ignition FIAT 124 SPIDER 2017 2.G Manual Online

[x] Cancel search | Manufacturer: FIAT, Model Year: 2017, Model line: 124 SPIDER, Model: FIAT 124 SPIDER 2017 2.GPages: 300, PDF Size: 121.24 MB

Page 192 of 300

5. Turn the socket and bulb assembly

counterclockwise and remove it.

6. Disconnect the bulb from the

socket.7. Install the new bulb in the reverse

order of the removal procedure.

Fog Lights

Proceed as follows:

1. If you are changing the right bulb,

start the engine, turn the steering wheel

all the way to the right, and turn off

engine. If you are changing the left bulb,

turn the steering wheel to the left.

2. Make sure the ignition is switched

off, and the headlight switch is off.

3. Remove the fasteners in the five

locations and partially peel back the

mud guard.

4. Disconnect the connector from the

unit by pressing the tab on the

connector with your finger and pulling

the connector.

5. Turn the socket and bulb assembly

counterclockwise, extract the bulb and

remove it;

6. Disconnect the bulb from the

socket.

7. Install the new bulb in the reverse

order of the removal procedure.Brake lights / Tail lights

Go to your authorized dealer when the

replacement of this lights is necessary.

Side Direction Indicator Lights

Proceed as follows:

1. Make sure the ignition is placed in

the OFF mode, and the headlight

switch is off.

2. If you are changing the right bulb,

start the engine, turn the steering wheel

all the way to the right, and turn off

engine. If you are changing the left bulb,

turn the steering wheel to the left.

3. Remove the fasteners in the five

locations and partially peel back the

mud guard.

4. Disconnect the electrical connector

from the bulb by pressing the tab on

the connector with your finger and

pulling the connector.

5. Remove the lens assembly by

pressing the tab on the unit with your

finger and pulling the unit forward to

compress in the internal catch, then pull

the cluster outwards.

6. Lift up the lens assembly, and then

remove the cluster and install the new

side direction indicator lens assembly in

the reverse order of the removal

procedure.

07031501-207-001Front Direction Indicator Housing

1 — Socket Assembly

2 — Bulb

GUID-07031501208002Direction Indicator Lamp Connector

190

IN CASE OF EMERGENCY

Page 195 of 300

5. Turn the socket and bulb assembly

counterclockwise to remove from

taillight housing, and remove bulb.6. Install the new bulb in the reverse

order of the removal procedure.

Reverse Light

Proceed as follows:

1. Make sure the ignition is placed in

the OFF mode, and the headlight

switch is off.

2. Turn the socket assembly

counterclockwise to remove, and

remove bulb.

3. Install the new bulb in the reverse

order of the removal procedure.Rear Side Marker

Proceed as follows:

1. Push the lens assembly rearward to

compress the internal catch, then pull

the lens assembly outwards.

2. Turn the socket and bulb assembly

counterclockwise to remove, and

remove bulb.

07031501-216-001Rear of Vehicle

6 — Taillight Housing

07031501-203-002Taillight Housing

7 — Socket and Bulb Assembly

07031501-219-001Reverse Light

1 — Socket Assembly

2 — Bulb

08070605-123-100Rear Side Marker

1 — Rear Side Marker Lens Assembly

193

Page 196 of 300

3. Install the new bulb and then

reinstall the socket in the reverse order

of the removal procedure.License Plate Lights

Proceed as follows:

1. Make sure the ignition is placed in

the OFF mode, and the headlight

switch is off.

2. Slide the unit as shown in the figure

to remove it.

3. Turn the socket and bulb assembly

counterclockwise and remove, remove

bulb.

4. Install the new bulb in the reverse

order of the removal procedure. Insert

catch and push the housing back into

place.

08070606-123-100Side Marker Housing

2 — Socket and Bulb Assembly

GUID-07031501220001Trunk Lid

1 — License Plate Light Assembly

07031501-221-001License Plate Light Housing

2 — Socket and Bulb Assembly

194

IN CASE OF EMERGENCY

Page 198 of 300

REPLACING FUSES

General Information

Warning!

When replacing a blown fuse, always

use an appropriate replacement fuse with

the same amp rating as the original fuse.

Never replace a fuse with another fuse of

higher amp rating. Never replace a blown

fuse with metal wires or any other material.

Failure to use proper fuses may result in

serious personal injury, fire and/or property

damage.

Before replacing a fuse, make sure that

the ignition is off and that all the other

services are switched off and/or

disengaged.

If the replaced fuse blows again, contact

an authorized dealer.

If a general protection fuse for safety

systems (air bag system, braking system),

power unit systems (engine system,

gearbox system) or steering system blows,

contact an authorized dealer.

Your vehicle's electrical system is

protected by fuses.

If any lights, accessories, or controls do

not work, inspect the appropriate circuit

protector. If a fuse has blown, the inside

element will be melted. If the same fuse

blows again, go to an Authorized Dealer

as soon as possible.

Fuse location

Fuses are grouped together in two fuse

boxes located in the interior on the left

side of the vehicle and under the hood.

