air condition FIAT 500 1966 1.G User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 1966, Model line: 500, Model: FIAT 500 1966 1.GPages: 128, PDF Size: 9.01 MB

Page 64 of 128

of wear, distorting or unevenness of the surfaces as this

part is very heavily pressed when the vehicle is negotia-

ting a corner. If the clearance to the idle pinions exceeds

.0059 inch the shaft must be renewed.

2 Inspect the ring gear and pinion seat, the side gears.and

the idle pinions for correct meshing. This will be shown

up by white marks on the sides of the gear teeth. Check

that none of the teeth are broken, chipped or exces-

sively worn and if any part is suspect then it must be

renewed not forgetting that the ring gear and pinion

come as a matched pair.

3 Inspect the condition of the ball and roller bearings, the

rollers and balls and working faces must not show signs

of pitting wear or cracking and if any part is suspect then

the race must be renewed.

4 Check that there is not any undue wear on the faces of

the thrust rings. Any slight indentations may be evened

out using a fine oil stone but if the damage is excessive

then new rings or oversize rings must befitted as neces-

sary. Thrust rings are supplied as service spares in the

following thicknesses.

Standard .0394 inch

Oversize .0512-.0591 inch

6:6 Reassembly—differential unit

To reassemble the differential case proceed as follows:

1 Press onto the differential half housing which carries

the ring gear one differential bearing inner race ensuring

that it is pushed fully home onto its seating. Install the

thrust ring and side gear (see FIG 6 : 7).

2 From t h e inside of the case insert the axle shaft com-

plete with pivot and runners that form the slip joint.

Also install the idle pinions and carrier shaft. Position

the ring gear onto the housing half and install the

differential pinion shaft retainer ring.

3 Press the other differential bearing inner race onto its

seating on the left differential housing half and replace

the left axle shaft complete with slip joint.

4 J o i n the t w o case halves together and tighten the

retaining screws and also the retaining screws of the

ring gear to a torque wrench setting of 23.1 Ib ft. Secure

all screws by bending up the lockplates.

5 Press t h e differential bearing outer races into their

seatings in the bearing housings and also f i t the o i l seals.

Also install the bearing housings over the driving shafts

together with the adjuster rings.

6 Install the differential unit assembly into the final drive

housing front half and bolt the rear

half onto it. Tighten

the six mounting nuts to a torque wrench setting of

27.5 Ib ft. Finally place the bearing housings in their

seats and tighten the mounting nuts to a torque wrench

setting of 13 lb ft.

It should be noted that after the gearbox has been over-

hauled the complete differential unit should only be in-

stalled after the drive pinion depth adjustments has been

carried out.

6 : 7 Final drive gear set adjustment

The installation and adjustment of the final drive gear

set requires special care otherwise the unit may have to be

dismantled again for further adjustment. So as to establish

the correct mesh of the t w o gears, their relative position is

accurately set during initial assembly at the factory.

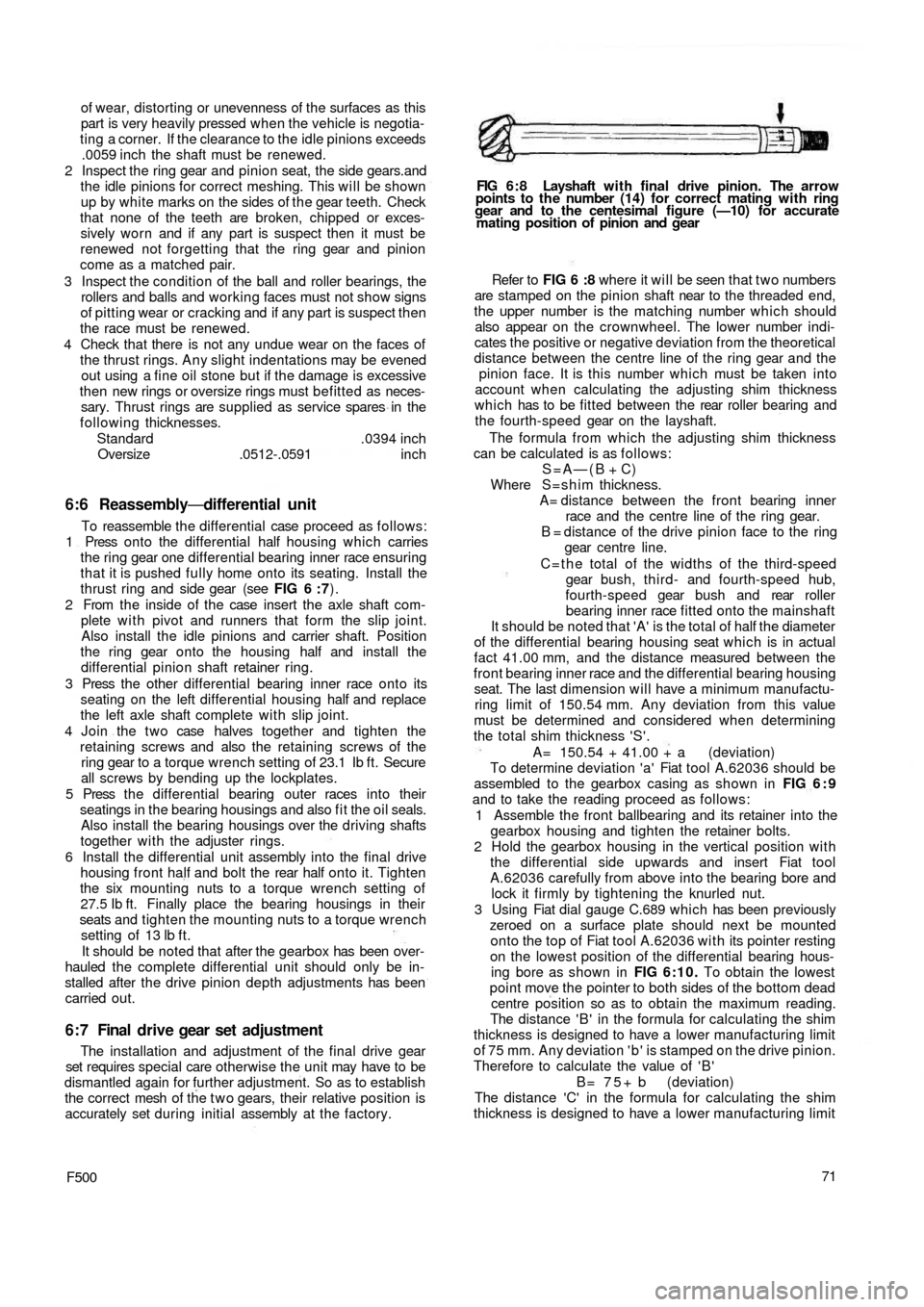

F50071 Refer to FIG 6 :8 where it will be seen that t w o numbers

are stamped on the pinion shaft near to the threaded end,

the upper number is the matching number which should

also appear on the crownwheel. The lower number indi-

cates the positive or negative deviation from the theoretical

distance between the centre line of the ring gear and the

pinion face. It is this number which must be taken into

account when calculating the adjusting shim thickness

which has to be fitted between the rear roller bearing and

the fourth-speed gear on the layshaft.

The formula from which the adjusting shim thickness

can be calculated is as follows:

S=A—(B + C)

Where S=shim thickness.

A= distance between the front bearing inner

race and the centre line of the ring gear.

B = distance of the drive pinion face to the ring

gear centre line.

C = t h e total of the widths of the third-speed

gear bush, third- and fourth-speed hub,

fourth-speed gear bush and rear roller

bearing inner race fitted onto the mainshaft

It should be noted that 'A' is the total of half the diameter

of the differential bearing housing seat which is in actual

fact 41.00 mm, and the distance measured between the

front bearing inner race and the differential bearing housing

seat. The last

dimension will have a minimum manufactu-

ring limit of 150.54 mm. Any deviation from this value

must be determined and considered when determining

the total shim thickness 'S'.

A= 150.54 + 41.00 + a (deviation)

To determine deviation 'a' Fiat tool A.62036 should be

assembled to the gearbox casing as shown in FIG 6 : 9

and to take the reading proceed as follows:

1 Assemble the front ballbearing and its retainer into the

gearbox housing and tighten the retainer bolts.

