ECU FIAT 124 SPIDER 2017 2.G Owner's Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 2017, Model line: 124 SPIDER, Model: FIAT 124 SPIDER 2017 2.GPages: 300, PDF Size: 121.24 MB

Page 179 of 300

VEHICLE LOADING

Certification Label

As required by National Highway Traffic

Safety Administration regulations, your

vehicle has a certification label affixed to

the driver's side door or pillar.

This label contains the month and year

of manufacture, Gross Vehicle Weight

Rating (GVWR), Gross Axle Weight

Rating (GAWR) front and rear, and

Vehicle Identification Number (VIN). A

Month-Day-Hour (MDH) number is

included on this label and indicates the

Month, Day and Hour of manufacture.

The bar code that appears on the

bottom of the label is your VIN.

Gross Vehicle Weight Rating

(GVWR)

The GVWR is the total permissible

weight of your vehicle including driver,

passengers, vehicle, options and cargo.

The label also specifies maximum

capacities of front and rear axle

systems (GAWR). Total load must be

limited so GVWR and front and rear

GAWR are not exceeded.

Payload

The payload of a vehicle is defined as

the allowable load weight a truck can

carry, including the weight of the driver,

all passengers, options and cargo.

Gross Axle Weight Rating

(GAWR)

The GAWR is the maximum permissible

load on the front and rear axles. The

load must be distributed in the cargo

area so that the GAWR of each axle is

not exceeded.

Each axle GAWR is determined by the

components in the system with the

lowest load carrying capacity (axle,

springs, tires or wheels). Heavier axles

or suspension components sometimes

specified by purchasers for increased

durability does not necessarily increase

the vehicle's GVWR.

Tire Size

The tire size on the Vehicle Certification

Label represents the actual tire size on

your vehicle. Replacement tires must be

equal to the load capacity of this tire

size.

Rim Size

This is the rim size that is appropriate

for the tire size listed.

Inflation Pressure

This is the cold tire inflation pressure for

your vehicle for all loading conditions up

to full GAWR.

Curb Weight

The curb weight of a vehicle is defined

as the total weight of the vehicle with all

fluids, including vehicle fuel, at full

capacity conditions, and with no

occupants or cargo loaded into the

vehicle. The front and rear curb weight

values are determined by weighing your

vehicle on a commercial scale before

any occupants or cargo are added.

Loading

The actual total weight and the weight

of the front and rear of your vehicle at

the ground can best be determined by

weighing it when it is loaded and ready

for operation.

The entire vehicle should first be

weighed on a commercial scale to

insure that the GVWR has not been

exceeded. The weight on the front and

rear of the vehicle should then be

determined separately to be sure that

the load is properly distributed over the

front and rear axle. Weighing the vehicle

may show that the GAWR of either the

front or rear axles has been exceeded

but the total load is within the specified

GVWR. If so, weight must be shifted

from front to rear or rear to front as

appropriate until the specified weight

limitations are met. Store the heavier

items down low and be sure that the

weight is distributed equally. Stow all

loose items securely before driving.

177

Page 181 of 300

Follow the maintenance schedule

and contact your Authorized Dealer.

Use the air conditioner only when

necessary.

Slow down on rough roads.

Keep the tires properly inflated.

Do not carry unnecessary weight.

Do not rest your foot on the brake

pedal while driving.

Keep the wheels in correct

alignment.

Keep windows closed at high

speeds.

Slow down when driving in

crosswinds and headwinds.

Hazardous Driving

When driving on ice or in water, snow,

mud, sand, or similar hazards:

Be cautious and allow extra distance

for braking.

Avoid sudden braking and sudden

maneuvering.

Do not pump the brakes. Continue to

press down on the brake pedal.

If you get stuck, select a lower gear

and accelerate slowly. Do not spin the

rear wheels.

For more traction in starting on

slippery surfaces such as ice or packed

snow, use sand, rock salt, chains,

carpeting, or other nonslip material

under the rear wheels.

Note: Usesnowchainsonlyonthe

rear wheels.

Floor Mat Safety

Information

Always use floor mats designed to fit

the footwell of your vehicle. Use only

floor mats that leave the pedal area

unobstructed and that are firmly

secured so that they cannot slip out of

position and interfere with the pedals or

impair safe operation of your vehicle in

other ways.

Warning!

