light FIAT 500 1962 1.G Owner's Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 1962, Model line: 500, Model: FIAT 500 1962 1.GPages: 128, PDF Size: 9.01 MB

Page 116 of 128

Lamp brilliance varies w i t h the speed of t h e car:

Check the condition of the battery. Examine the battery

connections. Make sure they are tight and renew faulty

cables.

11:10 Panel and warning lights:

All the gauges are clustered in a single instrument

mounted on the dashboard above the steering column.

Incorporated in this cluster is the parking light pilot light,

generator charge indicator, fuel reserve supply indicator,

low oil pressure indicator, and the speedometer w i t h

mileage recorder.

The parking lamp indicator glows green when the

ignition lock switch key is in either position 1 or 2 once

the toggle switch on the instrument panel has been

operated.

The generator charge indicator shows red only when

the ignition is turned on. It should be extinguished when

the generator output is sufficient for battery charge

(12.6 ± 0.2 volts) with the engine running at a speed

of 1100 rev/min and the headlights switched off.

The fuel reserve supply indicator shows red only when

the ignition is turned on and the amount of fuel in the

petrol tank has dropped to approximately .8 to 1.1

Imp. gallons.

The low oil pressure indicator shows red only when the

ignition is turned on and should be extinguished when

the oil pressure reaches 7.1 to 21.3 Ib/sq in, and opens

the sending unit contacts. Once the engine is at normal

operating temperature but at a speed below 1000 rev/

min the indicator might light up even the pressure is under

control and with normal operation.

All the bulbs fitted to the above described units are of

the tubular 2.5W type and to renew a bulb extract the

bulb holder from the rear of t h e instrument cluster and

release the bulb which is attached by a normal bayonet

coupling.

Fuel reserve supply indicator sender u n i t:

The fuel reserve supply indicator should be checked for

correct indication by allowing the fuel tank to empty and

then inserting .8 to 1.1 Imp. gallons at which stage the

light should extinguish. Any failure to do so should be

checked as follows:

1 Ensure that the indicator bulb operates correctly.

2 Check for complete circuit between the sender unit and

the indicator bulb.

3 If the sender unit float bracket is distorted the bulb

will

indicate a reserve supply of fuel greater or smaller than

specified. The bracket should be adjusted to give

correct indication of fuel level.

4 The sender unit could have been inadvertantly

damaged in which case the unit must be renewed.

11 :11 The horn

The horn circuit comprises the horn, push button at the

centre of the steering wheel and normal earth return

electrical circuit through the car body. One terminal is

connected to the battery whilst the other to the push

button on the steering wheel which when the button is

depressed the circuit will be closed so causing the horn

to operate.

