warning light FIAT 124 SPIDER 2021 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2021, Model line: 124 SPIDER, Model: FIAT 124 SPIDER 2021Pages: 228, PDF Size: 5.08 MB

Page 131 of 228

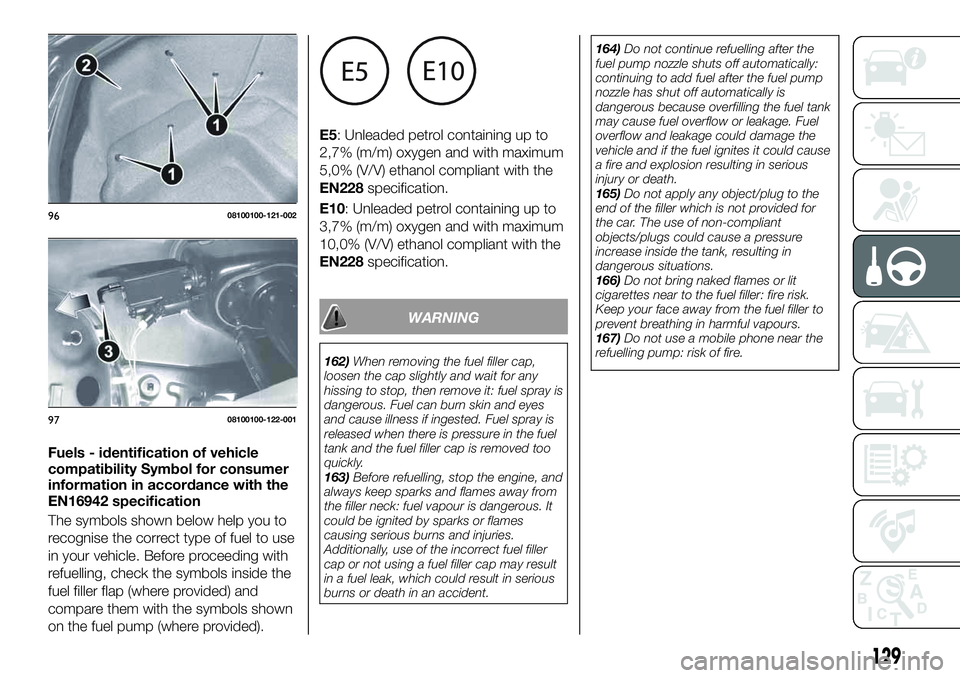

Fuels - identification of vehicle

compatibility Symbol for consumer

information in accordance with the

EN16942 specification

The symbols shown below help you to

recognise the correct type of fuel to use

in your vehicle. Before proceeding with

refuelling, check the symbols inside the

fuel filler flap (where provided) and

compare them with the symbols shown

on the fuel pump (where provided).E5: Unleaded petrol containing up to

2,7% (m/m) oxygen and with maximum

5,0% (V/V) ethanol compliant with the

EN228specification.

E10: Unleaded petrol containing up to

3,7% (m/m) oxygen and with maximum

10,0% (V/V) ethanol compliant with the

EN228specification.

WARNING

162)When removing the fuel filler cap,

loosen the cap slightly and wait for any

hissing to stop, then remove it: fuel spray is

dangerous. Fuel can burn skin and eyes

and cause illness if ingested. Fuel spray is

released when there is pressure in the fuel

tank and the fuel filler cap is removed too

quickly.

163)Before refuelling, stop the engine, and

always keep sparks and flames away from

the filler neck: fuel vapour is dangerous. It

could be ignited by sparks or flames

causing serious burns and injuries.

Additionally, use of the incorrect fuel filler

cap or not using a fuel filler cap may result

in a fuel leak, which could result in serious

burns or death in an accident.164)Do not continue refuelling after the

fuel pump nozzle shuts off automatically:

continuing to add fuel after the fuel pump

nozzle has shut off automatically is

dangerous because overfilling the fuel tank

may cause fuel overflow or leakage. Fuel

overflow and leakage could damage the

vehicle and if the fuel ignites it could cause

a fire and explosion resulting in serious

injury or death.

