Esp 500 FIAT 500 1958 1.G Workshop Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1958, Model line: 500, Model: FIAT 500 1958 1.GPages: 128, PDF Size: 9.01 MB

Page 13 of 128

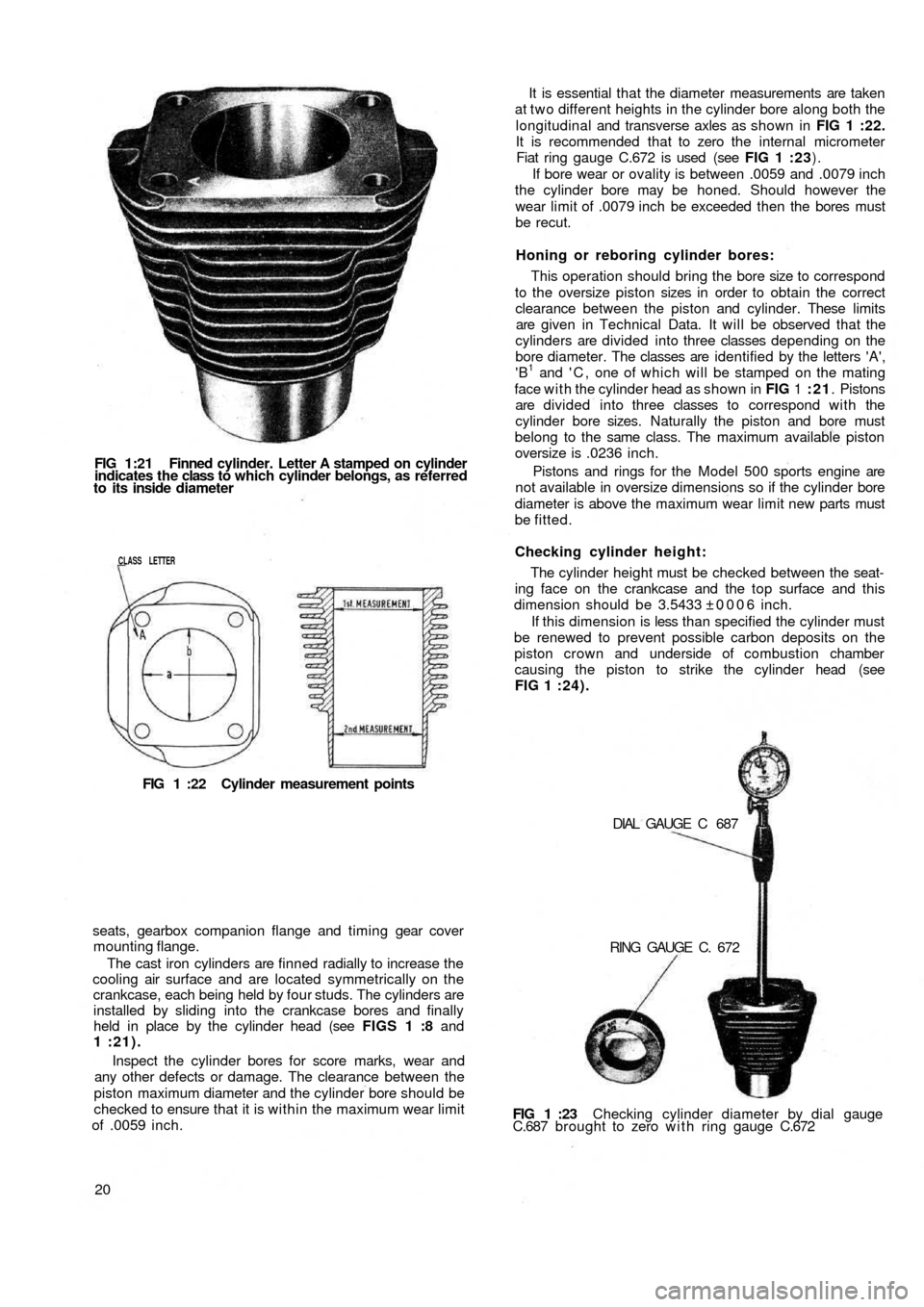

FIG 1:21 Finned cylinder. Letter A stamped on cylinder

indicates the class to which cylinder belongs, as referred

to its inside diameter

CLASS LETTER

FIG 1 :22 Cylinder measurement points

seats, gearbox companion flange and timing gear cover

mounting flange.

The cast iron cylinders are finned radially to increase the

cooling air surface and are located symmetrically on the

crankcase, each being held by four studs. The cylinders are

installed by sliding into the crankcase bores and finally

held in place by the cylinder head (see FIGS 1 :8 and

1 :21).

Inspect the cylinder bores for score marks, wear and

any other defects or damage. The clearance between the

piston maximum diameter and the cylinder bore should be

checked to ensure that it is within the maximum wear limit

of .0059 inch.

20FIG 1 :23 Checking cylinder diameter by dial gauge

C.687 brought to zero w i t h ring gauge C.672 DIAL GAUGE C 687

RING GAUGE C. 672 The cylinder height must be checked between the seat-

ing face on the crankcase and the top surface and this

dimension should be 3.5433 ±0006 inch.

If this dimension is less than specified the cylinder must

be renewed to prevent possible carbon deposits on the

piston crown and underside of combustion chamber

causing the piston to strike the cylinder head (see

FIG 1 :24). Checking cylinder height: This operation should bring the bore size to correspond

to the oversize piston sizes in order to obtain the correct

clearance between the piston and cylinder. These

limits

are given in Technical Data. It will be observed that the

cylinders are divided into three classes depending on the

bore diameter. The classes are identified by the letters 'A',

'B

1 and ' C , one of which will be stamped on the mating

face with the cylinder head as shown in FIG 1 :21. Pistons

are divided into three classes to correspond with the

cylinder bore sizes. Naturally the piston and bore must

belong to the same class. The maximum available piston

oversize is .0236 inch.

Pistons and rings for the Model 500 sports engine are

not available in oversize dimensions so if the cylinder bore

diameter is above the maximum wear limit new parts must

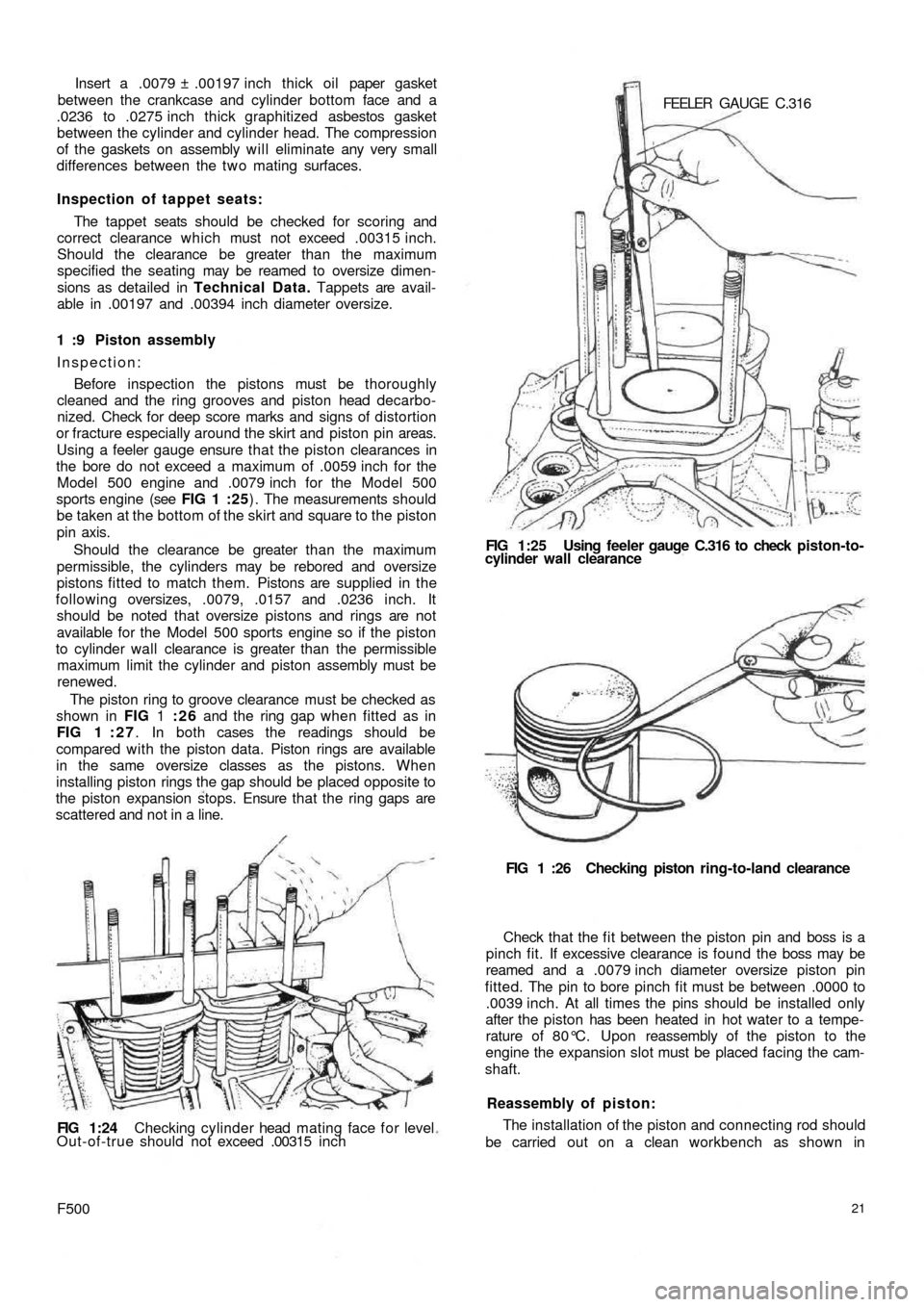

be fitted.Honing or reboring cylinder bores: It is essential that the diameter measurements are taken

at t w o different heights in the cylinder bore along both the

longitudinal and transverse axles as shown in FIG 1 :22.