2 Hold the gearbox housing in the vertical position with

the differential side upwards and insert Fiat tool

A.62036 carefully from above into the bearing bore and

lock it firmly by tightening the knurled nut.

3 Using Fiat dial gauge C.689 which has been previously

zeroed on a surface plate should next be mounted

onto the t o p of Fiat tool A.62036 with its pointer resting

on the lowest position of the differential bearing hous-

ing bore as shown in FIG 6:10. To obtain the lowest

point move the pointer to both sides of the bottom dead

centre position so as to obtain the maximum reading.

The distance ' B ' in the formula for calculating the shim

thickness is designed to have a lower manufacturing limit

of 75 mm. Any deviation ' b ' is stamped on the drive pinion.

Therefore to calculate the value of ' B '

B = 7 5 + b (deviation)

The distance 'C' in the formula for calculating the shim

thickness is designed to have a lower manufacturing limit

FIG 6 : 8 Layshaft w i t h final drive pinion. The arrow

points to the number (14) for correct mating with ring

gear and to the centesimal figure (—10) for accurate

mating position of pinion and gear

Page 69 of 128

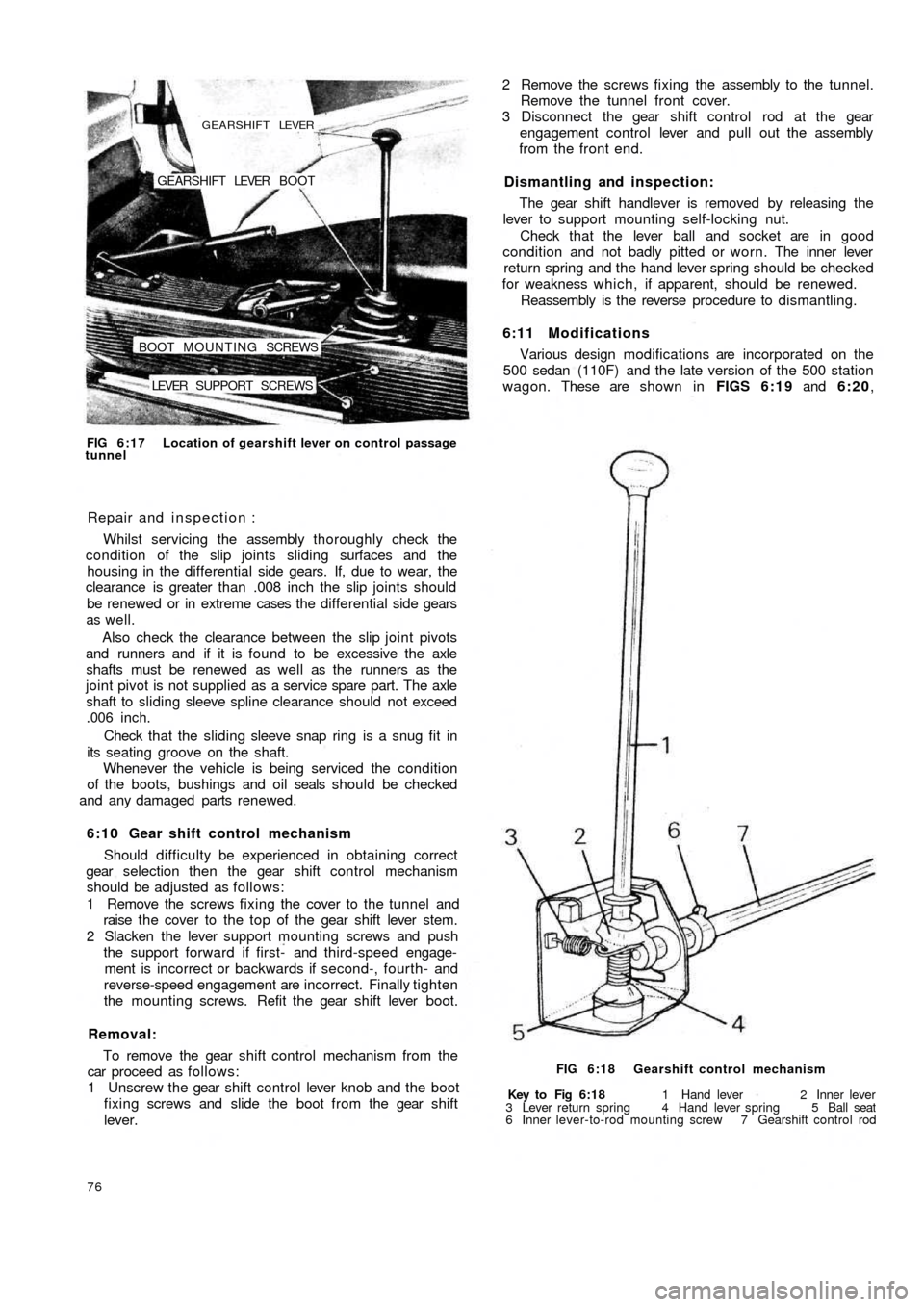

LEVER SUPPORT SCREWS BOOT MOUNTING SCREWSGEARSHIFT LEVER BOOT

GEARSHIFT LEVER

FIG 6:17 Location of gearshift lever on control passage

tunnel

Repair and inspection :

Whilst servicing the assembly thoroughly check the

condition of the slip joints sliding surfaces and the

housing in the differential side gears. If, due to wear, the

clearance is greater than .008 inch the slip joints should

be renewed or in extreme cases the differential side gears

as well.

Also check the clearance between the slip joint pivots

and runners and if it is found to be excessive the axle

shafts must be renewed as well as the runners as the

joint pivot is not supplied as a service spare part. The axle

shaft to sliding sleeve spline clearance should not exceed

.006 inch.

Check that the sliding sleeve snap ring is a snug fit in

its seating groove on the shaft.

Whenever the vehicle is being serviced the condition

of the boots, bushings and oil seals should be checked

and any damaged parts renewed.

6:10 Gear shift control mechanism

Should difficulty be experienced in obtaining correct

gear selection then the gear shift control mechanism

should be adjusted as follows:

1 Remove the screws fixing the cover to the tunnel and

raise t h e cover to t h e t o p of the gear shift lever stem.

2 Slacken the lever support mounting screws and push

the support forward if first- and third-speed engage-

ment is incorrect or backwards if second-, fourth- and

reverse-speed engagement are incorrect. Finally tighten

the mounting screws. Refit the gear shift lever boot.

Removal:

To remove the gear shift control mechanism from the

car proceed as follows:

1 Unscrew the gear shift control lever knob and the boot

fixing screws and slide the boot from the gear shift

lever.

76Key to Fig 6:18 1 Hand lever 2 Inner lever

3 Lever return spring 4 Hand lever spring 5 Ball seat

6 Inner lever-to-rod mounting screw 7 Gearshift control rod FIG 6:18 Gearshift control mechanism

6:11 Modifications

Various design modifications are incorporated on the

500 sedan (110F) and the late version of the 500 station

wagon. These are shown in FIGS 6:19 and 6:20, The gear shift handlever is removed by releasing the

lever to support mounting self-locking nut.

Check that the lever ball and socket are in good

condition and not badly pitted or worn. The inner lever

return spring and the hand lever spring should be checked

for weakness which, if apparent, should be renewed.

Reassembly is the reverse procedure to dismantling. Dismantling and inspection: 2 Remove the screws fixing the assembly to the tunnel.

Remove the tunnel front cover.

3 Disconnect the gear shift control rod at the gear

engagement control lever and pull out the assembly

from the front end.