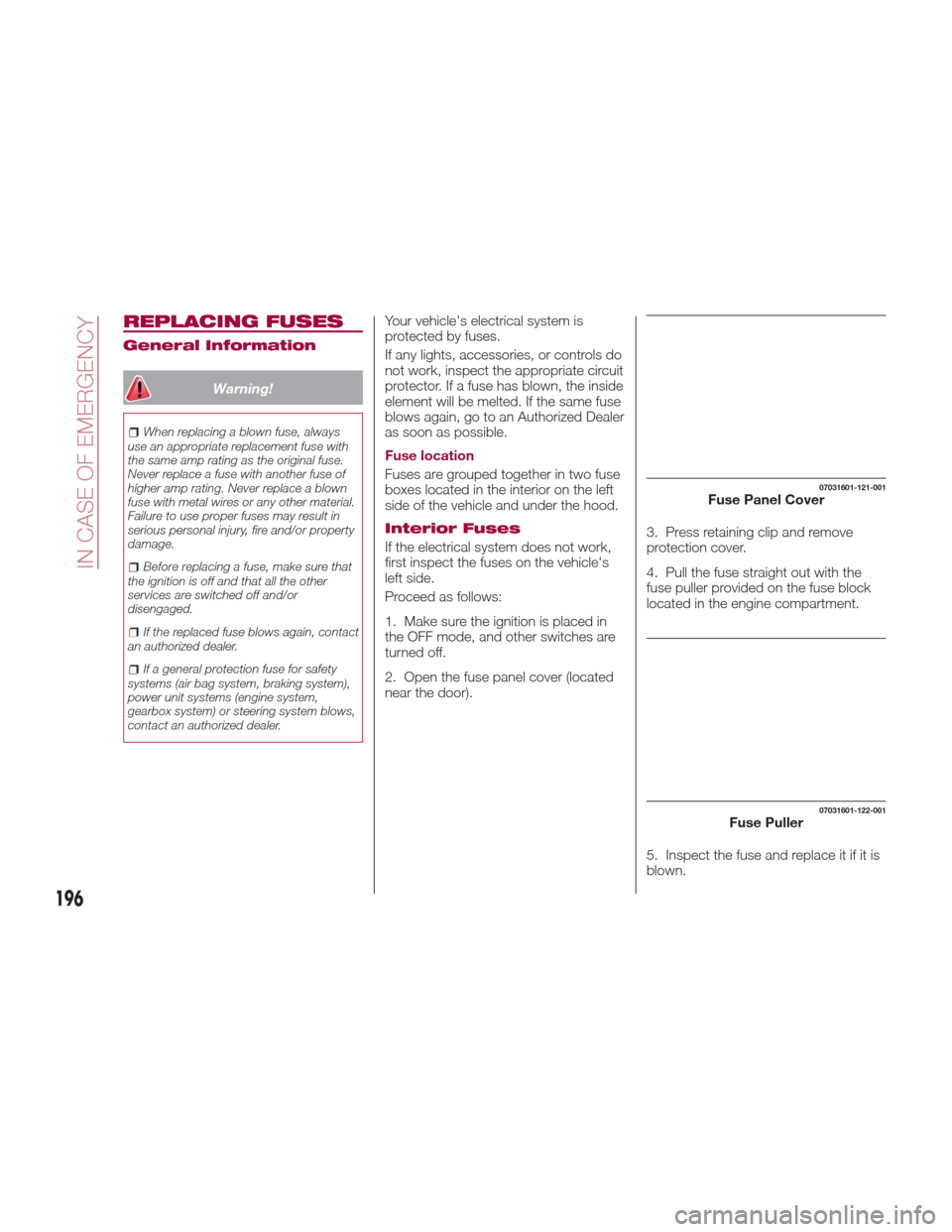

Interior Fuses

If the electrical system does not work,

first inspect the fuses on the vehicle's

left side.

Proceed as follows:

1. Make sure the ignition is placed in

the OFF mode, and other switches are

turned off.

2. Open the fuse panel cover (located

near the door). 3. Press retaining clip and remove

protection cover.

4. Pull the fuse straight out with the

fuse puller provided on the fuse block

located in the engine compartment.

5. Inspect the fuse and replace it if it is

blown.

07031601-121-001Fuse Panel Cover

07031601-122-001Fuse Puller

196

IN CASE OF EMERGENCY

Page 199 of 300

6. Insert a new fuse of the same

amperage rating, and make sure it fits

tightly. If it does not fit tightly, contact an

Authorized Dealer. If you have no spare

fuses, borrow one of the same rating

from a circuit not essential to vehicle

operation, such as the audio or outlet

circuit.

7. Reinstall the cover and make sure

that it is securely installed.

Note:Always replace a fuse with a

genuine FCA fuse or equivalent of the

same rating. Otherwise you may

damage the electric system.

Underhood Fuses

If the headlights or other electrical

components do not work and the fuses

in the cabin are normal, inspect the fuse

block in the engine compartment. If a

fuse is blown, it must be replaced.