It is recommended that to zero the internal micrometer

Fiat ring gauge C.672 is used (see FIG 1 :23).

If bore wear or ovality is between .0059 and .0079 inch

the cylinder bore may be honed. Should however the

wear limit of .0079 inch be exceeded then the bores must

be recut.

Page 14 of 128

Insert a .0079 ± .00197 inch thick oil paper gasket

between the crankcase and cylinder bottom face and a

.0236 to .0275 inch thick graphitized asbestos gasket

between the cylinder and cylinder head. The compression

of the gaskets on assembly will eliminate any very small

differences between the t w o mating surfaces.

Inspection of tappet seats:

The tappet seats should be checked for scoring and

correct clearance which must not exceed .00315 inch.

Should the clearance be greater than the maximum

specified the seating may be reamed to oversize dimen-

sions as detailed in Technical Data. Tappets are avail-

able in .00197 and .00394 inch diameter oversize.

1 :9 Piston assembly

Inspection:

Before inspection the pistons must be thoroughly

cleaned and the ring grooves and piston head decarbo-

nized. Check for deep score marks and signs of distortion

or fracture especially around the skirt and piston pin areas.

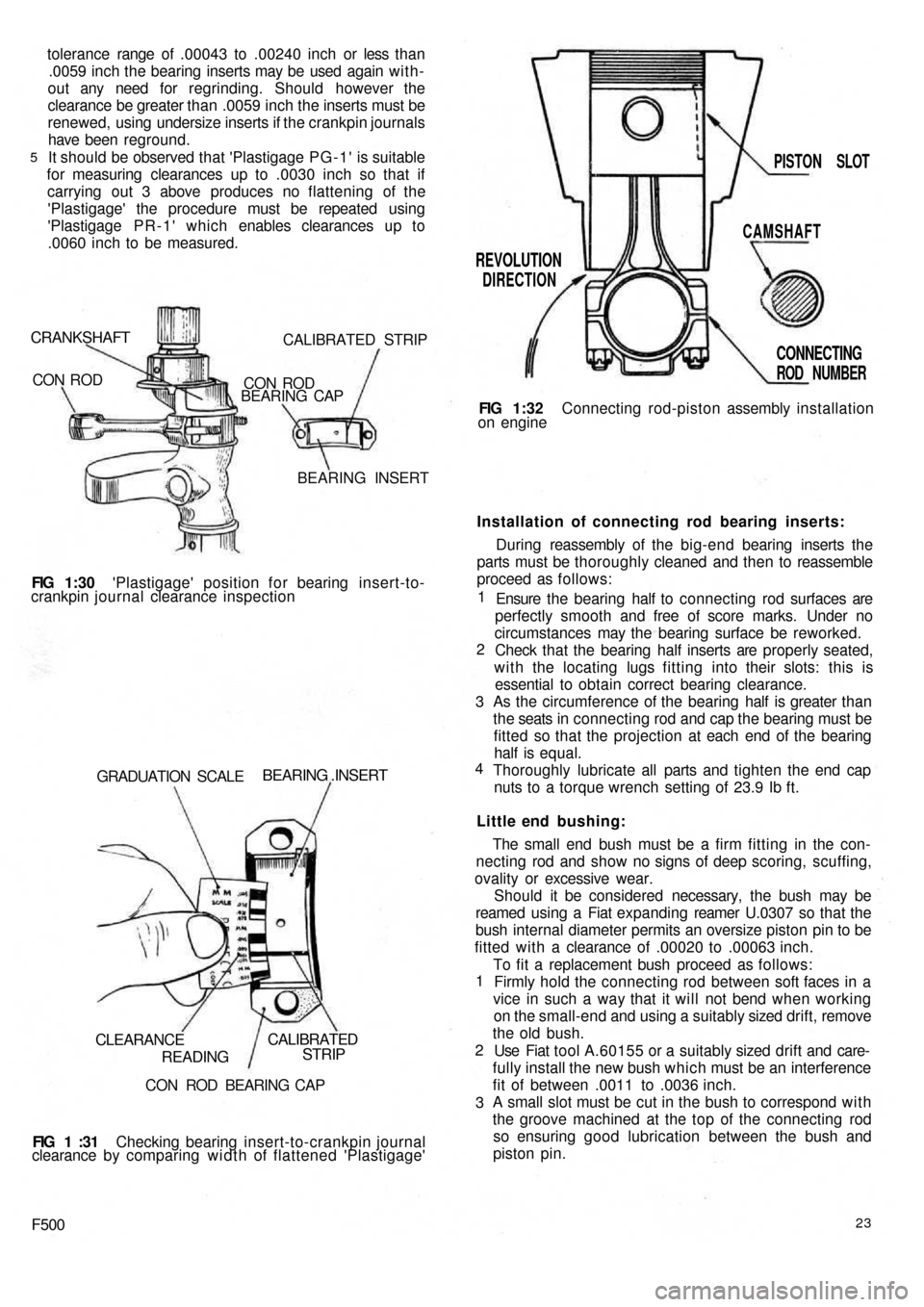

Using a feeler gauge ensure that the piston clearances in

the bore do not exceed a maximum of .0059 inch for the

Model 500 engine and .0079 inch for the Model 500

sports engine (see FIG 1 :25) . The measurements should

be taken at the bottom of the skirt and square to the piston

pin axis.

Should the clearance be greater than the maximum

permissible, the cylinders may be rebored and oversize

pistons fitted to m

atch them. Pistons are supplied in the

following oversizes, .0079, .0157 and .0236 inch. It

should be noted that oversize pistons and rings are not

available for the Model 500 sports engine so if the piston

to cylinder wall clearance is greater than the permissible

maximum limit the cylinder and piston assembly must be

renewed.

The piston ring to groove clearance must be checked as

shown in FIG 1 :26 and the ring gap when fitted as in

FIG 1 : 2 7. In both cases the readings should be

compared with the piston data. Piston rings are available

in the same oversize classes as the pistons. When

installing piston rings the gap should be placed opposite to

the piston expansion stops. Ensure that the ring gaps are

scattered and not in a line.

FIG 1:24 Checking cylinder head mating face f o r level

Out-of-true should not exceed .00315 i n c h

F50021

The installation of the piston and connecting rod should

be carried out on a clean workbench as shown in Reassembly of piston: Check that the f i t between the piston pin and boss is a

pinch fit. If excessive clearance is found the boss may be

reamed and a .0079 inch diameter oversize piston pin

fitted. The pin to bore pinch fit must be between .0000 to

.0039 inch. At all times the pins should be installed only

after the piston has been heated in hot water to a tempe-

rature of 80°C. Upon reassembly of the piston to the

engine the expansion slot must be placed facing the cam-

shaft.FIG 1 :26 Checking piston ring-to-land clearance FEELER GAUGE C.316

FIG 1:25 Using feeler gauge C.316 to check piston-to-

cylinder wall clearance

Page 16 of 128

tolerance range of .00043 to .00240 inch or less than

.0059 inch the bearing inserts may be used again with-

out any need for regrinding. Should however the

clearance be greater than .0059 inch the inserts must be

renewed, using undersize inserts if the crankpin journals

have been reground.

It should be observed that 'Plastigage PG-1' is suitable

for measuring clearances up to .0030 inch so that if

carrying out 3 above produces no flattening of the

'Plastigage' the procedure must be repeated using

'Plastigage PR-1' which enables clearances up to

.0060 inch to be measured.