An improperly attached, damaged, folded,

or stacked floor mat, or damaged floor mat

fasteners may cause your floor mat to

interfere with the accelerator, brake, or

clutch pedals and cause a loss of vehicle

control. To prevent SERIOUS INJURY or

DEATH:

ALWAYS securely attachyour floor

mat using the floor mat fasteners. DO NOT

install your floor mat upside down or turn

your floor mat over. Lightly pull to confirm

mat is secured using the floor mat

fasteners on a regular basis.

ALWAYS REMOVE THE EXISTING

FLOOR MAT FROM THE VEHICLE

before installing any other floor mat.

NEVER install or stack an additional floor

mat on top of an existing floor mat.

ONLY install floor mats designed to fit

your vehicle. NEVER install a floor mat that

cannot be properly attached and secured

to your vehicle. If a floor mat needs to be

replaced, only use a FCA approved floor

mat for the specific make, model, and year

of your vehicle.

04090400-USA-001Floor Mat Retention Post Location

179

Page 182 of 300

ONLY use the driver’s side floor mat on

the driver’s side floor area. To check for

interference, with the vehicle properly

parked with the engine off, fully depress the

accelerator, the brake, and the clutch pedal

(if present) to check for interference. If your

floor mat interferes with the operation of

any pedal, or is not secure to the floor,

remove the floor mat from the vehicle and

place the floor mat in your trunk.

ONLY use the passenger’s side floor

mat on the passenger’s side floor area.

ALWAYS make sure objects cannot fall

or slide into the driver’s side floor area

when the vehicle is moving. Objects can

become trapped under accelerator, brake,

or clutch pedals and could cause a loss of

vehicle control.

NEVER place any objects under the

floor mat (e.g., towels, keys, etc.). These

objects could change the position of the

floor mat and may cause interference with

the accelerator, brake, or clutch pedals.

If the vehicle carpet has been removed

and re-installed, always properly attach

carpet to the floor and check the floor mat

fasteners are secure to the vehicle carpet.

Fully depress each pedal to check for

interference with the accelerator, brake, or

clutch pedals then re-install the floor mats.

It is recommended to only use mild soap

and water to clean your floor mats. After

cleaning, always check your floor mat has

been properly installed and is secured to

your vehicle using the floor mat fasteners

by lightly pulling mat.

Rocking The Vehicle

Note: Too much rocking may cause

engine overheating, transmission failure,

and tire damage.

If you must rock the vehicle to free it

from snow, sand or mud, depress the

accelerator slightly and slowly move the

gear selector from 1 (D) to R.

Warning!

Fast spinning tires can be dangerous.

Forces generated by excessive wheel

speeds may cause damage, or even

failure, of the axle and tires. A tire could

explode and injure someone. Do not spin

your vehicle's wheels faster than 30 mph

(48 km/h) or for longer than 30 seconds

continuously without stopping when you

are stuck and do not let anyone near a

spinning wheel, no matter what the speed.

Caution!

When “rocking” a stuck vehicle by

shifting between DRIVE and REVERSE, do

not spin the wheels faster than 15 mph

(24 km/h), or drivetrain damage may result.

Revving the engine or spinning the

wheels too fast may lead to transmission

overheating and failure. It can also damage

the tires. Do not spin the wheels above

30 mph (48 km/h) while in gear (no

transmission shifting occurring).

Winter Driving

Carry emergency gear, including tire

chains, window scraper, flares, a small

shovel, jumper leads, and a small bag

of sand or salt.

Contact an Authorized Dealer to check

the following:

Have the proper ratio of antifreeze in

the radiator.

Inspect the battery and its leads.

Cold reduces battery capacity.

Use an engine oil appropriate for the

lowest ambient temperatures that the

vehicle will be driven in.

Inspect the ignition system for

damage and loose connections.

Use winter windshield washer fluid

that will not freeze.

