fuel type FIAT 127 1973 1.G Workshop Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1973, Model line: 127, Model: FIAT 127 1973 1.GPages: 34, PDF Size: 6.87 MB

Page 4 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

4/34

2. Specifications

Capacities (1049 cc models )

Engine oil (including filter change)

L, C and CL ... ... ... ... ... ... ... ... … 5.5 pints (3.1 litres)

Sport ... ... ... ... ... ... ... ... ... 7.7 pi nts (4.4 litres)

Coolant ... ... ... ... ... ... ... ... … 9.7 pints (5.5 litres)

Fuel ... ... ... ... ... ... ... ... … 6.7 gallons (30 .5 litres) including 6.2 pints

(3.5 litres) reserve

Transmission oil ... … ... ... ... ... ... ... . 4.2 pints (2.4 l itres)

1049 cc OHC engine

General

Type number ... ... ... ... ... ... ... ... … 127 A 000 (C, L and CL);

127 A1.000 (Sport)

Bore ... ... ... ... ... ... ... ... … 2.992 in (76 mm)

Stroke ... ... ... ... ... ... ... ... ... 2.276 in (57.8 mm)

Capacity ... ... ... ... ... ... ... ... … 64 cu in (1049 cc)

Compression ratio ... ... ... ... ... … 9,3 : 1 (C, L and CL);

9,8 : 1 (Sport)

Maximum horsepower (DIN) ... ... ... ... 50 HP a t 5600 rpm (C, L and CL);

70 HP at 5600 rpm (Sport)

Valve mechanism C, L and CL Sport

Inlet :

Opens ... ... ... ... ... ... ... ... ... 2° B TDC 6° BTDC

Closes ... ... ... ... ... ... ... ... ... 42° ABDC 46°ABDC

Exhaust :

Opens ... ... ... ... ... ... ... ... ... 42° BBDC 47° BBDC

Closes ... ... ... ... ... ... ... … … 2° ATDC 7° ATDC

Valve clearances (cold) :

For checking valve timing:

Inlet ... ... ... ... ... ... ... ... 0.02 8 in (0.70 mm) 0.032 in (0.80 mm)

Exhaust ... ... ... ... ... ... ... 0.028 in (0.70 mm) 0.032 in (0.80 mm)

Adjustment for running (engine cold) :

Inlet ... ... ... ... ... ... ... ... 0.01 2 in (0.30 mm) 0.016 in (0.40 mm)

Exhaust ... ... ... ... ... ... ... 0.016 i n (0 40 mm) 0.020 in (0.50 mm)

Cylinder block and connecting rods inches mm

Cylinder bore diameter * 2.992 to 2.994 76.00 to 7 6.05

* Cylinder bores are graded and have a variation of 0.0004 inch (0.01 mm) between each grade

Main bearing housing bore diameter 2.044 to 2.045 51.921 to 51.934

Width of centre main bearing cap between

thrust washers 1.088 to 1.091 27.64 to 27.70

Connecting rod big-end diameter 1.85 to 1.8560 47. 130 to 47.142

Connecting rod small-end diameter 0.8638 to 0.8646 21.94 to 21.96

Big-end bearing shell thickness 0.0606 to 0.8646 1. 539 to 1.55

Page 7 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

7/34

Camshaft bearing bore diameter in head:

Valve gear end 1.1807 to 1.1817 29.990 to 30.015

Centre 1.0648 to 1.0657 27.045 to 27.070

Flywheel end 0.9860 to 0.9870 25.045 to 25.070

Camshaft journals fit clearance 0.0012 to 0.0028 0. 030 to 0.070

Cam lift (C, L and CL) 0.3425 8.700

Cam lift (Sport):

Inlet 0.3622 9.200

Exhaust 0.3642 9.250

Standard tappet bore diameter 1.4567 to 1.4577 37.0 00 to 37.025

Standard tappet outside diameter 1.4557 to 1.4565 36.975 to 36.995

Tappet fit clearance 0.0002 to 0.0020 0.005 to 0.05 0

Shim thickness 0.1279; 0.1299; then

0.0039 steps to 0.1850

3.2b; 3.30; then

0.10 steps to 4.70

Auxiliary shaft inches mm

Diameter of bush bores in crankcase:

Front 1.6339 to 1.6350 41.500 to 41.530

Rear 1.5733 to 1.5745 39.962 to 39.992

Fitted bush internal diameter:

