suspension FIAT 127 1979 2.G Workshop Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1979, Model line: 127, Model: FIAT 127 1979 2.GPages: 34, PDF Size: 6.87 MB

Page 10 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

10/34

Lamps

Headlamps (C, L and CL)

Headlamps (Sport)

Brake and rear light

Turn indicators

Reversing lights

Parking lights

Number plate

Courtesy light

Boot light

Turn repeaters

Cigar lighter light

Instrument panel

Ignition warning

Turn indicator warning

Headlamp warning

Coolant temperature warning (L models)

Oil pressure warning

Fuel warning

Hazard warning

Sidelamp (out) warning (Sport only)

Brake warning (Sport only)

Heated rear window warning (Sport only)

40/45 watts

55/60 watts (Halogen)

5/21 watts

21 watts

21 watts

5 watts

5 watts

5 watts

5 watts

4 watts

4 watts

3 watts

3 watts

1.2 watts

1.2 watts

1.2 watts

1.2 watts

1.2 watts

1.2 watts

3 watts

1.2 watts

1.2 watts

Fuses

For fuse details (127 Special, L, C, CL and Sport) see Sections 23 or 24

Steering and suspension (Sport only)

Steering angles

Inner wheel 34° 50’

Outer wheel 32° 10’

Front wheel alignment (toe setting)

Laden 0.079 in (2.0 mm) toe-in to 0.079 in (2.0 mm) toe-o ut

Unladen 0.138 in (3.5 mm) to 0.217 in (5.5 mm) toe-in

Roadwheels

Size 4½ B x 13

Tyres 135 SR-13 or 155/70 SR-13

All 1049 cc models Ibf ft kgf m

Main bearing cap bolts 59 8.2

Engine mounting securing bolts 43 6

Cylinder head to block bolts and nuts:

1 st stage 30 4.1

2nd stage 45 6.2

Final stage 61 8.5

Manifold to head nuts 20 2.8

Connecting rod big-end nuts 38 5.2

Flywheel to crankshaft bolts 61 8.5

Driven gear (Plastic) to camshaft retaining bolt 87 12

Driven gear (steel) to camshaft retaining bolt 87 1 2

Camshaft cap nuts 14 2

Page 11 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

11/34

Ignition distributor clamp nut 11 1.5

Oil pump to crankcase bolts 13 1.8

Cylinder head outlet pipe bolt 16 2.2

Water pump/alternator drive pulley nut 101 14

Alternator bracket to crankcase bolt 20 2.8

Alternator to lower bracket bolt 36 5

Cylinder head upper bracket bolt 20 2.8

Alternator to upper bracket nut 36 5

Upper bracket securing bolt 13 1.8

Oil pressure switch 24 3.3

Coolant temperature switch 36 5

Spark plug 27 3.8

Sport models only

Engine

Flexible mounting to body (engine side) 65 9.0

Flexible mounting support (engine side to body)