Make sure the ignition is placed in the

OFF mode, and other switches are

turned off and remove the fuse block

cover. If the lock is forcefully opened,

the fuse block cover may come in

contact with the frame when it is

removed and become scratched.

When removing the cover, remove it

slowly according to the following

procedure:

1. Disengage the rear lock by pressing

down on the front tab with your fingers. 2. Remove the front tab while slightly

lifting the front of the cover.

3. Remove the cover while lifting it and

sliding it to the rear.

4. If any fuse but the main fuse is

blown, replace it with a new one of the

same amperage rating.

5. Reinstall the cover and make sure

that it is securely installed.

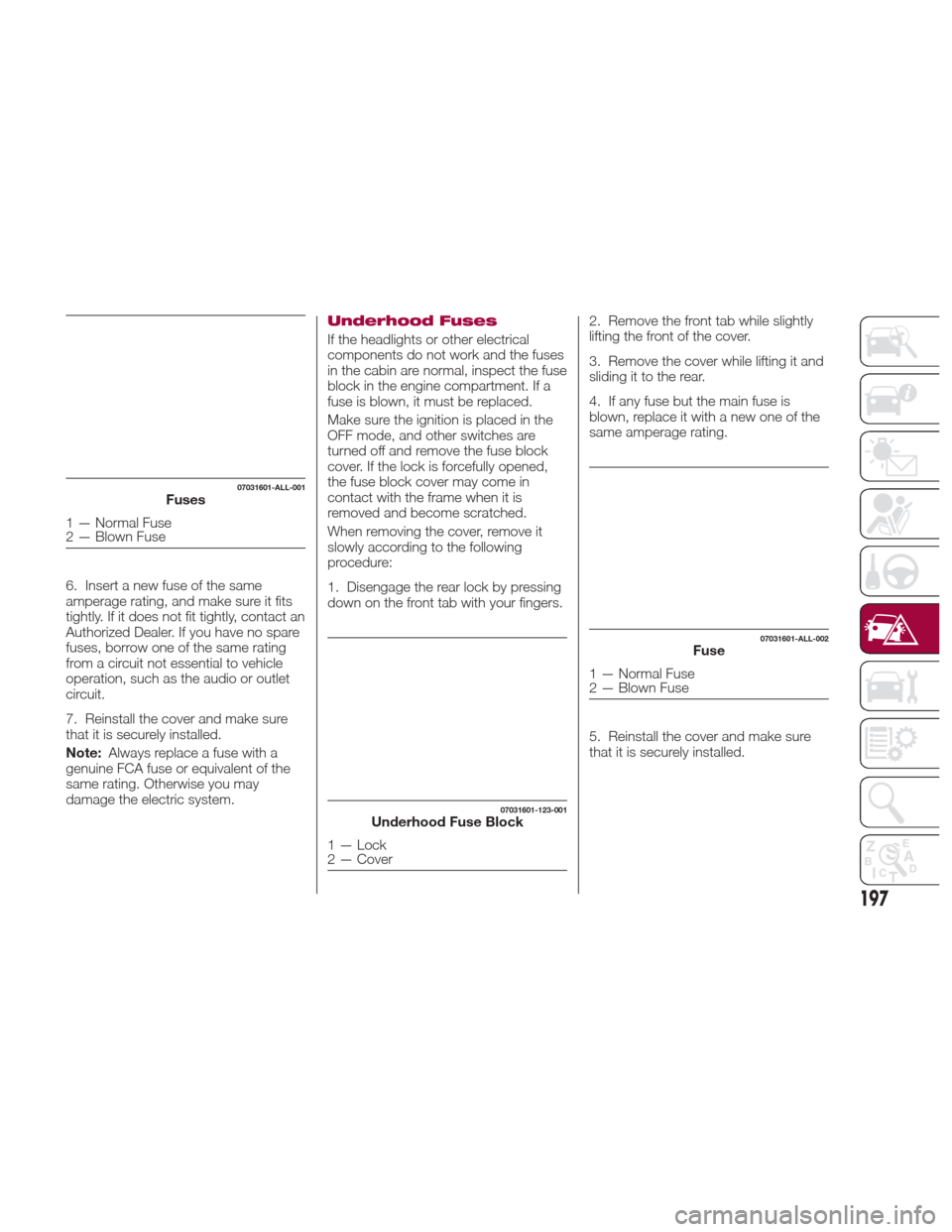

07031601-ALL-001Fuses

1 — Normal Fuse

2 — Blown Fuse

07031601-123-001Underhood Fuse Block

1 — Lock

2 — Cover

07031601-ALL-002Fuse

1 — Normal Fuse

2 — Blown Fuse

197

Page 214 of 300

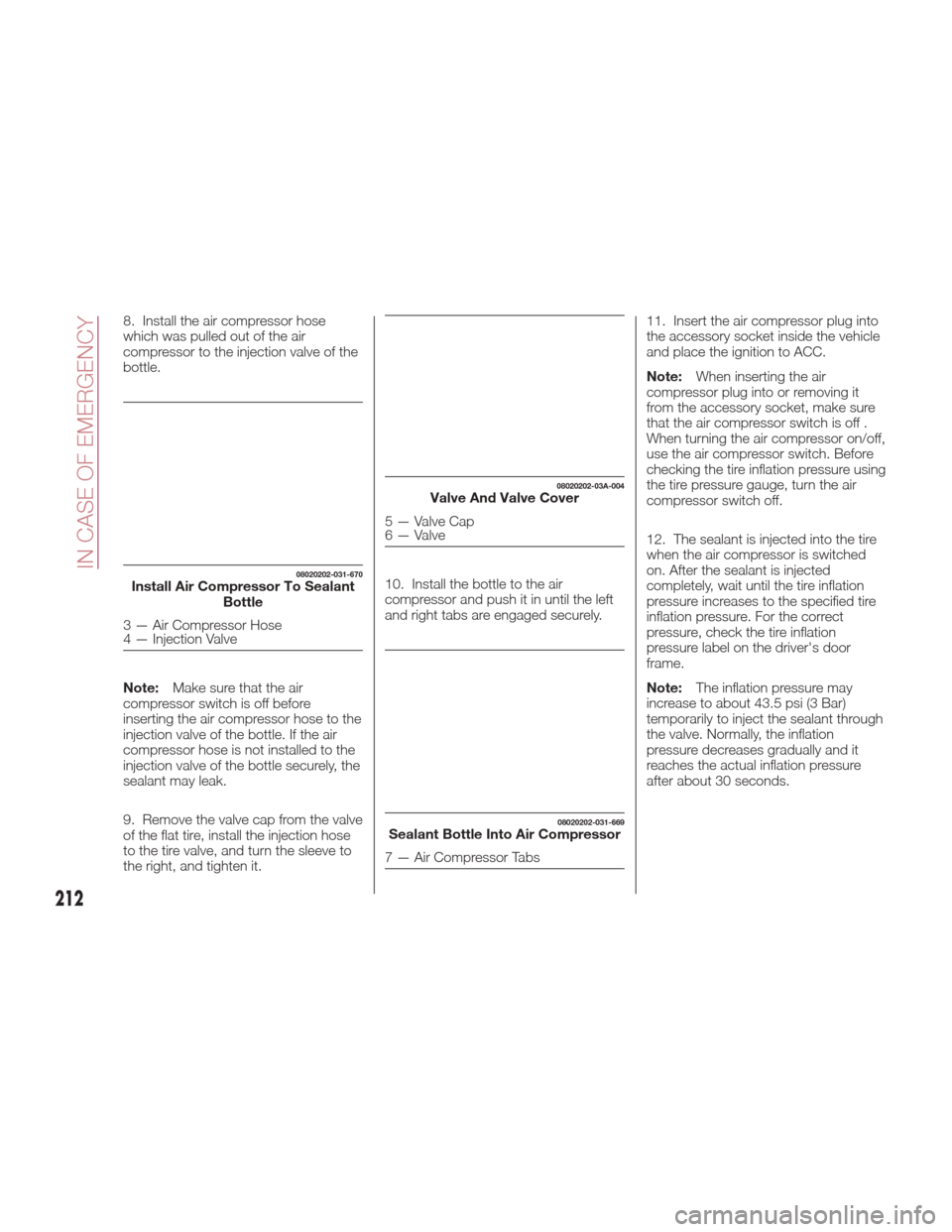

8. Install the air compressor hose

which was pulled out of the air

compressor to the injection valve of the

bottle.

Note:Make sure that the air

compressor switch is off before

inserting the air compressor hose to the

injection valve of the bottle. If the air

compressor hose is not installed to the

injection valve of the bottle securely, the

sealant may leak.

9. Remove the valve cap from the valve

of the flat tire, install the injection hose

to the tire valve, and turn the sleeve to

the right, and tighten it. 10. Install the bottle to the air

compressor and push it in until the left

and right tabs are engaged securely.11. Insert the air compressor plug into

the accessory socket inside the vehicle

and place the ignition to ACC.

Note:

When inserting the air

compressor plug into or removing it

from the accessory socket, make sure

that the air compressor switch is off .

When turning the air compressor on/off,

use the air compressor switch. Before

checking the tire inflation pressure using

the tire pressure gauge, turn the air

compressor switch off.

12. The sealant is injected into the tire

when the air compressor is switched

on. After the sealant is injected

completely, wait until the tire inflation

pressure increases to the specified tire

inflation pressure. For the correct

pressure, check the tire inflation

pressure label on the driver's door

frame.

Note: The inflation pressure may

increase to about 43.5 psi (3 Bar)

temporarily to inject the sealant through

the valve. Normally, the inflation

pressure decreases gradually and it

reaches the actual inflation pressure

after about 30 seconds.

