FIAT 127 1971 1.G Owner's Manual

Manufacturer: FIAT, Model Year: 1971, Model line: 127, Model: FIAT 127 1971 1.GPages: 34, PDF Size: 6.87 MB

Page 21 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

21/34

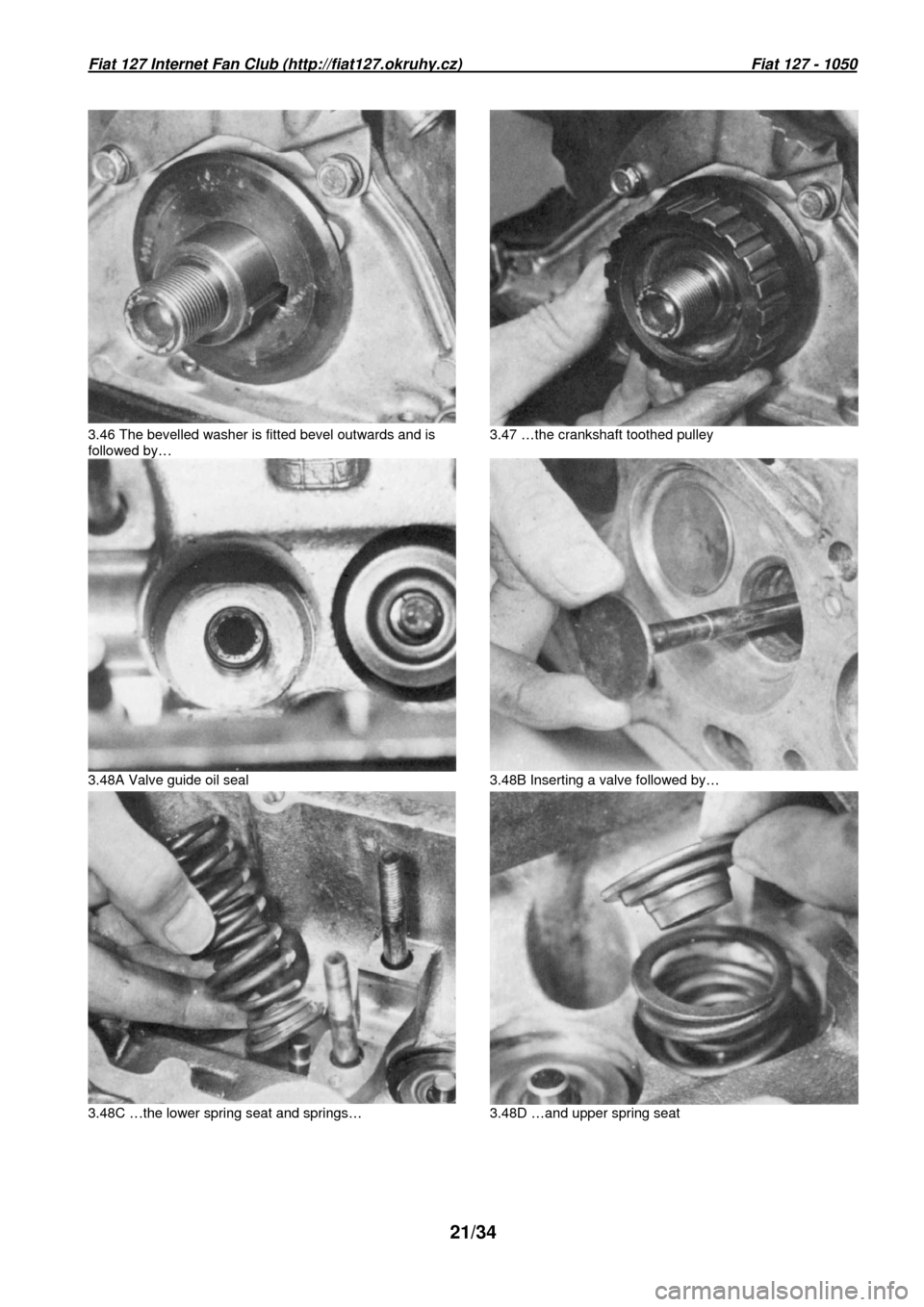

3.46 The bevelled washer is fitted bevel outwards a nd is

followed by… 3.47 …the crankshaft toothed pulley

3.48A Valve guide oil seal 3.48B Inserting a valve followed by…

3.48C …the lower spring seat and springs… 3.48D …and upper spring seat

Page 22 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

22/34

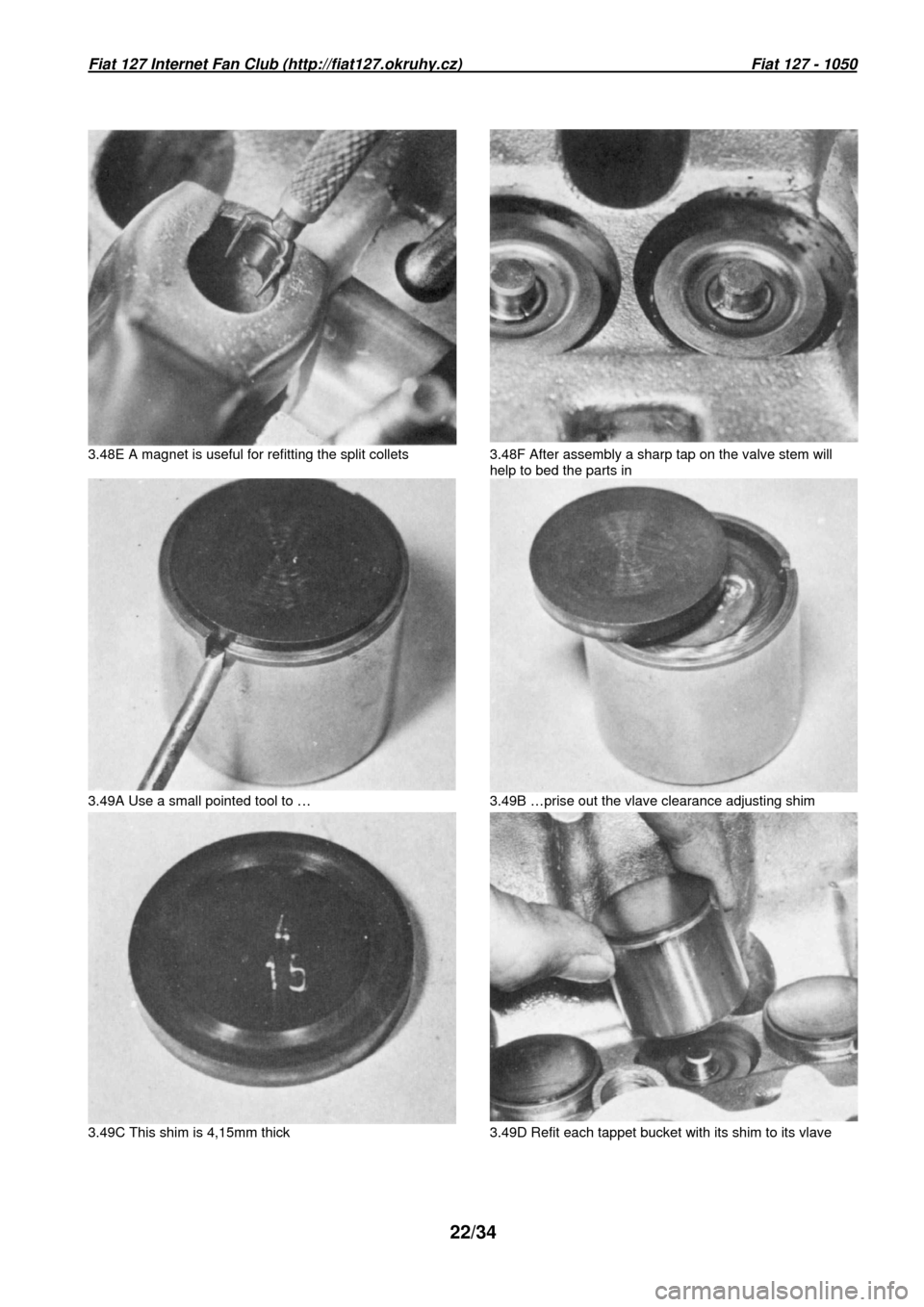

3.48E A magnet is useful for refitting the split co llets 3.48F After assembly a sharp tap on the valve stem will

help to bed the parts in

3.49A Use a small pointed tool to … 3.49B …prise out the vlave clearance adjusting shim

3.49C This shim is 4,15mm thick 3.49D Refit each tappet bucket with its shim to its vlave

Page 23 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

23/34

32 Carefully ease the lip of the seal onto the

spigot and secure the carrier with the bolts and

washers (photo).

33 Similarly clean the crankshaft at the timing

belt end and fit the seal and carrier. Retain by

the two bottom bolts (photo). 34 Put the timing

indicator bracket over the two top bolt holes in

the seal carrier and fit the two top bolts (photo).

Sump - refitting

35 Make sure that there are no remnants of the

old gasket on the sump flange and fit a new

gasket using a little grease to hold it in position .

Check that it is bedded down evenly all round

the flange.

36 Fit the sump to the crankcase. Put the load

spreading washers on each bolt and screw into

the crankcase (photo).

37 Tighten the bolts evenly to avoid warping the

flange.

Auxiliary shaft and seal - refitting

38 Clean the auxiliary shaft bearings and

lubricate with clean engine oil.

