Tappet FIAT 500 1967 1.G Workshop Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1967, Model line: 500, Model: FIAT 500 1967 1.GPages: 128, PDF Size: 9.01 MB

Page 3 of 128

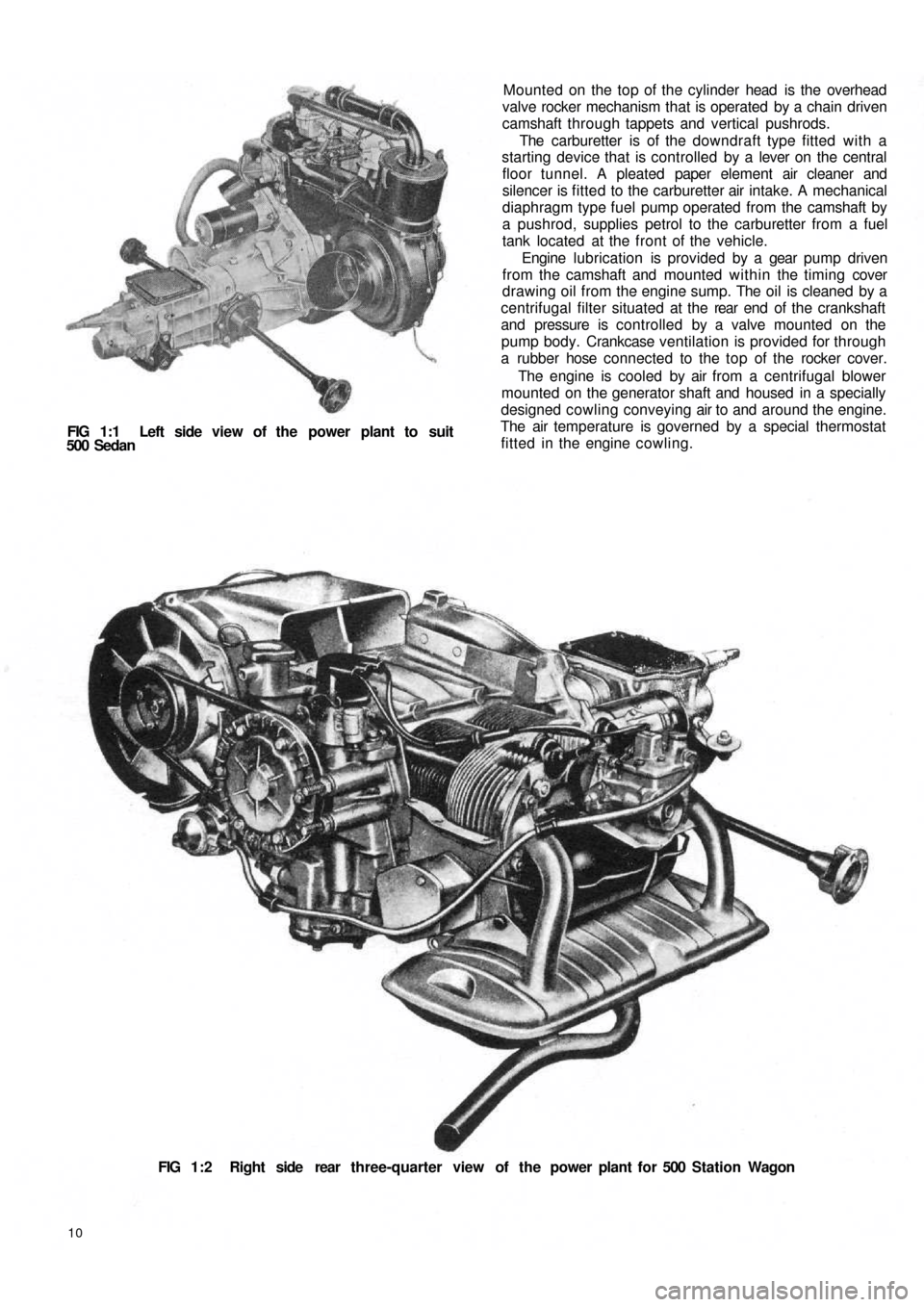

FIG 1:1 Left side view of the power plant to suit

500 Sedan

10

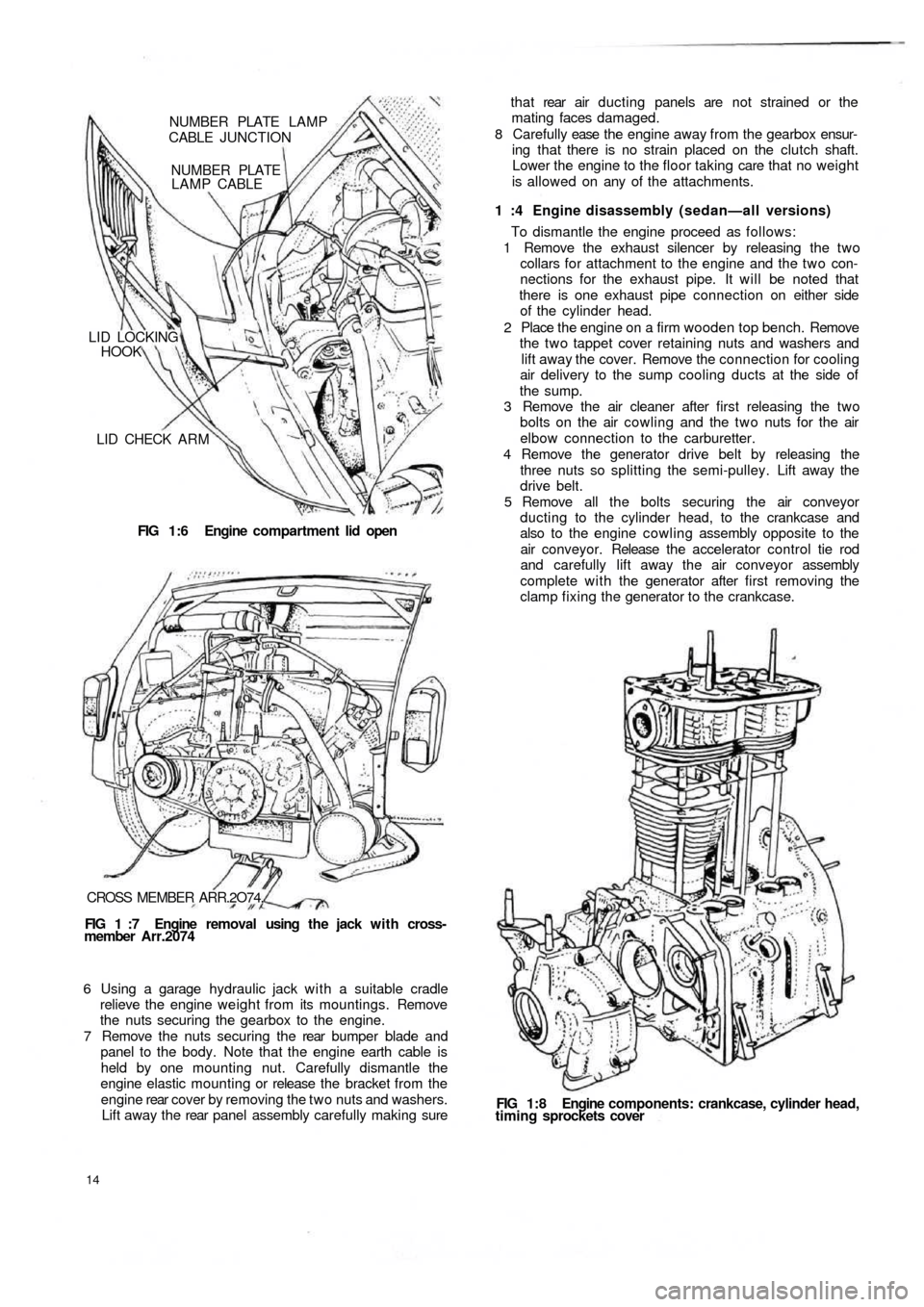

FIG 1:2 Right side rear three-quarter view of the power plant for 500 Station Wagon Mounted on the top of the cylinder head is the overhead

valve rocker mechanism that is operated by a chain driven

camshaft through tappets and vertical pushrods.