5

CRANKSHAFT

CON RODCALIBRATED STRIP

CON ROD

BEARING CAP

BEARING INSERT

FIG 1:30 'Plastigage' position for bearing insert-to-

crankpin journal clearance inspection

GRADUATION SCALE

BEARING .INSERT

CLEARANCE

READINGCALIBRATED

STRIP

CON ROD BEARING CAP

FIG 1 :31 Checking bearing insert-to-crankpin journal

clearance by comparing width of flattened 'Plastigage'

F50023

To fit a replacement bush proceed as follows:

Firmly hold the connecting rod between soft faces in a

vice in such a way that it will not bend when working

on the small-end and using a suitably sized drift, remove

the old bush.

Use Fiat tool A.60155 or a suitably sized drift and care-

fully install the new bush which must be an interference

fit of between .0011 to .0036 inch.

A small slot must be cut in the bush to correspond w i t h

the groove machined at the top of the connecting rod

so ensuring good lubrication between the bush and

piston pin. 1

2

3The small end bush must be a firm fitting in the con-

necting rod and show no signs of deep scoring, scuffing,

ovality or excessive wear.

Should it be considered necessary, the bush may be

reamed using a Fiat expanding reamer U.0307 so that the

bush internal diameter permits an oversize piston pin to be

fitted with a clearance of .00020 to .00063 inch. Little end bushing:Installation of connecting rod bearing inserts:

During reassembly of the big-end bearing inserts the

parts must be thoroughly cleaned and then to reassemble

proceed as follows:

Ensure the bearing half to connecting rod surfaces are

perfectly smooth and free of score marks. Under no

circumstances may the bearing surface be reworked.

Check that the bearing half inserts are properly seated,

with the locating lugs fitting into their slots: this is

essential to obtain

correct bearing clearance.

As the circumference of the bearing half is greater than

the seats in connecting rod and cap the bearing must be

fitted so that the projection at each end of the bearing

half is equal.

Thoroughly lubricate all parts and tighten the end cap

nuts to a torque wrench setting of 23.9 Ib ft. 1

2

3

4FIG 1:32 Connecting rod-piston assembly installation

on engine

REVOLUTION

DIRECTIONPISTON SLOT

CAMSHAFT

CONNECTING

ROD NUMBER

Page 32 of 128

3 Engine warm-up:

As the engine begins to warm up to its normal operating

temperature, gradually push home the starting device

lever so as only to supply the engine with the richened

charge enabling the cold engine operation to be smooth

and regular. Position ' B ' (FIG 2:6).

4 Normal car driving:

Once the engine has reached its normal operating

temperature the starting device should be completely

brought out of operation by bringing the control lever to

the position 'C (FIG 2:6).

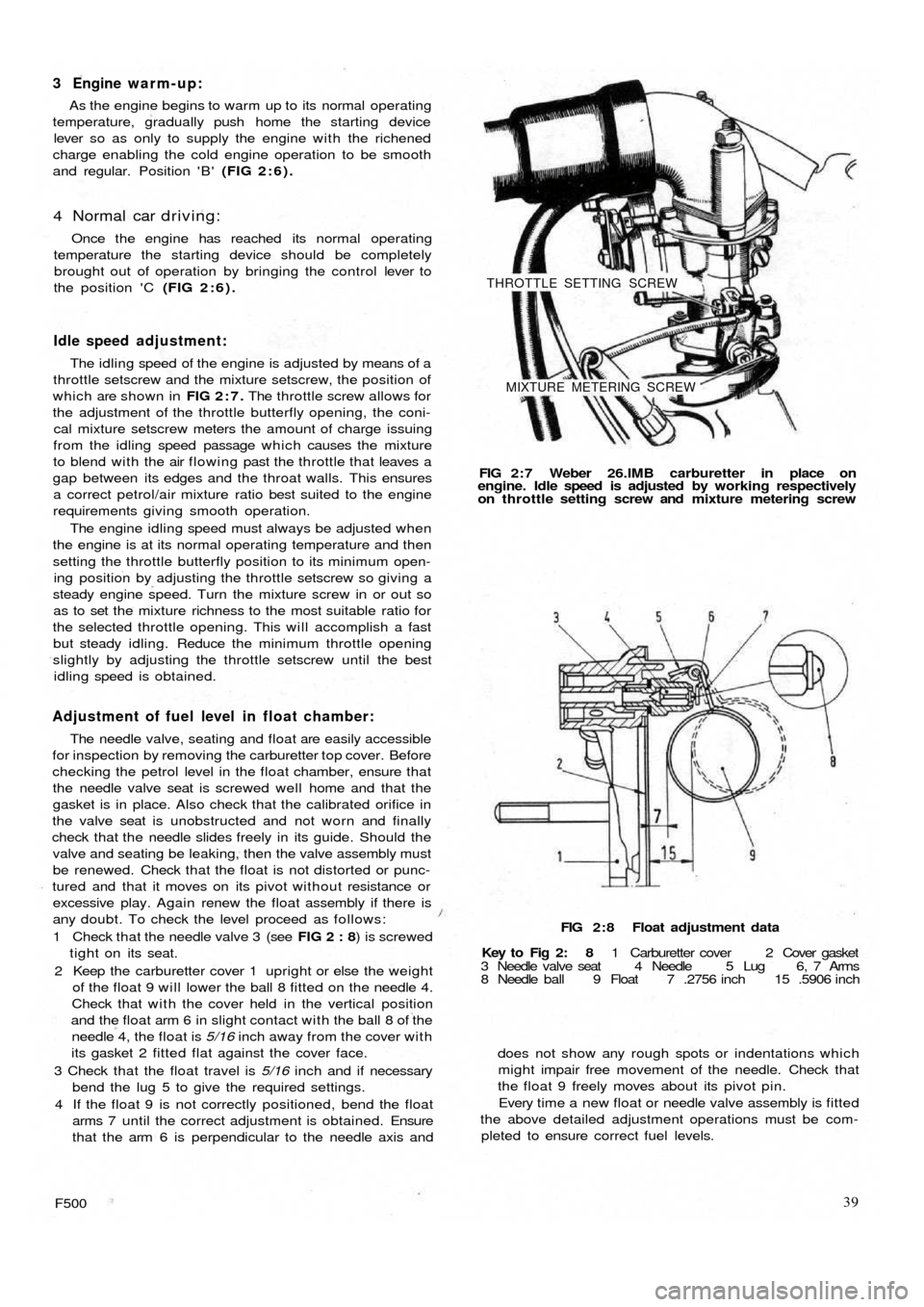

Idle speed adjustment:

The idling speed of the engine is adjusted by means of a

throttle setscrew and the mixture setscrew, the position of

which are shown in FIG 2:7. The throttle screw allows for

the adjustment of the throttle butterfly opening, the coni-

cal mixture setscrew meters the amount of charge issuing

from the idling speed passage which causes the mixture

to blend with the air flowing past the throttle that leaves a

gap between its edges and the throat walls. This ensures

a correct petrol/air mixture ratio best suited to the engine

requirements giving smooth operation.

The engine idling speed must always be adjusted when

the engine is at its normal operating temperature and then

setting the throttle butterfly position to its minimum open-

ing position by adjusting the throttle setscrew so giving a

steady engine speed. Turn the mixture screw in or out so

as to set the mixture richness to the most suitable ratio for

the selected throttle opening. This will accomplish a fast

but steady idling. Reduce the minimum throttle opening

slightly by adjusting the throttle setscrew until the best

idling speed is obtained.

Adjustment of fuel level in float chamber:

The needle valve, seating and float are easily accessible

for inspection by removing the carburetter top cover. Before

checking the petrol level in the float chamber, ensure that

the needle valve seat is screwed well home and that the

gasket is in place. Also check that the calibrated orifice in

the valve seat is unobstructed and not worn and finally

check that the needle slides freely in its guide. Should the

valve and seating be leaking, then the valve assembly must

be renewed. Check that the float is not distorted or punc-

tured and that it moves on its pivot without resistance or

excessive play. Again renew the float assembly if there is

any doubt. To check the level proceed as follows:

1 Check that the needle valve 3 (see FIG 2 : 8) is screwed

tight on its seat.

2 Keep the carburetter cover 1 upright or else the weight

of the float 9 will lower the ball 8 fitted on the needle 4.

Check that with the cover held in the vertical position

and the float arm 6 in slight contact with the ball 8 of the

needle 4, the float is 5/16 inch away from the cover with

its gasket 2

fitted flat against the cover face.

3 Check that the float travel is 5/16 inch and if necessary

bend the lug 5 to give the required settings.

4 If the float 9 is not correctly positioned, bend the float

arms 7 until the correct adjustment is obtained. Ensure

that the arm 6 is perpendicular to the needle axis and

F50039

does not show any rough spots or indentations which

might impair free movement of the needle. Check that

the float 9 freely moves about its pivot pin.