39 Insert the shaft into the crankcase bushes

and rotate the shaft to spread the oil (photo).

40 Lubricate the auxiliary shaft seal in its carrie r

and carefully ease the seal over the shaft spigot

(photo).

41 Fit the seal carrier retaining bolts and

washers and tighten.

Belt pulleys and tensioner - refitting

42 Fit the toothed pulley to the auxiliary shaft.

The recess in the pulley fits on the auxiliary shaf t

with the dowel on the shaft in the hole in the

pulley (photo). Fit the retaining bolt and washer

and partially tighten, as it will be necessary to

wait until the drivebelt has been fitted before

finally tightening this bolt. Alternatively, it is

possible to hold the auxiliary shaft carefully in a

vice, fit the seal and carrier to the shaft, follow ed

by the toothed pulley and its retaining bolt and

washer, and then tighten the bolt fully before

fitting the complete assembly to the block.

43 The belt tensioner bracket can now be fitted.

Clean off all traces of old gasket from the

bracket and block and use a new gasket on

assembly. Fit the retaining bolts and washers

and tighten (photo).

44 Insert the spring-loaded plunger assembly

into the tensioner bracket (photo).

45 The tensioning wheel in its carrier can now

be fitted. Put the top bolt and washer in first and

then bear down to compress the spring and fit the bottom bolt through the kidney-shaped slot.

Note that this latter bolt has an additional, large

washer against the wheel carrier. Temporarily

tighten the two bolts they will have to be

retightened after the belt has been fitted (photo).

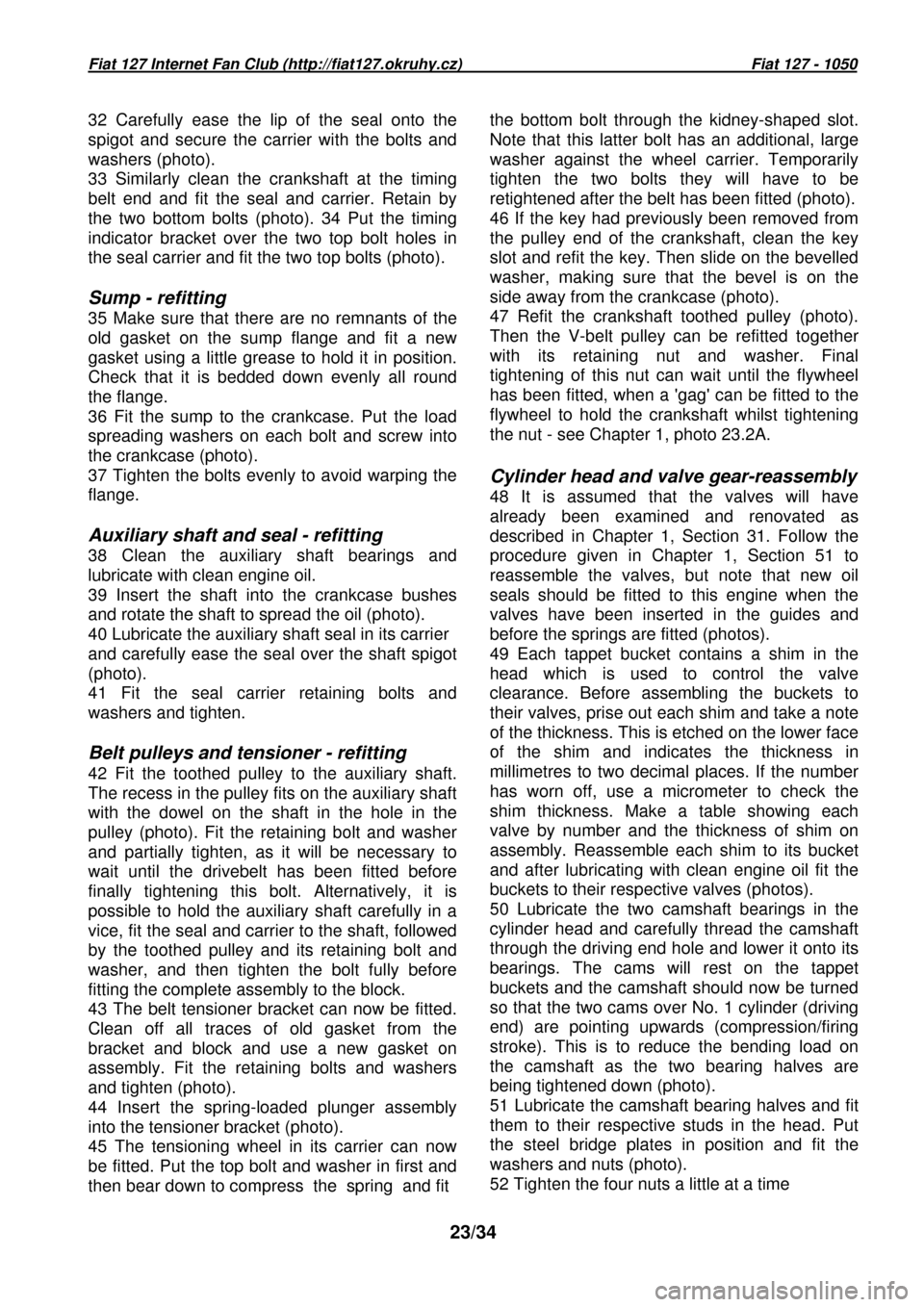

46 If the key had previously been removed from

the pulley end of the crankshaft, clean the key

slot and refit the key. Then slide on the bevelled

washer, making sure that the bevel is on the

side away from the crankcase (photo).