Front 1.5143 to 1.5151 38.464 to 38.484

Rear 1.4553 to 1.4561 36.964 to 36.984

Diameter of shaft journals:

Front 1.5115 to 1.5125 38.393 to 38.418

Rear 1.4525 to 1.4535 36.893 to 36.918

Bush fit There must always be an interference fit

Shaft/bush fit clearance (front and rear) 0.0018 to 0.0036 0.046 to 0.091

Lubrication system

Oil pump Four lobe rotor type

Pump drive Through auxiliary shaft

Oil pressure relief valve Incorporated in pu mp

Pump rotors endfloat 0.0018 to 0.0047 0.045 to 0.120

Outer rotor to body clearance 0.0006 to 0.002 2 0.016 to 0.055

Inner to outer rotor clearance 0.0010 to 0.00 39 0.025 to 0.100

Oil pressure at 212°F (100°C) 50 to 70 Ibf/in

2 (3.5 to 5 kgf/cm2)

Cooling system

Radiator fan thermal switch

Cuts in . 194° to 201°F (90° to 94°C)

Cuts out 185° to 192°F (85° to 89°C)

Engine coolant thermostat

Starts to open 176° to 183°F (80° to 84°C)

Fully open 205°F (96°C)

Impellor vanes to pump body fit clearance 0.0315 to 0.0512 in (0.8 to 1.3 mm)

Radiator cap relief pressure 11.4 Ibf/in

2 (0.8 kgf/cm2)

Fuel system

Weber 32 ICEV 16/150 carburettor (C, L and CL model s)

Venturi diameter 0.8465 in (21.5 mm)

Main jet . 0.0453 in (1.15 mm)

Page 8 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

8/34

Air correction jet 0.0728 in (1.85 mm)

Slow running jet 0.0177 in (0.45 mm)

Emulsion tube type F74

Accelerator pump jet 0.0157 in (0.40 mm)

Needle valve seat 0.0591 in (1.50 mm)

Accelerator pump output (10 strokes) 2 to 3 cm

3

Cold starting device Automatic choke

Float level 1.4016 to 1.4213 in (35.6 to 36. 1 mm)

CO level 2.5%

Solex C32 TDI/4 carburettor (C, L and CL models)

Venturi diameter 0.8465 in (21.5 mm)

Main jet 0.0453 in (1.15 mm)

Air correction jet 0.0768 in (1.95 mm)

Slow running jet 0.0177 in (0.45 mm)

Emulsion tube type 71

Accelerator pump jet 0.0177 in (0.45 mm)

Needle valve seat 0.0630 in (1.60 mm)

Accelerator pump output I10 strokes) 3 to 5 cm

3

Cold starting device Automatic choke

Float level 0.8661 to 0.9449 in (22.0 to 24. 0 mm)

CO level 2.5%

Weber 34 DMTR 47/250 carburettor (Sport models) Primary venturi Secondary venturi

Venturi diameter 0.8661 in (22.0 mm) 0.9449 in (24.0 mm)

Main jet 0.0421 in (1.07 mm) 0.0500 in (1. 27 mm)

Air correction jet 0.0728 in (1.85 mm) 0.086 6 in (2.20 mm)

Slow running jet 0.0177 in (0.45 mm) 0.0276 in (0. 70 mm)

Slow running air bleed 0.0413 in (1.05 mm) 0.027 6 in (0.70 mm)

Accelerator pump jet 0.0157 in (0.40 mm) ---

Needle valve seat 0.0689 in (1.75 mm)

Accelerator pump output (10 strokes) 8.55 cm

3

Cold starting device Manually operated strangler ch oke

Float level 0.2657 to 0.2854 in (6.75 to 7.25 mm)

Fuel pump

Output 75 litres/hr (16.5 gal/hr)

Actuating lever stroke (C, L and CL) 2.4 to 2.6 mm (0.0949 to 0.1024 in)

Actuating lever stroke (Sport) 2.4 to 2.9 mm (0.09 49 to 0.1142 in)

Delivery pressure at 4000 engine rpm 0.17 kgf/cm2 (2.55 Ibf/in2)

and fuel temp 30°C (86°F)

lgnition system

Distributor

Type and code Magneti Marelli S155HX

Automatic centrifugal advance 25° ± 2° at 4500 rpm

Condenser capacity (50 to 1000 Hz) 0.20 to 0.25 µF

Clutch

Lining outer diameter 181.5 mm (7.146 in)

