tow FIAT 500 1967 1.G User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 1967, Model line: 500, Model: FIAT 500 1967 1.GPages: 128, PDF Size: 9.01 MB

Page 121 of 128

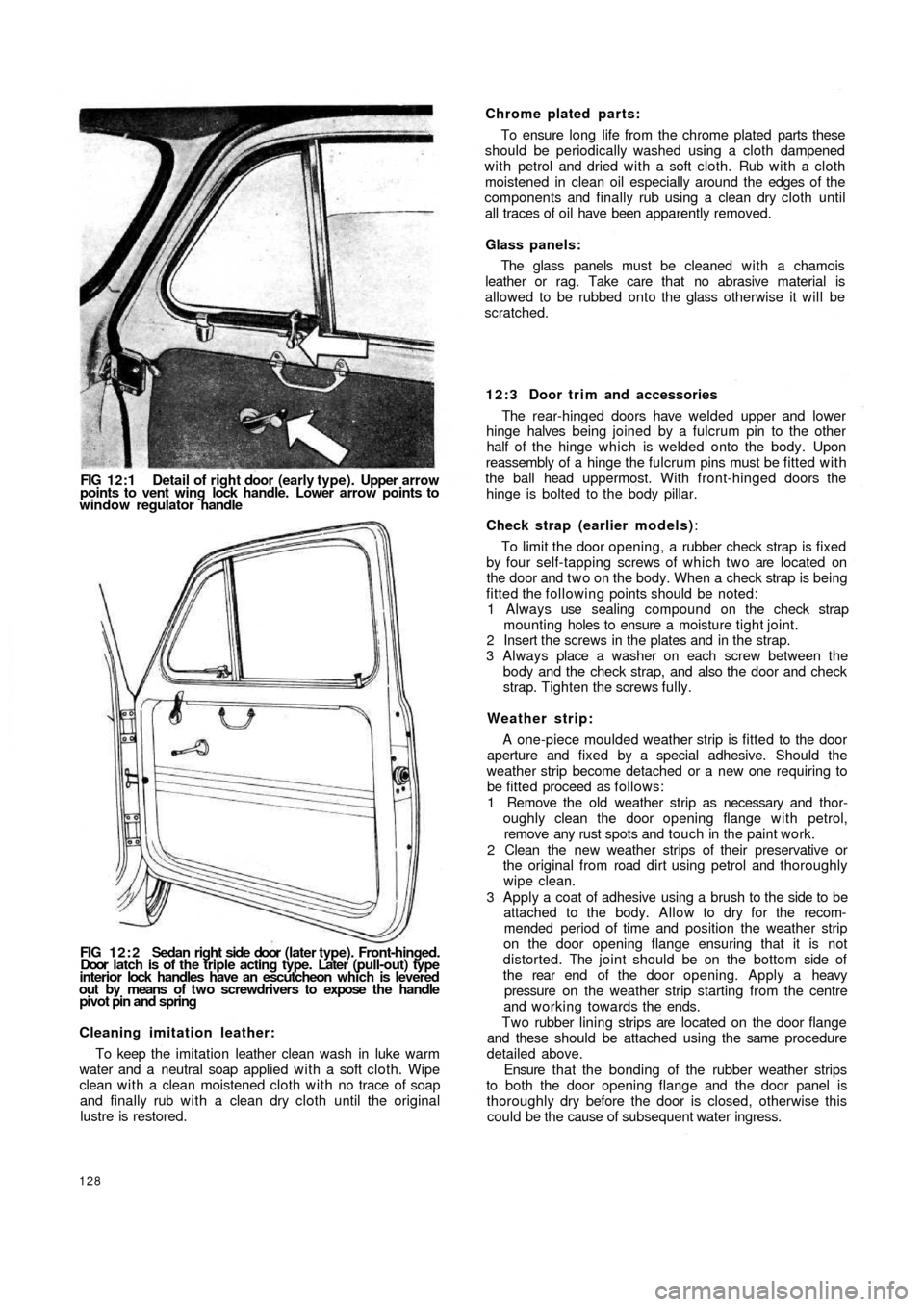

FIG 12:1 Detail of right door (early type). Upper arrow

points to vent wing lock handle. Lower arrow points to

window regulator handle

FIG 1 2 : 2 Sedan right side door (later type). Front-hinged.

Door latch is of the triple acting type. Later (pull-out) type

interior lock handles have an escutcheon which is levered

out by means of t w o screwdrivers to expose the handle

pivot pin and spring

Cleaning imitation leather:

To keep the imitation leather clean wash in luke warm

water and a neutral soap applied with a soft cloth. Wipe

clean with a clean moistened cloth with no trace of soap

and finally rub with a clean dry cloth until the original

lustre is restored.

