FIAT 127 1973 1.G User Guide

Manufacturer: FIAT, Model Year: 1973, Model line: 127, Model: FIAT 127 1973 1.GPages: 34, PDF Size: 6.87 MB

Page 11 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

11/34

Ignition distributor clamp nut 11 1.5

Oil pump to crankcase bolts 13 1.8

Cylinder head outlet pipe bolt 16 2.2

Water pump/alternator drive pulley nut 101 14

Alternator bracket to crankcase bolt 20 2.8

Alternator to lower bracket bolt 36 5

Cylinder head upper bracket bolt 20 2.8

Alternator to upper bracket nut 36 5

Upper bracket securing bolt 13 1.8

Oil pressure switch 24 3.3

Coolant temperature switch 36 5

Spark plug 27 3.8

Sport models only

Engine

Flexible mounting to body (engine side) 65 9.0

Flexible mounting support (engine side to body)

18 2.5

Flexible mounting upper support to gearbox 18 2.5

Engine crossmember to body 18 2.5

Flexible mounting support nut (gearbox side) 18 2.5

Flexible mounting support bolt to body

(gearbox LH side) 65 9.0

Steering and suspension

Steering wheel retaining nut 22 3.0

Front wheel bearing ring nut 44 6.0

Front wheel hub nut 160 22.0

Roadwheel bolts 64 8.8

Front suspension track control arm to body 20 2.7

Front suspension balljoint to hub carrier 40 5.5

Rear wheel hub nut 160 22

Transmission

Starter motor bolt to bellhousing lower support 18 2.5

Gear selector shaft nut 18 2.5

Upper gear lever relay lever 22 3.0

Idler support securing nut 18 2.5

Differential case flange to gearbox housing 18 2.5

Page 12 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

12/34

3. Engine

1049 cc engine - general

1 This engine is of overhead camshaft design,

using shims for valve clearance adjustment. The

crankshaft is supported in five main bearings,

the centre one incorporating the thrust washers

which control crankshaft endfloat.

2 An auxiliary shaft, driven by the toothed

camshaft belt, is used to drive the distributor and

the fuel pump. 3 Most major engine components

can be removed while the engine is in the car,

but operations on the crankshaft, main bearings

and flywheel can only be carried out after the

engine has been removed.

4 Engine removal and subsequent dismantling

follows closely the information given for the

overhead valve engine in Chapter 1, but the

following sequence for complete engine

dismantling is recommended:

(a) Engine ancillaries (alternator, fuel pump, distributor)

(b) Timing belt cover

(c) Water pump

(d) Timing belt tensioner and belt

(e) Manifolds

(f) Cylinder head complete with camshaft

(g) Crankshaft pulley

(h) Auxiliary shaft sprocket

(i) Sump

(j) Oil pump and auxiliary shaft

(k) Connecting rods and pistons

(l) Flywheel and crankshaft oil seal carriers

(m) Crankshaft and main bearings

5 If the cylinder head is to be dismantled, before

withdrawing the camshaft, have a suitably divided

container ready so that the valve clearance

adjusting shims can be extracted and kept in strict

originally installed order together with their

appropriate valves, springs etc.

6 All engine parts must be thoroughly cleaned

and examined as explained in Chapter 1. Where

required, all defective parts should be renewed

before reassembly starts.

Crankshaft – refitting

7 Fit the main bearing shells to their seats in the

crankcase after making sure that both shells and

seats are spotlessly clean and dry (photos).

8 With a light smear of grease, fit the two half

thrust washers each side of the centre bearing

with the oil grooves in each washer facing away

from the bearing shell (photo).

9 Using clean engine oil lubricate the bearing

shells and crankshaft main bearing journals

(photo).

10 Carefully lower the crankshaft into its bearings

in the crankcase after making sure that it is the

right way round. Spin the shaft to distribute the o il

(photo).

11 Fit the clean and dry bearing shells to the main

bearing caps. Oil the bearing face and fit the

bearing caps to the crankcase. Make sure that

each cap is fitted to its own location by checking

the groove marks in the base, and that each cap

is the right way round. This is achieved when the

axial locating tags in each half bearing shell butt

on the same side (photos).

