoir.

Inspect the fluid level in the reservoir

regularly.

It should be kept between the MAX

and MIN lines.

The level normally drops with

accumulated use, a condition

associated with wear of brake and

clutch linings. If it is excessively low,

have the brake/clutch system

inspected. Contact your Authorized

Dealer.

Warning!

Use only manufacturer's recommended

brake fluid. Refer to “Fluids And Lubricants”

in “Technical Specifications” for further

information. Using the wrong type of brake

fluid can severely damage your brake

system and/or impair its performance. The

proper type of brake fluid for your vehicle is

also identified on the original factory

installed hydraulic master cylinder reservoir.

To avoid contamination from foreign

matter or moisture, use only new brake

fluid or fluid that has been in a tightly

closed container. Keep the master cylinder

reservoir cap secured at all times. Brake

fluid in a open container absorbs moisture

from the air resulting in a lower boiling

point. This may cause it to boil

unexpectedly during hard or prolonged

braking, resulting in sudden brake failure.

This could result in a collision.

07030501-121-001Coolant Reservoir

07030601-121-002Brake Fluid Reservoir

234

SERVICING AND MAINTENANCE

Page 237 of 300

Overfilling the brake fluid reservoir can

result in spilling brake fluid on hot engine

parts, causing the brake fluid to catch fire.

Brake fluid can also damage painted and

vinyl surfaces, care should be taken to

avoid its contact with these surfaces.

Do not allow petroleum based fluid to

contaminate the brake fluid. Brake seal

components could be damaged, causing

partial or complete brake failure. This could

result in a collision.

Windshield And

Headlight Washer Fluid

Inspecting Washer Fluid Level

Inspect fluid level in the washer fluid

reservoir, open the cap and add fluid if

necessary.

Use plain water if washer fluid is

unavailable. But use only washer fluid in

cold weather to prevent it from freezing.

Automatic Transmission

Control Unit

The transmission oil level should only be

checked at your Authorized Dealer.

Battery Maintenance

To get the best service from a battery:

Keep it securely mounted.

Keep the top clean and dry.

Keep terminals and connections

clean, tight, and coated with petroleum

jelly or terminal grease.

Rinse off spilled electrolyte

immediately with a solution of water

and baking soda.

If the vehicle will not be used for an

extended time, disconnect the battery

leads and charge the battery every six

weeks.

Battery Replacement

Contact your Authorized Dealer to

purchase a replacement battery.

Warning!

Battery fluid is a corrosive acid solution

and can burn or even blind you. Do not

allow battery fluid to contact your eyes,

skin, or clothing. Do not lean over a battery

when attaching clamps. If acid splashes in

eyes or on skin, flush the area immediately

with large amounts of water. Refer to

“Jump-Starting” in “In Case Of Emergency”

for further information.

Battery gas is flammable and explosive.

Keep flame or sparks away from the

battery. Do not use a booster battery or

any other booster source with an output

greater than 12 Volts. Do not allow cable

clamps to touch each other.

Battery posts, terminals, and related

accessories contain lead and lead

compounds. Wash hands after handling.

07030901-121-001Windshield Washer Fluid Reservoir

235

Page 238 of 300

BATTERY

RECHARGING

BATTERY CHARGING

PROCEDURE

Warning!

Battery fluid is a corrosive acid solution

and can burn or even blind you. Do not

allow battery fluid to contact your eyes,

skin, or clothing. Do not lean over a battery

when attaching clamps. If acid splashes in

eyes or on skin, flush the area immediately

with large amounts of water. Refer to

“Jump-Starting” in “In Case Of Emergency”

for further information.

Battery gas is flammable and explosive.

Keep flame or sparks away from the

battery. Do not use a booster battery or

any other booster source with an output

greater than 12 Volts. Do not allow cable

clamps to touch each other.

Battery posts, terminals, and related

accessories contain lead and lead

compounds. Wash hands after handling.

Caution!