128

Chrome plated parts:

To ensure long life from the chrome plated parts these

should be periodically washed using a cloth dampened

with petrol and dried with a soft cloth. Rub with a cloth

moistened in clean oil especially around the edges of the

components and finally rub using a clean dry cloth until

all traces of oil have been apparently removed.

Glass panels:

The glass panels must be cleaned w i t h a chamois

leather or rag. Take care that no abrasive material is

allowed to be rubbed onto the glass otherwise it will be

scratched.

12:3 Door trim and accessories

The rear-hinged doors have welded upper and lower

hinge halves being joined by a fulcrum pin to the other

half of the hinge which is welded onto the body. Upon

reassembly of a hinge the fulcrum pins must be fitted with

the ball head uppermost. With front-hinged doors the

hinge is bolted to the body pillar.

Check strap (earlier models):

To limit the door opening, a rubber check strap is fixed

by four self-tapping screws of which two are located on

the door and t w o on the body. When a check strap is being

fitted the following points should be noted:

1 Always use sealing compound on the check strap

mounting holes to ensure a moisture t i g h t j o i n t .

2 Insert the screws in the plates and in the strap.

3 Always place a washer on each screw between the

body and the check strap, and also the door and check

strap. Tighten the screws fully.

Weather strip:

A one-piece moulded weather strip is fitted to the door

aperture and fixed by a special adhesive. Should the

weather strip become detached or a new one requiring to

be fitted proceed as follows:

1 Remove the old weather strip as necessary and thor-

oughly clean the door opening flange with petrol,

remove any rust spots and touch in the paint work.

2 Clean the new weather strips of their preservative or

the original from road dirt using petrol and thoroughly

wipe

clean.

3 Apply a coat of adhesive using a brush to the side to be

attached to the body. Allow to dry for the recom-

mended period of time and position the weather strip

on the door opening flange ensuring that it is not

distorted. The joint should be on the bottom side of

the rear end of the door opening. Apply a heavy

pressure on the weather strip starting from the centre

and working towards the ends.

Two rubber lining strips are located on the door flange

and these should be attached using the same procedure

detailed above.

Ensure that the bonding of the rubber weather strips

to both the door opening flange and the door panel is

thoroughly dry before the door is closed, otherwise this

could be the cause of subsequent water ingress.