Lining inner diameter 127.0 mm (5.0 in)

Page 31 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

31/34

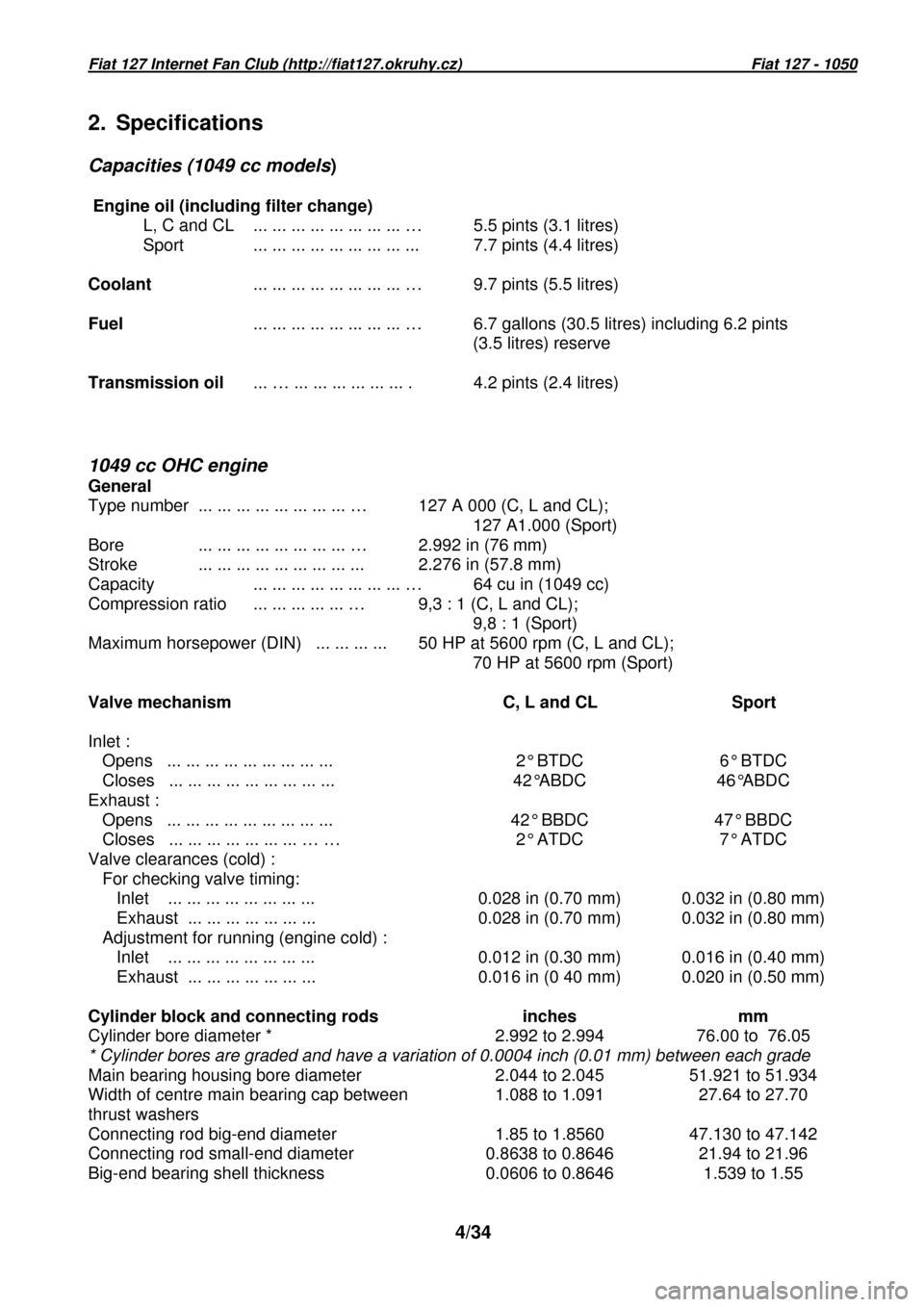

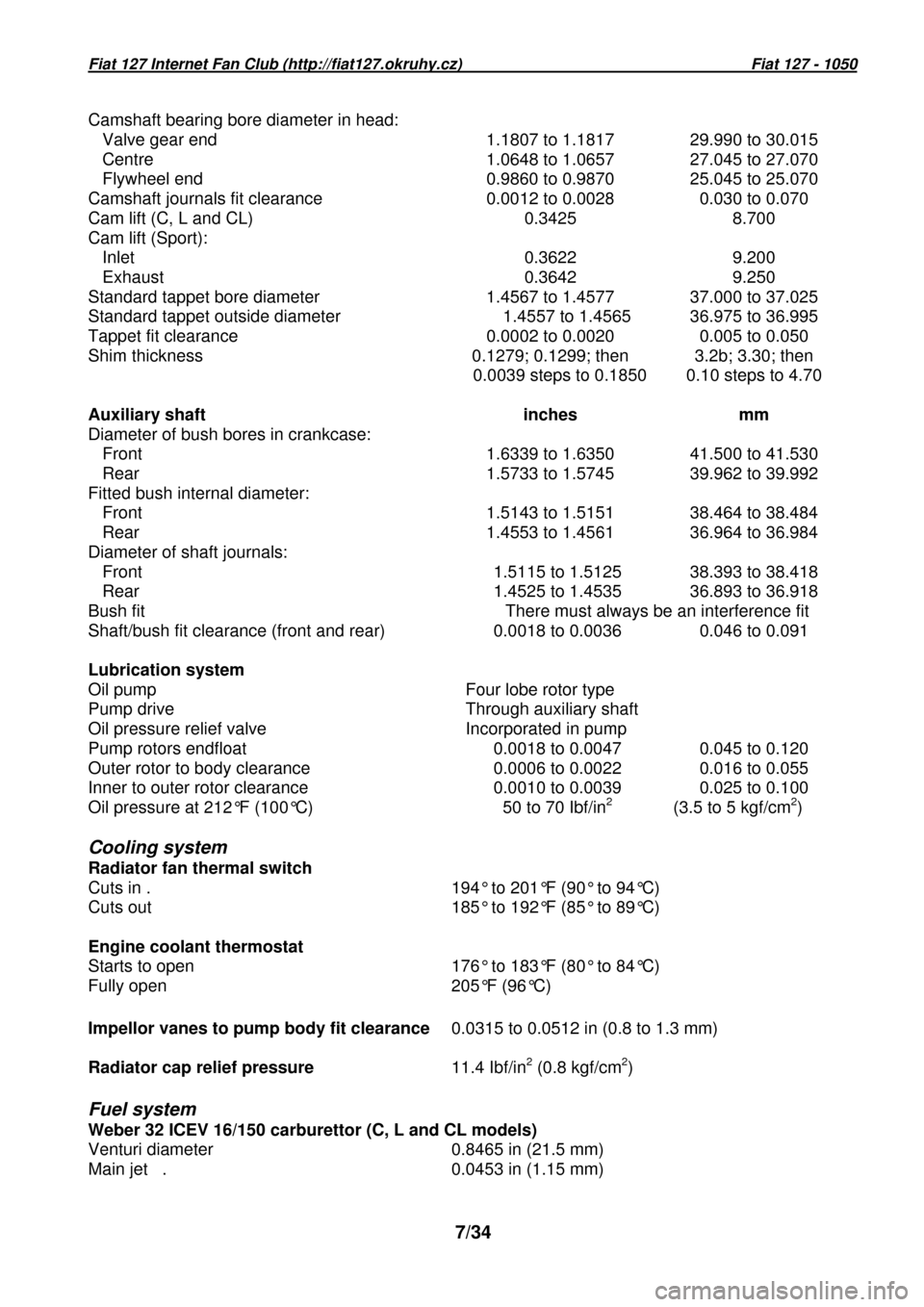

Fig. 13.4 Engine mounting (right-hand side) (Sec.3) Fig. 13.5. Engine mounting (left-hand side) (Sec.3)

1 – Mounting

2 – Crankcase

1 – Mounting to chassis bolts

2 – Mounting

3 – Mounting to transmission bracket

both the inlet and exhaust manifolds which are

on the same side of the engine.

Engine removal - 127 Special and 127

from chassis number 1104290 onwards

94 The removal of the engine assembly from

these models is slightly different from that

described in Chapter 1, owing to redesigned

engine mountings.