The carburetter is of the downdraft type fitted with a

starting device that is controlled by a lever on the central

floor tunnel. A pleated paper element air cleaner and

silencer is fitted to the carburetter air intake. A mechanical

diaphragm type fuel pump operated from the camshaft by

a pushrod, supplies petrol to the carburetter from a fuel

tank located at the front of the vehicle.

Engine lubrication is provided by a gear pump driven

from the camshaft and mounted within the timing cover

drawing oil from the engine sump. The oil is cleaned by a

centrifugal filter situated at the rear end of t h e crankshaft

and pressure is controlled by a valve mounted on the

pump body. Crankcase ventilation is provided for through

a rubber hose connected to the top of the rocker cover.

The engine is cooled by air from a centrifugal blower

mounted on the generator shaft and housed in a specially

designed cowling conveying air to and around the engine.

The air temperature is governed by a special thermostat

fitted in the engine cowling.

Page 7 of 128

LID CHECK A R M

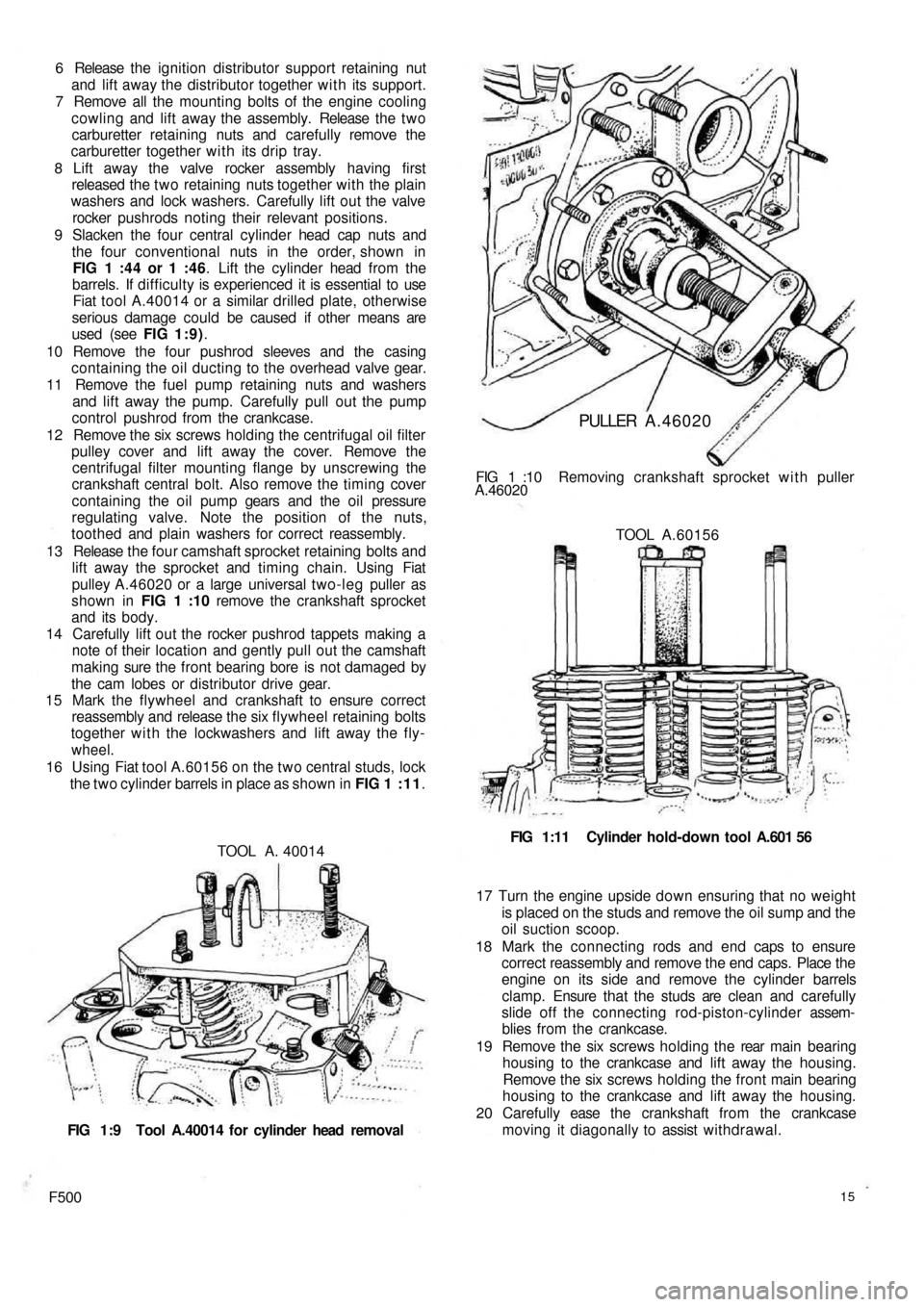

FIG 1:6 Engine compartment lid open LID LOCKING

HOOK

NUMBER PLATE

LAMP CABLE NUMBER PLATE LAMP

CABLE JUNCTION

CROSS MEMBER ARR.2O74.

FIG 1 :7 Engine removal using the jack with cross-

member Arr.2074

6 Using a garage hydraulic jack with a suitable cradle

relieve the engine weight from its mountings. Remove

the nuts securing the gearbox to the engine.

7 Remove the nuts securing the rear bumper blade and

panel to the body. Note that the engine earth cable is

held by one mounting nut. Carefully dismantle the

engine elastic mounting or release the bracket from the

engine rear cover by removing the two nuts and washers.

