recommended oil FIAT 500 1965 1.G Workshop Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1965, Model line: 500, Model: FIAT 500 1965 1.GPages: 128, PDF Size: 9.01 MB

Page 12 of 128

Cylinder head installation:

To refit the cylinder head proceed as follows:

Place a new cylinder head joint on the cleaned faces of

the cylinder barrels. Insert the rocker pushrod and

lubrication pipe sleeves together with the relevant

gaskets and rings.

Fit the washers and nuts to the studs and tighten to

fingertight.

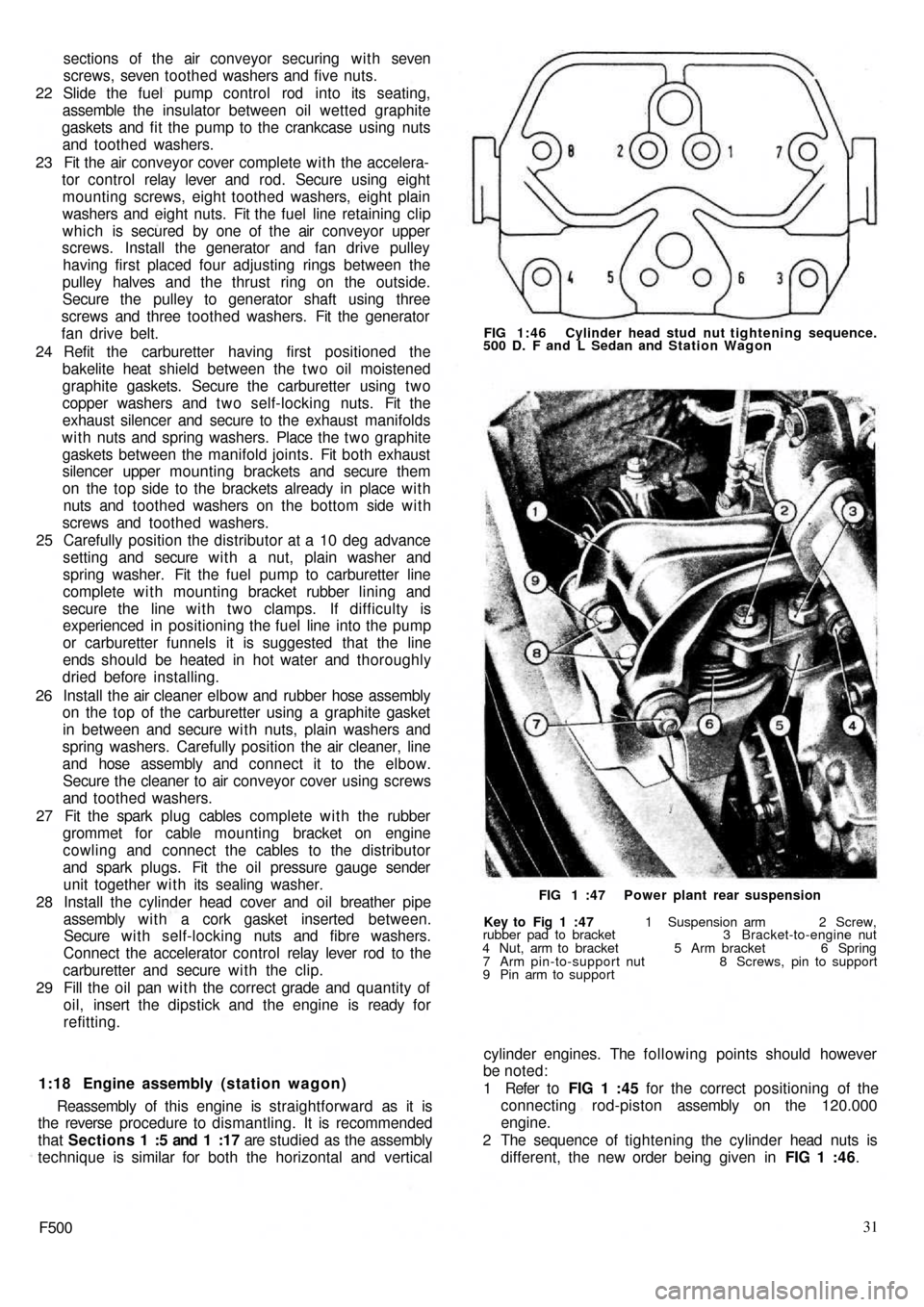

Tighten the nuts in the order shown in FIG 1 :44 and

FIG 1 :46 to a torque wrench setting of 18.1 Ibft. Reset

the torque wrench to a new setting of 23.9 Ibft and

tighten the nuts once more in the recommended order.

Replace the pushrods in the correct order.

Refit the rocker shaft ensuring correct location of the

lubrication tube to the rocker shaft and replace the

plain and lockwashers. Tighten the nuts to a torque

wrench setting of 15.2 Ibft. Reset the tappet to rocker

clearance adjustment.

Connect the t w o exhaust side manifolds to the cylinder

head. Using new gasket refit the spark plugs and HT

cables. Replace the rocker cover fitted with a new cork

gasket and blower conveyor to the cylinder head

securing screws. Refit the carburetter and reconnect its

fuel line and controls. Refit the air cleaner and elbow

and connect the rocker cover breather pipe (if fitted).

1

2

3

4

5

1 :7 Timing gear overhaul

Camshaft:

The cast iron camshaft is located in the crankcase and is

supported at either end in sets machined directly in the

crankcase. No bushes are used. The camshaft is driven by

a chain from the crankshaft at half engine speed and

operates the overhead valves through tappets, pushrods

and rockers (see

FIG 1 :20).During engine overhaul the camshaft journals and cam

faces should be free of score marks or signs of seizure and

have a bright mirror finish.

The distributor drive gear should be inspected for tooth

wear which if excessive means that the camshaft must be

replaced.

Tappets:

The tappets should be inspected for signs of seizure or

excessive wear. The end surface that is in contact with the

camshaft should be smooth without signs of excessive

wear. Any slight scratches or indentations may be

removed using a very fine oil stone.

Pushrods and sleeves:

The pushrods operate in special axially resilient sleeves

that are compressed on assembly between the cylinder

head and the crankcase. It is through these sleeves that

the engine sump is vented also through which the oil

returning from the cylinder head passes.

Two rubber O-ring seals are fitted to each sleeve to

ensure an oil t i g h t seal between the cylinder head and

crankcase. The sleeves should be checked for distortion

and exact equal length and when refitting new seals must

always be fitted.

The pushrods should be checked for straightness and

the t w o ends that contact the rocker setscrew and the

F50019

The crankcase is an aluminium casting suitably ribbed

to ensure correct air cooling. The main bearing and cam-

shaft bearing bores are machined as also are the tappet 1 :8 Crankcase and cylinders During valve gear overhauls the clearance between the

rocker shaft bore and the rocker must be checked. The

maximum permissable wear between these t w o parts is

.0059 inch. It is recommended that the part which is most

worn be renewed, or in extreme cases both parts. Rocker and rocker shaft: tappet seat must not show any signs of roughness or