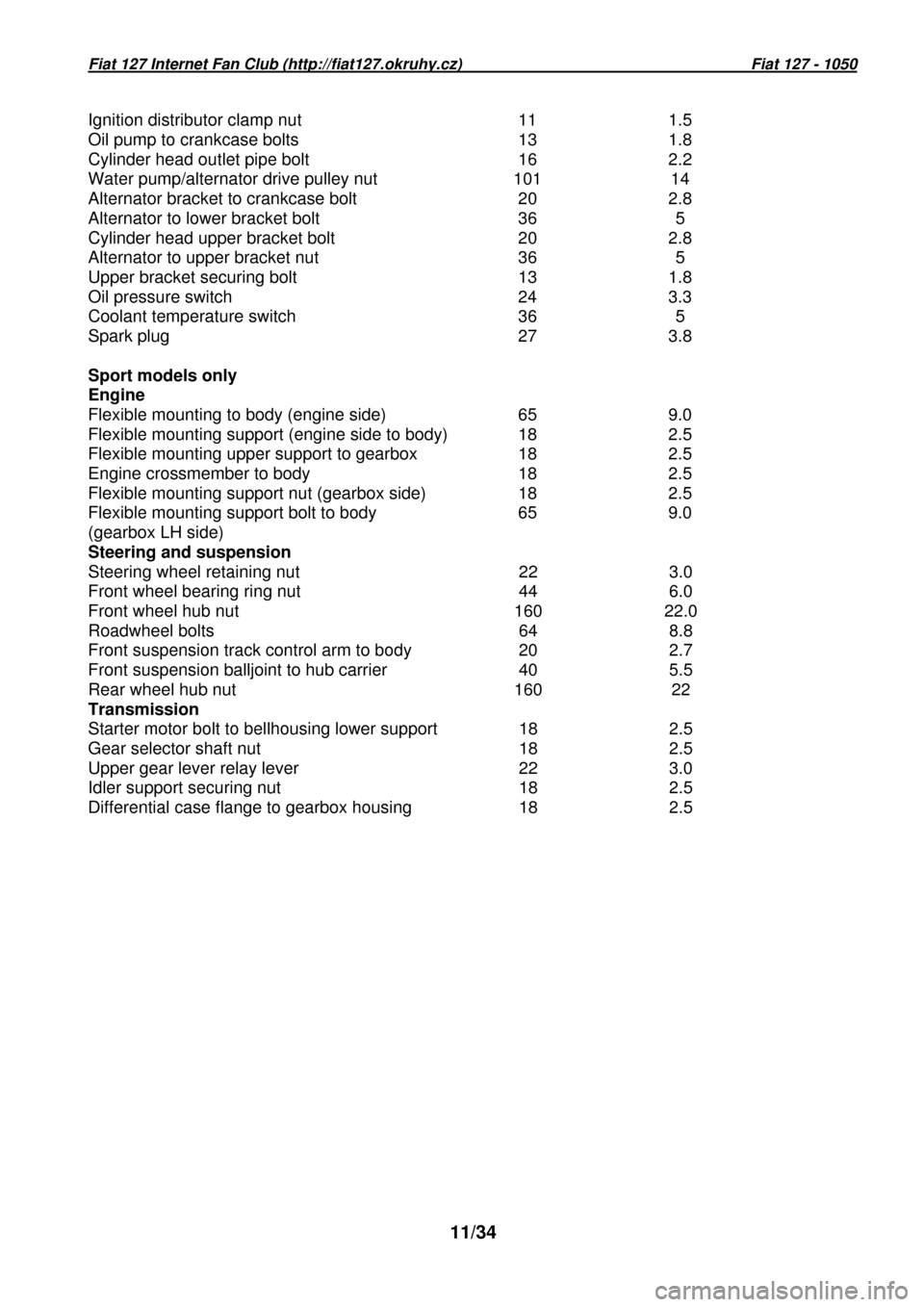

3.7A Thoroughly clean the bearing shells and seats

before

assembly 3.7B Note that central bearing shell has no oil gro ove but all

shell are axially located by an offset tag

Page 13 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

13/34