Lift away t h e rear panel assembly carefully making sure

14

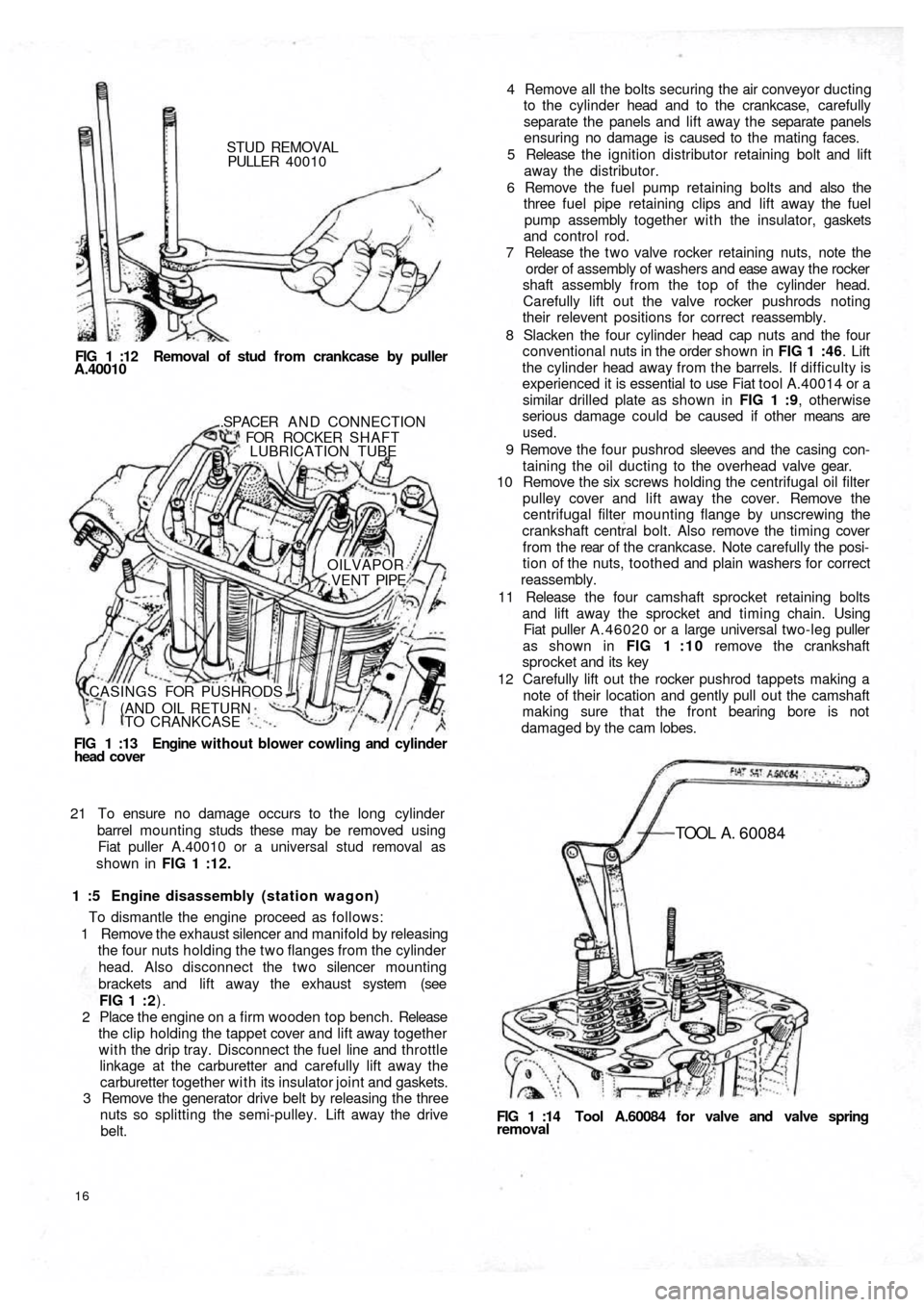

FIG 1 : 8 Engine components: crankcase, cylinder head,

timing sprockets cover To dismantle the engine proceed as follows:

1 Remove the exhaust silencer by releasing the two

collars for attachment to the engine and the two con-

nections for the exhaust pipe. It will be noted that

there is one exhaust pipe connection on either side

of the cylinder head.

2 Place the engine on a firm wooden top bench. Remove

the two tappet cover retaining nuts and washers and

lift away the cover. Remove the connection for cooling

air delivery to the sump cooling ducts at the side of

the sump.

3 Remove the air cleaner after first releasing the two

bolts on the air cowling and the two nuts for the air

elbow connection to the carburetter.

4 Remove the generator drive belt by releasing the

three nuts so splitting the semi-pulley. Lift away the

drive belt.

5 Remove all the bolts securing the air conveyor

ducting to the cylinder head, to the crankcase and

also to the engine cowling assembly opposite to the

air conveyor. Release the accelerator control tie rod

and carefully lift away the air conveyor assembly

complete with the generator after first removing the

clamp fixing the generator to the crankcase. 1 :4 Engine disassembly (sedan—all versions) t h a t rear air ducting panels are not strained or the

mating faces damaged.

8 Carefully ease the engine away from the gearbox ensur-

ing that there is no strain placed on the clutch shaft.

Lower the engine to the floor taking care that no weight

is allowed on any of the attachments.

Page 8 of 128

6 Release the ignition distributor support retaining nut

and lift away the distributor together w i t h its support.

7 Remove all the mounting bolts of the engine cooling

cowling and lift away the assembly. Release the t w o

carburetter retaining nuts and carefully remove the

carburetter together with its drip tray.

8 Lift away the valve rocker assembly having first

released the t w o retaining nuts together with the plain

washers and lock washers. Carefully lift out the valve

rocker pushrods noting their relevant positions.

9 Slacken the four central cylinder head cap nuts and

the four conventional nuts in the order, shown in

FIG 1 :44 or 1 :46. Lift the cylinder head from the

barrels. If difficulty is experienced it is essential to use

Fiat tool A.40014 or a similar drilled plate, otherwise

serious damage could be caused if other means are

used (see FIG 1:9).

10 Remove the four pushrod sleeves and the casing

containing the oil ducting to the overhead valve gear.

11 Remove the fuel pump retaining nuts and washers

and lift away the pump. Carefully pull out the pump

control pushrod from the crankcase.

12 Remove the six screws holding the centrifugal oil filter

pulley cover and lift away the cover. Remove the

centrifugal filter mounting flange by unscrewing the

crankshaft central bolt. Also remove the timing cover

containing the oil pump gears and the oil pressure

regulating valve. Note the position of the nuts,

toothed and plain

washers for correct reassembly.

13 Release t h e four camshaft sprocket retaining bolts and

lift away the sprocket and timing chain. Using Fiat

pulley A.46020 or a large universal two-leg puller as

shown in FIG 1 :10 remove the crankshaft sprocket

and its body.

14 Carefully lift out the rocker pushrod tappets making a

note of their location and gently pull out the camshaft

making sure the front bearing bore is not damaged by

the cam lobes or distributor drive gear.

15 Mark the flywheel and crankshaft to ensure correct

reassembly and release the six f l y w h e e l retaining bolts

together w i t h the lockwashers and lift away the fly-

wheel.

16 Using Fiat tool A.60156 on the two central studs, lock

the two cylinder barrels in place as shown in FIG 1 : 1 1.

TOOL A. 40014

FIG 1:9 Tool A.40014 for cylinder head removal

F50015

17 Turn the engine upside down ensuring that no weight

is placed on the studs and remove the oil sump and the

oil suction scoop.

18 Mark the connecting rods and end caps to ensure

correct reassembly and remove the end caps. Place the

engine on its side and remove the cylinder barrels

clamp. Ensure that the studs are clean and carefully

slide off the connecting rod-piston-cylinder assem-

blies from the crankcase.

19 Remove the six screws holding the rear main bearing

housing to the crankcase and lift away the housing.

Remove the six screws holding the front main bearing

housing to the crankcase and lift away the housing.

20 Carefully ease the crankshaft from the crankcase

moving it diagonally to assist withdrawal. FIG 1:11 Cylinder hold-down tool A.601 56 TOOL A.60156 FIG 1 :10 Removing crankshaft sprocket w i t h puller

A.46020

PULLER A.46020

Page 9 of 128

STUD REMOVAL

PULLER 40010

FIG 1 :12 Removal of stud from crankcase by puller

A.40010

FIG 1 :13 Engine without blower cowling and cylinder

head cover.SPACER A N D CONNECTION

FOR ROCKER SHAFT

LUBRICATION TUBE

OILVAPOR

.VENT PIPE

CASINGS FOR PUSHRODS

(AND OIL RETURN

TO CRANKCASE

21 To ensure no damage occurs to the long cylinder

barrel mounting studs these may be removed using

Fiat puller A.40010 or a universal stud removal as

shown in FIG 1 :12.

