wheel size FIAT 127 1972 1.G Workshop Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1972, Model line: 127, Model: FIAT 127 1972 1.GPages: 34, PDF Size: 6.87 MB

Page 6 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

6/34

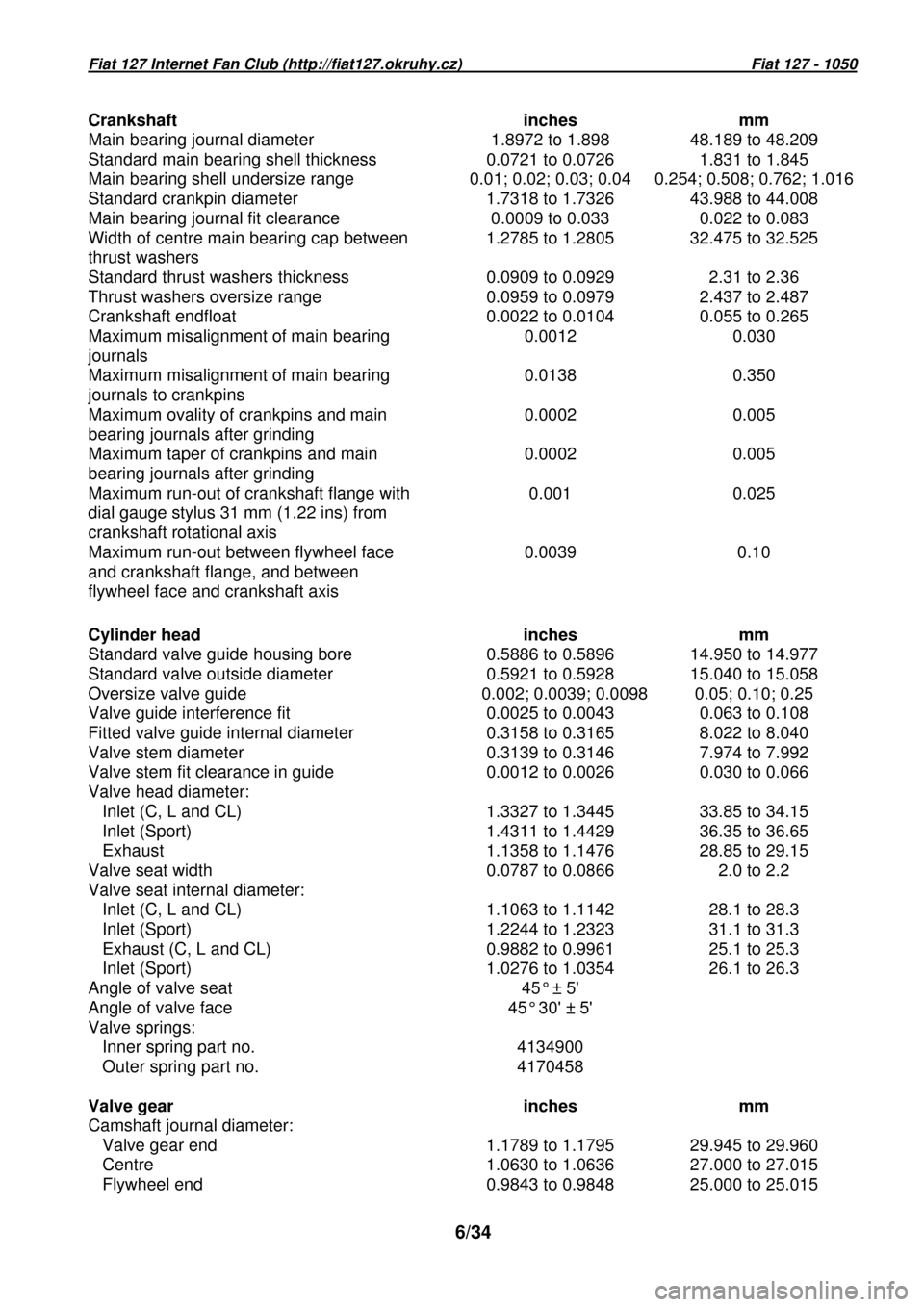

Crankshaft inches mm

Main bearing journal diameter 1.8972 to 1.898 48.1 89 to 48.209

Standard main bearing shell thickness 0.0721 to 0.0 726 1.831 to 1.845

Main bearing shell undersize range 0.01; 0.02; 0.03 ; 0.04 0.254; 0.508; 0.762; 1.016

