engine FIAT 124 SPIDER 2018 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2018, Model line: 124 SPIDER, Model: FIAT 124 SPIDER 2018Pages: 220, PDF Size: 3.18 MB

Page 125 of 220

REFUELLING THE

VEHICLE

152) 153) 154) 155) 156) 157)

Always stop the engine before

refuelling.

FUEL REQUIREMENTS

Only use premium unleaded fuel

(conforming to EN 228 specification

within E10) with a number of octanes

not lower than 95.

IMPORTANT USE ONLY UNLEADED

FUEL. Leaded fuel is harmful to the

catalytic converter and oxygen sensors

and will lead to deterioration of the

emission control system and or failures.

IMPORTANT The use of E10 fuel with

10% ethanol in Europe is safe for your

vehicle. Damage to your vehicle may

occur when ethanol exceeds this

recommendation.

IMPORTANT Never add fuel system

additives, otherwise the emission

control system could be damaged.

Contact a Fiat Dealership for details.

REFUELLING

PROCEDURE

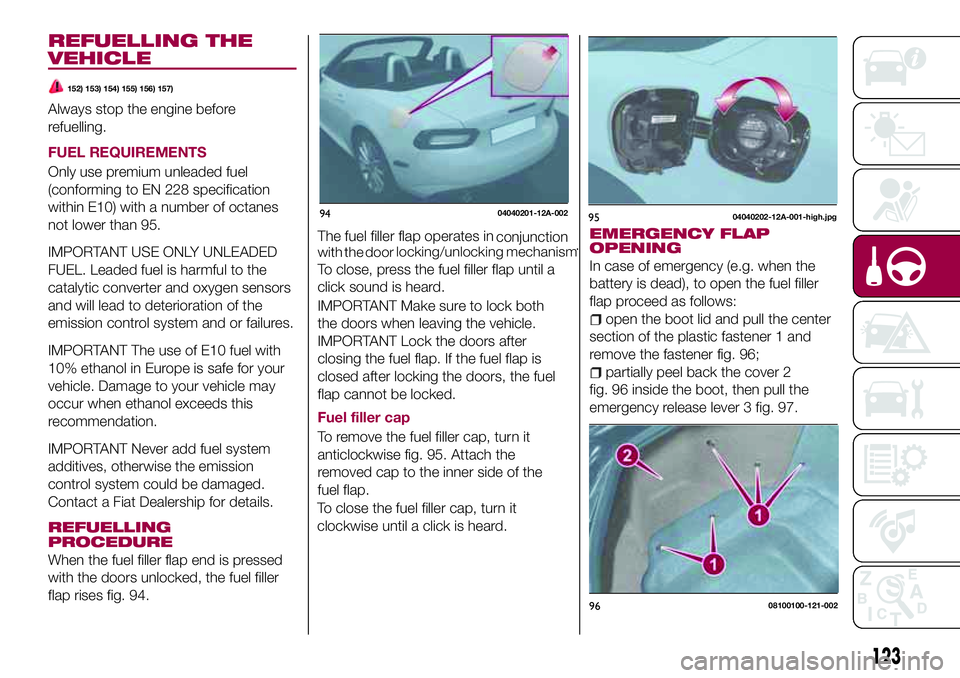

When the fuel filler flap end is pressed

with the doors unlocked, the fuel filler

flap rises fig. 94.The fuel filler flap operates in

conjunction

with the doorlocking/unlocking mechanism.

To close, press the fuel filler flap until a

click sound is heard.

IMPORTANT Make sure to lock both

the doors when leaving the vehicle.

IMPORTANT Lock the doors after

closing the fuel flap. If the fuel flap is

closed after locking the doors, the fuel

flap cannot be locked.

Fuel filler cap

To remove the fuel filler cap, turn it

anticlockwise fig. 95. Attach the

removed cap to the inner side of the

fuel flap.

To close the fuel filler cap, turn it

clockwise until a click is heard.