08020202-031-670Install Air Compressor To Sealant Bottle

3 — Air Compressor Hose

4 — Injection Valve

08020202-03A-004Valve And Valve Cover

5 — Valve Cap

6 — Valve

08020202-031-669Sealant Bottle Into Air Compressor

7 — Air Compressor Tabs

212

IN CASE OF EMERGENCY

Page 219 of 300

13. Reinsert the valve core into the

valve and turn it clockwise to install.

Note:

The tire sealant cannot be reused.

If the tire sealant kit has been used, or

is expired, purchase new one at an

Authorized Dealer.

Do not throw away the empty tire

sealant bottle after use. Return the

empty tire sealant bottle to an

Authorized Dealer when replacing the

tire. The empty tire sealant bottle will

need to be used to extract and dispose

of the used sealant from the tire.

14. Install the injection hose to the tab

of the bottle to prevent leakage of any

remaining sealant.

15. Adhere the speed restriction sticker

to an area where it can be viewed easily

by the driver.

Warning!

Do not adhere the speed restriction sticker

to the padded area on the steering wheel.

Adhering the speed restriction sticker to

the padded area on the steering wheel is

dangerous because the air bag may not

operate (deploy) normally resulting in

serious injury. In addition, do not adhere

the sticker to areas where warning lights or

the speedometer cannot be viewed.

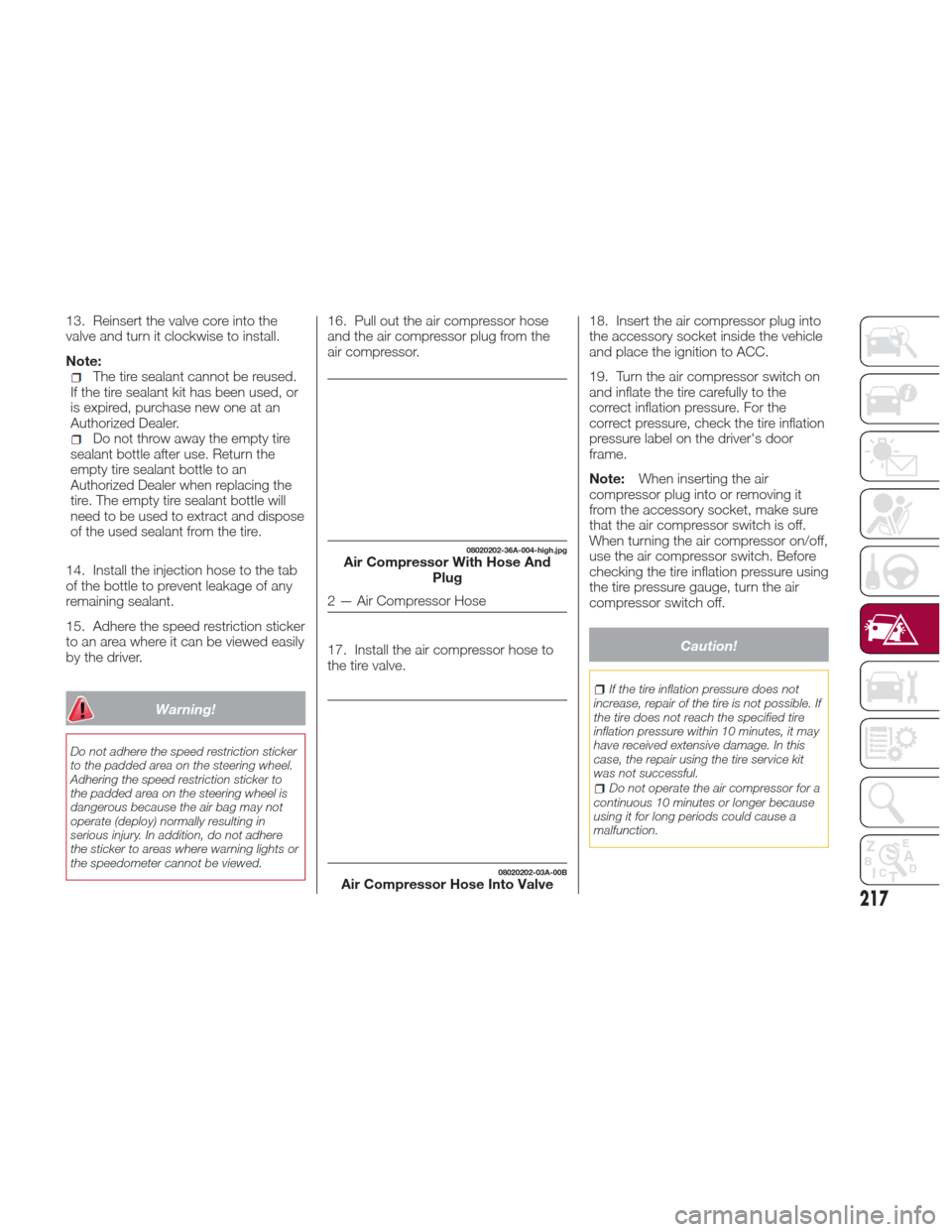

16. Pull out the air compressor hose

and the air compressor plug from the

air compressor.