Standard crankpin diameter 1.7318 to 1.7326 43.988 to 44.008

Main bearing journal fit clearance 0.0009 to 0.033 0.022 to 0.083

Width of centre main bearing cap between

thrust washers 1.2785 to 1.2805 32.475 to 32.525

Standard thrust washers thickness 0.0909 to 0.0929 2.31 to 2.36

Thrust washers oversize range 0.0959 to 0.0979 2.43 7 to 2.487

Crankshaft endfloat 0.0022 to 0.0104 0.055 to 0.265

Maximum misalignment of main bearing

journals 0.0012 0.030

Maximum misalignment of main bearing

journals to crankpins 0.0138 0.350

Maximum ovality of crankpins and main

bearing journals after grinding 0.0002 0.005

Maximum taper of crankpins and main

bearing journals after grinding 0.0002 0.005

Maximum run-out of crankshaft flange with

dial gauge stylus 31 mm (1.22 ins) from

crankshaft rotational axis 0.001 0.025

Maximum run-out between flywheel face

and crankshaft flange, and between

flywheel face and crankshaft axis 0.0039 0.10

Cylinder head inches mm

Standard valve guide housing bore 0.5886 to 0.5896 14.950 to 14.977

Standard valve outside diameter 0.5921 to 0.5928 15 .040 to 15.058

Oversize valve guide 0.002; 0.0039; 0.0098

0.05; 0.10; 0.25

Valve guide interference fit 0.0025 to 0.0043 0.063 to 0.108

Fitted valve guide internal diameter 0.3158 to 0.31 65 8.022 to 8.040

Valve stem diameter 0.3139 to 0.3146 7.974 to 7.992

Valve stem fit clearance in guide 0.0012 to 0.0026 0.030 to 0.066

Valve head diameter:

Inlet (C, L and CL) 1.3327 to 1.3445 33.85 to 34 .15

Inlet (Sport) 1.4311 to 1.4429 36.35 to 36.65

Exhaust 1.1358 to 1.1476 28.85 to 29.15

Valve seat width 0.0787 to 0.0866 2.0 to 2.2

Valve seat internal diameter:

Inlet (C, L and CL) 1.1063 to 1.1142 28.1 to 28. 3

Inlet (Sport) 1.2244 to 1.2323 31.1 to 31.3

Exhaust (C, L and CL) 0.9882 to 0.9961 25.1 to 2 5.3

Inlet (Sport) 1.0276 to 1.0354 26.1 to 26.3

Angle of valve seat 45° ± 5'

Angle of valve face 45° 30' ± 5'

Valve springs:

Inner spring part no. 4134900

Outer spring part no. 4170458

Valve gear inches mm

Camshaft journal diameter:

Valve gear end 1.1789 to 1.1795 29.945 to 29.96 0

Centre 1.0630 to 1.0636 27.000 to 27.015

Flywheel end 0.9843 to 0.9848 25.000 to 25.015

Page 10 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

10/34

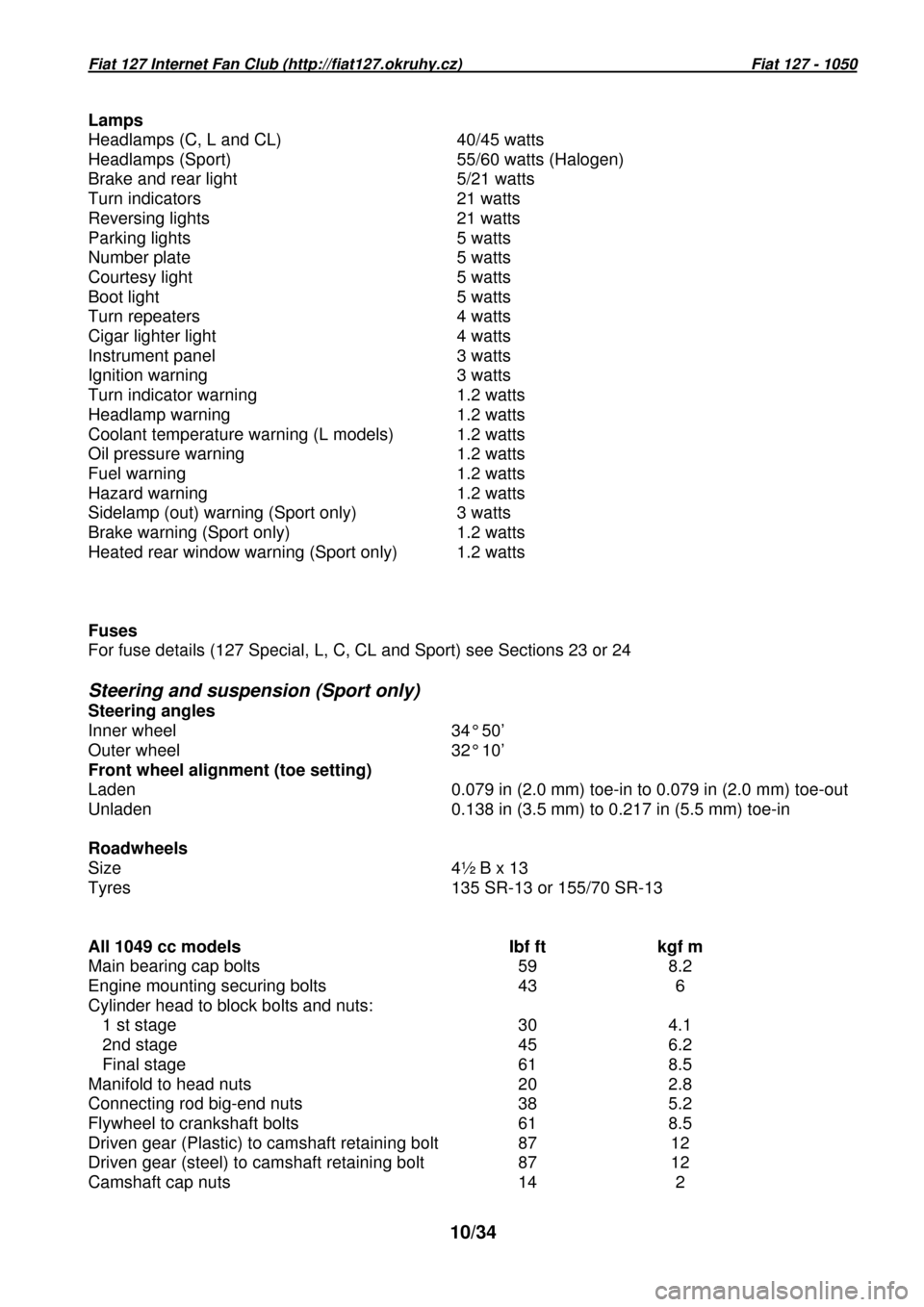

Lamps

Headlamps (C, L and CL)

Headlamps (Sport)

Brake and rear light

Turn indicators

Reversing lights

Parking lights

Number plate

Courtesy light

Boot light

Turn repeaters

Cigar lighter light

Instrument panel

Ignition warning

Turn indicator warning

Headlamp warning

Coolant temperature warning (L models)

Oil pressure warning

Fuel warning

Hazard warning

Sidelamp (out) warning (Sport only)

Brake warning (Sport only)

Heated rear window warning (Sport only)

40/45 watts

55/60 watts (Halogen)

5/21 watts

21 watts

21 watts

5 watts

5 watts

5 watts

5 watts

4 watts

4 watts

3 watts

3 watts

1.2 watts

1.2 watts

1.2 watts

1.2 watts

1.2 watts

1.2 watts

3 watts

1.2 watts

1.2 watts

Fuses

For fuse details (127 Special, L, C, CL and Sport) see Sections 23 or 24

Steering and suspension (Sport only)

Steering angles

Inner wheel 34° 50’

Outer wheel 32° 10’

Front wheel alignment (toe setting)

Laden 0.079 in (2.0 mm) toe-in to 0.079 in (2.0 mm) toe-o ut

Unladen 0.138 in (3.5 mm) to 0.217 in (5.5 mm) toe-in

Roadwheels

Size 4½ B x 13

Tyres 135 SR-13 or 155/70 SR-13

All 1049 cc models Ibf ft kgf m

Main bearing cap bolts 59 8.2

Engine mounting securing bolts 43 6

Cylinder head to block bolts and nuts:

1 st stage 30 4.1

2nd stage 45 6.2

Final stage 61 8.5

Manifold to head nuts 20 2.8

Connecting rod big-end nuts 38 5.2

Flywheel to crankshaft bolts 61 8.5

Driven gear (Plastic) to camshaft retaining bolt 87 12

Driven gear (steel) to camshaft retaining bolt 87 1 2

Camshaft cap nuts 14 2

Page 29 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

29/34

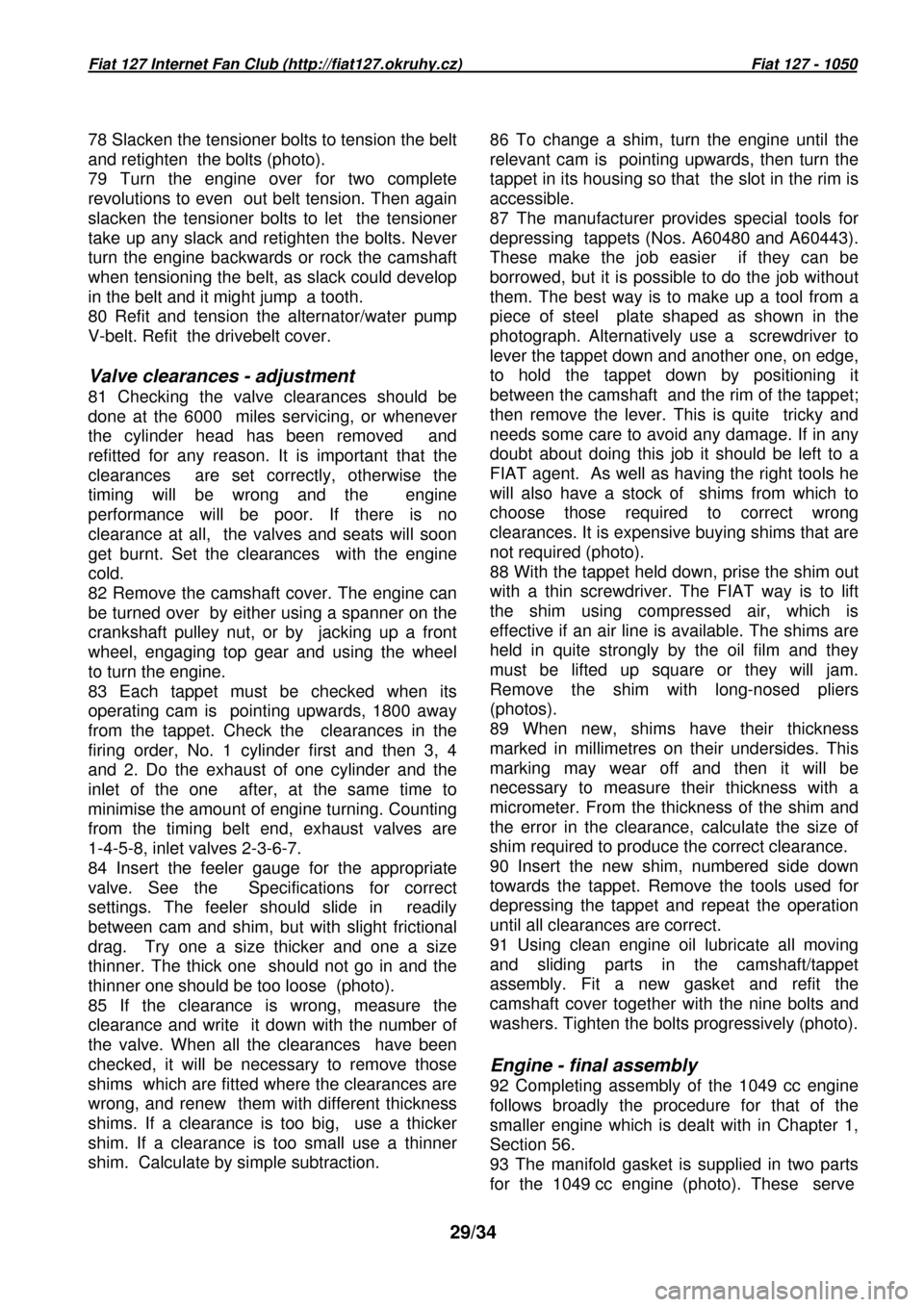

78 Slacken the tensioner bolts to tension the belt

and retighten the bolts (photo).