Every time a new float or needle valve assembly is fitted

the above detailed adjustment operations must be com-

pleted to ensure correct fuel levels. FIG 2 : 8 Float adjustment data

Key to Fig 2: 8 1 Carburetter cover 2 Cover gasket

3 Needle valve seat 4 Needle 5 Lug 6, 7 Arms

8 Needle ball 9 Float 7 .2756 inch 15 .5906 inch FIG 2 : 7 Weber 26.IMB carburetter in place on

engine. Idle speed is adjusted by working respectively

on throttle setting screw and mixture metering screw

THROTTLE SETTING SCREW

MIXTURE METERING SCREW

Page 38 of 128

Air cleaner—station wagon:

A pleated paper air cleaner element is housed in a

special air intake chamber connected to the front of the

engine air cooling cowling (see FIG 4 : 2) . This chamber

will be seen located towards the rear of t h e power unit

compartment. Remove the retaining wing nut, lift off the

lid and the element can be withdrawn by lifting upwards.

2:10 Blow-by-gases recirculation device

Engine 110 F.000

All the oil vapours and blow-by-gases that are formed

in the engine crankcase are drawn to the cylinder head

cover recess 1 (see FIG 2:18). From here they travel into

the pipe 5 via a breather valve 2 which is firmly attached to

the oil filler cap 3 and the strainer 4 located in the filler

neck. The oil vapours and gases are then d r a w n back into

the duct 9 from the pipe 5 which connects the air cleaner

6 to the carburetter 7. This ensures a complete closed cir-

cuit circulation.

Engine 120.000:

From engine No. 288156 the oil vapours and blow-by-

gases instead of being exhausted to the atmosphere are

conveyed to the air cleaner and from here they are drawn

back into the combustion chambers. To ensure that an

excessive of oil vapour does not pass along the piping

with the blow-by-gases a diaphragm is fitted in the duct

in front of the breather valve 2 (see FIG 2 :18), the dia-

phragm comprising a filter gauze 11 and moveable parti-

tion 10.

It should be noted that the oil vapour strainer 4 (see

FIG 2:18) and the flame trap 8 can easily be removed

from their seating for cleaning or renewal.

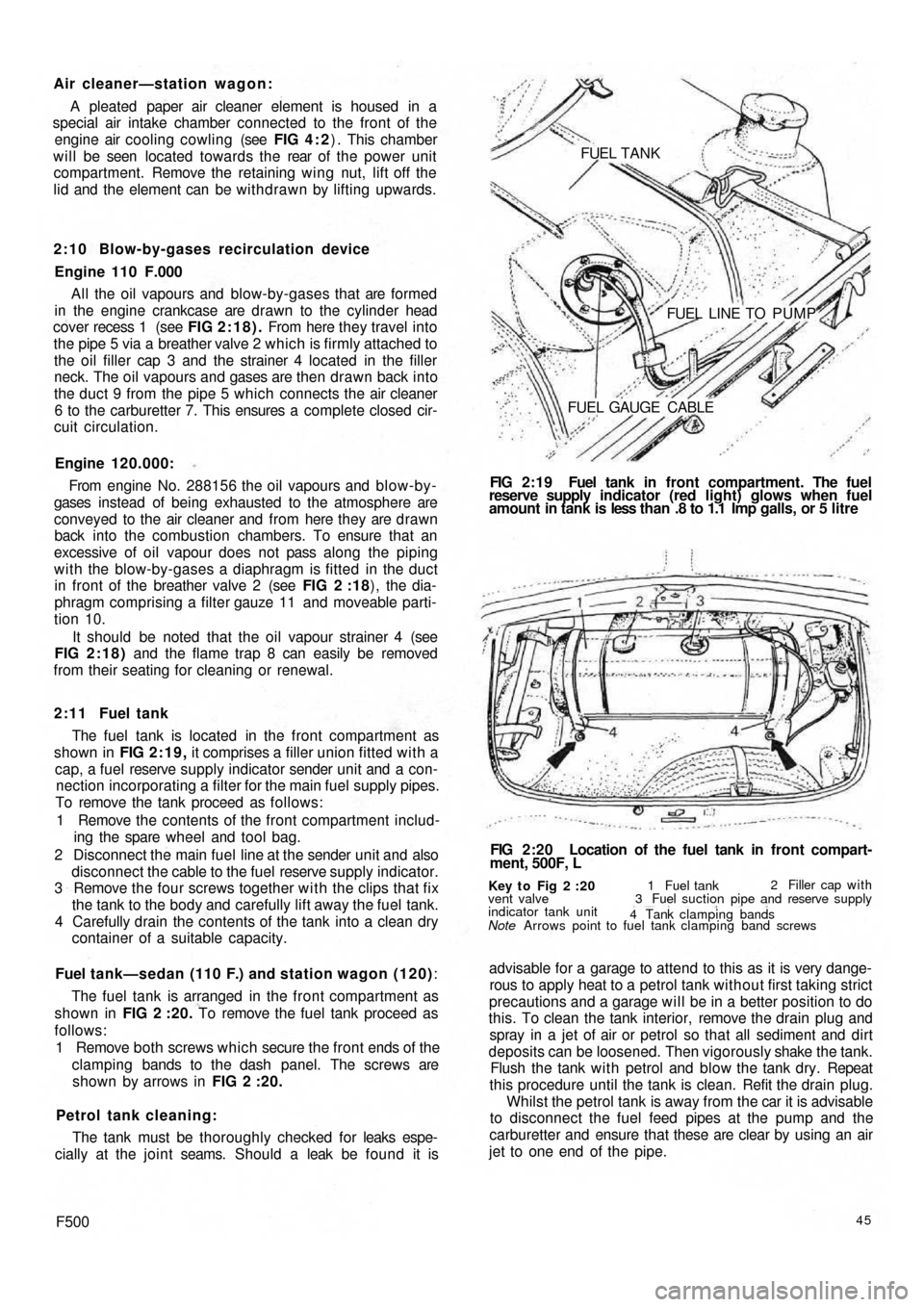

2 : 1 1 Fuel tank

The fuel tank is located in the front compartment as

shown in FIG 2:19, it comprises a filler union fitted with a

cap, a fuel reserve supply indicator sender unit and a con-

nection incorporating a filter for the main fuel supply pipes.

To remove the tank proceed as follows:

1 Remove the contents of the front compartment includ-

ing the spare wheel and tool bag.

2 Disconnect the main fuel line at the sender unit and also

disconnect the cable to the fuel reserve supply indicator.

3 Remove the four screws together w i t h the clips that fix

the tank to the body and carefully lift away the fuel tank.

4 Carefully drain the contents of the tank into a clean dry

container of a suitable capacity.

Fuel tank—sedan (110 F.) and station wagon (120):

The fuel tank is arranged in the front compartment as

shown in FIG 2 :20. To remove the fuel tank proceed as

follows:

1 Remove both screws which secure the front ends of the

clamping bands to the dash panel. The screws are

shown by arrows in FIG 2 :20.

Petrol tank cleaning:

The tank must be thoroughly checked for leaks espe-

cially at the joint seams. Should a leak be found it is

F50045

advisable for a garage to attend to this as it is very dange-

rous to apply heat to a petrol tank without first taking strict

precautions and a garage will be in a better position to do

this. To clean the tank interior, remove the drain plug and

spray in a jet of air or petrol so that all sediment and dirt

deposits can be loosened. Then vigorously shake the tank.

Flush the tank w i t h petrol and blow the tank dry. Repeat

this procedure until the tank is clean. Refit the drain plug.

Whilst the petrol tank is away from the car it is advisable

to disconnect the fuel feed pipes at the pump and the

carburetter and ensure that these are clear by using an air

jet to one end of the pipe.