47 Refit the crankshaft toothed pulley (photo).

Then the V-belt pulley can be refitted together

with its retaining nut and washer. Final

tightening of this nut can wait until the flywheel

has been fitted, when a 'gag' can be fitted to the

flywheel to hold the crankshaft whilst tightening

the nut - see Chapter 1, photo 23.2A.

Cylinder head and valve gear-reassembly

48 It is assumed that the valves will have

already been examined and renovated as

described in Chapter 1, Section 31. Follow the

procedure given in Chapter 1, Section 51 to

reassemble the valves, but note that new oil

seals should be fitted to this engine when the

valves have been inserted in the guides and

before the springs are fitted (photos).

49 Each tappet bucket contains a shim in the

head which is used to control the valve

clearance. Before assembling the buckets to

their valves, prise out each shim and take a note

of the thickness. This is etched on the lower face

of the shim and indicates the thickness in

millimetres to two decimal places. If the number

has worn off, use a micrometer to check the

shim thickness. Make a table showing each

valve by number and the thickness of shim on

assembly. Reassemble each shim to its bucket

and after lubricating with clean engine oil fit the

buckets to their respective valves (photos).

50 Lubricate the two camshaft bearings in the

cylinder head and carefully thread the camshaft

through the driving end hole and lower it onto its

bearings. The cams will rest on the tappet

buckets and the camshaft should now be turned

so that the two cams over No. 1 cylinder (driving

end) are pointing upwards (compression/firing

stroke). This is to reduce the bending load on

the camshaft as the two bearing halves are

being tightened down (photo).

51 Lubricate the camshaft bearing halves and fit

them to their respective studs in the head. Put

the steel bridge plates in position and fit the

washers and nuts (photo).

52 Tighten the four nuts a little at a time

Page 24 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

24/34

progressively until the bearing halves meet.

53 Oil the camshaft seal and carefully fit it with

its carrier and a new gasket to the cylinder head

(photo).

54 Position the drivebelt guard backplate over

the camshaft seal carrier and fit the three bolts

and washers (photo). 55 Tighten the three bolts

retaining the backplate and seal carrier. Torque

load the four camshaft bearing securing nuts to

the specified setting.

56 Fit the camshaft toothed driving pulley with its

bolt and washer. Leave the final tightening until

the drivebelt is fitted (photo).

57 Check the valve clearances; the camshaft

can be turned by a spanner on the pulley

retaining bolt. Readjust any clearance if

necessary, as described later in this Section.

58 Owing to the small clearance between a

piston at TDC and the open valves during

exhaust/inlet overlap, it is imperative to get the

crankshaft and camshaft in their correct related

positions before turning the engine after fitting

the cylinder head. If this relationship is out then

serious damage could be done to the valves or

pistons by turning the crankshaft, as the pistons

will impinge on the valve heads. To avoid this

the following sequence should be observed. Set

the crankshaft as described in paragraph 59,

and the camshaft (before assembling the

cylinder head to the block) also as described in

paragraph 59. Fit the head to the block taking

care not to disturb the set positions and, finally,

fit the toothed drivebelt. Then the crankshaft can

be turned with no likelihood of damage.

59 Set the crankshaft by using a spanner on the

pulley retaining nut and aligning the mark on the

pulley with the long pointer on the timing

indicator bracket. Then set the camshaft by

aligning the hole in the camshaft pulley with the

cast ridge on the top of the camshaft seal carrier

just behind the toothed pulley (photo).

60 Fit a new cylinder head gasket with the word

ALTO upwards (photo). Do not use grease or

any other jointing compound. 61 Taking care not

to disturb the crankshaft or camshaft lower the

cylinder head onto the block (photo).

