Timing FIAT 500 1967 1.G User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 1967, Model line: 500, Model: FIAT 500 1967 1.GPages: 128, PDF Size: 9.01 MB

Page 21 of 128

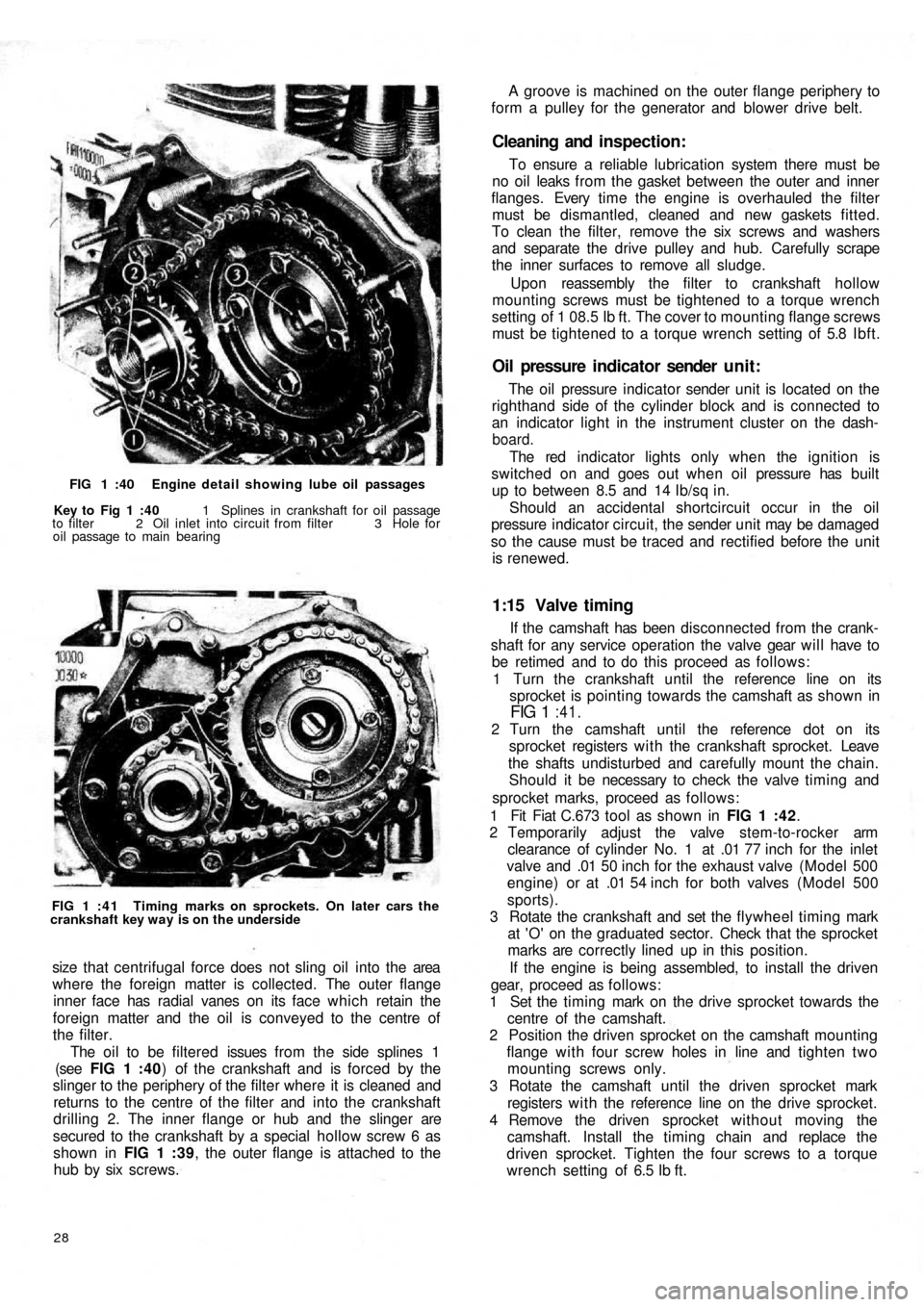

FIG 1 :40 Engine detail showing lube oil passages

Key to Fig 1 :40 1 Splines in crankshaft for oil passage

to filter 2 Oil inlet into circuit from filter 3 Hole for

oil passage to main bearing

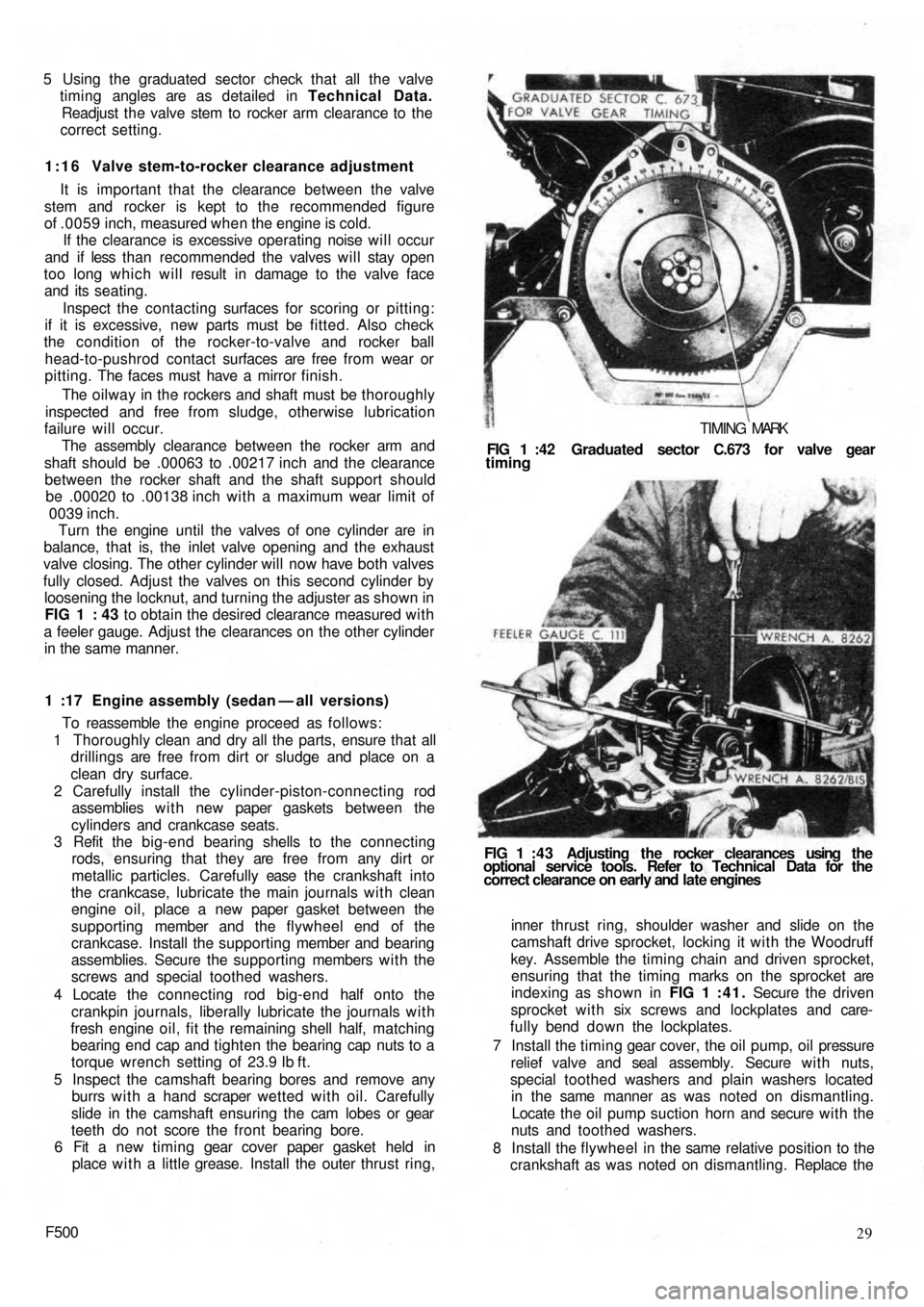

FIG 1 : 4 1 Timing marks on sprockets. On later cars the

crankshaft key way is on the underside

size that centrifugal force does not sling oil into the area

where the foreign matter is collected. The outer flange

inner face has radial vanes on its face which retain the

foreign matter and the oil is conveyed to the centre of

the filter.

The oil to be filtered issues from the side splines 1

(see FIG 1 :40) of the crankshaft and is forced by the

slinger to the periphery of the filter where it is cleaned and

returns to the centre of the filter and into the crankshaft

drilling 2. The inner flange or hub and the slinger are

secured to the crankshaft by a special hollow screw 6 as

shown in FIG 1 :39, the outer flange is attached to the

hub by six screws.

28

If the camshaft has been disconnected from the crank-

shaft for any service operation the valve gear will have to

be retimed and to do this proceed as follows:

1 Turn the crankshaft until the reference line on its

sprocket is pointing towards the camshaft as shown in

FIG 1 :41.

2 Turn the camshaft until the reference dot on its

sprocket registers w i t h the crankshaft sprocket. Leave

the shafts undisturbed and carefully mount the chain.

Should it be necessary to check the valve timing and

sprocket marks, proceed as follows:

1 Fit Fiat C.673 tool as shown in FIG 1 :42.

2 Temporarily adjust the valve stem-to-rocker arm

clearance of cylinder No. 1 at .01 77 inch for the inlet

valve and .01 50 inch for the exhaust valve (Model 500

engine) or at .01 54 inch for both valves (Model 500

sports).

3 Rotate the crankshaft and set the flywheel timing mark

at 'O' on the graduated sector. Check that the sprocket

marks are correctly lined up in this position.

If the engine is being assembled, to install the driven

gear, proceed as follows:

1 Set the timing mark on the drive sprocket towards the

centre of the camshaft.

2 Position the driven sprocket on the camshaft mounting

flange with four screw holes in line and tighten two

mounting screws only.

3 Rotate the camshaft until the driven sprocket mark

registers w i t h the reference line on the drive sprocket.

4 Remove the driven sprocket without moving the

camshaft. Install the timing chain and replace the

driven sprocket. Tighten the four screws to a torque

wrench setting of 6.5 Ib ft.

1:15 Valve timing

The oil pressure indicator sender unit is located on the

righthand side of the cylinder block and is connected to

an indicator light in the instrument cluster on the dash-

board.

The red indicator lights only when the ignition is

switched on and goes out when o i l pressure has built

up to between 8.5 and 14 Ib/sq in.

Should an accidental shortcircuit occur in the oil

pressure indicator circuit, the sender unit may be damaged

so the cause must be traced and rectified before the unit

is renewed.

Oil pressure indicator sender unit:

To ensure a reliable lubrication system there must be