180

STARTING AND OPERATING

Page 199 of 300

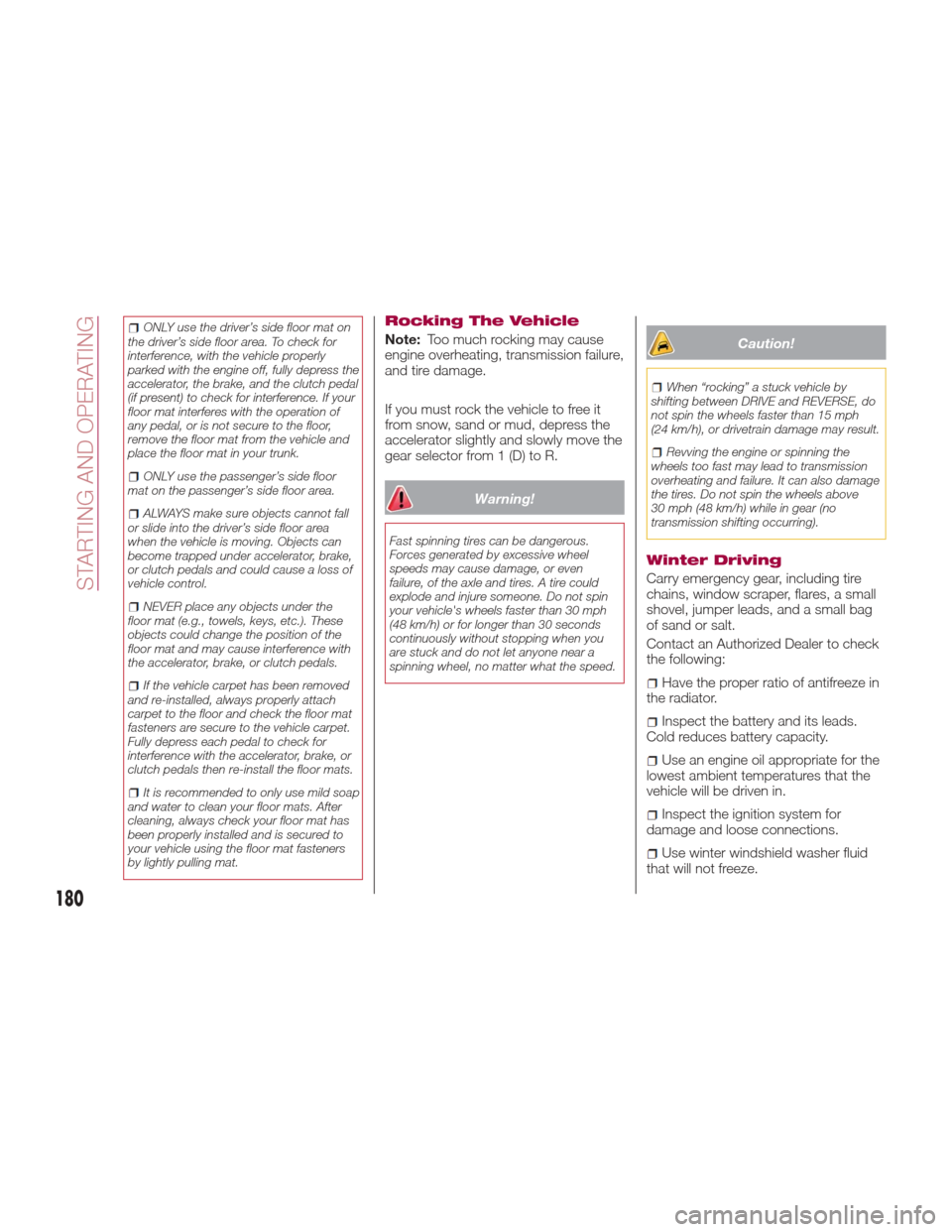

6. Insert a new fuse of the same

amperage rating, and make sure it fits

tightly. If it does not fit tightly, contact an

Authorized Dealer. If you have no spare

fuses, borrow one of the same rating

from a circuit not essential to vehicle

operation, such as the audio or outlet

circuit.

7. Reinstall the cover and make sure

that it is securely installed.

Note:Always replace a fuse with a

genuine FCA fuse or equivalent of the

same rating. Otherwise you may

damage the electric system.

Underhood Fuses

If the headlights or other electrical

components do not work and the fuses

in the cabin are normal, inspect the fuse

block in the engine compartment. If a

fuse is blown, it must be replaced.

Make sure the ignition is placed in the

OFF mode, and other switches are

turned off and remove the fuse block

cover. If the lock is forcefully opened,

the fuse block cover may come in

contact with the frame when it is

removed and become scratched.

When removing the cover, remove it

slowly according to the following

procedure:

1. Disengage the rear lock by pressing

down on the front tab with your fingers. 2. Remove the front tab while slightly

lifting the front of the cover.

3. Remove the cover while lifting it and

sliding it to the rear.

4. If any fuse but the main fuse is

blown, replace it with a new one of the

same amperage rating.

5. Reinstall the cover and make sure

that it is securely installed.

07031601-ALL-001Fuses

1 — Normal Fuse

2 — Blown Fuse

07031601-123-001Underhood Fuse Block

1 — Lock

2 — Cover

07031601-ALL-002Fuse

1 — Normal Fuse

2 — Blown Fuse

197

Page 207 of 300

To Secure The Jack

Proceed as follows:

1. Insert the wing bolt into the jack with

the jack screw pointing back, and turn

the wing bolt clockwise to temporarily

tighten it.