Page 83 of 128

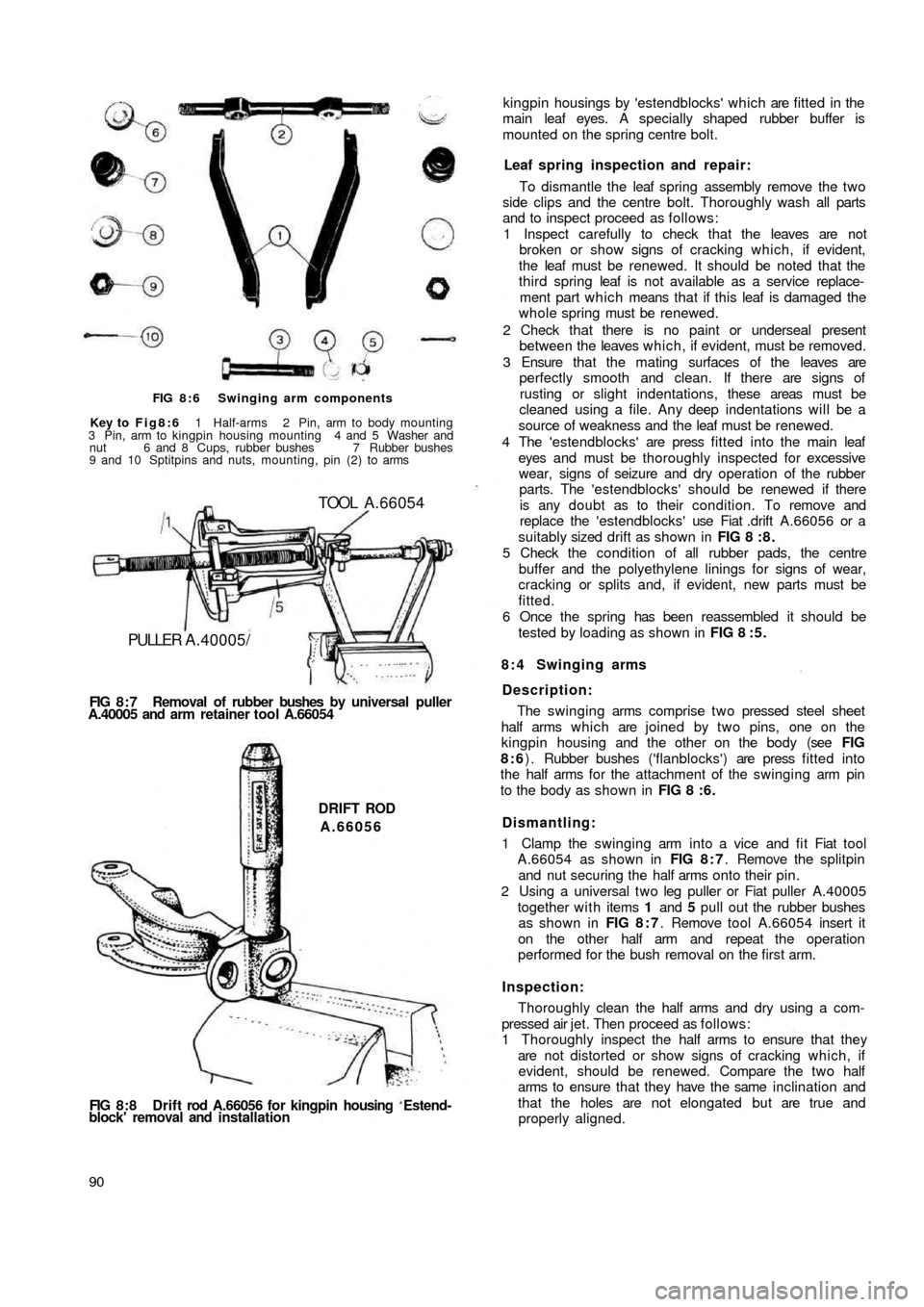

FIG 8:6 Swinging arm components

Key to Fig8:6 1 Half-arms 2 Pin, arm to body mounting

3 Pin, arm to kingpin housing mounting 4 and 5 Washer and

nut 6 and 8 Cups, rubber bushes 7 Rubber bushes

9 and 10 Sptitpins and nuts, mounting, pin (2) to arms

TOOL A.66054

PULLER A.40005/

FIG 8 : 7 Removal of rubber bushes by universal puller

A.40005 and arm retainer tool A.66054

DRIFT ROD

A.66056

FIG 8:8 Drift rod A.66056 for kingpin housing Estend-

block' removal and installation

90Inspection:

Thoroughly clean the half arms and dry using a com-

pressed air jet. Then proceed as follows:

1 Thoroughly inspect the half arms to ensure that they

are not distorted or show signs of cracking which, if

evident, should be renewed. Compare the t w o half

arms to ensure that they have the same inclination and

that the holes are not elongated but are true and

properly aligned. kingpin housings by 'estendblocks' which are fitted in the

main leaf eyes. A specially shaped rubber buffer is

mounted on the spring centre bolt.

Leaf spring inspection and repair:

To dismantle the leaf spring assembly remove the t w o

side clips and the centre bolt. Thoroughly wash all parts

and to inspect proceed as follows:

1 Inspect carefully to check that the leaves are not

broken or show signs of cracking which, if evident,

the leaf must be renewed. It should be noted that the

third spring leaf is not available as a service replace-

ment part which means that if this leaf is damaged the

whole spring must be renewed.

2 Check that there is no paint or underseal present

between the leaves which, if evident, must be removed.

3 Ensure that the mating surfaces of the leaves are

perfectly smooth and clean. If there are signs of

rusting or slight indentations, these areas must be

cleaned using a file. Any deep indentations will be a

source of weakness and the leaf must be renewed.

4 The 'estendblocks' are press fitted into the main leaf

eyes and must be thoroughly inspected for excessive

wear, signs of seizure and dry operation of the rubber

parts. The 'estendblocks' should be renewed if there

is any doubt as to their condition. To remove and

replace the 'estendblocks' use Fiat .drift A.66056 or a

suitably sized drift as shown in FIG 8 : 8 .

5 Check the condition of all rubber pads, the centre

buffer and the polyethylene linings for signs of wear,

cracking or splits and, if evident, new parts must be

fitted.

6 Once the spring has been reassembled it should be

tested by loading as shown in FIG 8 : 5 .

8:4 Swinging arms

Description:

The swinging arms comprise t w o pressed steel sheet

half arms which are joined by two pins, one on the

kingpin housing and the other on the body (see FIG

8:6) . Rubber bushes ('flanblocks') are press fitted into

the half arms for the attachment of the swinging arm pin

to the body as shown in FIG 8 : 6 .

Dismantling:

1 Clamp the swinging arm into a vice and fit Fiat tool

A.66054 as shown in FIG 8 : 7. Remove the splitpin

and nut securing the half arms onto their pin.

2 Using a universal t w o leg puller or Fiat puller A.40005

together with items 1 and 5 pull out the rubber bushes

as shown in FIG 8 : 7. Remove tool A.66054 insert it

on the other half arm and repeat the operation

performed for the bush removal on the first arm.

Page 84 of 128

2 Check that the surface of the pin that is in contact with

the camber and castor adjuster shims does not show

any signs of indentation or roughness which could

affect the accuracy of adjustment on reassembly. If

there are any signs of rust or small markings these

should be smoothed out using a file.

3 Inspect the condition of the half arm bushes, the inner

surface of which must not show signs of seizure and

the clearance of the bush to pin must not be greater

than .01 57 inch. Upon initial assembly the fit clearance

is .00059 to .0059 inch. Ensure t h a t the rubber parts

of the bush are not torn, cracked or show signs of

weakness which, if evident, must be renewed.

4 Use Fiat tool A.66058 or a suitably sized drift for

refitting the rubber bushes into the swinging arms.

Upon reassembly it should be observed that the

tightening of the two swinging arms m o u n t i n g nuts 5

(see FIG 8 : 3) , must be carried out whilst keeping

the axis of the swinging arm and the pin hole for the

screws 7 on the same plane otherwise distortion can

occur.

8 : 5 Kingpin housing

1 To remove and replace the 'estendblocks' use Fiat

tool A.66056 as shown in FIG 8 : 8. Ensure t h a t the

'estendblocks' is not worn and that there are no signs

of seizure on its inner surface, or that the rubber has

hardened. Renew if necessary.

2 Check that the kingpin to bush clearance is not

greater than .0079 inch. The clearance when fitted

new is .00063 to .00213 inch. If the clearance is

excessive the t w o bushes must be renewed and also

the kingpin if excessive wear is evident. To remove and

refit the kingpin bushes use Fiat tool A.66016 and

after reassembly the bushes must be accurately

refaced using a reamer set to a diameter of .5912 to

.5922 inch. If considered necessary use Fiat Fixture

C.1004 to check that the kingpin housing has not been

distorted which, if evident, the housing must be

renewed.