no oil leaks from the gasket between the outer and inner

flanges. Every t i m e t h e engine is overhauled the filter

must be dismantled, cleaned and new gaskets fitted.

To clean the filter, remove the six screws and washers

and separate the drive pulley and hub. Carefully scrape

the inner surfaces to remove all sludge.

Upon reassembly the filter to crankshaft hollow

mounting screws must be tightened to a torque wrench

setting of 1 08.5 Ib ft. The cover to mounting flange screws

must be tightened to a torque wrench setting of 5.8 Ibft.

Cleaning and inspection:

A groove is machined on the outer flange periphery to

form a pulley for the generator and blower drive belt.

Page 22 of 128

5 Using the graduated sector check that all the valve

timing angles are as detailed in Technical Data.

Readjust the valve stem to rocker arm clearance to the

correct setting.

1:16 Valve stem-to-rocker clearance adjustment

It is important that the clearance between the valve

stem and rocker is kept to the recommended figure

of .0059 inch, measured when the engine is cold.

If the clearance is excessive operating noise will occur

and if less than recommended the valves will stay open

too long which will result in damage to the valve face

and its seating.

Inspect the contacting surfaces for scoring or pitting:

if it is excessive, new parts must be fitted. Also check

the condition of the rocker-to-valve and rocker ball

head-to-pushrod contact surfaces are free from wear or

pitting. The faces must have a mirror finish.

The oilway in the rockers and shaft must be thoroughly

inspected and free from sludge, otherwise lubrication

failure will occur.

The assembly clearance between the rocker arm and

shaft should be .00063 to .00217 inch and the clearance

between the rocker shaft and the shaft support should

be .00020 to .00138 inch with a maximum wear limit of

0039 inch.

Turn the engine until the valves of one cylinder are in

balance, that is, the inlet valve opening and the exhaust

valve closing. The other cylinder will now have both valves

fully closed. Adjust the valves on this second cylinder by

loosening the locknut, and turning the

adjuster as shown in

FIG 1 : 43 to obtain the desired clearance measured with

a feeler gauge. Adjust the clearances on the other cylinder

in the same manner.

1 :17 Engine assembly (sedan — all versions)

To reassemble the engine proceed as follows:

1 Thoroughly clean and dry all the parts, ensure that all

drillings are free from dirt or sludge and place on a

clean dry surface.

2 Carefully install the cylinder-piston-connecting rod

assemblies w i t h new paper gaskets between the

cylinders and crankcase seats.

3 Refit the big-end bearing shells to the connecting

rods, ensuring that they are free from any dirt or

metallic particles. Carefully ease t h e crankshaft into

the crankcase, lubricate the main journals with clean

engine oil, place a new paper gasket between the

supporting member and the flywheel end of the

crankcase. Install the supporting member and bearing

assemblies. Secure the supporting members with the

screws and special toothed washers.

4 Locate the connecting rod big-end half onto the

crankpin journals, liberally lubricate the journals with

fresh engine oil, fit the remaining shell half, matching

bearing end cap and tighten the bearing cap nuts to a

torque wrench setting of 23.9 Ib ft.