Key t o Fig 2 :20

Note Arrows point to fuel tank clamping band screws vent valve

indicator tank unit1 Fuel tank2 Filler cap with

3 Fuel suction pipe and reserve supply

4 Tank clamping bands

FIG 2:20 Location of the fuel tank in front compart-

ment, 500F, L FIG 2:19 Fuel tank in front compartment. The fuel

reserve supply indicator (red light) glows when fuel

amount in tank is less than .8 to 1.1 Imp galls, or 5 litre FUEL TANK

FUEL LINE TO PUMP

FUEL GAUGE CABLE

Page 43 of 128

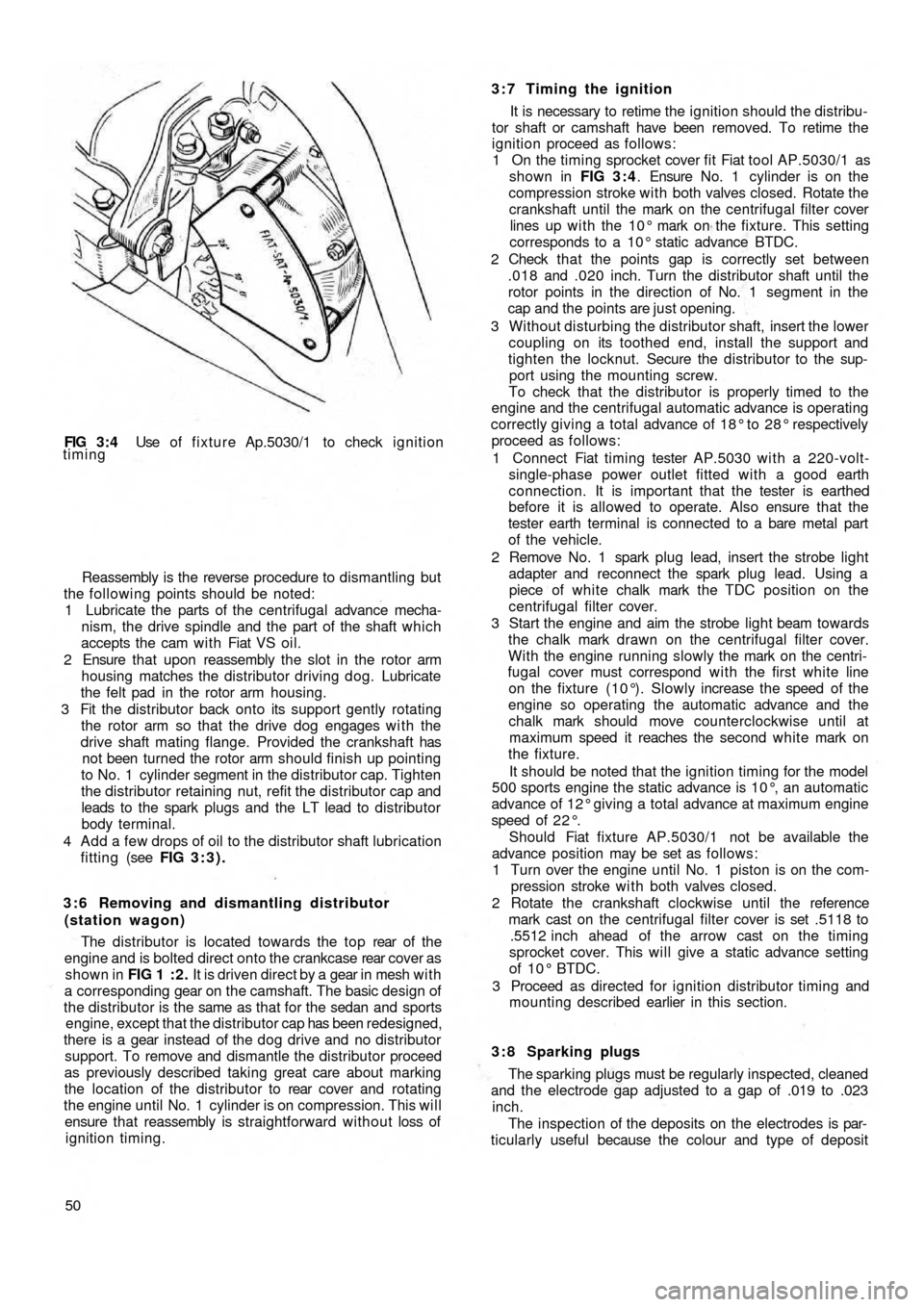

FIG 3 : 4 Use of fixture Ap.5030/1 to check ignition

timing

Reassembly is the reverse procedure to dismantling but

the following points should be noted:

1 Lubricate the parts of the centrifugal advance mecha-

nism, the drive spindle and the part of the shaft which

accepts the cam w i t h Fiat VS oil.

2 Ensure that upon reassembly the slot in the rotor arm

housing matches the distributor driving dog. Lubricate

the felt pad in the rotor arm housing.

3 Fit the distributor back onto its support gently rotating

the rotor arm so that the drive dog engages w i t h the

drive shaft mating flange. Provided the crankshaft has

not been turned the rotor arm should finish up pointing

to No. 1 cylinder segment in the distributor cap. Tighten

the distributor retaining nut, refit the distributor cap and

leads to the spark plugs and the LT lead to distributor

body terminal.

4 Add a few drops of oil to the distributor shaft lubrication

fitting (see FIG 3:3).

3 : 6 Removing and dismantling distributor

(station wagon)

The distributor is located towards the top rear of t h e

engine and is bolted direct onto the crankcase rear cover as

shown in FIG 1 : 2 . It is driven direct by a gear in mesh w i t h

a corresponding gear on the camshaft. The basic design of

the distributor is the same as that for the sedan and sports

engine, except that the distributor cap has been redesigned,

there is a gear instead of the dog

drive and no distributor

support. To remove and dismantle the distributor proceed

as previously described taking great care about marking

the location of the distributor to rear cover and rotating

the engine until No. 1 cylinder is on compression. This will

ensure that reassembly is straightforward without loss of

ignition timing.

503:7 Timing the ignition

It is necessary to retime the ignition should the distribu-

tor shaft or camshaft have been removed. To retime the

ignition proceed as follows:

1 On the timing sprocket cover fit Fiat tool AP.5030/1 as

shown in FIG 3 : 4. Ensure No. 1 cylinder is on the

compression stroke with both valves closed. Rotate the

crankshaft until the mark on the centrifugal filter cover

lines up w i t h the 10° mark on the fixture. This setting

corresponds to a 10° static advance BTDC.

2 Check t h a t the points gap is correctly set between

.018 and .020 inch. Turn the distributor shaft until the

rotor points in the direction of No. 1 segment in the

cap and the points are just opening.

3 Without disturbing the distributor shaft, insert the lower

coupling on its toothed end, install the support and

tighten the locknut. Secure the distributor to the sup-

port using the mounting screw.

To check that the distributor is properly timed to the

engine and the centrifugal automatic advance is operating

correctly giving a

total advance of 18° to 28° respectively

proceed as follows:

1 Connect Fiat timing tester AP.5030 with a 220-volt-

single-phase power outlet fitted with a good earth

connection. It is important that the tester is earthed

before it is allowed to operate. Also ensure that the

tester earth terminal is connected to a bare metal part

of the vehicle.

2 Remove No. 1 spark plug lead, insert the strobe light

adapter and reconnect the spark plug lead. Using a

piece of white chalk mark the TDC position on the

centrifugal filter cover.

3 Start the engine and aim the strobe light beam towards

the chalk mark drawn on the centrifugal filter cover.

With the engine running slowly the mark on the centri-

fugal cover must correspond wi th the first white line

on the fixture (10°). Slowly increase the speed of the

engine so operating the automatic advance and the

chalk mark should move counterclockwise until at

maximum speed it reaches the second white mark on

the fixture.

It should be noted that the ignition timing for the model

500 sports engine the static advance is 10°, an automatic

advance of 12° giving a total advance at maximum engine

speed of 2 2 ° .

Should Fiat fixture AP.5030/1 not be available the

advance position may be set as follows:

1 Turn over the

engine until No. 1 piston is on the com-

pression stroke w i t h both valves closed.

2 Rotate the crankshaft clockwise until the reference

mark cast on the centrifugal filter cover is set .5118 to

.5512 inch ahead of the arrow cast on the timing

sprocket cover. This will give a static advance setting

of 10° BTDC.

3 Proceed as directed for ignition distributor timing and

mounting described earlier in this section.

3 : 8 Sparking plugs

The sparking plugs must be regularly inspected, cleaned

and the electrode gap adjusted to a gap of .019 to .023

inch.