79 Turn the engine over for two complete

revolutions to even out belt tension. Then again

slacken the tensioner bolts to let the tensioner

take up any slack and

retighten the bolts. Never

turn the engine backwards or rock the camshaft

when tensioning the belt, as slack could develop

in the belt and it might jump a tooth.

80 Refit and tension the alternator/water pump

V-belt. Refit the drivebelt cover.

Valve clearances - adjustment

81 Checking the valve clearances should be

done at the 6000 miles servicing, or whenever

the cylinder head has been removed and

refitted for any reason. It is important that the

clearances are set correctly, otherwise the

timing will be wrong and the engine

performance will be poor. If there is no

clearance at all, the valves and seats will soon

get burnt. Set the clearances with the engine

cold.

82 Remove the camshaft cover. The engine can

be turned over by either using a spanner on the

crankshaft pulley nut, or by jacking up a front

wheel, engaging top gear and using the wheel

to turn the engine.

83 Each tappet must be checked when its

operating cam is pointing upwards, 1800 away

from the tappet. Check the clearances in the

firing order, No. 1 cylinder first and then 3, 4

and 2. Do the exhaust of one cylinder and the

inlet of the one after, at the same time to

minimise the amount of engine turning. Counting

from the timing belt end, exhaust valves are

1-4-5-8, inlet valves 2-3-6-7.

84 Insert the feeler gauge for the appropriate

valve. See the Specifications for correct

settings. The feeler should slide in readily

between cam and shim, but with slight frictional

drag. Try one a size thicker and one a size

thinner. The thick one should not go in and the

thinner one should be too loose (photo).

85 If the clearance is wrong, measure the

clearance and write it down with the number of

the valve. When all the clearances have been

checked, it will be necessary to remove those

shims which are fitted where the clearances are

wrong, and renew them with different thickness

shims. If a clearance is too big, use a thicker

shim. If a clearance is too small use a thinner

shim. Calculate by simple subtraction. 86 To change a shim, turn the engine until the

relevant cam is pointing upwards, then turn the

tappet in its housing so that the slot in the rim is

accessible.

87 The manufacturer provides special tools for

depressing tappets (Nos. A60480 and A60443).

These make the job easier if they can be

borrowed, but it is possible to do the job without

them. The best way is to make up a tool from a

piece of steel plate shaped as shown in the

photograph. Alternatively use a screwdriver to

lever the tappet down and another on

e, on edge,

to hold the tappet down by positioning it

between the camshaft and the rim of the tappet;

then remove the lever. This is quite tricky and

needs some care to avoid any damage. If in any

doubt about doing this job it should be left to a

FIAT agent. As well as having the right tools he

will also have a stock of shims from which to

choose those required to correct wrong

clearances. It is expensive buying shims that are

not required (photo).

88 With the tappet held down, prise the shim out

with a thin screwdriver. The FIAT way is to lift

the shim using compressed air, which is

effective if an air line is available. The shims are

held in quite strongly by the oil film and they

must be lifted up square or they will jam.

Remove the shim with long-nosed pliers

(photos).

89 When new, shims have their thickness

marked in millimetres on their undersides. This

marking may wear off and then it will be

necessary to measure their thickness with a

micrometer. From the thickness of the shim and

the error in the clearance, calculate the size of

shim required to produce the correct clearance.

90 Insert the new shim, numbered side down

towards the tappet. Remove the tools used for

depressing the tappet and repeat the operation

until all clearances are correct.

91 Using clean engine oil lubricate all moving

and sliding parts in the camshaft/tappet

assembly. Fit a new gasket and refit the

camshaft cover together with the nine bolts and

washers. Tighten the bolts progressively (photo).

Engine - final assembly

92 Completing assembly of the 1049 cc engine

follows broadly the procedure for that of the

smaller engine which is dealt with in Chapter 1,

Section 56.

93 The manifold gasket is supplied in two parts

for the 1049 cc engine (photo). These serve