165)Do not apply any object/plug to the

end of the filler which is not provided for

the car. The use of non-compliant

objects/plugs could cause a pressure

increase inside the tank, resulting in

dangerous situations.

166)Do not bring naked flames or lit

cigarettes near to the fuel filler: fire risk.

Keep your face away from the fuel filler to

prevent breathing in harmful vapours.

167)Do not use a mobile phone near the

refuelling pump: risk of fire.

9608100100-121-002

9708100100-122-001

129

Page 136 of 228

IN CASE OF EMERGENCY

A punctured tyre or a burnt-out bulb?

At times, a problem may interfere with

our journey.

The pages on emergencies can help

you to deal with critical situations

independently and with calm.

In an emergency we recommend that

you call the freephone number found in

the Warranty Booklet.

It is also possible to call the national or

international universal freephone

number to search for the nearest

Dealership.HAZARD WARNING LIGHTS.....135

REPLACING A BULB..........136

REPLACING FUSES..........144

TIRE SERVICE KIT...........152

JUMP STARTING............157

TOWING THE VEHICLE........159

EMERGENCY TOWING........161

134

IN CASE OF EMERGENCY

Page 137 of 228

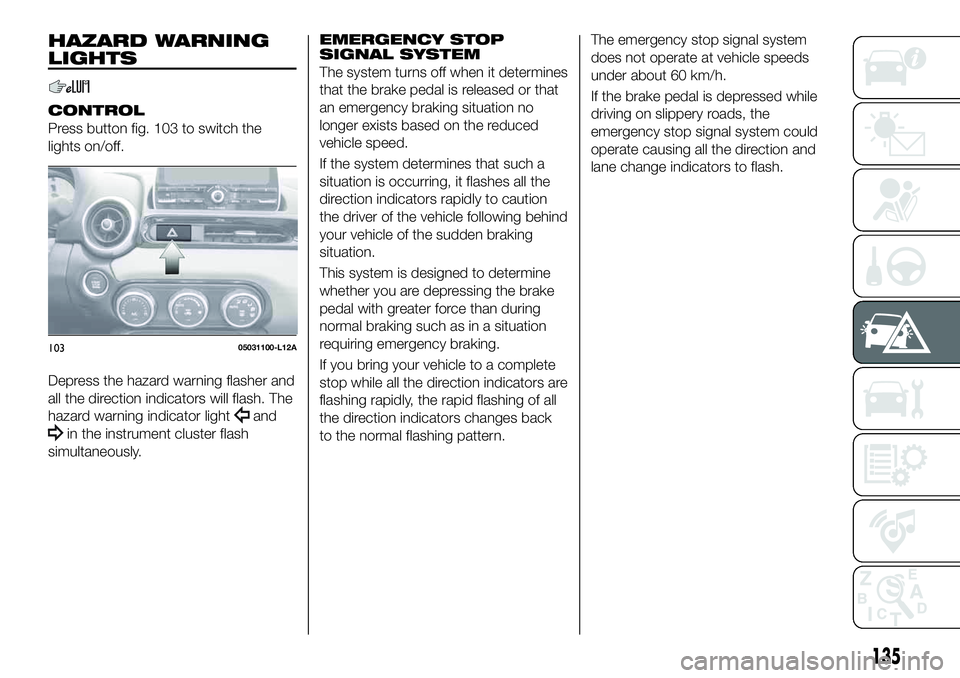

HAZARD WARNING

LIGHTS

CONTROL

Press button fig. 103 to switch the

lights on/off.

Depress the hazard warning flasher and

all the direction indicators will flash. The

hazard warning indicator light

and

in the instrument cluster flash

simultaneously.

EMERGENCY STOP

SIGNAL SYSTEM

The system turns off when it determines

that the brake pedal is released or that

an emergency braking situation no

longer exists based on the reduced

vehicle speed.

If the system determines that such a

situation is occurring, it flashes all the

direction indicators rapidly to caution

the driver of the vehicle following behind

your vehicle of the sudden braking

situation.