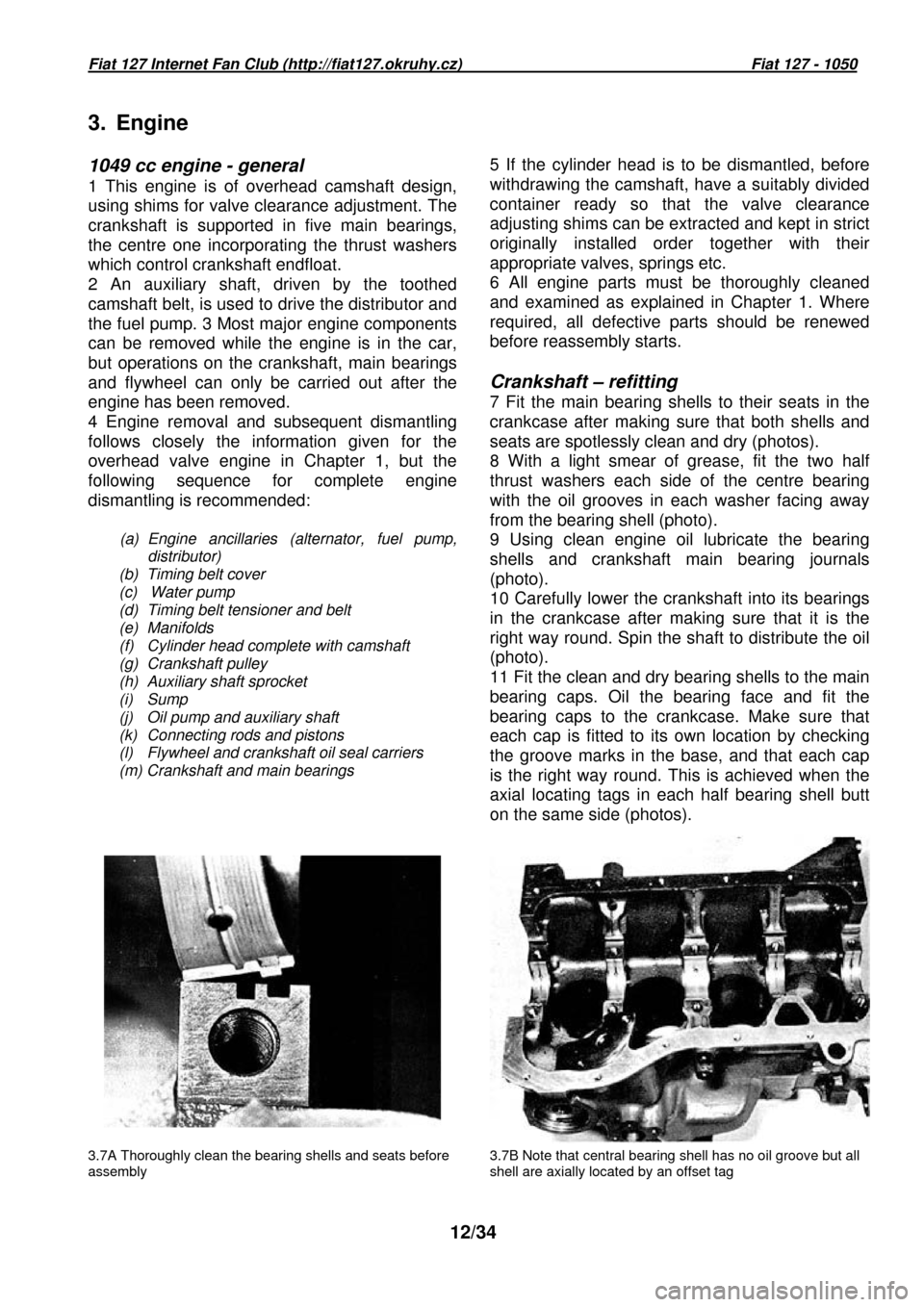

13.1. 1049 cc engine, longitudinal section (Sec.3 )

Page 14 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

14/34

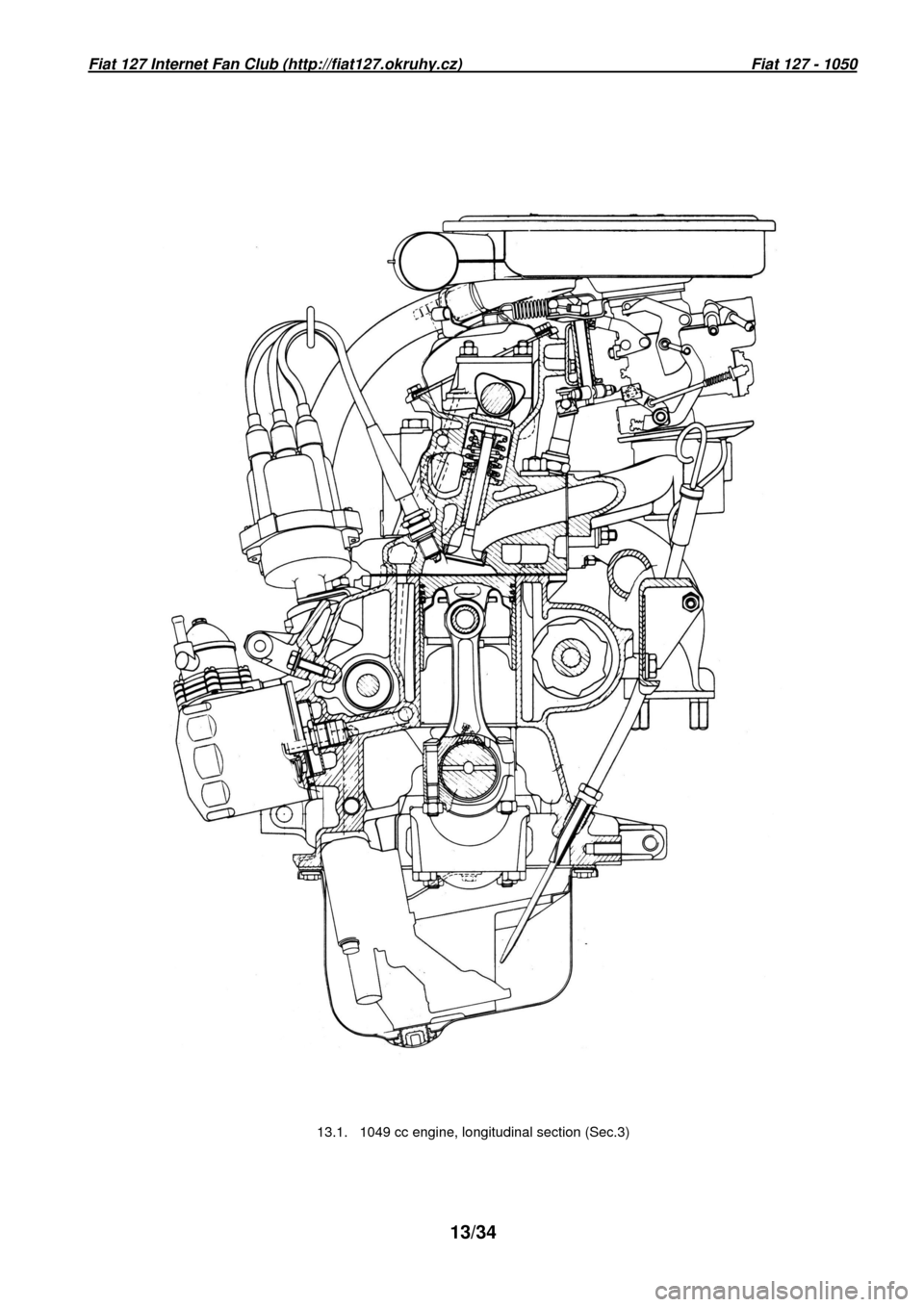

13.2. 1049 cc engine, cross section (Sec.3)

(The engine is installed inclined 6°rearwards)