1 :5 Engine disassembly (station wagon)

To dismantle the engine proceed as follows:

1 Remove the exhaust silencer and manifold by releasing

the four nuts holding the two flanges from the cylinder

head. Also disconnect the two silencer mounting

brackets and lift away the exhaust system (see

FIG 1 : 2).

2 Place the engine on a firm wooden top bench. Release

the clip holding the tappet cover and lift away together

with the drip tray. Disconnect the fuel line and throttle

linkage at the carburetter and carefully lift away the

carburetter together with its insulator joint and gaskets.

3 Remove the generator drive belt by releasing the three

nuts so splitting the semi-pulley. Lift away the drive

belt.

16

FIG 1 :14 Tool A.60084 for valve and valve springremoval

TOOL A . 60084

4 Remove all the bolts securing the air conveyor ducting

to the cylinder head and to the crankcase, carefully

separate the panels and lift away the separate panels

ensuring no damage is caused to the mating faces.

5 Release the ignition distributor retaining bolt and lift

away the distributor.

6 Remove the fuel pump retaining bolts and also the

three fuel pipe retaining clips and lift away the fuel

pump assembly together with the insulator, gaskets

and control rod.

7 Release the t w o valve rocker retaining nuts, note the

order of assembly of washers and ease away the rocker

shaft assembly from the top of the cylinder head.

Carefully lift out the valve rocker pushrods noting

their relevent positions for correct reassembly.

8 Slacken the four cylinder head cap nuts and the four

conventional nuts in the order shown in FIG 1 :46. Lift

the cylinder head away from the barrels. If difficulty is

experienced it is essential to use Fiat tool A.40014 or a

similar drilled plate as shown in FIG 1 :9, otherwise

serious damage could be caused if other means are

used.

9 Remove the four pushrod sleeves and the casing con-

taining the oil ducting to the overhead valve gear.

10 Remove the six screws holding the centrifugal oil filter

pulley cover and lift away the cover. Remove the

centrifugal filter mounting flange by unscrewing the

crankshaft central bolt. Also remove the timing cover

f r o m t h e rear of t h e crankcase. Note carefully the posi-

tion of the nuts, toothed and plain washers for correct

reassembly.

11 Release the four camshaft sprocket retaining bolts

and lift away the sprocket and timing chain. Using

Fiat puller A.46020 or a large universal two-leg puller

as shown in FIG 1 : 1 0 remove the crankshaft

sprocket and its key

12 Carefully lift out the rocker pushrod tappets making a

note of their location and gently pull out the camshaft

making sure that the front bearing bore is not

damaged by the cam lobes.

Page 10 of 128

13 Remove all the bolts and washers joining the sump

casting to the crankcase making a special note of the

location of bolts of different lengths.

14 Mark the flywheel and crankshaft to ensure correct

reassembly and release the six flywheel retaining bolts

together with the lockwashers and lift away the fly-

wheel.

15 Using Fiat tool A.60156 on the two central studs, lock

the t w o cylinder barrels in place (see FIG 1 :11).

16 Turn the engine upside down ensuring that no weight

is placed on the studs.

17 Mark the connecting rods and end caps to ensure cor-

rect reassembly and remove the end caps. Place the

engine on its side and remove the cylinder barrels

clamp. Ensure t h a t t h e studs are clean and carefully

slide off the connecting rod-piston-cylinder assem-

blies from the crankcase.

18 Remove the six screws holding the rear bearing hous-

ing to the crankcase and lift away the housing. Remove

the six screws holding the front main bearing housing

to the crankcase and lift away its housing.

19 Carefully ease t h e crankshaft from the crankcase

moving it diagonally to assist w i t h d r a w a l .

20 To ensure no damage occurs to the long cylinder

barrel mounting studs these may be removed using

Fiat puller A.40010 or a universal stud remover as

shown in FIG 1 :12.

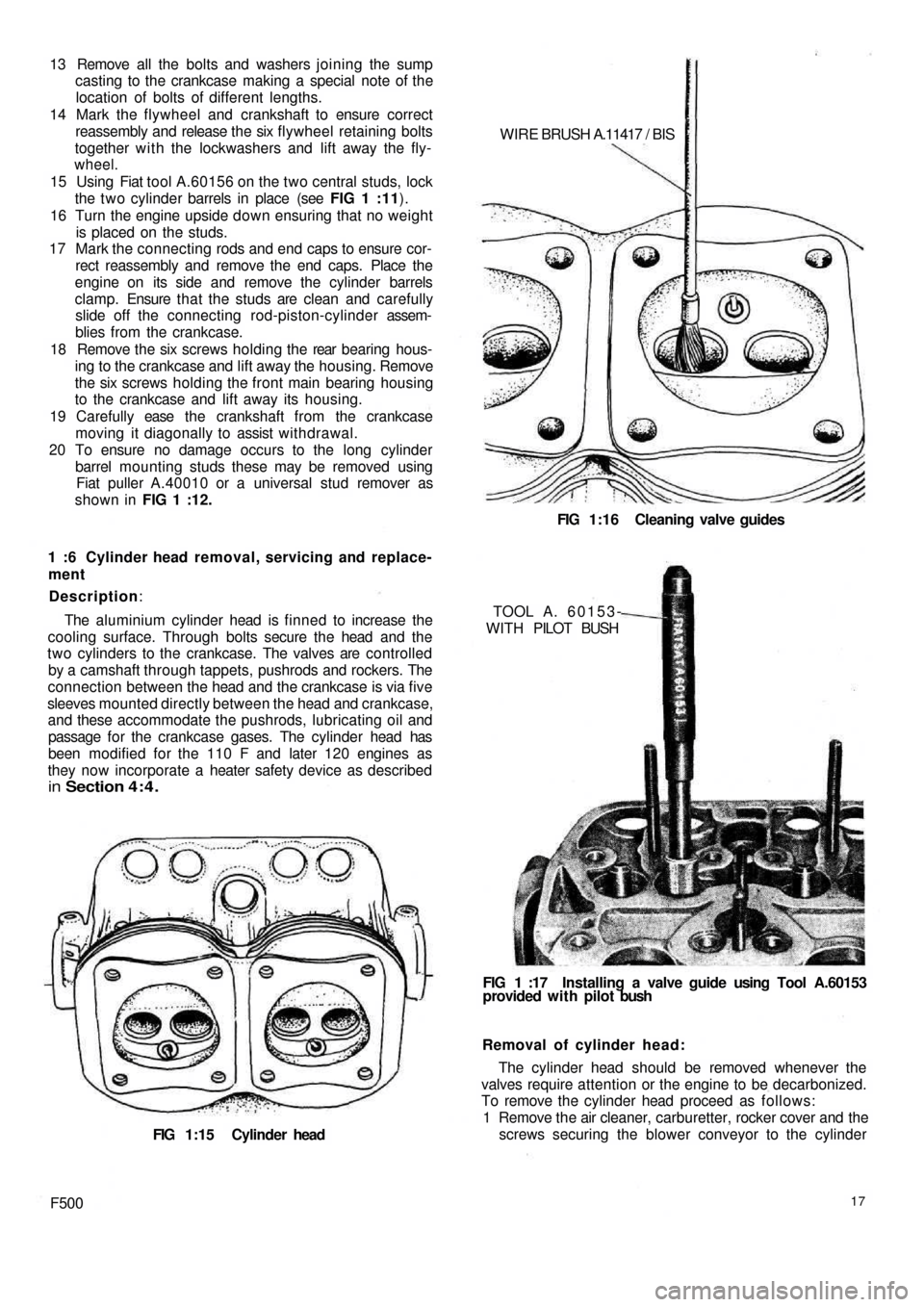

1 :6 Cylinder head removal, servicing and replace-

ment

Description:

The aluminium cylinder head is finned to increase the

cooling surface. Through bolts secure the head and the

two cylinders to the crankcase. The valves are controlled

by a camshaft through tappets, pushrods and rockers. The

connection between the head and the crankcase is via five

sleeves mounted directly between the head and crankcase,

and these accommodate the pushrods, lubricating oil and

passage for the crankcase gases. The cylinder head has

been

modified for the 110 F and later 120 engines as

they now incorporate a heater safety device as described

in Section 4 : 4 .