18 2.5

Flexible mounting upper support to gearbox 18 2.5

Engine crossmember to body 18 2.5

Flexible mounting support nut (gearbox side) 18 2.5

Flexible mounting support bolt to body

(gearbox LH side) 65 9.0

Steering and suspension

Steering wheel retaining nut 22 3.0

Front wheel bearing ring nut 44 6.0

Front wheel hub nut 160 22.0

Roadwheel bolts 64 8.8

Front suspension track control arm to body 20 2.7

Front suspension balljoint to hub carrier 40 5.5

Rear wheel hub nut 160 22

Transmission

Starter motor bolt to bellhousing lower support 18 2.5

Gear selector shaft nut 18 2.5

Upper gear lever relay lever 22 3.0

Idler support securing nut 18 2.5

Differential case flange to gearbox housing 18 2.5

Page 31 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

31/34

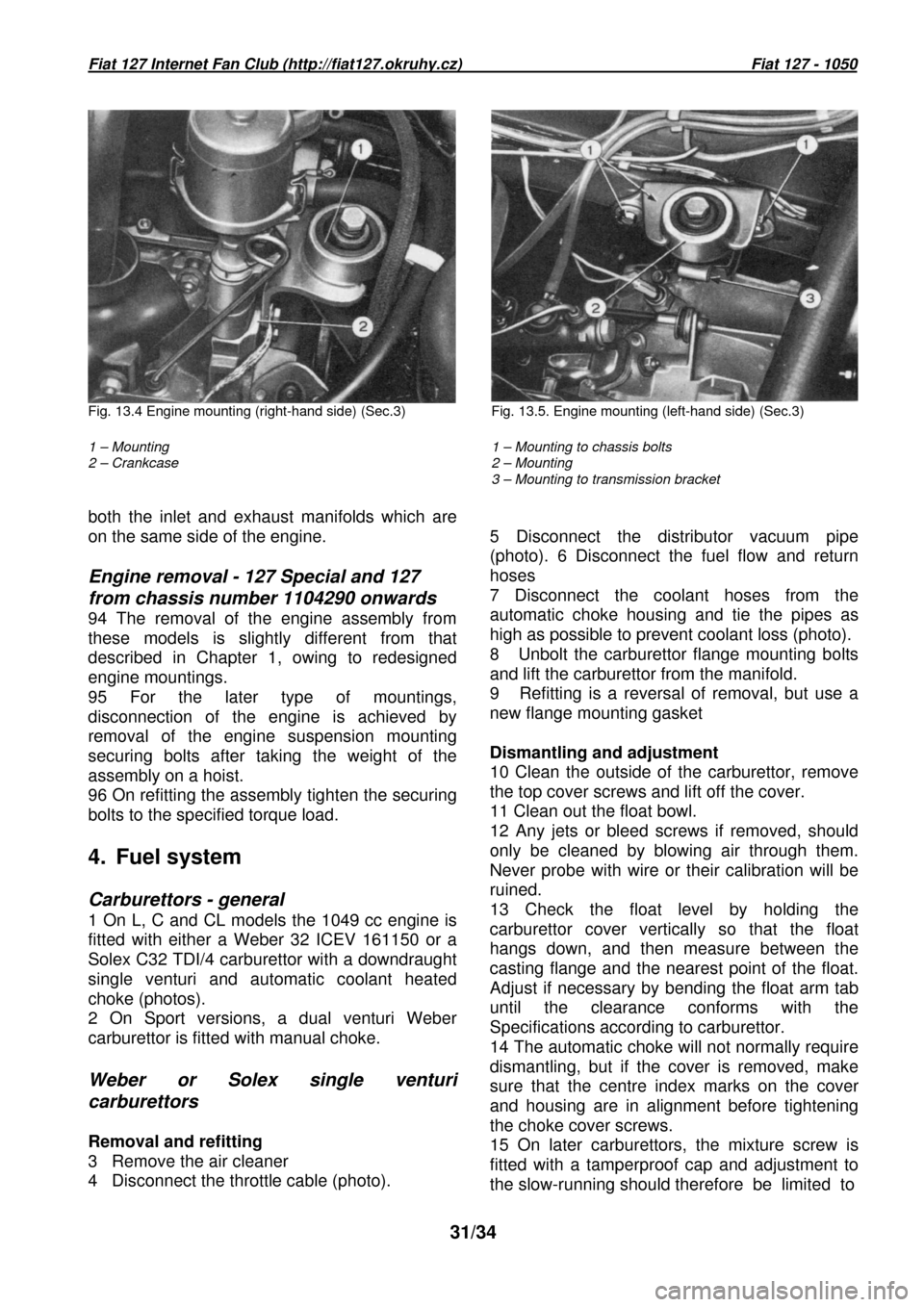

Fig. 13.4 Engine mounting (right-hand side) (Sec.3) Fig. 13.5. Engine mounting (left-hand side) (Sec.3)

1 – Mounting

2 – Crankcase

1 – Mounting to chassis bolts

2 – Mounting

3 – Mounting to transmission bracket

both the inlet and exhaust manifolds which are

on the same side of the engine.

Engine removal - 127 Special and 127

from chassis number 1104290 onwards

94 The removal of the engine assembly from

these models is slightly different from that

described in Chapter 1, owing to redesigned

engine mountings.

95 For the later type of mountings,

disconnection of the engine is achieved by

removal of the engine suspension mounting

securing bolts after taking the weight of the

assembly on a hoist.

96 On refitting the assembly tighten the securing

bolts to the specified torque load.

4. Fuel system

Carburettors - general

1 On L, C and CL models the 1049 cc engine is

fitted with either a Weber 32 ICEV 161150 or a

Solex C32 TDI/4 carburettor with a downdraught

single venturi and automatic coolant heated

choke (photos).

2 On Sport versions, a dual venturi Weber

carburettor is fitted with manual choke.

Weber or Solex single venturi

carburettors

Removal and refitting

3 Remove the air cleaner

4 Disconnect the throttle cable (photo).

5 Disconnect the distributor vacuum pipe

(photo). 6 Disconnect the fuel flow and return

hoses 7 Disconnect the coolant hoses from the

automatic choke housing and tie the pipes as

high as possible to prevent coolant loss (photo).

8 Unbolt the carburettor flange mounting bolts

and lift the carburettor from the manifold.

9 Refitting is a reversal of removal, but use a

new flange mounting gasket

Dismantling and adjustment

10 Clean the outside of the carburettor, remove

the top cover screws and lift off the cover.

11 Clean out the float bowl.

12 Any jets or bleed screws if removed, should

only be cleaned by blowing air through them.

Never probe with wire or their calibration will be

ruined.

13 Check the float level by holding the

carburettor cover vertically so that the float

hangs down, and then measure between the

casting flange and the nearest point of the float.

Adjust if necessary by bending the float arm tab

until the clearance conforms with the

Specifications according to carburettor.

14 The automatic choke will not normally require

dismantling, but if the cover is removed, make

sure that the centre index marks on the cover

and housing are in alignment before tightening

the choke cover screws.

15 On later carburettors, the mixture screw is

fitted with a tamperproof cap and adjustment to

the slow-running should therefore be limited to