2. Turn the jack screw clockwise.

3. Turn the wing bolt completely to

secure the jack.

4. Insert the cover tabs and install the

cover.

Warning!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided. Have the deflated (flat) tire

repaired or replaced immediately.

Maintenance

Always keep the jack clean.

Make sure the moving parts are kept

free from dirt or rust.

Make sure the screw thread is

adequately lubricated. Conditions Of Non-Use

Temperatures below -40°F (−40°C)

On sandy or muddy ground

On uneven ground

On steep roads

In extreme weather conditions

In direct contact with the engine or

for repairs under the vehicle

On boats

Changing Procedure

Note: Make sure the jack is well

lubricated before using it.

Warning!

Do not attempt to change a tire on the side

of the vehicle close to moving traffic, pull

far enough off the road to avoid being hit

when operating the jack or changing the

wheel.

Proceed as follows:

1. Stop the vehicle in a position that

does not cause any danger to traffic

and lets you change the tire in safety, as

far as possible from the edge of the

driving lane. The ground must be flat

and sufficiently compact. 2. Turn on the hazard warning lights

and engage the parking brake.

3. For vehicles with automatic

transmission, place the gear selector in

Park (P). For vehicles with manual

transmission, place gear selector in

Reverse (R) and turn off the engine.

4. Stop the engine. The motor must be

kept off as long as the vehicle is lifted

off the ground.