Page 15 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

15/34

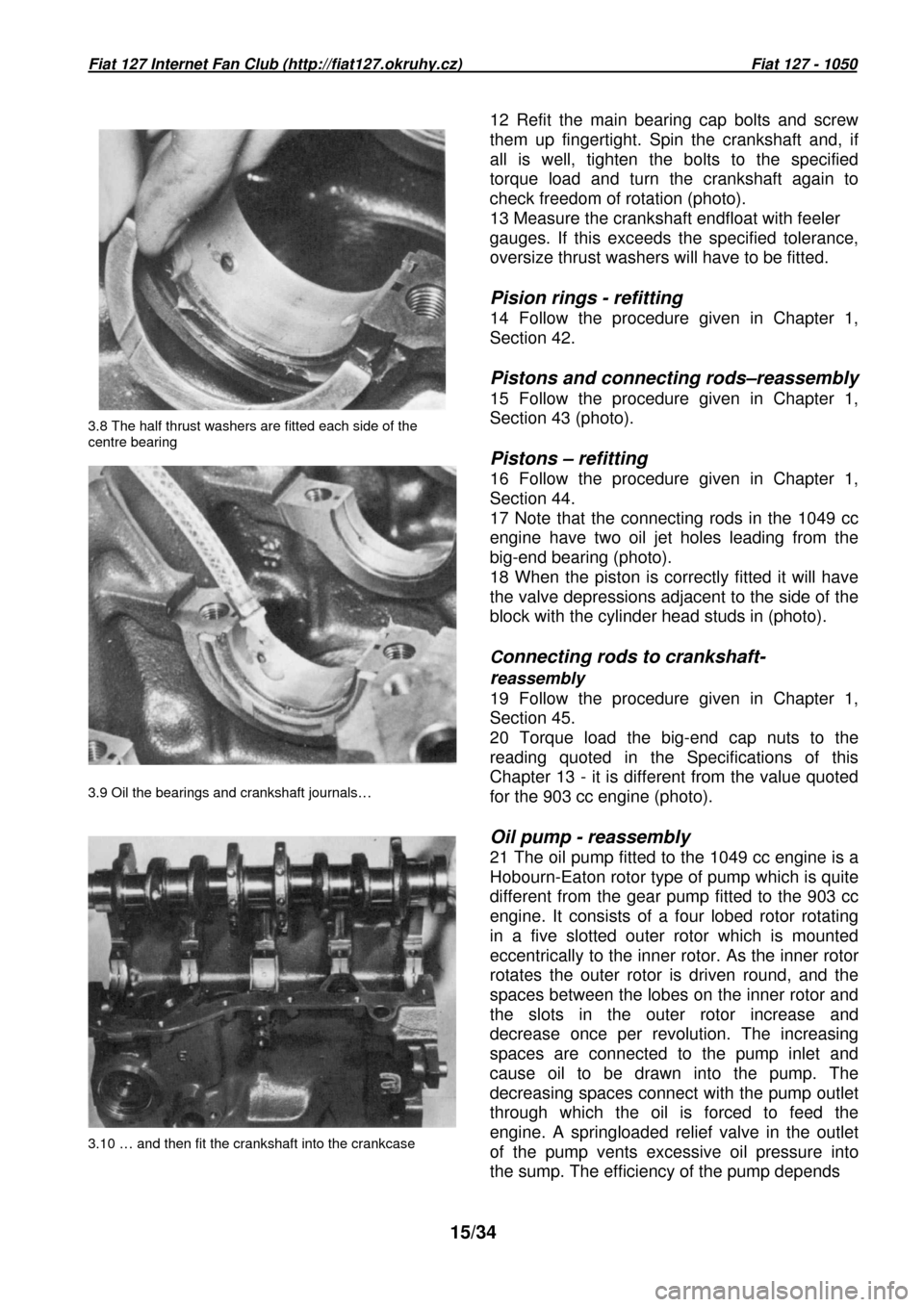

3.8 The half thrust washers are fitted each side of

the

centre bearing

3.9 Oil the bearings and crankshaft journals…

3.10 … and then fit the crankshaft into the crankca se 12 Refit the main bearing cap bolts and screw

them up fingertight. Spin the crankshaft and, if

all is well, tighten the bolts to the specified

torque load and turn the crankshaft again to

check freedom of rotation (photo).

13 Measure the crankshaft endfloat with feeler

gauges. If this exceeds the specified tolerance,

oversize thrust washers will have to be fitted.

Pision rings - refitting

14 Follow the procedure given in Chapter 1,

Section 42.

Pistons and connecting rods–reassembly

15 Follow the procedure given in Chapter 1,

Section 43 (photo).

Pistons – refitting

16 Follow the procedure given in Chapter 1,

Section 44.

17 Note that the connecting rods in the 1049 cc

engine have two oil jet holes leading from the

big-end bearing (photo).

18 When the piston is correctly fitted it will have

the valve depressions adjacent to the side of the

block with the cylinder head studs in (photo). C

onnecting rods to crankshaft-

r

eassembly

19 Follow the procedure given in Chapter 1,

Section 45.

20 Torque load the big-end cap nuts to the

reading quoted in the Specifications of this

Chapter 13 - it is different from the value quoted

for the 903 cc engine (photo).