95 For the later type of mountings,

disconnection of the engine is achieved by

removal of the engine suspension mounting

securing bolts after taking the weight of the

assembly on a hoist.

96 On refitting the assembly tighten the securing

bolts to the specified torque load.

4. Fuel system

Carburettors - general

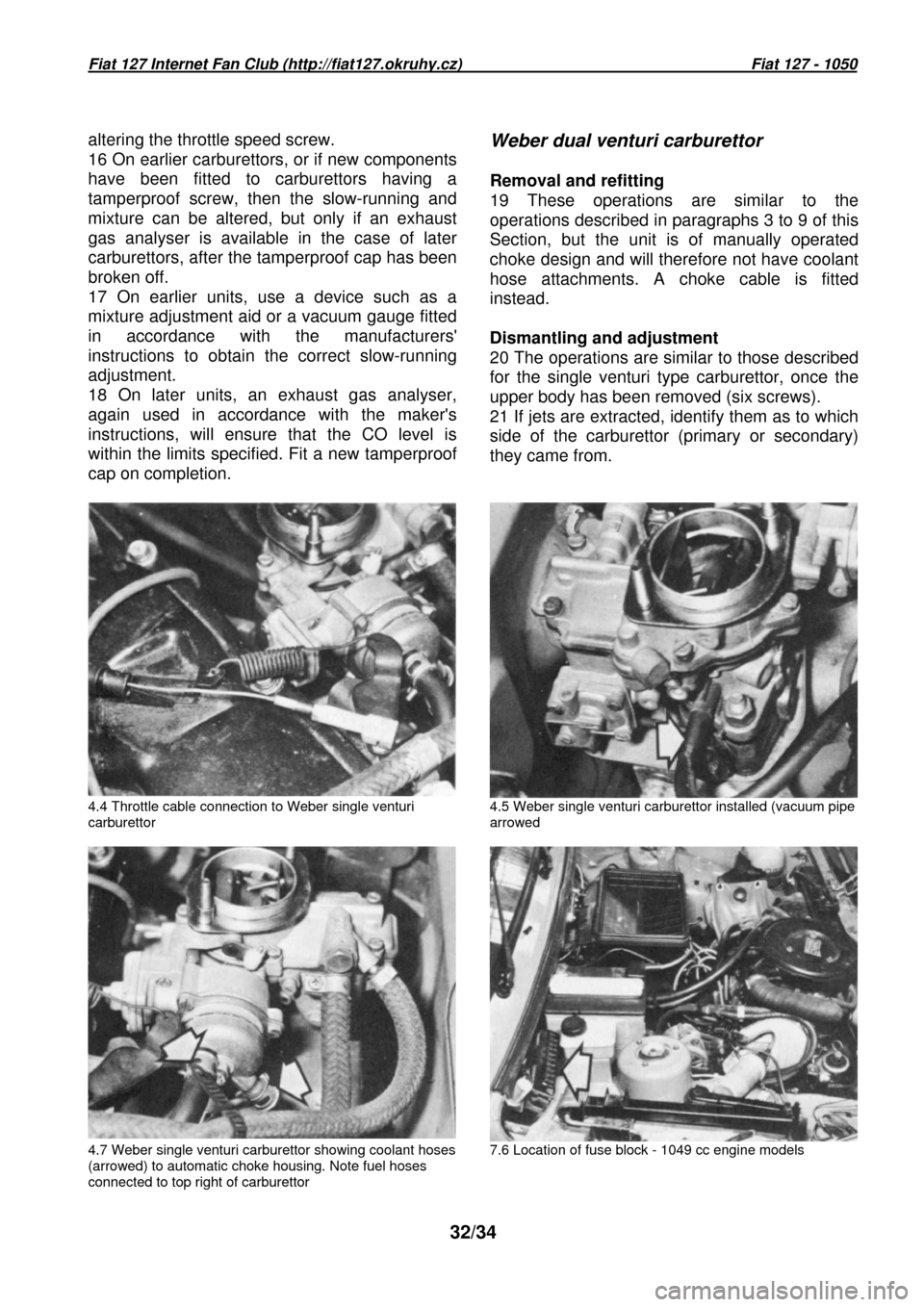

1 On L, C and CL models the 1049 cc engine is

fitted with either a Weber 32 ICEV 161150 or a

Solex C32 TDI/4 carburettor with a downdraught

single venturi and automatic coolant heated

choke (photos).