This system is designed to determine

whether you are depressing the brake

pedal with greater force than during

normal braking such as in a situation

requiring emergency braking.

If you bring your vehicle to a complete

stop while all the direction indicators are

flashing rapidly, the rapid flashing of all

the direction indicators changes back

to the normal flashing pattern.The emergency stop signal system

does not operate at vehicle speeds

under about 60 km/h.

If the brake pedal is depressed while

driving on slippery roads, the

emergency stop signal system could

operate causing all the direction and

lane change indicators to flash.

10305031100-L12A

135

Page 145 of 228

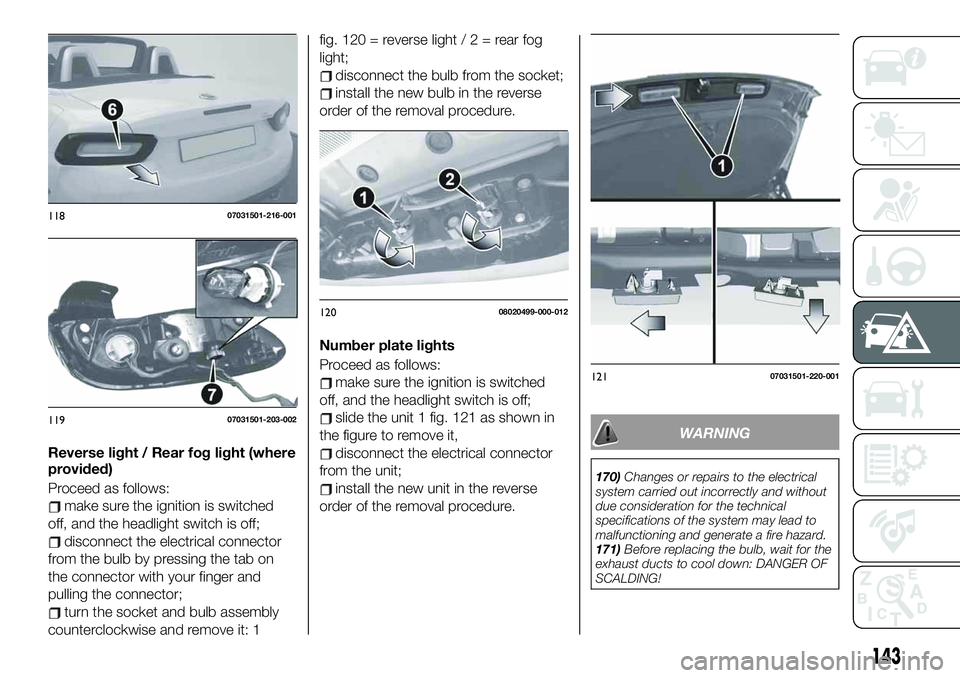

Reverse light / Rear fog light (where

provided)

Proceed as follows:

make sure the ignition is switched

off, and the headlight switch is off;

disconnect the electrical connector

from the bulb by pressing the tab on

the connector with your finger and

pulling the connector;

turn the socket and bulb assembly

counterclockwise and remove it: 1fig. 120 = reverse light/2=rearfog

light;

disconnect the bulb from the socket;

install the new bulb in the reverse

order of the removal procedure.

Number plate lights

Proceed as follows:

make sure the ignition is switched

off, and the headlight switch is off;

slide the unit 1 fig. 121 as shown in

the figure to remove it,

disconnect the electrical connector

from the unit;

install the new unit in the reverse

order of the removal procedure.

WARNING

170)Changes or repairs to the electrical

system carried out incorrectly and without

due consideration for the technical

specifications of the system may lead to

malfunctioning and generate a fire hazard.

171)Before replacing the bulb, wait for the

exhaust ducts to cool down: DANGER OF

SCALDING!