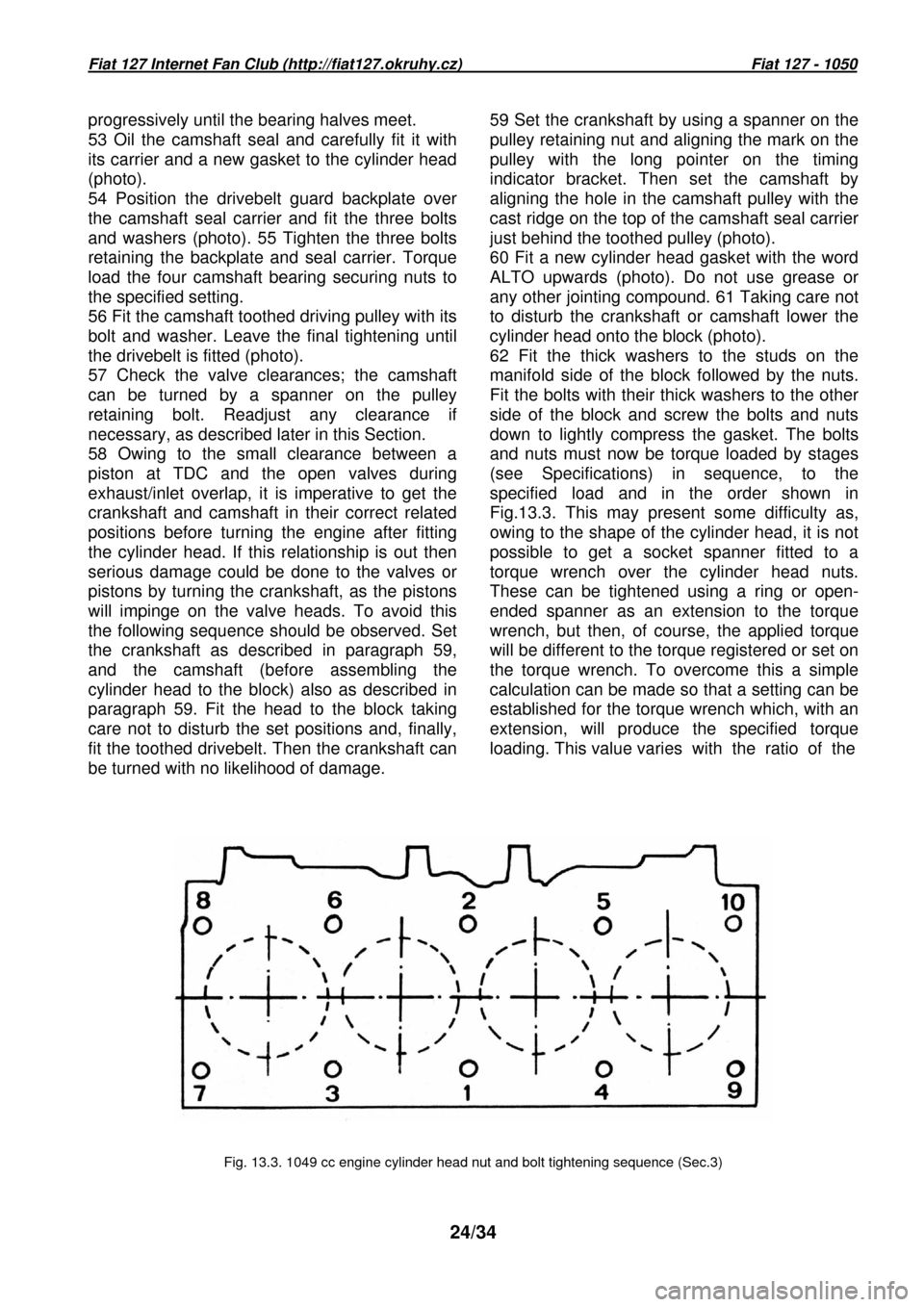

62 Fit the thick washers to the studs on the

manifold side of the block followed by the nuts.

Fit the bolts with their thick washers to the other

side of the block and screw the bolts and nuts

down to lightly compress the gasket. The bolts

and nuts must now be torque loaded by stages

(see Specifications) in sequence, to the

specified load and in the order shown in

Fig.13.3. This may present some difficulty as,

owing to the shape of the cylinder head, it is not

possible to get a socket spanner fitted to a

torque wrench over the cylinder head nuts.

These can be tightened using a ring or open-

ended spanner as an extension to the torque

wrench, but then, of course, the applied torque

will be different to the torque registered or set o n

the torque wrench. To overcome this a simple

calculation can be made so that a setting can be

established for the torque wrench which, with an

extension, will produce the specified torque

loading. This value varies with the ratio of t he

Fig. 13.3. 1049 cc engine cylinder head nut and bol t tightening sequence (Sec.3)