F500

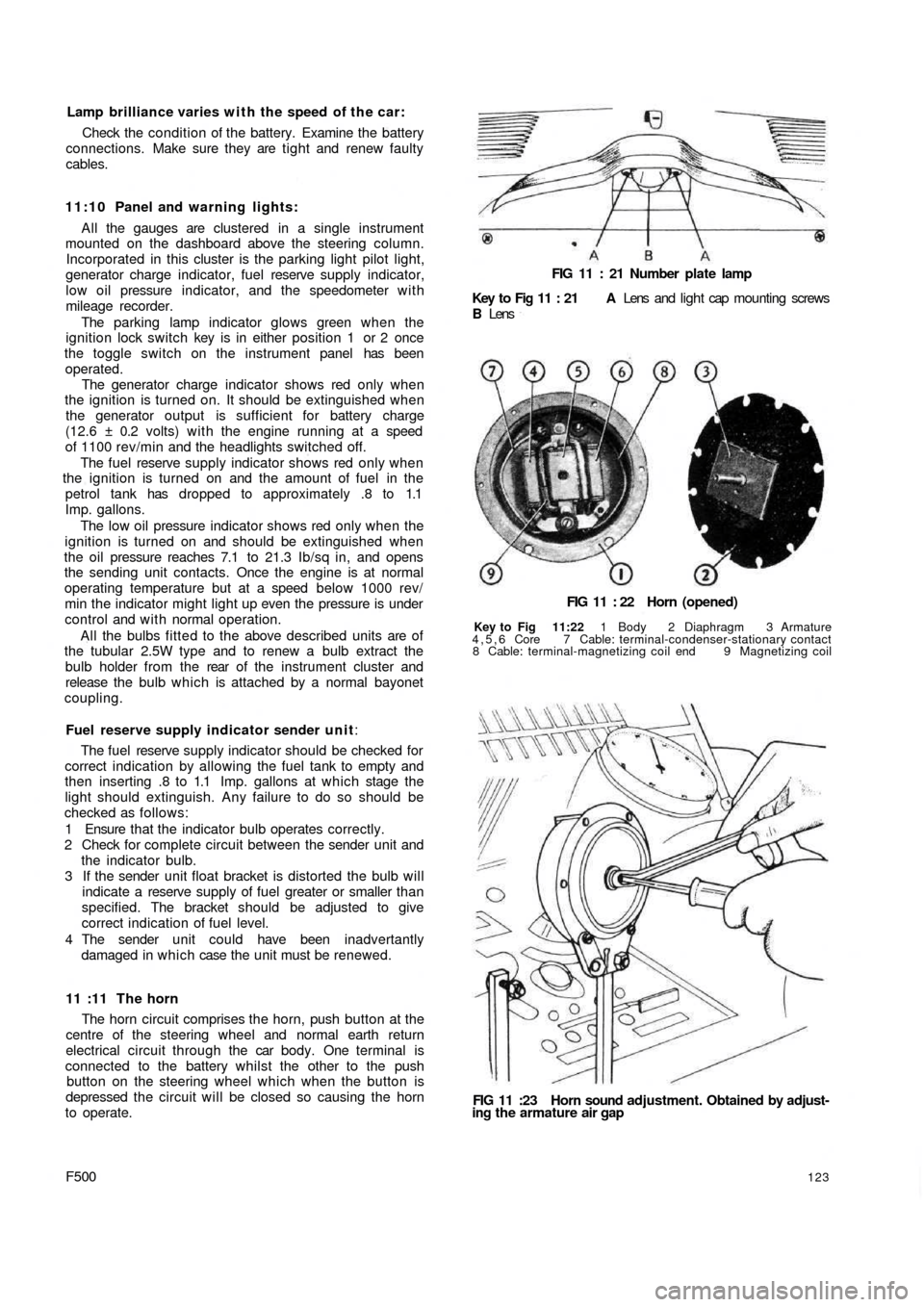

FIG 11 : 21 Number plate lamp

Key to Fig 11 : 21 A Lens