EMERGENCY FLAP

OPENING

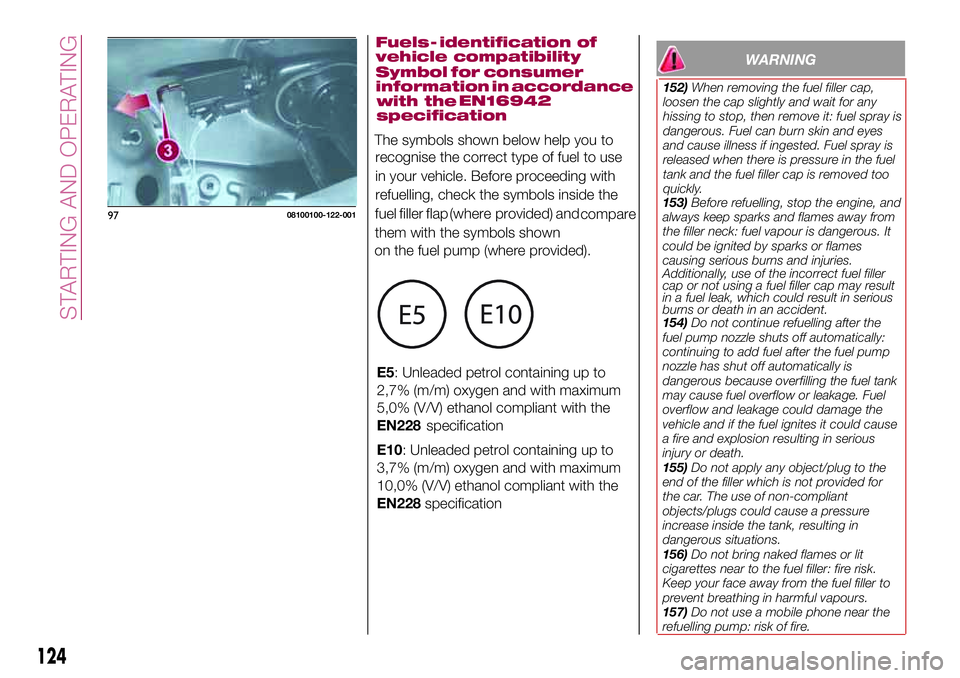

In case of emergency (e.g. when the

battery is dead), to open the fuel filler

flap proceed as follows:

open the boot lid and pull the center

section of the plastic fastener 1 and

remove the fastener fig. 96;

partially peel back the cover 2

fig. 96 inside the boot, then pull the

emergency release lever 3 fig. 97.

9404040201-12A-0029504040202-12A-001-high.jpg

123

9608100100-121-002

Page 126 of 220

WARNING

152)When removing the fuel filler cap,

loosen the cap slightly and wait for any

hissing to stop, then remove it: fuel spray is

dangerous. Fuel can burn skin and eyes

and cause illness if ingested. Fuel spray is

released when there is pressure in the fuel

tank and the fuel filler cap is removed too

quickly.

153)Before refuelling, stop the engine, and

always keep sparks and flames away from

the filler neck: fuel vapour is dangerous. It

could be ignited by sparks or flames

causing serious burns and injuries.

Additionally, use of the incorrect fuel filler

cap or not using a fuel filler cap may result

in a fuel leak, which could result in serious

burns or death in an accident.

154)Do not continue refuelling after the

fuel pump nozzle shuts off automatically:

continuing to add fuel after the fuel pump

nozzle has shut off automatically is

dangerous because overfilling the fuel tank

may cause fuel overflow or leakage. Fuel

overflow and leakage could damage the

vehicle and if the fuel ignites it could cause

a fire and explosion resulting in serious

injury or death.

155)Do not apply any object/plug to the

end of the filler which is not provided for

the car. The use of non-compliant

objects/plugs could cause a pressure

increase inside the tank, resulting in

dangerous situations.

156)Do not bring naked flames or lit

cigarettes near to the fuel filler: fire risk.

Keep your face away from the fuel filler to

prevent breathing in harmful vapours.

157)Do not use a mobile phone near the

refuelling pump: risk of fire.

9708100100-122-001

124

STARTING AND OPERATING

Fuels - identification of

vehicle compatibility

Symbol for consumer

information in accordance

with theEN16942

specification

The symbols shown below help you to

recognise the correct type of fuel to use

in your vehicle. Before proceeding with

refuelling, check the symbols inside the

fuel filler flap (where provided) and

compare

them

with

the

symbols

shown

on the fuel pump (where provided).