excessive wear. 3 Oil shield (for intake valves only) 4 Snap ring

5 Rocker 6 Upper spring cup 7 Valve spring

8 Lower spring cup 9 Pushrod 10 Tappet

11 Oil seal ring 12 Pushrod sleeve 13 Seal ring 1 Intake valve 2 Upper cup lock Key t o Fiq

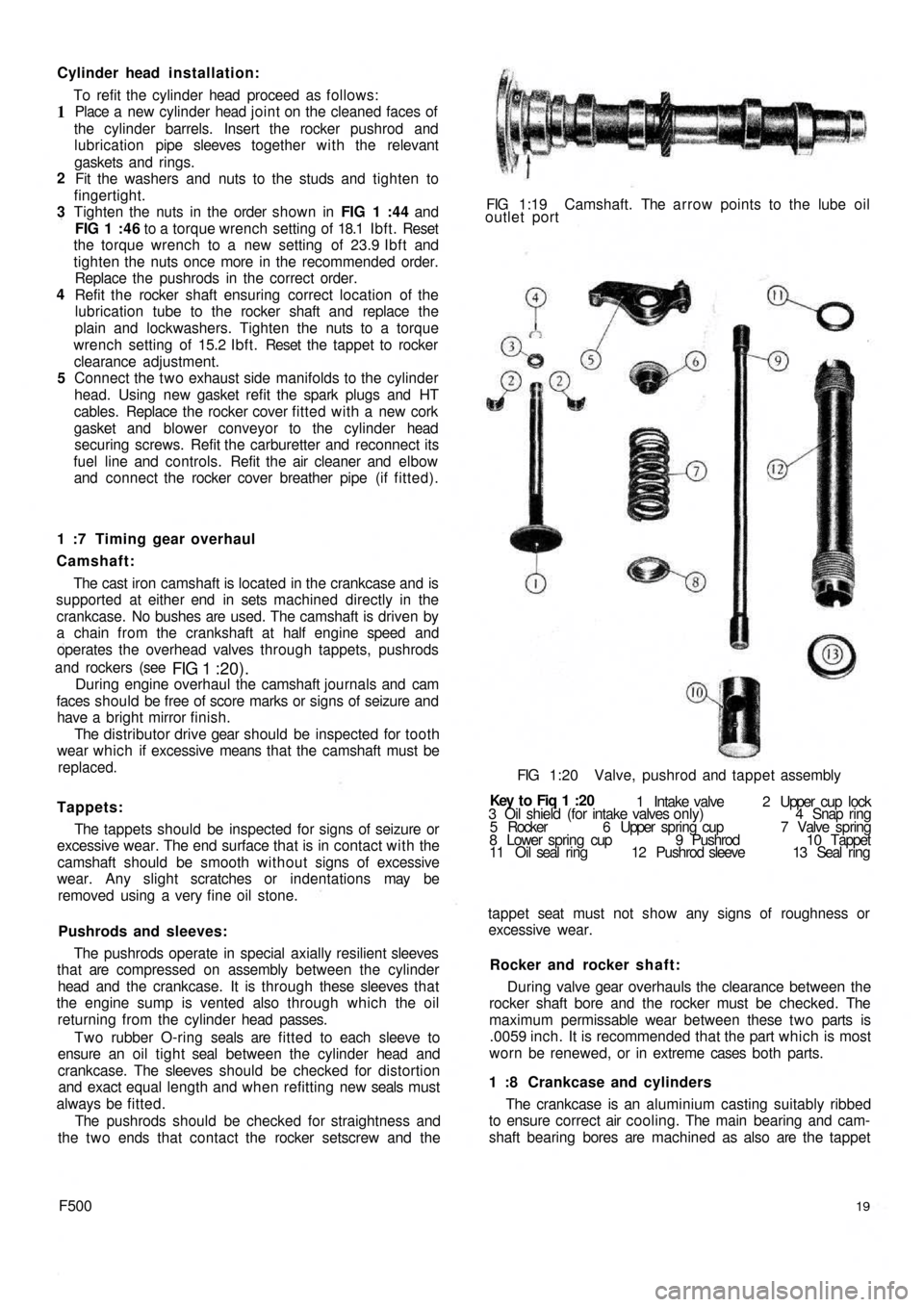

1 :20 FIG 1:20 Valve, pushrod and tappet assembly FIG 1:19 Camshaft. The arrow points to the lube oil

outlet port

Page 18 of 128

After the crankshaft has been reground it is important

that all traces of swarf are removed by constant washing

and then drying with a non-fluffy rag.

The clearance between the main bearings and journals

must be checked before installing the crankshaft in the

engine. It should also serve as a recheck after the

crankshaft has been reground.

Measure the maximum main bearing internal

diameter and the minimum journal diameter using

accurate measuring equipment. The clearance must not

exceed .0039 inch otherwise the journals must be

reground and undersize bearings fitted.

Undersize bearings w i t h .0394 inch stock on the

internal diameter are also supplied unmounted. They

must be press fitted in the supports, the recommended

interference fit being .00039 to .00197 inch. After

pressing the bearing into the support, a hole is drilled in

the bearing in line with the location dowel hole in the

support. The hole is finished with a suitable expanding

reamer, such as Fiat U.0334, and the dowel pressed i n ,

noting that the hollow dowel fits in the flywheel end

support.

The next stage is to heat the assembly in an oven or

oil bath for a period of one hour at 150°C (302°F).

When the assembly has cooled to room temperature,

the bearing is reamed in a lathe to match the crankshaft

journal size.

3

Crankshaft oil seals:

Two inner spring rubber oil seals are located, one in a

special seat in the timing gear cover and the other in the

flywheel end of the crankshaft support and provide oil

tightness. These seals are shown in FIGS 1 :3 and 1 :34.

Whenever the engine is dismantled for overhaul these

seals should be carefully inspected for correct seating and

that the inner seal surface is not worn and that the contact

area is perfect both on the crankshaft and on the fan and

generator drive pulley hub.

Clutch shaft pilot bushing:

A self-lubricating bronze bush is fitted in the end of the

crankshaft as shown in FIG 1 :34 and provides a bearing

for the clutch shaft. Should the bush be worn use Fiat

puller A.40006/1 /2 to remove the worn bush. A new bush

should be fitted using a suitably sized drift.

1:12 Flywheel and starter ring gear

The flywheel should be inspected for wear at the clutch

driven plate contact area. It should be flat and have a

smooth finish.

The ring gear teeth should be cheeked for damage

which if evident, the ring gear must be replaced. To facili-

tate the fitting of a new ring gear on the flywheel, the new

ring gear should be heated in an oil bath to a temperature

of 80°C (176°F). Using a press gently ease the

expanded

ring gear over the flywheel and press fully home.

1:13 The oil pump

Sedan :

A helical-spur gear type oil pump is driven by the cam-

shaft through a front dog drive coupling. The gears are

F50025 To remove the pump from the engine proceed as

follows:Pump removal and reassembly:

Remove the engine rear central support from the timing

gear casing. Remove the filter cover pulley and lift

away the drive belt.

Release the hollow screw attaching the slinger and the

mounting flange of the filter on the crankshaft. Also

release the nuts fixing the timing gear cover to the

crankcase.

Remove the timing gear cover together with the oil

pump assembly and the pressure relief valve.

Lift out the oil pump suction scoop with the filter

screen attached from the sump.

Reassembly of the pump to the engine is the reverse

procedure to dismantling. 1

2

3

4

5 located in a special housing in the timing gear cover and

held in place by a cover plate. The oil pressure relief valve

is mounted on the drive gear shaft guide.

A pump suction scoop fitted with a filter screen is

secured in the crankcase and connects to a duct in the

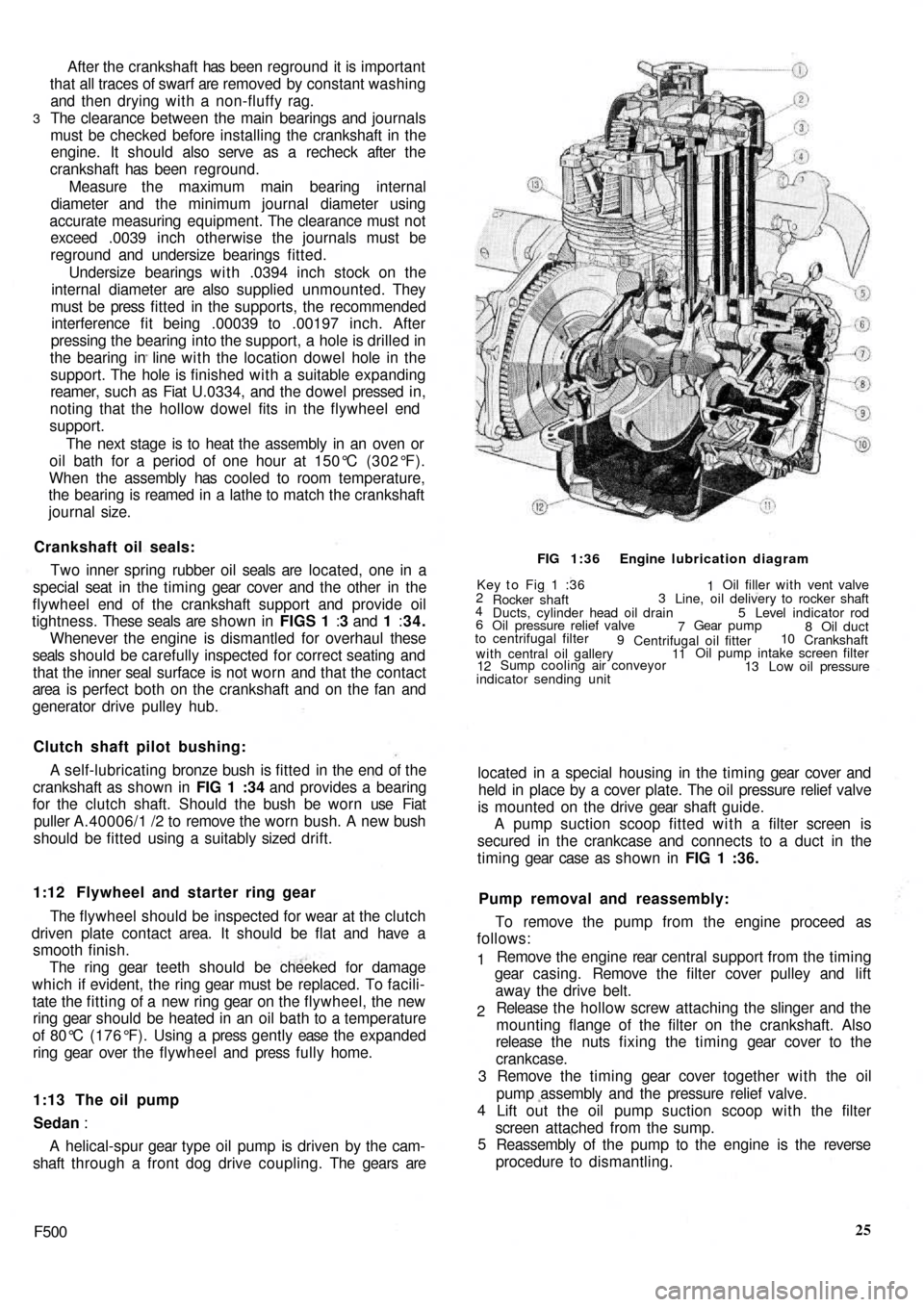

timing gear case as s h o w n in FIG 1 :36.