3 Whilst the kingpin assembly is being inspected ensure

that the lubrication hole is free to allow the passage of

oil.

4 To prevent incorrect loading of the 'estendblocks' that

is press fitted into the kingpin housing, the housing

to swinging arm pin nut must be tightened with the

parts so arranged that the angle between the swinging

arm plane and the housing axis is approximately

95 deg. as shown in FIG 8:14.

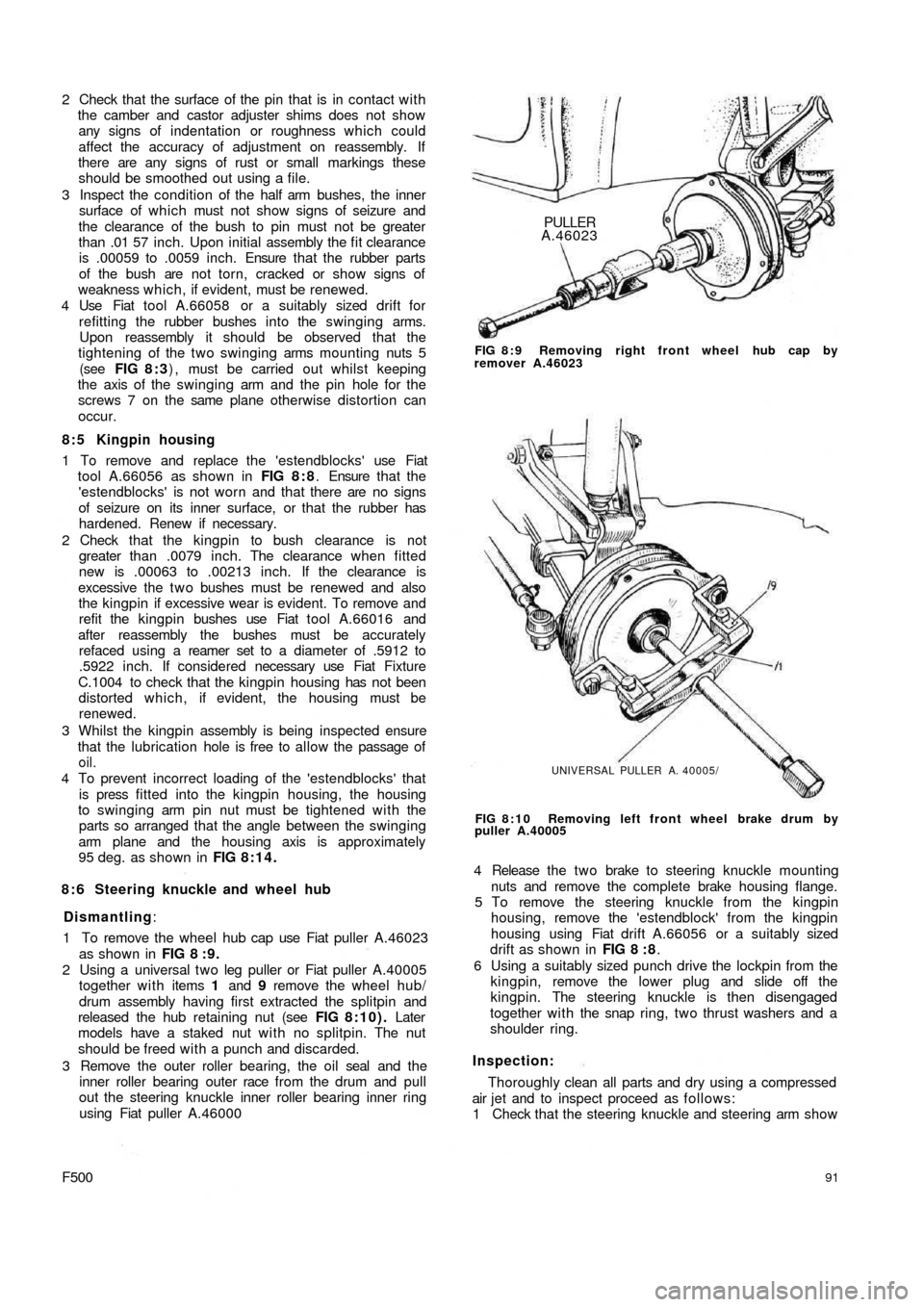

8:6 Steering knuckle and wheel hub

Dismantling:

1 To remove the wheel hub cap use Fiat puller A.46023

as shown in FIG 8 : 9 .

2 Using a universal t w o leg puller or Fiat puller A.40005

together with items 1 and 9 remove the wheel hub/

drum assembly having first extracted the splitpin and

released the hub retaining nut (see FIG 8:10). Later

models have a staked nut w i t h no splitpin. The nut

should be freed with a punch and discarded.

3 Remove the outer roller bearing, the oil seal and the

inner roller bearing outer race from the drum and pull

out the steering knuckle inner roller bearing inner ring

using Fiat puller A.46000

F500PULLER

A.46023

FIG 8 : 9 Removing right front wheel hub cap by

remover A.46023

UNIVERSAL PULLER A. 40005/

FIG 8:10 Removing left front wheel brake drum by

puller A.40005

4 Release the t w o brake to steering knuckle mounting

nuts and remove the complete brake housing flange.

5 To remove the steering knuckle from the kingpin

housing, remove the 'estendblock' from the kingpin

housing using Fiat drift A.66056 or a suitably sized

drift as shown in FIG 8 : 8.

6 Using a suitably sized punch drive the lockpin from the

kingpin, remove the lower plug and slide off the

kingpin. The steering knuckle is then disengaged

together with the snap ring, two thrust washers and a

shoulder ring.

Inspection:

Thoroughly clean all parts and dry using a compressed

air jet and to inspect proceed as follows:

1 Check that the steering knuckle and steering arm show

91

Page 104 of 128

CHAPTER 11

THE ELECTRICAL EQUIPMENT

11:1 Description

11:2 Battery

11:3 The generator

11:4 The starter

11:5 The control box

1 1 : 6 Fuses

1 1 : 7 Flasher unit

11:1 Description

All models covered by this manual have 12 volts

electrical systems in which the negative battery terminal

is earthed. There are three units in the regulator box to

control the charging circuit; a cut-out, a current regulator

and a voltage regulator. These are adjustable but it must

be stressed that accurate moving coil meters are required

when checking or altering the settings. Cheap and

unreliable instruments will make accurate adjustments

impossible.

There are wiring diagrams in Technical Data at the end

of this manual to enable those with electrical experience

to trace and correct wiring faults.

For t h e U.K. Market the headlamps are of the double

filament dipping renewable bulb type with adjustments

for individual beam settings.

The battery is located in the front compartment

forward of the petrol tank and the fuses to the rear o f the

petrol tank.

Detailed instructions for servicing the electrical equip-

ment will be found in this chapter, but it must be pointed

out that it is not sensible to try to repair that which is

seriously defective, electrically or mechanically. Such

equipment should be replaced by new units which can

be obtained on an exchange basis.

F500111

11 :8 Windscreen wipers

1 1 : 9 The lighting system

11:10 Panel and warning lights

11:11 The horn

11:12 Lighting and flasher switch

1 1 : 1 3 Fault diagnosis

11.2 The battery

This of the 12-volt lead/acid type and has to meet

heavy demands for current particularly in the winter. To

maintain the performance of the battery at its maximum

it is essential to carry out the following operations.

Keep the top of the battery and surrounding parts dry

and clean, as dampness can cause leakage between the

securing clamps and the battery terminals. Clean off any

corrosion from the metal parts of the battery mounting

with diluted ammonia and paint them with an anti-

sulphuric paint. If the terminal posts are corroded,

remove the cables and clean w i t h diluted ammonia.

Smear the posts w i t h petroleum jelly before remaking the

connections and fit the terminals securely. High electrical

resistance due to corrosion at the terminal posts is often

responsible for lack of sufficient current to operate the

starter motor.

Ensure t h a t the filler plugs are in good condition and

show no signs of cracks. This may cause leakage of

electrolyte and consequent corrosion. Test the condition

of the cells after topping-up the electrolyte level with

distilled water to just above the tops of the separators as

shown in FIG 11 :2 . Never add neat acid. If it is

necessary to make a new electrolyte due to loss by

spillage add sulphuric acid to the

distilled water.