FIG 1:15 Cylinder head

17F500

The cylinder head should be removed whenever the

valves require attention or the engine to be decarbonized.

To remove the cylinder head proceed as f o l l o w s :

1 Remove the air cleaner, carburetter, rocker cover and the

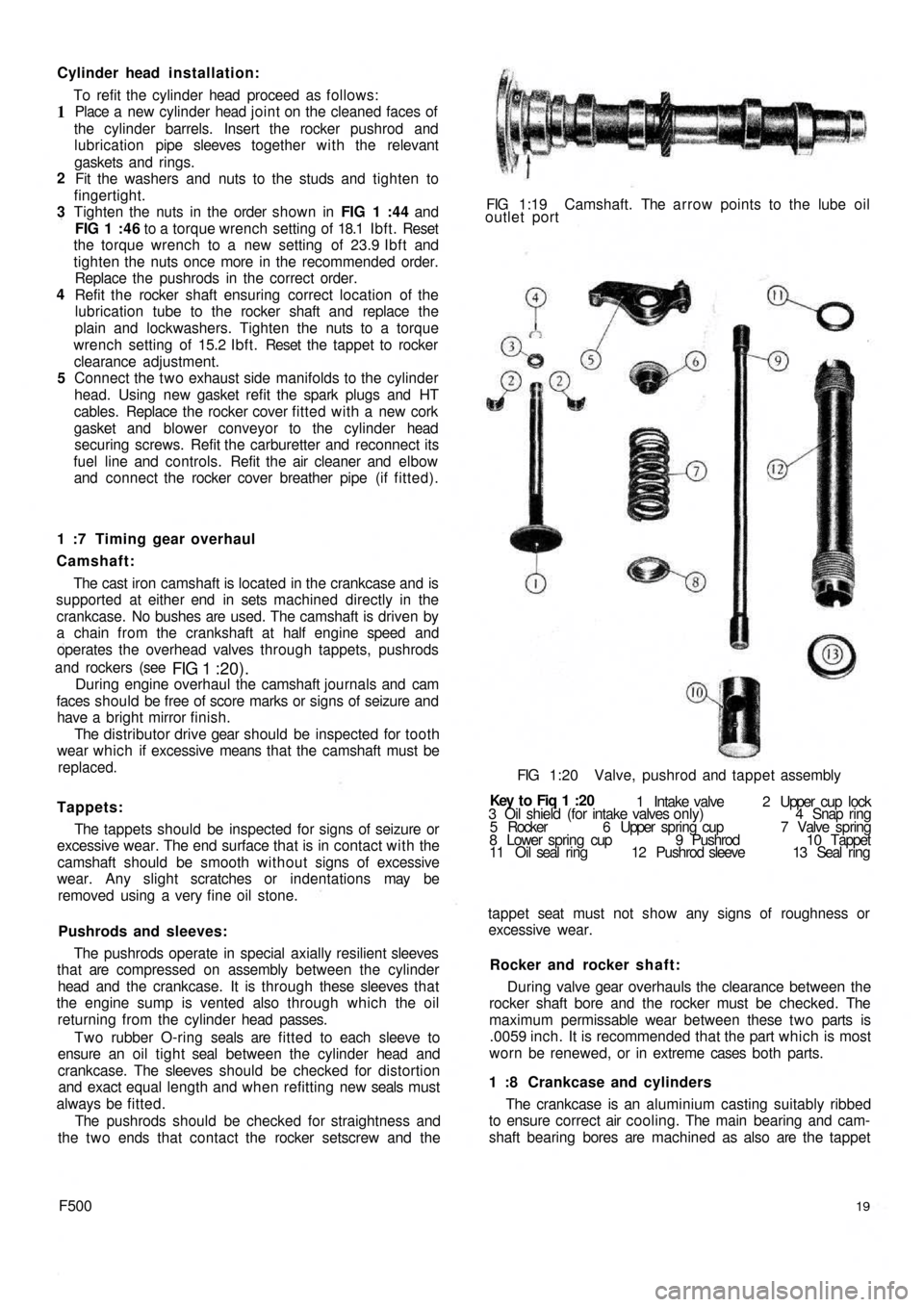

screws securing the blower conveyor to the cylinder Removal of cylinder head: FIG 1 :17 Installing a valve guide using Tool A.60153

provided with pilot bush TOOL A. 6 0 1 5 3 -

WITH PILOT BUSH FIG 1:16 Cleaning valve guides

W I R E BRUSH A.11417 / BIS

Page 12 of 128

Cylinder head installation:

To refit the cylinder head proceed as follows:

Place a new cylinder head joint on the cleaned faces of

the cylinder barrels. Insert the rocker pushrod and

lubrication pipe sleeves together with the relevant

gaskets and rings.

Fit the washers and nuts to the studs and tighten to

fingertight.

Tighten the nuts in the order shown in FIG 1 :44 and

FIG 1 :46 to a torque wrench setting of 18.1 Ibft. Reset

the torque wrench to a new setting of 23.9 Ibft and

tighten the nuts once more in the recommended order.

Replace the pushrods in the correct order.

Refit the rocker shaft ensuring correct location of the

lubrication tube to the rocker shaft and replace the

plain and lockwashers. Tighten the nuts to a torque

wrench setting of 15.2 Ibft. Reset the tappet to rocker

clearance adjustment.

Connect the t w o exhaust side manifolds to the cylinder

head. Using new gasket refit the spark plugs and HT

cables. Replace the rocker cover fitted with a new cork

gasket and blower conveyor to the cylinder head

securing screws. Refit the carburetter and reconnect its

fuel line and controls. Refit the air cleaner and elbow

and connect the rocker cover breather pipe (if fitted).