2

4

6Key t o Fig 1 :36

Rocker shaft

Ducts, cylinder head oil drain

Oil pressure relief valve

to centrifugal filter

9

with central oil gallery

12Sump cooling air conveyor

indicator sending unitOil filler with vent valve

Line, oil delivery to rocker shaft

Level indicator rod 31

5

7Gear pump

8 Oil duct

Centrifugal oil fitter

1110

Crankshaft

Oil pump intake screen filter

13 Low oil pressure FIG 1:36 Engine lubrication diagram

Page 19 of 128

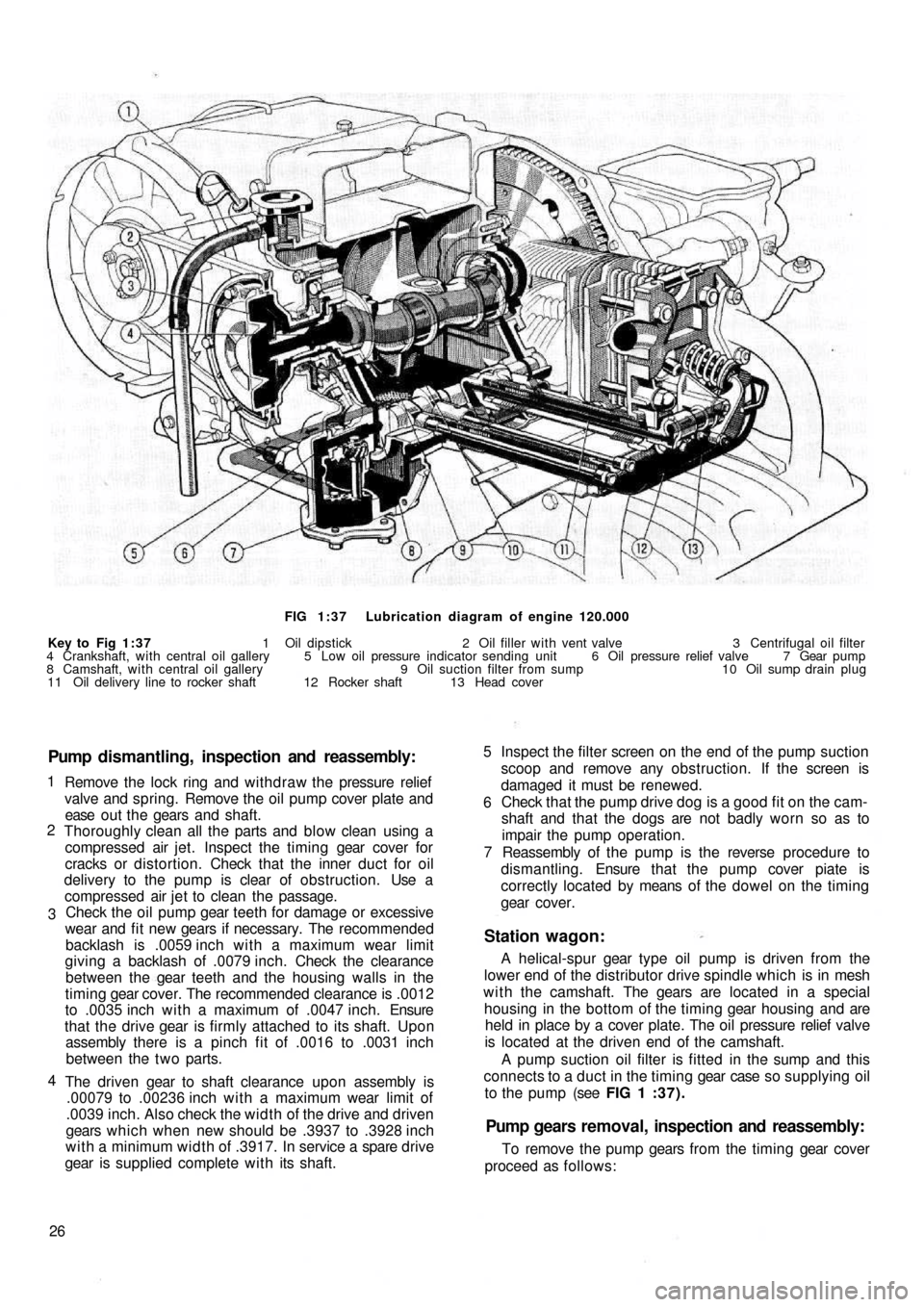

FIG 1:37 Lubrication diagram of engine 120.000

Key to Fig 1:37 1 Oil dipstick 2 Oil filler with vent valve 3 Centrifugal oil filter

4 Crankshaft, with central oil gallery 5 Low oil pressure indicator sending unit 6 Oil pressure relief valve 7 Gear pump

8 Camshaft, with central oil gallery 9 Oil suction filter from sump 10 Oil sump drain plug

11 Oil delivery line to rocker shaft 12 Rocker shaft 13 Head cover

Pump dismantling, inspection and reassembly:

Remove the lock ring and withdraw the pressure relief

valve and spring. Remove the oil pump cover plate and

ease o u t t h e gears and shaft.

Thoroughly clean all the parts and blow clean using a

compressed air jet. Inspect the timing gear cover for

cracks or distortion. Check that the inner duct for oil

delivery to the pump is clear of obstruction. Use a

compressed air jet to clean the passage.

Check the oil pump gear teeth for damage or excessive

wear and fit new gears if necessary. The recommended

backlash is .0059 inch w i t h a maximum wear limit

giving a backlash of .0079 inch. Check the clearance

between the gear teeth and the housing walls in the

timing gear cover. The recommended clearance is .0012

to .0035 inch w i t h a maximum of .0047 inch. Ensure

that the drive gear is firmly attached to its shaft. Upon

assembly there is a pinch fit of .0016 to .0031 inch

between the t w o parts.

The driven gear to shaft clearance upon assembly is

.00079 to .00236 inch with a maximum wear limit of

.0039 inch. Also check the width of the drive and driven

gears which when new should be .3937 to .3928 inch

with a minimum width of .3917. In service a spare drive

gear is supplied complete with its shaft.

26 4 3 2 1

Station wagon:

A helical-spur gear type oil pump is driven from the

lower end of the distributor drive spindle which is in mesh

w i t h the camshaft. The gears are located in a special

housing in the bottom of the timing gear housing and are

held in place by a cover plate. The oil pressure relief valve

is located at the driven end of the camshaft.

A pump suction oil filter is fitted in the sump and this

connects to a duct in the timing gear case so supplying oil

to the pump (see FIG 1 : 3 7 ) .

Pump gears removal, inspection and reassembly:

To remove the pump gears from the timing gear cover

proceed as follows:Inspect the filter screen on the end of the pump suction

scoop and remove any obstruction. If the screen is

damaged it must be renewed.

Check that the pump drive dog is a good fit on the cam-

shaft and that the dogs are not badly worn so as to

impair the pump operation.