E5: Unleaded petrol containing up to

2,7% (m/m) oxygen and with maximum

5,0% (V/V) ethanol compliant with the

EN228

E10: Unleaded petrol containing up to

3,7% (m/m) oxygen and with maximum

10,0% (V/V) ethanol compliant with the

EN228

specification

specification

Page 136 of 220

REPLACING EXTERIOR

LIGHT BULBS

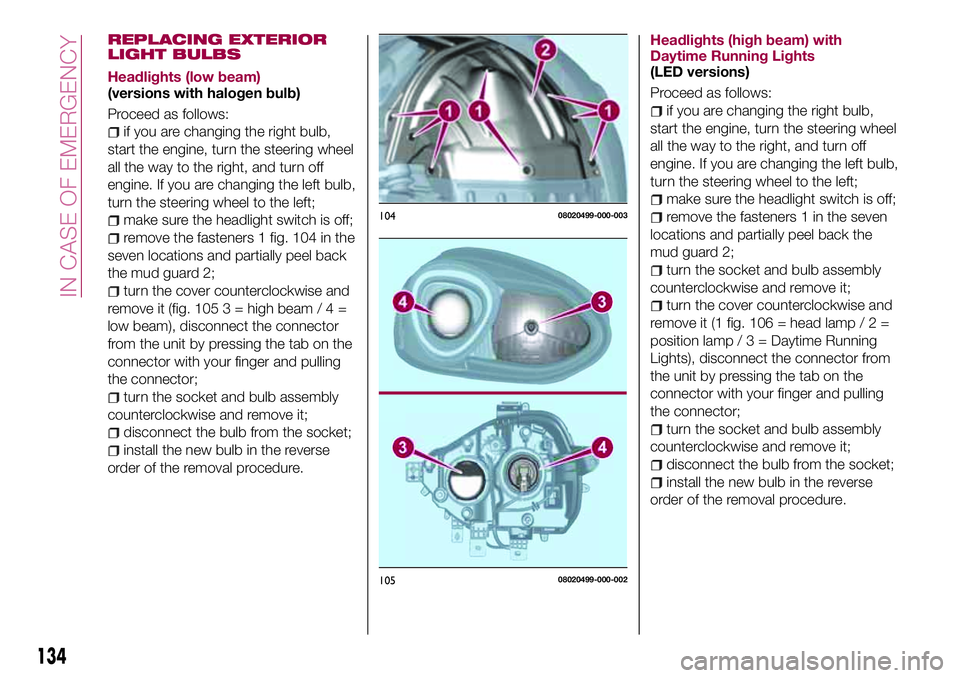

Headlights (low beam)

(versions with halogen bulb)

Proceed as follows:

if you are changing the right bulb,

start the engine, turn the steering wheel

all the way to the right, and turn off

engine. If you are changing the left bulb,

turn the steering wheel to the left;

make sure the headlight switch is off;

remove the fasteners 1 fig. 104 in the

seven locations and partially peel back

the mud guard 2;

turn the cover counterclockwise and

remove it (fig. 105 3 = high beam/4=

low beam), disconnect the connector

from the unit by pressing the tab on the

connector with your finger and pulling

the connector;

turn the socket and bulb assembly

counterclockwise and remove it;

disconnect the bulb from the socket;

install the new bulb in the reverse

order of the removal procedure.Headlights (high beam) with

Daytime Running Lights

(LED versions)

Proceed as follows:

if you are changing the right bulb,

start the engine, turn the steering wheel

all the way to the right, and turn off

engine. If you are changing the left bulb,

turn the steering wheel to the left;

make sure the headlight switch is off;

remove the fasteners 1 in the seven

locations and partially peel back the

mud guard 2;

turn the socket and bulb assembly

counterclockwise and remove it;

turn the cover counterclockwise and

remove it (1 fig. 106 = head lamp / 2 =

position lamp / 3 = Daytime Running

Lights), disconnect the connector from

the unit by pressing the tab on the

connector with your finger and pulling

the connector;

turn the socket and bulb assembly

counterclockwise and remove it;

disconnect the bulb from the socket;

install the new bulb in the reverse

order of the removal procedure.

10408020499-000-003

10508020499-000-002

134

IN CASE OF EMERGENCY

Page 137 of 220

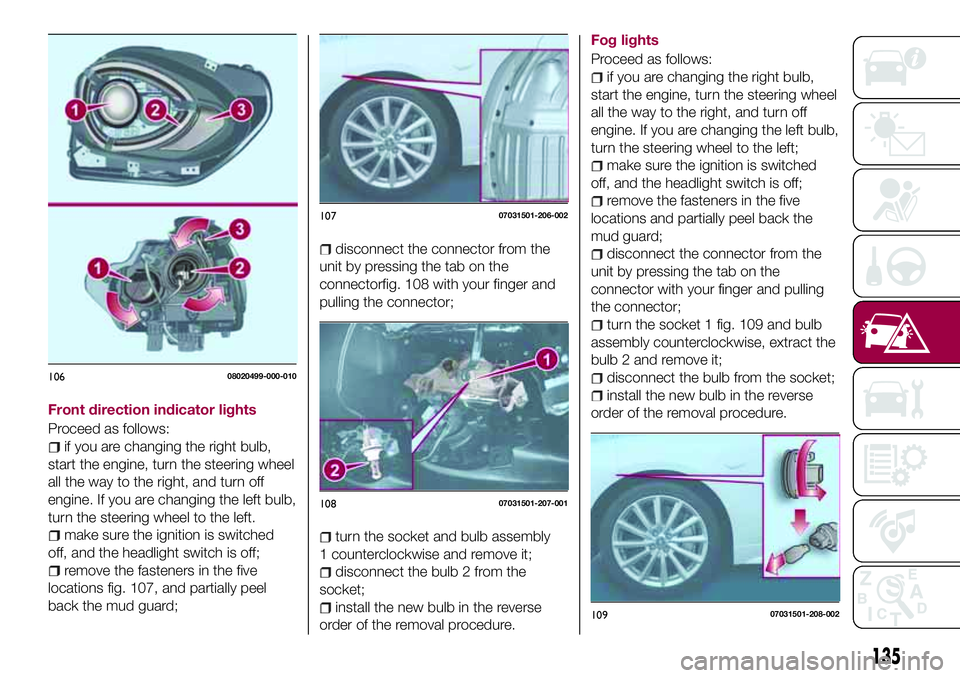

Front direction indicator lights

Proceed as follows:

if you are changing the right bulb,

start the engine, turn the steering wheel

all the way to the right, and turn off

engine. If you are changing the left bulb,

turn the steering wheel to the left.

make sure the ignition is switched

off, and the headlight switch is off;

remove the fasteners in the five

locations fig. 107, and partially peel

back the mud guard;

disconnect the connector from the

unit by pressing the tab on the

connectorfig. 108 with your finger and

pulling the connector;

turn the socket and bulb assembly

1 counterclockwise and remove it;

disconnect the bulb 2 from the

socket;

install the new bulb in the reverse

order of the removal procedure.Fog lights

Proceed as follows:

if you are changing the right bulb,

start the engine, turn the steering wheel

all the way to the right, and turn off

engine. If you are changing the left bulb,

turn the steering wheel to the left;

make sure the ignition is switched

off, and the headlight switch is off;

remove the fasteners in the five

locations and partially peel back the

mud guard;

disconnect the connector from the

unit by pressing the tab on the

connector with your finger and pulling

the connector;

turn the socket 1 fig. 109 and bulb

assembly counterclockwise, extract the

bulb 2 and remove it;

disconnect the bulb from the socket;

install the new bulb in the reverse

order of the removal procedure.

10608020499-000-010

10707031501-206-002

10807031501-207-001

10907031501-208-002

135

Page 138 of 220

Brake lights / Tail lights

Go to a Fiat Dealership when the

replacement of this lights is necessary.

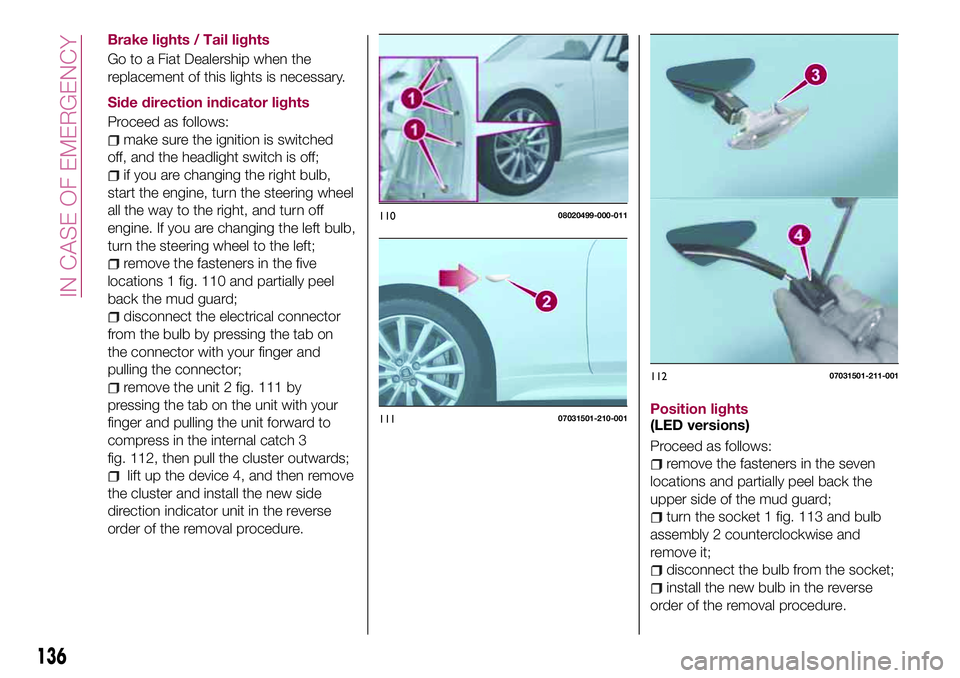

Side direction indicator lights

Proceed as follows:

make sure the ignition is switched

off, and the headlight switch is off;

if you are changing the right bulb,

start the engine, turn the steering wheel

all the way to the right, and turn off

engine. If you are changing the left bulb,

turn the steering wheel to the left;

remove the fasteners in the five

locations 1 fig. 110 and partially peel

back the mud guard;

disconnect the electrical connector

from the bulb by pressing the tab on

the connector with your finger and

pulling the connector;

remove the unit 2 fig. 111 by

pressing the tab on the unit with your

finger and pulling the unit forward to

compress in the internal catch 3

fig. 112, then pull the cluster outwards;

lift up the device 4, and then remove

the cluster and install the new side

direction indicator unit in the reverse

order of the removal procedure.Position lights

(LED versions)

Proceed as follows:remove the fasteners in the seven

locations and partially peel back the

upper side of the mud guard;

turn the socket 1 fig. 113 and bulb

assembly 2 counterclockwise and

remove it;

disconnect the bulb from the socket;

install the new bulb in the reverse

order of the removal procedure.