5 Inspect the camshaft bearing bores and remove any

burrs w i t h a hand scraper wetted with oil. Carefully

slide in the camshaft ensuring the cam lobes or gear

teeth do not score the front bearing bore.

6 Fit a new timing gear cover paper gasket held in

place w i t h a little grease. Install the outer thrust ring,

F50029 inner thrust ring, shoulder washer and slide on the

camshaft drive sprocket, locking it with the Woodruff

key. Assemble the timing chain and driven sprocket,

ensuring that the timing marks on the sprocket are

indexing as shown in FIG 1 :41. Secure the driven

sprocket with six screws and lockplates and care-

fully bend down the lockplates.

7 Install the timing gear cover, the oil pump, oil pressure

relief valve and seal assembly. Secure w i t h nuts,

special toothed washers and plain washers located

in the same manner as was noted on dismantling.

Locate the oil pump suction horn and secure with the

nuts and toothed washers.

8 Install the flywheel in the same relative position to the

crankshaft as was noted on dismantling. Replace the FIG 1 : 4 3 Adjusting the rocker clearances using the

optional service tools. Refer to Technical Data for the

correct clearance on early and late engines FIG 1 :42 Graduated sector C.673 for valve gear

timing

TIMING MARK

Page 23 of 128

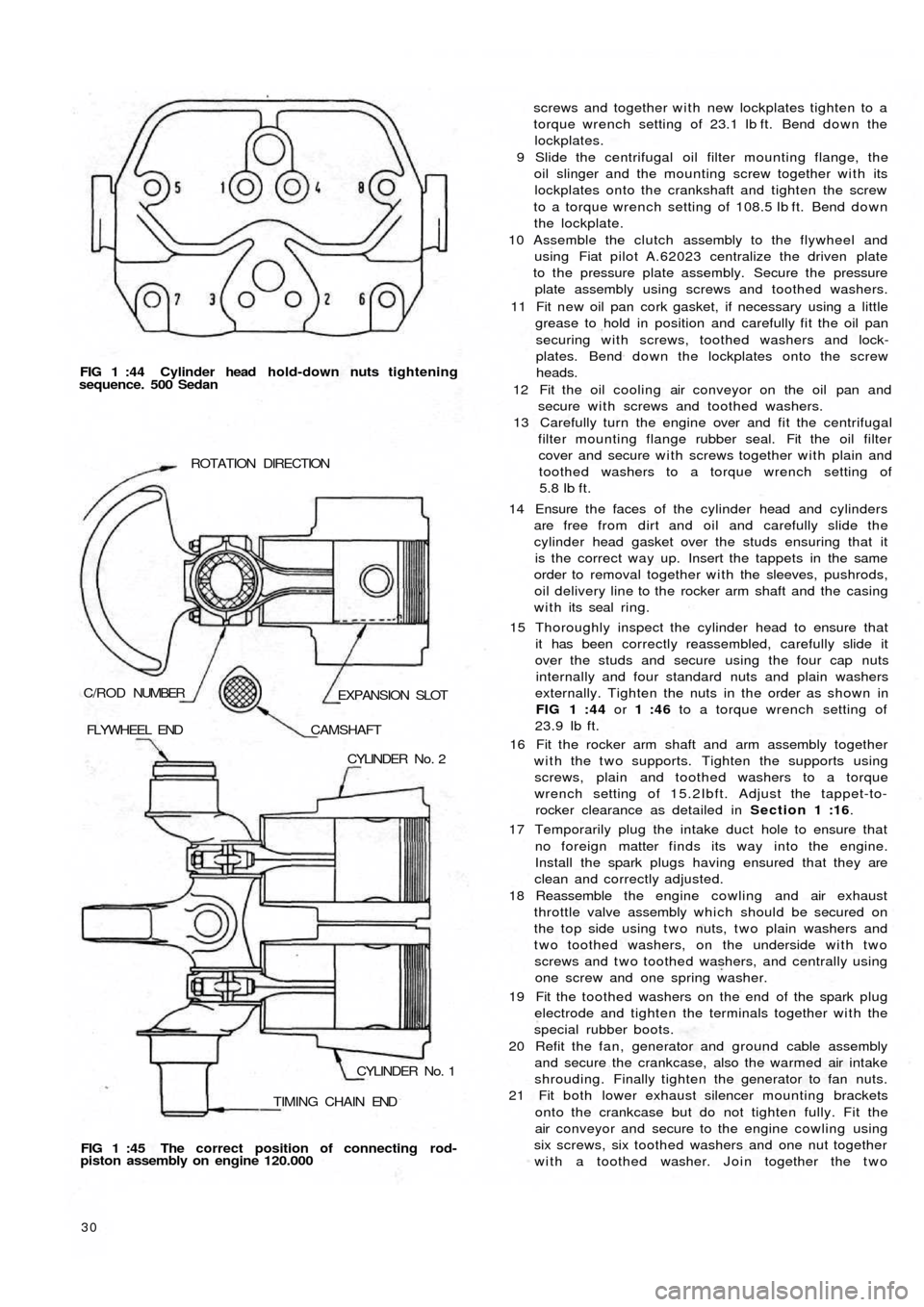

FIG 1 :44 Cylinder head h o ld-down nuts tightening

sequence. 500 Sedan

TIMING CHAIN ENDCYLINDER No. 1 CYLINDER No. 2 FLYWHEEL END

CAMSHAFT

EXPANSION SLOT C/ROD NUMBERROTATION DIRECTION

FIG 1 :45 The correct position of connecting rod-

piston assembly on engine 120.000

30

screws and together with new lockplates tighten to a

torque wrench setting of 23.1 Ib ft. Bend down the

lockplates.

9 Slide the centrifugal oil filter mounting flange, the

oil slinger and the mounting screw together with its

lockplates onto the crankshaft and tighten the screw

to a torque wrench setting of 108.5 Ib ft. Bend down

the lockplate.

10 Assemble the clutch assembly to the flywheel and

using Fiat pilot A.62023 centralize the driven plate

to the pressure plate assembly. Secure the pressure

plate assembly using screws and toothed washers.

11 Fit new oil pan cork gasket, if necessary using a little

grease to hold in position and carefully fit the oil pan

securing with screws, toothed washers and lock-

plates. Bend down the lockplates onto the screw

heads.

12 Fit the oil cooling air conveyor on the oil pan and

secure with screws and toothed washers.

13 Carefully turn the engine over and fit the centrifugal

filter mounting flange rubber seal. Fit the oil filter

cover and secure with screws together with plain and

toothed washers to a torque wrench setting of

5.8

Ib ft.

14 Ensure t h e faces of the cylinder head and cylinders

are free from dirt and oil and carefully slide the

cylinder head gasket over the studs ensuring that it

is the correct way up. Insert the tappets in the same

order to removal together with the sleeves, pushrods,

oil delivery line to the rocker arm shaft and the casing

with its seal ring.