Page 25 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

25/34

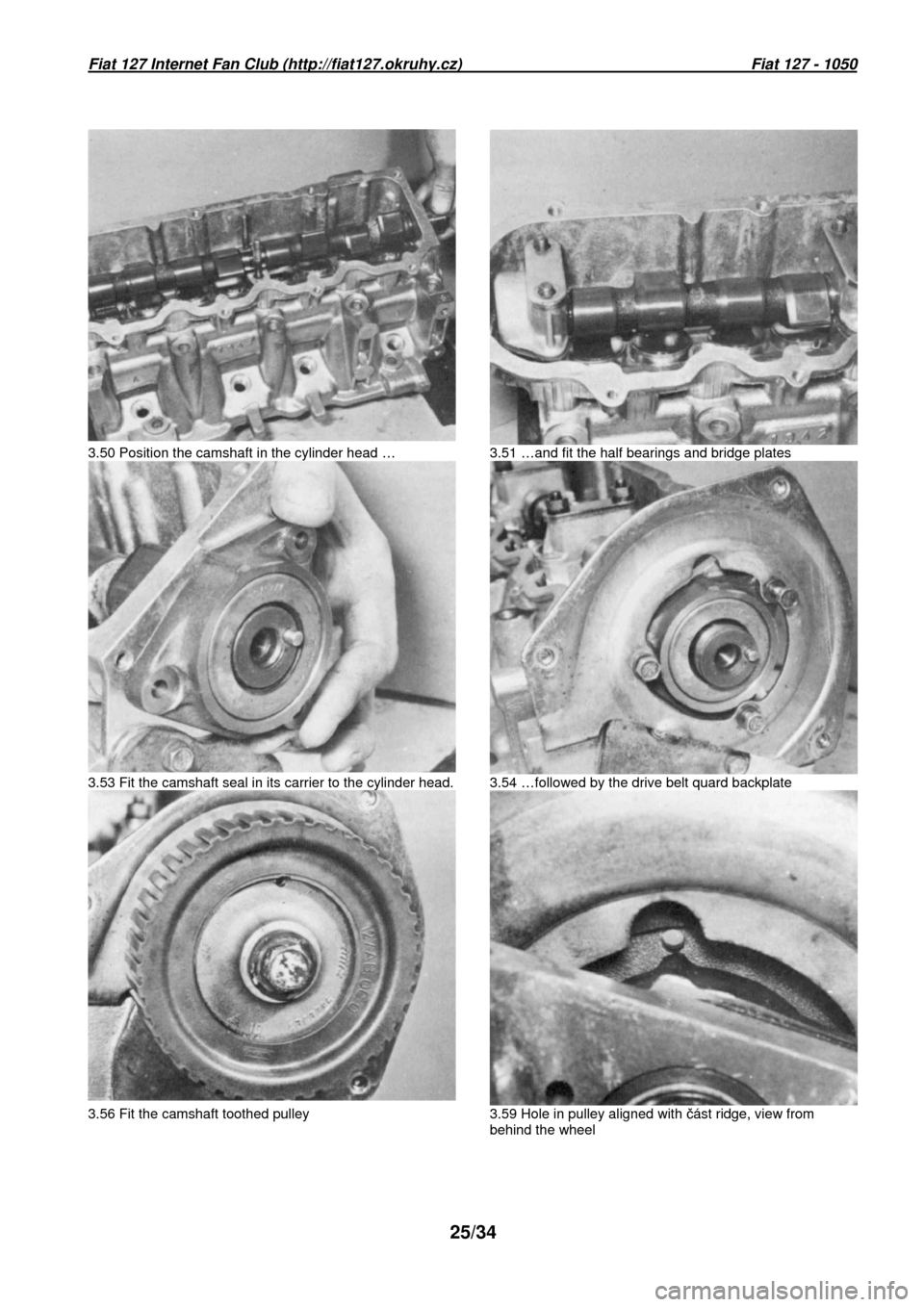

3.50 Position the camshaft in the cylinder head … 3.51 …and fit the half bearings and bridge plates

3.53 Fit the camshaft seal in its carrier to the cylinder head. 3.54 …followed by the drive belt quard backplate

3.56 Fit the camshaft toothed pulley 3.59 Hole in pulley aligned with �ást ridge, view from

behind the wheel

Page 26 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

26/34

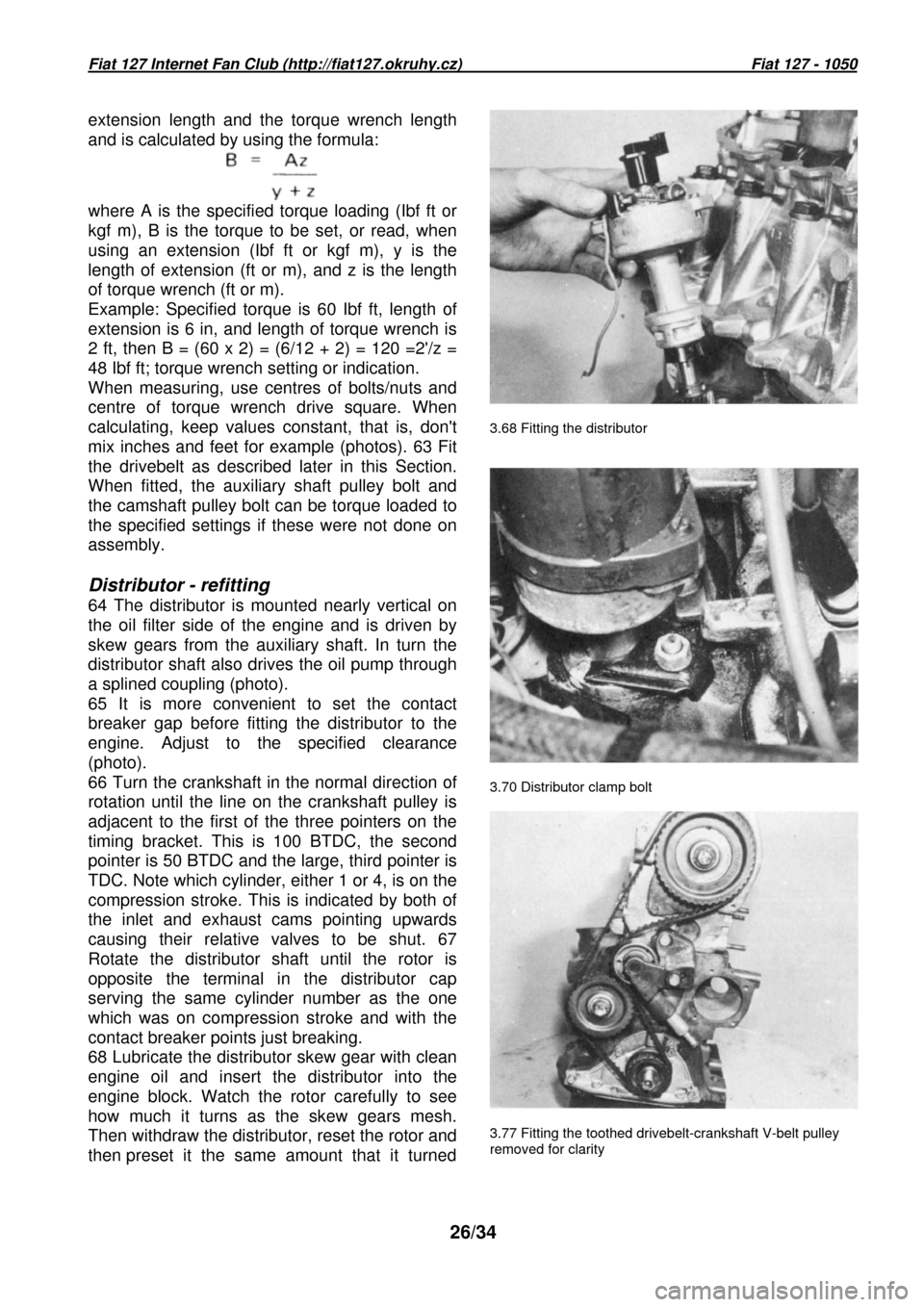

3.68 Fitting the distributor

3.70 Distributor clamp bolt

extension length and the torque wrench length

and is calculated by using the formula:

where A is the specified torque loading (Ibf ft or

kgf m), B is the torque to be set, or read, when

using an extension (Ibf ft or kgf m), y is the

length of extension (ft or m), and z is the length

of torque wrench (ft or m).

Example: Specified torque is 60 Ibf ft, length of

extension is 6 in, and length of torque wrench is

2 ft, then B = (60 x 2) = (6/12 + 2) = 120 =2'/z =

48 Ibf ft; torque wrench setting or indication.

When measuring, use centres of bolts/nuts and

centre of torque wrench drive square. When

calculating, keep values constant, that is, don't

mix inches and feet for example (photos). 63 Fit

the drivebelt as described later in this Section.

When fitted, the auxiliary shaft pulley bolt and

the camshaft pulley bolt can be torque loaded to

the specified settings if these were not done on

assembly.

Distributor - refitting

64 The distributor is mounted nearly vertical on

the oil filter side of the engine and is driven by

skew gears from the auxiliary shaft. In turn the

distributor shaft also drives the oil pump through

a splined coupling (photo).

65 It is more convenient to set the contact

breaker gap before fitting the distributor to the

engine. Adjust to the specified clearance

(photo).

66 Turn the crankshaft in the normal direction of

rotation until the line on the crankshaft pulley is

adjacent to the first of the three pointers on the

timing bracket. This is 100 BTDC, the second

pointer is 50 BTDC and the large, third pointer is

TDC. Note which cylinder, either 1 or 4, is on the

compression stroke. This is indicated by both of

the inlet and exhaust cams pointing upwards

causing their relative valves to be shut. 67

Rotate the distributor shaft until the rotor is

opposite the terminal in the distributor cap

serving the same cylinder number as the one

which was on compression stroke and with the

contact breaker points just breaking.

68 Lubricate the distributor skew gear with clean

engine oil and insert the distributor into the

engine block. Watch the rotor carefully to see

how much it turns as the skew gears mesh.