and light cap mounting screws

B Lens

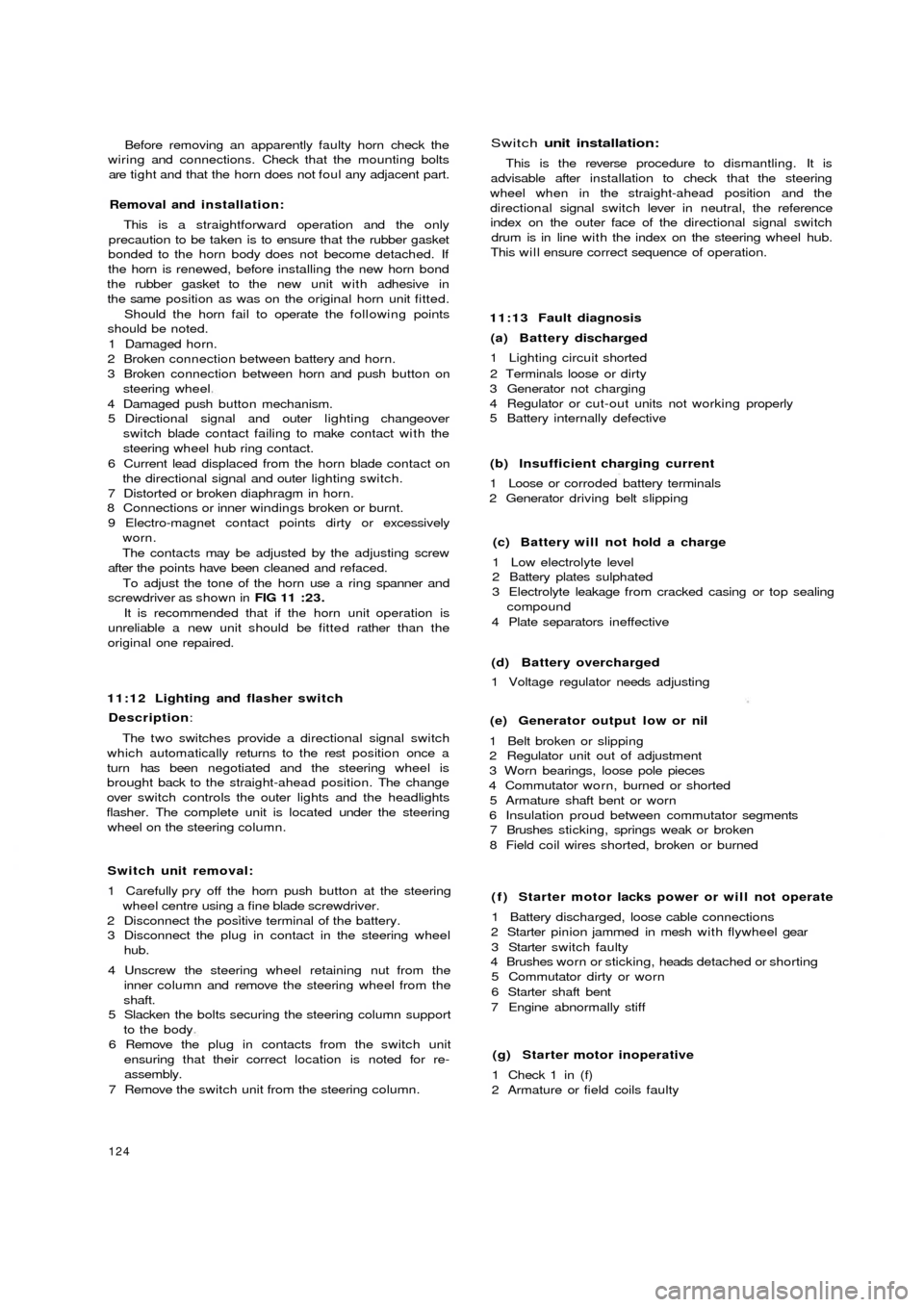

FIG 11 : 22 Horn (opened)