15 Thoroughly inspect the cylinder head to ensure that

it has been correctly reassembled, carefully slide it

over the studs and secure using the four cap nuts

internally and four standard nuts and plain washers

externally. Tighten the nuts in the order as shown in

FIG 1 :44 or 1 :46 to a torque wrench setting of

23.9 Ib ft.

16 Fit the rocker arm shaft and arm assembly together

with the two supports. Tighten the supports using

screws, plain and toothed washers to a torque

wrench setting of 15.2Ibft. Adjust the tappet-to-

rocker clearance as detailed in Section 1 :16.

17 Temporarily plug the intake duct hole to ensure that

no foreign matter finds its way into the engine.

Install the spark plugs having ensured that they are

clean and correctly adjusted.

18 Reassemble the engine cowling and air

exhaust

throttle valve assembly which should be secured on

the top side using t w o nuts, t w o plain washers and

two toothed washers, on the underside with two

screws and t w o toothed washers, and centrally using

one screw and one spring washer.

19 Fit the toothed washers on the end of the spark plug

electrode and tighten the terminals together with the

special rubber boots.

20 Refit the fan, generator and ground cable assembly

and secure the crankcase, also the warmed air intake

shrouding. Finally tighten the generator to fan nuts.

21 Fit both lower exhaust silencer mounting brackets

onto the crankcase but do not tighten fully. Fit the

air conveyor and secure to the engine cowling using

six screws, six toothed washers and one nut together

with a toothed washer. Join together the t w o

Page 25 of 128

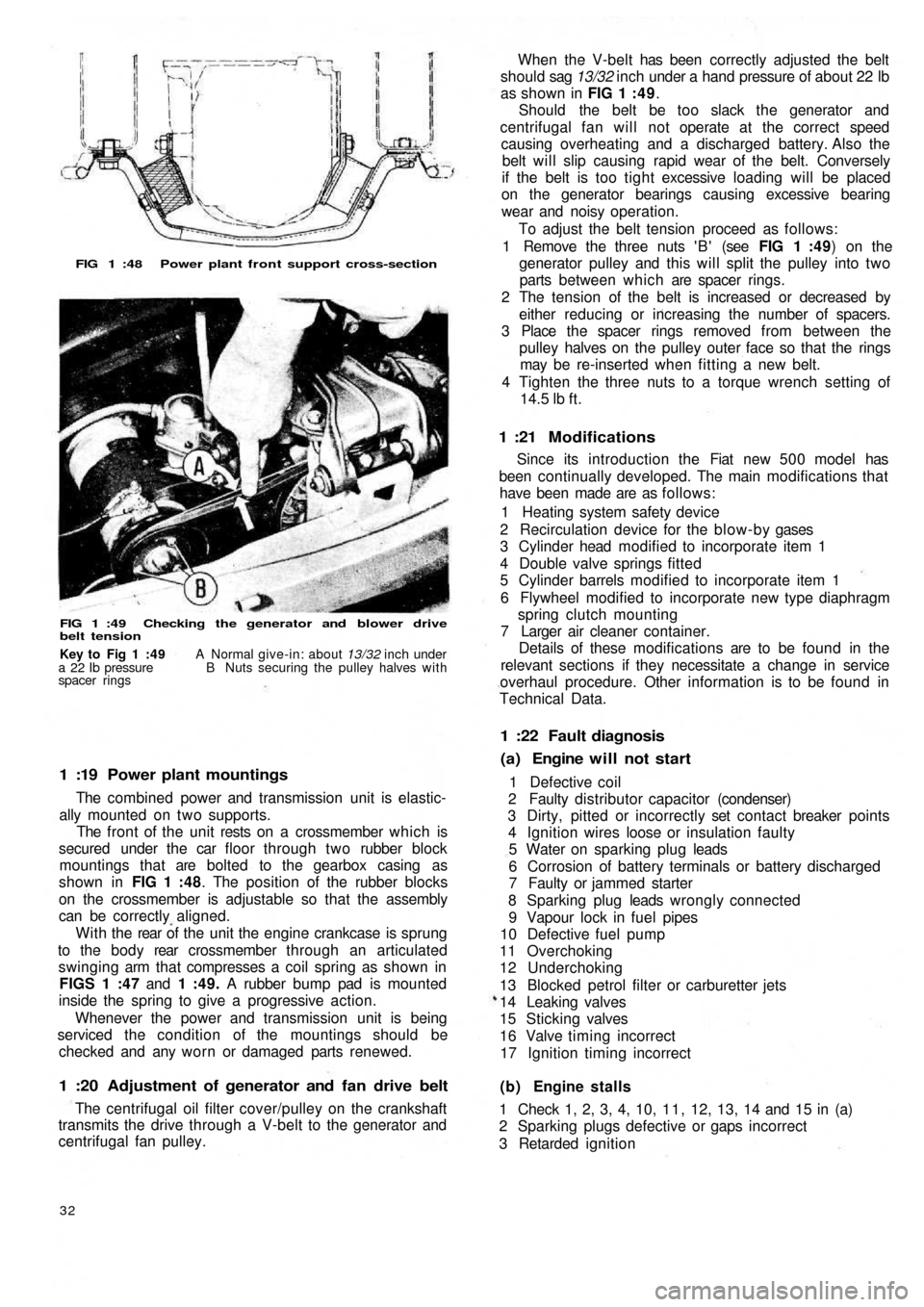

FIG 1 :48 Power plant front support cross-section

FIG 1 :49 Checking the generator and blower drive

belt tension

1 :19 Power plant mountings

The combined power and transmission unit is elastic-

ally mounted on two supports.

The front of the unit rests on a crossmember which is

secured under the car floor through two rubber block

mountings that are bolted to the gearbox casing as

shown in FIG 1 :48. The position of the rubber blocks

on the crossmember is adjustable so that the assembly

can be correctly aligned.

W i t h t h e rear of the unit the engine crankcase is sprung

to the b o d y rear crossmember through an articulated

swinging arm that compresses a coil spring as shown in

FIGS 1 :47 and 1 :49. A rubber bump pad is mounted

inside the spring to give a progressive action.

Whenever the power and transmission unit is being

serviced the condition of the mountings should be

checked and any worn or damaged parts renewed.

1 :20 Adjustment of generator and fan drive belt

The centrifugal oil filter cover/pulley on the crankshaft

transmits the drive through a V-belt to the generator and

centrifugal fan pulley.

32

(b) Engine stalls

1 Check 1, 2, 3, 4, 10, 1 1 , 12, 13, 14 and 15 in (a)

2 Sparking plugs defective or gaps incorrect

3 Retarded ignition 1 Defective coil

2 Faulty distributor capacitor (condenser)

3 Dirty, pitted or incorrectly set contact breaker points

4 Ignition wires loose or insulation faulty

5 Water on sparking plug leads

6 Corrosion of battery terminals or battery discharged

7 Faulty or jammed starter

8 Sparking plug leads wrongly connected

9 Vapour lock in fuel pipes

10 Defective fuel pump

11 Overchoking

12 Underchoking

13 Blocked petrol filter or carburetter jets

14 Leaking valves

15 Sticking valves

16 Valve timing incorrect

17 Ignition timing incorrect

(a) Engine will not start 1 :22 Fault diagnosis

Since its introduction the Fiat new 5 0 0 model has

been continually developed. The main modifications that

have been made are as follows:

1 Heating system safety device

2 Recirculation device for the blow-by gases

3 Cylinder head modified to incorporate item 1

4 Double valve springs fitted

5 Cylinder barrels modified to incorporate item 1

6 Flywheel modified to incorporate new type diaphragm

spring clutch mounting

7 Larger air cleaner container.

Details of these modifications are to be found in the

relevant sections if they necessitate a change in service

overhaul procedure. Other information is to be found in

Technical Data.