Then withdraw the distributor, reset the rotor and

then preset it the same amount that it turne d

3.77 Fitting the toothed drivebelt-crankshaft V-bel t pulley

removed for clarity

Page 27 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

27/34

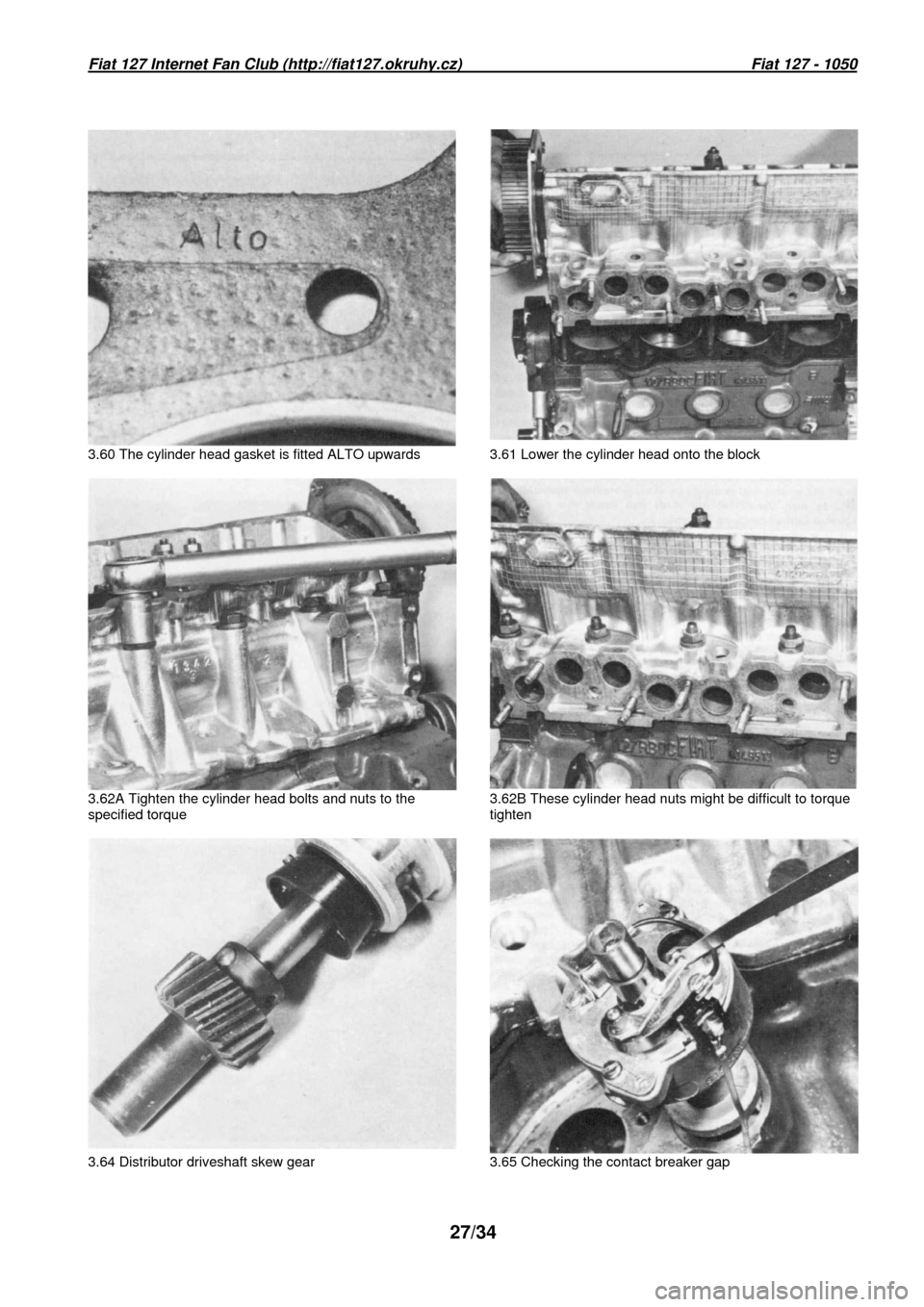

3.60 The cylinder head gasket is fitted ALTO upward s 3.61 Lower the cylinder head onto the block

3.62A Tighten the cylinder head bolts and nuts to t he

specified torque 3.62B These cylinder head nuts might be difficult

to torque

tighten

3.64 Distributor driveshaft skew gear 3.65 Checkin g the contact breaker gap

Page 28 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

28/34

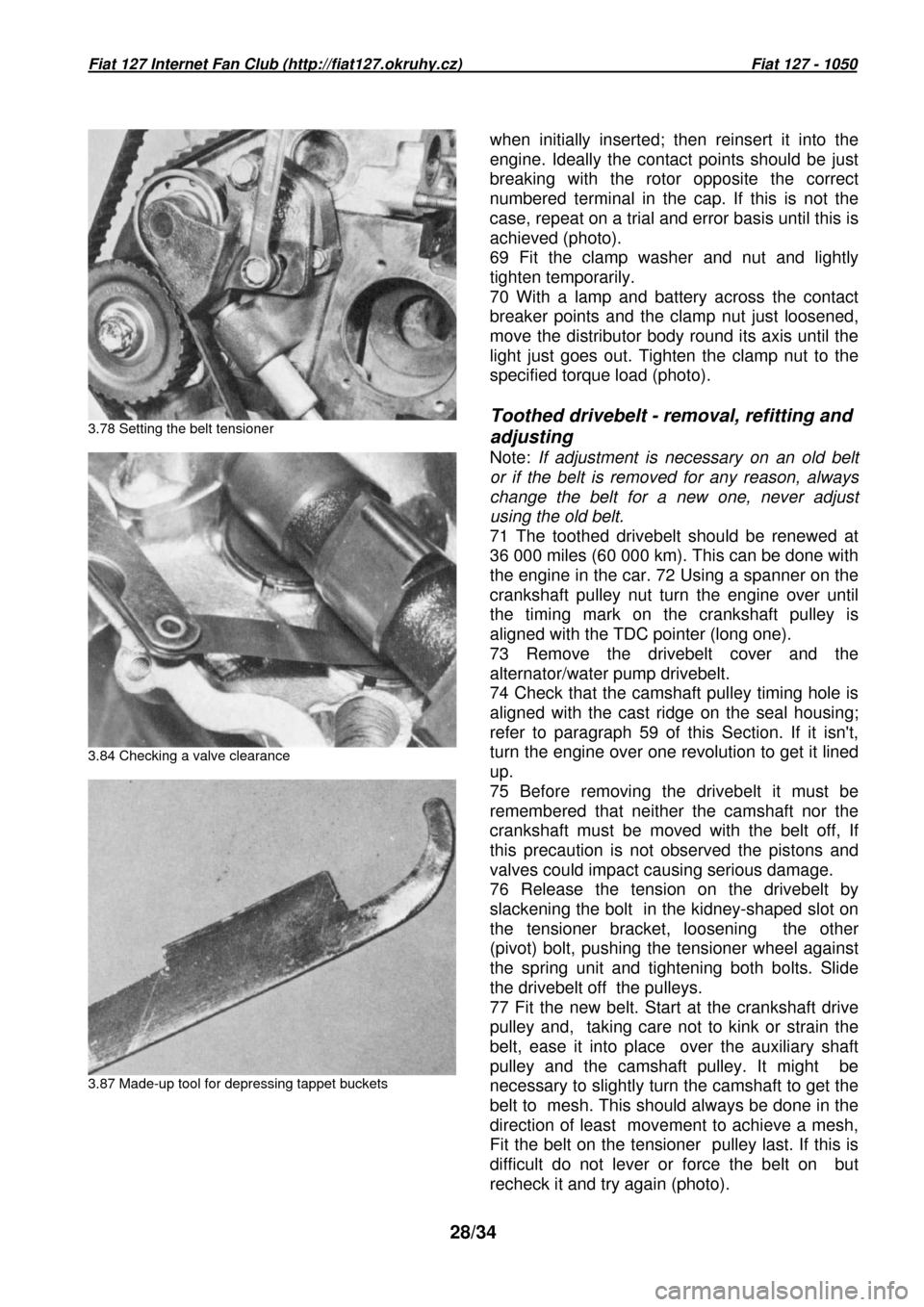

3.78 Setting the belt tensioner

3.84 Checking a valve clearance

3.87 Made-up tool for depressing tappet buckets

when initially inserted; then reinsert it into the

engine. Ideally the contact points should be just

breaking with the rotor opposite the correct

numbered terminal in the cap. If this is not the

case, repeat on a trial and error basis until this

is

achieved (photo).