1

2

3

4

5

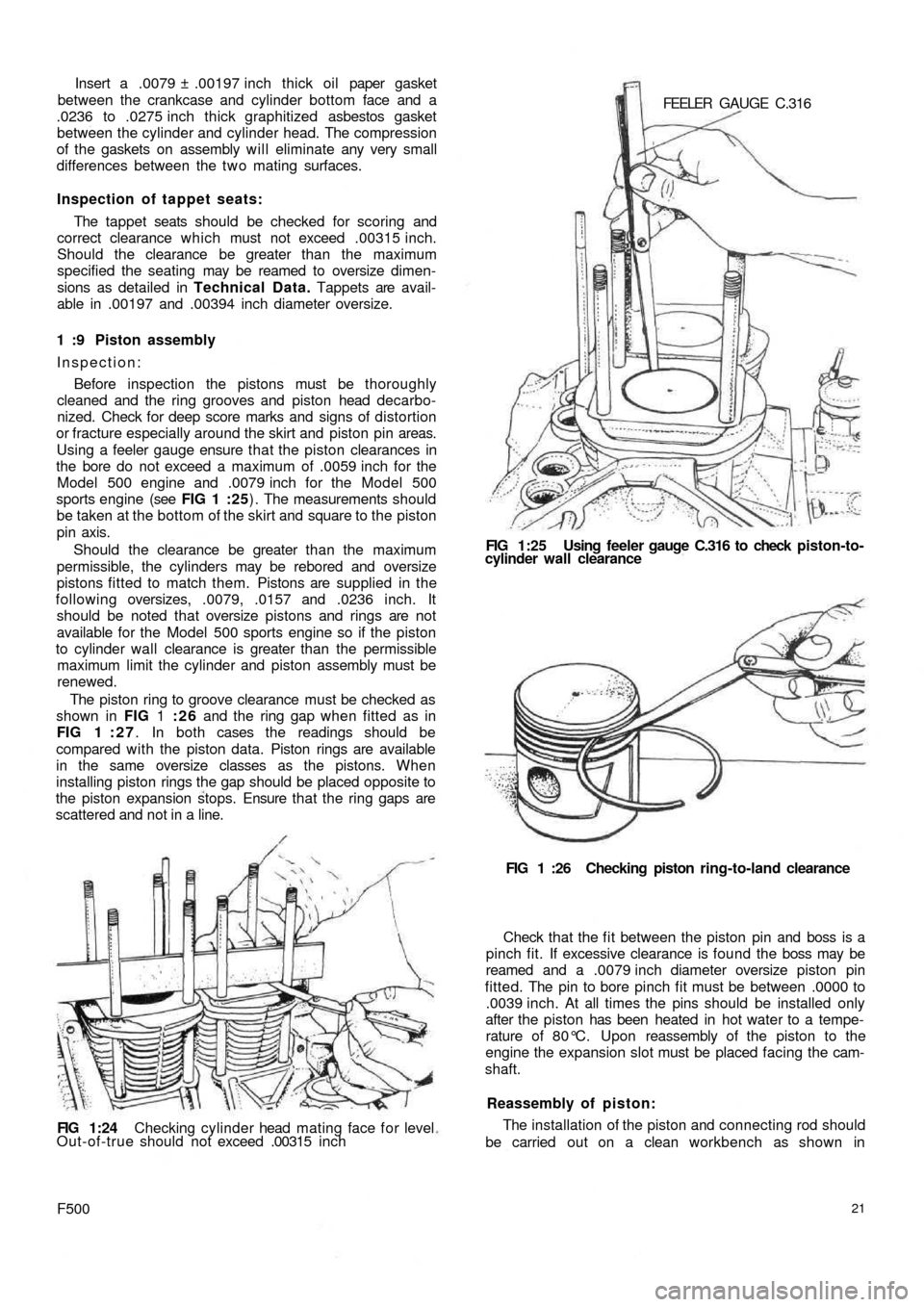

1 :7 Timing gear overhaul

Camshaft:

The cast iron camshaft is located in the crankcase and is

supported at either end in sets machined directly in the

crankcase. No bushes are used. The camshaft is driven by

a chain from the crankshaft at half engine speed and

operates the overhead valves through tappets, pushrods

and rockers (see

FIG 1 :20).During engine overhaul the camshaft journals and cam

faces should be free of score marks or signs of seizure and

have a bright mirror finish.

The distributor drive gear should be inspected for tooth

wear which if excessive means that the camshaft must be

replaced.

Tappets:

The tappets should be inspected for signs of seizure or

excessive wear. The end surface that is in contact with the

camshaft should be smooth without signs of excessive

wear. Any slight scratches or indentations may be

removed using a very fine oil stone.

Pushrods and sleeves:

The pushrods operate in special axially resilient sleeves

that are compressed on assembly between the cylinder

head and the crankcase. It is through these sleeves that

the engine sump is vented also through which the oil

returning from the cylinder head passes.

Two rubber O-ring seals are fitted to each sleeve to

ensure an oil t i g h t seal between the cylinder head and

crankcase. The sleeves should be checked for distortion

and exact equal length and when refitting new seals must

always be fitted.

The pushrods should be checked for straightness and

the t w o ends that contact the rocker setscrew and the

F50019

The crankcase is an aluminium casting suitably ribbed

to ensure correct air cooling. The main bearing and cam-

shaft bearing bores are machined as also are the tappet 1 :8 Crankcase and cylinders During valve gear overhauls the clearance between the

rocker shaft bore and the rocker must be checked. The

maximum permissable wear between these t w o parts is

.0059 inch. It is recommended that the part which is most

worn be renewed, or in extreme cases both parts. Rocker and rocker shaft: tappet seat must not show any signs of roughness or

excessive wear. 3 Oil shield (for intake valves only) 4 Snap ring

5 Rocker 6 Upper spring cup 7 Valve spring

8 Lower spring cup 9 Pushrod 10 Tappet

11 Oil seal ring 12 Pushrod sleeve 13 Seal ring 1 Intake valve 2 Upper cup lock Key t o Fiq

1 :20 FIG 1:20 Valve, pushrod and tappet assembly FIG 1:19 Camshaft. The arrow points to the lube oil

outlet port

Page 14 of 128

Insert a .0079 ± .00197 inch thick oil paper gasket

between the crankcase and cylinder bottom face and a

.0236 to .0275 inch thick graphitized asbestos gasket

between the cylinder and cylinder head. The compression

of the gaskets on assembly will eliminate any very small

differences between the t w o mating surfaces.

Inspection of tappet seats:

The tappet seats should be checked for scoring and

correct clearance which must not exceed .00315 inch.

Should the clearance be greater than the maximum

specified the seating may be reamed to oversize dimen-

sions as detailed in Technical Data. Tappets are avail-

able in .00197 and .00394 inch diameter oversize.

1 :9 Piston assembly

Inspection:

Before inspection the pistons must be thoroughly

cleaned and the ring grooves and piston head decarbo-

nized. Check for deep score marks and signs of distortion

or fracture especially around the skirt and piston pin areas.

Using a feeler gauge ensure that the piston clearances in

the bore do not exceed a maximum of .0059 inch for the

Model 500 engine and .0079 inch for the Model 500

sports engine (see FIG 1 :25) . The measurements should

be taken at the bottom of the skirt and square to the piston

pin axis.

Should the clearance be greater than the maximum

permissible, the cylinders may be rebored and oversize

pistons fitted to m

atch them. Pistons are supplied in the

following oversizes, .0079, .0157 and .0236 inch. It

should be noted that oversize pistons and rings are not

available for the Model 500 sports engine so if the piston

to cylinder wall clearance is greater than the permissible

maximum limit the cylinder and piston assembly must be

renewed.

The piston ring to groove clearance must be checked as

shown in FIG 1 :26 and the ring gap when fitted as in

FIG 1 : 2 7. In both cases the readings should be

compared with the piston data. Piston rings are available

in the same oversize classes as the pistons. When

installing piston rings the gap should be placed opposite to

the piston expansion stops. Ensure that the ring gaps are

scattered and not in a line.