11807031501-216-001

11907031501-203-002

12008020499-000-012

12107031501-220-001

143

Page 149 of 228

147

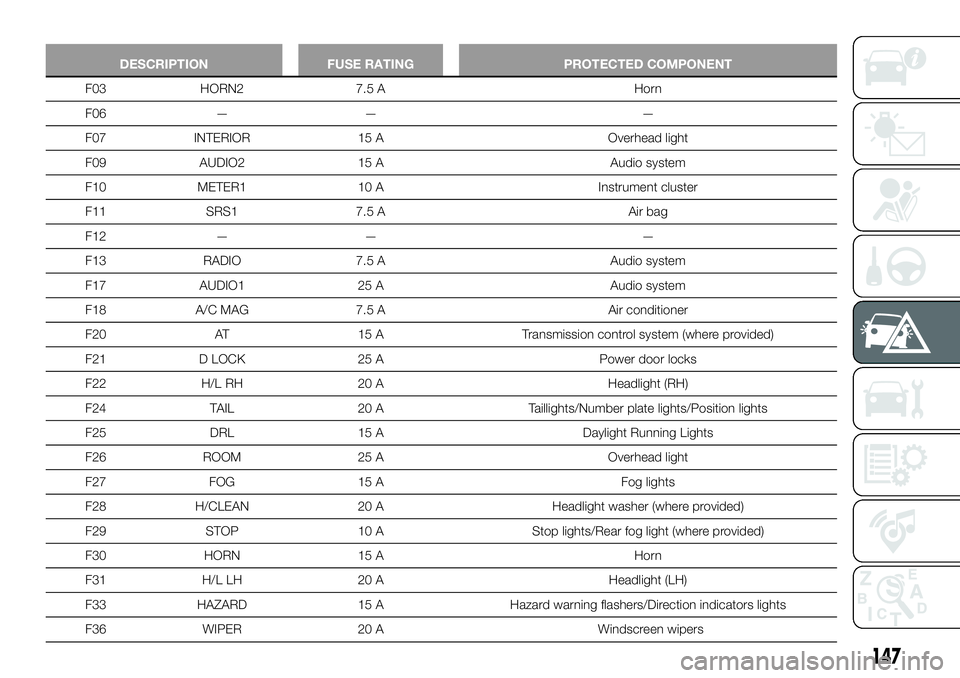

DESCRIPTION FUSE RATING PROTECTED COMPONENT

F03 HORN2 7.5 A Horn

F06 — — —

F07 INTERIOR 15 A Overhead light

F09 AUDIO2 15 A Audio system

F10 METER1 10 A Instrument cluster

F11 SRS1 7.5 A Air bag

F12 — — —

F13 RADIO 7.5 A Audio system

F17 AUDIO1 25 A Audio system

F18 A/C MAG 7.5 A Air conditioner

F20 AT 15 A Transmission control system (where provided)

F21 D LOCK 25 A Power door locks

F22 H/L RH 20 A Headlight (RH)

F24 TAIL 20 A Taillights/Number plate lights/Position lights

F25 DRL 15 A Daylight Running Lights

F26 ROOM 25 A Overhead light

F27 FOG 15 A Fog lights

F28 H/CLEAN 20 A Headlight washer (where provided)

F29 STOP 10 A Stop lights/Rear fog light (where provided)

F30 HORN 15 A Horn

F31 H/L LH 20 A Headlight (LH)

F33 HAZARD 15 A Hazard warning flashers/Direction indicators lights

F36 WIPER 20 A Windscreen wipers

Page 155 of 228

SEALING A TIRE WITH

TIRE SERVICE

Proceed as follows:

move the vehicle off the right-of-way

to a safe place on a level and hard

surface where the vehicle does not

obstruct traffic;

shift the shift lever to the 1 or

Reverse (R) position (manual

transmission), and shift the selector

lever to the P position (automatic

transmission);

apply the parking brake with the

brake pedal depressed and turn off the

engine;

if necessary, flash the hazard warning

lights and set up the roadside

emergency triangle;

unload passengers and cargo and

remove the tire service kit;

shake the tire sealant well.