The inspection of the deposits on the electrodes is par-

ticularly useful because the colour and type of deposit

Page 53 of 128

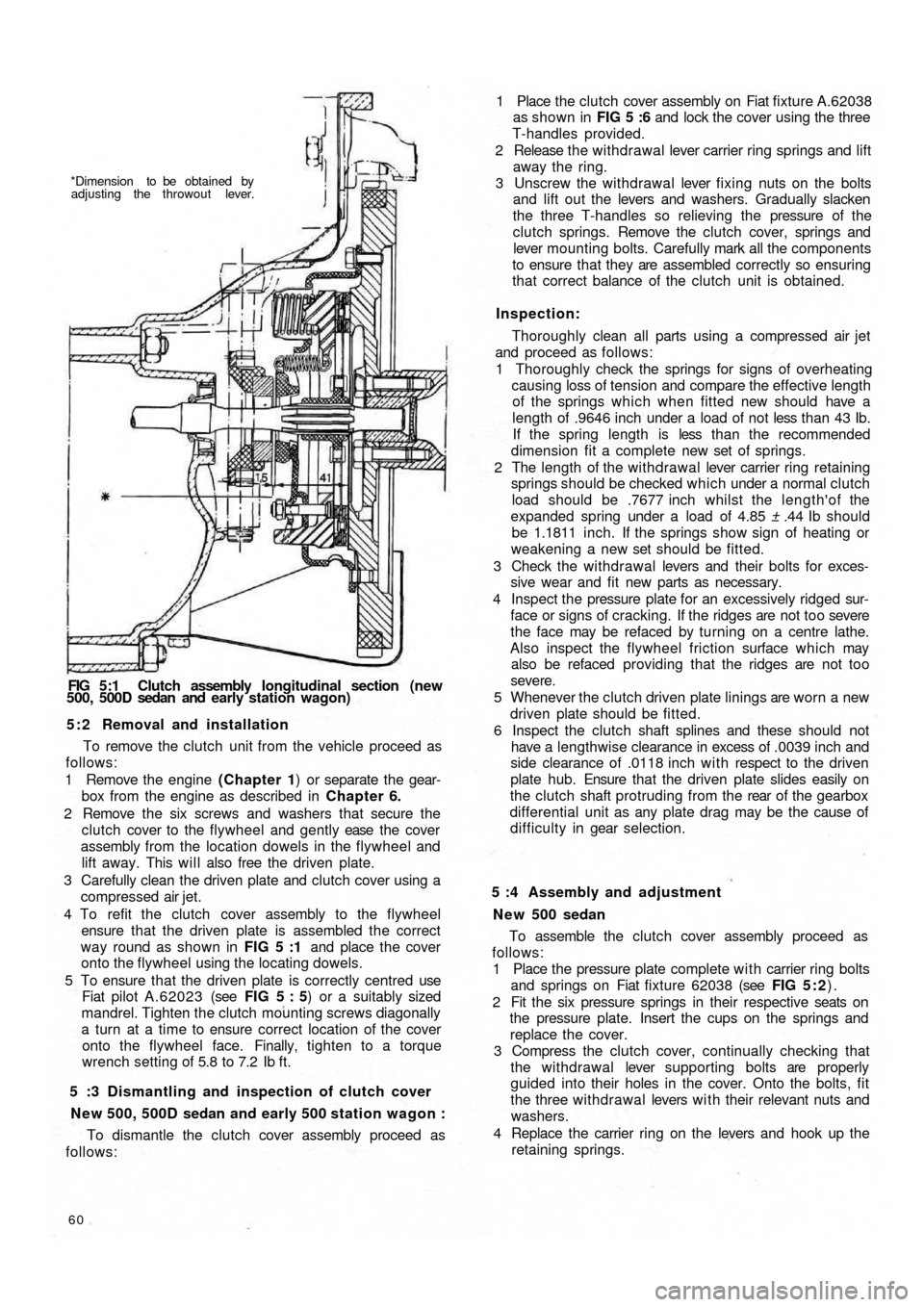

*Dimension to be obtained by

adjusting the throwout lever.

FIG 5:1 Clutch assembly longitudinal section (new

500, 500D sedan and early station wagon)

5 : 2 Removal and installation

To remove the clutch unit from the vehicle proceed as

follows:

1 Remove the engine (Chapter 1) or separate the gear-

box from the engine as described in Chapter 6.

2 Remove the six screws and washers that secure the

clutch cover to the flywheel and gently ease the cover

assembly from the location dowels in the flywheel and

lift away. This will also free the driven plate.

3 Carefully clean the driven plate and clutch cover using a

compressed air jet.

4 To refit the clutch cover assembly to the flywheel

ensure that the driven plate is assembled the correct

way round as shown in FIG 5 :1 and place the cover

onto the flywheel using the locating dowels.

5 To ensure that the driven plate is correctly centred use

Fiat pilot A.62023 (see FIG 5 : 5) or a suitably sized

mandrel. Tighten the clutch mounting screws diagonally

a turn at a time to ensure correct location of the cover

onto the flywheel face. Finally, tighten to a torque

wrench setting of 5.8 to 7.2 Ib ft.

5 :3 Dismantling and inspection of clutch cover

New 500, 500D sedan and early 500 station wagon :

To dismantle the clutch cover assembly proceed as

follows:

60

To assemble the clutch cover assembly proceed as

follows:

1 Place the pressure plate complete with carrier ring bolts

and springs on Fiat fixture 62038 (see FIG 5 : 2).

2 Fit the six pressure springs in their respective seats on

the pressure plate. Insert the cups on the springs and

replace the cover.

3 Compress the clutch cover, continually checking that

the withdrawal lever supporting bolts are properly

guided into their holes in the cover. Onto the bolts, fit

the three withdrawal levers w i t h their relevant nuts and

washers.

4 Replace the carrier ring on the levers and hook up the

retaining springs. 5 :4 Assembly and adjustment

N e w 500 sedan1 Place the clutch cover assembly on Fiat fixture A.62038

as shown in FIG 5 :6 and lock the cover using the three

T-handles provided.

2 Release the w i thdrawal lever carrier ring springs and lift

away the ring.

3 Unscrew the withdrawal lever fixing nuts on the bolts

and lift out the levers and washers. Gradually slacken

the three T-handles so relieving the pressure of the

clutch springs. Remove the clutch cover, springs and

lever mounting bolts. Carefully mark all the components

to ensure that they are assembled correctly so ensuring

that correct balance of the clutch unit is obtained.

Inspection:

Thoroughly clean all parts using a compressed air jet

and proceed as follows:

1 Thoroughly check the springs for signs of overheating

causing loss of tension and compare the effective length

of the springs which when fitted new should have a

length of .9646 inch under a load of not less than 43 Ib.

If the spring length is less t h a n t h e recommended

dimension fit a complete new set of springs.

2 The length of the withdrawal lever carrier ring retaining

springs should be checked which under a normal clutch

load should be .7677 inch whilst the length'of the

expanded spring under a load of 4.85 ± .44 Ib should

be 1.1811 inch. If the springs show sign of heating or

weakening a new set should be fitted.

3 Check the withdrawa l levers and their bolts for exces-

sive wear and fit new parts as necessary.

4 Inspect the pressure plate for an excessively ridged sur-

face or signs of cracking. If the ridges are not too severe

the face may be refaced by turning on a centre lathe.

Also inspect the flywheel friction surface which may

also be refaced providing that the ridges are not too

severe.

5 Whenever the clutch driven plate linings are worn a new

driven plate should be fitted.

6 Inspect the clutch shaft splines and these should not

have a lengthwise clearance in excess of .0039 inch and

side clearance of .0118 inch w i t h respect to the driven

plate hub. Ensure that the driven plate slides easily on

the clutch shaft protruding from the rear of the gearbox

differential unit as any plate drag may be the cause of

d i f f i c u l t y in gear selection.

Page 57 of 128

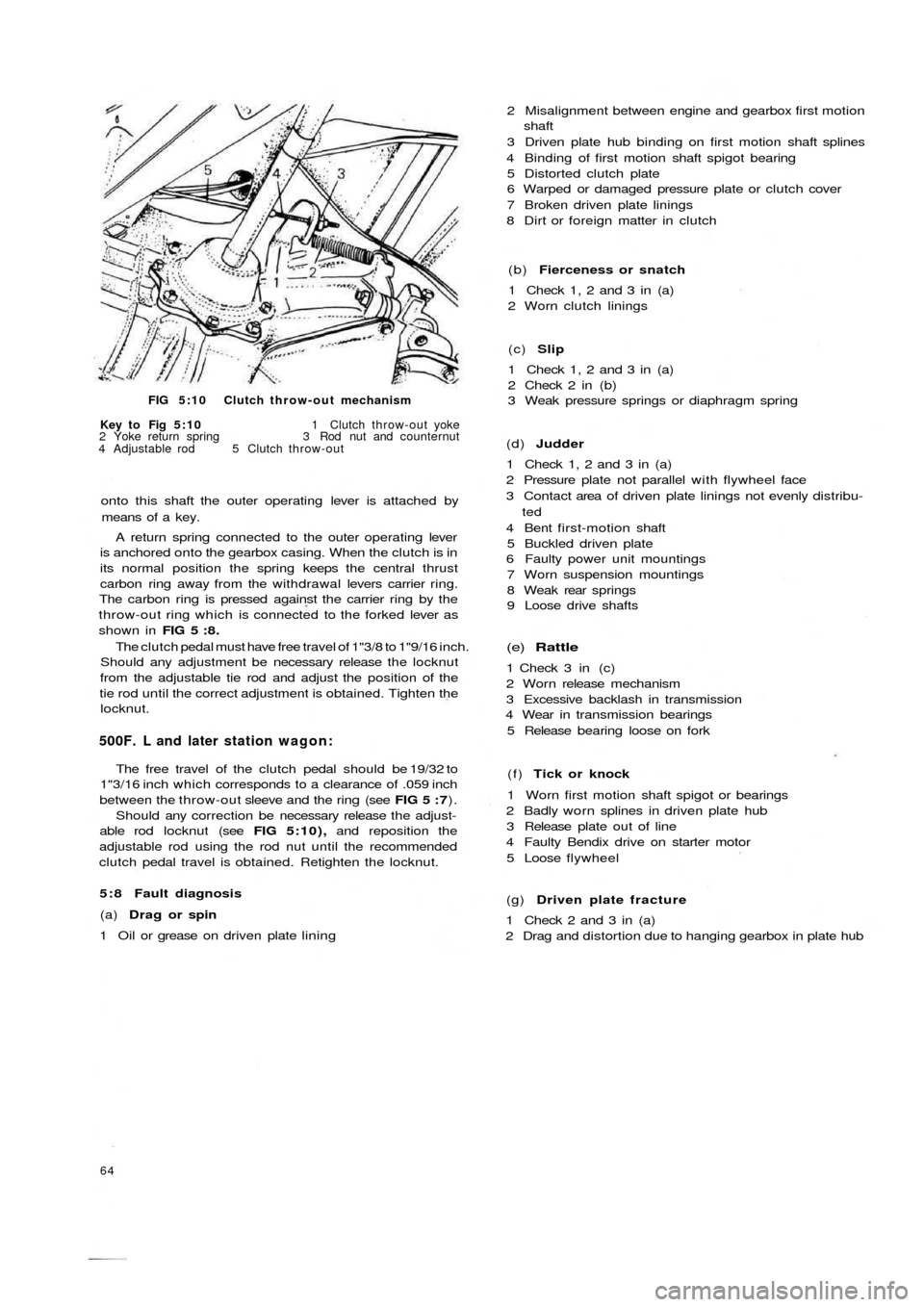

FIG 5:10 Clutch throw-out mechanism

Key to Fig 5:10 1 Clutch throw-out yoke

2 Yoke return spring 3 Rod nut and counternut

4 Adjustable rod 5 Clutch throw-out

onto this shaft the outer operating lever is attached by

means of a key.