It is essential when replacing the cables

on the battery that the positive cable is

attached to the positive post and the

negative cable is attached to the negative

post. Battery posts are marked positive (+)

and negative (-) and are identified on the

battery case. Cable clamps should be tight

on the terminal posts and free of corrosion.

If a “fast charger” is used while the

battery is in the vehicle, disconnect both

vehicle battery cables before connecting

the charger to the battery. Do not use a

“fast charger” to provide starting voltage.

Charge battery as follows:

Before recharging the battery, turn off

all accessories and turn the engine off

by placing the ignition in the OFF mode.

Disconnect the negative battery cable.

Connect the charger cables to

the battery terminals, observing the

polarity (+,–).

Turn on the charger.

When finished, turn the charger off

before disconnecting the battery.

Reconnect the negative battery

terminal.

MAINTENANCE

PROCEDURES

The following pages contain

instructions on the required

maintenance from the technical

personnel who designed the vehicle.

In addition to these specific

maintenance instructions specified for

routine scheduled servicing, there are

other components which may require

periodic maintenance or replacement

over the vehicle’s life cycle.

Body Lubrication

Ensure that the locks and bodywork

junction points, including components

such as the seat guides, door hinges

(and rollers), trunk and hood are

periodically lubricated with lithium

based grease to ensure correct, silent

operation and to protect them from rust

and wear.

Thoroughly clean the components,

eliminating every trace of dirt and dust.

After lubricating, eliminate excess oil

and grease. Also pay particular

attention to the hood closing devices,

to ensure correct operation.

During operations on the hood, be sure

to perform with the engine cold, also

remember to check, clean and lubricate

the locking, release and safety devices.

Make sure the hood's secondary latch

keeps the hood from opening when the

primary latch is released.

236

SERVICING AND MAINTENANCE

Page 240 of 300

Warning!

To prevent damage to the windshield let

the wiper arm down easily, do not let it slap

down on the windshield.

4. Pull down the blade rubber and

slide it out of blade holder.

5. Remove the metal stiffeners from

each blade rubber and install them in

the new blade.6. Carefully insert the new blade

rubber. Then install the blade assembly

in the reverse order of removal.

RAISING THE

VEHICLE

If the vehicle needs to be raised, go to

an Authorized Dealer which is equipped

with arm hoists or workshop lifts.

The car lifting points are marked on the

side skirts with the

symbols.