Key to Fig 11:22 1 Body 2 Diaphragm 3 Armature

4,5,6 Core 7 Cable: terminal-condenser-stationary contact

8 Cable: terminal-magnetizing coil end 9 Magnetizing coil

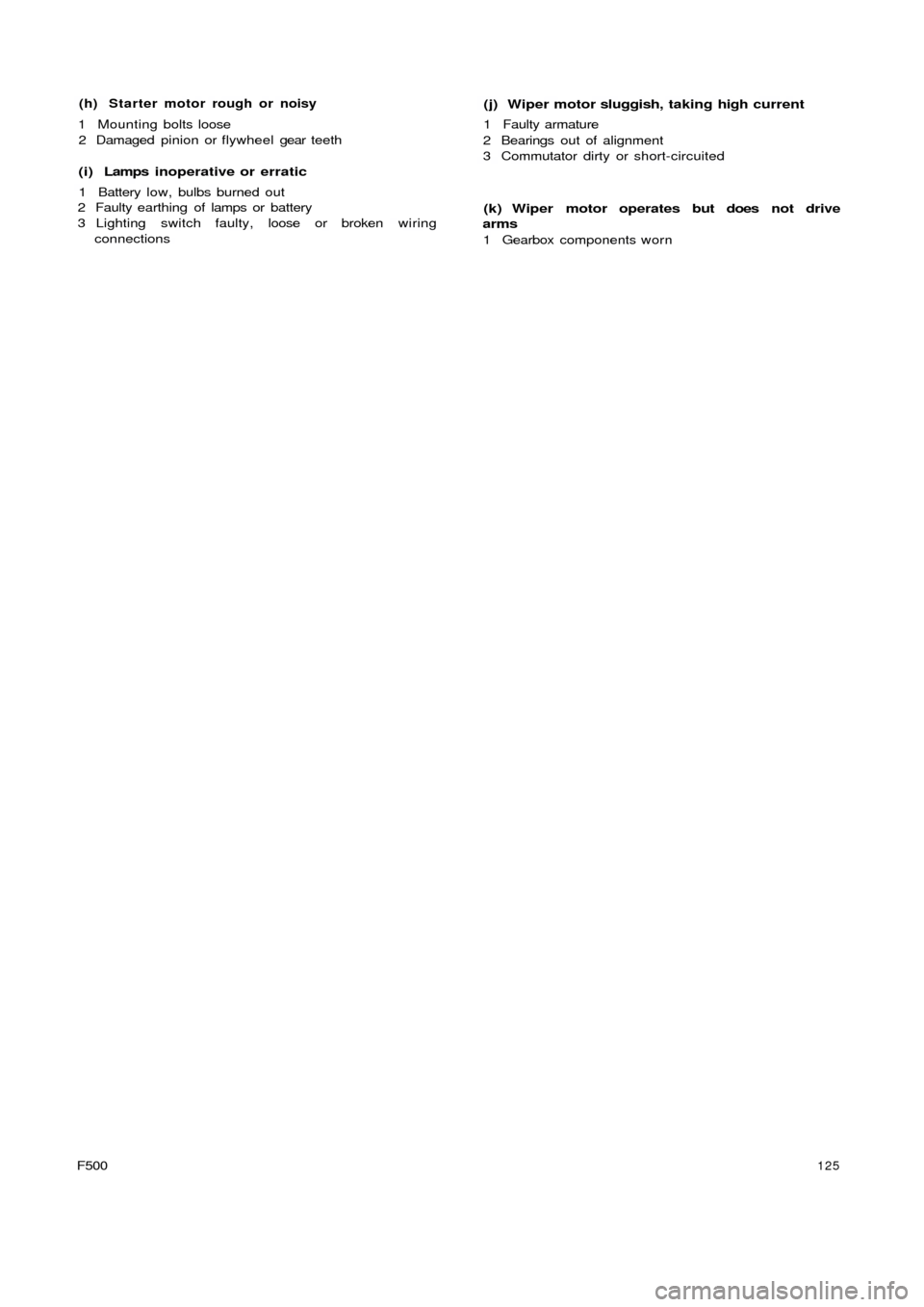

FIG 11 :23 Horn sound adjustment. Obtained by adjust-

ing the armature air gap

123

Page 117 of 128

Before removing an apparently faulty horn check the

wiring and connections. Check that the mounting bolts

are tight and that the horn does not foul any adjacent part.

Removal and installation:

This is a straightforward operation and the only

precaution to be taken is to ensure that the rubber gasket

bonded to the horn body does not become detached. If

the horn is renewed, before installing the new horn bond

the rubber gasket to the new unit with adhesive in

the same position as was on the original horn unit fitted.

Should the horn fail to operate the following points

should be noted.

1 Damaged horn.

2 Broken connection between battery and horn.

3 Broken connection between horn and push button on

steering wheel

4 Damaged push button mechanism.

5 Directional signal and outer lighting changeover

switch blade contact failing to make contact with the

steering wheel hub ring contact.

6 Current lead displaced from the horn blade contact on

the directional signal and outer lighting switch.

7 Distorted or broken diaphragm in horn.

8 Connections or inner windings

broken or burnt.

9 Electro-magnet contact points dirty or excessively

worn.The contacts may be adjusted by the adjusting screw

after the points have been cleaned and refaced.

To adjust the tone of the horn use a ring spanner and

screwdriver as shown in FIG 11 :23.

It is recommended that if the horn unit operation is

unreliable a new unit should be fitted rather than the

original one repaired.

11:12 Lighting and flasher switch

Description:

The two switches provide a directional signal switch

which automatically returns to the rest position once a

turn has been negotiated and the steering wheel is

brought back to the straight-ahead position. The change

over switch controls the outer lights and the headlights

flasher. The complete unit is located under the steering

wheel on the steering column.