Oil pump - reassembly

21 The oil pump fitted to the 1049 cc engine is a

Hobourn-Eaton rotor type of pump which is quite

different from the gear pump fitted to the 903 cc

engine. It consists of a four lobed rotor rotating

in a five slotted outer rotor which is mounted

eccentrically to the inner rotor. As the inner roto r

rotates the outer rotor is driven round, and the

spaces between the lobes on the inner rotor and

the slots in the outer rotor increase and

decrease once per revolution. The increasing

spaces are connected to the pump inlet and

cause oil to be drawn into the pump. The

decreasing spaces connect with the pump outlet

through which the oil is forced to feed the

engine. A springloaded relief valve in the outlet

of the pump vents excessive oil pressure into

the sump. The efficiency of the pump depends

Page 16 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

16/34

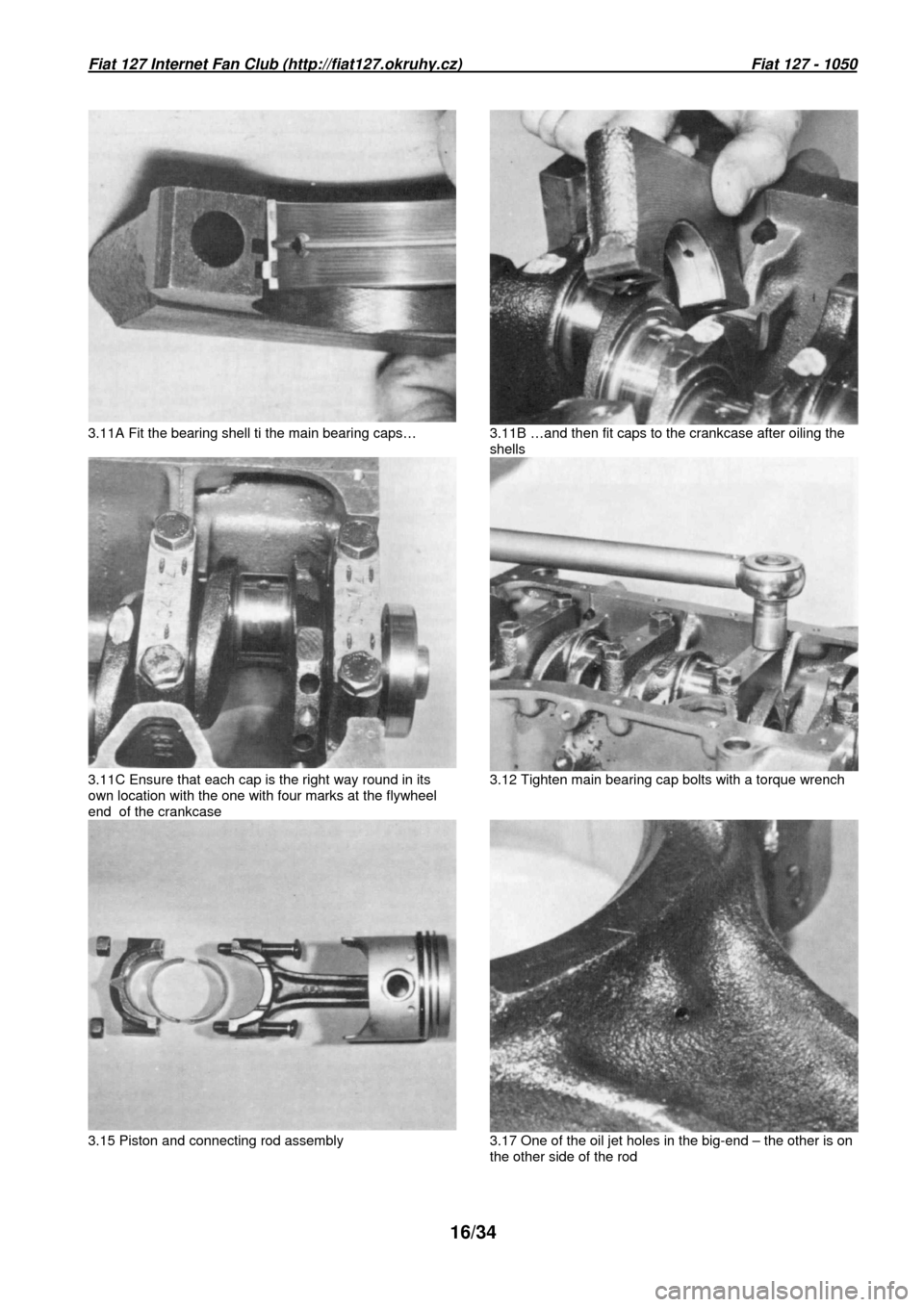

3.11A Fit the bearing shell ti the main bearing cap s… 3.11B …and then fit caps to the crankcase after oil ing the