2 On Sport versions, a dual venturi Weber

carburettor is fitted with manual choke.

Weber or Solex single venturi

carburettors

Removal and refitting

3 Remove the air cleaner

4 Disconnect the throttle cable (photo).

5 Disconnect the distributor vacuum pipe

(photo). 6 Disconnect the fuel flow and return

hoses 7 Disconnect the coolant hoses from the

automatic choke housing and tie the pipes as

high as possible to prevent coolant loss (photo).

8 Unbolt the carburettor flange mounting bolts

and lift the carburettor from the manifold.

9 Refitting is a reversal of removal, but use a

new flange mounting gasket

Dismantling and adjustment

10 Clean the outside of the carburettor, remove

the top cover screws and lift off the cover.

11 Clean out the float bowl.

12 Any jets or bleed screws if removed, should

only be cleaned by blowing air through them.

Never probe with wire or their calibration will be

ruined.

13 Check the float level by holding the

carburettor cover vertically so that the float

hangs down, and then measure between the

casting flange and the nearest point of the float.

Adjust if necessary by bending the float arm tab

until the clearance conforms with the

Specifications according to carburettor.

14 The automatic choke will not normally require

dismantling, but if the cover is removed, make

sure that the centre index marks on the cover

and housing are in alignment before tightening

the choke cover screws.

15 On later carburettors, the mixture screw is

fitted with a tamperproof cap and adjustment to

the slow-running should therefore be limited to

Page 32 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

32/34

altering the throttle speed screw.

16 On earlier carburettors, or if new components

have been fitted to carburettors having a

tamperproof screw, then the slow-running and

mixture can be altered, but only if an exhaust

gas analyser is available in the case of later

carburettors, after the tamperproof cap has been

broken off.

17 On earlier units, use a device such as a

mixture adjustment aid or a vacuum gauge fitted

in accordance with the manufacturers'

instructions to obtain the correct slow-running

adjustment.

18 On later units, an exhaust gas analyser,

again used in accordance with the maker's

instructions, will ensure that the CO level is

within the limits specified. Fit a new tamperproof

cap on completion.

Weber dual venturi carburettor

Removal and refitting

19 These operations are similar to the

operations described in paragraphs 3 to 9 of this

Section, but the unit is of manually operated

choke design and will therefore not have coolant

hose attachments. A choke cable is fitted

instead.

Dismantling and adjustment

20 The operations are similar to those described

for the single venturi type carburettor, once the

upper body has been removed (six screws).

21 If jets are extracted, identify them as to which

side of the carburettor (primary or secondary)

they came from.

4.4 Throttle cable connection to Weber single ventu ri

carburettor 4.5 Weber single venturi carburettor installed (va

cuum pipe

arrowed

4.7 Weber single venturi carburettor showing coolan t hoses

(arrowed) to automatic choke housing. Note fuel hos es

connected to top right of carburettor 7.6 Location of fuse block - 1049 cc engine models

Page 33 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

33/34

is an economical proposition if the original one

has seen service to a high mileage. Very often a

generous allowance is made for the old unit.