Reassembly of the pump is the reverse procedure to

dismantling. Ensure that the pump cover piate is

correctly located by means of the dowel on the timing

gear cover. 5

6

7

Page 22 of 128

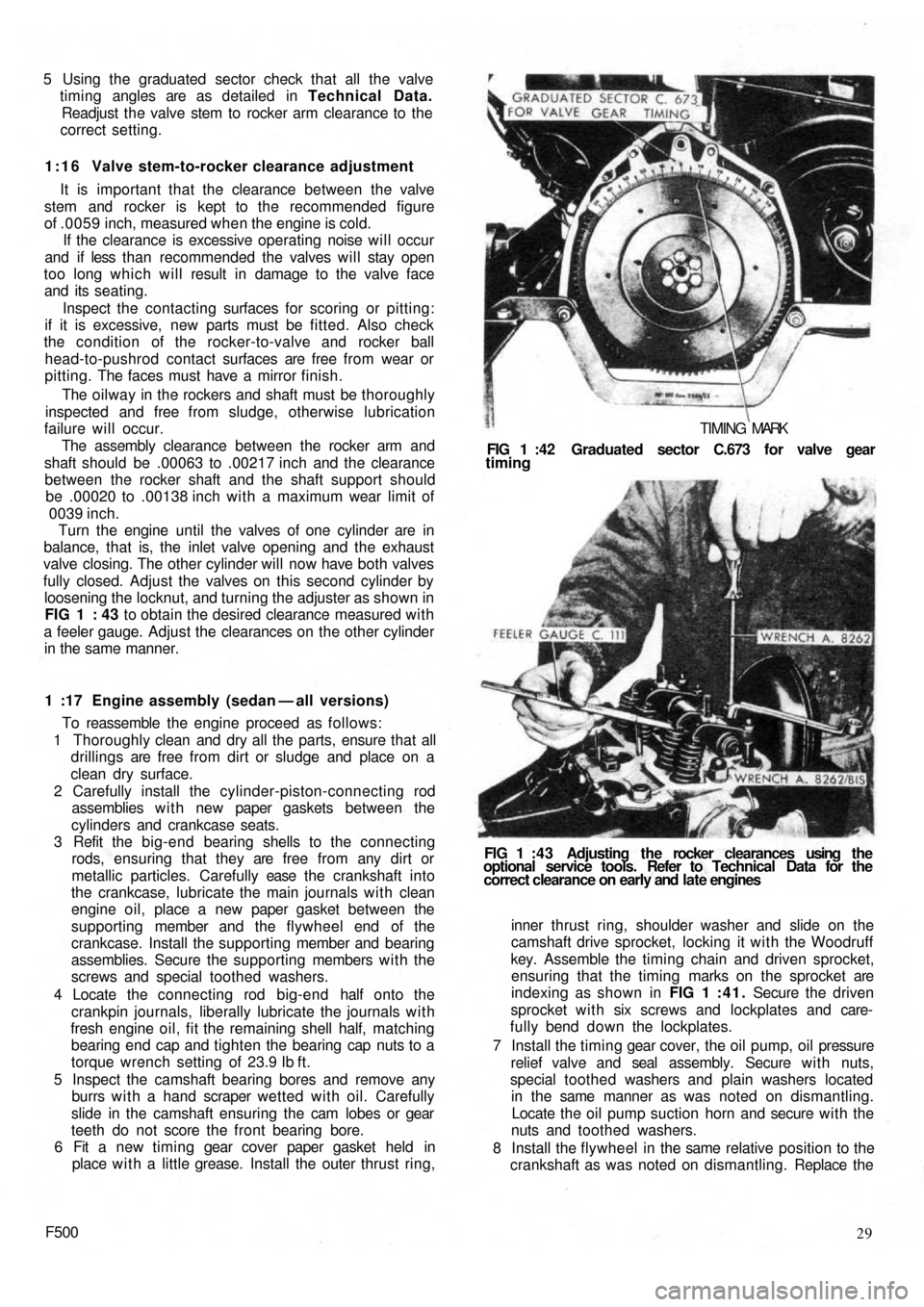

5 Using the graduated sector check that all the valve

timing angles are as detailed in Technical Data.

Readjust the valve stem to rocker arm clearance to the

correct setting.

1:16 Valve stem-to-rocker clearance adjustment

It is important that the clearance between the valve

stem and rocker is kept to the recommended figure

of .0059 inch, measured when the engine is cold.

If the clearance is excessive operating noise will occur

and if less than recommended the valves will stay open

too long which will result in damage to the valve face

and its seating.

Inspect the contacting surfaces for scoring or pitting:

if it is excessive, new parts must be fitted. Also check

the condition of the rocker-to-valve and rocker ball

head-to-pushrod contact surfaces are free from wear or

pitting. The faces must have a mirror finish.

The oilway in the rockers and shaft must be thoroughly

inspected and free from sludge, otherwise lubrication

failure will occur.

The assembly clearance between the rocker arm and

shaft should be .00063 to .00217 inch and the clearance

between the rocker shaft and the shaft support should

be .00020 to .00138 inch with a maximum wear limit of

0039 inch.

Turn the engine until the valves of one cylinder are in

balance, that is, the inlet valve opening and the exhaust

valve closing. The other cylinder will now have both valves

fully closed. Adjust the valves on this second cylinder by

loosening the locknut, and turning the

adjuster as shown in

FIG 1 : 43 to obtain the desired clearance measured with

a feeler gauge. Adjust the clearances on the other cylinder

in the same manner.

1 :17 Engine assembly (sedan — all versions)

To reassemble the engine proceed as follows:

1 Thoroughly clean and dry all the parts, ensure that all

drillings are free from dirt or sludge and place on a

clean dry surface.

2 Carefully install the cylinder-piston-connecting rod

assemblies w i t h new paper gaskets between the

cylinders and crankcase seats.

3 Refit the big-end bearing shells to the connecting

rods, ensuring that they are free from any dirt or

metallic particles. Carefully ease t h e crankshaft into

the crankcase, lubricate the main journals with clean

engine oil, place a new paper gasket between the

supporting member and the flywheel end of the

crankcase. Install the supporting member and bearing

assemblies. Secure the supporting members with the

screws and special toothed washers.

4 Locate the connecting rod big-end half onto the

crankpin journals, liberally lubricate the journals with

fresh engine oil, fit the remaining shell half, matching

bearing end cap and tighten the bearing cap nuts to a

torque wrench setting of 23.9 Ib ft.

5 Inspect the camshaft bearing bores and remove any

burrs w i t h a hand scraper wetted with oil. Carefully

slide in the camshaft ensuring the cam lobes or gear

teeth do not score the front bearing bore.

6 Fit a new timing gear cover paper gasket held in

place w i t h a little grease. Install the outer thrust ring,

F50029 inner thrust ring, shoulder washer and slide on the

camshaft drive sprocket, locking it with the Woodruff

key. Assemble the timing chain and driven sprocket,

ensuring that the timing marks on the sprocket are

indexing as shown in FIG 1 :41. Secure the driven

sprocket with six screws and lockplates and care-

fully bend down the lockplates.

7 Install the timing gear cover, the oil pump, oil pressure

relief valve and seal assembly. Secure w i t h nuts,

special toothed washers and plain washers located

in the same manner as was noted on dismantling.

Locate the oil pump suction horn and secure with the

nuts and toothed washers.

8 Install the flywheel in the same relative position to the

crankshaft as was noted on dismantling. Replace the FIG 1 : 4 3 Adjusting the rocker clearances using the

optional service tools. Refer to Technical Data for the

correct clearance on early and late engines FIG 1 :42 Graduated sector C.673 for valve gear

timing

TIMING MARK

Page 24 of 128

sections of the air conveyor securing with seven

screws, seven toothed washers and five nuts.

22 Slide the fuel pump control rod into its seating,

assemble the insulator between oil wetted graphite

gaskets and fit the pump to the crankcase using nuts

and toothed washers.

23 Fit the air conveyor cover complete with the accelera-

tor control relay lever and rod. Secure using eight

mounting screws, eight toothed washers, eight plain

washers and eight nuts. Fit the fuel line retaining clip

which is secured by one of the air conveyor upper

screws. Install the generator and fan drive pulley

having first placed four adjusting rings between the

pulley halves and the thrust ring on the outside.

Secure the pulley to generator shaft using three

screws and three toothed washers. Fit the generator

fan drive belt.

24 Refit the carburetter having first positioned the

bakelite heat shield between the t w o oil moistened

graphite gaskets. Secure the carburetter using t w o

copper washers and t w o self-locking nuts. Fit the

exhaust silencer and secure to the exhaust manifolds

with nuts and spring washers. Place the t w o graphite

gaskets between the manifold joints. Fit both exhaust

silencer upper mounting brackets and secure them

on the top side to the brackets already in place w i t h

nuts and toothed washers on the bottom side w i t h

screws and toothed washers.

25 Carefully position the distributor at a 10 deg advance

setting and secure w i t h a

nut, plain washer and

spring washer. Fit the fuel pump to carburetter line

complete w i t h mounting bracket rubber lining and

secure the line with two clamps. If difficulty is

experienced in positioning the fuel line into the pump

or carburetter funnels it is suggested that the line

ends should be heated in hot water and thoroughly

dried before installing.

26 Install the air cleaner elbow and rubber hose assembly

on the top of the carburetter using a graphite gasket

in between and secure w i t h nuts, plain washers and

spring washers. Carefully position the air cleaner, line

and hose assembly and connect it to the elbow.

Secure the cleaner to air conveyor cover using screws

and toothed washers.

27 Fit the spark plug cables complete with the rubber

grommet for cable mounting bracket on engine

cowling and connect the cables to the distributor

and spark plugs. Fit the oil pressure gauge sender

unit together w i t h its sealing washer.

28 Install the cylinder head cover and oil breather pipe

assembly w i t h a cork gasket inserted between.

Secure w i t h self-locking nuts and fibre washers.

Connect the accelerator control relay lever rod to the

carburetter and secure with the clip.

29 Fill the oil pan with the correct grade and quantity of

oil, insert the dipstick and the engine is ready for

refitting.

1:18 Engine assembly (station wagon)

Reassembly of this engine is straightforward as it is

the reverse procedure to dismantling. It is recommended

that Sections 1 :5 and 1 :17 are studied as the assembly

technique is similar for both the horizontal and vertical

F50031 cylinder engines. The following points should however

be noted:

1 Refer to FIG 1 :45 for the correct positioning of the

connecting rod-piston assembly on the 120.000

engine.