shells

3.11C Ensure that each cap is the right way round i n its

own location with the one with four marks at the fl ywheel

end of the crankcase 3.12 Tighten main bearing cap bolts with a torque w rench

3.15 Piston and connecting rod assembly 3.17 One of the oil jet holes in the big-end – the other is on

the other side of the rod

Page 17 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

17/34

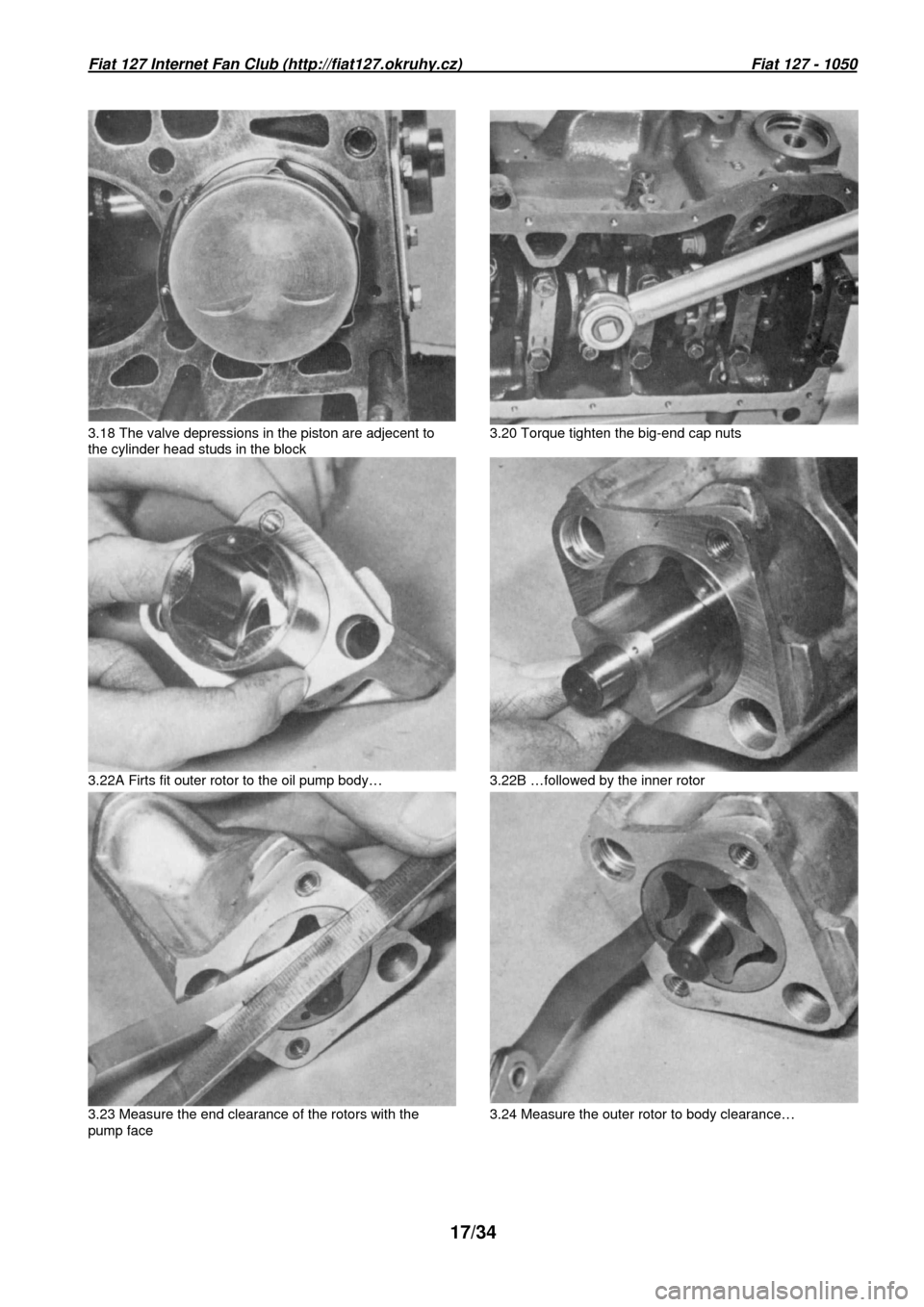

3.18 The valve depressions in the piston are adjece nt to

the cylinder head studs in the block 3.20 Torque tighten the big-end cap nuts

3.22A Firts fit outer rotor to the oil pump body… 3.22B …followed by the inner rotor