Switch unit removal:

1 Carefully pry off the horn push button at the steering

wheel centre using a fine blade screwdriver.

2 Disconnect the positive terminal of the battery.

3 Disconnect the plug in contact in the steering wheel

hub.

4 Unscrew the steering wheel retaining nut from the

inner column and remove the steering wheel from the

shaft.

5 Slacken the bolts securing the steering column support

to the body

6 Remove the plug in contacts from the switch unit

ensuring that their correct location is noted for re-

assembly.7 Remove the switch unit from the steering column.

124

Switch unit installation:

This is the reverse procedure to dismantling. It is

advisable after installation to check that the steering

wheel when in the straight-ahead position and the

directional signal switch lever in neutral, the reference

index on the outer face of the directional signal switch

drum is in line with the index on the steering wheel hub.

This will ensure correct sequence of operation.

11:13 Fault diagnosis

(a) Battery discharged

1 Lighting circuit shorted

2 Terminals loose or dirty

3 Generator not charging

4 Regulator or cut-out units not working properly

5 Battery internally defective

(b) Insufficient charging current

1 Loose or corroded battery terminals

2 Generator driving belt slipping

(c) Battery will not hold a charge

1 Low electrolyte level

2 Battery plates sulphated

3 Electrolyte leakage from cracked casing or top sealing

compound

4 Plate separators ineffective

(d) Battery overcharged

1 Voltage regulator needs adjusting

(e) Generator output low or nil

1 Belt broken or slipping

2 Regulator unit out of adjustment

3 Worn bearings, loose pole pieces

4 Commutator worn, burned or shorted

5 Armature shaft bent or worn

6 Insulation proud between commutator segments

7 Brushes sticking, springs weak or broken

8 Field coil wires shorted, broken or burned

( f ) Starter motor lacks power or will not operate

1 Battery discharged, loose cable connections

2 Starter pinion jammed in mesh with flywheel gear

3 Starter switch faulty

4 Brushes worn or sticking, heads detached or shorting

5 Commutator dirty or worn

6 Starter shaft bent

7 Engine abnormally stiff

(g) Starter motor inoperative

1 Check 1 in (f)

2 Armature or field coils faulty

Page 118 of 128

(h) Starter motor rough or noisy

1 Mounting bolts loose

2 Damaged pinion or flywheel gear teeth

( i ) Lamps inoperative or erratic

1 Battery low, bulbs burned out

2 Faulty earthing of lamps or battery

3 Lighting switch faulty, loose or broken wiring

connections

F500

125

(j) Wiper motor sluggish, taking high current

1 Faulty armature

2 Bearings out of alignment

3 Commutator dirty or short-circuited

(k) Wiper motor operates but does not drive

arms

1 Gearbox components worn

Page 120 of 128

CHAPTER 12

THE BODYWORK

12:1

12:2

12:3

12:4

12:5

12:6

12:7Bodywork finish

Interior and chrome cleaning

Door trim and accessories

Door handles and locks

Removing regulator and door glass

Removing windshield glass

Removing rear side windows12:8

12:9

12:10

12:11

12:12

12:13

12:14Removing rear window glass

Front compartment lid

Engine compartment lid

Folding top

Sun roof

Seats

Interior heater

12:1 Bodywork finish

Large scale repairs to body panels are best left to

expert panel beaters. Even small dents can be tricky, as too

much hammering will stretch the metal and make things

worse instead of better. Filling minor dents and scratches

is probably the best method of restoring the surface. The

touching up of paintwork is well within the powers of

most car owners, particularly as self-spraying cans of

paint in the correct colours are now readily available. It

must be remembered, however, that paint changes colour

w i t h age and it is better to spray a whole wing rather than

try to touch up a small area.

Before spraying it is essential to remove all traces of

wax polish with white spirit. More drastic treatment is

required if silicone polishes have been applied. Use a

primer surfacer or paste stopper according to the amount

of filling required, and when it is dry, rub it down with

400 grade Wet or Dry paper until the surface is smooth

and flush with the surrounding area. Spend time on

getting the best finish as this will control the final effect.

