hood open FIAT 127 1982 3.G Workshop Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1982, Model line: 127, Model: FIAT 127 1982 3.GPages: 34, PDF Size: 6.87 MB

Page 24 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

24/34

progressively until the bearing halves meet.

53 Oil the camshaft seal and carefully fit it with

its carrier and a new gasket to the cylinder head

(photo).

54 Position the drivebelt guard backplate over

the camshaft seal carrier and fit the three bolts

and washers (photo). 55 Tighten the three bolts

retaining the backplate and seal carrier. Torque

load the four camshaft bearing securing nuts to

the specified setting.

56 Fit the camshaft toothed driving pulley with its

bolt and washer. Leave the final tightening until

the drivebelt is fitted (photo).

57 Check the valve clearances; the camshaft

can be turned by a spanner on the pulley

retaining bolt. Readjust any clearance if

necessary, as described later in this Section.

58 Owing to the small clearance between a

piston at TDC and the open valves during

exhaust/inlet overlap, it is imperative to get the

crankshaft and camshaft in their correct related

positions before turning the engine after fitting

the cylinder head. If this relationship is out then

serious damage could be done to the valves or

pistons by turning the crankshaft, as the pistons

will impinge on the valve heads. To avoid this

the following sequence should be observed. Set

the crankshaft as described in paragraph 59,

and the camshaft (before assembling the

cylinder head to the block) also as described in

paragraph 59. Fit the head to the block taking

care not to disturb the set positions and, finally,

fit the toothed drivebelt. Then the crankshaft can

be turned with no likelihood of damage.

59 Set the crankshaft by using a spanner on the

pulley retaining nut and aligning the mark on the

pulley with the long pointer on the timing

indicator bracket. Then set the camshaft by

aligning the hole in the camshaft pulley with the

cast ridge on the top of the camshaft seal carrier

just behind the toothed pulley (photo).

60 Fit a new cylinder head gasket with the word

ALTO upwards (photo). Do not use grease or

any other jointing compound. 61 Taking care not

to disturb the crankshaft or camshaft lower the

cylinder head onto the block (photo).

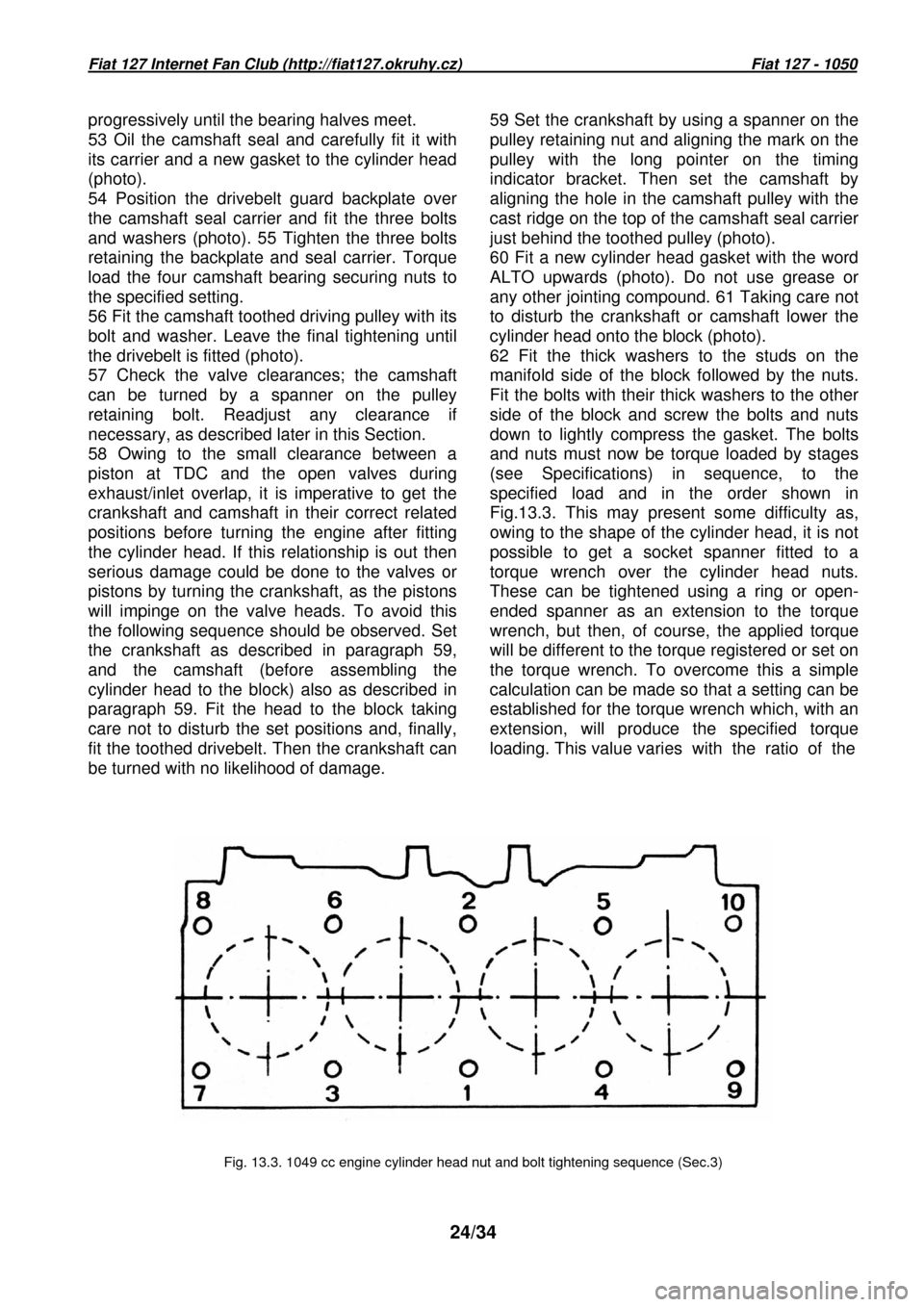

62 Fit the thick washers to the studs on the

manifold side of the block followed by the nuts.

Fit the bolts with their thick washers to the other

side of the block and screw the bolts and nuts

down to lightly compress the gasket. The bolts

and nuts must now be torque loaded by stages

(see Specifications) in sequence, to the

specified load and in the order shown in

Fig.13.3. This may present some difficulty as,

owing to the shape of the cylinder head, it is not

possible to get a socket spanner fitted to a

torque wrench over the cylinder head nuts.

These can be tightened using a ring or open-

ended spanner as an extension to the torque

wrench, but then, of course, the applied torque

will be different to the torque registered or set o n

the torque wrench. To overcome this a simple

calculation can be made so that a setting can be

established for the torque wrench which, with an

extension, will produce the specified torque

loading. This value varies with the ratio of t he

Fig. 13.3. 1049 cc engine cylinder head nut and bol t tightening sequence (Sec.3)