1 :21 Modifications

When the V-belt has been correctly adjusted the belt

should sag 13/32 inch under a hand pressure of about 22 lb

as shown in FIG 1 : 4 9.

Should the belt be too slack the generator and

centrifugal fan will not operate at the correct speed

causing overheating and a discharged battery. Also the

belt will slip causing rapid wear of the belt. Conversely

if the belt is too tight excessive loading will be placed

on the generator bearings causing excessive bearing

wear and noisy operation.

To adjust the belt tension proceed as follows:

1 Remove the three nuts ' B ' (see FIG 1 :49) on the

generator pulley and this will split the pulley into two

parts between which are spacer rings.

2 The tension of the belt is increased or decreased by

either reducing or increasing the number of spacers.

3 Place the spacer rings removed from between the

pulley halves on the pulley outer face so that the rings

may be re-inserted when fitting a new belt.

4 Tighten the three nuts to a torque wrench setting of

14.5

lb ft.

Key to Fig 1 :49 A Normal give-in: about 13/32 inch under

a 22 Ib pressure B Nuts securing the pulley halves with

spacer rings

Page 40 of 128

3:1

3:2

3:3

3:4

3:5Description

Operation

Routine maintenance

Ignition faults

Removing and dismantling distributor (sedan

and sports)

CHAPTER 3

THE IGNITION SYSTEM

3:6

3:7

3:8

3:9

3:10

Removing and dismantling

(station wagon)

Timing the ignition

Sparking plugs

The distributor drive spindle

Fault diagnosisdistributor

3 :1 Description

The ignition system fitted to all the models covered by

this manual consists of an ignition coil, ignition distributor

fitted with contact breaker points, a centrifugal automatic

advance system, condenser, low- and high-tension

wiring, spark plugs and a power supply provided by a

generator and battery. The wiring diagram is shown in

FIG 3 : 1

1 The low-tension circuit which is sometimes called the

primary circuit includes the power supply, contact

breaker points, condenser and ignition coil primary

winding.

2 The high-tension circuit which is sometimes called the

secondary circuit includes the ignition coil secondary

winding, distributor rotor, distributor cap with terminals

and the central brush, high-tension cables and the spark

plugs.

3 : 2 Operation

The contact breaker unit in the distributor interrupts

the primary circuit by the points opening. The sudden stop

in the flow of current in the primary winding, does not cause

arcing at the contact breaker points because it discharges

into the condenser connected in parallel w i t h the contact

F50047

breaker points. With the sudden collapse of the primary

circuit, the intensity of the magnetic field drops causing

an induced high-tension current in the ignition coil

secondary winding. The high EMF is distributed to the

sparking plugs by the ignition distributor rotor.

The automatic advance mechanism comprises a plate

carrying t w o weights which are symmetrically pivoted on

the plate at one end. Also attached to the weights at

opposite ends to the pivots is the cam carrier shaft with

special tension return springs. Under the action of centri-

fugal force as the rotational speed increases, the weights

move outwards causing the cam carrier shaft to move

angularly compared to the distributor drive shaft thus

causing advancement of the ignition timing.

The contact breaker assembly comprises the cam on the

drive shaft and t w o contact points, one of which is

stationary while the other is under the influence of the

cam, the action of which is transmitted by a rubbing block.

The cam has t w o lobes to control the opening and closing

of contact points. The stationary contact point is mounted

on an adjustable support to enable the contact breaker

point gap to be adjusted.

The HT current reaches the distributor cap central

terminal, from the ignition coil and is distributed to each

of the spark plugs at the correct time by the rotor arm.

Page 42 of 128

a n 0—20 v o ltmeter. If the circuit is in order the meter

should read approximately 12-volts.

3 Battery to fuse box terminal 30. Connect the volt-

meter between the terminal 30 and earth. No reading

indicates a faulty cable or loose connection.

4 Fuse box. Connect the voltmeter between the other

auxiliary terminal 30 and earth. No reading indicates a

broken or loose connection.

5 Fuse box auxiliary terminal 30 to terminal

number 30 on ignition switch. Connect the meter

between terminal number 30 on the ignition switch

and earth. No reading indicates a damaged cable or

loose connection.

6 Ignition switch. Connect the meter between termi-

nal 15/54 and earth. Switch onto the ignition position,

when no reading indicates a fault in the switch.

7 Ignition switch to low-tension cable connection

on the coil (blue cable). Connect the meter

between ignition coil terminal (blue cable) and earth.

No reading indicates a damaged cable or loose con-

nection.

8 Ignition coil. Disconnect the black low-tension cable

connecting the coil to the distributor side terminal at

the coil and connect the meter between this terminal

and earth. No reading indicates a fault in the primary

winding of the coil and a replacement coil must be

fitted. If the reading is correct remake the connections

to the coil.

9 Ignition coil to distributor. Disconnect the thin

black low-tension cable at the side of the distributor

and connect the meter between the end of this cable

and earth. No reading indicates a damaged cable or

loose connections.

10 Contact breaker and capacitor. Connect the

meter across the contact breaker points. No reading

indicates a faulty capacitor.

Capacitor:

The best method of testing a capacitor (condenser) is

by substitution. Disconnect the original capacitor and

connect a new one between the low-tension terminal on

the side of the distributor and earth.

If a new capacitor is needed, fit a new one complete

w i t h bracket, but if necessary unsolder the original bracket

and solder it onto the new capacitor using as little heat as

possible. Capacitor capacity is .15-.20 microfarads.

3 : 5 Removing and dismantling distributor (sedan

and sports)

To remove the distributor proceed as follows:

1 Rotate the engine slowly until the distributor rotor arm

is opposite the brass segment in the distributor cap

connected to No. 1 plug lead. This will provide a datum

for replacement.

2 Disconnect the cable from the low-tension terminal on

the side of the distributor body. Mark position of distri-

butor on support. Release the distributor retaining nut

and washer from the underside of the top flange of the

distributor support and carefully lift away the dis-

tributor.

3 Pull off the rotor arm. Remove the insulated terminal

assembly from the side of distributor body. Release the

contact breaker carrier plate retaining screws and con-

denser flange screw from the outside of the distributor

F50049 body. Carefully lift out the contact breaker plate

assembly.

4 Before further dismantling note the relative positions of

the driving dog and the rotor arm driving slot at the top

of the distributor cam spindle. The driving dog is offset

and can only engage its driving spindle in one position.