Apply the retouching paint, keeping it wet in the centre

and light and dry round the edges. After a few hours of

drying, use a cutting compound to remove the dry spray

and finish with liquid polish.

F500127

12:2 Interior and chrome cleaning

The cloth upholstery of the seating and the rear

compartment lining must be regularly cleaned to ensure

long life and preserve its attractive appearance. Any dust

or dirt that is blown into the car will settle on the uphol-

stery and will tend to wear the cloth causing an unsightly

appearance. It is recommended that the dust is wiped off

using either a vacuum cleaner or a stiff brush. To remove

ordinary soiling of the upholstery cloth proceed as

follows:

1 Using luke warm water and a neutral soap and a piece

of clean cloth wipe over the upholstery in the direction

of the nap.

2 Repeat the operation using a clean damp cloth and

warm water but no soap.

3 Allow the upholstery cloth to dry, use a stiff brush

against the direction of the upholstery nap to restore

its original fluffy look.

To obtain best results, any stains must be removed as

soon as possible otherwise as time passes they will

become more difficult, if not impossible to remove.

Certain stains require specific solvents and the instruc-

tions must be strictly adhered to.

Page 125 of 128

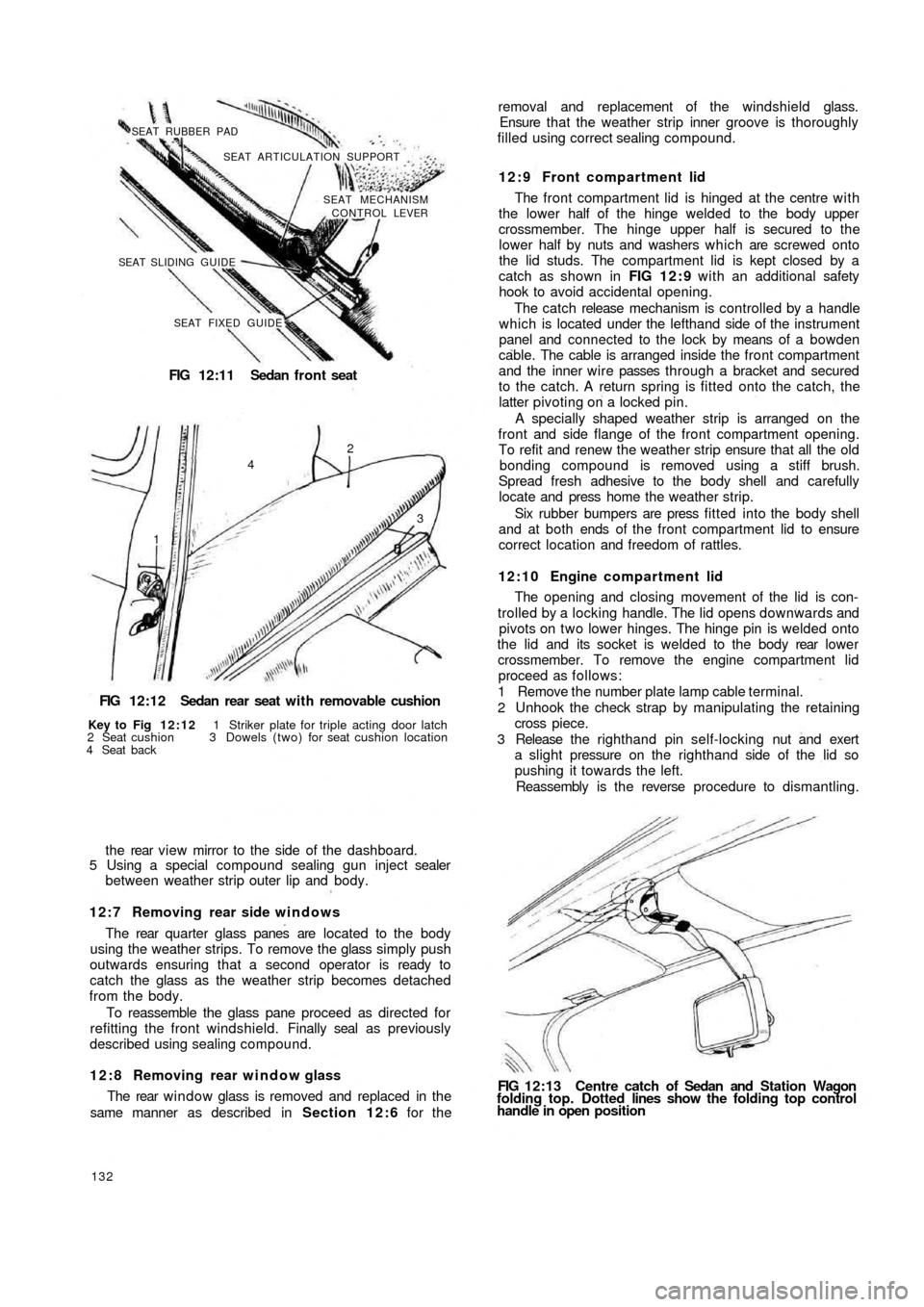

SEAT RUBBER PAD

SEAT ARTICULATION SUPPORT

SEAT MECHANISM

CONTROL LEVER

SEAT SLIDING GUIDE

SEAT FIXED GUIDE

FIG 12:11 Sedan front seat

42

3

1

FIG 12:12 Sedan rear seat w i t h removable cushion

Key to Fig 12:12 1 Striker plate for triple acting door latch

2 Seat cushion 3 Dowels (two) for seat cushion location

4 Seat back

t h e rear v i e w mirror to the side of the dashboard.

5 Using a special compound sealing gun inject sealer

between weather strip outer lip and body.

12:7 Removing rear side windows

The rear quarter glass panes are located to the body

using the weather strips. To remove the glass simply push

outwards ensuring that a second operator is ready to

catch the glass as the weather strip becomes detached

from the body.

To reassemble the glass pane proceed as directed for

refitting the front windshield. Finally seal as previously

described using sealing compound.