3.23 Measure the end clearance of the rotors with t he

pump face 3.24 Measure the outer rotor to body clearance…

Page 18 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

18/34

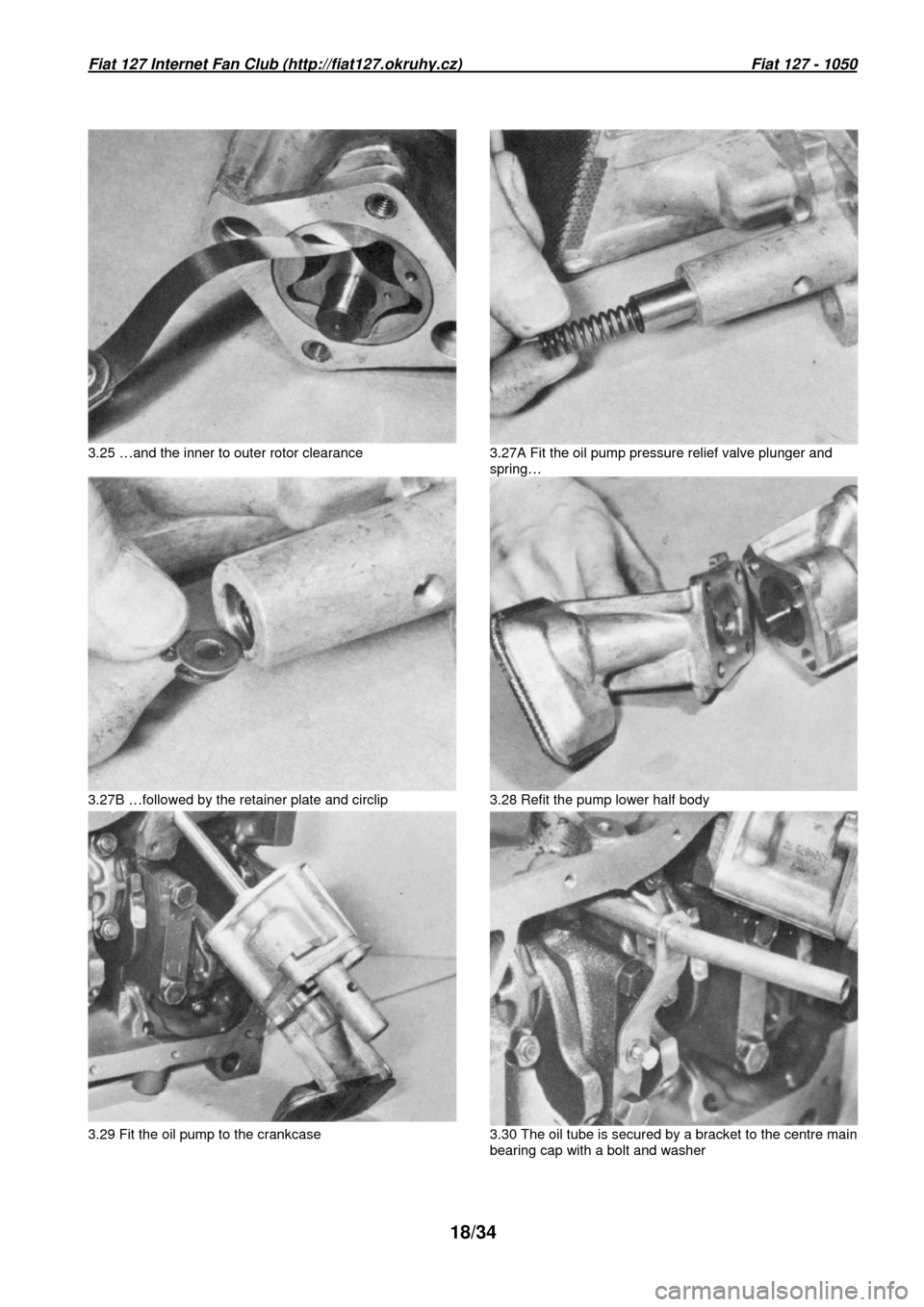

3.25 …and the inner to outer rotor clearance 3.27A Fit the oil pump pressure relief valve plunge r and

spring…

3.27B …followed by the retainer plate and circlip 3.28 Refit the pump lower half body

3.29 Fit the oil pump to the crankcase 3.30 The oil tube is secured by a bracket to the ce ntre main

bearing cap with a bolt and washer

Page 19 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

19/34

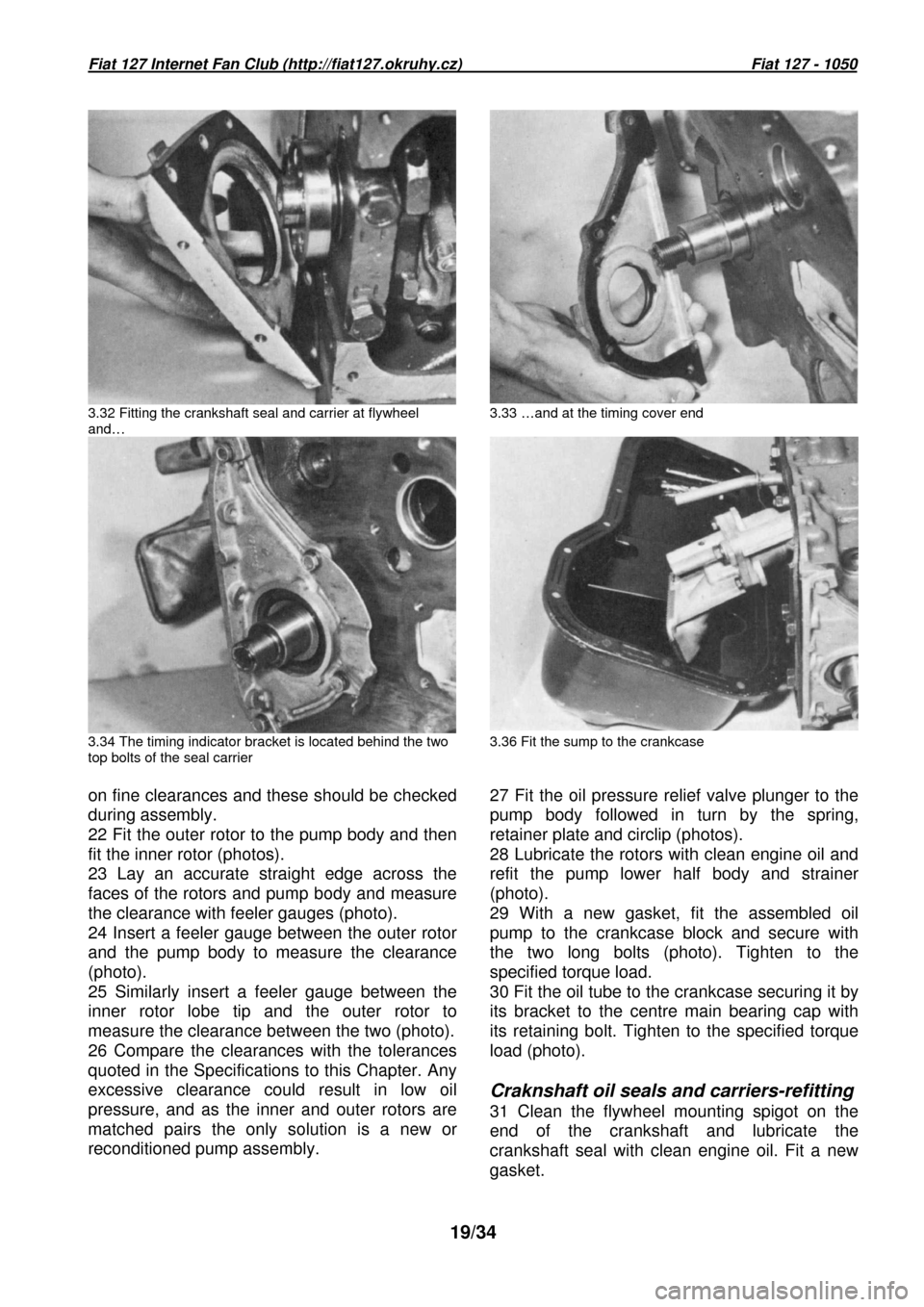

3.32 Fitting the crankshaft seal and carrier at fly wheel

and… 3.33 …and at the timing cover end

3.34 The timing indicator bracket is located behind the two

top bolts of the seal carrier 3.36 Fit the sump to the crankcase

on fine clearances and these should be checked

during assembly.