FIG 1:24 Checking cylinder head mating face f o r level

Out-of-true should not exceed .00315 i n c h

F50021

The installation of the piston and connecting rod should

be carried out on a clean workbench as shown in Reassembly of piston: Check that the f i t between the piston pin and boss is a

pinch fit. If excessive clearance is found the boss may be

reamed and a .0079 inch diameter oversize piston pin

fitted. The pin to bore pinch fit must be between .0000 to

.0039 inch. At all times the pins should be installed only

after the piston has been heated in hot water to a tempe-

rature of 80°C. Upon reassembly of the piston to the

engine the expansion slot must be placed facing the cam-

shaft.FIG 1 :26 Checking piston ring-to-land clearance FEELER GAUGE C.316

FIG 1:25 Using feeler gauge C.316 to check piston-to-

cylinder wall clearance

Page 20 of 128

Drain the oil sump to ensure that the oil does not syphon

out. Thoroughly clean the area around the pump body

(see FIG 1 :37).

Remove the end cover plate by releasing the retaining

bolts and washers. Carefully ease t h e driven gear down-

wards followed by the driving gear and shaft

Clean all parts removed and blow clean using a com-

pressed air jet. Inspect the timing gear cover pump area

for cracks or distortion. Check that the inner duct for oil

delivery to the pump is clear of obstruction. If in doubt

remove the drain plug and filler cap and use a com-

pressed air j e t to clean the passage.

Check the gear teeth for damage or excessive wear,

ensure that the drive gear is firmly attached to its spindle

and that the end cover plate is not badly scored or pitted.

Fit new parts as necessary.

Reassembly is the reverse procedure to dismantling,

taking care that all parts are assembled clean and the

end cover plate seating correctly with a new gasket. 5 43 21

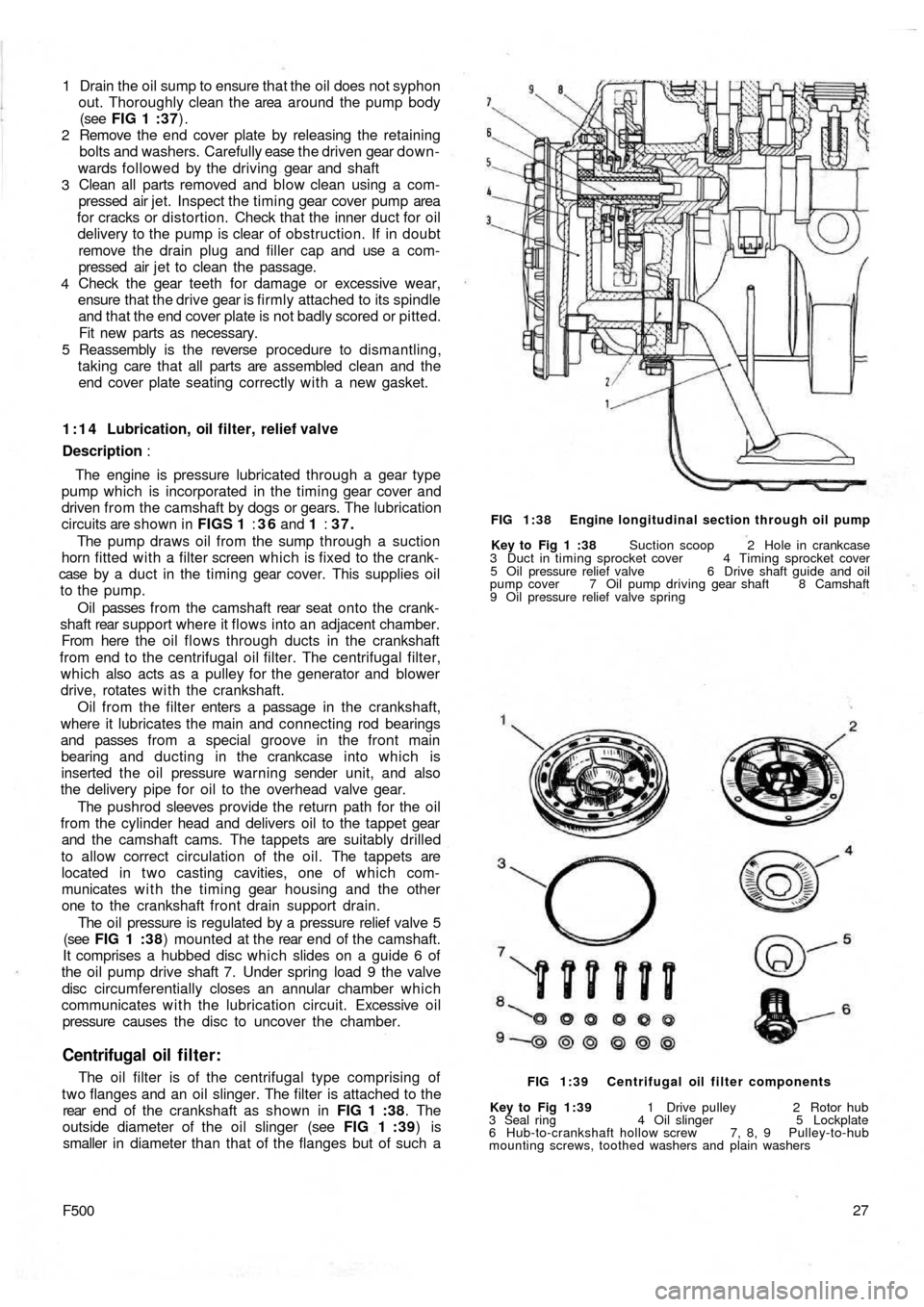

1:14 Lubrication, oil filter, relief valve

Description :

The engine is pressure lubricated through a gear type

pump which is incorporated in the timing gear cover and

driven from the camshaft by dogs or gears. The lubrication

circuits are shown in FIGS 1 :36 and 1 : 37.

The pump draws oil from the sump through a suction

horn fitted with a filter screen which is fixed to the crank-

case by a d u c t in t h e timing gear cover. This

supplies oil

to the pump.

Oil passes f r o m the camshaft rear seat o n t o t h e crank-

shaft rear support where it flows into an adjacent chamber.

From here the o i l flows through ducts in the crankshaft

from end to the centrifugal oil filter. The centrifugal filter,

which also acts as a pulley for the generator and blower

drive, rotates w i t h the crankshaft.

Oil from the filter enters a passage in the crankshaft,

where it lubricates the main and connecting rod bearings

and passes f r o m a special groove in the front main

bearing and ducting in the crankcase into which is

inserted the oil pressure warning sender unit, and also

the delivery pipe for oil to the overhead valve gear.

The pushrod sleeves provide the return path for the oil

from the cylinder head and delivers oil to the tappet gear

and the camshaft cams. The tappets are suitably drilled

to allow correct circulation of the oil. The tappets are

located in t w o casting cavities, one of which com-

municates w i t h the timing gear housing and the other

one to the crankshaft front drain support drain.

The oil pressure is regulated by a pressure relief valve 5

(see FIG 1 : 3 8) mounted at the rear end of t h e camshaft.

It comprises a hubbed disc which slides on a guide 6 of

the oil pump drive shaft 7. Under spring load 9 the valve

disc circumferentially closes an annular chamber which

communicates w i t h the lubrication circuit. Excessive o i l

pressure causes the disc to uncover the chamber.