2 The sequence of tightening the cylinder head nuts is

different, the new order being given in FIG 1 :46.

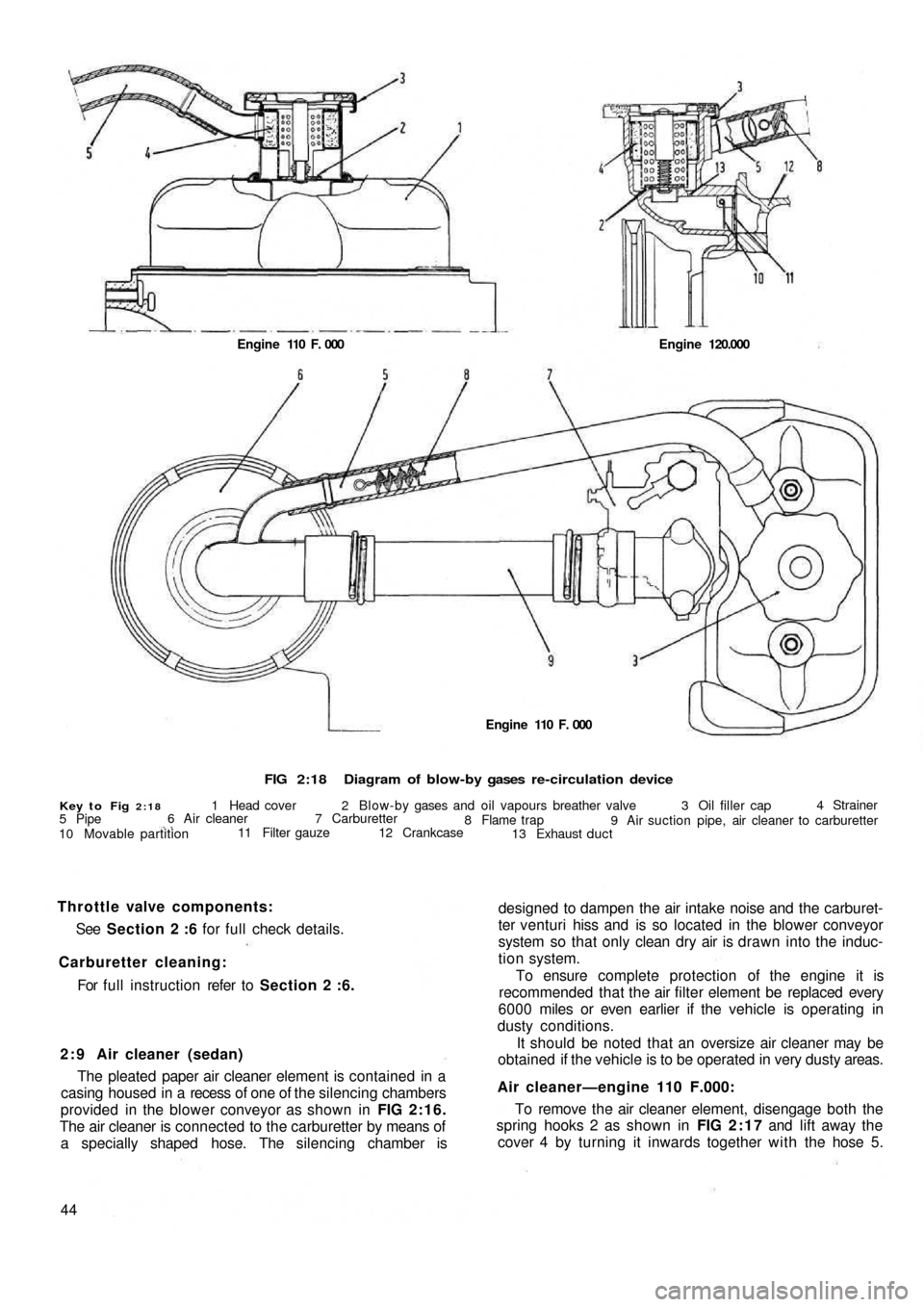

Key to Fig 1 :47 1 Suspension arm 2 Screw,

rubber pad to bracket 3 Bracket-to-engine nut

4 Nut, arm to bracket 5 Arm bracket 6 Spring

7 Arm pin-to-support nut 8 Screws, pin to support

9 Pin arm to supportFIG 1 :47 Power plant rear suspension FIG 1:46 Cylinder head stud nut tightening sequence.

500 D. F and L Sedan and Station Wagon

Page 37 of 128

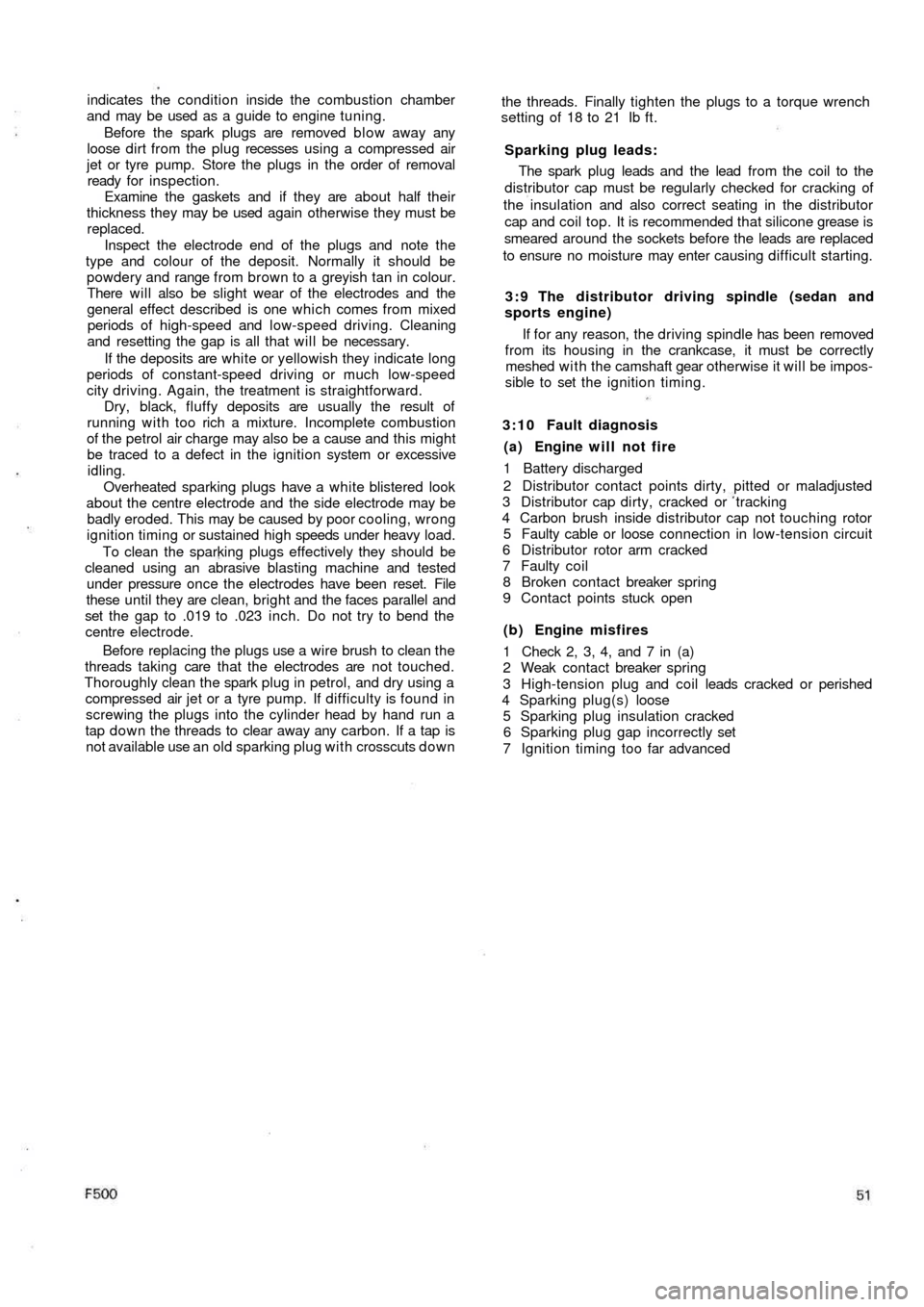

FIG 2:18Diagram of blow-by gases re-circulation device

Key to Fig 2:181 Head cover 2 Blow-by gases and oil vapours breather valve 3 Oil filler cap4 Strainer

9 Air suction pipe, air cleaner to carburetter 8 Flame trap

13 Exhaust duct 12 Crankcase 7 Carburetter 6 Air cleaner

11 Filter gauze

10 Movable partition 5 PipeEngine 110 F. 000 Engine 120.000

designed to dampen the air intake noise and the carburet-

ter venturi hiss and is so located in the blower conveyor

system so that only clean dry air is drawn into the induc-

tion system.