IMPORTANT If the bottle is shaken after

the injection hose is screwed on, tire

sealant could spray out from the

injection hose. Tire sealant contacting

clothing or other objects may be

impossible to remove. Shake the bottle

before screwing on the injection hose.

IMPORTANT The sealant hardens easily

and injecting it will be difficult under

cold weather conditions (0°C or below).

Warm the sealant inside the vehicle to

facilitate injection.

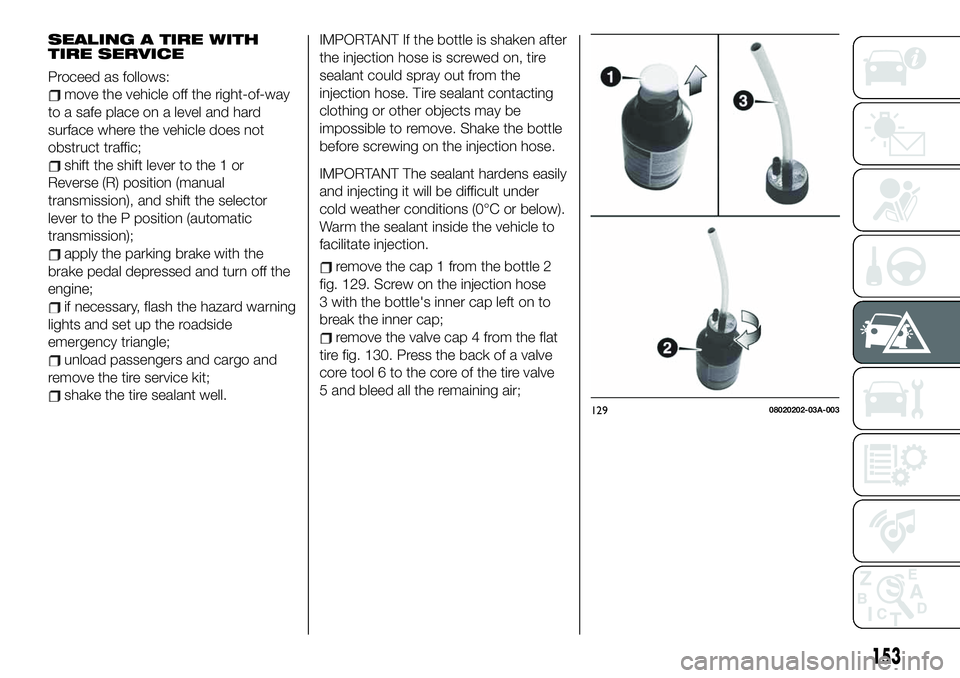

remove the cap 1 from the bottle 2

fig. 129. Screw on the injection hose

3 with the bottle's inner cap left on to

break the inner cap;

remove the valve cap 4 from the flat

tire fig. 130. Press the back of a valve

core tool 6 to the core of the tire valve

5 and bleed all the remaining air;

12908020202-03A-003

153

Page 157 of 228

the tab 14 fig. 135 of the bottle to

prevent leakage of any remaining

sealant;

adhere the speed restriction sticker

to an area where it can be viewed easily

by the driver;