07031101-36A-003Blade Holder

07031101-36A-004Metal Stiffeners

07031101-36A-005Reassemble Blade

238

SERVICING AND MAINTENANCE

Page 242 of 300

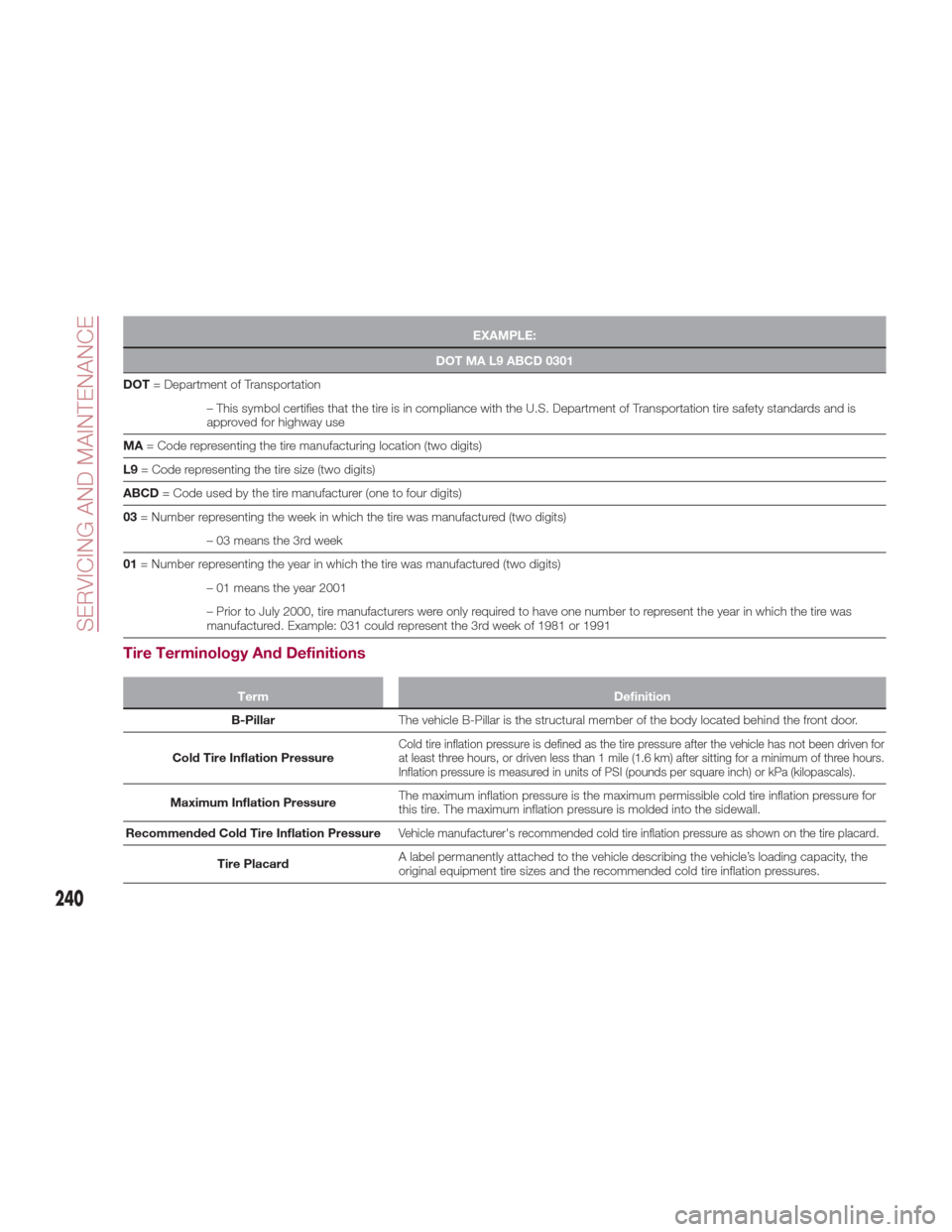

EXAMPLE:

DOT MA L9 ABCD 0301

DOT =

Department of Transportation

– This symbol certifies that the tire is in compliance with the U.S. Department of Transportation tire safety standards and is

approved for highway use

MA = Code representing the tire manufacturing location (two digits)

L9 = Code representing the tire size (two digits)

ABCD = Code used by the tire manufacturer (one to four digits)

03 = Number representing the week in which the tire was manufactured (two digits)

– 03 means the 3rd week

01 = Number representing the year in which the tire was manufactured (two digits)

– 01 means the year 2001

– Prior to July 2000, tire manufacturers were only required to have one number to represent the year in which the tire was

manufactured. Example: 031 could represent the 3rd week of 1981 or 1991

Tire Terminology And Definitions

Term Definition

B-Pillar The

vehicle B-Pillar is the structural member of the body located behind the front door.

Cold Tire Inflation Pressure

Cold tire inflation pressure is defined as the tire pressure after the vehicle has not been driven for

at least three hours, or driven less than 1 mile (1.6 km) after sitting for a minimum of three hours.

Inflation pressure is measured in units of PSI (pounds per square inch) or kPa (kilopascals).

Maximum Inflation Pressure The maximum inflation pressure is the maximum permissible cold tire inflation pressure for

this tire. The maximum inflation pressure is molded into the sidewall.

Recommended Cold Tire Inflation Pressure

Vehicle manufacturer's recommended cold tire inflation pressure as shown on the tire placard.

Tire Placard A label permanently attached to the vehicle describing the vehicle’s loading capacity, the

original equipment tire sizes and the recommended cold tire inflation pressures.

240

SERVICING AND MAINTENANCE