To ensure complete protection of the engine it is

recommended that the air filter element be replaced every

6000 miles or even earlier if the vehicle is operating in

dusty conditions.

It should be noted that an oversize air cleaner may be

obtained if the vehicle is to be operated in very dusty areas.

Air cleaner—engine 110 F.000:

To remove the air cleaner element, disengage both the

spring hooks 2 as shown in FIG 2:17 and lift away the

cover 4 by turning it inwards together with the hose 5. 2 : 9 Air cleaner (sedan)

The pleated paper air cleaner element is contained in a

casing housed in a recess of one of the silencing chambers

provided in the blower conveyor as shown in FIG 2:16.

The air cleaner is connected to the carburetter by means of

a specially shaped hose. The silencing chamber is

44For full instruction refer to Section 2 :6. Carburetter cleaning:See Section 2 :6 for full check details. Throttle valve components:

Engine 110 F. 000

Page 44 of 128

indicates the condition inside the combustion chamber

and may be used as a guide to engine tuning.

Before the spark plugs are removed b l o w away any

loose dirt from the plug recesses using a compressed air

jet or tyre pump. Store the plugs in the order of removal

ready for inspection.

Examine the gaskets and if they are about half their

thickness they may be used again otherwise they must be

replaced.

Inspect the electrode end of the plugs and note the

type and colour of the deposit. Normally it should be

powdery and range from b r o w n to a greyish tan in colour.

There will also be slight wear of the electrodes and the

general effect described is one which comes from mixed

periods of high-speed and low-speed driving. Cleaning

and resetting the gap is all that will be necessary.

If the deposits are white or yellowish they indicate long

periods of constant-speed driving or much low-speed

city driving. Again, the treatment is straightforward.

Dry, black, fluffy deposits are usually the result of

running with too rich a mixture. Incomplete combustion

of the petrol air charge may also be a cause and this might

be traced to a defect in the ignition system or excessive

idling.

Overheated sparking plugs have a white blistered look

about the centre electrode and the side electrode may be

badly eroded. This may be caused by poor cooling, wrong

ignition timing or sustained high speeds under heavy load.

To clean the sparking plugs effectively they should be

cleaned using an abrasive blasting machine and tested

under pressure once the electrodes have been reset. File

these until they are clean, bright and the faces parallel and

set the gap to .019 to .023 inch. Do not try to bend the

centre electrode.

Before replacing the plugs use a wire brush to clean the

threads taking care that the electrodes are not touched.

Thoroughly clean the spark plug in petrol, and dry using a

compressed air jet or a tyre pump. If difficulty is found in

screwing the plugs into the cylinder head by hand run a

tap d o w n the threads to clear away any carbon. If a tap is

not available use an old sparking plug with crosscuts d o w nthe threads. Finally tighten the plugs to a torque wrench

setting of 18 to 21 Ib ft.

Sparking plug leads:

The spark plug leads and the lead from the coil to the

distributor cap must be regularly checked for cracking of

the insulation and also correct seating in the distributor

cap and coil top. It is recommended that silicone grease is

smeared around the sockets before the leads are replaced

to ensure no moisture may enter causing difficult starting.

3 : 9 The distributor driving spindle (sedan and

sports engine)

If for any reason, the driving spindle has been removed

from its housing in the crankcase, it must be correctly

meshed w i t h the camshaft gear otherwise it

will be impos-

sible to set the ignition timing.

3:10 Fault diagnosis

(a) Engine w i l l not fire

1 Battery discharged

2 Distributor contact points dirty, pitted or maladjusted

3 Distributor cap dirty, cracked or tracking

4 Carbon brush inside distributor cap not touching rotor

5 Faulty cable or loose connection in low-tension circuit

6 Distributor rotor arm cracked

7 Faulty coil

8 Broken contact breaker spring

9 Contact points stuck open

(b) Engine misfires

1 Check 2, 3, 4, and 7 in (a)

2 Weak contact breaker spring

3 High-tension plug and coil leads cracked or perished

4 Sparking plug(s) loose

5 Sparking plug insulation cracked

6 Sparking plug gap incorrectly set

7 Ignition timing too far advanced

Page 57 of 128

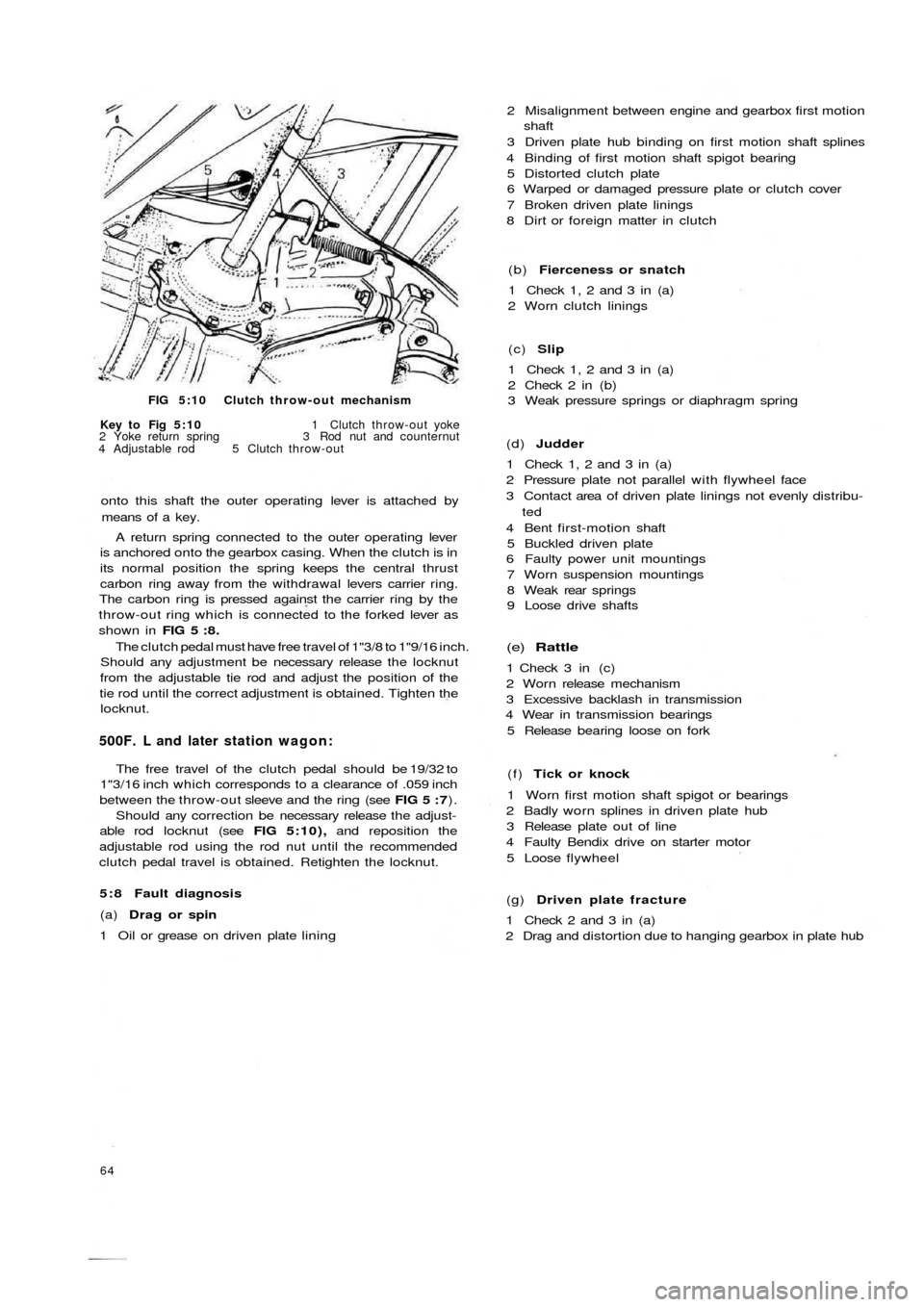

FIG 5:10 Clutch throw-out mechanism

Key to Fig 5:10 1 Clutch throw-out yoke

2 Yoke return spring 3 Rod nut and counternut

4 Adjustable rod 5 Clutch throw-out

onto this shaft the outer operating lever is attached by

means of a key.

A return spring connected to the outer operating lever

is anchored onto the gearbox casing. When the clutch is in

its normal position the spring keeps the central thrust

carbon ring away from the withdrawal levers carrier ring.

The carbon ring is pressed against the carrier ring by the

throw-out ring which is connected to the forked lever as

shown in FIG 5 : 8 .

The clutch pedal must have free travel of 1"3/8 to 1"9/16 inch.

Should any adjustment be necessary release the locknut

from the adjustable tie rod and adjust the position of the

tie rod until the correct adjustment is obtained. Tighten the

locknut.

500F. L and later station wagon:

The free travel of the clutch pedal should be 19/32 to

1"3/16 inch which corresponds to a clearance of .059 inch

between the throw-out sleeve and the ring (see FIG 5 : 7).