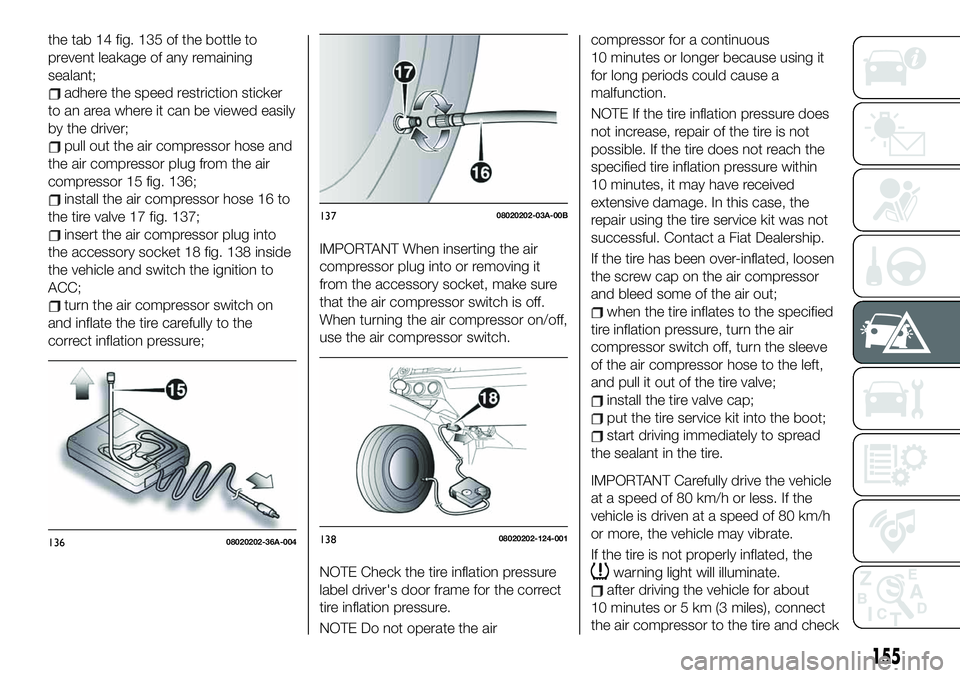

pull out the air compressor hose and

the air compressor plug from the air

compressor 15 fig. 136;

install the air compressor hose 16 to

the tire valve 17 fig. 137;

insert the air compressor plug into

the accessory socket 18 fig. 138 inside

the vehicle and switch the ignition to

ACC;

turn the air compressor switch on

and inflate the tire carefully to the

correct inflation pressure;

IMPORTANT When inserting the air

compressor plug into or removing it

from the accessory socket, make sure

that the air compressor switch is off.

When turning the air compressor on/off,

use the air compressor switch.

NOTE Check the tire inflation pressure

label driver's door frame for the correct

tire inflation pressure.

NOTE Do not operate the aircompressor for a continuous

10 minutes or longer because using it

for long periods could cause a

malfunction.

NOTE If the tire inflation pressure does

not increase, repair of the tire is not

possible. If the tire does not reach the

specified tire inflation pressure within

10 minutes, it may have received

extensive damage. In this case, the

repair using the tire service kit was not

successful. Contact a Fiat Dealership.

If the tire has been over-inflated, loosen

the screw cap on the air compressor

and bleed some of the air out;

when the tire inflates to the specified

tire inflation pressure, turn the air

compressor switch off, turn the sleeve

of the air compressor hose to the left,

and pull it out of the tire valve;

install the tire valve cap;

put the tire service kit into the boot;

start driving immediately to spread

the sealant in the tire.

IMPORTANT Carefully drive the vehicle

at a speed of 80 km/h or less. If the

vehicle is driven at a speed of 80 km/h

or more, the vehicle may vibrate.

If the tire is not properly inflated, the

warning light will illuminate.

after driving the vehicle for about

10 minutes or 5 km (3 miles), connect

the air compressor to the tire and check

13608020202-36A-004

13708020202-03A-00B

13808020202-124-001

155

Page 158 of 228

the tire inflation pressure using the tire

pressure gauge on the air compressor.

If the tire inflation pressure is lower than

the specified tire inflation pressure, turn

the air compressor on and wait until it

reaches the specified tire inflation

pressure;

the emergency flat tire repair is

completed successfully if the tire

inflation pressure does not decrease.

Carefully drive the vehicle to the nearest

Fiat Dealership and have the flat tire

replaced. Replacement with a new tire

is recommended. If the tire is to be

repaired or reused, contact a Fiat

Dealership.

IMPORTANT Before checking the tire

inflation pressure using the tire pressure

gauge, turn the air compressor switch

off.

NOTEIf an emergency flat tire repair has

been performed using the tire service

kit, FCA recommends that the tire be

replaced with a new one as soon as

possible. If the tire is to be repaired or

reused, contact a Fiat Dealership.

The wheel can be reused if the

sealant adhering to it is removed.