69 Fit the clamp washer and nut and lightly

tighten temporarily.

70 With a lamp and battery across the contact

breaker points and the clamp nut just loosened,

move the distributor body round its axis until the

light just goes out. Tighten the clamp nut to the

specified torque load (photo).

Toothed drivebelt - removal, refitting and

adjusting

Note: If adjustment is necessary on an old belt

or if the belt is removed for any reason, always

change the belt for a new one, never adjust

using the old belt.

71 The toothed drivebelt should be renewed at

36 000 miles (60 000 km). This can be done with

the engine in the car. 72 Using a spanner on the

crankshaft pulley nut turn the engine over until

the timing mark on the crankshaft pulley is

aligned with the TDC pointer (long one).

73 Remove the drivebelt cover and the

alternator/water pump drivebelt.

74 Check that the camshaft pulley timing hole is

aligned with the cast ridge on the seal housing;

refer to paragraph 59 of this Section. If it isn't,

turn the engine over one revolution to get it lined

up.

75 Before removing the drivebelt it must be

remembered that neither the camshaft nor the

crankshaft must be moved with the belt off, If

this precaution is not observed the pistons and

valves could impact causing serious damage.

76 Release the tension on the drivebelt by

slackening the bolt in the kidney-shaped slot on

the tensioner bracket, loosening the other

(pivot) bolt, pushing the tensioner wheel against

the spring unit and tightening both bolts. Slide

the drivebelt off the pulleys.

77 Fit the new belt. Start at the crankshaft drive

pulley and, taking care not to kink or strain the

belt, ease it into place over the auxiliary shaft

pulley and the camshaft pulley. It might be

necessary to slightly turn the camshaft to get the

belt to mesh. This should always be done in the

direction of least movement to achieve a mesh,

Fit the belt on the tensioner pulley last. If this is

difficult do not lever or force the belt on but

recheck it and try again (photo).

Page 29 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

29/34

78 Slacken the tensioner bolts to tension the belt

and retighten the bolts (photo).

79 Turn the engine over for two complete

revolutions to even out belt tension. Then again

slacken the tensioner bolts to let the tensioner

take up any slack and

retighten the bolts. Never

turn the engine backwards or rock the camshaft

when tensioning the belt, as slack could develop

in the belt and it might jump a tooth.

80 Refit and tension the alternator/water pump

V-belt. Refit the drivebelt cover.

Valve clearances - adjustment

81 Checking the valve clearances should be

done at the 6000 miles servicing, or whenever

the cylinder head has been removed and

refitted for any reason. It is important that the

clearances are set correctly, otherwise the

timing will be wrong and the engine

performance will be poor. If there is no

clearance at all, the valves and seats will soon

get burnt. Set the clearances with the engine

cold.

82 Remove the camshaft cover. The engine can

be turned over by either using a spanner on the

crankshaft pulley nut, or by jacking up a front

wheel, engaging top gear and using the wheel

to turn the engine.

83 Each tappet must be checked when its

operating cam is pointing upwards, 1800 away

from the tappet. Check the clearances in the

firing order, No. 1 cylinder first and then 3, 4

and 2. Do the exhaust of one cylinder and the

inlet of the one after, at the same time to

minimise the amount of engine turning. Counting

from the timing belt end, exhaust valves are

1-4-5-8, inlet valves 2-3-6-7.

84 Insert the feeler gauge for the appropriate

valve. See the Specifications for correct

settings. The feeler should slide in readily

between cam and shim, but with slight frictional

drag. Try one a size thicker and one a size

thinner. The thick one should not go in and the

thinner one should be too loose (photo).

85 If the clearance is wrong, measure the

clearance and write it down with the number of

the valve. When all the clearances have been

checked, it will be necessary to remove those

shims which are fitted where the clearances are

wrong, and renew them with different thickness

shims. If a clearance is too big, use a thicker

shim. If a clearance is too small use a thinner

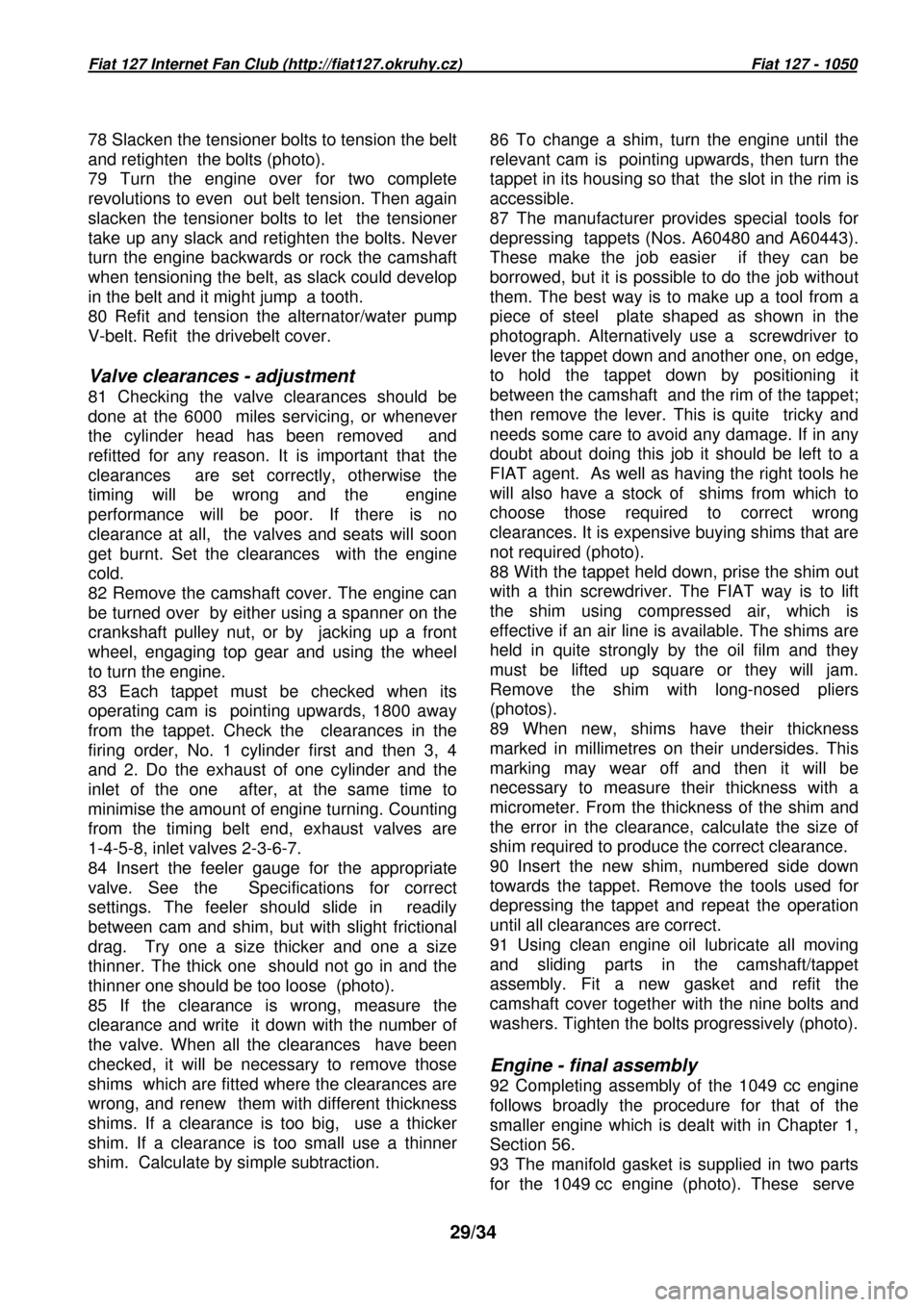

shim. Calculate by simple subtraction. 86 To change a shim, turn the engine until the

relevant cam is pointing upwards, then turn the

tappet in its housing so that the slot in the rim is

accessible.