5. Remove the jack and tools.

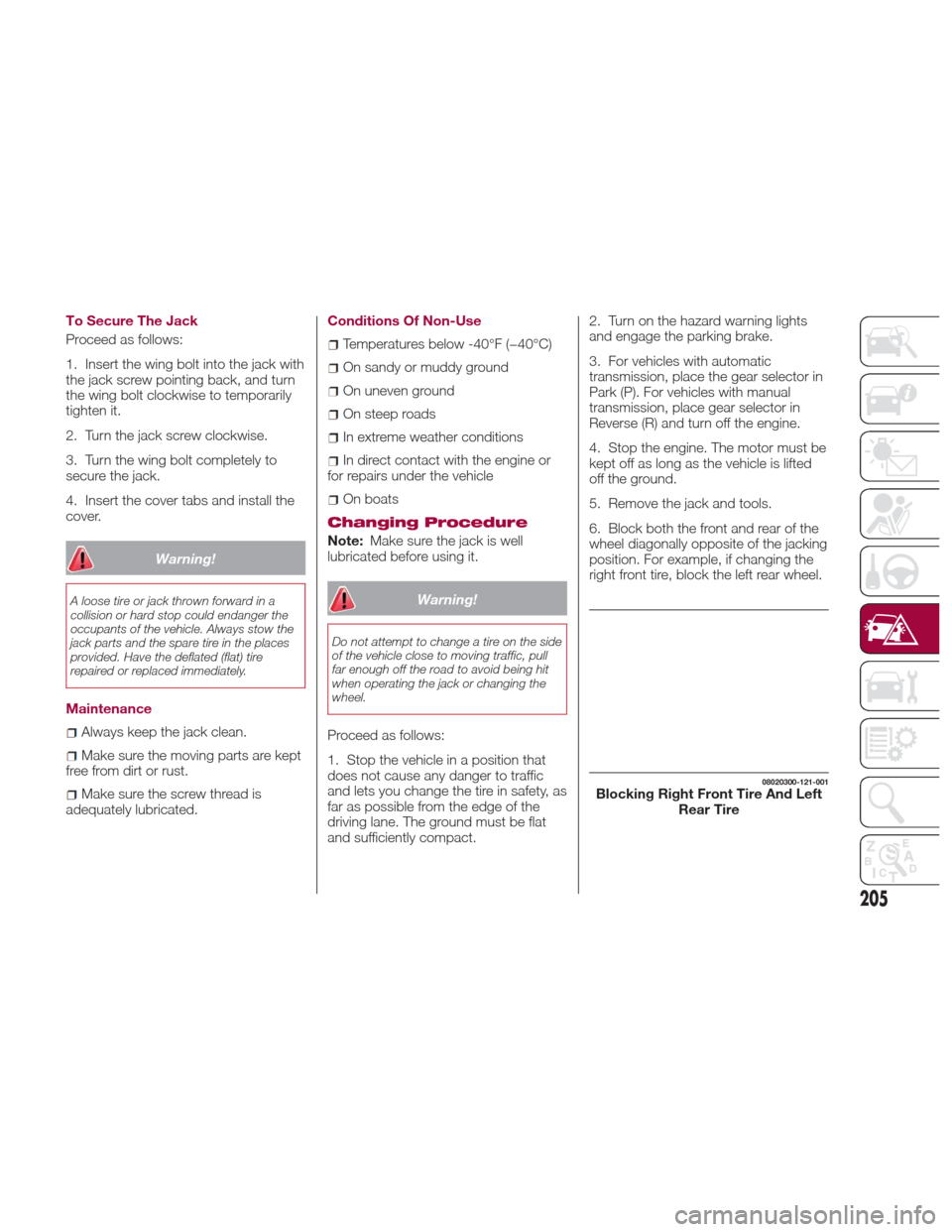

6. Block both the front and rear of the

wheel diagonally opposite of the jacking

position. For example, if changing the

right front tire, block the left rear wheel.

08020300-121-001Blocking Right Front Tire And Left

Rear Tire

205

Page 214 of 300

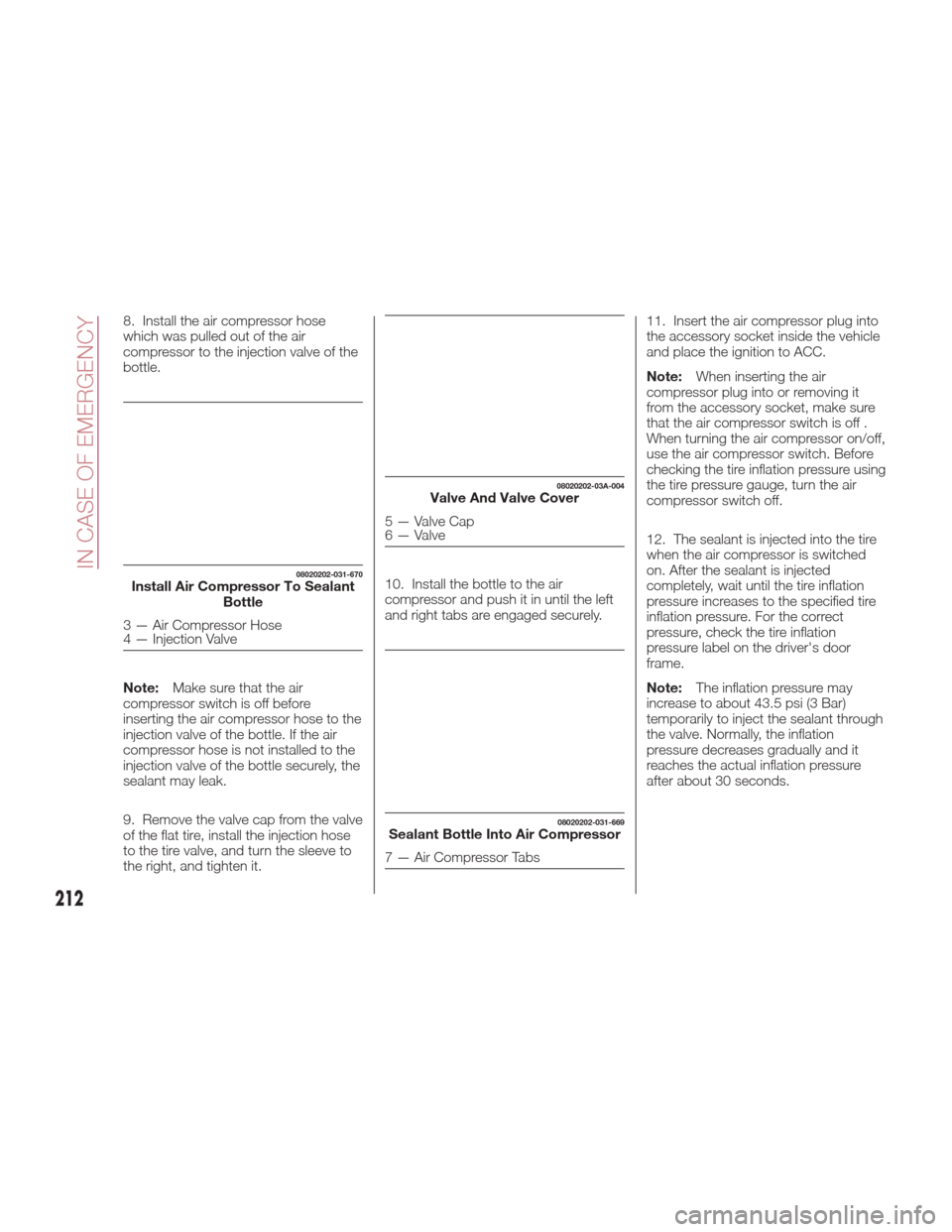

8. Install the air compressor hose

which was pulled out of the air

compressor to the injection valve of the

bottle.