However, replace the valve with a new

one.

WARNING

180)Punctures on the sides of the tire may

not be repaired. Do not use the kit if the tire

was damaged as a result of being used

when underinflated.

181)Do not adhere the speed restriction

sticker to the padded area on the steering

wheel. Adhering the speed restriction

sticker to the padded area on the steering

wheel is dangerous because the air bag

may not operate (deploy) normally resulting

in serious injury. In addition, do not adhere

the sticker to areas where warning lights or

the speedometer cannot be viewed.

182)If the tire inflation pressure has

decreased below 130 kPa (1.3 kgf/cm

2or

bar, 18.9 psi), stop driving and contact a

Fiat Dealership. The repair using the

emergency at tire repair kit was not

successful. If you see a decrease in the tire

inflation pressure, stop driving. Contact a

Fiat Dealership.

183)You must always indicate that the tyre

was repaired using the kit. Give the booklet

to the technicians who will be handling the

tire that was treated using the kit.

184)Repairs are not possible in the case of

damage to the wheel rim (bad groove

distortion causing air loss). Do not remove

foreign bodies (screws or nails) from the

tire.185)The information required by the

applicable regulation is indicated on the tire

service kit package label. Compliance with

the indications on the label is an essential

condition to ensure the safety and the

effectiveness of the tire service kit. Carefully

read the label before use, avoid improper

use. Tire service kit is subject to expiration

and must be replaced periodically. The kit

should be used by adults and cannot be

used by children.

186)Do not allow children to touch the tire

sealant: ingestion of tire sealant is

dangerous. In the event tire sealant is

accidentally swallowed, drink large

amounts of water immediately and seek

medical assistance. Tire sealant that

comes into contact with the eyes and skin

is dangerous. If tire sealant enters the eyes

or contacts the skin, flush immediately with

large amounts of water and seek medical

assistance.

IMPORTANT

3)Dispose of the bottle and the sealant

liquid properly. Have them disposed of in

compliance with national and local

regulations.

156

IN CASE OF EMERGENCY

Page 166 of 228

OWNER MAINTENANCE

PRECAUTIONS

197) 198) 199)

38)

Routine service

We highly recommend that these items

be inspected daily, or at least every

week:

Engine oil level

Engine coolant level

Brake and clutch fluid Level

Washer fluid level

Battery maintenance

Tire inflation pressure

Improper or incomplete service may

result in problems. This section gives

instructions only for items that are easy

to perform.

As explained in the “Introduction”

paragraph, several procedures can be

done only by a qualified service

technician with special tools.

Improper do-it yourself maintenance

during the warranty period may affect

warranty coverage. For details, read the

separate Warranty statement provided

with the vehicle. If you are unsure about

any servicing or maintenance

procedure, have it done by an expert

repairer, we recommend a Fiat

Dealership.There are strict environmental laws

regarding the disposal of waste oil and

fluids. Please dispose of your waste

properly and with due regard to the

environment.

We recommend that you entrust the oil

and fluid changes of your vehicle to a

Fiat Dealership.

PERIODIC CHECKS

Every1,000 kmor before long trips

check and, if necessary, top up:

engine coolant level;

brake fluid level;

windscreen washer fluid level;

tire inflation pressure and condition;

operation of lighting system

(headlights, direction indicators, hazard

warning lights, etc.);

operation of windscreen

washer/wiper system and

positioning/wear of windscreen window

wiper blades.

Every 3,000 km, check and top up if

required: engine oil level.

HEAVY-DUTY USE OF THE

VEHICLE

If the vehicle is used under one of the

following conditions:

dusty roads;

short, repeated journeys (less than

7-8 km) at sub-zero outside

temperatures;

engine often idling or driving long

distances at low speeds or long periods

of inactivity;

the following checks must be carried

out more often than indicated in the

Scheduled Servicing Plan:

check front disc brake pad condition

and wear;

check cleanliness of bonnet and

luggage compartment locks,

cleanliness and lubrication of linkage;

visually inspect conditions of: engine,

gearbox, transmission, pipes and hoses

(exhaust/fuel system/brakes) and

rubber elements (gaiters/sleeves/

bushes, etc.);

check battery charge and battery

fluid level (electrolyte);

visually inspect conditions of the

accessory drive belts;

check and, if necessary, change

engine oil and replace oil filter;

check and, if necessary, replace

pollen filter;

check and, if necessary, replace air

cleaner.