A return spring connected to the outer operating lever

is anchored onto the gearbox casing. When the clutch is in

its normal position the spring keeps the central thrust

carbon ring away from the withdrawal levers carrier ring.

The carbon ring is pressed against the carrier ring by the

throw-out ring which is connected to the forked lever as

shown in FIG 5 : 8 .

The clutch pedal must have free travel of 1"3/8 to 1"9/16 inch.

Should any adjustment be necessary release the locknut

from the adjustable tie rod and adjust the position of the

tie rod until the correct adjustment is obtained. Tighten the

locknut.

500F. L and later station wagon:

The free travel of the clutch pedal should be 19/32 to

1"3/16 inch which corresponds to a clearance of .059 inch

between the throw-out sleeve and the ring (see FIG 5 : 7).

Should any correction be necessary release the adjust-

able rod locknut (see FIG 5:10), and reposition the

adjustable rod using the rod nut until the recommended

clutch pedal travel is obtained. Retighten the locknut.

5 : 8 Fault diagnosis

(a) Drag or spin

1 Oil or grease on driven plate lining

64

(g) Driven plate fracture

1 Check 2 and 3 in (a)

2 Drag and distortion due to hanging gearbox in plate hub (f) Tick or knock

1 Worn first motion shaft spigot or bearings

2 Badly worn splines in driven plate hub

3 Release plate out of line

4 Faulty Bendix drive on starter motor

5 Loose flywheel

(e) Rattle

1 Check 3 in (c)

2 Worn release mechanism

3 Excessive backlash in transmission

4 Wear in transmission bearings

5 Release bearing loose on fork (d) Judder

1 Check 1, 2 and 3 in (a)

2 Pressure plate not parallel with flywheel face

3 Contact area of driven plate linings not evenly distribu-

ted

4 Bent first-motion shaft

5 Buckled driven plate

6 Faulty power unit mountings

7 Worn suspension mountings

8 Weak rear springs

9 Loose drive shafts (c) Slip

1 Check 1, 2 and 3 in (a)

2 Check 2 in (b)

3 Weak pressure springs or diaphragm spring (b) Fierceness or snatch

1 Check 1, 2 and 3 in (a)

2 Worn clutch linings 2 Misalignment between engine and gearbox first motion

shaft

3 Driven plate hub binding on first motion shaft splines

4 Binding of first motion shaft spigot bearing

5 Distorted clutch plate

6 Warped or damaged pressure plate or clutch cover

7 Broken driven plate linings

8 Dirt or foreign matter in clutch

Page 76 of 128

high bearing preload. To reset remove the wheel shaft

and fit a new resilient spacer. Repeat the rotation

torque test.

Swinging arm adjustment:

To adjust the swinging arm use Fiat fixture A.66064 as

shown in FIG 7 : 3 and proceed as follows:

1 At points A and B as indicated in FIG 7 : 4 between the

'estendblock' and the swinging arm to body front

mounting bracket fit three shims on each side. To

ensure that the shims are correctly centred use Fiat

alignment bar A.66057.

2 Whilst removing the alignment bar, carefully slip in the

mounting pin and screw on the nut. Once the rear

wheel geometry adjustment has been completed this

nut should be tightened to a torque wrench setting

of 43.4 to 50.6 Ib ft.

3 At points C and D (see FIG 7 : 4) , insert the number of

shims required to fill in the gap between the 'estend-

block' and the two fixture shoulders. Having deter-

mined the number of shims required both at locations

C and D, these must later be fitted between the

'estendblock' and the shoulders on the swinging arm

to body mounting bracket.

7 : 4 Coil springs

The coil springs should be thoroughly cleaned and all

traces of rust removed. Inspect the spring coils for hair

line cracks, which if evident, a new pair of springs must

be fitted to ensure correct vehicle height and stability.

Check the free

height and the height under loading of

the coil springs and these must correspond to the figures

quoted in Technical Data.

7:5 Installation of rear suspension assembly

To replace the rear suspension assembly proceed as

follows:

1 Insert the swinging arm inner end in the mounting

bracket which is welded onto the body floor. Place

between the 'estendblock' and bracket the number of

adjustment shims as previously determined using Fiat

fixture A.66064 as shown in FIG 7 : 4. Insert the Fiat

alignment bar A.66057 through 'estendblock' and

shims, aligning them with the holes in the mounting

bracket. Firmly hold the entire assembly using a garage

hydraulic jack if necessary, and carefully remove the

alignment bar and at the same time ease in t h e

mounting pin. Secure the nut which once the rear

wheels geometry has been checked must be tightened

to a torque wrench setting of 43.4 to 50.6 Ib/ft.

2 Screw in finger tight the three swinging arm external

bracket to body floor mounting screws together w i t h

the plain and spring washers. The screws will have to

be tightened to a torque wrench setting of 28.9 to

36.2 Ib/ft once the rear wheel geometry has been

adjusted.

3 Carefully insert the coil spring, lower insulator ring

onto the swinging arm, insert the spring on the shock

absorber which should be previously secured to the

arm and position the spring onto its seat on the arm.

Place the upper insulator ring onto the spring, raise the

suspension assembly using a garage hydraulic jack and

insert the spring onto its seating under the body floor.

F50083 4 Ensure that the shock absorber to floor rubber ring has

been correctly fitted and extend the shock absorber

until its upper mounting pin protrudes into the vehicle

through the hump in the floor panel. Secure the shock

absorber by its mounting nut and lockwasher having

first inserted the rubber ring and plain washer.

5 Refit the rear wheel housing in place, reconnect the

brake line to the connection on body floor and remove

the plug from the output hole in the brake fluid

reservoir. Bleed the hydraulic brake system as

described in Chapter 10.

Key to Fig 7:8 k Distance of centre rear bracket, for

jacking up the vehicle, from floor level (8.90 inch)