11008020499-000-011

11107031501-210-001

11207031501-211-001

136

IN CASE OF EMERGENCY

Page 141 of 220

162)Halogen bulbs contain pressurised

gas, in the case of breakage they may

burst causing glass fragments to be

projected outwards.

163)Only replace bulbs when the engine is

off. Also ensure that the engine is cold, to

prevent the risk of burns.

IMPORTANT

30)Where possible, it is advisable to have

bulbs changed at a Fiat Dealership. Proper

operation and direction of the external

lights are essential for driving in safety and

comply with law.

31)Halogen bulbs must be handled

holding the metallic part only. Touching the

transparent part of the bulb with your

fingers may reduce the intensity of the

emitted light and even reduce the lifespan

of the bulb. In the event of accidental

contact, wipe the bulb with a cloth

moistened with alcohol and let the bulb dry

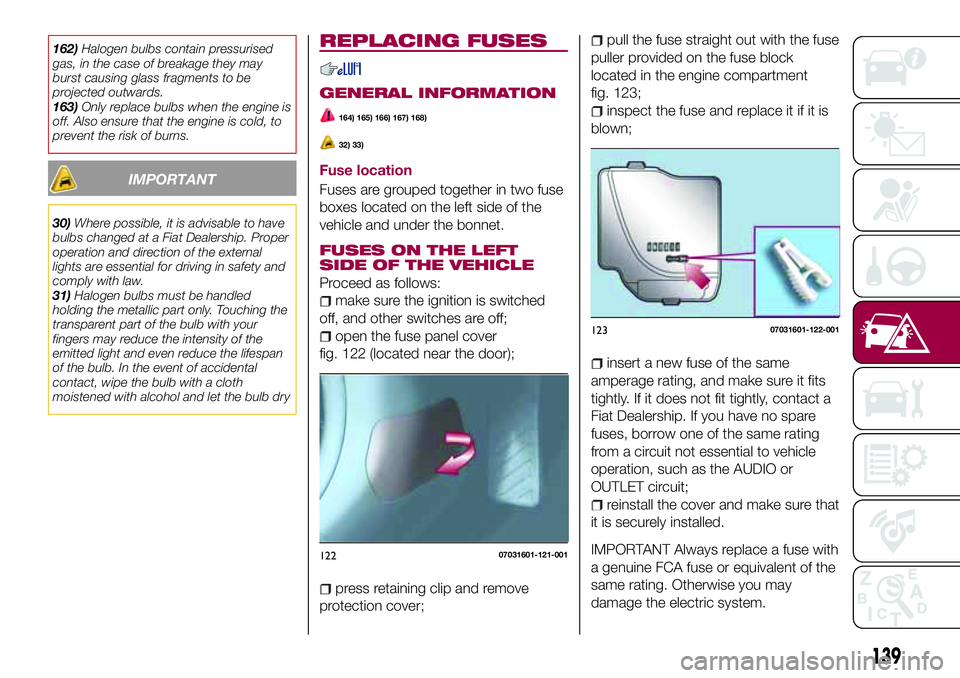

REPLACING FUSES

GENERAL INFORMATION

164) 165) 166) 167) 168)

32) 33)

Fuse location

Fuses are grouped together in two fuse

boxes located on the left side of the

vehicle and under the bonnet.

FUSES ON THE LEFT

SIDE OF THE VEHICLE

Proceed as follows:

make sure the ignition is switched

off, and other switches are off;

open the fuse panel cover

fig. 122 (located near the door);

press retaining clip and remove

protection cover;

pull the fuse straight out with the fuse

puller provided on the fuse block

located in the engine compartment

fig. 123;

inspect the fuse and replace it if it is

blown;

insert a new fuse of the same

amperage rating, and make sure it fits

tightly. If it does not fit tightly, contact a

Fiat Dealership. If you have no spare

fuses, borrow one of the same rating

from a circuit not essential to vehicle

operation, such as the AUDIO or

OUTLET circuit;

reinstall the cover and make sure that

it is securely installed.