Note:Make sure that the air

compressor switch is off before

inserting the air compressor hose to the

injection valve of the bottle. If the air

compressor hose is not installed to the

injection valve of the bottle securely, the

sealant may leak.

9. Remove the valve cap from the valve

of the flat tire, install the injection hose

to the tire valve, and turn the sleeve to

the right, and tighten it. 10. Install the bottle to the air

compressor and push it in until the left

and right tabs are engaged securely.11. Insert the air compressor plug into

the accessory socket inside the vehicle

and place the ignition to ACC.

Note:

When inserting the air

compressor plug into or removing it

from the accessory socket, make sure

that the air compressor switch is off .

When turning the air compressor on/off,

use the air compressor switch. Before

checking the tire inflation pressure using

the tire pressure gauge, turn the air

compressor switch off.

12. The sealant is injected into the tire

when the air compressor is switched

on. After the sealant is injected

completely, wait until the tire inflation

pressure increases to the specified tire

inflation pressure. For the correct

pressure, check the tire inflation

pressure label on the driver's door

frame.

Note: The inflation pressure may

increase to about 43.5 psi (3 Bar)

temporarily to inject the sealant through

the valve. Normally, the inflation

pressure decreases gradually and it

reaches the actual inflation pressure

after about 30 seconds.

08020202-031-670Install Air Compressor To Sealant Bottle

3 — Air Compressor Hose

4 — Injection Valve

08020202-03A-004Valve And Valve Cover

5 — Valve Cap

6 — Valve

08020202-031-669Sealant Bottle Into Air Compressor

7 — Air Compressor Tabs

212

IN CASE OF EMERGENCY

Page 222 of 300

4. Connect one end of a jumper cables

to the positive terminal on the

discharged battery.

5. Connect the other end to the

positive terminal on the booster battery.

6. Connect one end of the other

jumper cables to the negative terminal

of the booster battery.

7. Connect the other end to a good

engine ground of the vehicle with the

discharged battery (exposed metal part

of the engine) away from the battery

and the fuel injection system.

8. Start the engine of the booster

vehicle and run it a few minutes. Then

start the engine of the other vehicle.

9. Once the engine is started, remove

the jumper cables in the reverse

sequence.

10. Replace the positive terminal

cover. Make sure cover is secure.

Bump Starting

Never jump start the engine by pushing,

towing or coasting downhill.

Note:

You cannot start a vehicle with an

automatic transmission by pushing it.

Do not push-start a vehicle that has

a manual transmission. It can damage

the emission control system.

STARTING A FLOODED

ENGINE

If the engine fails to start, it may be

flooded (excessive fuel in the engine).

Follow this procedure:

1. If the engine does not start within

5 seconds on the first try, wait

10 seconds and try again.

2. Make sure the parking brake is on.

3. Depress the accelerator all the way

and hold it there.

4. Depress the clutch pedal (manual

transmission) or the brake pedal

(automatic transmission), then push the

push button start. If the engine starts,

release the accelerator immediately

because the engine will suddenly rev

up.

5. If the engine fails to start, crank it

without depressing the accelerator.

If the engine still does not start using

the above procedure, have your vehicle

inspected an Authorized Dealer.

OVERHEATING

Overheating

In any of the following situations, you

can reduce the potential for overheating

by taking the appropriate action.

On the highways — slow down.

In city traffic — while stopped, place

the transmission in NEUTRAL, but do

not increase engine idle speed.

Note: There are steps that you can

take to slow down an impending

overheat condition:

If your air conditioner (A/C) is on,

turn it off. The A/C system adds heat

to the engine cooling system and

turning the A/C off can help remove

this heat.

You can also turn the temperature

control to maximum heat, the mode

control to floor and the blower control

to high. This allows the heater core to

act as a supplement to the radiator

and aids in removing heat from the

engine cooling system.

220

IN CASE OF EMERGENCY

Page 224 of 300

Caution!

The tow eye must be used exclusively

for roadside assistance operations. Only

use the tow eye with an appropriate device

in accordance with the highway code (a

rigid bar or rope) to flat tow the vehicle for

a short distance to the nearest service

location.