Half-track = 22.264 inch ±.059 inch

FIG 7 : 8 Position of rear suspension f o r rear wheel

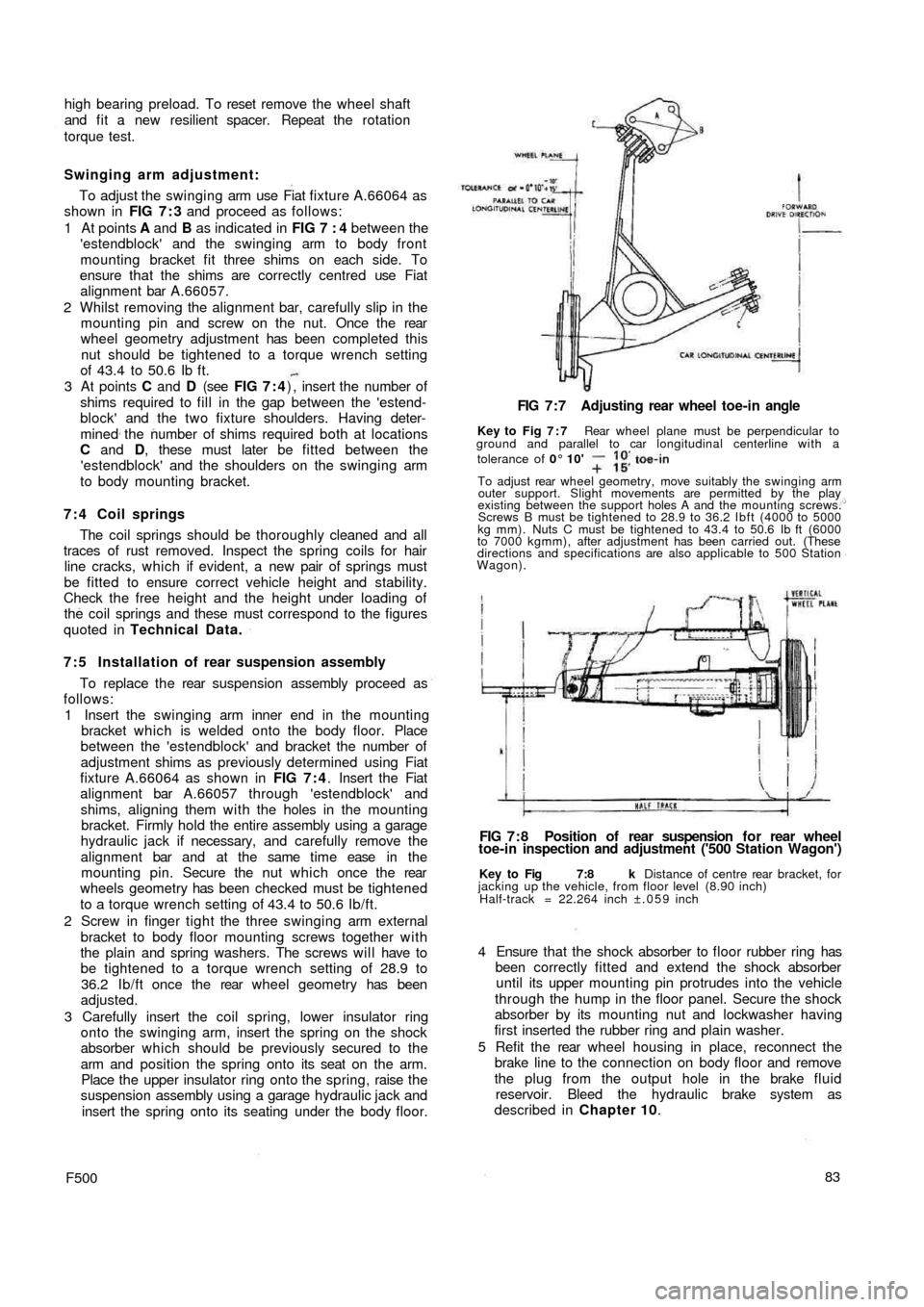

toe-in inspection and adjustment ('500 Station Wagon') FIG 7 : 7 Adjusting rear wheel toe-in angle

Key to Fig 7 : 7 Rear wheel plane must be perpendicular to

ground and parallel to car longitudinal centerline with a

tolerance of 0° 10'

To adjust rear wheel geometry, move suitably the swinging arm

outer support. Slight movements are permitted by the play

existing between the support holes A and the mounting screws.

Screws B must be tightened to 28.9 to 36.2 Ibft (4000 to 5000

kg mm). Nuts C must be tightened to 43.4 to 50.6 Ib ft (6000

to 7000 kgmm), after adjustment has been carried out. (These

directions and specifications are also applicable to 500 Station

Wagon).

Page 97 of 128

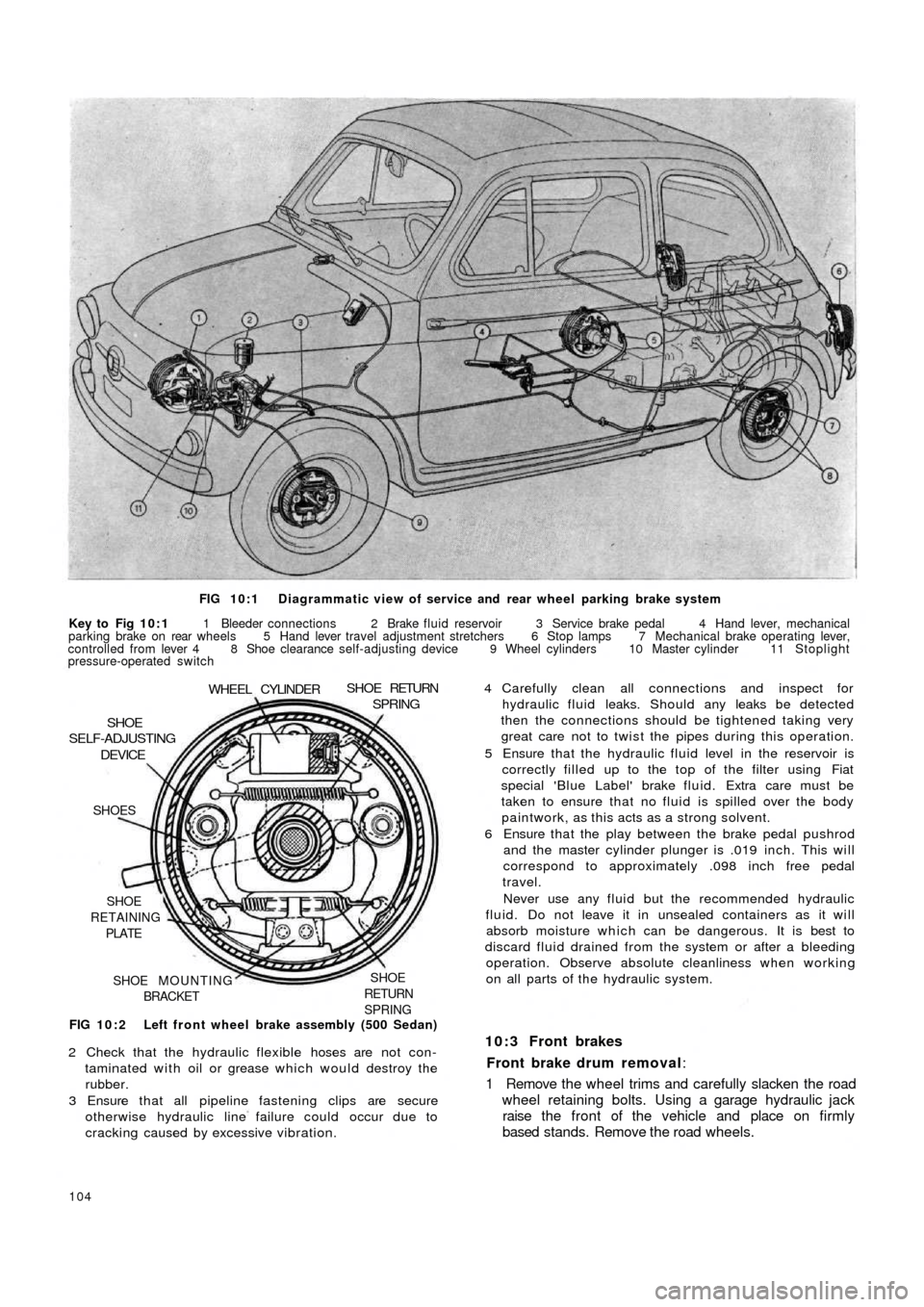

FIG 10:1 Diagrammatic view of service and rear wheel parking brake system

Key to Fig 10:1 1 Bleeder connections 2 Brake fluid reservoir 3 Service brake pedal 4 Hand lever, mechanical

parking brake on rear wheels 5 Hand lever travel adjustment stretchers 6 Stop lamps 7 Mechanical brake operating lever,

controlled from lever 4 8 Shoe clearance self-adjusting device 9 Wheel cylinders 10 Master cylinder 11 Stoplight

pressure-operated switch

FIG 10:2 Left front wheel brake assembly (500 Sedan)

SHOE

RETURN

SPRINGSHOE MOUNTING

BRACKET SHOE

RETAINING

PLATE SHOES

DEVICESHOE

SELF-ADJUSTING

WHEEL CYLINDERSHOE RETURNSPRING

2 Check that the hydraulic flexible hoses are not con-

taminated with oil or grease which would destroy the

rubber.

3 Ensure that all pipeline fastening clips are secure

otherwise hydraulic line failure could occur due to

cracking caused by excessive vibration.

104

4 Carefully clean all connections and inspect for

hydraulic fluid leaks. Should any leaks be detected

then the connections should be tightened taking very

great care not to twist the pipes during this operation.

5 Ensure that the hydraulic fluid level in the reservoir is

correctly filled up to the top of the filter using Fiat

special 'Blue Label' brake fluid. Extra care must be

taken to ensure that no fluid is spilled over the body

paintwork, as this acts as a strong solvent.

6 Ensure that the play between the brake pedal pushrod

and the master cylinder plunger is .019 inch. This will

correspond to approximately .098 inch free pedal

travel.

Never use any fluid but the recommended hydraulic

fluid. Do not leave it in unsealed containers as it will

absorb moisture which can be dangerous. It is best to

discard fluid drained from the system or after a bleeding

operation. Observe absolute cleanliness when working

on all parts of the hydraulic system.

10:3 Front brakes

Front brake drum removal:

1 Remove the wheel trims and carefully slacken the road

wheel retaining bolts. Using a garage hydraulic jack

raise the front of the vehicle and place on firmly

based stands. Remove the road wheels.