IMPORTANT Always replace a fuse with

a genuine FCA fuse or equivalent of the

same rating. Otherwise you may

damage the electric system.12207031601-121-001

12307031601-122-001

139

Page 143 of 220

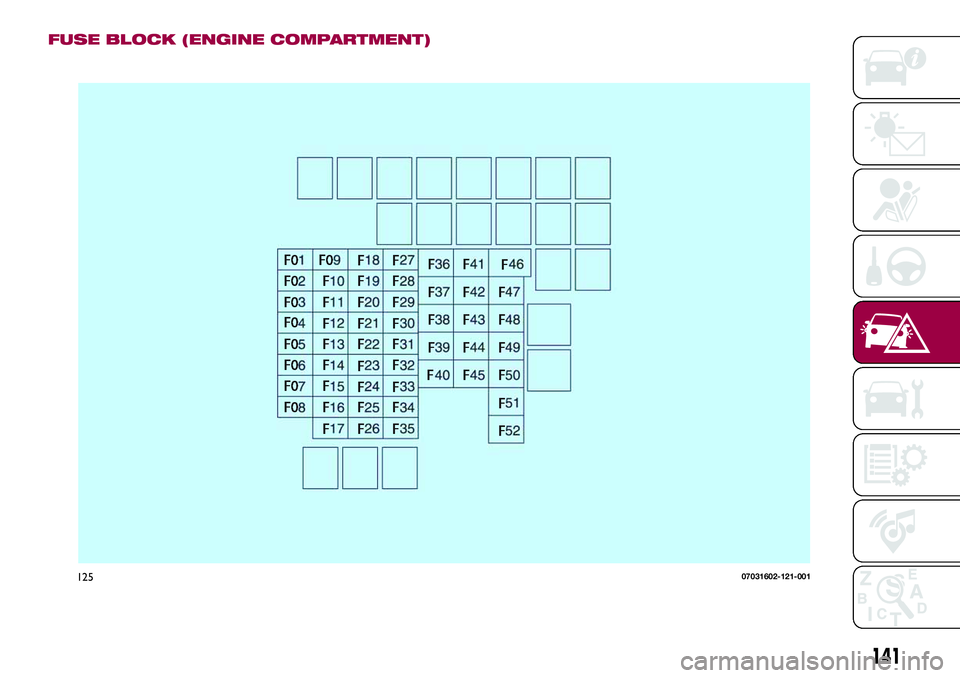

FUSE BLOCK (ENGINE COMPARTMENT)

12507031602-121-001

141

Page 148 of 220

WARNING

164)If the fuse blows again contact a Fiat

Dealership.

165)Never replace a fuse with another

with a higher amp rating; DANGER OF

FIRE.

166)Contact a Fiat Dealership if a safety

system (airbags, brakes), power unit

system (engine, gearbox) or steering

system general protection fuse blows.

167)Do not replace the main fuse and

multiplex slow blow fuse by yourself.

Contact a Fiat Dealership to perform the

replacement. Replacing these fuses by

yourself is dangerous because they are

high current fuses. Incorrect replacement

could cause an electrical shock or a short

circuit resulting in a fire.

168)Before replacing a fuse, make sure

that the ignition device is in OFF position

and that all the other services are switched

off and/or deactivated.

IMPORTANT

32)Never replace a fuse with metal wires

or anything else.

33)If it is necessary to wash the engine

compartment, take care not to directly hit

the junction unit and the window wiper

motors with the water jet.