164

MAINTENANCE AND CARE

Page 167 of 228

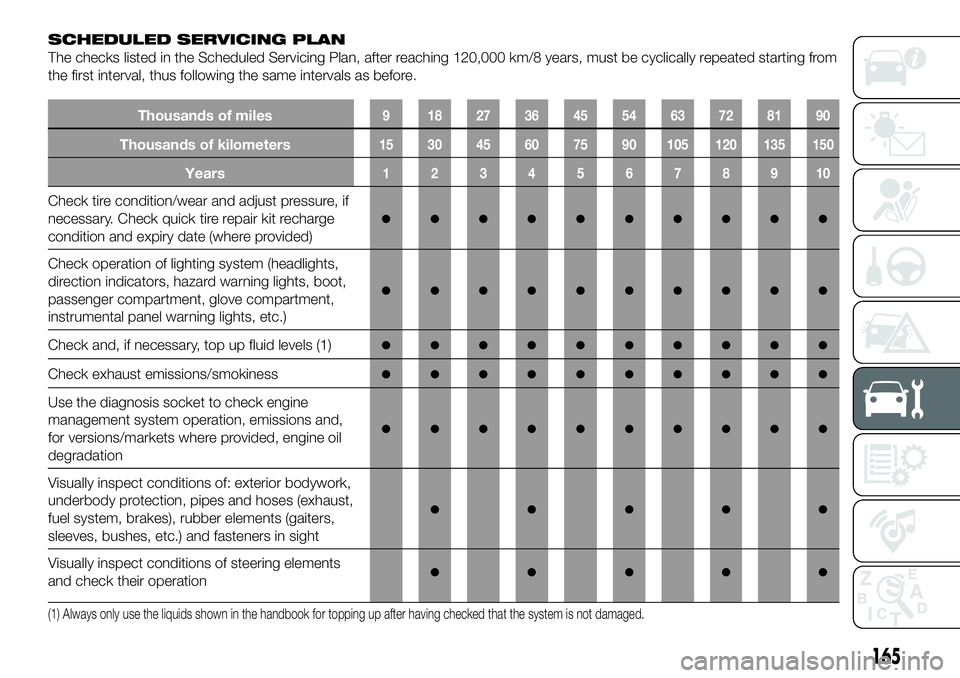

SCHEDULED SERVICING PLAN

The checks listed in the Scheduled Servicing Plan, after reaching 120,000 km/8 years, must be cyclically repeated starting from

the first interval, thus following the same intervals as before.

Thousands of miles9 182736455463728190

Thousands of kilometers15 30 45 60 75 90 105 120 135 150

Years12345678910

Check tire condition/wear and adjust pressure, if

necessary. Check quick tire repair kit recharge

condition and expiry date (where provided)

●●●●●●●●●●

Check operation of lighting system (headlights,

direction indicators, hazard warning lights, boot,

passenger compartment, glove compartment,

instrumental panel warning lights, etc.)

●●●●●●●●●●

Check and, if necessary, top up fluid levels (1)●●●●●●●●●●

Check exhaust emissions/smokiness●●●●●●●●●●

Use the diagnosis socket to check engine

management system operation, emissions and,

for versions/markets where provided, engine oil

degradation

●●●●●●●●●●

Visually inspect conditions of: exterior bodywork,

underbody protection, pipes and hoses (exhaust,

fuel system, brakes), rubber elements (gaiters,

sleeves, bushes, etc.) and fasteners in sight

●●●●●

Visually inspect conditions of steering elements

and check their operation●●●●●

(1) Always only use the liquids shown in the handbook for topping up after having checked that the system is not damaged.

165