22 Fit the outer rotor to the pump body and then

fit the inner rotor (photos).

23 Lay an accurate straight edge across the

faces of the rotors and pump body and measure

the clearance with feeler gauges (photo).

24 Insert a feeler gauge between the outer rotor

and the pump body to measure the clearance

(photo).

25 Similarly insert a feeler gauge between the

inner rotor lobe tip and the outer rotor to

measure the clearance between the two (photo).

26 Compare the clearances with the tolerances

quoted in the Specifications to this Chapter. Any

excessive clearance could result in low oil

pressure, and as the inner and outer rotors are

matched pairs the only solution is a new or

reconditioned pump assembly. 27 Fit the oil pressure relief valve plunger to th

e

pump body followed in turn by the spring,

retainer plate and circlip (photos).

28 Lubricate the rotors with clean engine oil and

refit the pump lower half body and strainer

(photo).

29 With a new gasket, fit the assembled oil

pump to the crankcase block and secure with

the two long bolts (photo). Tighten to the

specified torque load.

30 Fit the oil tube to the crankcase securing it by

its bracket to the centre main bearing cap with

its retaining bolt. Tighten to the specified torque

load (photo).

Craknshaft oil seals and carriers-refitting

31 Clean the flywheel mounting spigot on the

end of the crankshaft and lubricate the

crankshaft seal with clean engine oil. Fit a new

gasket.

Page 20 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

20/34

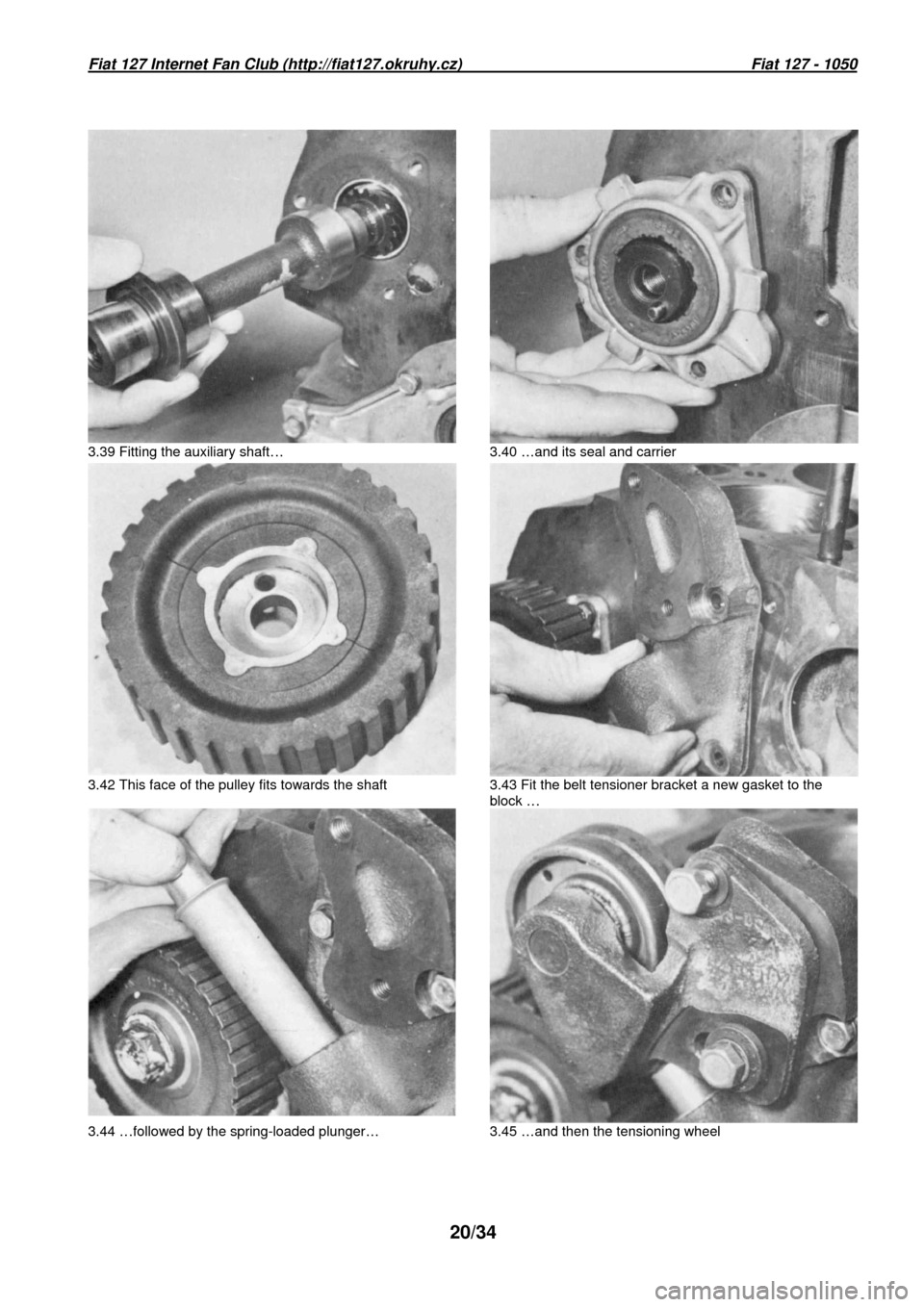

3.39 Fitting the auxiliary shaft… 3.40 …and its seal and carrier

3.42 This face of the pulley fits towards the shaft 3.43 Fit the belt tensioner bracket a new gasket to the

block …

3.44 …followed by the spring-loaded plunger… 3.45 …and then the tensioning wheel