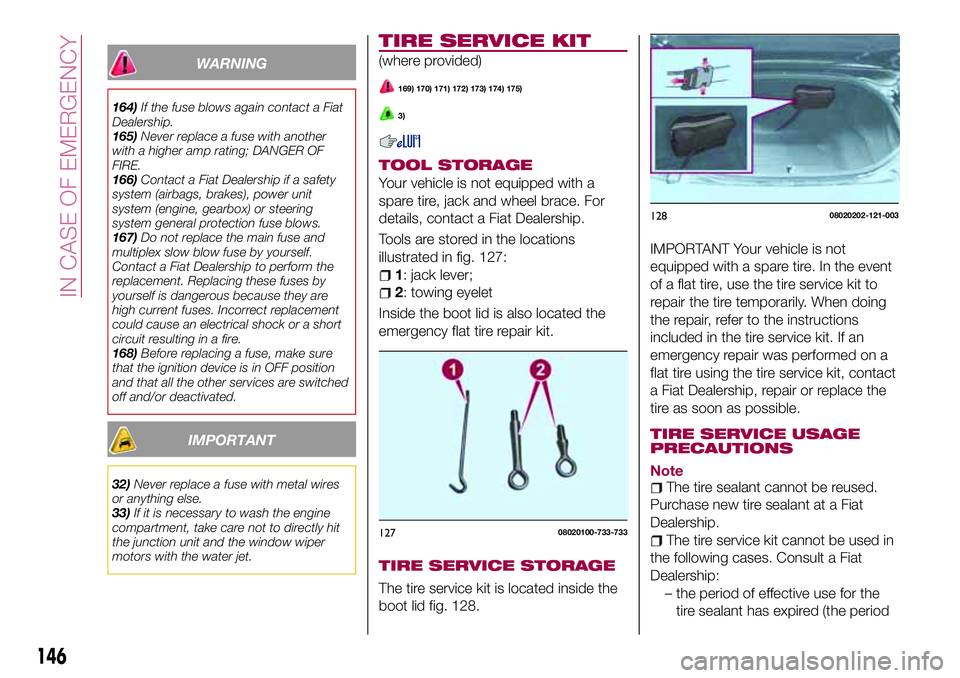

TIRE SERVICE KIT

(where provided)

169) 170) 171) 172) 173) 174) 175)

3)

TOOL STORAGE

Your vehicle is not equipped with a

spare tire, jack and wheel brace. For

details, contact a Fiat Dealership.

Tools are stored in the locations

illustrated in fig. 127:

1: jack lever;

2: towing eyelet

Inside the boot lid is also located the

emergency flat tire repair kit.

TIRE SERVICE STORAGE

The tire service kit is located inside the

boot lid fig. 128.

IMPORTANT Your vehicle is not

equipped with a spare tire. In the event

of a flat tire, use the tire service kit to

repair the tire temporarily. When doing

the repair, refer to the instructions

included in the tire service kit. If an

emergency repair was performed on a

flat tire using the tire service kit, contact

a Fiat Dealership, repair or replace the

tire as soon as possible.

TIRE SERVICE USAGE

PRECAUTIONS

NoteThe tire sealant cannot be reused.

Purchase new tire sealant at a Fiat

Dealership.

The tire service kit cannot be used in

the following cases. Consult a Fiat

Dealership:

– the period of effective use for the

tire sealant has expired (the period12708020100-733-733

12808020202-121-003

146

IN CASE OF EMERGENCY

Page 149 of 220

of effectiveness is indicated on the

bottle label);

– the tear or puncture exceeds about

4 mm;

– the damage has occurred to an

area of the tire other than the tread;

– the vehicle has been driven with

nearly no air remaining in the tire;

– the tire has come off the wheel rim;

– damage to the wheel rim has

occurred;

– the tire has two or more punctures.

SEALING A TIRE WITH

TIRE SERVICE

Proceed as follows:

move the vehicle off the right-of-way

to a safe place on a level and hard

surface where the vehicle does not

obstruct traffic;

shift the shift lever to the 1 or

Reverse (R) position (manual

transmission), and shift the selector

lever to the P position (automatic

transmission);

apply the parking brake with the

brake pedal depressed and turn off the

engine;

if necessary, flash the hazard warning

lights and set up the roadside

emergency triangle;

unload passengers and cargo and

remove the tire service kit;

shake the tire sealant well. If the

bottle is shaken after the injection hose

is screwed on, tire sealant could spray

out from the injection hose. Tire sealant

contacting clothing or other objects

may be impossible to remove. Shake

the bottle before screwing on the

injection hose;

IMPORTANT The sealant hardens easily

and injecting it will be difficult under

cold weather conditions (0°C or below).

Warm the sealant inside the vehicle to

facilitate injection.