Should any correction be necessary release the adjust-

able rod locknut (see FIG 5:10), and reposition the

adjustable rod using the rod nut until the recommended

clutch pedal travel is obtained. Retighten the locknut.

5 : 8 Fault diagnosis

(a) Drag or spin

1 Oil or grease on driven plate lining

64

(g) Driven plate fracture

1 Check 2 and 3 in (a)

2 Drag and distortion due to hanging gearbox in plate hub (f) Tick or knock

1 Worn first motion shaft spigot or bearings

2 Badly worn splines in driven plate hub

3 Release plate out of line

4 Faulty Bendix drive on starter motor

5 Loose flywheel

(e) Rattle

1 Check 3 in (c)

2 Worn release mechanism

3 Excessive backlash in transmission

4 Wear in transmission bearings

5 Release bearing loose on fork (d) Judder

1 Check 1, 2 and 3 in (a)

2 Pressure plate not parallel with flywheel face

3 Contact area of driven plate linings not evenly distribu-

ted

4 Bent first-motion shaft

5 Buckled driven plate

6 Faulty power unit mountings

7 Worn suspension mountings

8 Weak rear springs

9 Loose drive shafts (c) Slip

1 Check 1, 2 and 3 in (a)

2 Check 2 in (b)

3 Weak pressure springs or diaphragm spring (b) Fierceness or snatch

1 Check 1, 2 and 3 in (a)

2 Worn clutch linings 2 Misalignment between engine and gearbox first motion

shaft

3 Driven plate hub binding on first motion shaft splines

4 Binding of first motion shaft spigot bearing

5 Distorted clutch plate

6 Warped or damaged pressure plate or clutch cover

7 Broken driven plate linings

8 Dirt or foreign matter in clutch

Page 63 of 128

3 Check the layshaft and the primary shaft between

centres and using a dial gauge ensure that there is no

distortion. The out of true reading for bearing seats

should be less than .0008 inch. Inspect the splines and

ensure that the side and outerfaces are not indented.

Replace if there are signs of wear. Also inspect the

reverse shaft to ensure that it is perfectly smooth and

not showing signs of pitting or partial seizure.

4 Carefully inspect all gear teeth for signs of excessive

wear or damage. The contact faces must be smooth and

show no signs of indentation marks. Also check that

the backlash between the gears, when correctly

mounted on the surface plate is not greater than .0039

inch. The maximum wear limit is .0079 inch. Check that

the quick engagement front teeth of the second-, third-

and fourth-speed gears are not damaged or excessively

worn. Renew if there are signs of gearchange lever

misuse.

5 Inspect the sliding sleeves and the relevent hubs, ensure

that all the working surfaces are perfectly smooth. The

clearance between the mating parts should not be

greater than .0059 inch. Also inspect the meshing teeth

and ensure that they are in good condition.

6 Check that the gear shifting selector forks are not dis-

torted and that the striker rods freely slide in their seats

in the gearbox casing.

7 Carefully inspect that all the oil seals are in perfect con-

dition and if there is any doubt they should be renewed.

8 Inspect the striker rod locking balls and the safety rollers

and ensure that they slide freely in their seatings. Also

check the ball load spring efficiency and if this shows

signs of weakness then it should be renewed. Any

faults with these items will cause difficulty in engaging

gears or autodisengagement during engine acceleration.

6 : 4 Reassembly—gearbox

To reassemble the components to the gearbox ensure

that all components are thoroughly clean and then pro-

ceed as follows:

1 Press t h e pinion rear roller bearing onto the layshaft.

Install the layshaft in the casing, and at the same time

fit the adjustment shim, the fourth-speed driven gear

together w i t h its bush, the sleeve and hub for third and

fourth gear engagement, the first-speed and reverse

driven gear and the third-speed driven gear with its

hub.

2 Install the front layshaft ballbearing securing the

bearing retainment plate w i t h the screws and finally

lock the screws in position.

3 Insert the primary shaft together with the first, third

and fourth driving gear train in the gearbox housing

and slide t h e rear bearing onto the shaft. Push the

input shaft forward to enable the clutch shaft coupling

to be inserted in t h e rear and to be pulled up the

primary shaft by means of the pin. Do not forget the

retaining ring.

4 Slide the primary shaft backwards so pushing the rear

bearing into its bore. Refit the front bearing onto the

primary shaft.

5 On the layshaft insert the second-speed driven shaft

and bush, the second gear sliding dog sleeve and the

hub. Also insert the second-speed striker rod and the

first-speed fork. Do not forget to fit the safety roller

into its seating.

70

6 Slide the second-speed driving gear onto the primary

shaft. Place the engagement fork on the third- and

fourth-speed engagement sliding sleeve, and insert

the striker rod, lock the relevent fork and fit the safety

roller.

7 Insert the third safety roller and install the reverse shaft

and insert the reverse gear cluster onto it and secure

the shaft by tightening its block bolt. Install the reverse

striker rod w i t h its relevent fork.

8 Now refit the speedometer drive worm gear onto the

layshraft. Tighten the nuts on the primary shaft and the

layshaft, not forgetting to interpose the plain washer

between the speedometer driving worm and the nut,

to a torque wrench setting of 1 8.1 Ib ft to 25.3 Ib ft

(primary shaft) and 28.9 to 36.2 Ib ft (layshaft). It is

recommended that the input shaft and layshaft are

locked together by engaging t w o gears at the same

time. Finally, fit the splitpins.

9 Lock the shifter forks onto their shafts by tightening

their respective bolts and bend up the special locking

plates. Install the three positioning balls and relevant

springs into their bores and refit the cover plate.

10 Install the casing cover together with its relevant

gasket. This will enable correct positioning of the shift

shaft lever so that it engages in the outer ends of the

shifter shafts protruding from the gearbox casing.

11 Install the speedometer drive support on the gearbox

casing and refit the upper gearbox cover.

For subsequent differential operations and adjustments

see Sections 6:6.

6:5 Dismantling—differential and final drive

For the removal of the differential and final drive unit

from the gearbox refer to Section 6:3. To dismantle the

differential assembly

proceed as follows:

1 Remove the retaining ring 2 (see FIG 6 : 7) retaining

the splined sleeve 4 and slide the sleeve off the drive

shaft.

2 Remove t h e retaining covers 7 and the oil boots all

together with the bushes and seals, adjuster ring lock

rings 13, adjuster rings housing 14, and bearing

adjuster and roller bearing outer races.

3 Separate the differential housing halves by unscrewing

and removing the six bolts that keep both the halves and

the crownwheel together. It is advisable to mark the

respective components to ensure correct matching

upon reassembly.

4 Remove the differential pinion shaft retainer ring, also

the differential pinions 10 by removing the shaft and

withdrawing the two axle shafts 1.

5 Remove the differential side gears 6 and relevent thrust

rings 8.

6 Using a press remove the differential bearing inner

races from their seats on the carrier halves.

7 Thoroughly clean all parts and dry using a compressed

air jet.

Inspection:

The components of the differential unit must be

thoroughly inspected for correct operation and to deter-

mine the presence of any wear, damage or other irregulari-

ties. To check the items concerned proceed as follows:

1 Check thoroughly the idle pinion carrier shaft for signs

Page 94 of 128

reassembling and during assembly liberally lubricated

using Fiat W90/M oil (SAE90 EP).

2 The pitman arm nut should be correctly positioned on

reassembly to the sector shaft and both are marked

with notches or a master tooth on the sector will mate

with a double tooth on the pitman arm which will

prevent incorrect reassembly.

3 The pitman arm nut must be tightened to a torque

wrench setting of 72 Ib/ft.

4 Fill the box up to the level and filler plug with SAE90 EP

gear oil.

Refitting the steering box:

To refit the steering box to the vehicle proceed as

follows:

1 Engage the w o r m screw f r o m the steering shaft by

gently manipulating the steering box.

2 Replace the steering box to body nuts and tighten to a

torque wrench setting of 14 to 18 Ib/ft.

3 Replace the t w o track rod pins in their seatings in the

pitman arm and tighten the self-locking nuts to a

torque wrench setting of 18 to 21 Ib/ft.

4 Replace the steering shaft to worm screw mounting

bolt, lock washer and nut.