Tow eyes MUST NOT be used to tow

vehicles off the road or where there are

obstacles.

In compliance with the above

conditions, towing with a tow eye must

take place with two vehicles (one towing,

the other towed) aligned as much as

possible along the same center line.

Damage to your vehicle may occur if these

guidelines are not followed.

When towing, only use a facility that can

tow vehicles with low ground clearances as

extensive damage can result by using a

standard tow truck platform.

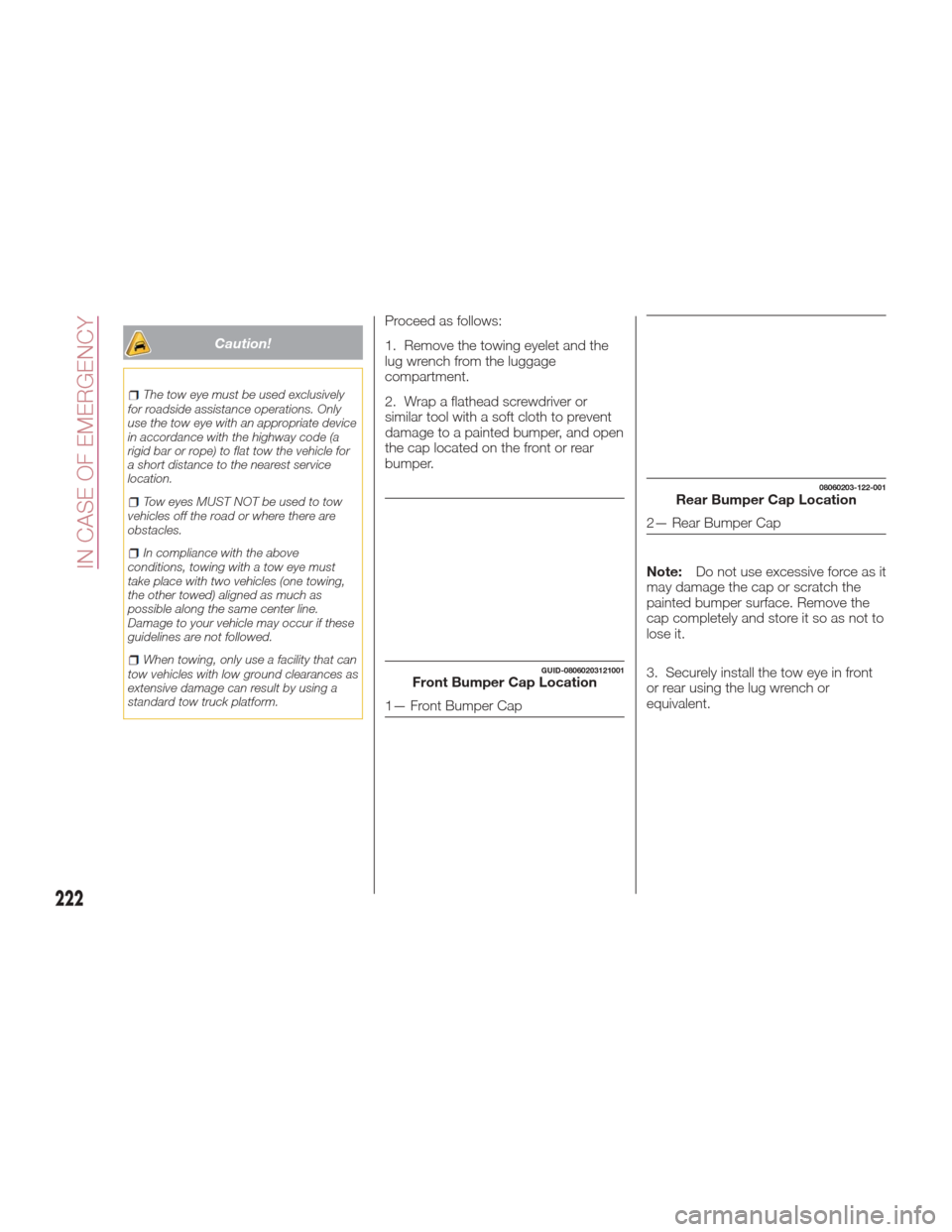

Proceed as follows:

1. Remove the towing eyelet and the

lug wrench from the luggage

compartment.

2. Wrap a flathead screwdriver or

similar tool with a soft cloth to prevent

damage to a painted bumper, and open

the cap located on the front or rear

bumper.

Note:Do not use excessive force as it

may damage the cap or scratch the

painted bumper surface. Remove the

cap completely and store it so as not to

lose it.