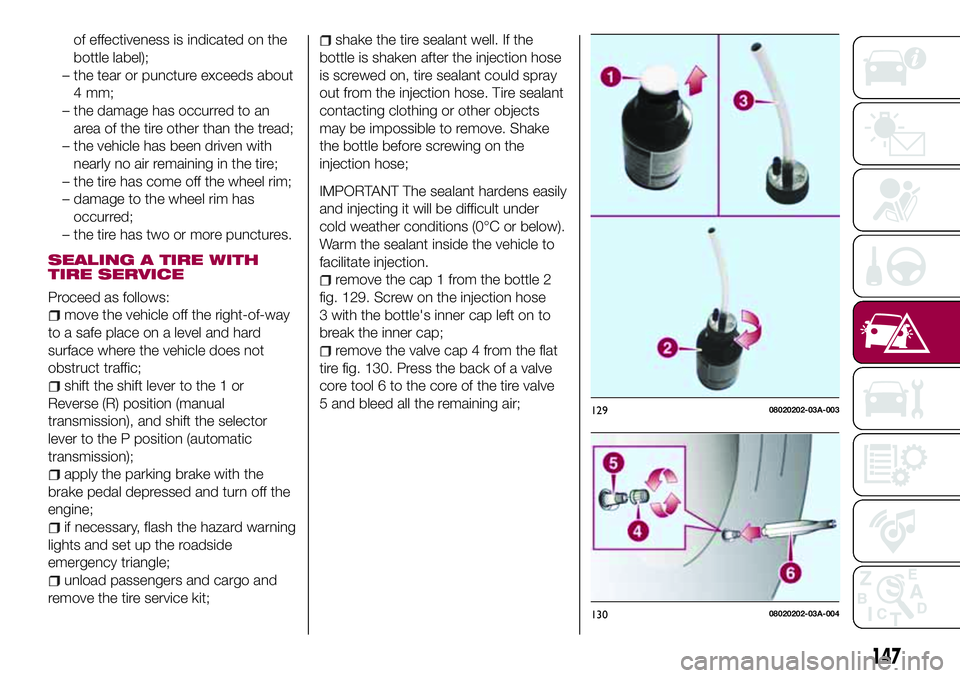

remove the cap 1 from the bottle 2

fig. 129. Screw on the injection hose

3 with the bottle's inner cap left on to

break the inner cap;

remove the valve cap 4 from the flat

tire fig. 130. Press the back of a valve

core tool 6 to the core of the tire valve

5 and bleed all the remaining air;

12908020202-03A-003

13008020202-03A-004

147

Page 153 of 220

JUMP STARTING

PREPARATIONS FOR

JUMP STARTING

176) 177) 178) 179) 180) 181) 182) 183) 184) 185)

34)

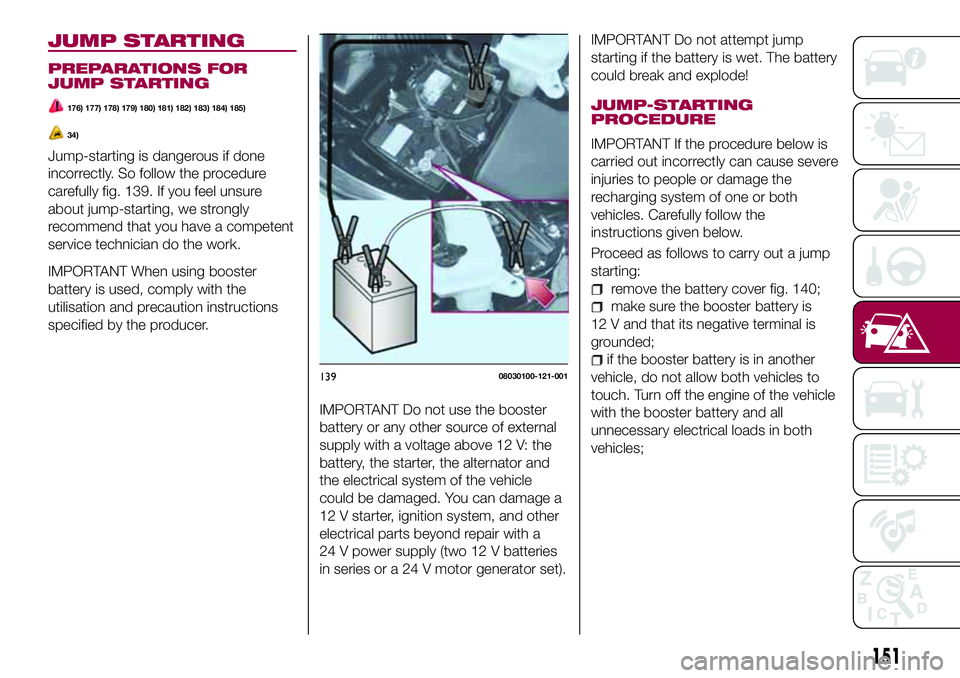

Jump-starting is dangerous if done

incorrectly. So follow the procedure

carefully fig. 139. If you feel unsure

about jump-starting, we strongly

recommend that you have a competent

service technician do the work.

IMPORTANT When using booster

battery is used, comply with the

utilisation and precaution instructions

specified by the producer.

IMPORTANT Do not use the booster

battery or any other source of external

supply with a voltage above 12 V: the

battery, the starter, the alternator and

the electrical system of the vehicle

could be damaged. You can damage a

12 V starter, ignition system, and other

electrical parts beyond repair with a

24 V power supply (two 12 V batteries

in series or a 24 V motor generator set).IMPORTANT Do not attempt jump

starting if the battery is wet. The battery

could break and explode!

JUMP-STARTING

PROCEDURE

IMPORTANT If the procedure below is

carried out incorrectly can cause severe

injuries to people or damage the

recharging system of one or both

vehicles. Carefully follow the

instructions given below.

Proceed as follows to carry out a jump

starting:

remove the battery cover fig. 140;

make sure the booster battery is

12 V and that its negative terminal is

grounded;

if the booster battery is in another

vehicle, do not allow both vehicles to

touch. Turn off the engine of the vehicle

with the booster battery and all

unnecessary electrical loads in both

vehicles;

13908030100-121-001

151