It is highly dangerous to add water to acid.

Page 106 of 128

indicates a break in the cable from the generator to

regulator. Repeat the test on terminal 67. Finally,

remove the temporary link from the generator. If the

readings are correct, test the regulator as described in

Section 11:5.

Removing generator:

1 Disconnect the leads from the generator.

2 Remove the drive belt as previously described.

3 Release t h e rear mounting bracket at the side of the

power unit.

4 Remove the air cooling ducting from around the fan

and generator area and lift away the unit.

5 Release the blower from the end of the armature shaft

and finally, the mounting bolts from the air ducting.

Dismantling generator:

1 Release the pulley self-locking nut and slide the pulley

off the armature shaft.

2 Remove the t w o Woodruff keys on armature shaft.

3 Unscrew the t w o through bolt nuts and pull out the

bolts.

4 Partially remove the commutator end head to the point

where the brushes are. s t i l l seating on the commutator.

Using a piece of hooked wire relieve the load of the

springs on the brushes by arranging the spring ends

on the brush sides. The brushes will be locked in their

holders and cannot be chipped by striking against the

armature shaft during the commutator end head

removal.

5 Gently ease the commutator and fan end heads apart

and, slide out the armature.

Servicing brushes:

Lift the brushes up in the boxes and hold them in that

position by letting each brush spring bear on the side of

its brush. Fit the commutator end bracket over the

commutator end of the armature shaft and release the

brushes by hooking up the springs using a thin screw

driver. Hold back each spring in turn and move the brush

by pulling gently on the flexible connector. If the brush

moves sluggishly remove it and polish the sides using a

smooth file. Before this operation is actually carried out it

is suggested that the brush is marked before removal so

that it is replaced in its original working position.

inch,The minimum permissible length of a brush is

so renew any t h a t are less than this figure. Test the brush

springs using a spring tension scale. New springs should

have a tension of 1.3 to 1.6 Ib. In service this value could

fall slightly before performance is affected. Always bed in

new brushes by wrapping fine sandpaper round the

commutator, pressing down on the brush and rotating

the commutator under it, or draw the paper t o o and f r o .

If new brushes are fitted always fit genuine Fiat replace-

ments.

Servicing the commutator:

A commutator in good condition should be smooth and

free from pitting or signs of the segments burning. Clean

with a rag moistened in petrol. If necessary, polish using

a fine glasspaper whilst rotating the armature. Never use

emerycloth.