3. Securely install the tow eye in front

or rear using the lug wrench or

equivalent.

GUID-08060203121001Front Bumper Cap Location

1— Front Bumper Cap

08060203-122-001Rear Bumper Cap Location

2— Rear Bumper Cap

222

IN CASE OF EMERGENCY

Page 225 of 300

4. Hook the towing rope to the tow

eye.

Caution!

Tow hooks are for emergency use only, to

rescue a vehicle stranded off road. Do not

use tow hooks for tow truck hookup or

highway towing. You could damage your

vehicle.

When using the tow eyes, always pull

the lead or chain in a straight direction

with respect to the eyelet. Never apply

a sideways force.

Note:Be careful not to damage the

towing eyelet and towing hook, vehicle

body, or transmission system when

towing under the following conditions:

Do not tow a vehicle heavier than

yours.

Do not suddenly accelerate your

vehicle as it will apply a severe shock

to the tow eye and towing hook or

rope.

Do not attach any rope other than

to the tow eye and towing hook.

EMERGENCY TOWING

TOWING DESCRIPTION

Proper lifting and towing are necessary

to prevent damage to the vehicle.

Government and local laws must be

followed.

A towed vehicle usually should have its

drive wheels (rear wheels) off the ground.

If excessive damage or other conditions

prevent this, use wheel dollies.

When towing with the rear wheels on the

ground, release the parking brake.

Caution!

DO NOT use sling-type equipment when

towing. When securing the vehicle to a

flatbed truck, do not attach to front or rear

suspension components. Damage to your

vehicle may result from improper towing.

If towing service is not available in an

emergency, the vehicle may be towed

with all four wheels on the ground using

the towing hook at the front of the

vehicle. Only tow the vehicle on paved

surfaces for short distances at low

speeds.

Follow these instructions when towing

the vehicle with all wheels on the

ground:

1. Shift to neutral (manual

transmission), or the N position

(automatic transmission).

2. Place the ignition to ACC.

3. Release the parking brake.

Note:

Remember that power assist for the

brakes and steering will not be available

when the engine is not running.

08060201-121-001Installing Front Towing Eye

08060201-122-001Installing Rear Tow Eye

223

Page 236 of 300

Warning!

Do not open hot engine cooling system.

Never add engine coolant (antifreeze) when

the engine is overheated. Do not loosen or

remove the cap to cool an overheated

engine. Heat causes pressure to build up in

the cooling system. To prevent scalding or

injury, do not remove the pressure cap

while the system is hot or under pressure.

Do not use a pressure cap other than

the one specified for your vehicle. Personal

injury or engine damage may result.

The coolant should be at full in the

radiator and between the F (Full) and L

(Low) marks on the coolant reservoir

when the engine is cool. If it is at or near L (Low), add coolant by

mixing a minimum solution of 50%

Mopar Long Life Coolant Concentrate

for FIAT Spider. Use higher

concentrations (not to exceed 70%) if

temperatures below −34°F (−37°C) are

anticipated. Bring the level to F (Full).

Please contact your Authorized Dealer

for assistance.

Securely tighten the coolant reservoir

tank cap after adding coolant.

If the coolant reservoir is empty or new

coolant is required frequently, contact

your Authorized Dealer.

Brake/Clutch Fluid

Inspecting Brake/Clutch Fluid Level

The brakes and clutch draw fluid

from the same reservoir.

Inspect the fluid level in the reservoir

regularly.

It should be kept between the MAX

and MIN lines.

The level normally drops with

accumulated use, a condition

associated with wear of brake and

clutch linings. If it is excessively low,

have the brake/clutch system

inspected. Contact your Authorized

Dealer.

Warning!

Use only manufacturer's recommended

brake fluid. Refer to “Fluids And Lubricants”

in “Technical Specifications” for further

information. Using the wrong type of brake

fluid can severely damage your brake

system and/or impair its performance. The

proper type of brake fluid for your vehicle is

also identified on the original factory

installed hydraulic master cylinder reservoir.

To avoid contamination from foreign

matter or moisture, use only new brake

fluid or fluid that has been in a tightly

closed container. Keep the master cylinder

reservoir cap secured at all times. Brake

fluid in a open container absorbs moisture

from the air resulting in a lower boiling

point. This may cause it to boil

unexpectedly during hard or prolonged

braking, resulting in sudden brake failure.

This could result in a collision.

07030501-121-001Coolant Reservoir

07030601-121-002Brake Fluid Reservoir

234

SERVICING AND MAINTENANCE