Page 125 of 128

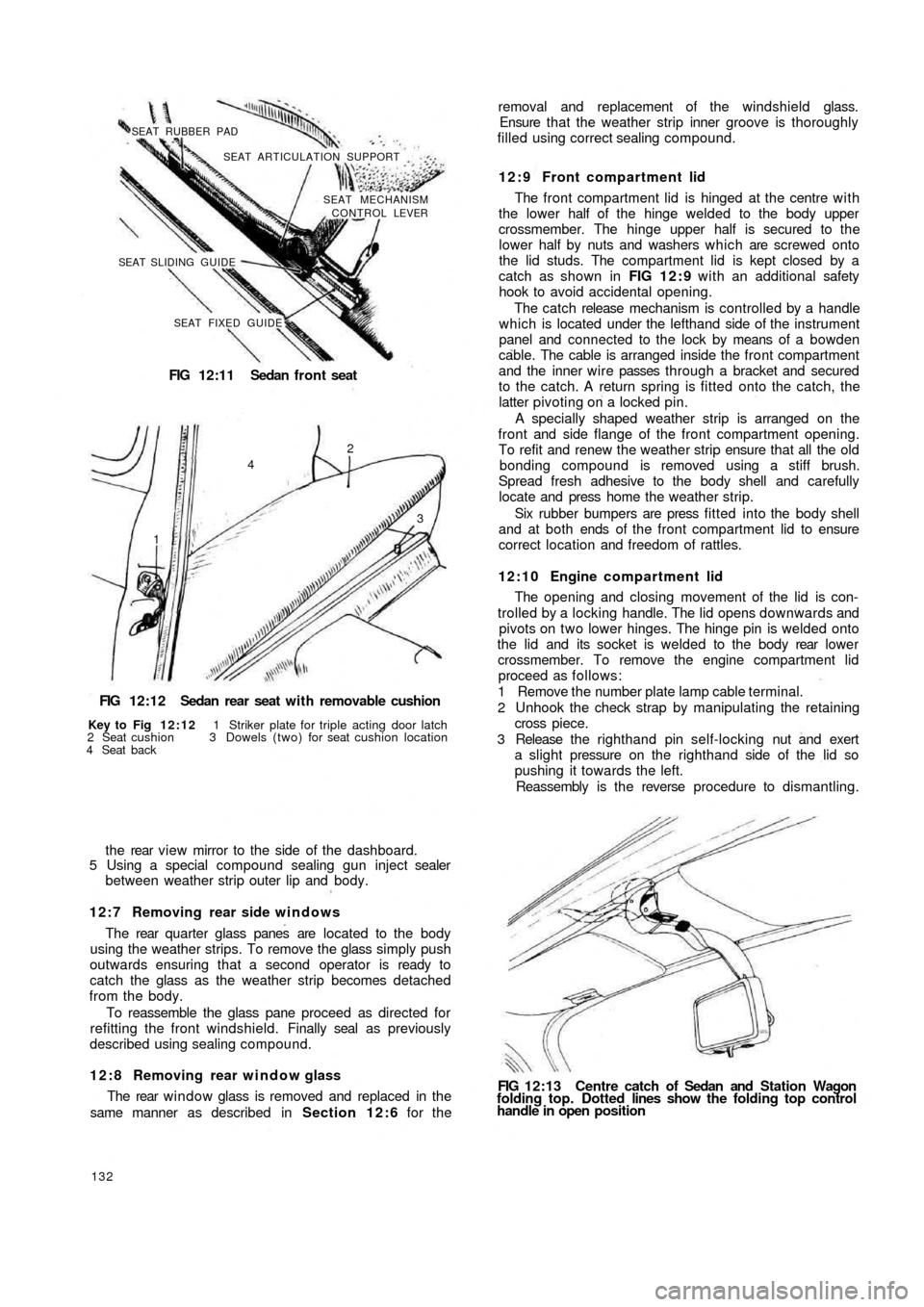

SEAT RUBBER PAD

SEAT ARTICULATION SUPPORT

SEAT MECHANISM

CONTROL LEVER

SEAT SLIDING GUIDE

SEAT FIXED GUIDE

FIG 12:11 Sedan front seat

42

3

1

FIG 12:12 Sedan rear seat w i t h removable cushion

Key to Fig 12:12 1 Striker plate for triple acting door latch

2 Seat cushion 3 Dowels (two) for seat cushion location

4 Seat back

t h e rear v i e w mirror to the side of the dashboard.

5 Using a special compound sealing gun inject sealer

between weather strip outer lip and body.

12:7 Removing rear side windows

The rear quarter glass panes are located to the body

using the weather strips. To remove the glass simply push

outwards ensuring that a second operator is ready to

catch the glass as the weather strip becomes detached

from the body.

To reassemble the glass pane proceed as directed for

refitting the front windshield. Finally seal as previously

described using sealing compound.

12:8 Removing rear window glass

The rear window glass is removed and replaced in the

same manner as described in Section 12:6 for the

132

FIG 12:13 Centre catch of Sedan and Station Wagon

folding top. Dotted lines show the folding top control

handle in open position removal and replacement of the windshield glass.

Ensure t h a t the weather strip inner groove is thoroughly

filled using correct sealing compound.

1 2 : 9 Front compartment lid

The front compartment lid is hinged at the centre w i t h

the lower half of the hinge welded to the body upper

crossmember. The hinge upper half is secured to the

lower half by nuts and washers which are screwed onto

the lid studs. The compartment lid is kept closed by a

catch as shown in FIG 1 2 : 9 with an additional safety

hook to avoid accidental opening.

The catch release mechanism is controlled by a handle

which is located under the lefthand side of the instrument

panel and connected to the lock by means of a bowden

cable. The cable is arranged inside the front compartment

and the inner wire passes through a bracket and secured

to the catch. A return spring is fitted onto the catch, the

latter pivoting on a locked pin.

A specially shaped weather strip is arranged on the

front and side flange of the front compartment opening.

To refit and renew the weather strip ensure that all the old

bonding compound is removed using a stiff brush.

Spread fresh adhesive to the body shell and carefully

locate and press home the weather strip.

Six rubber bumpers are press fitted into the body shell

and at both ends of the front compartment lid to ensure

correct location and freedom of rattles.

12:10 Engine compartment lid

The opening and closing movement of the lid is con-

trolled by a locking handle. The lid opens downwards and

pivots on two lower hinges. The hinge pin is welded onto

the lid and its socket is welded to the body rear lower

crossmember. To remove the engine compartment lid

proceed as follows:

1 Remove the number plate lamp cable terminal.

2 Unhook the check strap by manipulating the retaining

cross piece.

3 Release the righthand pin self-locking nut and exert

a slight pressure on the righthand side of the lid so

pushing it towards the left.

Reassembly is the reverse procedure to dismantling.