If the commutator is badly worn it may be skimmed

using a centre lathe. Use a high rotational speed and take

F500113

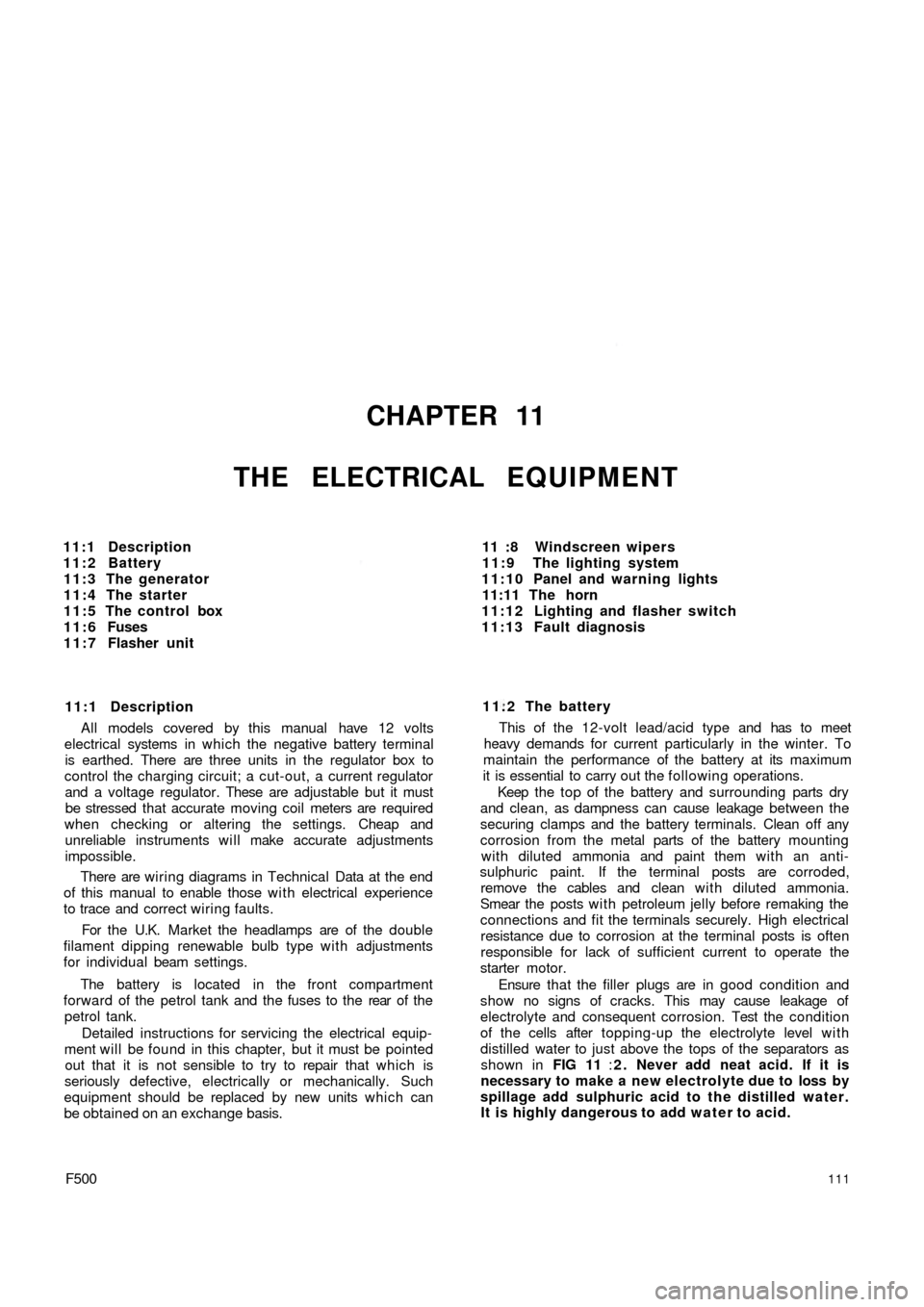

FIG 11 :3 Components of generator

Key to Fig 11 : 3 1 Terminal 51 2 Bearing outer ring

retainment terminal nut 3 Commutator end head 4 Brushes

5 Terminal 67 6 Frame 7 Blower end head

8 Bearing retainer nuts and screws 9 Pulley retainment nut

10 Pulley 11 Head mounting tie rods and nuts

12 Armature 13 Blower retainment nut

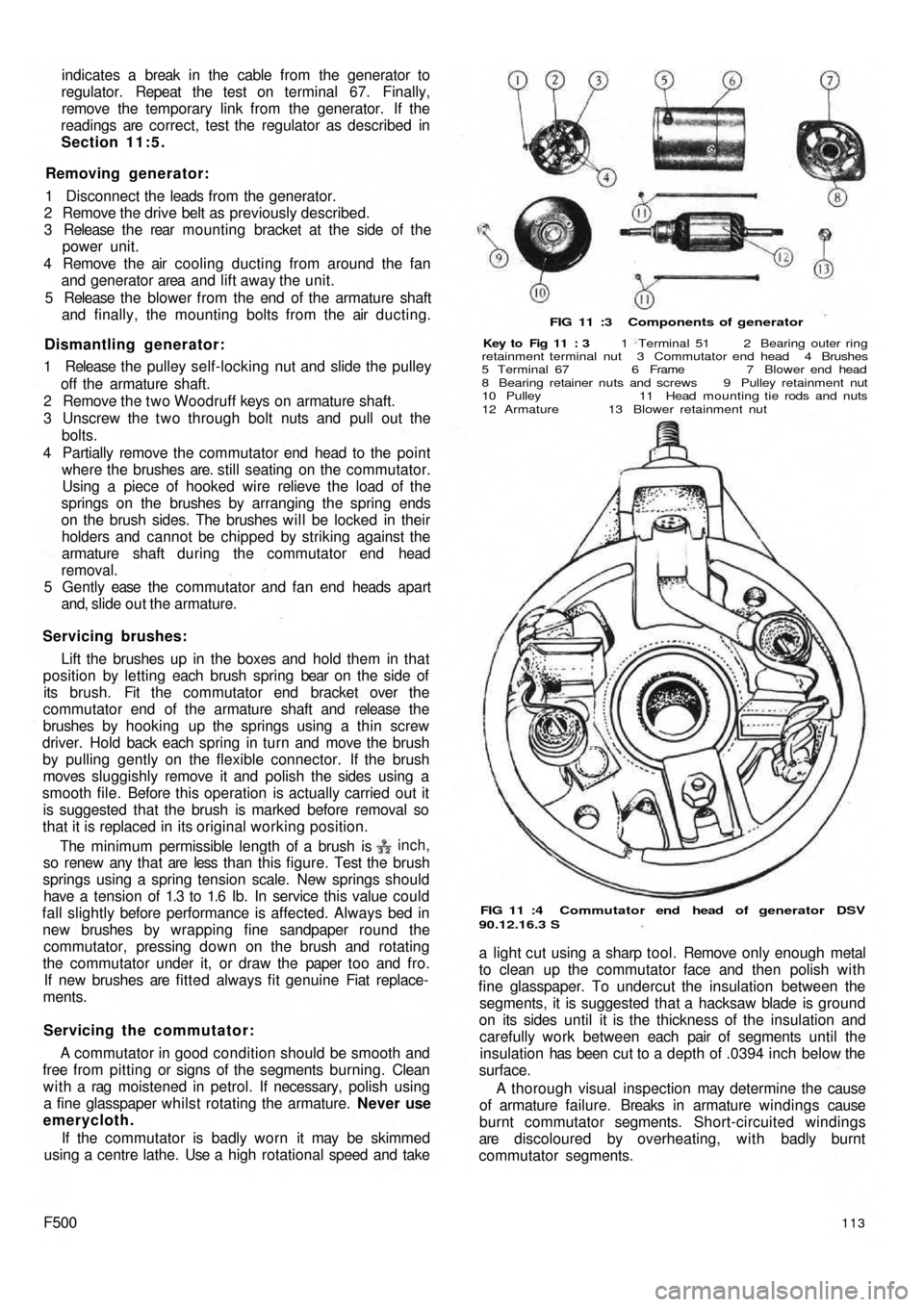

FIG 11 :4 Commutator end head of generator DSV

90.12.16.3 S

a light cut using a sharp tool. Remove only enough metal

to clean up the commutator face and then polish with

fine glasspaper. To undercut the insulation between the

segments, it is suggested that a hacksaw blade is ground

on its sides until it is the thickness of the insulation and

carefully work between each pair of segments until the

insulation has been cut to a depth of .0394 inch below the

surface.

A thorough visual inspection may determine the cause

of armature failure. Breaks in armature windings cause

burnt commutator segments. Short-circuited windings

are discoloured by overheating, with badly burnt

commutator segments.

Page 108 of 128

switch contacts. The starter motor rotates driving the

engine through the pinion and ring gear. As soon as the

engine fires the starter hand lever must be released which

will open the starter switch contacts so stopping the

starter motor and the pinion will return under the action

of a spring to a neutral position.

Tests for a starter which does not operate:

Check the condition of the battery and particularly

the connections to the terminals and to earth. If the

battery is charged, switch on the lights and operate the

starter hand lever control. If the lights go dim but the

starter does not operate it shows that current is reaching

the starter motor. The probability is that the pinion of the

starter shaft is jammed in mesh due to dirty pinion splines

or a broken spring. To release the pinion engage a low

gear with the ignition switched off and rock the vehicle

backwards and forwards which should allow the pinion

to be disengaged from the flywheel ring gear. If it proves

impossible to free a jammed pinion the starter motor must

be removed for examination and repair.

If the lamps do not go dim, check the starter switch and

also check the connection between the battery and the

starter switch to ensure that they are tight and making

good electrical connection. If the starter motor still does

not work it should be removed from the power unit for

inspection.

Removing the starter:

To remove the starter motor from the power unit

proceed as follows:

1 Disconnect the positive terminal from the

battery post.

2 Release the hand lever control cable from the starter

motor engagement lever.

3 Disconnect the battery cable terminal from the starter

motor switch.

4 Remove the retaining nuts and washers holding the

starter motor to body to the transmission bellhousing

and gently ease backwards and lift away the starter

motor.

Examining the commutator and brush gear :

Refer to FIG 11:5 and remove the coverband 5. Hold

back each spring in turn and pull gently on the flexible

connection to the brush. If the brush does not move

freely remove it from its holder and polish the sides using

a fine file. Mark the brushes so that they will be replaced

in their original positions. If the brushes are so worn that

they no longer bear onto the commutator, or the brush

connector has become exposed on the running face, the

brushes must be renewed.

If the commutator is blackened it should be cleaned by

turning it against a petrol-moistened cloth. With the

brushes and commutator overhauled hold the body of the

starter motor in a vice and connect it with thick cables to a

12 volt battery. One cable should go to the starter

switch terminal and the other to the body of the starter.

The starter should run at high speed. If it does not, it

must be dismantled for further examination and testing.

F500115 Dismantling the starter:

To dismantle the starter proceed as follows:

1 Remove the coverband 5 (see FIG 11:5) and hold

back the brush springs and take out the brushes.

2 Remove the starter switch by releasing the t w o

mounting screws and lift away the switch.

3 Remove the commutator end head 16, slide off the

armature assembly from the drive unit and from the

pole shoes.

4 Release the engagement lever pin 6 and spring 7 from

the lever operating bracket on the drive end head. Lift

away the lever and withdraw the pinion assembly

complete which is shown in FIG 11:5.

Servicing the brushes

Test the brush springs with a balance, the correct

tension is 2.5 to 2.9 Ib. according to the wear of the

brushes. Fit a new spring if the tension is low.

The life of the brushes depends on the type of service

in which the vehicle is being used. In normal circum-

stances even when the starter is being used frequently,

the brushes should last more than 18,000 miles. If the

wear is found to be abnormal it will probably be found

that the commutator is either damaged or excessively

w o r n . Only Fiat replacement brushes must be used.

Testing the field coils:

Use a 12 volt bulb in one lead of a 12 volt battery.

Connect one lead to the brush connection joint to the coil

field and the other to the field coil current supply lead.

If the bulb does not light there is a break in the f i e l d coil

windings. This is not a complete test as it is still possible

for a coil to be earthed. Check this by moving the lead

from the brush connection and holding it on a clean

metal

surface on the yoke or body. If the bulb lights it shows

that the field coils are earthed.

The only sure way of curing faulty field coils is to take

the starter motor to a service station.

Examining the armature:

The armature shaft may be bent due to the starter

being operated whilst the engine is operating. Do not try

to straighten a bent shaft or machine the armature core to

obtain the correct clearance.

If the commutator is damaged or any wires or segments

have lifted from it, the assembly will have to be renewed.

Starter bearings:

Bearing bushes are of the porous bronzed type and

must not be reamed after fitting. Worn bearings should

be withdrawn by screwing a tap into them and pulling

on the tap. New bushes must be immersed in engine oil

for approximately twenty four hours before fitting. Press

them into place using a suitably sized drift which has a

spigot the length of the bearing and the diameter of the

starter shaft. When this is withdrawn after fitting, the

bore of the bush should be correct to size.

The pinion drive:

This unit is shown in FIG 11:5. The chief sources of

trouble are a dirty unit or a broken starting engagement

Page 116 of 128

Lamp brilliance varies w i t h the speed of t h e car:

Check the condition of the battery. Examine the battery

connections. Make sure they are tight and renew faulty

cables.

11:10 Panel and warning lights:

All the gauges are clustered in a single instrument

mounted on the dashboard above the steering column.

Incorporated in this cluster is the parking light pilot light,

generator charge indicator, fuel reserve supply indicator,

low oil pressure indicator, and the speedometer w i t h

mileage recorder.

The parking lamp indicator glows green when the

ignition lock switch key is in either position 1 or 2 once

the toggle switch on the instrument panel has been

operated.