Centrifugal oil filter:

The oil filter is of the centrifugal type comprising of

two flanges and an oil slinger. The filter is attached to the

rear end o f t h e c r a n k s h a f t a s s h o w n i n FIG 1 :38. The

outside diameter of the oil slinger (see FIG 1 :39) is

smaller in diameter than that of the flanges but of such a

F50027

Key to Fig 1:39 1 Drive pulley 2 Rotor hub

3 Seal ring 4 Oil slinger 5 Lockplate

6 Hub-to-crankshaft hollow screw 7, 8, 9 Pulley-to-hub

mounting screws, toothed washers and plain washers FIG 1:39 Centrifugal oil filter components Key to Fig 1 :38 Suction scoop 2 Hole in crankcase

3 Duct in timing sprocket cover 4 Timing sprocket cover

5 Oil pressure relief valve 6 Drive shaft guide and oil

pump cover 7 Oil pump driving gear shaft 8 Camshaft

9 Oil pressure relief valve spring FIG 1:38 Engine longitudinal section through oil pump

Page 23 of 128

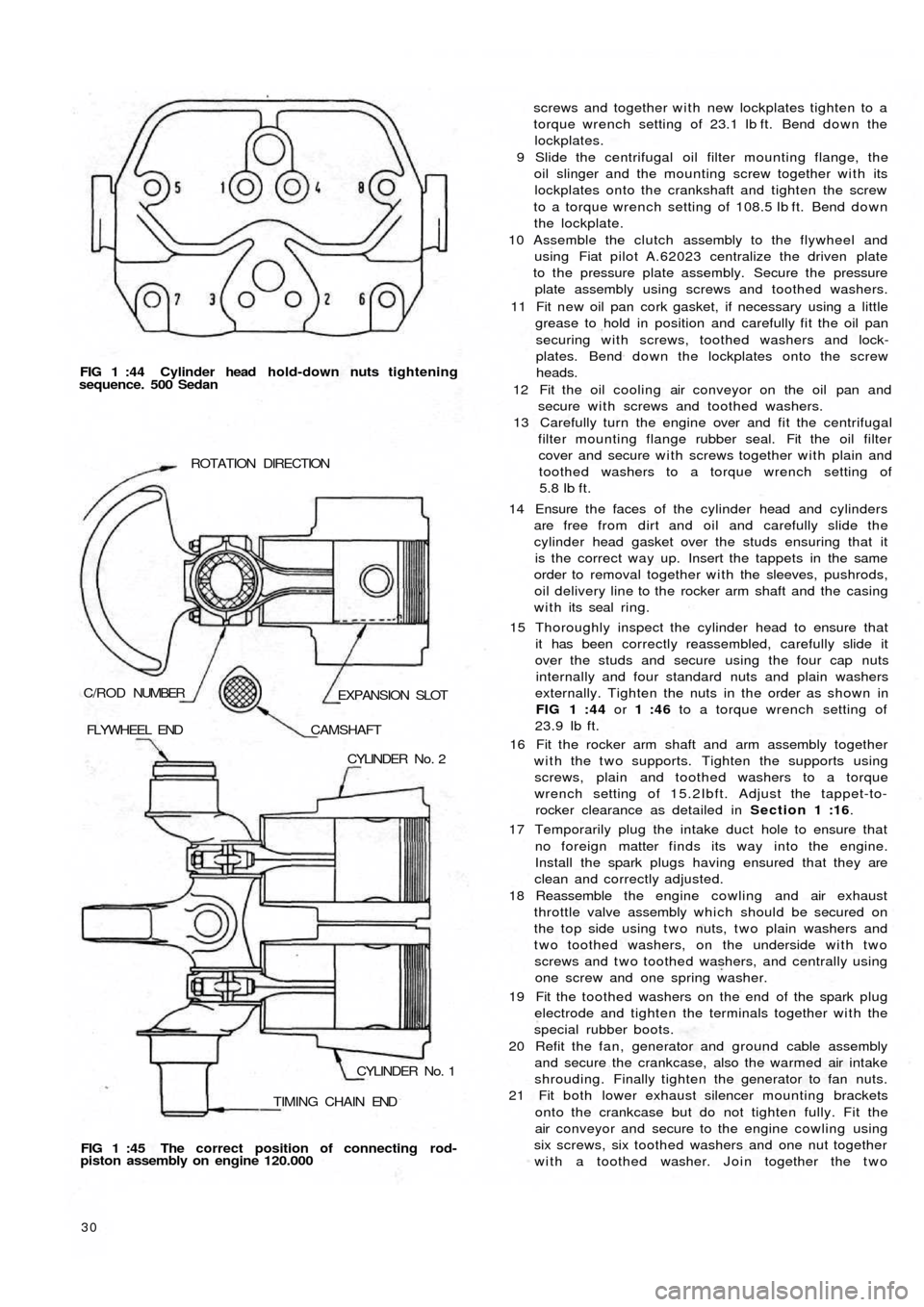

FIG 1 :44 Cylinder head h o ld-down nuts tightening

sequence. 500 Sedan

TIMING CHAIN ENDCYLINDER No. 1 CYLINDER No. 2 FLYWHEEL END

CAMSHAFT

EXPANSION SLOT C/ROD NUMBERROTATION DIRECTION

FIG 1 :45 The correct position of connecting rod-

piston assembly on engine 120.000

30

screws and together with new lockplates tighten to a

torque wrench setting of 23.1 Ib ft. Bend down the

lockplates.

9 Slide the centrifugal oil filter mounting flange, the

oil slinger and the mounting screw together with its

lockplates onto the crankshaft and tighten the screw

to a torque wrench setting of 108.5 Ib ft. Bend down

the lockplate.

10 Assemble the clutch assembly to the flywheel and

using Fiat pilot A.62023 centralize the driven plate

to the pressure plate assembly. Secure the pressure

plate assembly using screws and toothed washers.

11 Fit new oil pan cork gasket, if necessary using a little

grease to hold in position and carefully fit the oil pan

securing with screws, toothed washers and lock-

plates. Bend down the lockplates onto the screw

heads.

12 Fit the oil cooling air conveyor on the oil pan and

secure with screws and toothed washers.

13 Carefully turn the engine over and fit the centrifugal

filter mounting flange rubber seal. Fit the oil filter

cover and secure with screws together with plain and

toothed washers to a torque wrench setting of

5.8

Ib ft.

14 Ensure t h e faces of the cylinder head and cylinders

are free from dirt and oil and carefully slide the

cylinder head gasket over the studs ensuring that it

is the correct way up. Insert the tappets in the same

order to removal together with the sleeves, pushrods,

oil delivery line to the rocker arm shaft and the casing

with its seal ring.

15 Thoroughly inspect the cylinder head to ensure that

it has been correctly reassembled, carefully slide it

over the studs and secure using the four cap nuts

internally and four standard nuts and plain washers

externally. Tighten the nuts in the order as shown in

FIG 1 :44 or 1 :46 to a torque wrench setting of

23.9 Ib ft.

16 Fit the rocker arm shaft and arm assembly together

with the two supports. Tighten the supports using

screws, plain and toothed washers to a torque

wrench setting of 15.2Ibft. Adjust the tappet-to-

rocker clearance as detailed in Section 1 :16.

17 Temporarily plug the intake duct hole to ensure that

no foreign matter finds its way into the engine.

Install the spark plugs having ensured that they are

clean and correctly adjusted.

18 Reassemble the engine cowling and air

exhaust

throttle valve assembly which should be secured on

the top side using t w o nuts, t w o plain washers and

two toothed washers, on the underside with two

screws and t w o toothed washers, and centrally using

one screw and one spring washer.

19 Fit the toothed washers on the end of the spark plug

electrode and tighten the terminals together with the

special rubber boots.

20 Refit the fan, generator and ground cable assembly

and secure the crankcase, also the warmed air intake

shrouding. Finally tighten the generator to fan nuts.

21 Fit both lower exhaust silencer mounting brackets

onto the crankcase but do not tighten fully. Fit the

air conveyor and secure to the engine cowling using

six screws, six toothed washers and one nut together

with a toothed washer. Join together the t w o