87 The manufacturer provides special tools for

depressing tappets (Nos. A60480 and A60443).

These make the job easier if they can be

borrowed, but it is possible to do the job without

them. The best way is to make up a tool from a

piece of steel plate shaped as shown in the

photograph. Alternatively use a screwdriver to

lever the tappet down and another on

e, on edge,

to hold the tappet down by positioning it

between the camshaft and the rim of the tappet;

then remove the lever. This is quite tricky and

needs some care to avoid any damage. If in any

doubt about doing this job it should be left to a

FIAT agent. As well as having the right tools he

will also have a stock of shims from which to

choose those required to correct wrong

clearances. It is expensive buying shims that are

not required (photo).

88 With the tappet held down, prise the shim out

with a thin screwdriver. The FIAT way is to lift

the shim using compressed air, which is

effective if an air line is available. The shims are

held in quite strongly by the oil film and they

must be lifted up square or they will jam.

Remove the shim with long-nosed pliers

(photos).

89 When new, shims have their thickness

marked in millimetres on their undersides. This

marking may wear off and then it will be

necessary to measure their thickness with a

micrometer. From the thickness of the shim and

the error in the clearance, calculate the size of

shim required to produce the correct clearance.

90 Insert the new shim, numbered side down

towards the tappet. Remove the tools used for

depressing the tappet and repeat the operation

until all clearances are correct.

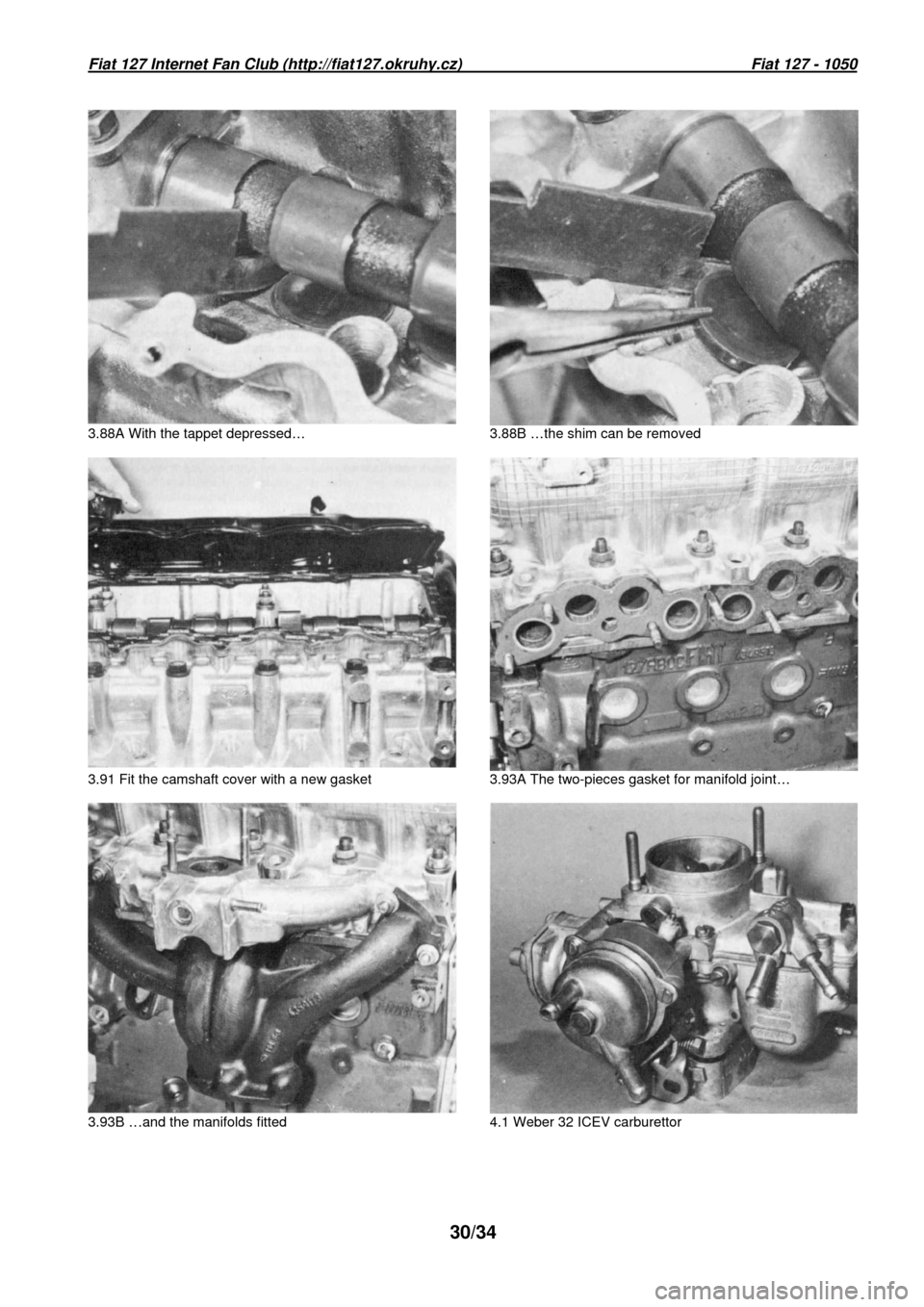

91 Using clean engine oil lubricate all moving

and sliding parts in the camshaft/tappet

assembly. Fit a new gasket and refit the

camshaft cover together with the nine bolts and

washers. Tighten the bolts progressively (photo).

Engine - final assembly

92 Completing assembly of the 1049 cc engine

follows broadly the procedure for that of the

smaller engine which is dealt with in Chapter 1,

Section 56.

93 The manifold gasket is supplied in two parts

for the 1049 cc engine (photo). These serve

Page 30 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

30/34

3.88A With the tappet depressed… 3.88B …the shim can be removed

3.91 Fit the camshaft cover with a new gasket 3.93A The two-pieces gasket for manifold joint…

3.93B …and the manifolds fitted 4.1 Weber 32 ICEV carburettor