The generator charge indicator shows red only when

the ignition is turned on. It should be extinguished when

the generator output is sufficient for battery charge

(12.6 ± 0.2 volts) with the engine running at a speed

of 1100 rev/min and the headlights switched off.

The fuel reserve supply indicator shows red only when

the ignition is turned on and the amount of fuel in the

petrol tank has dropped to approximately .8 to 1.1

Imp. gallons.

The low oil pressure indicator shows red only when the

ignition is turned on and should be extinguished when

the oil pressure reaches 7.1 to 21.3 Ib/sq in, and opens

the sending unit contacts. Once the engine is at normal

operating temperature but at a speed below 1000 rev/

min the indicator might light up even the pressure is under

control and with normal operation.

All the bulbs fitted to the above described units are of

the tubular 2.5W type and to renew a bulb extract the

bulb holder from the rear of t h e instrument cluster and

release the bulb which is attached by a normal bayonet

coupling.

Fuel reserve supply indicator sender u n i t:

The fuel reserve supply indicator should be checked for

correct indication by allowing the fuel tank to empty and

then inserting .8 to 1.1 Imp. gallons at which stage the

light should extinguish. Any failure to do so should be

checked as follows:

1 Ensure that the indicator bulb operates correctly.

2 Check for complete circuit between the sender unit and

the indicator bulb.

3 If the sender unit float bracket is distorted the bulb

will

indicate a reserve supply of fuel greater or smaller than

specified. The bracket should be adjusted to give

correct indication of fuel level.

4 The sender unit could have been inadvertantly

damaged in which case the unit must be renewed.

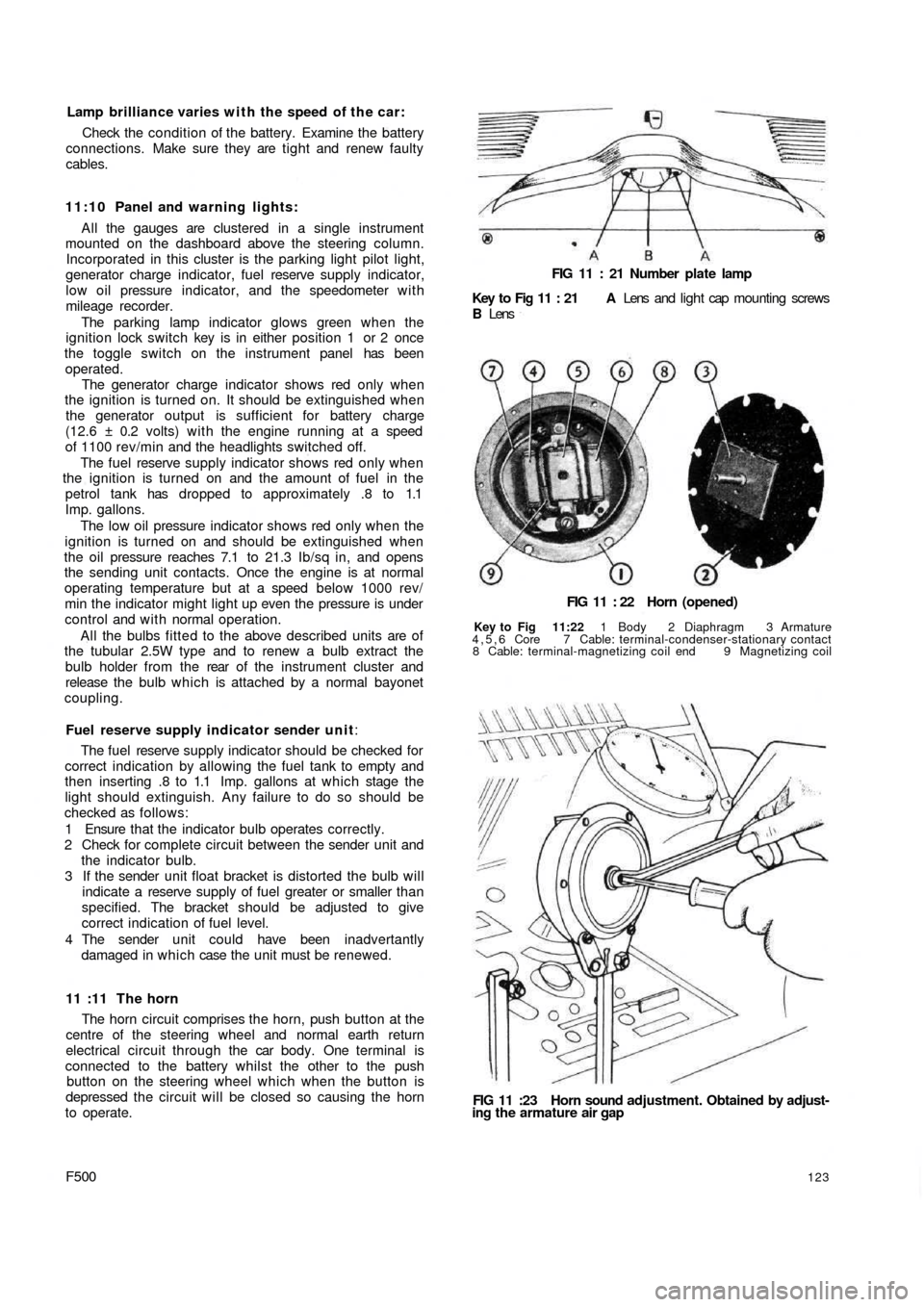

11 :11 The horn

The horn circuit comprises the horn, push button at the

centre of the steering wheel and normal earth return

electrical circuit through the car body. One terminal is

connected to the battery whilst the other to the push

button on the steering wheel which when the button is

depressed the circuit will be closed so causing the horn

to operate.