17. Install the air compressor hose to

the tire valve. 18. Insert the air compressor plug into

the accessory socket inside the vehicle

and place the ignition to ACC.

19. Turn the air compressor switch on

and inflate the tire carefully to the

correct inflation pressure. For the

correct pressure, check the tire inflation

pressure label on the driver's door

frame.

Note:

When inserting the air

compressor plug into or removing it

from the accessory socket, make sure

that the air compressor switch is off.

When turning the air compressor on/off,

use the air compressor switch. Before

checking the tire inflation pressure using

the tire pressure gauge, turn the air

compressor switch off.

Caution!

If the tire inflation pressure does not

increase, repair of the tire is not possible. If

the tire does not reach the specified tire

inflation pressure within 10 minutes, it may

have received extensive damage. In this

case, the repair using the tire service kit

was not successful.

Do not operate the air compressor for a

continuous 10 minutes or longer because

using it for long periods could cause a

malfunction.

08020202-36A-004-high.jpgAir Compressor With Hose And Plug

2 — Air Compressor Hose

08020202-03A-00BAir Compressor Hose Into Valve

217

Page 225 of 300

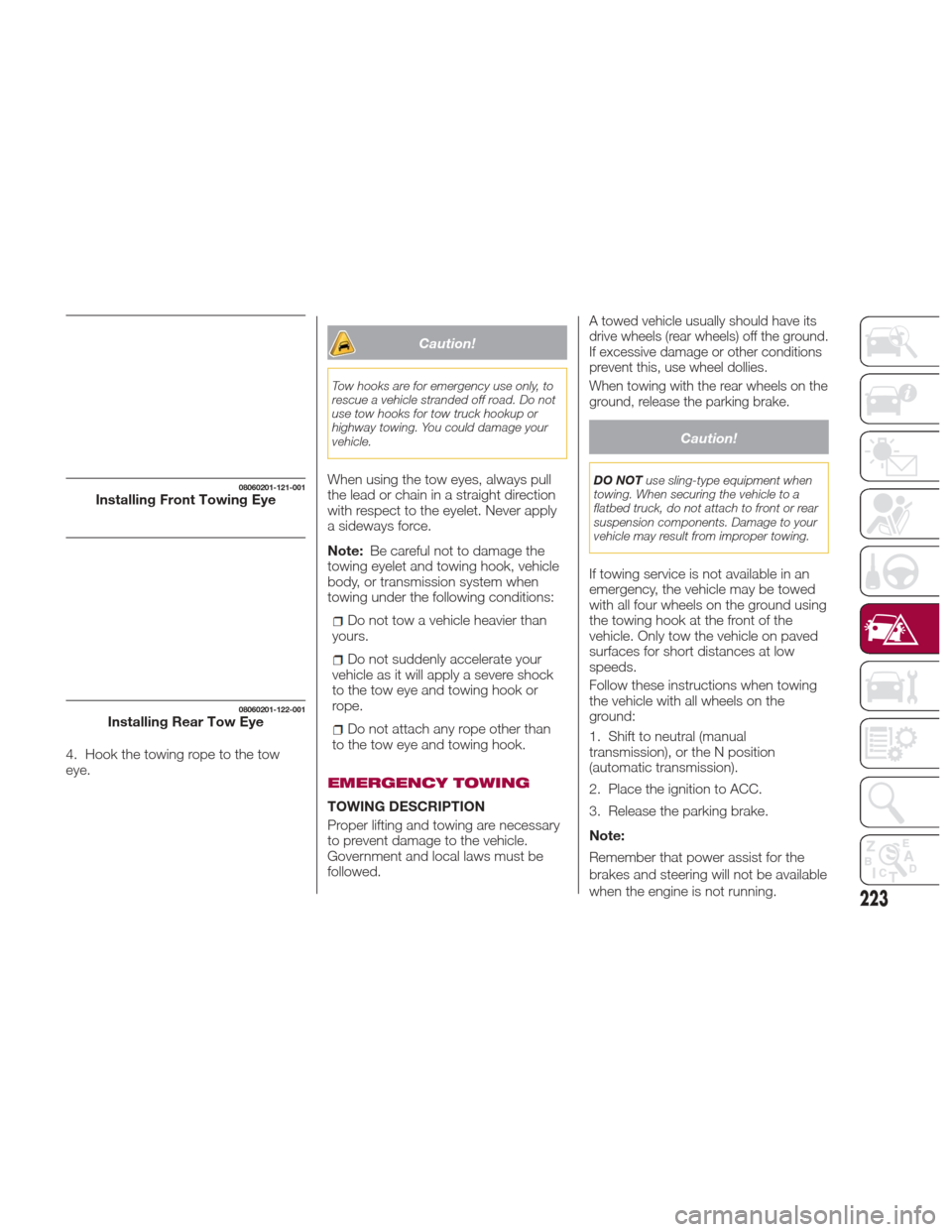

4. Hook the towing rope to the tow

eye.

Caution!

Tow hooks are for emergency use only, to

rescue a vehicle stranded off road. Do not

use tow hooks for tow truck hookup or

highway towing. You could damage your

vehicle.