12:8 Removing rear window glass

The rear window glass is removed and replaced in the

same manner as described in Section 12:6 for the

132

FIG 12:13 Centre catch of Sedan and Station Wagon

folding top. Dotted lines show the folding top control

handle in open position removal and replacement of the windshield glass.

Ensure t h a t the weather strip inner groove is thoroughly

filled using correct sealing compound.

1 2 : 9 Front compartment lid

The front compartment lid is hinged at the centre w i t h

the lower half of the hinge welded to the body upper

crossmember. The hinge upper half is secured to the

lower half by nuts and washers which are screwed onto

the lid studs. The compartment lid is kept closed by a

catch as shown in FIG 1 2 : 9 with an additional safety

hook to avoid accidental opening.

The catch release mechanism is controlled by a handle

which is located under the lefthand side of the instrument

panel and connected to the lock by means of a bowden

cable. The cable is arranged inside the front compartment

and the inner wire passes through a bracket and secured

to the catch. A return spring is fitted onto the catch, the

latter pivoting on a locked pin.

A specially shaped weather strip is arranged on the

front and side flange of the front compartment opening.

To refit and renew the weather strip ensure that all the old

bonding compound is removed using a stiff brush.

Spread fresh adhesive to the body shell and carefully

locate and press home the weather strip.

Six rubber bumpers are press fitted into the body shell

and at both ends of the front compartment lid to ensure

correct location and freedom of rattles.

12:10 Engine compartment lid

The opening and closing movement of the lid is con-

trolled by a locking handle. The lid opens downwards and

pivots on two lower hinges. The hinge pin is welded onto

the lid and its socket is welded to the body rear lower

crossmember. To remove the engine compartment lid

proceed as follows:

1 Remove the number plate lamp cable terminal.

2 Unhook the check strap by manipulating the retaining

cross piece.

3 Release the righthand pin self-locking nut and exert

a slight pressure on the righthand side of the lid so

pushing it towards the left.

Reassembly is the reverse procedure to dismantling.