F500

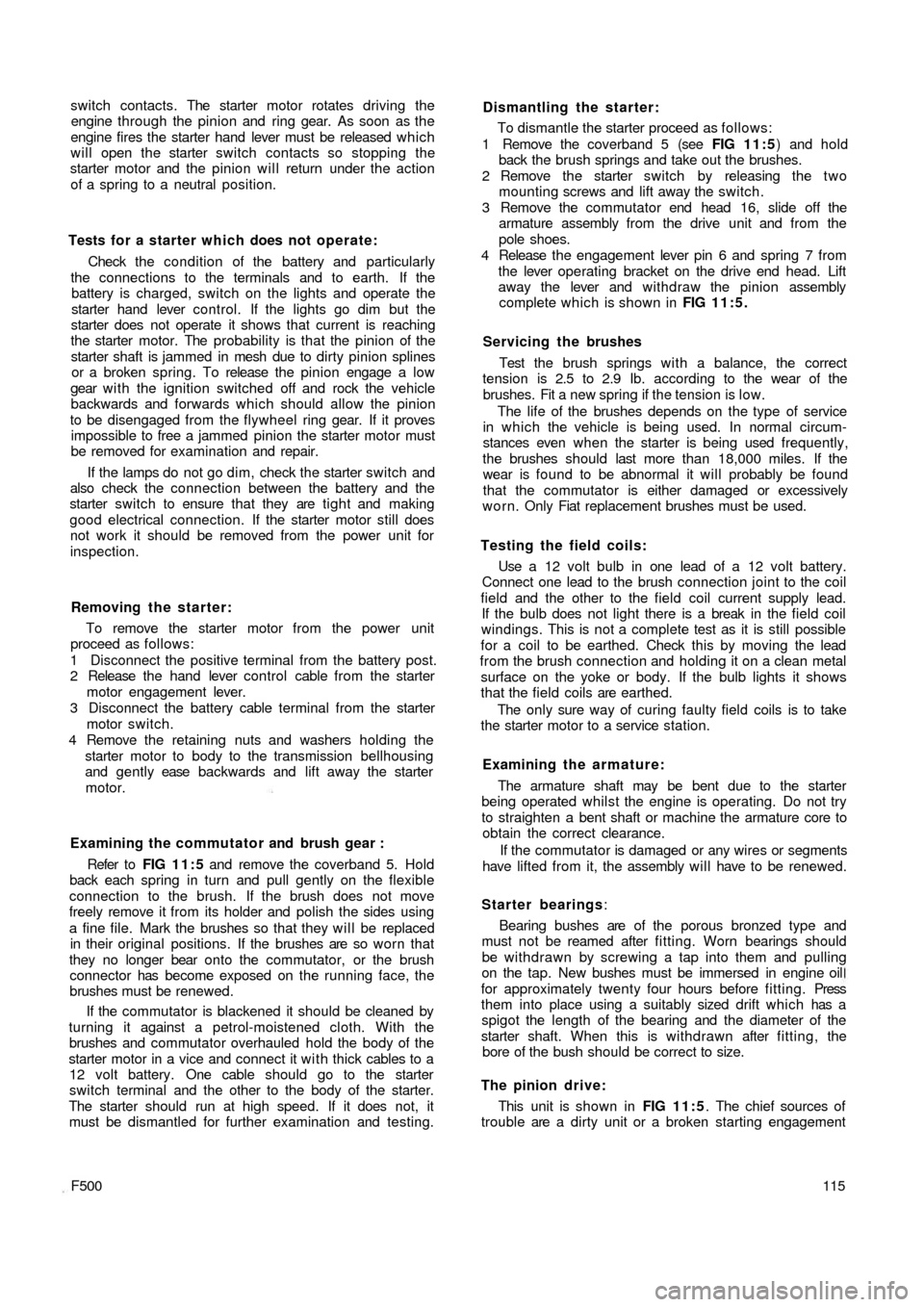

FIG 11 : 21 Number plate lamp

Key to Fig 11 : 21 A Lens and light cap mounting screws

B Lens

FIG 11 : 22 Horn (opened)

Key to Fig 11:22 1 Body 2 Diaphragm 3 Armature

4,5,6 Core 7 Cable: terminal-condenser-stationary contact

8 Cable: terminal-magnetizing coil end 9 Magnetizing coil

FIG 11 :23 Horn sound adjustment. Obtained by adjust-

ing the armature air gap

123

Page 128 of 128

cushion and back rest. A number of rubber straps are

hooked across the frame under the cushion and in a

sheath covering on the seat back.

The bottom of the front seat frame ends are provided

with sliding guides which run in guide rails attached to

the floor. The sliding guides are pivoted on the frame

tubes to allow for forward tilting of the seats giving better

access to the rear compartment. Two rubber pads

provide cushioning of the seat frame on the guide rails

as shown in FIG 12:11. The control lever for seat

adjustment is fitted in the frame righthand tube to permit

unlocking of the seats so that they may be adjusted to

individual drivers requirements.

Rear seats (Sedan):

The rear seat comprises of a foam rubber cushion and

back. The seat back is cemented to the rear floor and

body shell bulkhead. The rear seat lining is of fabric and

imitation leather. The seat lining is held in place by four

self-tapping screws, t w o of which secure the floor below

the back window and two the lining at the base of t h e

back rest. Included with the seat assembly is a masonite

floor which is fitted below the rear window.

Rear Seat (Station Wagon):

The rear seat back rest is pivoted at the base of its

frame so that it can be folded down to form a load plat-

form surface. In the upright position it is retained in place

by t w o brackets mounted on either side of the body below

the side

windows.

12:14 Interior heater

Description:

Interior heating is accomplished by recirculation of

warm air from the engine cooling system through engine

cowling. Referring to FIG 12:18 a hose conveys warmed

air from the engine cowling to the centre tunnel floor

where warm air flows out through two slots being cut on

the windshield delivery hoses. Air admission can be

adjusted by turning the control lever to the right which

operates the tunnel throttle valve at the rear seat.

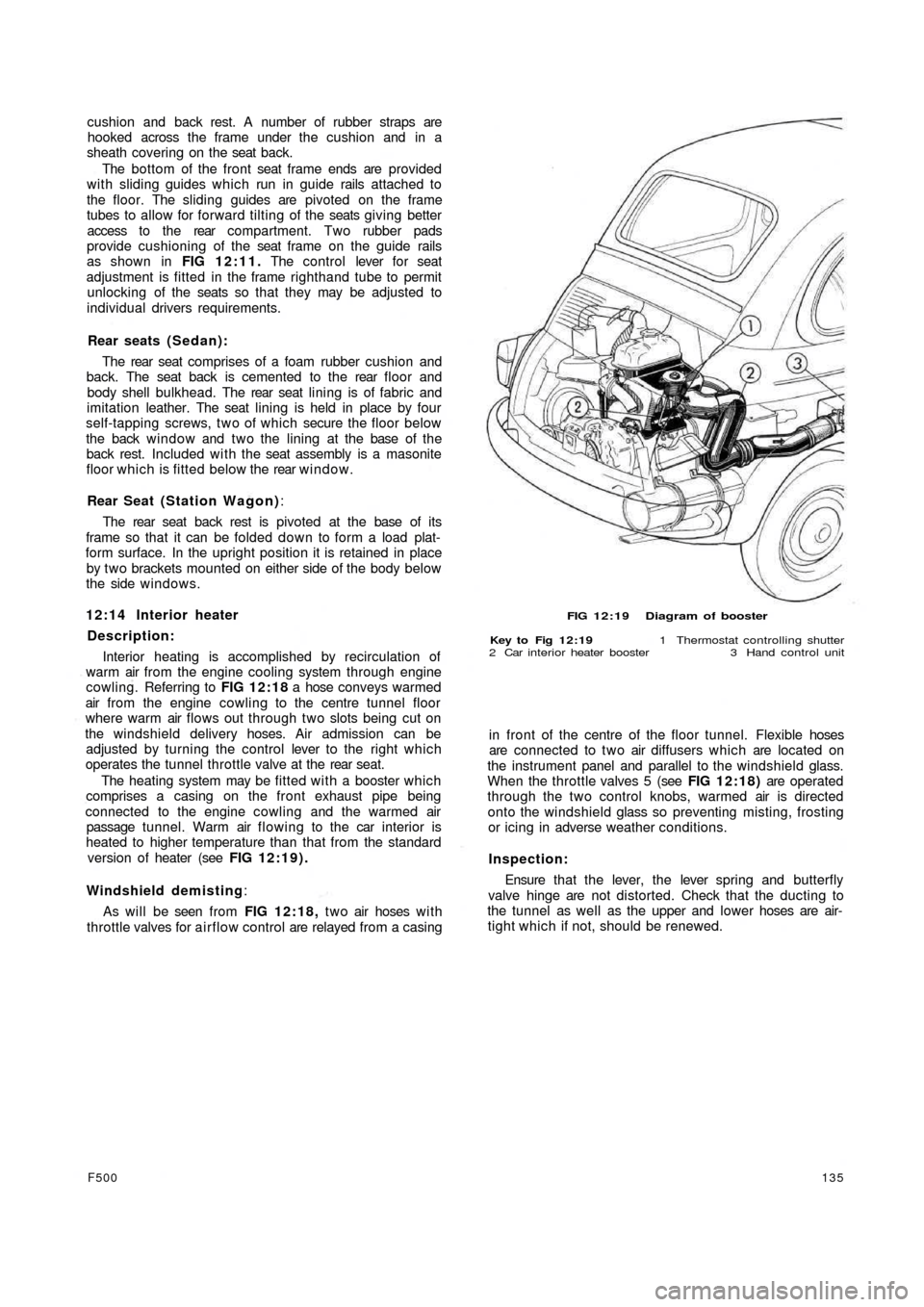

The heating system may be fitted with a booster which

comprises a casing on the front exhaust pipe being

connected to the engine cowling and the warmed air

passage tunnel. Warm air flowing to the car interior is

heated to higher temperature than that from the standard

version of heater (see FIG 12:19).

Windshield demisting:

As will be seen from FIG 12:18, t w o air hoses w i t h

throttle valves for airflow control are relayed from a casing

F500135

FIG 12:19 Diagram of booster

Key to Fig 12:19 1 Thermostat controlling shutter

2 Car interior heater booster 3 Hand control unit

in front of the centre of the floor tunnel. Flexible hoses

are connected to two air diffusers which are located on

the instrument panel and parallel to the windshield glass.

When the throttle valves 5 (see FIG 12:18) are operated

through the two control knobs, warmed air is directed

onto the windshield glass so preventing misting, frosting

or icing in adverse weather conditions.

Inspection:

Ensure that t h e lever, the lever spring and butterfly

valve hinge are not distorted. Check that the ducting to

the tunnel as well as the upper and lower hoses are air-

tight which if not, should be renewed.