When using the tow eyes, always pull

the lead or chain in a straight direction

with respect to the eyelet. Never apply

a sideways force.

Note:Be careful not to damage the

towing eyelet and towing hook, vehicle

body, or transmission system when

towing under the following conditions:

Do not tow a vehicle heavier than

yours.

Do not suddenly accelerate your

vehicle as it will apply a severe shock

to the tow eye and towing hook or

rope.

Do not attach any rope other than

to the tow eye and towing hook.

EMERGENCY TOWING

TOWING DESCRIPTION

Proper lifting and towing are necessary

to prevent damage to the vehicle.

Government and local laws must be

followed.

A towed vehicle usually should have its

drive wheels (rear wheels) off the ground.

If excessive damage or other conditions

prevent this, use wheel dollies.

When towing with the rear wheels on the

ground, release the parking brake.

Caution!

DO NOT use sling-type equipment when

towing. When securing the vehicle to a

flatbed truck, do not attach to front or rear

suspension components. Damage to your

vehicle may result from improper towing.

If towing service is not available in an

emergency, the vehicle may be towed

with all four wheels on the ground using

the towing hook at the front of the

vehicle. Only tow the vehicle on paved

surfaces for short distances at low

speeds.

Follow these instructions when towing

the vehicle with all wheels on the

ground:

1. Shift to neutral (manual

transmission), or the N position

(automatic transmission).

2. Place the ignition to ACC.

3. Release the parking brake.

Note:

Remember that power assist for the

brakes and steering will not be available

when the engine is not running.

08060201-121-001Installing Front Towing Eye

08060201-122-001Installing Rear Tow Eye

223

Page 238 of 300

BATTERY

RECHARGING

BATTERY CHARGING

PROCEDURE

Warning!

Battery fluid is a corrosive acid solution

and can burn or even blind you. Do not

allow battery fluid to contact your eyes,

skin, or clothing. Do not lean over a battery

when attaching clamps. If acid splashes in

eyes or on skin, flush the area immediately

with large amounts of water. Refer to

“Jump-Starting” in “In Case Of Emergency”

for further information.

Battery gas is flammable and explosive.

Keep flame or sparks away from the

battery. Do not use a booster battery or

any other booster source with an output

greater than 12 Volts. Do not allow cable

clamps to touch each other.

Battery posts, terminals, and related

accessories contain lead and lead

compounds. Wash hands after handling.

Caution!

It is essential when replacing the cables

on the battery that the positive cable is

attached to the positive post and the

negative cable is attached to the negative

post. Battery posts are marked positive (+)

and negative (-) and are identified on the

battery case. Cable clamps should be tight

on the terminal posts and free of corrosion.

If a “fast charger” is used while the

battery is in the vehicle, disconnect both

vehicle battery cables before connecting

the charger to the battery. Do not use a

“fast charger” to provide starting voltage.

Charge battery as follows:

Before recharging the battery, turn off

all accessories and turn the engine off

by placing the ignition in the OFF mode.

Disconnect the negative battery cable.

Connect the charger cables to

the battery terminals, observing the

polarity (+,–).

Turn on the charger.

When finished, turn the charger off

before disconnecting the battery.

Reconnect the negative battery

terminal.

MAINTENANCE

PROCEDURES

The following pages contain

instructions on the required

maintenance from the technical

personnel who designed the vehicle.

In addition to these specific

maintenance instructions specified for

routine scheduled servicing, there are

other components which may require

periodic maintenance or replacement

over the vehicle’s life cycle.

Body Lubrication

Ensure that the locks and bodywork

junction points, including components

such as the seat guides, door hinges

(and rollers), trunk and hood are

periodically lubricated with lithium

based grease to ensure correct, silent

operation and to protect them from rust

and wear.

Thoroughly clean the components,

eliminating every trace of dirt and dust.

After lubricating, eliminate excess oil

and grease. Also pay particular

attention to the hood closing devices,

to ensure correct operation.

During operations on the hood, be sure

to perform with the engine cold, also

remember to check, clean and lubricate

the locking, release and safety devices.

Make sure the hood's secondary latch

keeps the hood from opening when the

primary latch is released.

236

SERVICING AND MAINTENANCE

Page 239 of 300

Lubricate the external lock cylinders

twice a year. Apply a small amount of

high-quality lubricant directly into the

lock cylinder. If necessary, contact your

Authorized Dealer.

Wiper Blades

Contamination of either the windshield

or the blades with foreign matter can

reduce wiper effectiveness. Common

sources are insects, tree sap, and hot

wax treatments used by some

commercial car washes.

If the blades are not wiping properly,

clean the window and blades with a

good cleaner or mild detergent; then

rinse thoroughly with clean water.

Repeat if necessary.

When the wiper lever is in the AUTO

position and the ignition is placed in the

ON mode, the wipers may move

automatically in the following cases:

If the windshield above the rain

sensor is touched.

If the windshield above the rain

sensor is wiped with a cloth.

If the windshield is struck with a hand

or other object.