Then when the cam assembly is fitted to the centrifugal

weights during reassembly the timing is not 180 deg.

out.

5 Take out the cam lubrication felt pad recessed in the

rotor arm housing on the end of the cam spindle.

Remove the retaining screw, carefully disengage the

springs and lift out the cam spindle. It should be noted

that there is a small retaining ball and spring located in a

drilling nearly at the top of the drive shaft spindle.

Carefully lift away the weights.

6 Thoroughly clean all parts and inspect for excessive

wear. The distributor cap must not be cracked or show

signs of tracking. The cap terminals, rotor and contact

breaker points can be cleaned with a very fine file.

Emerypaper must not be used. If the clearance between

the rotor and distributor cap segments exceeds .0118

inch both the rotor and distributor cap must be replaced.

Inspect the contact breaker arm rubbing block for exces-

sive wear and also the points for wear so that if the gap

exceeds the last setting limit of .0209 inch and adjust-

ment through the stationary contact carrier screw is no

longer possible (see FIG 3 : 2) , the contact breaker set

must be renewed.

If the distributor drive shaft side or vertical movement is

excessive the distributor must be renewed.

Weak centri-

fugal weight springs or damaged weights must be

renewed using original Fiat spares otherwise the auto-

matic ignition advance characteristics could be altered.

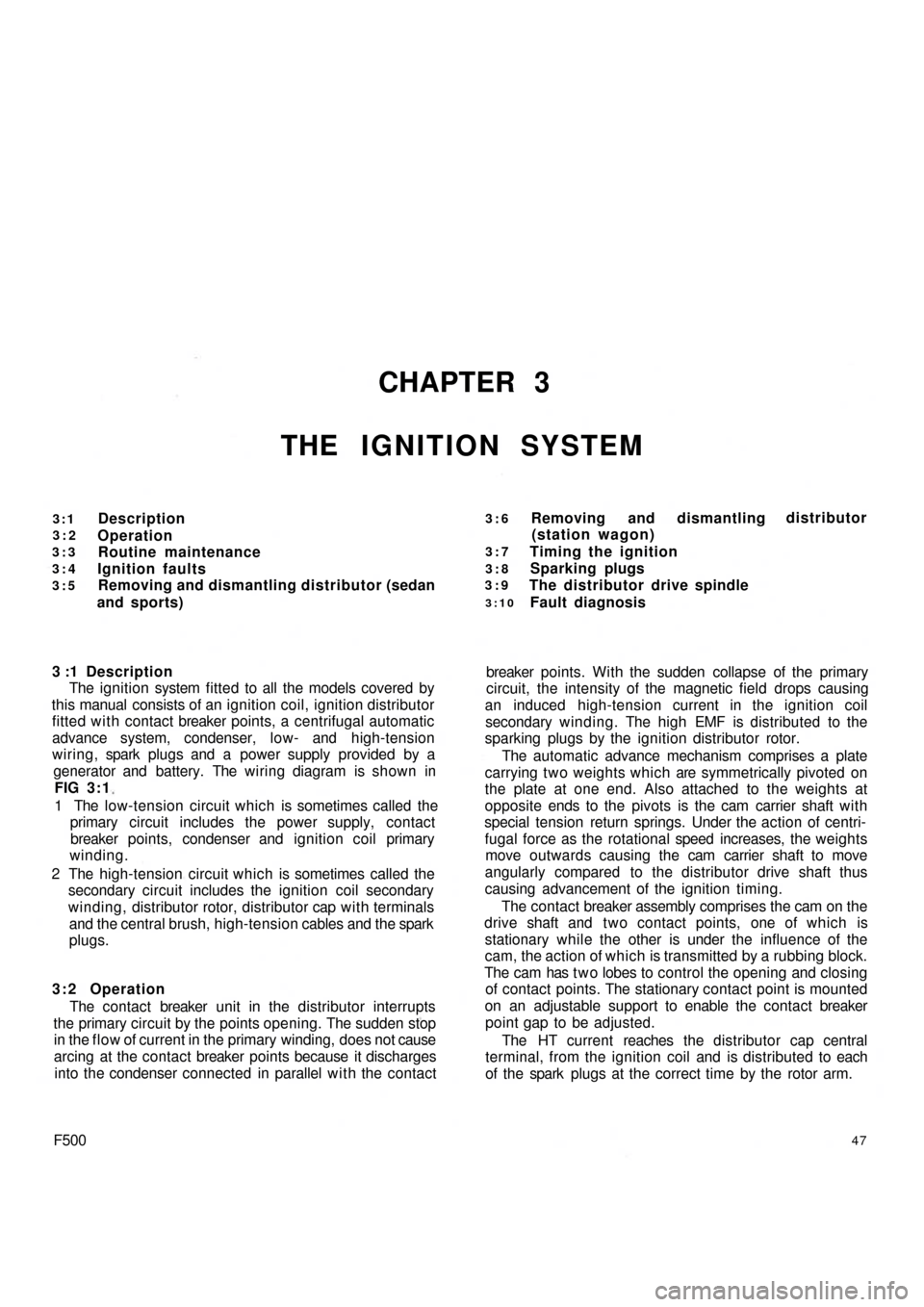

FIG 3 : 3 Ignition distributor in place on engine SPARK PLUG CABLES

IGNITION COIL CABLE!