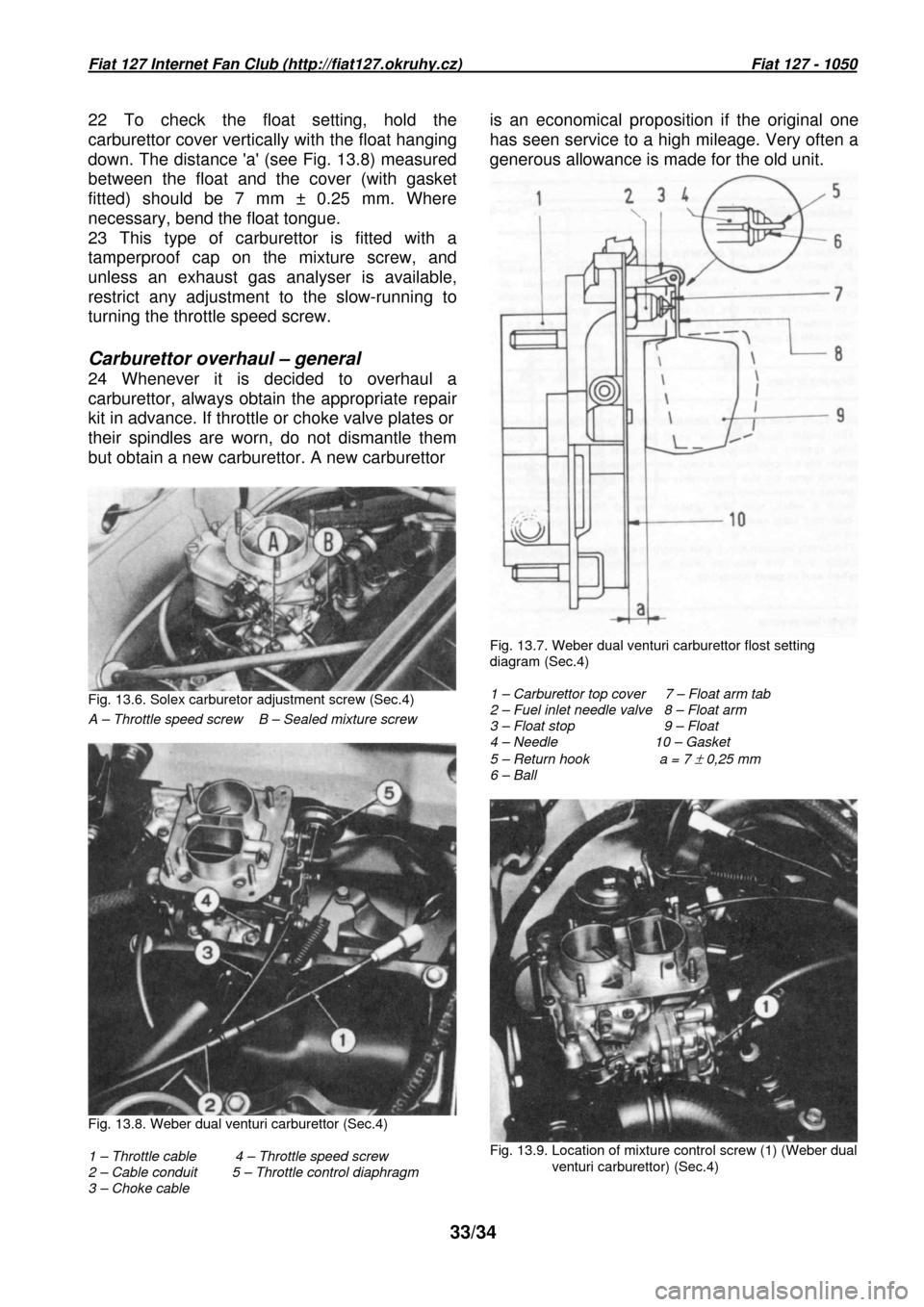

22 To check the float setting, hold the

carburettor cover vertically with the float hanging

down. The distance 'a' (see Fig. 13.8) measured

between the float and the cover (with gasket

fitted) should be 7 mm ± 0.25 mm. Where

necessary, bend the float tongue.

23 This type of carburettor is fitted with a

tamperproof cap on the mixture screw, and

unless an exhaust gas analyser is available,

restrict any adjustment to the slow-running to

turning the throttle speed screw.

Carburettor overhaul – general

24 Whenever it is decided to overhaul a

carburettor, always obtain the appropriate repair

kit in advance. If throttle or choke valve plates o r

their spindles are worn, do not dismantle them

but obtain a new carburettor. A new carburettor

Fig. 13.6. Solex carburetor adjustment screw (Sec.4)

Fig. 13.7. Weber dual venturi carburettor flost setting

diagram (Sec.4)

1 – Carburettor top cover 7 – Float arm tab

2 – Fuel inlet needle valve 8 – Float arm

3 – Float stop 9 – Float

4 – Needle 10 – Gasket

5 – Return hook a = 7

± 0,25 mm

6 – Ball

A – Throttle speed screw B – Sealed mixture scre w

Fig. 13.8. Weber dual venturi carburettor (Sec.4)

1 – Throttle cable 4 – Throttle speed scre w

2 – Cable conduit 5 – Throttle control diap hragm

3 – Choke cable

Fig. 13.9. Location of mixture control screw (1) (W eber dual

venturi carburettor) (Sec.4)