If the rain sensor is struck with a

hand or other object from inside the

vehicle. Note:

Hot waxes applied by automatic car

washers have been known to affect

the wiper's ability to clean windows.

To prevent damage to the wiper

blades, do not use gas, paraffin, paint

thinner, or other solvents on or near

them.

Be careful not to pinch hands or

fingers as it may cause injury, or

damage the wipers. When washing or

servicing the vehicle, make sure the

wiper lever is in the OFF position.

Replacing Windshield Wiper Blades

When the wipers no longer clean well,

the blades are probably worn or

cracked. Replace them.

When raising both windshield wiper

arms, raise the driver's side wiper arm

first.

When lowering the wiper arms, slowly

lower the wiper arm from the

passenger's side first while supporting

it with your hand. Forcefully lowering

the wiper arms could damage the wiper

arm and blade, and may scratch or

crack the windshield.

Note: To prevent damage to the wiper

arms and other components, do not try

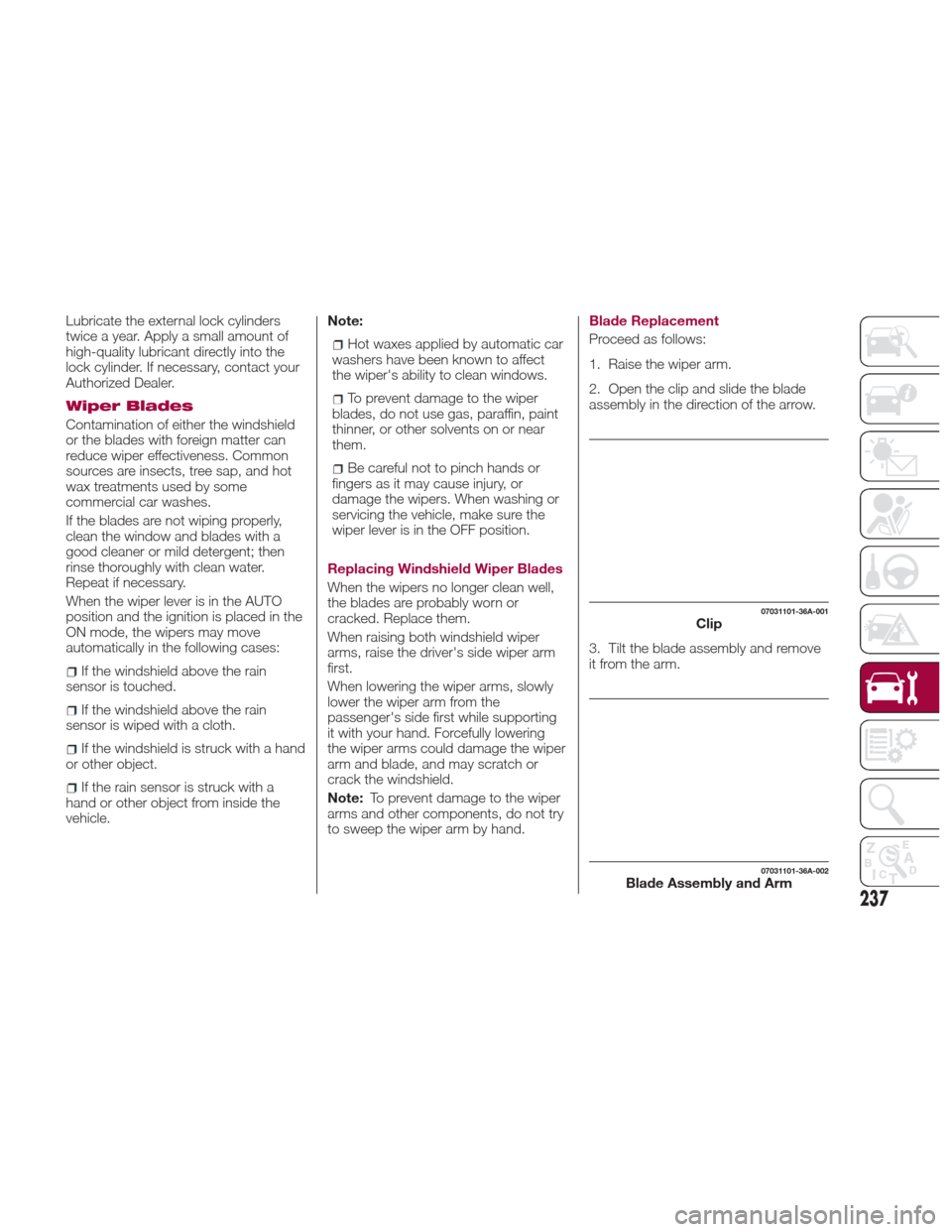

to sweep the wiper arm by hand. Blade Replacement

Proceed as follows:

1. Raise the wiper arm.

2. Open the clip and slide the blade

assembly in the direction of the arrow.

3. Tilt the blade assembly and remove

it from the arm.

07031101-36A-001Clip

07031101-36A-002Blade Assembly and Arm

237