DISTRIBUTOR CAP

DISTRIBUTOR BODY

GROUND CABLE

CONDENSER

DISTRIBUTOR SHAFT

LUBRICATION FITTING

DISTRIBUTORSUPPORT-TO--CRANKCASE NUT

[MOUNTING SCREWDISTRIBUTOR

DISTRIBUTOR SUPPORT

Page 43 of 128

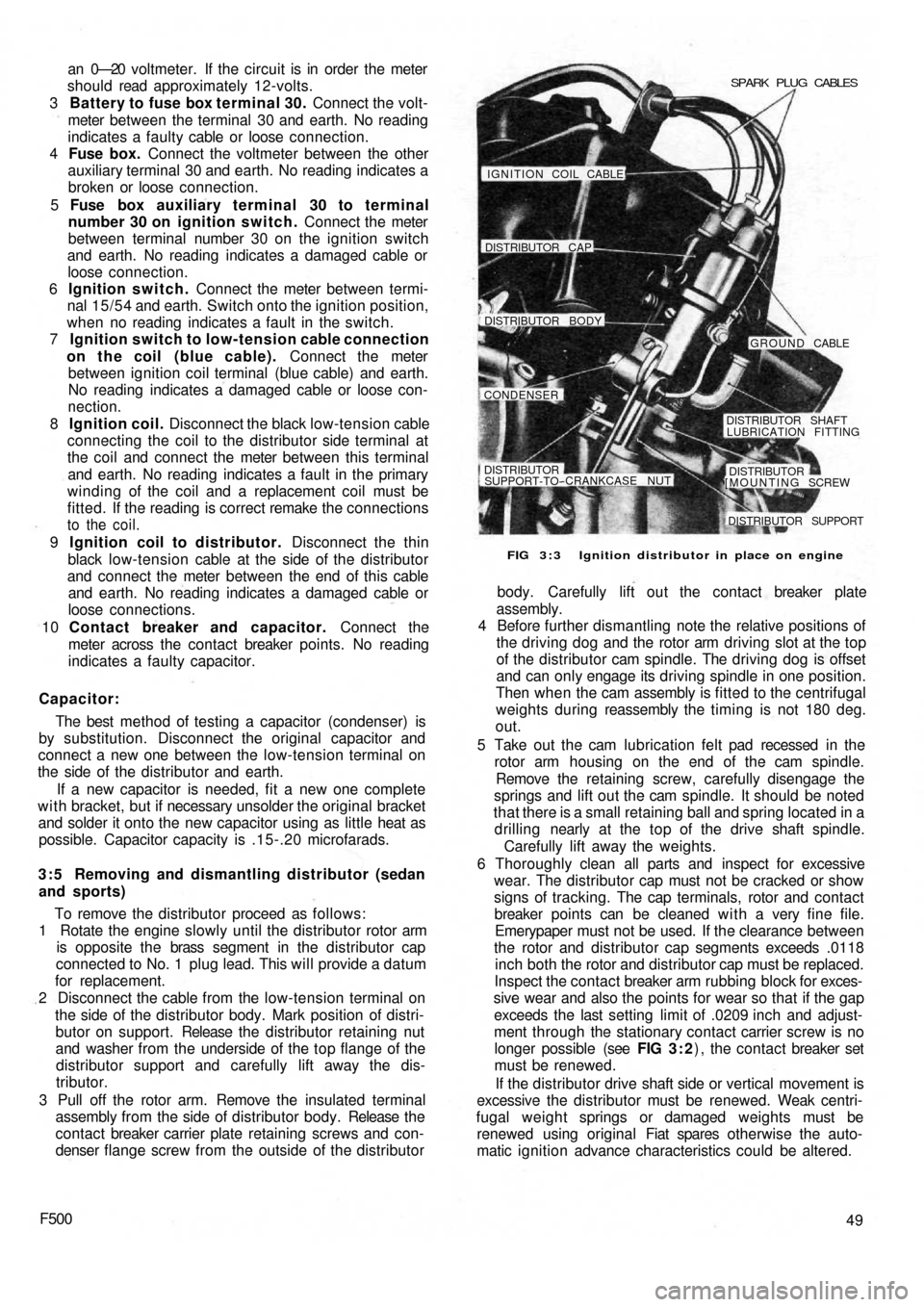

FIG 3 : 4 Use of fixture Ap.5030/1 to check ignition

timing

Reassembly is the reverse procedure to dismantling but

the following points should be noted:

1 Lubricate the parts of the centrifugal advance mecha-

nism, the drive spindle and the part of the shaft which

accepts the cam w i t h Fiat VS oil.

2 Ensure that upon reassembly the slot in the rotor arm

housing matches the distributor driving dog. Lubricate

the felt pad in the rotor arm housing.

3 Fit the distributor back onto its support gently rotating

the rotor arm so that the drive dog engages w i t h the

drive shaft mating flange. Provided the crankshaft has

not been turned the rotor arm should finish up pointing

to No. 1 cylinder segment in the distributor cap. Tighten

the distributor retaining nut, refit the distributor cap and

leads to the spark plugs and the LT lead to distributor

body terminal.

4 Add a few drops of oil to the distributor shaft lubrication

fitting (see FIG 3:3).

3 : 6 Removing and dismantling distributor

(station wagon)

The distributor is located towards the top rear of t h e

engine and is bolted direct onto the crankcase rear cover as

shown in FIG 1 : 2 . It is driven direct by a gear in mesh w i t h

a corresponding gear on the camshaft. The basic design of

the distributor is the same as that for the sedan and sports

engine, except that the distributor cap has been redesigned,

there is a gear instead of the dog

drive and no distributor

support. To remove and dismantle the distributor proceed

as previously described taking great care about marking

the location of the distributor to rear cover and rotating

the engine until No. 1 cylinder is on compression. This will

ensure that reassembly is straightforward without loss of

ignition timing.

503:7 Timing the ignition

It is necessary to retime the ignition should the distribu-

tor shaft or camshaft have been removed. To retime the

ignition proceed as follows:

1 On the timing sprocket cover fit Fiat tool AP.5030/1 as

shown in FIG 3 : 4. Ensure No. 1 cylinder is on the

compression stroke with both valves closed. Rotate the

crankshaft until the mark on the centrifugal filter cover

lines up w i t h the 10° mark on the fixture. This setting

corresponds to a 10° static advance BTDC.

2 Check t h a t the points gap is correctly set between

.018 and .020 inch. Turn the distributor shaft until the

rotor points in the direction of No. 1 segment in the

cap and the points are just opening.

3 Without disturbing the distributor shaft, insert the lower

coupling on its toothed end, install the support and

tighten the locknut. Secure the distributor to the sup-

port using the mounting screw.

To check that the distributor is properly timed to the

engine and the centrifugal automatic advance is operating

correctly giving a

total advance of 18° to 28° respectively

proceed as follows:

1 Connect Fiat timing tester AP.5030 with a 220-volt-

single-phase power outlet fitted with a good earth

connection. It is important that the tester is earthed

before it is allowed to operate. Also ensure that the

tester earth terminal is connected to a bare metal part

of the vehicle.

2 Remove No. 1 spark plug lead, insert the strobe light

adapter and reconnect the spark plug lead. Using a

piece of white chalk mark the TDC position on the

centrifugal filter cover.

3 Start the engine and aim the strobe light beam towards

the chalk mark drawn on the centrifugal filter cover.

With the engine running slowly the mark on the centri-

fugal cover must correspond wi th the first white line

on the fixture (10°). Slowly increase the speed of the

engine so operating the automatic advance and the

chalk mark should move counterclockwise until at

maximum speed it reaches the second white mark on

the fixture.

It should be noted that the ignition timing for the model

500 sports engine the static advance is 10°, an automatic

advance of 12° giving a total advance at maximum engine

speed of 2 2 ° .

Should Fiat fixture AP.5030/1 not be available the

advance position may be set as follows:

1 Turn over the

engine until No. 1 piston is on the com-

pression stroke w i t h both valves closed.

2 Rotate the crankshaft clockwise until the reference

mark cast on the centrifugal filter cover is set .5118 to

.5512 inch ahead of the arrow cast on the timing

sprocket cover. This will give a static advance setting

of 10° BTDC.

3 Proceed as directed for ignition distributor timing and

mounting described earlier in this section.

3 : 8 Sparking plugs

The sparking plugs must be regularly inspected, cleaned

and the electrode gap adjusted to a gap of .019 to .023

inch.

The inspection of the deposits on the electrodes is par-

ticularly useful because the colour and type of deposit

Page 44 of 128

indicates the condition inside the combustion chamber

and may be used as a guide to engine tuning.