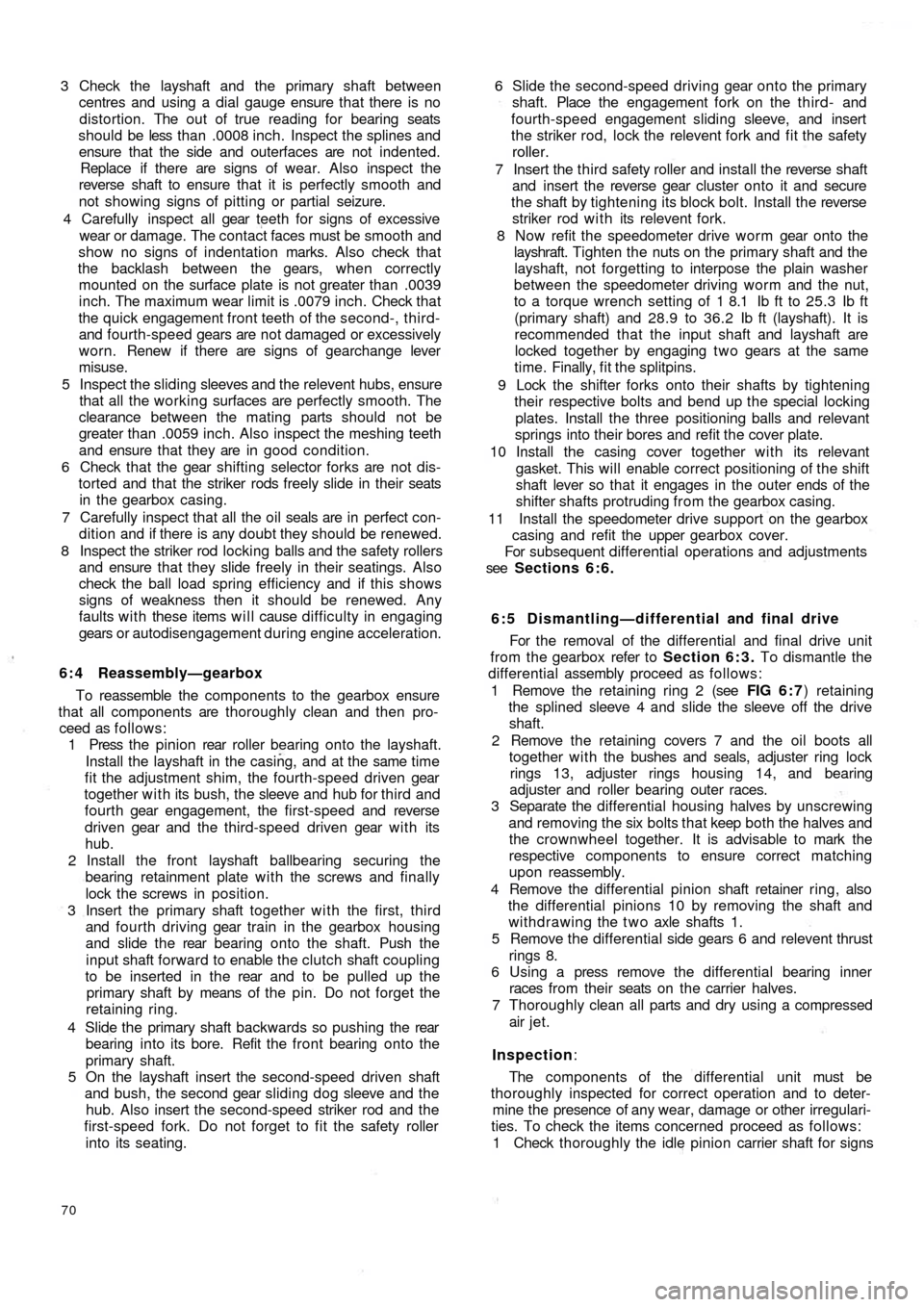

9 :5 Relay lever and support

The steering idler arm is secured to the body by means

of a support bracket and a rubber bushed pivot bolt. This

is shown in FIG 9 : 7. When this unit is being serviced

the following points should be noted.

1 If there is excessive play between the pin and the

bushes the bushes must be renewed. Also check the

condition of the pin and if there are signs of excessive

wear it must be renewed.

2 To eliminate torsional stresses in the rubber bushes

during assembly the pin nut must be tightened to

torque wrench setting of 39 to 43 Ib/ft, once the

front wheel toe-in has been correctly adjusted w i t h the

wheels set in the straight ahead position.

3 The relay lever support to body mounting nuts must

be tightened to a torque wrench setting of 14 to 18

Ib/ft.

9 : 6 Steering rods (tie rods)

The steering rod is connected to the idler arm and the

drop arm by means of non-adjustable ball joints. The

track rods are connected to the right and left steering

arms by non-adjustable ball joints and comprise t w o

sleeves which are split and having internally threaded

ends. The ball joints are clamped to either end of the

sleeves. To facilitate adjustment one ball joint end has a

lefthand thread and the other a righthand thread.

Adjustment is made by loosening both the clamping bolts

and turning the central sleeve.

To remove the steering rods from the pitman arm, the

relay lever and knuckle arms Fiat pullers A.46006 and

A.6473 or universal ball joint removers should be used.

If excessive play is evident in the ball joint linkage or

the pin is damaged the complete ball joint assembly must

be renewed.

Upon reassembly the tie rod to ball pin knuckle arm

nuts must be tightened to a torque wrench setting of

18 to 21 Ib/ft.

F500101

FIG 9:7 Relay lever support section

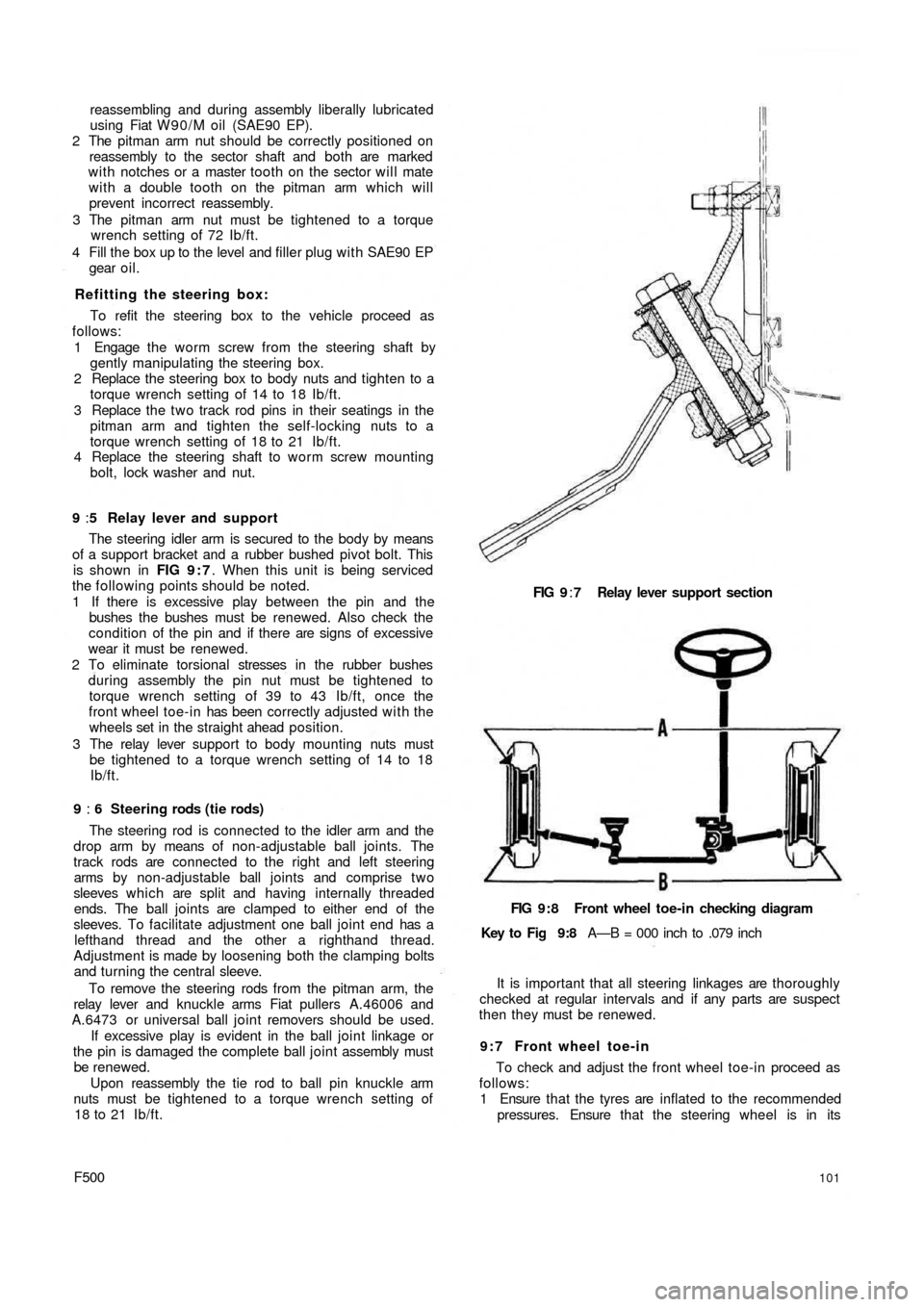

FIG 9:8 Front wheel toe-in checking diagram

Key to Fig 9:8 A—B = 000 inch to .079 inch

It is important that all steering linkages are thoroughly

checked at regular intervals and if any parts are suspect

then they must be renewed.

9 : 7 Front wheel toe-in

To check and adjust the front wheel toe-in proceed as

follows:

1 Ensure that the tyres are inflated to the recommended

pressures. Ensure that the steering wheel is in its