Before the spark plugs are removed b l o w away any

loose dirt from the plug recesses using a compressed air

jet or tyre pump. Store the plugs in the order of removal

ready for inspection.

Examine the gaskets and if they are about half their

thickness they may be used again otherwise they must be

replaced.

Inspect the electrode end of the plugs and note the

type and colour of the deposit. Normally it should be

powdery and range from b r o w n to a greyish tan in colour.

There will also be slight wear of the electrodes and the

general effect described is one which comes from mixed

periods of high-speed and low-speed driving. Cleaning

and resetting the gap is all that will be necessary.

If the deposits are white or yellowish they indicate long

periods of constant-speed driving or much low-speed

city driving. Again, the treatment is straightforward.

Dry, black, fluffy deposits are usually the result of

running with too rich a mixture. Incomplete combustion

of the petrol air charge may also be a cause and this might

be traced to a defect in the ignition system or excessive

idling.

Overheated sparking plugs have a white blistered look

about the centre electrode and the side electrode may be

badly eroded. This may be caused by poor cooling, wrong

ignition timing or sustained high speeds under heavy load.

To clean the sparking plugs effectively they should be

cleaned using an abrasive blasting machine and tested

under pressure once the electrodes have been reset. File

these until they are clean, bright and the faces parallel and

set the gap to .019 to .023 inch. Do not try to bend the

centre electrode.

Before replacing the plugs use a wire brush to clean the

threads taking care that the electrodes are not touched.

Thoroughly clean the spark plug in petrol, and dry using a

compressed air jet or a tyre pump. If difficulty is found in

screwing the plugs into the cylinder head by hand run a

tap d o w n the threads to clear away any carbon. If a tap is

not available use an old sparking plug with crosscuts d o w nthe threads. Finally tighten the plugs to a torque wrench

setting of 18 to 21 Ib ft.

Sparking plug leads:

The spark plug leads and the lead from the coil to the

distributor cap must be regularly checked for cracking of

the insulation and also correct seating in the distributor

cap and coil top. It is recommended that silicone grease is

smeared around the sockets before the leads are replaced

to ensure no moisture may enter causing difficult starting.

3 : 9 The distributor driving spindle (sedan and

sports engine)

If for any reason, the driving spindle has been removed

from its housing in the crankcase, it must be correctly

meshed w i t h the camshaft gear otherwise it

will be impos-

sible to set the ignition timing.

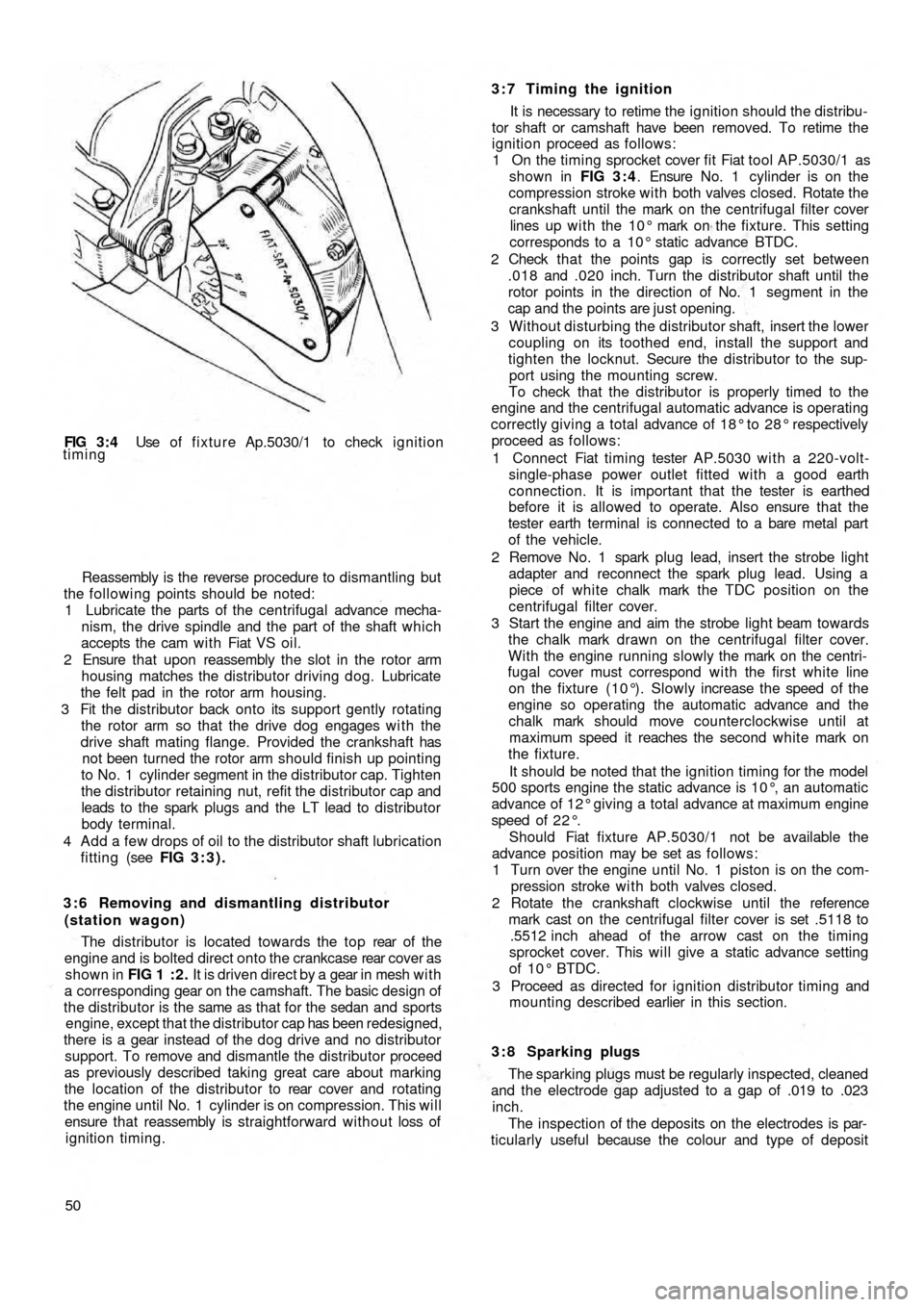

3:10 Fault diagnosis

(a) Engine w i l l not fire

1 Battery discharged

2 Distributor contact points dirty, pitted or maladjusted

3 Distributor cap dirty, cracked or tracking

4 Carbon brush inside distributor cap not touching rotor

5 Faulty cable or loose connection in low-tension circuit

6 Distributor rotor arm cracked

7 Faulty coil

8 Broken contact breaker spring

9 Contact points stuck open

(b) Engine misfires

1 Check 2, 3, 4, and 7 in (a)

2 Weak contact breaker spring

3 High-tension plug and coil leads cracked or perished

4 Sparking plug(s) loose

5 Sparking plug insulation cracked

6 Sparking plug gap incorrectly set

7 Ignition timing too far advanced